Содержание

- Коды ошибок – Инструкция по эксплуатации Xerox WorkCentre 5016

- Страница 98

- StavPr.ru

- Блог ленивого админа

- Расшифтовка кодов ошибок Xerox WorkCentre M15

- Обзор частых ошибок принтера Xerox и их устранение

- Ошибка температуры печки принтера

- Ошибка «Мотор»

- Ошибка Hsync

- Проблемы с принтером Xerox Phaser 3117

- Коды ошибок принтеров Xerox

- Ошибки Xerox

- Если у Вас возникли следующие ошибки, Вы можете вызвать наших инженеров, для ремонта Вашей техники. Диагностика — БЕСПЛАТНО. Напишите нам возникшую проблему, или вызовете инженера по телефонам: (495) 778-52-50, (495) 778-50-45

Страница 98

Процедура устранения неисправности

Руководство пользователя Xerox WorkCentre 5016/5020

Лоток 2

Этот зеленый индикатор загорается при выборе лотка 2.

Этот зеленый индикатор мигает, когда в лотке 2 заканчивается или

застревает бумага.

Сведения о загрузке бумаги в лоток 2 см. раздел «Загрузка бумаги в лоток 2» (стр. 45).

Информация об устранении застревания бумаги в лотке 2 приведена в разделе «C2:

Застревание бумаги в лотке 2» (стр. 115).

Примечание • Следующий индикатор отображается только тогда, когда на аппарате установлен

лоток для бумаги 2 (опция).

Обходной лоток

Этот зеленый индикатор загорается при выборе обходного лотка.

Сведения о загрузке бумаги в обходной лоток см. раздел «Загрузка бумаги в обходной

лоток» (стр. 46).

Информация об устранении застревания бумаги в обходном лотке приведена в разделе «C3:

Застревание бумаги в обходном лотке» (стр. 116).

Наличие оригинала

Этот зеленый индикатор загорается, когда оригинал в податчик

загружен правильно.

Примечание • Данная опция доступна только тогда, когда на аппарате установлен податчик

Застревание оригинала

в податчике.

Аккуратно вытащите застрявший

оригинал.

Сведения об удалении застрявшего

оригинала см. в разделе

«A1: Застревание оригиналов»

(стр. 117).

В податчик загружены оригиналы,

размер которых не

поддерживается. Это может

привести к застреванию

оригиналов.

Аккуратно вытащите застрявший

оригинал и используйте вместо него

стекло экспонирования.

Сведения об удалении застрявшего

оригинала см. в разделе

«A1: Застревание оригиналов»

(стр. 117).

Открыта крышка податчика

оригиналов.

Закройте крышку податчика

оригиналов.

Если при сканировании толстого

оригинала, например книги,

крышка стекла экспонирования

остается слегка приоткрытой, и

при этом в податчик загружен

другой оригинал, аппарат не будет

сканировать оригинал со стекла

экспонирования.

Для сканирования оригинала со

стекла экспонирования нужно

сначала убрать оригинал из

податчика.

Источник

StavPr.ru

Блог ленивого админа

Расшифтовка кодов ошибок Xerox WorkCentre M15

Bypass Jam Причина – Аппарат определяет отсутствие подачи из ручного лотка. Действие – Загрузите бумагу в ручной лоток.

Document Jam Причина – Застревание загруженного в АПД оригинала. Действие – Устраните застревание оригинала. См. раздел Застревания оригинала на стр. 11-3 Руководства пользователя.

Door Open Причина – Боковая крышка закрыта неплотно. Действие – Закройте боковую крышку, чтобы они зафиксировалась со щелчком.

DRUM WARNING. Причина – закончился срок службы копи-картриджа. Действие – замените DRUM (копи-картридж).

Duplex Jam Причина – Застревание бумаги при выполнении двусторонней печати. Действие – Устраните застревание. См. раздел Застревание в дуплексе на стр. 11-10 Руководства пользователя.

Fuser Error Причина – Неисправность в модуле фьюзера. Действие – Отсоедините и снова подсоедините кабель питания. Если проблема остается, обратитесь в сервисную службу.

LSU Error Причина – Неисправность LSU (модуля лазерного сканера). Действие – Отсоедините и снова подсоедините кабель питания. Если проблема остается, обратитесь в сервисную службу.

Overheat Причина – Принтер перегрелся. Действие – Аппарат автоматически вернется в режим ожидания после охлаждения до обычной рабочей температуры. Если проблема остается, обратитесь в сервисную службу.

No Developer Cartridge Причина – Тонер-картридж не установлен. Действие – Установите тонер-картридж. См. раздел Тонер-картридж на стр. 10-5 Руководства пользователя.

No Paper Причина – В кассете закончилась бумага для печати. Действие – Загрузите бумагу для печати в кассету.

Paper Jam 0 Причина – Застревание бумаги в зоне подачи бумаги. Действие – Устраните застревание. См. раздел Застревания бумаги на стр. 11-5 Руководства пользователя.

Paper Jam 1 Причина – Застревание бумаги в зоне фьюзера. Действие – Устраните застревание. См. раздел Застревания бумаги на стр. 11-5 Руководства пользователя.

Paper Jam 2 Причина – Застревание бумаги в зоне вывода бумаги. Действие – Устраните застревание. См. раздел Застревания бумаги на стр. 11-5 Руководства пользователя.

Toner Empty Причина – Закончился тонер в тонер-картридже. Аппарат остановится. Действие – Установите новый тонер-картридж. См. раздел Тонер-картридж на стр. 10-5 Руководства пользователя.

Toner Low Причина – Тонер в тонер-картридже заканчивается. Действие – Снимите тонер-картридж и осторожно встряхните его. После этого на некоторое время можно возобновить печать.

Retry Redial Причина – Аппарат ожидает указания времени для автоматического повторного набора номера. Действие – Нажмите [Старт] для немедленного повторного набора номера или [Стоп] для отмены операции повторного набора.

Comm. Error Причина – Сбой факсимильной связи. Действие – Попробуйте передать факс еще раз.

Group Not Available Причина – Выбран номер группы, когда можно использовать только номер индивидуального получателя. Например, при добавлении номеров для многоадресной передачи. Действие – Попробуйте еще раз, проверив номер группы.

Line Error Причина – Аппарат не может соединиться с удаленным факсом или нарушение связи из-за неисправности телефонной линии. Действие – Попробуйте передать факс еще раз. Если проблема остается, подождите час или больше, пока линия освободится, и повторите снова.

Function Full Причина – Переполнение памяти. Действие – Вы можете или удалить ненужные документы, или повторить передачу после освобождения памяти. При передаче большого документа вы можете разделить его на несколько частей.

No Answer Причина – Удаленный аппарат не отвечает после всех попыток повторного набора. Действие – Попробуйте передать факс еще раз. Проверьте, правильно ли работает удаленный аппарат.

Not Assigned Причина – Для выбранного номера ускоренного набора не задано телефонного номера. Действие – Введите номер получателя вручную с цифровой клавиатуры или укажите его для номера ускоренного набора.

Polling Error Причина – При настройке опроса удаленного аппарата введен неверный код опроса. Действие – Введите правильный код опроса. Опрашиваемый удаленный аппарат не готов ответить на запрос. Оператор удаленного аппарата должен заранее знать о запросе и загрузить в аппарат запрашиваемые документы.

Line Busy Причина – Удаленный факс не отвечает. Действие – Попробуйте передать факс еще раз.

Scaner locked. Причина – заблокирован сканер. Решение – под сканером есть защелка, сейчас она находится в положении – “замок закрыт”, ее нужно передвинуть в положение – “замок открыт”. В инструкции пользователя данная процедура подробно описана.

Источник

Обзор частых ошибок принтера Xerox и их устранение

Принтеры компании Xerox, как и других брендов, делают нашу жизнь и работу проще. Эта техника может располагаться дома, может быть на работе, в офисе, но все-таки она есть в наличии, и проблемы с ней тоже могут случиться.

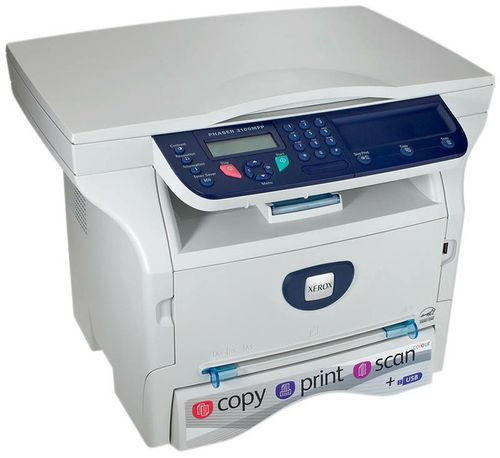

Xerox WorkCentre 5016

О чём пойдет речь:

Ошибка температуры печки принтера

Стоит подробнее разобрать ошибки принтера Xerox 3100 или Xerox WorkCentre 5016, чтобы всегда можно было решить их без проблем. Самая распространенная ошибка принтера Xerox – температура печки не может быть определена устройством, и оно выходит из строя.

Печка может перегреться, и ее температура не будет отображаться по нескольким причинам:

•термодатчик принтера вышел из строя;

•не работают мотор или отдельные части мотора;

•лампы нагрева сломались или отказали;

•инородное тело в термопредохранителе принтера.

Любые ошибки и поломки в принтере имеют свое решение.

Если дело в лампе нагрева, из-за чего возникла ошибка принтера Xerox 3100, температуру печки, естественно, не надо вычислять. При этом лампу нужно просканировать, прозвонить мультиметром. Если прибор укажет, что лампа сломана, то ее требуется заменить.

Термодатчик принтера, соответственно, тоже проверяется мультиметром. Если датчик печки грязный, его нужно почистить. Делается это с помощью тампона и ацетона.

Мультиметром проверяется и термопредохранитель печки. Чтобы он вновь заработал, можно попробовать его потрясти или постучать по нему. Если все вышеуказанные части печки исправны, то необходимо сбросить ошибку принтера, набрав определенную комбинацию кнопок и символов на клавиатуре. Эту комбинацию можно найти в инструкции.

Ошибка «Мотор»

Xerox Phaser 3100

Ошибка принтера Xerox Phaser 3100 или Xerox WorkCentre 5016 «Мотор» тоже довольно распространена. Появляется эта неисправность в тот момент, когда пользователь хочет распечатать что-то на принтере. Решается ошибка «Мотор» очень просто. Нужно несколько раз выключить и включить принтер заново, тогда ошибка «Мотор» исчезнет.

Ошибка Hsync

Ошибка Hsync – еще одна распространенная неисправность принтеров Xerox. Она подразумевает ошибку лазера. При попытке просканировать документ принтер начинает шуметь, треск длится около 30 секунд, а потом выходит чистый лист. При этом нужно проверить, замкнуты ли нормально оба контакта крышки сканера. Если замкнут только один контакт, может появиться эта ошибка. Тогда нужно замкнуть и второй контакт, и неисправность пропадет. Если все в порядке, то необходимо обратиться в сервисную службу для того, чтобы узнать, не сгорел ли сам лазер.

Проблемы с принтером Xerox Phaser 3117

Если у вас принтер Xerox Phaser 3117, то на нем могут встречаться аналогичные ошибки, которые были описаны выше. Чтобы ошибок не возникало в Xerox Phaser 3117 и другой подобной технике, необходимо регулярно чистить принтер, проводить обслуживание, проверять все контакты и подключения к сети и компьютеру, а также устанавливать новые драйвера и проверять их наличие. Это поможет избежать возникновения неисправностей в самый неудачный момент.

Коды ошибок принтеров Xerox

Коды ошибок принтеров Xerox для разных моделей могут быть разные, но основные значат одно и то же. Расшифровать коды можно с помощью инструкции по эксплуатации, где есть переводы подробное описание комбинаций для сброса ошибок и их кодов всех видов.

Будьте внимательны к вашей технике дома и в офисе, чтобы не допускать появления неисправностей. Приобретайте технику у проверенных производителей и вовремя проводите обслуживание.

Источник

Ошибки Xerox

Если у Вас возникли следующие ошибки, Вы можете вызвать наших инженеров, для ремонта Вашей техники. Диагностика — БЕСПЛАТНО.

Напишите нам возникшую проблему, или вызовете инженера по телефонам: (495) 778-52-50, (495) 778-50-45

Xerox 1012, 1012 (RE)

| Код ошибки | Описание |

|---|---|

| E1 | Jam between paper feed and fuser |

| E3 | Jam in fuser |

| E5 | Clam shell open |

| E6 | Paper feed section cover is open |

| J1 | Toner cartridge near empty |

| J3 | Drum cartridge not seated properly |

| J7 | Waste toner full (replace drum cartridge) |

| L6 | Key counter out |

| L8 | Exposure area overheat |

| U1 | No clock pulse (drive problem) |

| U2 | Scan problem |

| U3 | Lens/mirror problem (RE model only) |

| U4 | Heat problem |

| U8 | Exposure lamp control circuit problem |

| E1 | Jam between paper feed and fuser |

| E3 | Jam in fuser |

| E5 | Clam shell open |

| E6 | Paper feed section cover is open |

| J1 | Toner cartridge near empty |

| J3 | Drum cartridge not seated properly |

| J7 | Waste toner full (replace drum cartridge) |

| L6 | Key counter out |

| L8 | Exposure area overheat |

| U1 | No clock pulse (drive problem) |

| U2 | Scan problem |

| U3 | Lens/mirror problem (RE model only) |

| U4 | Heat problem |

| U8 | Exposure lamp control circuit problem |

| Код ошибки | Описание |

|---|---|

| LL | Probable bad heater lamp |

| Код ошибки | Описание |

|---|---|

| A1 | DF jam |

| C1 | PF jam cass. 1 |

| C2 | PF jam cass. 2 |

| C3 | PF jam cass. 3 |

| C9 | Bypass jam |

| E1-1 | Paper jam before exit switch |

| E1-2 | Paper jam |

| E1-5 | Paper jam |

| E1-6 | Paper jam |

| E3-3 | Paper jam at exit switch |

| E3-4 | Paper jam at exit switch |

| E5 | Front door open |

| F1 | Collator jam |

| F5 | Collator interlock |

| F8 | No power to collator |

| F9 | Collator bin home switch |

| J7 | 250 copies since toner waste was full |

| L5 | Original cass. not present after clearing interrupt |

| L6 | Key counter |

| L8 | Platen glass too hot |

| U1 | Main motor clock pulse |

| U2 | Scan problem |

| U3-1 | Lens problem |

| U4-1 | Open thermistor |

| U4-2 | Low temperature |

| U4-4 | Temperature |

| U4-5 | Main PWB |

| U6-1 | Main PWB |

| U6-2 | Main PWB |

| U6-3 | Main board battery |

| U6-4 | Initialization |

| U8 | Exposure lamp |

| Код ошибки | Описание |

|---|---|

| A9 | Scanner location |

| C1 | Paper feed — upper cassette |

| C2 | Paper feed — lower cassette |

| C9 | Bypass jam |

| E5 | Clam shell is open |

| L6 | Key counter |

| U1 | Off/On |

| U2 | Optics |

| U4 | Low fuser temperature |

| Код ошибки | Описание |

|---|---|

| A1 | DF jam |

| C1 | PF jam cass. 1 |

| C2 | PF jam cass. 2 |

| C3 | PF jam cass. 3 |

| C9 | Bypass jam |

| E1-1 | Paper jam before exit switch |

| E1-2 | Paper jam |

| E1-5 | Paper jam |

| E1-6 | Paper jam |

| E3-3 | Paper jam at exit switch |

| E3-4 | Paper jam at exit switch |

| E5 | Front door open |

| F1 | Collator jam |

| F5 | Collator interlock |

| F8 | No power to collator |

| F9 | Collator bin home switch |

| J7 | 250 copies since toner waste was full |

| L5 | Original cass. not present after clearing interrupt |

| L6 | Key counter |

| L8 | Platen glass too hot |

| U1 | Main motor clock pulse |

| U2 | Scan problem |

| U3-1 | Lens problem |

| U4-1 | Open thermistor |

| U4-2 | Low temperature |

| U4-4 | Temperature |

| U4-5 | Main PWB |

| U6-1 | Main PWB |

| U6-2 | Main PWB |

| U6-3 | Main board battery |

| U6-4 | Initialization |

| U8 | Exposure lamp |

| Код ошибки | Описание |

|---|---|

| A9 | Scanner location |

| C1 | Paper feed — upper cassette |

| C2 | Paper feed — lower cassette |

| C9 | Bypass jam |

| E5 | Clam shell is open |

| E5 | Clam shell open |

| L6 | Key counter |

| U1 | Off/On |

| U2 | Optics |

| U4 | Low fuser temperature |

Xerox 5011, 5012, 5014

| Код ошибки | Описание |

|---|---|

| C8 | Bypass jam/no paper |

| C9 | Bypass jam |

| E1 | Jam |

| E3 | Fuser jam |

| E5 | Clamshell open |

| E6 | PF section cover open |

| J1 | Toner cartridge amost empty |

| J3 | Copy cart (drum unit) missing/not seated right |

| J7 | Copy cartridge has run 18,000 copies |

| J8 | Copy cartridge. Improperly seated or possible only one of two fuses in the cartridge blew |

| L6 | Key counter |

| L8 | Exposure glass too hot |

| U1 | Drive problem |

| U2 | Scan problem |

| U3 | Lens or mirror drive problem |

| U4 | Fuser problem. Heat lamp, thermoswitch, SSR, thermistor |

| U6 | Battery on main board |

| U8 | Exposure lamp or exposure lamp circuit |

Xerox 5016, 5017, 5316, 5317

| Code | Description |

|---|---|

| A1-1 | Document feeder feed jam |

| A1-2 | Document feeder belt jam |

| A2-1 | Document feeder exit jam |

| A2-2 | Duplex jam |

| A3 | DAD interlock |

| A5 | Duplex and DAD right side interlock |

| A6 | Copier jams after |

| A9 | Document feed belt drive motor |

| C1-3 | Top cassette misfeed |

| C2-3 | Middle cassette misfeed |

| C3-3 | Bottom cassette misfeed |

| C9-3 | Bypass misfeed |

| E1-11 to E1-14 | Paper jam in machine. Did not reach exit switch soon enough |

| E1-6 | Paper path jam |

| E3-31 to E3-34 | Exit switch jam |

| E3-6 | Fuser jam |

| E5 | Front door interlock |

| E6 | Right side interlock or TTM interlock |

| F1 | Sorter jam |

| F5 | Sorter interlock |

| F8 | Sorter board to copier main board communication problem |

| F9 | Sorter bins |

Xerox 5018, 5028

| Code | Description |

|---|---|

| A1 | Document is ADF |

| A1-8 | Main board received reset signal |

| A2 | ADF jams |

| A6, A7 | ADF jams |

| A9 | ADF jams |

| C1 — C4 | Feed jam |

| C5-1 to C5-4 | Jams in various areas |

| C5-2 | Jams in various areas |

| C5-3 | Jams in various areas |

| C5-4 | Duplex jam |

| E0 | Machine has reset |

| E1 | Jam |

| E1-E0 | Registration jam |

| E1-E5 | Clamshell interlock |

| E1-E6 | Right side interlock |

| E1-E7 | Two tray interlock |

| E1-E8 | Sorter interlock |

| E1-E9 | Copy cartridge interlock |

| E2 | Reset signal happened |

| E3 | Jam |

| E4 | Exit jam |

| E4-10 | Exit jam |

| E4-5 | Clamshell interlock |

| E4-6 | Right side interlock |

| E4-7 | Two tray interlock. Duplex interlock |

| E4-8 | Sorter interlock |

| E4-9 | Copy cartridge interlock |

| E5 | Clamshell interlock |

| E6 | Right side interlock |

| E7 | Duplex interlock |

| E9 | Copy cartridge interlock |

| F3-1 | Sorter bin home switch |

| F3-2 | Sorter cam switch |

| F3-3 | Sorter cam switch |

| J1-1 | Add toner |

| J1-2 | Temporary low toner signal |

| J2-0 | Replace copy cartridge |

| L2 | 2000 copies left on copy cartridge |

| L3 | ADF to machine communication problem |

| L4 (flashing) | 1000 copies left on fuser web |

| rr | Bad EPROM on main board |

| U0 | Main board |

| U2 | Scan problem |

| U2-1 | Scan home |

| U3-00 | Cam drive problem |

| U3-01 | Cam movement slow |

| U3-04 | Main board to duplex communication |

| U3-09 | Cam problem |

| U3-12 | Jogger problem |

| U3-19 | Cam problem |

| U3-21 | Cam problem |

| U3-23 | Cam problem |

| U3-29 | Cam problem |

| U3-32 | Cam problem |

| U3-34 | Cam problem |

| U3-39 | Cam problem |

| U3-43 | Cam problem |

| U3-45 | Cam problem |

| U3-49 | Cam problem |

| U3-54 | Cam problem |

| U3-56 | Cam problem |

| U3-59 | Cam problem |

| U4-1 | Fuser problem. Long warm up |

| U4-2 | Low fuser temperature after warm up |

| U4-3 | High fuser temperature |

| U4-4 | Open fuser thermistor |

| U4-6 | Replace fuser web |

| U4-7 | Thermistor signal problem |

| U7-1 | Copy cartridge belt drive problem |

| U9-3 | Exposure lamp problem |

| U9-4 | Toner motor |

| U9-5 | Problem in warm up |

Xerox 5312, 5313, 5314

| Код ошибки | Описание |

|---|---|

| C1 | Upper paper feed problem. Did not reach feed sensor |

| C2 | Lower paper feed problem. Did not reach feed sensor |

| E1 | Exit jam. Paper did not reach exit sensor |

| E3 | Exit jam. Paper still on exit sensor |

| J1 | Add toner |

| J3 | Copy cartridge (drum unit) not installed |

| J7 | Copy cartridge (drum unit) must be replaced |

| J8 | Copy cartridge (drum unit) problem |

| L6 | Problem with an accessory. Installed but not initialized |

| U1 | Drive problem. Main motor, gear etc. |

| U2 | Scan problem |

| U3 | Main board dip switches wrong. Lens drive problem |

| U4 | Fuser problem. Heat lamp, thermal switch, overheat, thermistor. |

| U6 | EPROM error |

| U8 | Auto exposure sensor. No exposure lamp or weak lamp |

Xerox 5318, 5320, 5322

| Code | Description |

|---|---|

| A1-11 | Original ready switch |

| A1-12 | Feed sensor |

| A1-1 to A1-32 | All indicate a paper path problem, etc. in the ADF |

| A1-21 | Original ready switch and document registration sensor or both the document feed sensor and document registration sensor |

| A1-22 | ADF registration sensor |

| A1-23 | Original did not reach ADF registration sensor quickly enough |

| A1-24 | ADF sensor stuck down too long |

| A1-25 | ADF sensor actuated at the wrong time during single sheet feed |

| A1-26 | ADF sensor not actuated quickly enough in sheet feed mode |

| A1-31 | In reverse, ADF sensor is not actuated soon enough |

| A1-32 | In reverse, ADF sensor is actuated too long |

| A2 | ADF exit problems |

| A2-1 | Original ready sensor and ADF exit switch are actuated or ADF feed in sensor and ADF exit switch are both actuated |

| A2-2 | ADF exit switch |

| A2-3 | ADF exit switch is not actuated on time |

| A3 | Irregular size documents |

| A3-1 | Wrong size original sensed in 1:1 mode |

| A3-2 | Wrong size original sensed in the 2:1 mode |

| A5 | ADF interlock |

| A5 | ADF interlock |

| A6 | ADF single sheet document reset. |

| A6-1 | Reset original |

| A6-2 | Reset sheet feeder |

| A7 | Document cover interlock |

| A8 | ADF exit interlock |

| C1 | Tray 1 jam |

| C1-2 | Paper feed problem in tray 1 |

| C1-3 | Paper does not reach registration |

| C2 | Tray 2 jam |

| C3 | Tray 3 jam |

| C3-1 | Paper feed problem from tray 3 |

| C3-2 | Paper feed problem from tray 3 |

| C3-3 | Paper feed problem from tray 1 |

| C6-1 | Duplex paper feed problem |

| C6-2 | Duplex and/or tray 1 paper feed problem |

| C6-3 | Paper feed problem from tray 1 |

| C7-1 | Paper feed problem from HCF |

| C7-2 | Paper feed problem from HCF on tray 1 |

| C7-3 | Paper feed problem from tray 1 |

| C8 | Paper stays in tray or duplex or HCF |

| C8-1 | Paper on tray 1 feed sensor |

| C8-2 | Paper on tray 2 feed sensor |

| C8-3 | Paper on tray 3 feed sensor |

| C8-4 | Paper on HCF feed sensor |

| C8-5 | Paper in duplex section |

| C9 | Bypass feed problem |

| C9-3 | Paper from bypass did not reach registration sensor quickly enough |

| E1-10 to E1-25 | Internal jam |

| E1-6 | Paper on registration sensor |

| E2 | Reset signal happened. Might read E-2 something else. |

| E3-30 to E4-14 | Exit jam |

| E3-30 to E3-35 | Exit switch actuated too long |

| E3-6 | Exit jam |

| E3-6 | Paper on exit switch |

| E4-10 to E4-14 | Inverter sensor not actuated. |

| E4-10 to E4-45 | Paper did not reach inverter switch soon enough |

| E4-15 | Inverter sensor |

| E4-40 to E4-45 | Duplex entry sensor |

| E4-6 | Paper on inverter switch |

| E4-6 | Inverter sensor |

| E5 | Front door interlock |

| E6-1 | Tray 1 interlock |

| E6-2 | 2 tray or duplex interlock |

| E6-3 | HCF interlock |

| E7-2 | Duplex inverter interlock |

| E7-3 | Duplex interlock |

| E8-10 to E8-15 | Paper on duplex feed sensor is not actuated soon enough |

| E8-6 | Paper in duplex |

| E8-6 to E8-15 | Duplex entry sensor |

| F1-1 | Paper did not reach sorter |

| F1-2 | Paper stayed on sorter feed sensor |

| F1-6 | Sorter exit sensor |

| F3 | Paper size not available for sort/stack |

| F5 | Sorter interlock |

| H2-1 | Communication problem between main board and duplex board |

| H2-2 | Side guard sensor problem |

| H3-1 | Communication problem between main board and HCF |

| H3-2 | Upper limit sensor problem on HCF |

| H6-1 | ADF size sensor |

| H6-2 | ADF nudgeer sensor |

| H6-3 | Belt drive motor does not have 24 volts. Black toner is empty, but 100 copies have been run without changing toner |

| J1 | Black toner is empty, but 100 copies have been run without changing toner |

| J3 | Replace copy cartridge |

| J3 | No copy cartridge (drum unit) |

| J7 | Copy cartrige must be replaced |

| J8-1 | Wrong copy cartridge installed |

| J8-2 | Copy cartridge EEPROM must be changed |

| L6 | Auditron or other counter problem |

| L6 | Key counter not installed |

| L8 | Platen glass temperature is too high |

| L9 | Communication problem between interimage erase/edge lamps and main board |

| U1-1 | Main motor drive problem |

| U2-1 | Scan home problem |

| U2-1 to U2-4 | Scan home sensor |

| U2-2 | Scan home problem or optics problem |

| U2-3, U2-4 | Scan home problem |

| U3-1 | Lens sensor problem |

| U4-1 | Fuser thermistor open |

| U4-2 | Fuser did not warm up properly |

| U4-3 | Fuser temperature too high |

| U4-4 | Fuser problem. Staying on too long |

| U4-6 | High fuser temperature |

| U5-1 | Sorter bin home switch not activated |

| U5-2 | Sorter bin home switch stayed actuated |

| U5-3 | Sorter bin home switch |

| U5-4 | Sorter bin home switch |

| U6-1 | ROM problem |

| U6-2 | RAM problem |

| U6-3 | Low battery |

| U6-4 | Incorrect value in NVM. Reinitialize main board with code 20-96 |

| U8-1 | Exposure lamp problem |

| U8-2 | Communication problem main board and exposure board |

| U8-3 | Exposure lamp or exposure lamp board problem |

| U8-4 to U8-6 | Problem with exposure lamp, lamp sensor, lamp board |

| Code | Description |

|---|---|

| A1 | Document in ADF |

| A1-8 | Main board received reset signal |

| A2 | ADF jams |

| A6 | ADF registration jam |

| A7 | ADF interlock |

| A9 | Tray 1 jam |

| C1 | Tray 2 jam |

| C2 | Tray 3 jam |

| C3 | Bypass feed jams |

| C4 | Machine has reset |

| E1 | Jam |

| E1-5 | Clamshell interlock |

| E1-6 | Right side interlock |

| E1-7 | Two tray interlock, or duplex interlock |

| E1-8 | Sorter interlock |

| E1-9 | Copy cartridge interlock |

| E1 or E1-0 | Registration jam |

| E2 | Reset signal happened |

| E3 | Jam in transfer area |

| E4 | Exit jam |

| E4-0 | Exit jam |

| E4-5 | Clamshell interlock |

| E4-6 | Right side interlock |

| E4-7 | Two tray interlock |

| E4-8 | Sorter interlock |

| E4-9 | Copy cartridge interlock |

| E5 | Clamshell interlock |

| E6 | Right side interlock |

| E9 | Copy cartridge interlock |

| F3-1 | Sorter bin home switch |

| F3-2 | Sorter cam switch |

| F3-3 | Sorter cam switch |

| F5 | Sorter interlock |

| J1-1 | Add toner |

| J1-2 | Temporary low toner signal |

| J2-1, J2-2 | Replace copy cartridge |

| J5, J6 | ADF to machine communications problem |

| L2 | 2000 copies left on cartridge |

| L3 | ADF to machine communications problem |

| L4 | (flashing) 1000 copier left on fuser web |

| L6 | Auditron or other counter problem |

| LL | Main board. Try simulation 1.1 to initialize |

| rc | Wrong operation panel installed |

| rr | Bad EPROM on main board. Try 1.1 |

| U0 | Main board |

| U2 | Scan problem |

| U2-1 | Scan home |

| U2-2 | Scan home or scan encoder |

| U2-4 | Scan home or scan dual page sensor |

| U2-7 | Scan home |

| U4-1 | Fuser problem. Long warm up |

| U4-2 | Low fuser temperature after warm up |

| U4-3 | High fuser temperature |

| U4-4 | Open fuser thermistor |

| U4-6 | Replace fuser web. |

| U4-7 | Thermistor signal problem |

| U7-1 | Copy cartridge belt drive problem |

| U9-3 | Exposure lamp problem |

| U9-4 | Toner motor |

| U9-5 | Problem in warm-up |

| Code | Description |

|---|---|

| A1-1 to A1-32 | All indicate a paper path problem, etc. in the ADF. |

| A2 | ADF exit problems |

| A3 | Irregular size documents |

| A5 | ADF interlock |

| A6 | ADF single sheet document reset. |

| A7 | Platen interlock |

| A8 | ADF exit interlock |

| C1 | Tray 1 jam |

| C2 | Tray 2 jam |

| C3 | Tray 3 jam |

| C6-1, C6-2 | Jams related to duplex |

| C6-3 | Registration sensor, re tray 1 |

| C7-1, C7-2 | HCF feed problems |

| C7-3 | Tray 1 feed problem |

| C8 | Paper stays in tray or duplex or HCF |

| C9 | Bypass feed problem |

| E1-10 to E1-25 | Internal jam |

| E1-6 | Paper on registration sensor |

| E2 | Reset signal happened. Might read E-2 something else. |

| E3-30 to E4-14 | Exit jam |

| E3-6 | Exit jam |

| E4-10 to E4-14 | Inverter sensor not actuated. |

| E4-15 | Inverter sensor |

| E4-40 to E4-45 | Duplex entry sensor |

| E4-6 | Inverter sensor |

| E5 | Front door interlock |

| E6-1 | Tray 1 interlock |

| E6-2 | 2 tray or duplex interlock |

| E6-3 | HCF interlock |

| E7-2, E7-3 | Duplex interlock |

| E8-6 to E8-15 | Duplex entry sensor |

| F1-1 | Sorter entry sensor |

| F1-6 | Sorter exit sensor |

| F3 | Paper size not available for sort/stack |

| F5 | Sorter interlock |

| J1 | Add toner |

| J3 | Replace copy cartridge |

| J7 | Replace copy cartridge |

| J8-1 | Wrong copy cartridge installed |

| J8-2 | Copy cartridge EEPROM |

| L6 | Auditron or other counter problem |

| L8 | Platen glass temperature is too high |

| L9 | Communication problem between interimage erase/edge lamps and main board |

| U1-1 | Main motor drive problem |

| U2-1 to U2-4 | Scan home sensor |

| U3-1 | Lens sensor |

| U4-1 | Open fuser thermistor |

| U4-2 | Fuser did not warm up properly |

| U4-3 | Fuser temperature too high |

| U4-4 | Fuser problem. Staying on too long |

| U4-6 | High fuser temperature |

| U5-1 | Sorter bin home switch not activated |

| U5-2 | Sorter bin home switch stayed actuated |

| U5-3 | Sorter bin home switch |

| U5-4 | Sorter bin home switch |

| U6-1 | ROM problem |

| U6-2 | RAM problem |

| U6-3 | Low battery |

| U6-4 | Incorrect value in NVM. Reinitialize main board with code 20-96 |

| U8-1 to U8-6 | Problem with exposure lamp, lamp sensor, lamp board |

Выезд мастера на заправку картриджей — БЕСПЛАТНО.

Сделать заказ заправки картриджей:

1. позвоните по телефону: (495) 778-52-50, (495) 778-50-452.

Источник

Xerox WorkCentre 5016/5020 User Guide

Downloaded From ManualsPrinter.com Manuals

Document Present

The green indicator lights up when a document is loaded correctly in the

Document Feeder.

Note

• This option is only available when the Document Feeder is fitted on the machine.

A Codes

Error Code

A1

Documents jammed in the

Document Feeder.

A2

The size of documents that are

loaded in the Document Feeder is

not supported, and resulted in a

document jam.

A5

The Document Feeder Cover is

open.

When leaving the Document Cover

slightly open to scan a document

with a certain thickness such as a

book on the Document Glass, if

another document is also loaded in

the Document Feeder, the machine

does not allow you to scan a

document on the Document Glass.

Description

Fault Clearance Procedure

Remedy

Remove the jammed document

carefully.

For information on how to remove the

jammed document, refer to «A1:

Document Jams» (P.109).

Remove the jammed document

carefully, and use the Document

Glass instead.

For information on how to remove the

jammed document, refer to «A1:

Document Jams» (P.109).

Close the Document Feeder Cover.

Remove the document in the

Document Feeder before starting to

scan the document on the Document

Glass.

92

Процедура устранения неисправности

Руководство пользователя Xerox WorkCentre 5016/5020

98

Лоток 2

Этот зеленый индикатор загорается при выборе лотка 2.

Этот зеленый индикатор мигает, когда в лотке 2 заканчивается или

застревает бумага.

Сведения о загрузке бумаги в лоток 2 см. раздел «Загрузка бумаги в лоток 2» (стр. 45).

Информация об устранении застревания бумаги в лотке 2 приведена в разделе «C2:

Застревание бумаги в лотке 2» (стр. 115).

Примечание • Следующий индикатор отображается только тогда, когда на аппарате установлен

лоток для бумаги 2 (опция).

Обходной лоток

Этот зеленый индикатор загорается при выборе обходного лотка.

Сведения о загрузке бумаги в обходной лоток см. раздел «Загрузка бумаги в обходной

лоток» (стр. 46).

Информация об устранении застревания бумаги в обходном лотке приведена в разделе «C3:

Застревание бумаги в обходном лотке» (стр. 116).

Наличие оригинала

Этот зеленый индикатор загорается, когда оригинал в податчик

загружен правильно.

Примечание • Данная опция доступна только тогда, когда на аппарате установлен податчик

оригиналов.

Коды ошибок

А-коды

Код

ошибки

Описание

Метод устранения

A1

Застревание оригинала

в податчике.

Аккуратно вытащите застрявший

оригинал.

Сведения об удалении застрявшего

оригинала см. в разделе

«A1: Застревание оригиналов»

(стр. 117).

A2

В податчик загружены оригиналы,

размер которых не

поддерживается. Это может

привести к застреванию

оригиналов.

Аккуратно вытащите застрявший

оригинал и используйте вместо него

стекло экспонирования.

Сведения об удалении застрявшего

оригинала см. в разделе

«A1: Застревание оригиналов»

(стр. 117).

A5

Открыта крышка податчика

оригиналов.

Закройте крышку податчика

оригиналов.

Если при сканировании толстого

оригинала, например книги,

крышка стекла экспонирования

остается слегка приоткрытой, и

при этом в податчик загружен

другой оригинал, аппарат не будет

сканировать оригинал со стекла

экспонирования.

Для сканирования оригинала со

стекла экспонирования нужно

сначала убрать оригинал из

податчика.

– Compatible Printer model: Xerox WorkCentre 5016

– Xerox WorkCentre 5016 Error Codes with quick guides:

- Code: 005-170

- Description: DADF Feed Failure BSD-Reference: CH 5.2. The control logic has detected the failure of paper to reach the Document Feed Sensor after the Feed Clutch has energized.

- Troubleshooting Guides: Check for obstructions in the Document Tray. Clean the Feed Roll. Confirm that a document is feeding into the document handler. The Feed Roller feeds paper into the document handler. Y↓N→The Document Drive Motor operates. Y↓N→Enter the Diagnostic Mode. Enter Component Control Code [05-01]. The Document Drive Motor operates. Y↓N→There is +24 VDC at connector CN2 pin 1 and pin 4 on the DADF PWB. Y↓N→Check the following in order: 1. Check the connectors CN1 and CN2 on the DADF PWB for proper connections 2. Check the connector J414 on the SLCC PWB (AIOC) for proper connection. 3. Check the harness from the DADF PWB to the SLCC PWB for an open circuit. If the harness and the connectors are good, replace the DADF PWB Replace the Document Drive Motor (PL 13.5) The Feed Roller rotates. Y↓N→Enter the Diagnostic Mode. Enter Component Control Code [05-62]. The Document Feed Clutch operates. Y↓N→Check the connector of the Document Feed Clutch (PL 13.9) If the connector is good, replace the Document Feed Clutch (PL 13.9). Replace the Document Feed Clutch (PL 13.9) Replace the Pick Up Roller and Feed Roller. The Feed Roller rotates. Y↓N→Enter the Diagnostic Mode. Enter Component Control Code [05-62]. The Document Feed Clutch operates. Y↓N→Check the connector of the Document Feed Clutch (PL 13.9) If the connector is good, replace the Document Feed Clutch (PL 13.9). Replace the Document Feed Clutch (PL 13.9) Replace the Pick Up Roller and Feed Roller. Replace the Document Feed Sensor (PL 13.9).

- Code: 005-171

- Description: DADF Regi / Exit Failure BSD-Reference: CH 5.8. Control logic has detected no paper at the Registration Sensor after turning on the Registration Clutch or detected no paper at the Exit/Invert Sensor after turning on the Registration Clutch.

- Troubleshooting Guides: Check for obstructions in the Document Tray. Clean the Feed Roll. Confirm that a document is feeding into the document handler. The Feed Roller feeds paper into the document handler. Y↓N→The Document Drive Motor operates. Y↓N→Enter the Diagnostic Mode. Enter Component Control Code [05-01]. The Document Drive Motor operates. Y↓N→There is +24 VDC at connector CN2 pin 1 and pin 4 on the DADF PWB. Y↓N→Check the following in order: 1. Check the connectors CN1 and CN2 on the DADF PWB for proper connections 2. Check the connector J414 on the SLCC PWB (AIOC) for proper connection. 3. Check the harness from the DADF PWB to the SLCC PWB for an open circuit. If the harness and the connectors are good, replace the DADF PWB Replace the Document Drive Motor (PL 13.5) The Feed Roller rotates. Y↓N→Enter the Diagnostic Mode. Enter Component Control Code [05-62]. The Document Feed Clutch operates. Y↓N→Check the connector of the Document Feed Clutch (PL 13.9) If the connector is good, replace the Document Feed Clutch (PL 13.9). Replace the Document Feed Clutch (PL 13.9) Replace the Pick Up Roller and Feed Roller. The Feed Roller rotates. Y↓N→Enter the Diagnostic Mode. Enter Component Control Code [05-62]. The Document Feed Clutch operates. Y↓N→Check the connector of the Document Feed Clutch (PL 13.9) If the connector is good, replace the Document Feed Clutch (PL 13.9). Replace the Document Feed Clutch (PL 13.9) Replace the Pick Up Roller and Feed Roller. Enter the Diagnostic Mode. Enter Component Control Code [05-206]. Actuate the Document Registration Sensor acutator. The display changes from High to Low. Y↓N→Replace the Document Registration Sensor. (PL 13.7) Enter the Diagnostic Mode. Enter Component Control Code [05-205]. Actuate the Exit/Invert Sensor actuator. The display changes from High to Low. Y↓N→Replace the Exit/Invert Sensor. (PL 13.7) Replace the DADF PWB , or replace the SLCC PWB (AIOC/Network)

- Code: 005-172

- Description: DADF Inverted Document Jam BSD-Reference: CH 5.8. When inverting documents, the control logic detected a failure of a document at the Feed Sensor after turning off the Feedout Forward or document failure at the Exit/Invert Sensor after turning on the Document Registration Sensor.

- Troubleshooting Guides: Check for obstructions in the Document Tray. Clean the Feed Roll. Confirm that a document is feeding into the document handler. The Feed Roller feeds paper into the document handler. Y↓N→The Document Drive Motor operates. Y↓N→Enter the Diagnostic Mode. Enter Component Control Code [05-01]. The Document Drive Motor operates. Y↓N→There is +24 VDC at connector CN2 pin 1 and pin 4 on the DADF PWB. Y↓N→Check the following in order: 1. Check the connectors CN1 and CN2 on the DADF PWB for proper connections 2. Check the connector J414 on the SLCC PWB (AIOC) for proper connection. 3. Check the harness from the DADF PWB to the SLCC PWB for an open circuit. If the harness and the connectors are good, replace the DADF PWB Replace the Document Drive Motor (PL 13.5) The Feed Roller rotates. Y↓N→Enter the Diagnostic Mode. Enter Component Control Code [05-62]. The Document Feed Clutch operates. Y↓N→Check the connector of the Document Feed Clutch (PL 13.9) If the connector is good, replace the Document Feed Clutch (PL 13.9). Replace the Document Feed Clutch (PL 13.9) Replace the Pick Up Roller and Feed Roller. The Feed Roller rotates. Y↓N→Enter the Diagnostic Mode. Enter Component Control Code [05-62]. The Document Feed Clutch operates. Y↓N→Check the connector of the Document Feed Clutch (PL 13.9) If the connector is good, replace the Document Feed Clutch (PL 13.9). Replace the Document Feed Clutch (PL 13.9) Replace the Pick Up Roller and Feed Roller. Enter the Diagnostic Mode. Enter Component Control Code [05-204]. Actuate the Document Feed Sensor acutator. The display changes from High to Low. Y↓N→Replace the Document Feed Sensor. (PL 13.9) Enter the Diagnostic Mode. Enter Component Control Code [05-205]. Actuate the Exit/Invert Sensor actuator. The display changes from High to Low. Y↓N→Replace the Exit/Invert Sensor. (PL 13.7) Replace the DADF PWB , or replace the SLCC PWB (AIOC/Network)

- Code: 005-198

- Description: Short Scan Jam BSD-Reference: CH 6.2. The control logic has found that the length of slow scan is less than 80mm.

- Troubleshooting Guides: Choose a document size equal to or larger than A4 paper or 208mm SEF or larger, in the Document Tray. The problem is solved. Y↓N→Replace the Document Registration Sensor. (PL 13.7) Inform the customer of the minimum size limitation of documents used in the DADF Document Tray.

- Code: 005-199

- Description: 005-199 Long Scan Jam BSD-Reference: CH 6.2. The control logic has detected that the length of slow scan is 450mm or more.

- Troubleshooting Guides: Choose a document size equal to or less than A3 paper or 294mm SEF or less in the Document Tray. The problem is solved. Y↓N→Replace the Document Registration Sensor. (PL 13.7) Inform the customer of the maximum size limitation of documents used in the DADF Document Tray.

- Code: 005-305

- Description: Feeder Top Cover Open BSD-Reference: CH 5.6. The control logic has detected that the Feeder Top Cover is open.

- Troubleshooting Guides: Close the Feeder Top Cover. The problem continues. Y↓N→Adjust or repair the Feeder Top Cover latch. Replave the Feeder Top Cover Switch. (PL 13.9)

- Code: 005-920

- Description: Static Jam BSD-Reference: CH 5.6. At power on, the control logic detected either the Platen Interlock is close when the Feeder Cover is open or the Feeder Cover Interlock is close when the Platen Interlock is open.

- Troubleshooting Guides: If this occurs frequently, confirm if there is any interferance with the Feed Sensor (PL 13.9), the Document Registration Sensor (PL 13.7) or the Exit/Invert Sensor (PL 13.7). Check the sensor connectors for prober connection. Replace one sensor at a time until the problem is solved.

- Code: 062-300

- Description: Platen Interlock Open BSD-Reference: CH 5.6. Detected the opened Platen Interlock.

- Troubleshooting Guides: Ensure that the DADF can be closed normally. The DADF can be closed normally. Y↓N→Remove obstructions or repair the DADF Counter Balances. Check that the Platen Interlock is functioning properly. The Platen Interlock is functioning properly. Y↓N→Replace the Platen Interlock Sensor. Replace the SLCC PWB (AIOC/Network PWB). (PL 8.1)

- Code: 062-345

- Description: IISS EEPROM Failure BSD-Reference: CH 3.1. Error in writing on or communicatiing with the EEPROM.

- Troubleshooting Guides: Switch off the machine power then switch on the power. The problem is solved. Y↓N→Replace the SLCC PWB (AIOC/Network PWB). (PL 8.1) Problem is resolved.

- Code: 062-360

- Description: Carriage Position Fail BSD-Reference: CH 6.2. Detected no input of Regi Sensor when carriage was working or detected the failure of the Regi Sensor position, or detected the failure of the IIT Regi Sensor level.

- Troubleshooting Guides: Check that the Lamp Carriage can move freely and has no loose cables. The Lamp Carriage and cables are good. Y↓N→Repair the Lamp Carriage. Enter the Diagnostic Mode. Enter Component Control Code [62-212]. Check the operation of the IIT Regi Sensor. The Regi Sensor is good. Y↓N→Reseat the Regi Sensor connector. Check the wiring for proper operation and repair if necessary. Replace the Regi Sensor. (PL 10.6) Enter the Diagnostic Mode. Enter Component Control Code [05-22]. The Carriage moves in the scan direction. Y↓N→Check the connector of the Carriage Motor and repair if necessary. Replace the Carriage Motor. (PL 10.6) Replace the SLCC PWB (AIOC/Network PWB). (PL 8.1)

- Code: 062-371

- Description: Lamp Illumination Fail BSD-Reference: CH 6.1. Detected incufficient light provided from the Lamp to the CCD.

- Troubleshooting Guides: Check for any obstructions in the optical path between the lamp, the lens or the mirror. The optical path is clear of any obstructions. Y↓N→Remove the obstuctions. Check that the White Color Correction Plate (Reflector) is in place and not deterioarated. (PL 10.6) The White Color Correction Tape is good. Y↓N→Clean or replace the White Color Correction Plate. (PL 10.6) Enter the Diagnostic Mode. Enter Component Control Code [62-02]. The Illumination Lamp is good. Y↓N→Check that the Lamp harness is properly connected and repair if necessary. Replace the Illumination Lamp. Replace the SLCC PWB (AIOC/Network PWB). (PL 8.1)

- Code: 062-380

- Description: AGC Failure BSD-Reference: CH 6.2. Control logic has detected insufficient light from the Illumination Lamp during AGC (Automatic Gain Congrol) of the auto IIT Calibration at Start.

- Troubleshooting Guides: Check for any obstructions in the optical path. Clean the Mirror, lens and the white balance strip. Switch off the power then switch it on again. The problem has been resolved. Y↓N→Enter the Diagnostic Mode. Enter Component Control Code [62-02]. The lamp is good. Y↓N→Check that the Lamp harness is properly connected and repair if necessary. Replace the Illumination Lamp. Replace the SLCC PWB and (3) EEPROMS (AIOC/Network PWB). (PL 8.1) POPO the machine and retry.

Solve Xerox WorkCentre 5016 Error codes

- Code: 062-386

- Description: AOC Failure BSD-Reference: CH 6.1. Control logic has detected an output defect of the CCD at AOC (Automatic Offset Control) of the auto IIT Calibration at Start.

- Troubleshooting Guides: Check the connector P/J410 for proper connection. The problem has been resolved. Y↓N→Replace the SLCC PWB and (3) EEPROMS (AIOC/Network PWB). (PL 8.1) POPO the machine and retry.

- Code: 062-392

- Description: IPS PWB Memory Fail BSD-Reference: CH 3.1. Control logic has detected RAM malfunction of IISS PWB.

- Troubleshooting Guides: Switch off the power then switch it on again. If the problem is not solved, replace the SLCC PWB (AIOC/Network) and the 3 EEPROMs.

- Code: 062-393

- Description: IPS PWB Fail BSD-Reference: CH 3.1. Control logic has detected a test error or a writing error to the SLCC EEPROMs.

- Troubleshooting Guides: Switch off the power then switch it on again. If the problem is not solved, replace the SLCC PWB (AIOC/Network) and the 3 EEPROMs.

- Code: C0-1

- Description: APS NG Unselected. • Either Tray 1 or STM is in one of the ‘paper settings is of a size that causes missing image’ states when APS is selected during a copy job. • Or, either Tray 1 or STM is ‘set with paper size that is different from the one specified for the job’ when Auto Tray is selected during a print job

- Troubleshooting Guides: • Press the [Stop] button on the Control Panel. • Change the paper size of Tray 1 or STM to the one specified by the job.

- Code: C1-1

- Description: Tray1 F/O#1 SNR on JAM. Timeout between Tray1 Feed Clutch ON and Tray1 Feed Sensor ON.

- Troubleshooting Guides: I/O Diagnostic Codes • [08-07] Tray1 Feed Sensor • [08-12] Tray1 Feed Clutch

• Feed Roll or Retard Pad dirty, contaminated with paper dust, worn, or faulty • Tray1 Feed Sensor dirty and Sensor Actuator deformed or damaged • Paper damaged, not within specification, or not loaded correctly • Foreign matter, burrs, or paper in the paper path • Drive gear worn or damaged • Tray1 Feed Clutch faulty • Check that the following wires are connected securely with good electrical contact. If there is no problem, replace the Tray 1 Feed Sensor (PL 2.5) . – Wire between Tray 1 Feed Sensor J158-3 ( P/J158) and LVPS J501-6 ( P/J501) – Wire between Tray 1 Feed Sensor J158-2 and LVPS J501-7 – Wire between Tray 1 Feed Sensor J158-1 and LVPS J501-8 • Replace the Tray1 Feed Clutch (PL 2.2) and the AIOC PWB (PL 8.1) in that order.

- Code: C1-2

- Description: Tray1 Regi SNR on JAM. Timeout between Tray1 Feed Sensor ON and IOT Registration Sensor ON.

- Troubleshooting Guides: I/O Diagnostic Codes • [08-07] Tray1 Feed Sensor • [08-05] IOT Registration Sensor • [08-10] IOT Registration Clutch

Check Items: • Take Away Roll 1 dirty, contaminated with paper dust, worn, or faulty • Tray1 Feed Sensor dirty and Sensor Actuator deformed or damaged • Paper damaged, not within specification, or not loaded correctly • Foreign matter, burrs, or paper in the paper path • Drive gear worn or damaged • IOT Registration Clutch faulty • Check that the following wires are connected securely with good electrical contact. If there is no problem, replace the Tray 1 Feed Sensor (PL 2.5) . – Wire between Tray 1 Feed Sensor J158-3 ( P/J158) and LVPS J501-6 ( P/J501) – Wire between Tray 1 Feed Sensor J158-2 and LVPS J501-7 – Wire between Tray 1 Feed Sensor J158-1 and LVPS J501-8 • Check that the following wires are connected securely with good electrical contact. If there is no problem, replace the IOT Registration Sensor (PL 2.9). – Wire between IOT Registration Sensor J156-3 ( P/J156) and LVPS J503-1 ( P/J503) – Wire between IOT Registration Sensor J156-2 and LVPS J503-2 – Wire between IOT Registration Sensor J156-1 and LVPS J503-3 • Replace the IOT Registration Clutch (PL 2.9) and the AIOC PWB (PL 8.1) in that order.

- Code: C2-1

- Description: STM F/O#2 SNR on JAM. Timeout between STM Feed Motor ON and STM Feed Sensor ON.

- Troubleshooting Guides: I/O Diagnostic Codes • [08-06] STM Feed Sensor • [08-11] STM Feed Clutch • [08-13] STM Feed Motor

Check Items: • Tray2 Feed Roll or Tray2 Retard Roll dirty, contaminated with paper dust, worn, or faulty • STM Feed Sensor dirty and Sensor Actuator deformed or damaged • Paper damaged, not within specification, or not loaded correctly • Foreign matter, burrs, or paper in the paper path • Drive gear worn or damaged • STM Feed Clutch faulty • STM Feed Motor faulty • Check that the following wires are connected securely with good electrical contact. If there is no problem, replace the STM Feed Sensor (PL 11.5) . – – Wire between STM Feed Sensor J172-3 ( P/J172) and STM PWB J542-6 ( P/J542) – – Wire between STM Feed Sensor J172-2 and STM PWB J542-7 – – Wire between STM Feed Sensor J172-1 and STM PWB J542-8 • Replace the STM Feed Clutch (PL 11.6) , the STM Feed Motor (PL 11.6) , and the STM PWB (PL 11.5) in that order.

- Code: C2-2

- Description: Tray1 F/O#1 SNR on JAM from STM feed. Timeout between STM Feed Out Sensor ON and Tray 1 Feed Out Sensor ON.

- Troubleshooting Guides: I/O Diagnostic Codes • [08-06] STM Feed Sensor • [08-07] Tray1 Feed Sensor • [08-11] STM Feed Clutch • [08-13] STM Feed Motor

Check Items: • Take Away Roll 2 dirty, contaminated with paper dust, worn, or faulty • STM Feed Sensor dirty and Sensor Actuator deformed or damaged • Paper damaged, not within specification, or not loaded correctly • Foreign matter, burrs, or paper in the paper path • Drive gear worn or damaged • STM Feed Clutch faulty • STM Feed Motor faulty • Check that the following wires are connected securely with good electrical contact. If there is no problem, replace the STM Feed Sensor (PL 11.5) . – Wire between STM Feed Sensor J172-3 ( P/J172) and STM PWB J542-6 ( P/J542) – Wire between STM Feed Sensor J172-2 and STM PWB J542-7 – Wire between STM Feed Sensor J172-1 and STM PWB J542-8 • Check that the following wires are connected securely with good electrical contact. If there is no problem, replace the Tray 1 Feed Sensor (PL 2.5) . – Wire between Tray 1 Feed Sensor J158-3 ( P/J158) and STM PWB J501-6 ( P/J501) – Wire between Tray 1 Feed Sensor J158-2 and STM PWB J501-7 – Wire between Tray 1 Feed Sensor J158-1 and STM PWB J501-8 • Replace the STM Feed Clutch (PL 11.6) , the STM Feed Motor (PL 11.6) , and the STM PWB (PL 11.5) in that order.

- Code: C2-3

- Description: STM Regi SNR on JAM. • When feeding paper from the STM, timeout between Tray1 Feed Sensor ON and IOT Registration Sensor ON.

- Troubleshooting Guides: I/O Diagnostic Codes • [08-05] IOT Registration Sensor • [08-10] IOT Registration Clutch

Check Items: • Take Away Roll 1 dirty, contaminated with paper dust, worn, or faulty • IOT Registration Sensor dirty and Sensor Actuator deformed or damaged • Paper damaged, not within specification, or not loaded correctly • Foreign matter, burrs, or paper in the paper path • Drive gear worn or damaged • IOT Registration Clutch faulty • Check that the following wires are connected securely with good electrical contact. If there is no problem, replace the Tray 1 Feed Sensor (PL 2.5) . – Wire between Tray 1 Feed Sensor J158-3 ( P/J158) and LVPS J501-6 ( P/J502) – Wire between Tray 1 Feed Sensor J158-2 and LVPS J501-7 – Wire between Tray 1 Feed Sensor J158-1 and LVPS J501-8 • Check that the following wires are connected securely with good electrical contact. If there is no problem, replace the IOT Registration Sensor (PL 2.9). – Wire between Tray 1 Feed Sensor J156-3 ( P/J156) and LVPS J503-1 ( P/J503) – Wire between Tray 1 Feed Sensor J156-2 and LVPS J503-2 – Wire between Tray 1 Feed Sensor J156-1 and LVPS J503-3 • Replace the IOT Registration Clutch (PL 2.9) and the AIOC PWB (PL 8.1) in that order.

- Code: C5-0

- Description: No paper in the selected paper tray (Tray1). • No paper is detected in Tray1 when ATS function is disabled and Tray1 is selected during a copy job. • No paper is detected in Tray1 when Tray1 is selected during a print job (the paper size setting matches the one specified for the job).

- Troubleshooting Guides: I/O Diagnostic Codes [07-07] Tray1 No Paper Sensor

Check Items: • Press the [Stop] button on the Control Panel. • Check the tray to see if it is empty; if it is, add paper specified by the job. • Tray1 No Paper Sensor dirty and Sensor Actuator deformed or damaged • Check that the following wires are connected securely with good electrical contact. If there is no problem, replace the Tray 1 No Paper Sensor (PL 2.7) . – Wire between Tray1 No Paper Sensor J157-3 ( P/J157) and LVPS J501-3 ( P/J501) – Wire between Tray1 No Paper Sensor J157-2 and LVPS J501-4 – Wire between Tray1 No Paper Sensor J157-1 and LVPS J501-5 • Replace the AIOC PWB (PL 8.1) .

- Code: C5-1

- Description: Tray1 Paper Size Mismatch. • Paper that is different from the one in the Tray Settings is detected when feeding. • Or, paper size setting in Tray1 is different from the paper size specification of the job when Tray1 is selected during a print job.

- Troubleshooting Guides: • Press the [Stop] button on the Control Panel. • Change the paper size of Tray 1 to the one specified by the job.

- Code: C6-0

- Description: No paper in the selected paper tray (Tray2). • No paper is detected in the STM when ATS function is disabled and STM is selected during a copy job. • No paper is detected in the STM when STM is selected during a print job (the paper size setting matches the one specified for the job).

- Troubleshooting Guides: I/O Diagnostic Codes [07-08] STM No Paper Sensor

Check Items: • Press the [Stop] button on the Control Panel. • Load the correct paper into the STM. • STM No Paper Sensor dirty and Sensor Actuator deformed or damaged. • Check that the following wires are connected securely with good electrical contact. If there is no problem, replace the STM No Paper Sensor (PL 11.7) . – Wire between STM No Paper Sensor J171-3 ( P/J171) and STM PWB J542-3 ( P/J542) – Wire between STM No Paper Sensor J171-2 and STM PWB J542-4 – Wire between STM No Paper Sensor J171-1 and STM PWB J542-5 • Replace the STM PWB (PL 11.5) and the AIOC PWB (PL 8.1) .

- Code: C6-1

- Description: Tray2 Paper Size Mismatch. • Paper that is different from the one in the Tray Settings is detected when feeding. • Or, paper size setting in the STM is different from the paper size specification of the job when STM is selected during a print job.

- Troubleshooting Guides: • Press the [Stop] button on the Control Panel. • Change the paper size of STM to the one specified by the job.

- Code: C7-1

- Description: MSI Paper Size Mismatch. • Paper that is different from the one in the Tray Settings is detected when feeding. • Or, paper size setting in the MSI is different from the paper size specification of the job when MSI is selected during a print job.

- Troubleshooting Guides: • Press the [Stop] button on the Control Panel. • Change the paper size of Bypass to the one specified by the job.

- Code: C8-1

- Description: F/O#1 SNR Static JAM. Tray1 Feed Sensor ON is detected during standby.

- Troubleshooting Guides: I/O Diagnostic Codes [08-07] Tray1 Feed Sensor

Check Items: • Tray1 Feed Sensor dirty and Sensor Actuator deformed or damaged • Foreign matter, burrs, or paper in the paper path • Check that the following wires are connected securely with good electrical contact. If there is no problem, replace the Tray 1 Feed Sensor (PL 2.5) . – Wire between Tray 1 Feed Sensor J158-3 ( P/J158) and STM PWB J501-6 ( P/J501) – Wire between Tray 1 Feed Sensor J158-2 and STM PWB J501-7 – Wire between Tray 1 Feed Sensor J158-1 and STM PWB J501-8 • Replace the AIOC PWB (PL 8.1) .

- Code: C8-2

- Description: F/O#2 SNR Static JAM. STM Feed Sensor ON is detected during standby.

- Troubleshooting Guides: I/O Diagnostic Codes [08-06] STM Feed Sensor

Check Items: • STM Feed Sensor dirty and Sensor Actuator deformed or damaged • Foreign matter, burrs, or paper in the paper path • Check that the following wires are connected securely with good electrical contact. If there is no problem, replace the STM Feed Sensor (PL 11.5) . – Wire between STM Feed Sensor J172-3 ( P/J172) and STM PWB J542-6 ( P/J542) – Wire between STM Feed Sensor J172-2 and STM PWB J542-7 – Wire between STM Feed Sensor J172-1 and STM PWB J542-8 • Replace the STM PWB (PL 11.5) and the AIOC PWB (PL 8.1) in that order.

- Code: C9-3

- Description: MSI Regi SNR on JAM. Timeout between Bypass Solenoid ON and IOT Registration Sensor ON.

- Troubleshooting Guides: I/O Diagnostic Codes • [08-05] IOT Registration Sensor • [08-17] Bypass Solenoid

Check Items: • Bypass Feed Roll, Retard Pad, or Bypass Take Away Roll dirty, contaminated with paper dust, worn, or faulty • IOT Registration Sensor dirty and Sensor Actuator deformed or damaged • Paper damaged, not within specification, or not loaded correctly • Foreign matter, burrs, or paper in the paper path • Drive gear worn or damaged • Bypass Solenoid faulty • Check that the following wires are connected securely with good electrical contact. If there is no problem, replace the IOT Registration Sensor (PL 2.9). – Wire between Tray 1 Feed Sensor J156-3 ( P/J156) and LVPS J503-1 ( P/J503) – Wire between Tray 1 Feed Sensor J156-2 and LVPS J503-2 – Wire between Tray 1 Feed Sensor J156-1 and LVPS J503-3 • Check that the Bypass Solenoid and the LVPS J502-1/3 ( P/J502) pins are connected securely with good electrical contact. If there is no problem, replace the Bypass Solenoid (PL 7.5). • Replace the AIOC PWB (PL 8.1) .

- Code: E0-1

- Description: CPM Image Lost. During a copy job in CMP Priority Mode, it is detected that the paper containing an image cannot be output after the image is deleted.

- Troubleshooting Guides: Press the [Stop] button on the Control Panel.

- Code: E0-1

- Description: CPM Image Lost. During a copy job in CPM Priority Mode, the paper containing an image cannot be output after the image is deleted.

- Troubleshooting Guides: Press the [Stop] button on the Control Panel.

- Code: E1-2

- Description: Exit SNR on JAM. Timeout between IOT Registration Clutch ON and Fuser Exit Sensor ON.

- Troubleshooting Guides: I/O Diagnostic Codes • [08-10] IOT Registration Clutch • [10-23] Fuser Exit Sensor

Check Items: • Registration Roll dirty, contaminated with paper dust, worn, or faulty • Fuser Exit Sensor dirty and Sensor Actuator deformed or damaged • Paper damaged or not within specification • Foreign matter, burrs, or paper in the paper path • Drive gear worn or damaged • IOT Registration Clutch faulty • Check that the IOT Registration Clutch and the LVPS J503-4/5 ( P/J503) pins are connected securely with good electrical contact. If there is no problem, replace the IOT Registration Clutch (PL 2.9). • Check that the following wires are connected securely with good electrical contact. If there is no problem, replace the Fuser Exit Sensor (PL 6.2). – Wire between Fuser Exit Sensor J153-3 ( P/J153) and LVPS J505-1 ( P/J505) – Wire between Fuser Exit Sensor J153-2 and LVPS J505-2 – Wire between Fuser Exit Sensor J153-1 and LVPS J505-3 • Replace the AIOC PWB (PL 8.1) .

- Code: E1-6

- Description: Regi SNR Static JAM. IOT Registration Sensor ON is detected during standby.

- Troubleshooting Guides: I/O Diagnostic Codes [08-05] IOT Registration Sensor

Check Items: • Sensor dirty • Foreign matter, burrs, or paper in the paper path • Check that the following wires are connected securely with good electrical contact. If there is no problem, replace the IOT Registration Sensor (PL 2.9). – Wire between Tray 1 Feed Sensor J156-3 ( P/J156) and LVPS J503-1 ( P/J503) – Wire between Tray 1 Feed Sensor J156-2 and LVPS J503-2 – Wire between Tray 1 Feed Sensor J156-1 and LVPS J503-3 • Replace the AIOC PWB (PL 8.1) .

- Code: E3-1

- Description: Exit SNR off JAM. Timeout between Fuser Exit Sensor ON and Fuser Exit Sensor OFF.

- Troubleshooting Guides: I/O Diagnostic Codes [10-23] Fuser Exit Sensor

Check Items: • Fuser Exit Sensor dirty and Sensor Actuator deformed or damaged • Paper damaged or not within specification • Foreign matter, burrs, or paper in the paper path • Drive gear worn or damaged • Check that the following wires are connected securely with good electrical contact. If there is no problem, replace the Fuser Exit Sensor (PL 6.2). – Wire between Fuser Exit Sensor J153-3 ( P/J153) and LVPS J505-1 ( P/J505) – Wire between Fuser Exit Sensor J153-2 and LVPS J505-2 – Wire between Fuser Exit Sensor J153-1 and LVPS J505-3 • Replace the LVPS (PL 8.1) and the AIOC PWB (PL 8.1) in that order.

- Code: E3-6

- Description: Exit SNR JAM. Fuser Exit Sensor ON is detected during standby.

- Troubleshooting Guides: I/O Diagnostic Codes [10-23] Fuser Exit Sensor

Check Items: • Fuser Exit Sensor dirty and Sensor Actuator deformed or damaged • Foreign matter, burrs, or paper in the paper path • Check that the following wires are connected securely with good electrical contact. If there is no problem, replace the Fuser Exit Sensor (PL 6.2). – Wire between Fuser Exit Sensor J153-3 ( P/J153) and LVPS J505-1 ( P/J505) – Wire between Fuser Exit Sensor J153-2 and LVPS J505-2 – Wire between Fuser Exit Sensor J153-1 and LVPS J505-3 • Replace the AIOC PWB (PL 8.1) .

- Code: E5-1

- Description: IOT L/H Cover open. The Left Hand Cover is open.

- Troubleshooting Guides: I/O Diagnostic Codes [01-01] LH Cover Interlock Switch

Check Items: • Check that the Left Hand Cover closes correctly. • Check that the LH Cover Interlock Switch is correctly installed and that the electrical connection is good. • Check that the following wires are connected securely with good electrical contact. If there is no problem, replace the LH Cover Interlock Switch (PL 8.2). – Wire between LH Cover Interlock Switch FS151 ( FS151) and LVPS J506-4 ( P/J506) – Wire between LH Cover Interlock Switch FS152 ( FS152) and LVPS J506-3 • Replace the LVPS (PL 8.1) and the AIOC PWB (PL 8.1) in that order.

- Code: E5-2

- Description: IOT Front Cover open. The Front Cover is open.

- Troubleshooting Guides: I/O Diagnostic Codes [01-12] Front Cover Interlock Switch

Check Items: • Check that the Front Cover closes correctly. • Check that the Front Cover Interlock Switch is correctly installed and that the electrical connection is good. • Check that the following wires are connected securely with good electrical contact. If there is no problem, replace the Front Cover Interlock Switch (PL 8.2). – Wire between Front Cover Interlock Switch FS153 ( FS153) and LVPS J506-2 ( P/J506) – Wire between Front Cover Interlock Switch FS154 ( FS154) and LVPS J506-1 • Replace the LVPS (PL 8.1) and the AIOC PWB (PL 8.1) in that order.

- Code: E6-1

- Description: L/H Low Cover open. Access Cover 1 is open.

- Troubleshooting Guides: I/O Diagnostic Codes [01-11] Tray1 Interlock Switch

Check Items: • Check that Access Cover 1 closes correctly. • Check that the Tray 1 Interlock Switch is correctly installed and that the electrical connection is good. • Check that the following wires are connected securely with good electrical contact. If there is no problem, replace the Tray 1 Interlock Switch (PL 2.5). – Wire between Tray 1 Interlock Switch J161-2 ( P/J161) and LVPS J501-9 ( P/J501) – Wire between Tray 1 Interlock Switch J161-1 and LVPS J501-10 • Replace the LVPS (PL 8.1) and the AIOC PWB (PL 8.1) in that order.

- Code: E6-2

- Description: STM L/H Cover open. Access Cover 2 is open.

- Troubleshooting Guides: I/O Diagnostic Codes [01-10] STM Interlock Switch

Check Items: • Check that Access Cover 2 closes correctly. • Check that the STM Interlock Switch is correctly installed and that the electrical connection is good. • Check that the following wires are connected securely with good electrical contact. If there is no problem, replace the STM Interlock Switch (PL 11.5). – Wire between STM Interlock Switch J173-2 ( P/J173) and STM PWB J542-9 ( P/J542) – Wire between STM Interlock Switch J173-1 and STM PWB J542-10 • Replace the STM PWB (PL 11.5) , the LVPS (PL 8.1) , and the AIOC PWB (PL 8.1) in that order.

- Code: E8-1

- Description: Nup NG Out Of Range. The magnification is not within the range of 50 to 200% during Nup.

- Troubleshooting Guides: • Press the [Stop] button on the Control Panel. • Press the [Paper Supply] button on the Control Panel. • Press the [Special Copy] button on the Control Panel. • Press the [Original Size Input] button on the Control Panel. • Press the [Clear All] button on the Control Panel.

- Code: E8-2

- Description: Nup Paper direction mismatch. The paper orientation of the document and the tray are not aligned during Nup.

- Troubleshooting Guides: • Press the [Stop] button on the Control Panel. • Press the [Paper Supply] button on the Control Panel. • Press the [Special Copy] button on the Control Panel. • Press the [Original Size Input] button on the Control Panel. • Press the [Clear All] button on the Control Panel.

- Code: H9-7

- Description: • MCU-STM comm. error. A communication failure has occurred between the MCU and the Tray Module.

- Troubleshooting Guides: • Turn the power OFF then ON. • Check for any open circuit or short circuit between the STM connectors. • Replace the STM PWB (PL 11.5) and the AIOC PWB (PL 8.1) in that order.

- Code: J1-0

- Description: Toner Cartridge was PRENEAR empty. The toner cartridge is low.

- Troubleshooting Guides: • Refill the toner. • Foreign matter on the sensor. • Check that the Toner Empty Sensor and the LVPS J509-1-4 ( P/J509) pins are connected securely with good electrical contact. If there is no problem, replace the Toner Empty Sensor (PL 4.2). • Replace the AIOC PWB (PL 8.1) .

- Code: J1-2

- Description: Toner Empty. The Toner Cartridge is empty.

- Troubleshooting Guides: I/O Diagnostic Codes [09-07] Toner Empty Sensor

Check Items: • Refill the toner. • Foreign matter on the sensor. • Check that the Toner Empty Sensor and the LVPS J509 ( P/J509) 1-4 pins are connected securely with good electrical contact. If there is no problem, replace the Toner Empty Sensor (PL 4.2). • Replace the AIOC PWB (PL 8.1) .

- Code: J3-1

- Description: No Drum Cartridge. Unable to detect the Drum Cartridge.

- Troubleshooting Guides: I/O Diagnostic Codes [09-02] Drum Cartridge

Check Items: • Turn the power OFF then ON. • Check that the following wires are connected securely with good electrical contact. If there is no problem, replace the Drum Cartridge (PL 4.1) . – Wire between Drum Cartridge P610-7 ( P610) and AIOC PWB J402-1 ( P/J402) – Wire between Drum Cartridge P610-3 and AIOC PWB J402-4 – Wire between Drum Cartridge P610-2 and AIOC PWB J402-5 – Wire between Drum Cartridge P610-5 and AIOC PWB J402-2 – Wire between Drum Cartridge P610-4 and AIOC PWB J402-3 – Wire between Drum Cartridge P610-1 and AIOC PWB J402-6 • Replace the Drum Cartridge (PL 4.1) and the AIOC PWB (PL 8.1) in that order.

- Code: J6-0

- Description: Drum near end of life. The Drum Cartridge is near the end of its life.

- Troubleshooting Guides: Replace the Drum Cartridge (PL 4.1) .

- Code: J6-1

- Description: Drum cartridge life end. The Drum Cartridge has reached the end of its life.

- Troubleshooting Guides: Replace the Drum Cartridge (PL 4.1) .

- Code: J7-1

- Description: Drum CRUM comm. Error. The AIOC PWB is unable to communicate with the Drum Cartridge.

- Troubleshooting Guides: I/O Diagnostic Codes • [09-02] Drum Cartridge

Check Items: • Turn the power OFF then ON. • Check that the following wires are connected securely with good electrical contact. If there is no problem, replace the Drum Cartridge (PL 4.1) . – Wire between Drum Cartridge P610-7 ( P610) and AIOC PWB J402-1 ( P/J402) – Wire between Drum Cartridge P610-3 and AIOC PWB J402-4 – Wire between Drum Cartridge P610-2 and AIOC PWB J402-5 – Wire between Drum Cartridge P610-5 and AIOC PWB J402-2 – Wire between Drum Cartridge P610-4 and AIOC PWB J402-3 – Wire between Drum Cartridge P610-1 and AIOC PWB J402-6 • Replace the Drum Cartridge (PL 4.1) and the AIOC PWB (PL 8.1) in that order.

- Code: J7-2

- Description: Drum CRUM Market Identity Mismatch. The AIOC PWB has detected that the Drum CRUM destination does not match.

- Troubleshooting Guides: • Turn the power OFF then ON. • Replace the Drum Cartridge (PL 4.1) .

- Code: J7-3

- Description: Drum CRUM ID error. • The AIOC PWB has detected that the Drum CRUM ID is incorrect.

- Troubleshooting Guides: • Turn the power OFF then ON. • Replace the Drum Cartridge (PL 4.1) .

- Code: L9-0

- Description: Copy Counter Full. The user that is logged in has reached the allotted copy limit in the Account Mode.

- Troubleshooting Guides: Press the [Stop] button on the Control Panel.

- Code: N1-1

- Description: EPC Memory Full. • During a copy job in Collate Mode, the EPC memory is full. • Or, the machine has reached a state where it is unable to scan in any more documents.

- Troubleshooting Guides: Press the [Stop] button on the Control Panel.

- Code: N4-0

- Description: Name No Response from USB-Host. • Either ‘USB disconnected’ or ‘Communication timed-out’ is detected during a print job. • Or, either ‘USB disconnected’ or ‘Communication timed-out’ is detected during a scan job.

- Troubleshooting Guides: • Cancel the print job. • Reconnect the USB cable correctly.

- Code: N4-1

- Description: HBPL or XPJL Syntax Error. An abnormal command that cannot be ignored is received from the USB-Host during a print job.

- Troubleshooting Guides: • Cancel the print job. • Reconnect the USB cable correctly.

- Code: N4-2

- Description: Download File Error. There is an abnormal Product ID or there is a checksum error in the download file.

- Troubleshooting Guides: Press the [Stop] button on the Control Panel.

- Code: N4-3

- Description: Download Flash Write Error. Unable to write the downloaded file into flash memory.

- Troubleshooting Guides: Press the [Stop] button on the Control Panel.

- Code: N5-0

- Description: Push Scan TimeOut. • Push scan notification failed during a scan job. • Or, there is no scan job request from the PC after a push scan notification.

- Troubleshooting Guides: The error will clear itself after a set amount of time has passed.

- Code: N9-0

- Description: Controller Logic fail. A software defect that cannot be ignored is found in the Controller software.

- Troubleshooting Guides: Turn the power OFF then ON.

- Code: N9-1

- Description: IOT Communication Error. The AIOC PWB has detected a Type-Di communication error.

- Troubleshooting Guides: Turn the power OFF then ON.

- Code: U0-1

- Description: Main Motor Stop Error. The motor runs for over 120 seconds without any paper being fed.

- Troubleshooting Guides: The problem can be solved according to RAP U1- 1 Main Motor Rotation Error (U1-1).Y↓ N→Execute diagnostics [29-49] to check the ROM version. The ROM is the latest version. Y↓N→Upgrade the ROM to the latest version. Replace the IOT Motor (PL 1.1)and the AIOC PWB (PL 8.1) in that order. Completed

- Code: U1-1

- Description: Main Motor Rotation Error. 500 ms after the IOT Motor starts, the IOT Motor Lock signal is Low.

- Troubleshooting Guides: Close the Left Hand Cover and the Front Cover. Execute diagnostics [04–01 Main Motor On]. The IOT Motor can be heard rotating. Y↓N→Check P/J504 and P/J201. Both P/J504 and P/J201 are connected securely. Y↓N→Connect P/J504 and P/J201 securely. Measure the voltage between LVPS PWB P504-1 ( P/J504) (+) and GND (-). The voltage is approximately +24VDC. Y↓N→Replace the LVPS (PL 8.1). Check the wire between J504-3 ( P/J504) and J201-3 ( P/J201). The wire is not shorted or open. Y↓N→Repair the wire. Replace the IOT Motor (PL 1.1) and the AIOC PWB (PL 8.1) in that order. Check the installation of the IOT Motor (PL 1.1 ) . The IOT Motor is installed properly. Y↓N→Install the IOT Motor (PL 1.1 ) properly. Turn the rotor of the IOT Motor (PL 1.1 ) counterclockwise by hand. It rotates smoothly, without any abnormal load. Y↓N→Check for any foreign substances that obstruct the drive and for any incorrectly installed parts. There are foreign substances or incorrectly installed parts. Y↓N→Replace the IOT Motor (PL 1.1) . Remove any foreign substances and fix any installation errors. Check the wire between J504-3 ( P/J504) and J201-3 ( P/J201). The wire is not shorted or open. Y↓N→Repair the wire. Replace the IOT Motor (PL 1.1) and the AIOC PWB (PL 8.1) in that order.

- Code: U2-1

- Description: Carriage Module Fail. A carriage fault was detected.

- Troubleshooting Guides: Execute diagnostics [05-22 Move scanner to home position] and [05-23 Move scanner to maintenance position]. The carriage moves. Y↓N→Check each IIT Carriage connector. Each connector is connected securely. Y↓N→Connect each connector securely. Check for foreign substances and deformed parts in the carriage. None is found. Y↓N→Remove the foreign substances and repair the deformed parts. Replace the IIT Carriage (PL 10.3) . Execute diagnostics [05-23 Move scanner to maintenance position]. When the IIT Carriage has moved to the leftmost position, press the [Stop] button to put the Carriage Sensor into the blocked state. Execute diagnostics [5-11 Home Sensor], and ‘H’ is displayed. Y↓N→Check each IIT Carriage and Carriage Sensor connector. Each connector is connected securely. Y↓N→Connect each connector securely. Replace the Carriage Sensor (PL 10.6) and the IIT Carriage (PL 10.3) in that order. Check the Carriage Sensor (PL 10.6 ). The Carriage Sensor is installed properly. Y↓N→Install the Carriage Sensor (PL 10.6) properly. Replace the IIT Carriage (PL 10.3) .

- Code: U3-5

- Description: Laser Power Or ROS Motor Fail. The ROS Motor does not turn, or the laser output is not normal.

- Troubleshooting Guides: Execute diagnostics [6-15 ROS Motor ON]. The ROS Motor can be heard rotating. Y↓N→Measure the voltage between the AIOC PWB P403-7 ( P/J403) (+) and GND (-). The voltage is approximately +24VDC. Y↓N→Replace the AIOC PWB (PL 8.1) and the LVPS (PL 8.1) in that order. Replace the ROS (PL 3.1) and the AIOC PWB (PL 8.1) in that order. Measure the voltage between the AIOC PWB P403-1 ( P/J403) (+) and GND (-). The voltage is approximately +5VDC. Y↓N→Replace the AIOC PWB (PL 8.1) . Check the AIOC PWB P/J403 ( P/J403), LD PWB P/J140 ( P/J140), and P/J130 ( P/J130) connectors. The P/J403, P/J140, and P/J130 connectors are connected securely. Y↓N→Connect the AIOC PWB P/J403 ( P/J403), LD PWB P/J140 ( P/J140), and P/J130 ( P/ J130) connectors securely. Check the wires between J403 ( P/J403) and J140 ( P/J140) and between J403 and J130 ( P/ J130) The wires are not shorted or open. Y↓N→Repair the wire(s). Replace the ROS (PL 3.1) and the AIOC PWB (PL 8.1) in that order.

- Code: U4-1

- Description: Fuser On Time Fail. • The lamp did not turn OFF within the specified time after turning ON. • Or, Warm Up was not completed within the specified time after power ON.