Hello,

I’ve had my printer a little over 2 years and its been workign fine. Last week it started to generate an error message.

The code is 092-321 and it says remove black toner, reinsert and restart printer.

I did this,and it didn’t work. A couple of tries and it got going again.

It then happened again, so with a bit of google I found some possible issues (including through Xerox support). I checked the waste toner, one possibility,and found it was pretty full so got a replacement.

Everything started working again. Then today (I changed the waste toner yesterday) the message happens again. I have tried all the suggestions on the forums:

Turnign off and on

Tried a different toner cartridge

Taken the imaging drum out and cleaned.

The only thing I haven’t done is buy a new imaging drum (as seems an extreme fix if this isn’t the issue).

Does anyone have any ideas of what else I can try before accepting defeat and either getting a new printer or a new imaging drum.

Thanks

Lee

Модератор: vetal

-

Mayda

- Понюхал тонер

-

- Персональный альбом

-

-

Xerox Phaser 6600 «Invalid Yellow» / «Неверный желтый»

kotya-potya в форуме Принтеры, МФУ, факсы, копиры формата A4

- 5

- 5929

3100

Пн ноя 18, 2019 8:24 pm

-

Xerox Phaser 6600 «Invalid Yellow» / «Неверный желтый»

-

-

Xerox WC 3119: «Замятие 1»

kokubenko в форуме Принтеры, МФУ, факсы, копиры формата A4

- 22

- 40001

kokubenko

Ср ноя 23, 2011 4:47 pm

-

Xerox WC 3119: «Замятие 1»

-

-

Xerox 3315 «слетела» FIX прошивка

tekknik в форуме Принтеры, МФУ, факсы, копиры формата A4

- 7

- 7457

tekknik

Пн июн 10, 2019 4:22 am

-

Xerox 3315 «слетела» FIX прошивка

-

-

«Неисправность» финишера Xerox 7556

v1684 в форуме Принтеры, МФУ, копиры формата A3

- 21

- 13711

v1684

Ср сен 19, 2018 4:44 pm

-

«Неисправность» финишера Xerox 7556

-

-

Xerox 3428 «Установите Картридж»

Roller-ch в форуме Принтеры, МФУ, факсы, копиры формата A4

- 6

- 9734

SeMi

Сб авг 27, 2011 6:42 pm

-

Xerox 3428 «Установите Картридж»

Вернуться в Принтеры, МФУ, факсы, копиры формата A4

Кто сейчас на форуме

Сейчас этот форум просматривают: нет зарегистрированных пользователей и гости: 36

Hello,

I’ve had my printer a little over 2 years and its been workign fine. Last week it started to generate an error message.

The code is 092-321 and it says remove black toner, reinsert and restart printer.

I did this,and it didn’t work. A couple of tries and it got going again.

It then happened again, so with a bit of google I found some possible issues (including through Xerox support). I checked the waste toner, one possibility,and found it was pretty full so got a replacement.

Everything started working again. Then today (I changed the waste toner yesterday) the message happens again. I have tried all the suggestions on the forums:

Turnign off and on

Tried a different toner cartridge

Taken the imaging drum out and cleaned.

The only thing I haven’t done is buy a new imaging drum (as seems an extreme fix if this isn’t the issue).

Does anyone have any ideas of what else I can try before accepting defeat and either getting a new printer or a new imaging drum.

Thanks

Lee

Современные копировальные аппараты Xerox отличаются качество, надежностью и «быстрым» стартом. Также у них существует множество особенностей, которые отличают их от принтеров других производителей. Например, используется тефлоновый вал, а не термопленка.

Однако избегать различных поломок и ошибок пока не удается ни одному устройству. К самым частым неисправностям у принтеров Xerox относятся: залипание или повреждение датчика бумаги, повреждение роликов подачи, часто требуется перепрошивка программного обеспечения.

Если у вас возникнут вопросы насчет того, как исправить код ошибки копировального аппарата Xerox, то вы можете обратиться к специалистам нашего сервисного центра.

Основные коды ошибок копировальных аппаратов Xerox и способы их устранения:

- Коды ошибок Xerox 1012, 1012(RE)

- Коды ошибок Xerox 1020

- Коды ошибок Xerox 1025

- Коды ошибок Xerox 1035

- Коды ошибок Xerox 1038

- Коды ошибок Xerox 2830

- Коды ошибок Xerox 5011, 5012, 5014

- Коды ошибок Xerox 5016, 5017, 5316, 5317

- Коды ошибок Xerox 5018, 5028

- Коды ошибок Xerox 5312, 5313, 5314

- Коды ошибок Xerox 5318, 5320, 5322

- Коды ошибок Xerox 5328

- Коды ошибок Xerox 5330

- Коды ошибок Xerox 5340, 5343

- Коды ошибок Xerox 5345

- Коды ошибок Xerox 5350, 5352

- Коды ошибок Xerox 5355

- Коды ошибок Xerox 5622

- Коды ошибок Xerox XC520, 540, 560, 580

Xerox 1012, 1012(RE)

| Код ошибки | Описание |

|---|---|

| E1 | Jam between paper feed and fuser |

| E3 | Jam in fuser |

| E5 | Clam shell open |

| E6 | Paper feed section cover is open |

| J1 | Toner cartridge near empty |

| J3 | Drum cartridge not seated properly |

| J7 | Waste toner full (replace drum cartridge) |

| L6 | Key counter out |

| L8 | Exposure area overheat |

| U1 | No clock pulse (drive problem) |

| U2 | Scan problem |

| U3 | Lens/mirror problem (RE model only) |

| U4 | Heat problem |

| U8 | Exposure lamp control circuit problem |

| E1 | Jam between paper feed and fuser |

| E3 | Jam in fuser |

| E5 | Clam shell open |

| E6 | Paper feed section cover is open |

| J1 | Toner cartridge near empty |

| J3 | Drum cartridge not seated properly |

| J7 | Waste toner full (replace drum cartridge) |

| L6 | Key counter out |

| L8 | Exposure area overheat |

| U1 | No clock pulse (drive problem) |

| U2 | Scan problem |

| U3 | Lens/mirror problem (RE model only) |

| U4 | Heat problem |

| U8 | Exposure lamp control circuit problem |

Xerox 1020

| Код ошибки | Описание |

|---|---|

| LL | Probable bad heater lamp |

Xerox 1025

| Код ошибки | Описание |

|---|---|

| A1 | DF jam |

| C1 | PF jam cass. 1 |

| C2 | PF jam cass. 2 |

| C3 | PF jam cass. 3 |

| C9 | Bypass jam |

| E1-1 | Paper jam before exit switch |

| E1-2 | Paper jam |

| E1-5 | Paper jam |

| E1-6 | Paper jam |

| E3-3 | Paper jam at exit switch |

| E3-4 | Paper jam at exit switch |

| E5 | Front door open |

| F1 | Collator jam |

| F5 | Collator interlock |

| F8 | No power to collator |

| F9 | Collator bin home switch |

| J7 | 250 copies since toner waste was full |

| L5 | Original cass. not present after clearing interrupt |

| L6 | Key counter |

| L8 | Platen glass too hot |

| U1 | Main motor clock pulse |

| U2 | Scan problem |

| U3-1 | Lens problem |

| U4-1 | Open thermistor |

| U4-2 | Low temperature |

| U4-4 | Temperature |

| U4-5 | Main PWB |

| U6-1 | Main PWB |

| U6-2 | Main PWB |

| U6-3 | Main board battery |

| U6-4 | Initialization |

| U8 | Exposure lamp |

Xerox 1035

| Код ошибки | Описание |

|---|---|

| A9 | Scanner location |

| C1 | Paper feed — upper cassette |

| C2 | Paper feed — lower cassette |

| C9 | Bypass jam |

| E5 | Clam shell is open |

| L6 | Key counter |

| U1 | Off/On |

| U2 | Optics |

| U4 | Low fuser temperature |

Xerox 1038

| Код ошибки | Описание |

|---|---|

| A1 | DF jam |

| C1 | PF jam cass. 1 |

| C2 | PF jam cass. 2 |

| C3 | PF jam cass. 3 |

| C9 | Bypass jam |

| E1-1 | Paper jam before exit switch |

| E1-2 | Paper jam |

| E1-5 | Paper jam |

| E1-6 | Paper jam |

| E3-3 | Paper jam at exit switch |

| E3-4 | Paper jam at exit switch |

| E5 | Front door open |

| F1 | Collator jam |

| F5 | Collator interlock |

| F8 | No power to collator |

| F9 | Collator bin home switch |

| J7 | 250 copies since toner waste was full |

| L5 | Original cass. not present after clearing interrupt |

| L6 | Key counter |

| L8 | Platen glass too hot |

| U1 | Main motor clock pulse |

| U2 | Scan problem |

| U3-1 | Lens problem |

| U4-1 | Open thermistor |

| U4-2 | Low temperature |

| U4-4 | Temperature |

| U4-5 | Main PWB |

| U6-1 | Main PWB |

| U6-2 | Main PWB |

| U6-3 | Main board battery |

| U6-4 | Initialization |

| U8 | Exposure lamp |

Xerox 2830

| Код ошибки | Описание |

|---|---|

| A9 | Scanner location |

| C1 | Paper feed — upper cassette |

| C2 | Paper feed — lower cassette |

| C9 | Bypass jam |

| E5 | Clam shell is open |

| E5 | Clam shell open |

| L6 | Key counter |

| U1 | Off/On |

| U2 | Optics |

| U4 | Low fuser temperature |

Xerox 5011, 5012, 5014

| Код ошибки | Описание |

|---|---|

| C8 | Bypass jam/no paper |

| C9 | Bypass jam |

| E1 | Jam |

| E3 | Fuser jam |

| E5 | Clamshell open |

| E6 | PF section cover open |

| J1 | Toner cartridge amost empty |

| J3 | Copy cart (drum unit) missing/not seated right |

| J7 | Copy cartridge has run 18,000 copies |

| J8 | Copy cartridge. Improperly seated or possible only one of two fuses in the cartridge blew |

| L6 | Key counter |

| L8 | Exposure glass too hot |

| U1 | Drive problem |

| U2 | Scan problem |

| U3 | Lens or mirror drive problem |

| U4 | Fuser problem. Heat lamp, thermoswitch, SSR, thermistor |

| U6 | Battery on main board |

| U8 | Exposure lamp or exposure lamp circuit |

Xerox 5016, 5017, 5316, 5317

| Code | Description |

|---|---|

| A1-1 | Document feeder feed jam |

| A1-2 | Document feeder belt jam |

| A2-1 | Document feeder exit jam |

| A2-2 | Duplex jam |

| A3 | DAD interlock |

| A5 | Duplex and DAD right side interlock |

| A6 | Copier jams after |

| A9 | Document feed belt drive motor |

| C1-3 | Top cassette misfeed |

| C2-3 | Middle cassette misfeed |

| C3-3 | Bottom cassette misfeed |

| C9-3 | Bypass misfeed |

| E1-11 to E1-14 | Paper jam in machine. Did not reach exit switch soon enough |

| E1-6 | Paper path jam |

| E3-31 to E3-34 | Exit switch jam |

| E3-6 | Fuser jam |

| E5 | Front door interlock |

| E6 | Right side interlock or TTM interlock |

| F1 | Sorter jam |

| F5 | Sorter interlock |

| F8 | Sorter board to copier main board communication problem |

| F9 | Sorter bins |

Xerox 5018, 5028

| Code | Description |

|---|---|

| A1 | Document is ADF |

| A1-8 | Main board received reset signal |

| A2 | ADF jams |

| A6, A7 | ADF jams |

| A9 | ADF jams |

| C1 — C4 | Feed jam |

| C5-1 to C5-4 | Jams in various areas |

| C5-2 | Jams in various areas |

| C5-3 | Jams in various areas |

| C5-4 | Duplex jam |

| E0 | Machine has reset |

| E1 | Jam |

| E1-E0 | Registration jam |

| E1-E5 | Clamshell interlock |

| E1-E6 | Right side interlock |

| E1-E7 | Two tray interlock |

| E1-E8 | Sorter interlock |

| E1-E9 | Copy cartridge interlock |

| E2 | Reset signal happened |

| E3 | Jam |

| E4 | Exit jam |

| E4-10 | Exit jam |

| E4-5 | Clamshell interlock |

| E4-6 | Right side interlock |

| E4-7 | Two tray interlock. Duplex interlock |

| E4-8 | Sorter interlock |

| E4-9 | Copy cartridge interlock |

| E5 | Clamshell interlock |

| E6 | Right side interlock |

| E7 | Duplex interlock |

| E9 | Copy cartridge interlock |

| F3-1 | Sorter bin home switch |

| F3-2 | Sorter cam switch |

| F3-3 | Sorter cam switch |

| J1-1 | Add toner |

| J1-2 | Temporary low toner signal |

| J2-0 | Replace copy cartridge |

| L2 | 2000 copies left on copy cartridge |

| L3 | ADF to machine communication problem |

| L4 (flashing) | 1000 copies left on fuser web |

| rr | Bad EPROM on main board |

| U0 | Main board |

| U2 | Scan problem |

| U2-1 | Scan home |

| U3-00 | Cam drive problem |

| U3-01 | Cam movement slow |

| U3-04 | Main board to duplex communication |

| U3-09 | Cam problem |

| U3-12 | Jogger problem |

| U3-19 | Cam problem |

| U3-21 | Cam problem |

| U3-23 | Cam problem |

| U3-29 | Cam problem |

| U3-32 | Cam problem |

| U3-34 | Cam problem |

| U3-39 | Cam problem |

| U3-43 | Cam problem |

| U3-45 | Cam problem |

| U3-49 | Cam problem |

| U3-54 | Cam problem |

| U3-56 | Cam problem |

| U3-59 | Cam problem |

| U4-1 | Fuser problem. Long warm up |

| U4-2 | Low fuser temperature after warm up |

| U4-3 | High fuser temperature |

| U4-4 | Open fuser thermistor |

| U4-6 | Replace fuser web |

| U4-7 | Thermistor signal problem |

| U7-1 | Copy cartridge belt drive problem |

| U9-3 | Exposure lamp problem |

| U9-4 | Toner motor |

| U9-5 | Problem in warm up |

Xerox 5312, 5313, 5314

| Код ошибки | Описание |

|---|---|

| C1 | Upper paper feed problem. Did not reach feed sensor |

| C2 | Lower paper feed problem. Did not reach feed sensor |

| E1 | Exit jam. Paper did not reach exit sensor |

| E3 | Exit jam. Paper still on exit sensor |

| J1 | Add toner |

| J3 | Copy cartridge (drum unit) not installed |

| J7 | Copy cartridge (drum unit) must be replaced |

| J8 | Copy cartridge (drum unit) problem |

| L6 | Problem with an accessory. Installed but not initialized |

| U1 | Drive problem. Main motor, gear etc. |

| U2 | Scan problem |

| U3 | Main board dip switches wrong. Lens drive problem |

| U4 | Fuser problem. Heat lamp, thermal switch, overheat, thermistor. |

| U6 | EPROM error |

| U8 | Auto exposure sensor. No exposure lamp or weak lamp |

Xerox 5318, 5320, 5322

| Code | Description |

|---|---|

| A1-11 | Original ready switch |

| A1-12 | Feed sensor |

| A1-1 to A1-32 | All indicate a paper path problem, etc. in the ADF |

| A1-21 | Original ready switch and document registration sensor or both the document feed sensor and document registration sensor |

| A1-22 | ADF registration sensor |

| A1-23 | Original did not reach ADF registration sensor quickly enough |

| A1-24 | ADF sensor stuck down too long |

| A1-25 | ADF sensor actuated at the wrong time during single sheet feed |

| A1-26 | ADF sensor not actuated quickly enough in sheet feed mode |

| A1-31 | In reverse, ADF sensor is not actuated soon enough |

| A1-32 | In reverse, ADF sensor is actuated too long |

| A2 | ADF exit problems |

| A2-1 | Original ready sensor and ADF exit switch are actuated or ADF feed in sensor and ADF exit switch are both actuated |

| A2-2 | ADF exit switch |

| A2-3 | ADF exit switch is not actuated on time |

| A3 | Irregular size documents |

| A3-1 | Wrong size original sensed in 1:1 mode |

| A3-2 | Wrong size original sensed in the 2:1 mode |

| A5 | ADF interlock |

| A5 | ADF interlock |

| A6 | ADF single sheet document reset. |

| A6-1 | Reset original |

| A6-2 | Reset sheet feeder |

| A7 | Document cover interlock |

| A8 | ADF exit interlock |

| C1 | Tray 1 jam |

| C1-2 | Paper feed problem in tray 1 |

| C1-3 | Paper does not reach registration |

| C2 | Tray 2 jam |

| C3 | Tray 3 jam |

| C3-1 | Paper feed problem from tray 3 |

| C3-2 | Paper feed problem from tray 3 |

| C3-3 | Paper feed problem from tray 1 |

| C6-1 | Duplex paper feed problem |

| C6-2 | Duplex and/or tray 1 paper feed problem |

| C6-3 | Paper feed problem from tray 1 |

| C7-1 | Paper feed problem from HCF |

| C7-2 | Paper feed problem from HCF on tray 1 |

| C7-3 | Paper feed problem from tray 1 |

| C8 | Paper stays in tray or duplex or HCF |

| C8-1 | Paper on tray 1 feed sensor |

| C8-2 | Paper on tray 2 feed sensor |

| C8-3 | Paper on tray 3 feed sensor |

| C8-4 | Paper on HCF feed sensor |

| C8-5 | Paper in duplex section |

| C9 | Bypass feed problem |

| C9-3 | Paper from bypass did not reach registration sensor quickly enough |

| E1-10 to E1-25 | Internal jam |

| E1-6 | Paper on registration sensor |

| E2 | Reset signal happened. Might read E-2 something else. |

| E3-30 to E4-14 | Exit jam |

| E3-30 to E3-35 | Exit switch actuated too long |

| E3-6 | Exit jam |

| E3-6 | Paper on exit switch |

| E4-10 to E4-14 | Inverter sensor not actuated. |

| E4-10 to E4-45 | Paper did not reach inverter switch soon enough |

| E4-15 | Inverter sensor |

| E4-40 to E4-45 | Duplex entry sensor |

| E4-6 | Paper on inverter switch |

| E4-6 | Inverter sensor |

| E5 | Front door interlock |

| E6-1 | Tray 1 interlock |

| E6-2 | 2 tray or duplex interlock |

| E6-3 | HCF interlock |

| E7-2 | Duplex inverter interlock |

| E7-3 | Duplex interlock |

| E8-10 to E8-15 | Paper on duplex feed sensor is not actuated soon enough |

| E8-6 | Paper in duplex |

| E8-6 to E8-15 | Duplex entry sensor |

| F1-1 | Paper did not reach sorter |

| F1-2 | Paper stayed on sorter feed sensor |

| F1-6 | Sorter exit sensor |

| F3 | Paper size not available for sort/stack |

| F5 | Sorter interlock |

| H2-1 | Communication problem between main board and duplex board |

| H2-2 | Side guard sensor problem |

| H3-1 | Communication problem between main board and HCF |

| H3-2 | Upper limit sensor problem on HCF |

| H6-1 | ADF size sensor |

| H6-2 | ADF nudgeer sensor |

| H6-3 | Belt drive motor does not have 24 volts. Black toner is empty, but 100 copies have been run without changing toner |

| J1 | Black toner is empty, but 100 copies have been run without changing toner |

| J3 | Replace copy cartridge |

| J3 | No copy cartridge (drum unit) |

| J7 | Copy cartrige must be replaced |

| J8-1 | Wrong copy cartridge installed |

| J8-2 | Copy cartridge EEPROM must be changed |

| L6 | Auditron or other counter problem |

| L6 | Key counter not installed |

| L8 | Platen glass temperature is too high |

| L9 | Communication problem between interimage erase/edge lamps and main board |

| U1-1 | Main motor drive problem |

| U2-1 | Scan home problem |

| U2-1 to U2-4 | Scan home sensor |

| U2-2 | Scan home problem or optics problem |

| U2-3, U2-4 | Scan home problem |

| U3-1 | Lens sensor problem |

| U4-1 | Fuser thermistor open |

| U4-2 | Fuser did not warm up properly |

| U4-3 | Fuser temperature too high |

| U4-4 | Fuser problem. Staying on too long |

| U4-6 | High fuser temperature |

| U5-1 | Sorter bin home switch not activated |

| U5-2 | Sorter bin home switch stayed actuated |

| U5-3 | Sorter bin home switch |

| U5-4 | Sorter bin home switch |

| U6-1 | ROM problem |

| U6-2 | RAM problem |

| U6-3 | Low battery |

| U6-4 | Incorrect value in NVM. Reinitialize main board with code 20-96 |

| U8-1 | Exposure lamp problem |

| U8-2 | Communication problem main board and exposure board |

| U8-3 | Exposure lamp or exposure lamp board problem |

| U8-4 to U8-6 | Problem with exposure lamp, lamp sensor, lamp board |

Xerox 5328

| Code | Description |

|---|---|

| A1 | Document in ADF |

| A1-8 | Main board received reset signal |

| A2 | ADF jams |

| A6 | ADF registration jam |

| A7 | ADF interlock |

| A9 | Tray 1 jam |

| C1 | Tray 2 jam |

| C2 | Tray 3 jam |

| C3 | Bypass feed jams |

| C4 | Machine has reset |

| E1 | Jam |

| E1-5 | Clamshell interlock |

| E1-6 | Right side interlock |

| E1-7 | Two tray interlock, or duplex interlock |

| E1-8 | Sorter interlock |

| E1-9 | Copy cartridge interlock |

| E1 or E1-0 | Registration jam |

| E2 | Reset signal happened |

| E3 | Jam in transfer area |

| E4 | Exit jam |

| E4-0 | Exit jam |

| E4-5 | Clamshell interlock |

| E4-6 | Right side interlock |

| E4-7 | Two tray interlock |

| E4-8 | Sorter interlock |

| E4-9 | Copy cartridge interlock |

| E5 | Clamshell interlock |

| E6 | Right side interlock |

| E9 | Copy cartridge interlock |

| F3-1 | Sorter bin home switch |

| F3-2 | Sorter cam switch |

| F3-3 | Sorter cam switch |

| F5 | Sorter interlock |

| J1-1 | Add toner |

| J1-2 | Temporary low toner signal |

| J2-1, J2-2 | Replace copy cartridge |

| J5, J6 | ADF to machine communications problem |

| L2 | 2000 copies left on cartridge |

| L3 | ADF to machine communications problem |

| L4 | (flashing) 1000 copier left on fuser web |

| L6 | Auditron or other counter problem |

| LL | Main board. Try simulation 1.1 to initialize |

| rc | Wrong operation panel installed |

| rr | Bad EPROM on main board. Try 1.1 |

| U0 | Main board |

| U2 | Scan problem |

| U2-1 | Scan home |

| U2-2 | Scan home or scan encoder |

| U2-4 | Scan home or scan dual page sensor |

| U2-7 | Scan home |

| U4-1 | Fuser problem. Long warm up |

| U4-2 | Low fuser temperature after warm up |

| U4-3 | High fuser temperature |

| U4-4 | Open fuser thermistor |

| U4-6 | Replace fuser web. |

| U4-7 | Thermistor signal problem |

| U7-1 | Copy cartridge belt drive problem |

| U9-3 | Exposure lamp problem |

| U9-4 | Toner motor |

| U9-5 | Problem in warm-up |

Xerox 5330

| Code | Description |

|---|---|

| A1-1 to A1-32 | All indicate a paper path problem, etc. in the ADF. |

| A2 | ADF exit problems |

| A3 | Irregular size documents |

| A5 | ADF interlock |

| A6 | ADF single sheet document reset. |

| A7 | Platen interlock |

| A8 | ADF exit interlock |

| C1 | Tray 1 jam |

| C2 | Tray 2 jam |

| C3 | Tray 3 jam |

| C6-1, C6-2 | Jams related to duplex |

| C6-3 | Registration sensor, re tray 1 |

| C7-1, C7-2 | HCF feed problems |

| C7-3 | Tray 1 feed problem |

| C8 | Paper stays in tray or duplex or HCF |

| C9 | Bypass feed problem |

| E1-10 to E1-25 | Internal jam |

| E1-6 | Paper on registration sensor |

| E2 | Reset signal happened. Might read E-2 something else. |

| E3-30 to E4-14 | Exit jam |

| E3-6 | Exit jam |

| E4-10 to E4-14 | Inverter sensor not actuated. |

| E4-15 | Inverter sensor |

| E4-40 to E4-45 | Duplex entry sensor |

| E4-6 | Inverter sensor |

| E5 | Front door interlock |

| E6-1 | Tray 1 interlock |

| E6-2 | 2 tray or duplex interlock |

| E6-3 | HCF interlock |

| E7-2, E7-3 | Duplex interlock |

| E8-6 to E8-15 | Duplex entry sensor |

| F1-1 | Sorter entry sensor |

| F1-6 | Sorter exit sensor |

| F3 | Paper size not available for sort/stack |

| F5 | Sorter interlock |

| J1 | Add toner |

| J3 | Replace copy cartridge |

| J7 | Replace copy cartridge |

| J8-1 | Wrong copy cartridge installed |

| J8-2 | Copy cartridge EEPROM |

| L6 | Auditron or other counter problem |

| L8 | Platen glass temperature is too high |

| L9 | Communication problem between interimage erase/edge lamps and main board |

| U1-1 | Main motor drive problem |

| U2-1 to U2-4 | Scan home sensor |

| U3-1 | Lens sensor |

| U4-1 | Open fuser thermistor |

| U4-2 | Fuser did not warm up properly |

| U4-3 | Fuser temperature too high |

| U4-4 | Fuser problem. Staying on too long |

| U4-6 | High fuser temperature |

| U5-1 | Sorter bin home switch not activated |

| U5-2 | Sorter bin home switch stayed actuated |

| U5-3 | Sorter bin home switch |

| U5-4 | Sorter bin home switch |

| U6-1 | ROM problem |

| U6-2 | RAM problem |

| U6-3 | Low battery |

| U6-4 | Incorrect value in NVM. Reinitialize main board with code 20-96 |

| U8-1 to U8-6 | Problem with exposure lamp, lamp sensor, lamp board |

Xerox 5340, 5343

| Code | Description |

|---|---|

| 00-009; 030 to 033 | A door was opened while paper was being fed |

| 00-047 | Paper in duplex |

| 00-1 | Auditron |

| 00-2 | Diagnostic error |

| 00-3 | Faults error |

| 00-4 | Ric error |

| 00-5 | Job manager system error |

| 00-6 | LLM interface |

| 00-7 | Standby error |

| 00-8 | Communications error |

| 00-9 | Xerographic error |

| 01-300 | Front interlock |

| 01-310 | Right upper interlock |

| 01-315 | Left upper interlock |

| 01-320 | Left lower interlock |

| 01-325 | Fuser interlock |

| 02-910 | Key counter missing |

| 02-920 | Wrong combination of accessories |

| 03-321, 322, 326, 327 | LLM to ISIL communications problems |

| 03-328 | IOT communications problem with duplex or tray 4 |

| 03-330 | IOT communications problems with HCF |

| 03-335, 03-336 | LLM communications problems with edit |

| 03-340 | NVM memory |

| 03-341, 03-347 | Communications problems between IOT and sorter |

| 03-350, 03-354 | Communications problem with LLM and user interface |

| 03-363, 03-364 | Communications problem between LLM & optics |

| 03-370, 03-373 | Communications problem between LLM & DADF |

| 03-380, 384 | |

| 03-416, 03-422 | RAM memory problem |

| 03-424, 426 | NVM memory problem |

| 03-430, 432 | Billing problem |

| 03-439 | GRAIB communications problem |

| 03-440 | RIC communications problem |

| 03-441 | RIC NVM problem |

| 03-442 | Modem |

| 03-443, 03-458 | RIC problems |

| 03-460 | Serial communications processor problem |

| 04-300 | Main motor or drive problem |

| 05-100, 05-108 | DADF registration sensor |

| 05-110 | DADF exit sensor |

| 05-115, 120 | DADF jams |

| 05-305 | DADF document drive |

| 05-310, 312 | DADF document sensor |

| 05-316 | DADF registration sensor jam |

| 05-325 | DADF exit sensor |

| 05-335, 341, 345 | DADF interlock switches |

| 06-300, 06-310 | Scan problems |

| 06-315 | Scan drive |

| 06-320A, 320B, 320C, 325 | Scan problem |

| 06-330 | Lens drive |

| 06-340 | Exposure control problem |

| 06-342 | LLM CPU problem |

| 06-344, 06-350 | Exposure cvontrol problem |

| 06-352 | IOT CPU problem |

| 07-300, 315, 330, 345 | Tray faults |

| 07-360, 07-370 | HCF problems |

| 07-375, 380A, 380B | Duplex problems |

| 08-100, 08-110 | Feed problems. Lead edge of copy paper is late getting to feed sensor of tray 1 |

| 08-115, 08-162 | Feed problem. Lead edge of copy paper is late getting to registration sensor |

| 08-165 | Paper jam at registration sensor |

| 08-310, 08-370 | Paper at a sensor when power is turned on |

| 08-330 | DADF nudger sensor |

| 08-380 | Registration side to side problem with home position |

| 08-390 | Nip |

| 09-300 | Copy cartridge finished (drum unit) |

| 09-310 | Add black toner Add color toner |

| 09-320 | Add color toner |

| 09-330 | Wrong copy cartridge (wrong drum unit) |

| 09-340 | Drum cartridge not installed properly |

| 09-350 | Waste toner full |

| 100 | A fault has occurred |

| 10-100 | Exit jam |

| 10-105 | Exit jam |

| 10-110 | Vertical sensor jam |

| 10-120, 122, 125 | Duplex jam |

| 10-150, 155 | Too much or not enough paper in duplex tray |

| 10-300 | Fuser thermistor |

| 10-302 | Low fuser temperature |

| 10-304 | Bad fuser temp |

| 10-308 | High fuser temperature or open thermistor |

| 10-310 | High fuser temperature |

| 10-312 | Fuser not up to temperature after energy save |

| 10-314 | Fuser problem |

| 10-320 | Fuser web finished |

| 10-330, 335, 340 | Exit switch, vertical sensor switch actuated when power is turned on |

| 11-100, 11-116 | Sorter jam |

| 11-150, 11-176 | Sorter auto stapler jam |

| 11-310, 314, 316 | Sorter interlock |

| 11-325A, B, C, D, E, F, G | Sorter index |

| 11-352, 354, 356 | Sorter auto stapler interlocks |

| 11-365A, B, C, D, E | Sorter auto stapler bin |

| 11-370, 371, 372A, 373A, 373B, 374 | Sorter auto stapler staple failure, staple home problem or tamper home problem |

| 11-385A, 385B, 390A,B,C,D,E, 396A | Sorter auto stapler staple failure, staple home problem or tamper home problem |

| 301 | Fuser web must be replaced |

| 302 | Copy cartridge (drum unit) must be replaced |

| 501 | Tray 1 must be rebuilt |

| 502 | Tray 2 must be rebuilt |

| 503 | Tray 3 must be rebuilt |

| 504 | Tray 4 must be rebuilt |

| 505 | HCF must be rebuilt |

| 506 | Bypass must be rebuilt |

| 507 | Duplex unit must be rebuilt |

| 508 | Replace black developer |

| 509 | Replace red developer |

| 510 | Replace green developer |

| 512 | Replace brown developer |

| 513 | Copy cartridge (drum unit) will need replacing soon |

| 514 | Fuser web will need replacing soon |

| 515 | DADF belt should be replaced |

| 516 | DADF feed rollers should be replaced |

| 517 | Replace exposure lamp |

| 518 | Replace suction filter |

| 519 | Replace ozone filter |

| 520 | Replace optics filter |

| 521 | Replace particle filter |

| 522 | Replace upper fuser roller |

| 523 | Replace fuser pawls |

| 524 | Replace pressure roller |

| 525 | Replace pressure roller pawls |

| 900-905 | Key operator calls |

Xerox 5345

| Код ошибки | Описание |

|---|---|

| 01-01 | Frequency monitoring and zero cross problem |

| 01-02 | Interlock |

| 01-03 | AC power problem |

| 01-04 | Finisher interlock |

| 01-05 | 24v problem |

| 03-01 | Optics to main board communication problem |

| 03-02 | Software reset problem |

| 03-03 | Could be punched holes in the lead edge of the original |

| 03-04 | Software problem |

| 03-06 | Low battery |

| 03-07 | NVM not initialized or is missing or defective |

| 03-17 | Communication problem between main board and finisher board |

| 03-18 | Initializes one NVM counter to agree to others |

| 03-19 | All three NVM counter to agree with others |

| 03-20 | Main board/interface board problems |

| 03-21 | Problem with RIC NVM |

| 03-22 | RIC modem problem |

| 03-23 | RIC real time clock failure. |

| 03-25 | RIC NVM problem or not initialized |

| 03-27 | NVM problem |

| 03-28 | Watchdog software problem |

| 03-29 | Microprocessor crystal not at correct frequency |

| 03-30 | No software response from finisher after 20 seconds have elapsed |

| 06-01 | Lens did not reach 1.1 position |

| 06-02 | 1/2 rate scanner problem |

| 06-03 | Scan home problem |

| 06-04 | Scan home problem |

| 06-05 | Scan home problem |

| 06-06 | Scan encoder |

| 06-07 | Scan encoder |

| 06-08 | Scan drive boost |

| 06-09 | Scan encoder |

| 06-11 | Scan encoder pulse phases |

| 06-12 | Insufficient scan damping |

| 07-01 | Duplex tray not home during duplexing |

| 07-02 | Tray 2 not home when selected |

| 07-13 | Tray 2 height sensor problem |

| 07-15 | Tray 2 empty |

| 07-16 | Tray 1 door open |

| 07-18 | Tray 1 stack sensor |

| 07-22 | Tray 1 empty |

| 07-26 | Tray 1 bypass switch actuated too long |

| 07-27 | Tray 1 bypass switch deactuated too early |

| 07-30 | Paper in duplex |

| 07-31 | Paper in duplex |

| 07-32 | Duplex tray empty, when paper should be there |

| 08-10 | Paper did not reach tray 2 input tray sensor |

| 08-11 | Paper did not reach duplex input sensor |

| 08-12 | Paper did not reach tray 1 |

| 08-14 | Paper did not leave tray 2 input sensor quickly enough |

| 08-18 | Trail edge did not reach tray 2 input sensor quickly enough |

| 08-19 | Trail edge did not reach tray 1 input sensor quickly enough |

| 08-20 | Paper in duplex |

| 08-21 | Paper in tray 2 input |

| 08-22 | Paper in tray 2 or duplex at wrong time |

| 08-23 | Paper at tray 1 input at wrong time |

| 08-24 | Paper in tray 1 at wrong time |

| 08-28 | Upper and lower nips problem |

| 09-08 | Low toner condition |

| 09-12 | Drum signals are out of range |

| 09-13 | Unstable drum patch readings |

| 09-15 | Patch is too dark |

| 09-16 | Patch is too light |

| 09-17 | Open toner container access cover |

| 09-18 | Low toner level |

| 09-21 | Low toner sensor disconnected |

| 09-22 | Low toner condition, even after machine has been theoretically, adding toner |

| 10-02 | Low fuser temperature |

| 10-03 | High fuser temperature |

| 10-06 | Paper did not reach out put switch |

| 10-07 | Paper stayed on output switch |

| 10-10 | Paper did not reach decurler sensor |

| 10-11 | Paper did not reach decurler sensor |

| 10-12 | Paper on decurler sensor |

| 10-13 | Paper did not reach duplex entry sensor in time |

| 10-14 | Paper did not reach duplex entry sensor in time |

| 10-15 | Paper on entry sensor at wrong time |

| 10-17 | Fuser temperature is too high and fuser relay has deactuated |

| 12-01 | Paper at finisher input sensor |

| 12-02 | Paper did not reach finisher |

| 12-03 | Paper reached finisher too soon |

| 12-05 | Paper at stapler |

| 12-06 | Paper at stapler |

| 12-07 | Paper did not reach stapler |

| 12-08 | Paper did not reach stapler |

| 12-10 | Complied motor not working properly |

| 12-15 | Eject motor problem and/or eject encoder |

| 12-20 | Stacker motor problem |

| 12-21 | Stacker interlock |

| 12-22 | Stacker bottom sensor |

| 12-23 | Stacker bottom sensor |

| 12-24 | Stacker bottom sensor senses full |

| 12-25 | Stack height sensor |

| 12-26 | Stack height sensor |

| 12-27 | Stack height sensor |

| 12-30 | Offset home sensor |

| 12-31 | Offset home sensor |

| 12-32 | OCT switch |

| 12-35 | Eject nip carriage |

| 12-36 | Eject cam interlock |

| 12-37 | Eject nip carriage open timing |

| 12-38 | Eject cam interlock |

| 12-40 | Tamper motor |

| 12-41 | Tamper home problem |

| 12-42 | Tamper home sensor |

| 12-43 | Staple load sensor |

| 12-44 | Tamper home sensor |

| 12-45 | Tamper home sensor |

| 12-50 | Low on staples |

| 12-51 | Stapler home sensor |

| 12-52 | Stapler home sensor |

| 12-53 | Eject cam interlock |

| 33-37 | Too few documents |

| 55-01 | RDH interlock switch open during use |

| 55-04 | Paper on bypass sensor |

| 55-05 | Paper at vacuum timing sensor |

| 55-06 | Paper on output sensor |

| 55-10 | No paper reached S31 |

| 55-20 | Paper did not leave S31 at correct time |

| 55-24 | Set counter arm problem |

| 55-25 | Documents in input tray not detected |

| 55-27 | Lead edge did not reach S35 at correct time |

| 55-2955-30 | Trail edge did not reach S35 at correct time |

| 55-31 | S32, ADF registration sensor did not see paper at correct time |

| 55-32 | S32 did not see trail edge at correct time |

| 55-33 | S36 One too many documents |

| 55-36 | One too many documents |

| 55-39 | Hole count problem on document feeder belt |

| 55-40 | Document belt travel problem |

| 55-41 | Document belt mistracking or skewing |

| 55-45 | Paper at inverter sensor |

| 55-47 | Inverter sensor did not see paper lead edge at correct time |

| 55-49 | More than 50 sheets in input tray |

| 55-50 | Right side interlock |

| 55-51 | Left side interlock |

| 55-55 | Document on glass |

| 93-93 | NVM has to be initialized after new software installed |

Xerox 5350, 5352

| Code | Description |

|---|---|

| 00-009, 030, 031, 032, 033 | A door was opened while paper was being fed |

| 00-047 | Paper in duplex |

| 00-1 | Auditron |

| 00-2 | Diagnostic error |

| 00-3 | Faults error |

| 00-4 | Ric error |

| 00-5 | Job manager system error |

| 00-6 | LLM interface |

| 00-7 | Standby error |

| 00-8 | Communications error |

| 00-9 | Xerographic error |

| 01-300 | Front interlock |

| 01-310 | Right upper interlock |

| 01-315 | Left upper interlock |

| 01-320 | Left lower interlock |

| 01-325 | Fuser interlock |

| 02-910 | Key counter missing |

| 02-920 | Wrong combination of accessories |

| 03-321, 322, 326, 327 | LLM to ISIL communications problems |

| 03-328 | IOT communications problem with duplex or tray 4 |

| 03-330 | IOT communications problems with HCF |

| 03-335, 336 | LLM communications problems with edit |

| 03-340 | NVM memory |

| 03-341-347 | Communications problems between IOT and sorter |

| 03-350-354 | Communications problem with LLM and user interface |

| 03-363, 364 | Communications problem between LLM & optics |

| 03-370-03-373 | Communications problem between LLM & DADF |

| 03-380, 384 | |

| 03-416-422 | RAM memory problem |

| 03-424, 426 | NVM memory problem |

| 03-430, 432 | Billing problem |

| 03-439 | GRAIB communications problem |

| 03-440 | RIC communications problem |

| 03-441 | RIC NVM problem |

| 03-442 | Modem |

| 03-443-458 | RIC problems |

| 03-460 | Serial communications processor problem |

| 04-300 | Main motor or drive problem |

| 05-100-108 | DADF registration sensor |

| 05-110 | DADF exit sensor |

| 05-115, 120 | DADF jams |

| 05-305 | DADF document drive |

| 05-310, 312 | DADF document sensor |

| 05-316 | DADF registration sensor jam |

| 05-325 | DADF exit sensor |

| 05-335, 341, 345 | DADF interlock switches |

| 06-300-310 | Scan problems |

| 06-315 | Scan drive |

| 06-320A, 320B, 320C, 325 | Scan problem |

| 06-330 | Lens drive |

| 06-340 | Exposure control problem |

| 06-342 | LLM CPU problem |

| 06-344-350 | Exposure cvontrol problem |

| 06-352 | IOT CPU problem |

| 07-300, 315, 330, 345 | Tray faults |

| 07-360-370 | HCF problems |

| 07-375, 380A, 380B | Duplex problems |

| 08-100-110 | Feed problems. Lead edge of copy paper is late getting to feed sensor of tray 1 |

| 08-115-162 | Feed problem. Lead edge of copy paper is late getting to registration sensor |

| 08-165 | Paper jam at registration sensor |

| 08-310-370 | Paper at a sensor when power is turned on |

| 08-330 | DADF nudger sensor |

| 08-380 | Registration side to side problem with home position |

| 08-390 | Nip |

| 09-300 | Copy cartridge finished (drum unit) |

| 09-310 | Add black toner Add color toner |

| 09-320 | Add color toner |

| 09-330 | Wrong copy cartridge (wrong drum unit) |

| 09-340 | Drum cartridge not installed properly |

| 09-350 | Waste toner full |

| 100 | A fault has occurred |

| 10-100 | Exit jam |

| 10-105 | Exit jam |

| 10-110 | Vertical sensor jam |

| 10-120, 122, 125 | Duplex jam |

| 10-150, 155 | Too much or not enough paper in duplex tray |

| 10-300 | Fuser thermistor |

| 10-302 | Low fuser temperature |

| 10-304 | Bad fuser temp |

| 10-308 | High fuser temperature or open thermistor |

| 10-310 | High fuser temperature |

| 10-312 | Fuser not up to temperature after energy save |

| 10-314 | Fuser problem |

| 10-320 | Fuser web finished |

| 10-330, 335, 340 | Exit switch, vertical sensor switch actuated when power is turned on |

| 11-100-116 | Sorter jam |

| 11-150-176 | Sorter auto stapler jam |

| 11-310, 314, 316 | Sorter interlock |

| 11-325A,B,C,D,E,F,G | Sorter index |

| 11-352, 354, 356 | Sorter auto stapler interlocks |

| 11-365A,B,C,D,E | Sorter auto stapler bin |

| 11-370,371,372A,373A,373B,374 | Sorter auto stapler staple failure, staple home problem or tamper home problem |

| 11-385A,385B,390A,B,C,D,E,396A | Sorter auto stapler staple failure, staple home problem or tamper home problem |

| 301 | Fuser web must be replaced |

| 302 | Copy cartridge (drum unit) must be replaced |

| 501 | Tray 1 must be rebuilt |

| 502 | Tray 2 must be rebuilt |

| 503 | Tray 3 must be rebuilt |

| 504 | Tray 4 must be rebuilt |

| 505 | HCF must be rebuilt |

| 506 | Bypass must be rebuilt |

| 507 | Duplex unit must be rebuilt |

| 508 | Replace black developer |

| 509 | Replace red developer |

| 510 | Replace green developer |

| 512 | Replace brown developer |

| 513 | Copy cartridge (drum unit) will need replacing soon |

| 514 | Fuser web will need replacing soon |

| 515 | DADF belt should be replaced |

| 516 | DADF feed rollers should be replaced |

| 517 | Replace exposure lamp |

| 518 | Replace suction filter |

| 519 | Replace ozone filter |

| 520 | Replace optics filter |

| 521 | Replace particle filter |

| 522 | Replace upper fuser roller |

| 523 | Replace fuser pawls |

| 524 | Replace pressure roller |

| 525 | Replace pressure roller pawls |

| 900-905 | Key operator calls |

Xerox 5355

| Код ошибки | Описание |

|---|---|

| 01-01 | Frequency monitoring and zero cross problem |

| 01-02 | Interlock |

| 01-03 | AC power problem |

| 01-04 | Finisher interlock |

| 01-05 | 24v problem |

| 03-01 | Optics to main board communication problem |

| 03-02 | Software reset problem |

| 03-03 | Could be punched holes in the lead edge of the original |

| 03-04 | Software problem |

| 03-06 | Low battery |

| 03-07 | NVM not initialized or is missing or defective |

| 03-17 | Communication problem between main board and finisher board |

| 03-18 | Initializes one NVM counter to agree to others |

| 03-19 | All three NVM counter to agree with others |

| 03-20 | Main board/interface board problems |

| 03-21 | Problem with RIC NVM |

| 03-22 | RIC modem problem |

| 03-23 | RIC real time clock failure. |

| 03-25 | RIC NVM problem or not initialized |

| 03-27 | NVM problem |

| 03-28 | Watchdog software problem |

| 03-29 | Microprocessor crystal not at correct frequency |

| 03-30 | No software response from finisher after 20 seconds have elapsed |

| 06-01 | Lens did not reach 1.1 position |

| 06-02 | 1/2 rate scanner problem |

| 06-03 | Scan home problem |

| 06-04 | Scan home problem |

| 06-05 | Scan home problem |

| 06-06 | Scan encoder |

| 06-07 | Scan encoder |

| 06-08 | Scan drive boost |

| 06-09 | Scan encoder |

| 06-11 | Scan encoder pulse phases |

| 06-12 | Insufficient scan damping |

| 07-01 | Duplex tray not home during duplexing |

| 07-02 | Tray 2 not home when selected |

| 07-13 | Tray 2 height sensor problem |

| 07-15 | Tray 2 empty |

| 07-16 | Tray 1 door open |

| 07-18 | Tray 1 stack sensor |

| 07-22 | Tray 1 empty |

| 07-26 | Tray 1 bypass switch actuated too long |

| 07-27 | Tray 1 bypass switch deactuated too early |

| 07-30 | Paper in duplex |

| 07-31 | Paper in duplex |

| 07-32 | Duplex tray empty, when paper should be there |

| 08-10 | Paper did not reach tray 2 input tray sensor |

| 08-11 | Paper did not reach duplex input sensor |

| 08-12 | Paper did not reach tray 1 |

| 08-14 | Paper did not leave tray 2 input sensor quickly enough |

| 08-18 | Trail edge did not reach tray 2 input sensor quickly enough |

| 08-19 | Trail edge did not reach tray 1 input sensor quickly enough |

| 08-20 | Paper in duplex |

| 08-21 | Paper in tray 2 input |

| 08-22 | Paper in tray 2 or duplex at wrong time |

| 08-23 | Paper at tray 1 input at wrong time |

| 08-24 | Paper in tray 1 at wrong time |

| 08-28 | Upper and lower nips problem |

| 09-08 | Low toner condition |

| 09-12 | Drum signals are out of range |

| 09-13 | Unstable drum patch readings |

| 09-15 | Patch is too dark |

| 09-16 | Patch is too light |

| 09-17 | Open toner container access cover |

| 09-18 | Low toner level |

| 09-21 | Low toner sensor disconnected |

| 09-22 | Low toner condition, even after machine has been theoretically, adding toner |

| 10-02 | Low fuser temperature |

| 10-03 | High fuser temperature |

| 10-06 | Paper did not reach out put switch |

| 10-07 | Paper stayed on output switch |

| 10-10 | Paper did not reach decurler sensor |

| 10-11 | Paper did not reach decurler sensor |

| 10-12 | Paper on decurler sensor |

| 10-13 | Paper did not reach duplex entry sensor in time |

| 10-14 | Paper did not reach duplex entry sensor in time |

| 10-15 | Paper on entry sensor at wrong time |

| 10-17 | Fuser temperature is too high and fuser relay has deactuated |

| 12-01 | Paper at finisher input sensor |

| 12-02 | Paper did not reach finisher |

| 12-03 | Paper reached finisher too soon |

| 12-05 | Paper at stapler |

| 12-06 | Paper at stapler |

| 12-07 | Paper did not reach stapler |

| 12-08 | Paper did not reach stapler |

| 12-10 | Complied motor not working properly |

| 12-15 | Eject motor problem and/or eject encoder |

| 12-20 | Stacker motor problem |

| 12-21 | Stacker interlock |

| 12-22 | Stacker bottom sensor |

| 12-23 | Stacker bottom sensor |

| 12-24 | Stacker bottom sensor senses full |

| 12-25 | Stack height sensor |

| 12-26 | Stack height sensor |

| 12-27 | Stack height sensor |

| 12-30 | Offset home sensor |

| 12-31 | Offset home sensor |

| 12-32 | OCT switch |

| 12-35 | Eject nip carriage |

| 12-36 | Eject cam interlock |

| 12-37 | Eject nip carriage open timing |

| 12-38 | Eject cam interlock |

| 12-40 | Tamper motor |

| 12-41 | Tamper home problem |

| 12-42 | Tamper home sensor |

| 12-43 | Staple load sensor |

| 12-44 | Tamper home sensor |

| 12-45 | Tamper home sensor |

| 12-50 | Low on staples |

| 12-51 | Stapler home sensor |

| 12-52 | Stapler home sensor |

| 12-53 | Eject cam interlock |

| 33-37 | Too few documents |

| 55-01 | rdh interlock switch open during use |

| 55-04 | Paper on bypass sensor |

| 55-05 | Paper at vacuum timing sensor |

| 55-06 | Paper on output sensor |

| 55-10 | No paper reached S31 |

| 55-20 | Paper did not leave S31 at correct time |

| 55-24 | Set counter arm problem |

| 55-25 | Documents in input tray not detected |

| 55-27 | Lead edge did not reach S35 at correct time |

| 55-2955-30 | Trail edge did not reach S35 at correct time |

| 55-31 | S32, ADF registration sensor did not see paper at correct time |

| 55-32 | S32 did not see trail edge at correct time |

| 55-33 | S36 One too many documents |

| 55-36 | One too many documents |

| 55-39 | Hole count problem on document feeder belt |

| 55-40 | Document belt travel problem |

| 55-41 | Document belt mistracking or skewing |

| 55-45 | Paper at inverter sensor |

| 55-47 | Inverter sensor did not see paper lead edge at correct time |

| 55-49 | More than 50 sheets in input tray |

| 55-50 | Right side interlock |

| 55-51 | Left side interlock |

| 55-55 | Document on glass |

| 93-93 | NVM has to be initialized after new software installed |

Xerox XC520, 540, 560, 580

| Код ошибки | Описание |

|---|---|

| H2 | Fuser thermistor |

| H3 | Fuser temperature too high. Must be reset in diagnostics |

| H4 | Fuser temperature too low. Must be reset in diagnostics |

| L3 | Scan problem |

| L4 | Min motor drive problem |

| L8 | Exposure lamp not lightning or not enough light reaching auto exposure sensor |

| P | Paper did not feed |

Xerox 5622

| Code | Description |

|---|---|

| A1-1 to A1-32 | All indicate a paper path problem, etc. in the ADF |

| A2 | ADF exit problems |

| A3 | Irregular size documents |

| A5 | ADF interlock |

| A6 | ADF single sheet document reset |

| A7 | Platen interlock |

| A8 | ADF exit interlock |

| C1 | Tray 1 jam |

| C2 | Tray 2 jam |

| C3 | Tray 3 jam |

| C6-1, C6-2 | Jams related to duplex |

| C6-3 | Registration sensor, re tray 1 |

| C7-1, C7-2 | HCF feed problems |

| C7-3 | Tray 1 feed problem |

| C8 | Paper stays in tray or duplex or HCF |

| C9 | Bypass feed problem |

| E1-10 to E1-25 | Internal jam |

| E1-6 | Paper on registration sensor |

| E2 | Reset signal happened. Might read E-2 something else |

| E3-30 to E4-14 | Exit jam |

| E3-6 | Exit jam |

| E4-10 to E4-14 | Inverter sensor not actuated |

| E4-15 | Inverter sensor |

| E4-40 to E4-45 | Duplex entry sensor |

| E4-6 | Inverter sensor |

| E5 | Front door interlock |

| E6-1 | Tray 1 interlock |

| E6-2 | 2 tray or duplex interlock |

| E6-3 | HCF interlock |

| E7-2, E7-3 | Duplex interlock |

| E8-6 to E8-15 | Duplex entry sensor |

| F1-1 | Sorter entry sensor |

| F1-6 | Sorter exit sensor |

| F3 | Paper size not available for sort/stack |

| F5 | Sorter interlock |

| J1 | Add toner |

| J3 | Replace copy cartridge |

| J7 | Replace copy cartridge |

| J8-1 | Wrong copy cartridge installed |

| J8-2 | Copy cartridge EEPROM |

| L6 | Auditron or other counter problem |

| L8 | Platen glass temperature is too high |

| L9 | Communication problem between interimage erase/edge lamps and main board |

| U1-1 | Main motor drive problem |

| U2-1 to U2-4 | Scan home sensor |

| U3-1 | Lens sensor |

| U4-1 | Open fuser thermistor |

| U4-2 | Fuser did not warm up properly |

| U4-3 | Fuser temperature too high |

| U4-4 | Fuser problem. Staying on too long |

| U4-6 | High fuser temperature |

| U5-1 | Sorter bin home switch not activated |

| U5-2 | Sorter bin home switch stayed actuated |

| U5-3, U5-4 | Sorter bin home switch |

| U6-1 | ROM problem |

| U6-2 | RAM problem |

| U6-3 | Low battery |

| U6-4 | Incorrect value in NVM. Reinitialize main board with code 20-96 |

| U8-1 to U8-6 | Problem with exposure lamp, lamp sensor, lamp board |

092-312 to 315, 092-657 to 660, 092-665 to 668 ATC Sensor Fault RAP

BSD-ON: BSD 9.5 Development (2 of 2)

092-312 Toner density in the developer unit as detected by the yellow ATC sensor abnormal. This fault occurs when the difference between the maximum and minimum values in the ATC sensor measurement set is lower than the threshold value.

092-313 Toner density in the developer unit as detected by the magenta ATC sensor abnormal. This fault occurs when the difference between the maximum and minimum values in the ATC sensor measurement set is lower than the threshold value.

092-314 Toner density in the developer unit as detected by the cyan ATC sensor abnormal. This fault occurs when the difference between the maximum and minimum values in the ATC sensor measurement set is lower than the threshold value.

092-315 Toner density in the developer unit as detected by the black ATC sensor abnormal. This fault occurs when the difference between the maximum and minimum values in the ATC sensor measurement set is lower than the threshold value.

092-657 Toner density in the developer unit as detected by the yellow ATC sensor abnormal. This fault occurs when the difference between the maximum and minimum values in the ATC sensor measurement set is lower than the threshold value.

092-658 Toner density in the developer unit as detected by the magenta ATC sensor abnormal. This fault occurs when the difference between the maximum and minimum values in the ATC sensor measurement set is lower than the threshold value.

092-659 Toner density in the developer unit as detected by the cyan ATC sensor abnormal. This fault occurs when the difference between the maximum and minimum values in the ATC sensor measurement set is lower than the threshold value.

092-660 Toner density in the developer unit as detected by the black ATC sensor abnormal. This fault occurs when the difference between the maximum and minimum values in the ATC sensor measurement set is lower than the threshold value.

092-665 Toner density in the developer unit as detected by the yellow ATC sensor abnormal. This fault occurs when the average value of the ATC sensor measurement values is not between the upper and lower limit values.

092-666 Toner density in the developer unit as detected by the magenta ATC sensor abnormal. This fault occurs when the average value of the ATC sensor measurement values is not between the upper and lower limit values.

092-667 Toner density in the developer unit as detected by the cyan ATC sensor abnormal. This fault occurs when the average value of the ATC sensor measurement values is not between the upper and lower limit values.

092-668 Toner density in the developer unit as detected by the black ATC sensor abnormal. This fault occurs when the average value of the ATC sensor measurement values is not between the upper and lower limit values.

Initial Actions

• Perform IQ1 to check for a blank page image quality defect.

• Enter dC125. Check for the below faults and perform the applicable procedures as necessary:

– 024-923 to 024-925 Y/M/C Toner Cartridge Empty RAP

– 093-912 Black Toner Cartridge Empty RAP

Procedure

WARNING: Ensure that the electricity to the machine is switched off while performing tasks that do not need electricity. Refer to GP 10. Disconnect the power cord. Electricity can cause death or injury. Moving parts can cause injury.

NOTE: When this fault occurs, toner density control, by the ATC sensor, is not performed and ICDC (pixels) based toner supply control is performed instead. If the fault remains for a long time, image density error (too dark or too light) may occur.

Perform the steps that follow:

1. Switch off, then switch on the machine, GP 10.

2. Check the wiring between the applicable ATC sensor, yellow ( P/J120), magenta ( P/J119), cyan ( P/J118), black ( P/J117) and the drive PWB ( P/J414) for an open circuit, short circuit or damage.

3. If the fault persists, replace a new cartridge CRUM (toner chip or drum chip) listed as below or install new components as necessary:

• Drum cartridge:

– Black drum cartridge, PL 90.20 Item 5.

– Yellow drum cartridge, PL 90.20 Item 8.

– Magenta drum cartridge, PL 90.20 Item 7.

– Cyan drum cartridge, PL 90.20 Item 6.

• Toner cartridge:

– Black toner cartridge, PL 90.05 Item 13.

– Yellow toner cartridge, PL 90.05 Item 10.

– Magenta toner cartridge, PL 90.05 Item 11.

– Cyan toner cartridge, PL 90.05 Item 12.

• Drive PWB, PL 1.10 Item 4.

• ESS PWB, PL 3.10 Item 6.

• HVPS, PL 1.05 Item 7.

**This RAP is from Xerox Service Manual. All brand names and trademarks are their respective owner’s property.**

You may be also interested in below toner and drum chip (CRUM) for Xerox VersaLink C7020, C7025, C7030, C7000.

Toner Chip (For North America and West Europe Region):

• 106R03741 106R03744 106R03743 106R03742

• 106R03757 106R03760 106R03759 106R03758

• 106R03737 106R03740 106R03739 106R03738

Toner Chip (For South America and East Europe Region):

• 106R03749 106R03752 106R03751 106R03750

• 106R03745 106R03748 106R03747 106R03746

• 106R03765 106R03768 106R03767 106R03766

Toner Chip (For Metered Machine):

• 106R03733 106R03736 106R03735 106R03734

Drum Chip:

• 113R00780 113R00782

13 Problem Solving

13

470

Error Code

092-320

[Cause]

[Remedy] Switch off the machine power, make sure that the touch screen is

092-321

[Cause]

[Remedy] Switch off the machine power, make sure that the touch screen is

093-320

[Cause]

[Remedy] Switch off the machine power, make sure that the touch screen is

094-310

[Cause]

[Remedy] Switch off the machine power, make sure that the touch screen is

094-311

094-316

094-320

094-321

102-356

[Cause]

[Remedy] Switch off the machine power, make sure that the touch screen is

116-210

[Cause]

[Remedy] Switch off the machine power, make sure that the touch screen is

116-211

[Cause]

[Remedy] Switch off the machine power, make sure that the touch screen is

116-212

116-220

[Cause]

[Remedy] Contact our Customer Support Center.

Cause and Remedy

Density of Cyan color is low. Drum cartridge or toner cartridge

may not be set properly.

blank, and then switch on the machine power. If the same

message is displayed again, pull out the drum cartridge [R4] and

the toner cartridge [C] (cyan), and then insert them again. If the

error still is not resolved, contact our Customer Support Center.

Density of Black color is low. Drum cartridge or toner cartridge

may not be set properly.

blank, and then switch on the machine power. If the same

message is displayed again, pull out the drum cartridge [R4] and

the toner cartridge [K] (black), and then insert them again. If the

error still is not resolved, contact our Customer Support Center.

An error occurred in the machine.

blank, and then switch on the machine power. If the same

message is displayed again, contact our Customer Support

Center.

An error occurred.

blank, and then switch on the machine power. If the same

message is displayed again, contact our Customer Support

Center.

An error occurred in the machine.

blank, and then switch on the machine power. If the same

message is displayed again, contact our Customer Support

Center.

An error occurred in the USB memory device or media reader.

blank, and then switch on the machine power. If the error still is

not resolved, contact our Customer Support Center.

An error occurred in the USB memory device or media reader.

blank, and then switch on the machine power. If the error still is

not resolved, contact our Customer Support Center.

Failed to enter the Download mode.

Hello,

I’ve had my printer a little over 2 years and its been workign fine. Last week it started to generate an error message.

The code is 092-321 and it says remove black toner, reinsert and restart printer.

I did this,and it didn’t work. A couple of tries and it got going again.

It then happened again, so with a bit of google I found some possible issues (including through Xerox support). I checked the waste toner, one possibility,and found it was pretty full so got a replacement.

Everything started working again. Then today (I changed the waste toner yesterday) the message happens again. I have tried all the suggestions on the forums:

Turnign off and on

Tried a different toner cartridge

Taken the imaging drum out and cleaned.

The only thing I haven’t done is buy a new imaging drum (as seems an extreme fix if this isn’t the issue).

Does anyone have any ideas of what else I can try before accepting defeat and either getting a new printer or a new imaging drum.

Thanks

Lee

-

04-28-2020

#1

Trusted Tech

50+ Posts

- Rep Power

- 23

Xerox WC 6515 Toner problem

Customer bought one of these. She says has been running her own non OEM toner since the start. Now it says, «Non OEM toner» like normal, but now also states something like «Replace toner, turn off machine and back on if problems persists.» I tried 2 of my new toners for the exact same model and it says the same thing. Bring those back home(mine) and it installs just fine. I put tape on my connector and not the same symptom that she is having. I think it is a metered issue but my understanding is you put in a non metered toner it switches back to standard toner.

How do you tell if it is metered mode or standard? and any suggestions?

Thanks,

Tom

Last edited by Tonersniffer; 04-28-2020 at 02:36 PM.

-

04-28-2020

#2

Re: Xerox WC 6515 Toner problem

One question: has the toner been replaced with the toner low warning? A recommendation, wait for the display to tell you to replace the toner. Sometimes these machines do not accept toner replacement in advance. Reinsert the old toner and wait until the toner is empty. The message should disappear after replacing the empty toner.

Else ,this error usually means replacing the imaging unit for that color.

-

04-29-2020

#3

Senior Tech

100+ Posts

- Rep Power

- 30

Re: Xerox WC 6515 Toner problem

Non-OEM toners are famous for causing developer run off.

Basically the color doesn’t match what Xerox thinks it should be, so it gives it more developer.

As you were told this usually means replacement of the imaging unit (with new developer).

Any cost saving the customer thought they were getting, will soon be eaten up with developer replacements.

Hope this helps.

-

04-30-2020

#4

Trusted Tech

50+ Posts

- Rep Power

- 23

Re: Xerox WC 6515 Toner problem (Fixed)

I’m stupid. 30 years into this and I still forget the basics. On the customer screen it says reinsert black toner and restart device. I immediately think that the OM toners the issue (because mine did it) and I stopped by and hand them one of mine that is working. Still doesn’t work. I’m busy with my real job so I move on and tell her I will look into it. What did I forget? THE BASICS.. There was a code with it. 093-321. Look it up STUPID. Fault Code 092-321: Black (K) Patch Failure. LIGHT BULB clicks on. They need a new drum or something else. End of Story. DO NOT BE ME! STUPID! The screen is for the user, that is the only thing the user can do to possibly fix it. The code is for professionally STUPID, me!

Drum fixed it.

Tags for this Thread

Bookmarks

Bookmarks

Posting Permissions

- You may not post new threads

- You may not post replies

- You may not post attachments

- You may not edit your posts

- BB code is On

- Smilies are On

- [IMG] code is On

- [VIDEO] code is On

- HTML code is Off

Forum Rules

092-312 to 315, 092-657 to 660, 092-665 to 668 ATC Sensor Fault RAP

BSD-ON: BSD 9.5 Development (2 of 2)

092-312 Toner density in the developer unit as detected by the yellow ATC sensor abnormal. This fault occurs when the difference between the maximum and minimum values in the ATC sensor measurement set is lower than the threshold value.

092-313 Toner density in the developer unit as detected by the magenta ATC sensor abnormal. This fault occurs when the difference between the maximum and minimum values in the ATC sensor measurement set is lower than the threshold value.

092-314 Toner density in the developer unit as detected by the cyan ATC sensor abnormal. This fault occurs when the difference between the maximum and minimum values in the ATC sensor measurement set is lower than the threshold value.

092-315 Toner density in the developer unit as detected by the black ATC sensor abnormal. This fault occurs when the difference between the maximum and minimum values in the ATC sensor measurement set is lower than the threshold value.

092-657 Toner density in the developer unit as detected by the yellow ATC sensor abnormal. This fault occurs when the difference between the maximum and minimum values in the ATC sensor measurement set is lower than the threshold value.

092-658 Toner density in the developer unit as detected by the magenta ATC sensor abnormal. This fault occurs when the difference between the maximum and minimum values in the ATC sensor measurement set is lower than the threshold value.

092-659 Toner density in the developer unit as detected by the cyan ATC sensor abnormal. This fault occurs when the difference between the maximum and minimum values in the ATC sensor measurement set is lower than the threshold value.

092-660 Toner density in the developer unit as detected by the black ATC sensor abnormal. This fault occurs when the difference between the maximum and minimum values in the ATC sensor measurement set is lower than the threshold value.

092-665 Toner density in the developer unit as detected by the yellow ATC sensor abnormal. This fault occurs when the average value of the ATC sensor measurement values is not between the upper and lower limit values.

092-666 Toner density in the developer unit as detected by the magenta ATC sensor abnormal. This fault occurs when the average value of the ATC sensor measurement values is not between the upper and lower limit values.

092-667 Toner density in the developer unit as detected by the cyan ATC sensor abnormal. This fault occurs when the average value of the ATC sensor measurement values is not between the upper and lower limit values.

092-668 Toner density in the developer unit as detected by the black ATC sensor abnormal. This fault occurs when the average value of the ATC sensor measurement values is not between the upper and lower limit values.

Initial Actions

• Perform IQ1 to check for a blank page image quality defect.

• Enter dC125. Check for the below faults and perform the applicable procedures as necessary:

– 024-923 to 024-925 Y/M/C Toner Cartridge Empty RAP

– 093-912 Black Toner Cartridge Empty RAP

Procedure

WARNING: Ensure that the electricity to the machine is switched off while performing tasks that do not need electricity. Refer to GP 10. Disconnect the power cord. Electricity can cause death or injury. Moving parts can cause injury.

NOTE: When this fault occurs, toner density control, by the ATC sensor, is not performed and ICDC (pixels) based toner supply control is performed instead. If the fault remains for a long time, image density error (too dark or too light) may occur.

Perform the steps that follow:

1. Switch off, then switch on the machine, GP 10.

2. Check the wiring between the applicable ATC sensor, yellow ( P/J120), magenta ( P/J119), cyan ( P/J118), black ( P/J117) and the drive PWB ( P/J414) for an open circuit, short circuit or damage.

3. If the fault persists, replace a new cartridge CRUM (toner chip or drum chip) listed as below or install new components as necessary:

• Drum cartridge:

– Black drum cartridge, PL 90.20 Item 5.

– Yellow drum cartridge, PL 90.20 Item 8.

– Magenta drum cartridge, PL 90.20 Item 7.

– Cyan drum cartridge, PL 90.20 Item 6.

• Toner cartridge:

– Black toner cartridge, PL 90.05 Item 13.

– Yellow toner cartridge, PL 90.05 Item 10.

– Magenta toner cartridge, PL 90.05 Item 11.

– Cyan toner cartridge, PL 90.05 Item 12.

• Drive PWB, PL 1.10 Item 4.

• ESS PWB, PL 3.10 Item 6.

• HVPS, PL 1.05 Item 7.

**This RAP is from Xerox Service Manual. All brand names and trademarks are their respective owner’s property.**

You may be also interested in below toner and drum chip (CRUM) for Xerox VersaLink C7020, C7025, C7030, C7000.

Toner Chip (For North America and West Europe Region):

• 106R03741 106R03744 106R03743 106R03742

• 106R03757 106R03760 106R03759 106R03758

• 106R03737 106R03740 106R03739 106R03738

Toner Chip (For South America and East Europe Region):

• 106R03749 106R03752 106R03751 106R03750

• 106R03745 106R03748 106R03747 106R03746

• 106R03765 106R03768 106R03767 106R03766

Toner Chip (For Metered Machine):

• 106R03733 106R03736 106R03735 106R03734

Drum Chip:

• 113R00780 113R00782

092 910 очистите датчик ctd

КОНФЕРЕНЦИЯ СТАРТКОПИ

Принтеры, копировальные аппараты, МФУ, факсы и другая офисная техника:

вопросы ремонта, обслуживания, заправки, выбора

Доброго времени суток!

имеем вот такую проблему,

возил с этой пролемой в сервис, починили, гдето после 100копий опять имеем данную ошибку, узел переноса поставили новый, не помогло, опять везти в сервис и ждать 40 дней клиента не устраивает, единственное,что удалось найти на просторах рунета, что это ошибка датчика автоматической концентрации тонера, как можно исправить ее самому? небольшой опыт ремонта принтеров имеется, помогите плиз!

Возможно, и удастся. Чем кормите пациента и какой у него пробег на сегодняшний день?

пациент съел стартовую тубу, вторую он съел гдето на половину, поэтому пробег копеечный, вторая туба тоже оригинал

The frequency at which the ATC Average Fail or the ATC Amplitude Fail has been occurring is

at the threshold value or higher.

NOTE: To clear this Fail, clear the value of NVM 752 (ATC Fail) or NVM 752 (ATC

Fail Continuous Count) to ‘0’. If the machine is not repaired back to normal status, this Fail will

occur again during the operation.

NOTE: Setting the NVM 752 (Dispense Mode) to ‘0’ (Timer Disp) or ‘2’ (ICDC Disp) will

prevent ATC related fail from occurring and enable you to use the M/C. However, this means

that the Toner density will not be controlled.

Cause/Action

1. Install a Toner Cartridge that contains Toner. Copy a Test Chart (499T 00247), etc. and

check whether the density has recovered.

2. Check the Toner Dispense Motor (Output Check 92) for operation failure. (PL 8.2)

3. Check the Toner transport path for Toner blockage.

4. Check the connection between the ATC Sensor (Drum Cartridge) P615 and the ESS/

MCU PWB J409 for open circuit, short circuit, and poor contact.

5. Check for toner blockage within the Developer Unit.

6. If no problem is found, replace the following parts in sequence:

Drum Cartridge

ESS/MCU PWB

Пробовали по инструкции сбрасывать?

В инструкции нет про эту ошибку ничего

драм и тонер я поменял, я так понимаю осталось сбросить саму ошибку, но как? датчик ATC это тот, который на драме установлен?

SergeyS (6): сбросить саму ошибку, но как?

Вам подробно расписано тремя постами выше.

единственное что смог сделать — войти в сервисное меню (нажатие 0 и старт), повилось на дисплее (— —)может подскажете какая последовательность дальше?

(8) Если непонятен второй абзац («To clear. «) в (3) — откройте СМ на любой (почти?) Воркцентр этой модельной линейки, там будет расписано.

для это:

1. включам принтер, зажимаем кнопку «0» держим не менее 4 сек, и не отпуская нажимаем «старт», потом вводим «6789», кнопка СТАРТ,

попадаем в сервисное меню

2. вводим 752, кнопка СТАРТ, 059 кнопка старт, походу когда ошибка взведена видим «1» нажимаем старт, вводим «000» нажимаем старт, получам «ок», зажимаем кнопку «0» держим не менее 4 сек, и не отпуская нажимаем «старт», чудо техники перезагрузится уже без ошибки,

СПАСИБО ВСЕМ,КТО ПОМОГ.

SergeyS (10): включам принтер, зажимаем кнопку «0» держим не менее 4 сек, и не отпуская нажимаем «старт»

потом вводим 6789 и только потом

SergeyS (10): попадаем в сервисное меню

по крайней мере так было у меня, когда я входил в сервис 5021.

проблема со старым драмом осталась, с новым все ок!

(13) Значит, переходите к пунктам 1. 6 из (3).

Источник

Ошибка 092-910 на принтерах Xerox WorkCentre 5024

Ошибка 092-910 у Xerox WorkCentre 5024 возникает по разным причинам:

- выход из строя датчика плотности тонера ATC;

- недостаток тонера в картридже;

- неполадки драм-юнита и прочее.

Если чистка датчика ATC, а также замена расходников не помогли решить проблему, тогда остановка печатного процесса может быть вызвана поломкой материнской платы или ее отдельных компонентов.

Как сбросить ошибку 092-910?

Простой замены изношенного блока фотобарабана или отработанного картриджа порой недостаточно, чтобы сбросить ошибку 092-910 .

Для завершения операции потребуется войти в сервисное меню принтера Xerox 5024 и произвести следующий алгоритм действий:

- включите аппарат;

- зажмите кнопку с цифрой «0» на 5 секунд, не отпуская ее нажмите еще кнопку «Старт»;

- введите набор цифр «6789» и снова нажмите «Старт»;

- после того, как откроется сервисное меню, наберите «752», завершив комбинацию кнопкой «Старт»;

- далее наберите «059» — «Старт»;

- на дисплее должна показаться цифра «1», нажмите «Старт» — «000» — «Старт»;

- когда появится подтверждение сброса ошибки «OK», зажмите цифру «0» на 5 секунд, не отпуская кнопку нажмите «Старт».

После перезагрузки аппарат должен запуститься без отображения ошибки 092-910 .

Источник

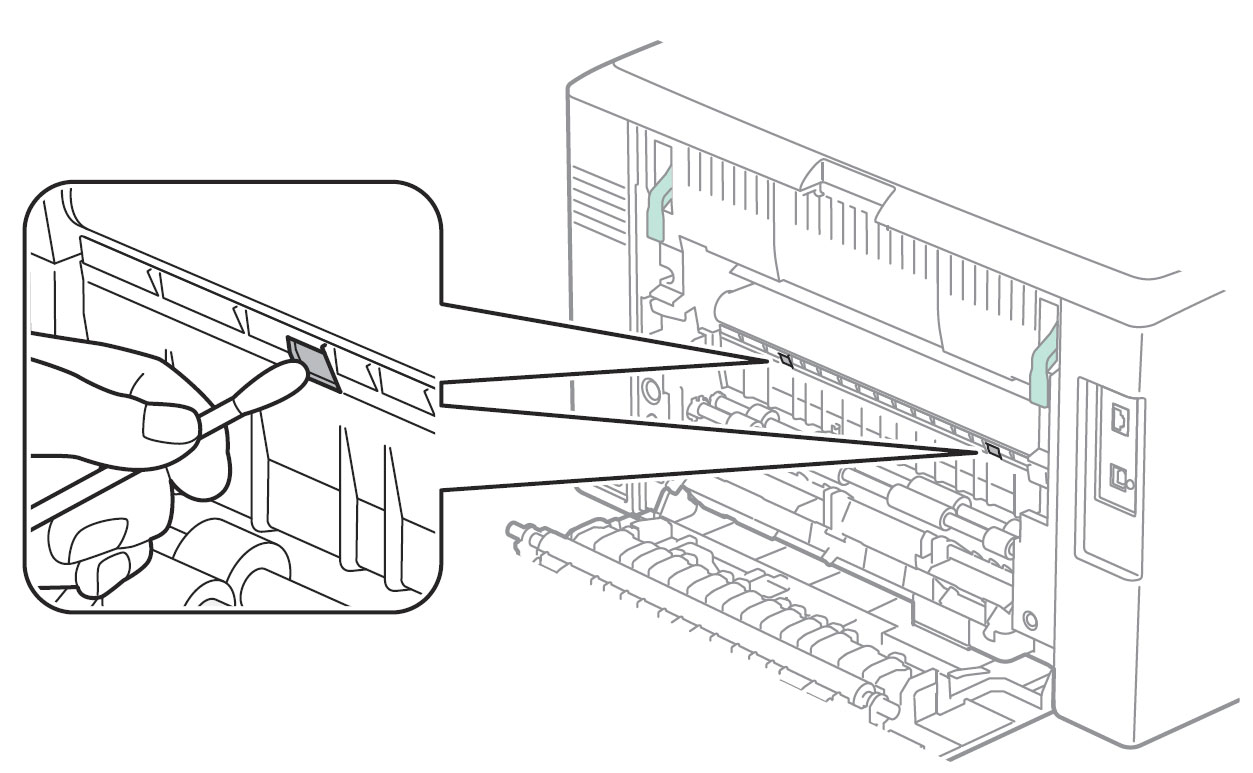

Чистка датчиков плотности цветных тонеров – Инструкция по эксплуатации Xerox Phaser 6000

Страница 56

Цветной принтер Phaser 6000/6010

Руководство пользователя

Чистка датчиков плотности

Датчики плотности цветных тонеров (Color Toner Density, CTD) измеряют оптическую

плотность тонера, отложившегося на маркировочном блоке при калибровке в процессе

печати. С каждой стороны маркировочного блока установлено по одному датчику. Это

обеспечивает одинаковую плотность тонера по всей длине ремня. Для достижения

оптимального качества печати принтер проверяет работу датчиков CTD в начале каждого

цикла калибровки. Датчики CTD следует чистить, когда происходит сбой датчика CTD, или

на панели управления появляется соответствующее сообщение, или Программа настройки

принтера выдает данное указание.

Если тонер попал на кожу или одежду, не удаляйте его тёплой водой или

чистящими растворителями. При использовании теплой воды тонер прилипнет —

тогда его будет трудно удалить. Если тонер попал на кожу или одежду, удалите его

щеткой, сдуйте его или смойте холодной водой с мылом.

Порядок чистки датчиков CTD:

1.

Выключите принтер и выньте вилку шнура питания из розетки.

Откройте заднюю крышку, нажав на фиксатор.

Очистите датчики CTD, протерев отверстия чистым сухим ватным валиком.

Не касайтесь помеченной наклейкой зоны на

нагревательном валу и вблизи него, во фьюзере. Можно получить ожог.

Источник

Ремонт МФУ Xerox WC 6015

Сервисный центр Комплэйс выполняет Ремонт Xerox WC 6015

Замятие бумаги WC 6015

МФУ Xerox WC 6015 поступило в ремонт с постоянным сообщением о замятии бумаги, бумаги не было нигде.

После разборки аппарата подбираемся к датчику бумаги. Сам датчик прохождения бумаги находится сзади, показан стрелкой.

Сломанный датчик заменяем. На этом ремонт МФУ Xerox закончен.

Второй датчик находится в узле закрепления.

Треск при работе WC 6015

Треск в узле ксерографии

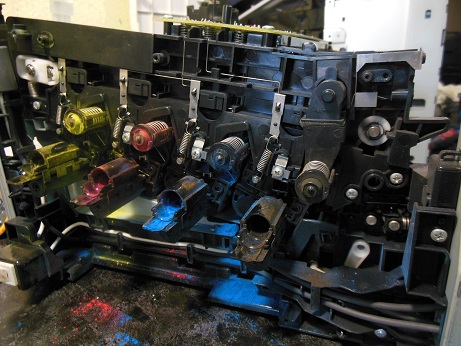

В другом МФУ Xerox WC 6015 при включении и работе раздавался сильный треск. Пришлось разбирать МФУ еще дальше.

Сильный треск был вызван тем, что в синем цвете забился тракт отвода отработанного тонера. После тщательной очистки спрессованного тонера, который превратился в камень, треск исчез. Отработанный тонер стал уходить в картридж.

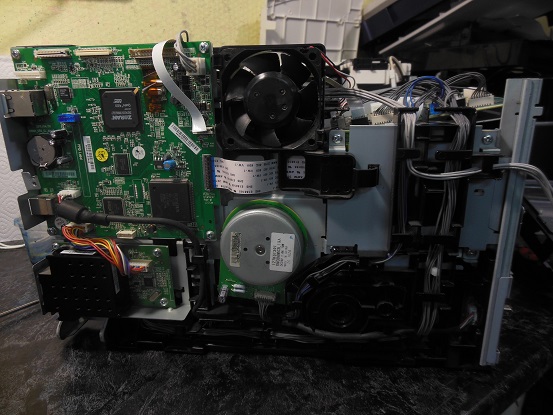

Треск Xerox WC 6015 в области печки

Треск в области печки означает проскальзывание шестерней. В Xerox WC 6015 такое вероятно, если сломалось крепление печки. При такой неисправности шестерня печки не прижимаются к шестерне редуктора принтера. Поэтому и происходит проскальзывание и сильный треск.

Печка в этом МФУ с задней стороны крепится двумя винтами. А снизу печка цепляется за основание с помощью железных полукруглых упоров.

Если упор отсутствует печка не держится. В нашем случае полукруглый упор был отломан.

Ремонт выполнили следующим образом.

Стоимость ремонта крепления печки 3500 руб. Полукруг не обязателен.

Ошибка 024-360

Разберите по-новой весь принтер и проверьте разъемы на целостность и правильное соединение.Особенно тщательно проверьте контактные концы шлейфов. Если они повреждены, то отремонтируйте.

Ремонт контактной группы картриджей

Если у вас произошло повреждение контактной группы картриджа , то вряд ли найдете новую группу в продаже. Вообще для Xerox WC 6015 с запчастями проблема. Мы научились восстанавливать сломанные контакты. Но есть сложности — контактные группы никто не продает.