Во время работы с аппаратом могут возникать проблемы, связанные с неисправностями «железа» или ПО. И если расходные материалы можно просто заменить, то с «мозгами» нужно разбираться. Поэтому, для экономии времени и удобства, ниже представлены возможные коды ошибок (FAULT ERROR CODE), которые показывают Xerox DocuColor DC 240/250/242/252/260 и WorkCentre WC 7655/7665/7675/7755/7765/7775 при неисправности, и их значение:

коды ошибок (fault code/error) продолжение. Часть 2

…

061-323 ERROR — RAP No SOS Failure.

061-324 ERROR — RAP No SOS Failure.

061-325 ERROR — RAP No SOS Failure.

061-326 ERROR — RAP ROS Connect Failure Yellow.

061-327 ERROR — RAP ROS Connect Failure.

061-328 ERROR — RAP ROS Connect Failure.

061-329 ERROR — RAP ROS Connect Failure Black.

061-334 ERROR — RAP ROS Y/M VDD Failure.

061-335 ERROR — RAP ROS C/K VDD Failure.

061-336 ERROR — RAP ROS Y/M VDD Down Failure.

061-337 ERROR — RAP ROS C/K VDD Down Failure.

061-338 ERROR — RAP SOS Stop Magenta Failure.

061-339 ERROR — RAP SOS Stop Black Failure.

061-340 ERROR — RAP ROS LD Failure Black.

061-341 ERROR — RAP ROS LD Failure Yellow.

061-342 ERROR — RAP ROS LD Failure Magenta.

061-343 ERROR — RAP ROS LD Failure Cyan.

061-600 ERROR — RAP ROS Data Failure Yellow.

061-601 ERROR — RAP ROS Data Failure Magenta.

061-602 ERROR — RAP ROS Data Failure Cyan.

061-603 ERROR — RAP ROS Data Failure Black.

061-604 ERROR — RAP LD Alarm Yellow.

061-605 ERROR — RAP LD Alarm Magenta.

061-606 ERROR — RAP LD Alarm Cyan.

061-607 ERROR — RAP LD Alarm Black.

062-210 ERROR — RAP IISS Hot Line Failure.

062-211 ERROR — RAP IIT/IPS EEPROM Failure (IPS).

062-220 ERROR — RAP IPS-EXT Connection Failure.

062-277 ERROR — RAP IIT/IPS-DADF Communication Failure.

062-278 ERROR — RAP IIT-Extension Communication Failure.

062-300 ERROR — RAP Platen Interlock Open.

062-310 ERROR — RAP IIT/IPS-ESS Communication Failure.

062-311 ERROR — RAP IIT Software Logic Failure.

062-321 ERROR — RAP IPS-YATA Connection Failure.

062-322 ERROR — RAP EXT-YATA Connection Failure.

062-323 ERROR — RAP YATA PWBA Failure.

062-345 ERROR — RAP IIT/IPS EEPROM Failure (IIT).

062-355 ERROR — RAP IPS Fan Failure.

062-356 ERROR — RAP Lamp Fan Failure.

062-357 ERROR — RAP CCD Fan Failure. An error signal was detected for the CCD fan.

062-360 ERROR — RAP Carriage Position Failure.

062-362 ERROR — RAP X Hard Failure.

062-371 ERROR — RAP Lamp Failure.

062-380 ERROR — RAP Platen AOC Failure.

062-386 ERROR — RAP Platen AOC Failure.

062-389 ERROR — RAP Carriage Over Run (Scan End).

062-392 ERROR — RAP IT/IPS Memory Failure.

062-393 ERROR — RAP IIT/IPS PWB Failure.

062-790 ERROR — RAP X Detect Failure.

063-210 ERROR — RAP Extension EEPROM Failure.

063-220 ERROR — RAP IPS-EXT Psync Failure.

063-230 ERROR — RAP EXT Image Parameter Failure.

063-240 ERROR — RAP EXT Image Parameter Failure.

065-210 ERROR — RAP Extension Page Memory Failure 1.

065-211 ERROR — RAP CIS Shading FROM Failure

065-212 ERROR — RAP CIS Shading Level Failure.

065-213 ERROR — RAP CIS Output Level Failure.

065-215 ERROR — RAP Extension Page Memory Failure 2.

065-216 ERROR — RAP Extension Page Memory Failure 3.

065-219 ERROR — RAP CIS Black White Level Failure.

065-220 ERROR — RAP 1P DUP PWB-EXT Psync Failure.

071-101 ERROR — RAP Feed Out Sensor 1 is not turned ON.

071-104 ERROR — RAP Pre Registration Sensor ON Jam (Tray 1).

071-105 ERROR — RAP Registration Sensor ON Jam (Tray 1).

071-210 ERROR — RAP Tray 1 Lift Up Failure.

072-101 ERROR — RAP Tray 2 Miss Feed Jam.

072-102 ERROR — RAP The Tray 1 Feed Out Sensor does not turn ON.

072-104 ERROR — RAP Pre-Registration Sensor ON Jam (Tray 2).

072-105 ERROR — RAP Registration Sensor ON Jam (Tray 2).

072-210 ERROR — RAP Tray 2 Lift Up Failure.

073-101 ERROR — RAP Tray 3 Miss Feed Jam.

073-102 ERROR — RAP Feed Out Sensor 1 ON Jam (Tray 3).

073-104 ERROR — RAP Pre Registration Sensor ON Jam (Tray 3).

073-105 ERROR — RAP Registration Sensor ON Jam (Tray 3).

073-210 ERROR — RAP Tray 3 Lift Up Failure.

074-101 ERROR — RAP Pre Feed Sensor 4 is not ON within the specified time after the start of feed from Tray 4.

074-102 ERROR — RAP Feed Out Sensor 1 ON Jam (Tray 4).

074-103 ERROR — RAP The Tray 4 Feed Out Sensor is not ON within the specified time for paper fed from Tray 4.

074-104 ERROR — RAP Pre Registration Sensor ON Jam (Tray 4).

074-105 ERROR — RAP Registration Sensor ON Jam (Tray 4).

074-210 ERROR — RAP Tray 4 Lift Up Failure.

075-100 ERROR — RAP Tray 5/Bypass Pre Feed Sensor is not ON within the specified time after the start of feed from Tray 5.

075-101 ERROR — RAP Tray 5/Bypass Feed Out Sensor is not ON within the specified time for paper fed from Tray 5.

075-109 ERROR — RAP Paper from Tray 5/Bypass does not turn ON Pre Regi Sensor within a specified time.

075-135 ERROR — RAP Paper from Tray 5/Bypass does not turn ON Regi Sensor within a specified time.

075-210 ERROR — RAP Tray 5/Bypass Lift Up Sensor does not turn ON within a specified time after Tray 5 begins to lift.

075-211 ERROR — RAP Tray 5/Bypass Lift Down Sensor does not turn ON within a specified time after Tray 5 begins to lower.

077-102 ERROR — RAP Paper from Tray 2 did not turn on the Transport Path Sensor 1 within the specified time.

077-103 ERROR — RAP The Fuser Exit Sensor did not turn off within the specified time in straight exit mode.

077-106 ERROR — RAP The Fuser Exit Sensor did not come on within the specified time after the Registration Motor.

077-107 ERROR — RAP The Fuser Exit Sensor did not turn off within the specified time in invert exit mode.

077-109 ERROR — RAP The IOT Exit Sensor did not come on at the specified time in non-invert mode.

077-111 ERROR — RAP The IOT Exit Sensor did not come on within the specified time in invert exit mode.

077-113 ERROR — RAP The IOT Exit Sensor did not turn off at the specified time in non-invert mode.

077-115 ERROR — RAP The IOT Exit Sensor did not turn off within the specified time in invert exit mode.

077-118 ERROR — RAP Paper from Duplex did not turn on the Pre Regi Sensor within the specified time.

077-120 ERROR — RAP Post 2nd BTR Sensor On JAM.

077-123 ERROR — RAP Duplex In Sensor does not turn ON a spec time after the start of invert.

077-129 ERROR — RAP Paper from Duplex did not turn on the Regi Sensor within the specified time.

077-130 ERROR — RAP Duplex Out Sensor does not turn ON witin a specified time after Duplex In Sensor turns ON.

077-300 ERROR — RAP The Front Cover is open.

077-301 ERROR — RAP The Left Hand Interlock is open.

077-302 ERROR — RAP The Right Hand Cover Interlock is open.

077-303 ERROR — RAP PH Drawer Interlock Open.

077-304 ERROR — RAP The Tray 5/Bypass Cover Interlock is open.

077-312 ERROR — RAP Feeder Communication Failure.

077-909 ERROR — RAP One of the IOT sensors detected paper when power was turned on or when an interlock was closed.

077-967 ERROR — RAP The specified paper type and the paper type being used are different.

077-968 ERROR — RAP The type of paper in the tray was changed.

078-100 ERROR — RAP Paper from Tray 6 does not turn ON Pre Regi Sensor within a specified time.

078-101 ERROR — RAP The Tray 6 Feed Out sensor is not ON within the specified time for paper fed from Tray 6.

078-102 ERROR — RAP Paper from Tray 6 does not turn ON the Regi Sensor within a specified time.

078-151 ERROR — RAP The Tray 6 Feed Out Sensor did not come on within the specified time after the start of feed.

078-250 ERROR — RAP HCF Tray #2 Lift Up Fail.

078-300 ERROR — RAP The HCF transport interlock is open.

078-301 ERROR — RAP HCF Side Out Interlock Open.

089-600 ERROR — RAP Incorrect Fast Scan positioning for the reference color Cyan was detected during fine adjustment.

089-601 ERROR — RAP The Inner MOB Sensor failed to detect the fine-adjustment patterns properly during fine adjustment.

089-602 ERROR — RAP The CENTER MOB Sensor failed to detect the fine-adjustment patterns properly during fine adjustment.

089-603 ERROR — RAP The OUTER MOB Sensor failed to detect the fine-adjustment patterns properly during fine adjustment.

089-604 ERROR — RAP The INNER MOB Sensor failed to detect the rough-adjustment patterns properly during Yellow rough adjustment.

089-605 ERROR — RAP The CENTER MOB Sensor failed to detect the rough-adjustment patterns properly during Yellow rough adjustment.

089-606 ERROR — RAP The OUTER MOB Sensor failed to detect the rough-adjustment patterns properly during Yellow rough adjustment.

089-607 ERROR — RAP The INNER MOB Sensor failed to detect the rough-adjustment patterns correctly during Magenta rough adjustment.

089-608 ERROR — RAP The CENTER MOB Sensor failed to detect the rough-adjustment patterns properly during Magenta rough adjustment.

089-609 ERROR — RAP The OUTER MOB Sensor failed to detect the rough-adjustment patterns properly during Magenta rough adjustment.

089-610 ERROR — RAP The INNER MOB Sensor failed to detect the rough-adjustment patterns properly during Cyan rough adjustment.

089-611 ERROR — RAP The CENTER MOB Sensor failed to detect the rough-adjustment patterns properly during Cyan rough adjustment.

089-612 ERROR — RAP The MOB Sensor OUT failed to detect the rough-adjustment patterns properly during Cyan rough adjustment.

089-613 ERROR — RAP The INNER MOB Sensor failed to detect the rough-adjustment patterns properly during Black rough adjustment.

089-614 ERROR — RAP The CENTER MOB Sensor failed to detect the rough-adjustment patterns properly during Black rough adjustment.

089-615 ERROR — RAP The MOB Sensor OUT failed to detect the rough-adjustment patterns properly during Black rough adjustment.

089-616 ERROR — RAP RC Data OverFlow Failure.

089-617 ERROR — RAP RC Data OverRange Failure.

091-311 ERROR — RAP The voltage level of the CC cleaner position sensor did not change within the specified time.

091-312 ERROR — RAP Charge (K) Preclean HVPS has failed.

091-313 ERROR — RAP DRUM CRUM ASIC Communication Failure.

091-320 ERROR — RAP Charge Corotron Wire is broken.

091-400 ERROR — RAP The replacement date for Waste Toner Bottle (regular) is near.

091-401 ERROR — RAP The black drum cartridge is near the end-of-life.

091-403 ERROR — RAP The CC Assembly is near the end-of-life.

091-404 ERROR — RAP The CC Assembly has reached the end-of-life.

091-411 ERROR — RAP The yellow drum cartridge is near the end-of-life.

091-421 ERROR — RAP The magenta drum cartridge is near the end-of-life.

091-431 ERROR — RAP The cyan drum cartridge is near the end-of-life.

091-910 ERROR — RAP The waste toner bottle is not present.

091-911 ERROR — RAP The waste toner bottle is full.

091-913 ERROR — RAP The black drum cartridge (K) has reached the end-of-life.

091-914 ERROR — RAP Communication failure between the MCU and the black Drum CRUM.

091-915 ERROR — RAP The MCU detected incorrect data in the black drum cartridge CRUM.

091-916 ERROR — RAP The CRUM authentication registration data on the drum cartridge is incorrect.

091-917 ERROR — RAP MCU cannot communicate with the CRUM in drum Y.

091-918 ERROR — RAP Communication failure with the magenta Drum CRUM.

091-919 ERROR — RAP Communication failure with the cyan Drum CRUM.

091-920 ERROR — RAP The MCU detected incorrect data in the Yellow drum cartridge CRUM.

091-921 ERROR — RAP Drum CRUM is disconnected.

091-922 ERROR — RAP Wrong Data in magenta drum cartridge.

091-923 ERROR — RAP Wrong data in cyan drum cartridge.

091-924 ERROR — RAP The CRUM authentication registration data on the yellow drum cartridge is incorrect.

091-925 ERROR — RAP Wrong data in yellow Magenta cartridge.

091-926 ERROR — RAP The CRUM authentication registration data on the cyan drum cartridge is incorrect.

091-927 ERROR — RAP Yellow Drum CRUM is disconnected.

091-928 ERROR — RAP Magenta Drum CRUM is disconnected.

091-929 ERROR — RAP Cyan Drum CRUM is disconnected.

091-932 ERROR — RAP The yellow drum cartridge (Y) has reached the end-of-life.

091-933 ERROR — RAP The magenta drum cartridge (M) has reached the end-of-life.

091-934 ERROR — RAP The cyan drum cartridge (C) has reached the end-of-life.

092-649 ERROR — RAP The MOB ADC Shutter remains open due to shutter failure.

092-650 ERROR — RAP The MOB ADC Shutter remains closed due to shutter failure.

092-651 ERROR — RAP The output read by ADC Sensor from the clean Photoreceptor surface is out of range.

092-652 ERROR — RAP The measured ADC Patch density is light. (Over 75% of Vclean).

092-653 ERROR — RAP ATC SNR-Yellow output signal failure.

092-654 ERROR — RAP ATC SNR-Magenta output signal failure.

092-655 ERROR — RAP ATC SNR-Cyan output signal failure.

092-656 ERROR — RAP ATC SNR-black output signal failure.

092-657 ERROR — RAP The amplitude of ATC Yellow Sensor output is out of range.

092-658 ERROR — RAP The amplitude of ATC Magenta Sensor output is out of range.

092-659 ERROR — RAP The amplitude of ATC Cyan Sensor output is out of range.

092-660 ERROR — RAP The amplitude of ATC Black Sensor output is out of range.

092-661 ERROR — RAP The temperature output of the environment sensor is out of range.

092-662 ERROR — RAP The humidity output of the environment sensor is out of range.

092-663 ERROR — RAP The two levels of ADC Patch density created in Mini-Setup are reversed.

093-300 ERROR — RAP Marking Drawer Interlock Open.

093-313 ERROR — RAP The Low Toner Sensor failed to detect any toner after the Toner Cartridge Motor was energized.

093-314 ERROR — RAP Yellow Dispense failure.

093-315 ERROR — RAP Magenta Dispense failure.

093-316 ERROR — RAP Cyan Dispense failure.

093-317 ERROR — RAP Black Dispense failure.

093-320 ERROR — RAP There was a problem with the developer motor rotation.

093-421 ERROR — RAP The Black Toner Cartridge (K1) is empty and the Black Toner Cartridge (K2) is near empty.

093-422 ERROR — RAP The Black Toner Cartridge (K2) is empty and the Black Toner Cartridge (K1) is near empty.

093-423 ERROR — RAP Yellow toner is near empty.

093-424 ERROR — RAP Magenta toner is near empty.

093-425 ERROR — RAP Cyan toner empty.

093-600 ERROR — RAP Yellow Dispense near failure.

093-601 ERROR — RAP Magenta Dispense near failure.

093-602 ERROR — RAP Cyan Dispense near failure.

093-603 ERROR — RAP Black Dispense near failure.

093-912 ERROR — RAP The Black Dispense Motor rotation timed out indicating that the Black Cartridge and Reserve Tank are empty.

093-918 ERROR — RAP A communication failure with Black Toner Cartridge CRUM K2.

093-924 ERROR — RAP A communication failure with Black Toner Cartridge CRUM K1.

093-925 ERROR — RAP The data written to the toner CRUM K1 did not agree with the data read.

093-926 ERROR — RAP Toner Cartridge CRUM K1 Authentication Data is different.

093-927 ERROR — RAP A communication failure with Yellow Toner Cartridge CRUM Y.

093-928 ERROR — RAP A communication failure with Magenta Toner Cartridge CRUM M.

093-929 ERROR — RAP A communication failure with Cyan Toner Cartridge CRUM C.

093-932 ERROR — RAP Cartridge Exchange Time Over.

093-934 ERROR — RAP The data written to the toner CRUM M did not agree with the data read.

093-935 ERROR — RAP The data written to the toner CRUM C did not agree with the data read.

093-936 ERROR — RAP The data written to the toner CRUM K2 did not agree with the data read.

093-937 ERROR — RAP Toner Cartridge CRUM Y Authentication Data is different.

093-938 ERROR — RAP Toner Cartridge CRUM M Authentication Data is different.

093-939 ERROR — RAP Toner Cartridge CRUM C Authentication Data is different.

093-940 ERROR — RAP Toner Cartridge CRUM K2 Authentication Data is different.

094-320 ERROR — RAP Retraction was not detected within the specified time after retraction of the 1st BTR started.

094-321 ERROR — RAP First BTR Contact Failure.

094-322 ERROR — RAP Second BTR Retract Failure.

094-323 ERROR — RAP Contact was not detected within the specified time after contact with the 2nd BTR started.

102-356 ERROR — RAP Fatal error related to the EWS.

102-380 ERROR — RAP Fatal error in the MF UI count.

102-381 ERROR — RAP ESS error during communication between ESS and the control panel.

102-382 ERROR — RAP A verification message was not returned from the Control Panel within the specified time.

112-700 ERROR — RAP The punch dust box is full.

116-210 ERROR — RAP Media Reader Fatal Error.

116-211 ERROR — RAP Media Reader Cable disconnected.

116-212 ERROR — RAP [Media Reader] MediaLib SW Logic Failure.

116-310 ERROR — RAP An error was detected while checking ESS font ROM DIMM #1.

116-312 ERROR — RAP An error was detected in the HDD encryption key during activation.

116-313 ERROR — RAP An encryption key was specified but the HDD itself was not encrypted.

116-314 ERROR — RAP An ethernet error was detected.

116-315 ERROR — RAP An error was detected during System Memory 1 R/W.

116-316 ERROR — RAP An error was detected during System Memory 2 R/W.

116-317 ERROR — RAP An error was detected when checking the MF ROM.

116-318 ERROR — RAP An error was detected when checking the expansion ROM R2.

116-321 ERROR — RAP System Software Fatal Error.

116-322 ERROR — RAP WebDAV S/W Failure.

116-323 ERROR — RAP An error was detected during the ESS PWB NVM Read/Write Check.

116-324 ERROR — RAP A fatal software exception error has occurred in the Controller PWB CPU.

116-325 ERROR — RAP An error occurred in ESS fan rotation.

116-329 ERROR — RAP A system call error related to the serial I/F was detected.

116-330 ERROR — RAP Error during HDD check.

116-331 ERROR — RAP An error related to the log was detected.

116-332 ERROR — RAP An error in the MF ROM ( ) was detected.

116-333 ERROR — RAP A problem occurred during software processing, and processing could no longer continue.

116-336 ERROR — RAP Redirector HD Failure. A problem was detected during HD access.

116-337 ERROR — RAP Fatal error with SNTP in general.

116-338 ERROR — RAP Fatal error with JBA in general.

116-340 ERROR — RAP There was insufficient page memory, input buffers, or work area.

116-341 ERROR — RAP Incorrect version or invalid combination ROM DIMMs are installed.

116-342 ERROR — RAP Fatal error related to the SNMP agent.

116-343 ERROR — RAP An IC error within the ESS PWB was detected.

116-346 ERROR — RAP Formatter failure. Error return from a system call.

116-348 ERROR — RAP Redirector failure. Error return from a system call.

116-349 ERROR — RAP There was an error with a call within SIF related to Pflite.

116-350 ERROR — RAP Fatal error with AppleTalk in general.

116-351 ERROR — RAP Fatal error related to EtherTalk.

116-352 ERROR — RAP Fatal error related to NetWare.

116-353 ERROR — RAP A physical problem was detected with the HDD during activation, causing the HDD not to activate.

116-354 ERROR — RAP A problem with the HDD product code was detected during activation.

116-355 ERROR — RAP Fatal error related to the SNMP agent.

116-356 ERROR — RAP The HDD was formatted, but an HDD failure occurred.

116-357 ERROR — RAP PostScript fatal system error.

116-358 ERROR — RAP Fatal error related to the salutation.

116-359 ERROR — RAP Fatal error in PLW.

116-360 ERROR — RAP Fatal error related to SMB.

116-361 ERROR — RAP SPL HDD fatal error. SpoolCont detected an error during HDD access.

116-362 ERROR — RAP SSDP software failure.

116-363 ERROR — RAP BMLinkS or print service software failure.

116-364 ERROR — RAP A timer error was detected.

116-365 ERROR — RAP SPL fatal error.

116-366 ERROR — RAP Report generator incorrect operation.

116-367 ERROR — RAP Parallel fatal error.

116-368 ERROR — RAP DumpPrint fatal error.

116-370 ERROR — RAP XJCL fatal error.

116-371 ERROR — RAP PCL Decomposer Software Failure. PCL fatal error.

116-373 ERROR — RAP Fatal error related to Dynamic DNS.

116-374 ERROR — RAP AutoSW fatal error.

116-376 ERROR — RAP Port 9100 Software Fail.

116-378 ERROR — RAP Fatal error related to MCR.

116-379 ERROR — RAP Fatal error related to MCC.

116-380 ERROR — RAP An error was detected while checking ESS font ROM DIMM #1.

116-381 ERROR — RAP The ABL did not agree with the ABL version information in NVM, or the data was corrupted.

116-382 ERROR — RAP An ABL access to NVM or HDD failed.

116-385 ERROR — RAP Fatal error related to the IDC.

116-388 ERROR — RAP It was detected that no HD is installed.

116-389 ERROR — RAP The system detected that no additional RAM was installed.

116-390 ERROR — RAP A version mismatch was detected between the standard ROM and NVM.

116-391 ERROR — RAP Incorrect specification of the country code, territory code, or paper size group.

116-395 ERROR — RAP Fatal error related to the USB.

116-701 ERROR — RAP Duplex printing is not possible due to insufficient memory.

116-702 ERROR — RAP Printing occurred with a substitute font.

116-703 ERROR — RAP PostScript data problem during PostScript grammar interpretation or language interpretation.

116-704 ERROR — RAP MediaReader No Insert (No Job).

116-705 ERROR — RAP MediaReader Format Error (No Job).

116-706 ERROR — RAP MediaReader: File Attribute Read Error (No Job).

116-707 ERROR — RAP MediaReader: Image File Read Error (No Job).

116-708 ERROR — RAP MediaReader: File Attribute Read Error (In Job).

116-709 ERROR — RAP MediaReader: Image File Read Error (Occurs during job).

116-710 ERROR — RAP Original size not correctly determined.

116-711 ERROR — RAP Mismatch in size and direction or ART EX form with paper to be printed.

116-712 ERROR — RAP PLW form / logo data cannot be registered due to insufficient RAM or HD space.

116-713 ERROR — RAP The job was divided because the HDD was full.

116-714 ERROR — RAP An HP-GL/2 (option) command error occurred.

116-715 ERROR — RAP The form could not be registered because the ART EX form registration upper limit was reached.

116-716 ERROR — RAP MediaReader File Does Not Exist.

116-717 ERROR — RAP MediaLib: Not Execute of New Request.

116-718 ERROR — RAP The specified ART EX form has not been registered.

116-720 ERROR — RAP PCL Memory Low, Page Simplified.

116-737 ERROR — RAP User defined data could not be registered because there was insufficient ART IV user definition memory.

116-738 ERROR — RAP Synthesis problem due to the specified ART IV form size and direction were different from the paper size and direction.

116-739 ERROR — RAP Form / logo data could not be registered because there was insufficient ART IV memory or HDD capacity.

116-740 ERROR — RAP An error occurred because the print data exceeded the printer limit.

116-741 ERROR — RAP No more forms can be registered because the number of ART IV Forms registered has reached the upper limit.

116-742 ERROR — RAP No more logo data can be registered because the number of ART IV log data registered has reached the upper limit.

116-743 ERROR — RAP The form or logo data could not be registered due to insufficient ART IV memory.

116-745 ERROR — RAP An ART IV command error occurred.

116-746 ERROR — RAP The specified form has not been registered.

116-747 ERROR — RAP The paper margin value is too large for the HP-GL/2 (option) effective coordinate area.

116-748 ERROR — RAP The HP-GL/2 (option) print data does not contain any image data.

116-749 ERROR — RAP The specified PostScript font is not in ROM or HDD.

116-771 ERROR — RAP Invalid JBIG Parameter DL Fixed.

116-772 ERROR — RAP Invalid JBIG Parameter D Fixed.

116-773 ERROR — RAP Invalid JBIG Parameter P Fixed.

116-774 ERROR — RAP Invalid JBIG Parameter YD Fixed.

116-775 ERROR — RAP Invalid JBIG Parameter LO Fixed.

116-776 ERROR — RAP Invalid JBIG Parameter MX Fixed.

116-777 ERROR — RAP Invalid JBIG Parameter MY Fixed.

116-778 ERROR — RAP Invalid JBIG Parameter VLENGTH Fixed.

116-780 ERROR — RAP There was a problem with the document attached to the received mail.

116-790 ERROR — RAP Stapling was cancelled.

123-200 ERROR — RAP The data received from ESS exceeded the buffer size of the storage destination within the control panel.

123-201 ERROR — RAP Data intended to be received from the control panel exceeded the buffer size of the storage destination within the control panel.

123-202 ERROR — RAP Events occurred that exceeded the processing capability for requests generated within the control panel.

123-203 ERROR — RAP UI Debug code.

123-204 ERROR — RAP SIO Parameter Failure (UI-Control panel).

123-205 ERROR — RAP SIO Command Failure (UI-Control panel).

123-206 ERROR — RAP SIO Status Failure (UI-Control panel).

123-207 ERROR — RAP Comm Manager Target Failure (UI-Control panel).

123-208 ERROR — RAP Comm Manager Command Failure (UI-Control panel).

123-209 ERROR — RAP EVM Returns Wrong Value (UI-Control panel).

123-310 ERROR — RAP Send Queue Full (UI-Control panel).

123-311 ERROR — RAP Receive Queue Full (UI-Control panel).

123-312 ERROR — RAP EVM Uses Wrong API (UI-Control panel).

123-313 ERROR — RAP AS Uses Wrong API (UI-Control panel).

123-314 ERROR — RAP Event-Waiting Timer Timeout (UI-Control panel).

123-315 ERROR — RAP CTS Internal Failure (UI-Control panel).

123-316 ERROR — RAP Send Request Queue Full SIO (UI-Control panel).

123-317 ERROR — RAP Receive Message Queue Full (UI-Control panel).

123-318 ERROR — RAP Receive Finish Queue Full (UI-Control panel).

123-319 ERROR — RAP Send Failure with No ACK (UI-Control panel).

123-320 ERROR — RAP Polling Failure (UI-Control panel).

123-321 ERROR — RAP Send Message Failure (UI-Control panel).

123-322 ERROR — RAP Target Failure (UI-Control panel).

123-323 ERROR — RAP Address Failure (UI-Control panel). Serial communication error.

123-324 ERROR — RAP Size Failure (UI-Control panel). Serial communication error.

123-325 ERROR — RAP Object Creation Failure (UI-Control panel).

123-326 ERROR — RAP Memory Overflow (UI-Control panel).

123-327 ERROR — RAP Button Overflow (UI-Control panel).

123-328 ERROR — RAP UI Internal Failure with Out of Area.

123-329 ERROR — RAP UI Internal Failure with Invalid Coordinates.

123-330 ERROR — RAP Interface Failure with Invalid Parameter LCD.

123-331 ERROR — RAP UI Internal Failure with Invalid LED Request.

123-332 ERROR — RAP I/F Failure (Invalid Parameter CP).

123-333 ERROR — RAP I/F Failure (No Communication).

123-334 ERROR — RAP I/F Failure (Receiving Error Key Code).

123-335 ERROR — RAP I/F Failure (Receiving Invalid Coordinates).

123-336 ERROR — RAP I/F Failure (DM-ACD Drv. I/F).

123-337 ERROR — RAP Frame Data Error with Invalid Data Type.

123-338 ERROR — RAP Frame Data Error Offset Address Out.

123-339 ERROR — RAP Display Request Code Invalid.

123-340 ERROR — RAP Interface Failure GUAM-DM I/F.

123-341 ERROR — RAP Event Queue Full (UI-Control panel).

123-342 ERROR — RAP Event Queue Empty (UI-Control panel).

123-343 ERROR — RAP Invalid Class (UI-Control panel).

123-344 ERROR — RAP Invalid Type (UI-Control panel).

123-345 ERROR — RAP Timer Queue Full (UI-Control panel).

123-346 ERROR — RAP Invalid Timer Number (UI-Control panel).

123-347 ERROR — RAP Undefined Trap (UI-Control panel).

123-348 ERROR — RAP Command Access Exception (UI-Control panel).

123-349 ERROR — RAP Invalid Command (UI-Control panel).

123-350 ERROR — RAP Privilege Command (UI-Control panel).

123-351 ERROR — RAP No FPU Exception (UI-Control panel).

123-352 ERROR — RAP Address Mis-align (UI-Control panel).

123-353 ERROR — RAP Data Access Exception (UI-Control panel).

123-354 ERROR — RAP Tag Overflow (UI-Control panel).

123-355 ERROR — RAP No Co Processor Exception (UI-Control panel).

123-356 ERROR — RAP Short of Area (UI-Control panel).

123-357 ERROR — RAP Cancel Wait Status (UI-Control panel).

123-358 ERROR — RAP Timeout (UI-Control panel).

123-359 ERROR — RAP Queue Overflow (UI-Control panel).

123-360 ERROR — RAP Context Failure (UI-Control panel).

123-361 ERROR — RAP Object Failure (UI-Control panel).

123-362 ERROR — RAP No Object (UI-Control panel).

123-363 ERROR — RAP Invalid ID (UI-Control panel).

123-364 ERROR — RAP Parameter Failure (UI-Control panel).

123-365 ERROR — RAP Reserve Attribute (UI-Control panel).

123-366 ERROR — RAP Reserve Function Code (UI-Control panel).

123-367 ERROR — RAP Unsupported Function (UI-Control panel).

123-368 ERROR — RAP Short of UI Memory (UI-Control panel).

123-369 ERROR — RAP Invalid Interface Value (UI-Control panel).

123-370 ERROR — RAP Interface Length Failure (UI-Control panel).

123-371 ERROR — RAP Interface Parameter Failure (UI-Control panel).

123-372 ERROR — RAP Interface Sequence Failure (UI-Control panel).

123-373 ERROR — RAP Channel Failure (UI-Control panel).

123-374 ERROR — RAP Invalid User Job ID (UI-Control panel).

123-375 ERROR — RAP Internal Resource Failure (UI-Control panel).

123-376 ERROR — RAP Internal Memory Failure (UI-Control panel).

123-377 ERROR — RAP UI Timer Failure (UI-Control panel).

123-378 ERROR — RAP Interface Format Failure (UI-Control panel).

123-379 ERROR — RAP Dispatch Failure (UI-Control panel).

123-380 ERROR — RAP Copy Interface Failure (UI-Control panel).

123-382 ERROR — RAP Scanner Interface Failure (UI-Control panel).

123-383 ERROR — RAP Report Interface Failure (UI-Control panel).

123-384 ERROR — RAP Server Access Failure (UI-Control panel).

123-385 ERROR — RAP Service Object Overflow (UI-Control panel).

123-386 ERROR — RAP Invalid Service Object (UI-Control panel).

123-387 ERROR — RAP Invalid Service Object Attribute (UI-Control panel).

123-388 ERROR — RAP Attribute Failure (UI-Control panel).

123-389 ERROR — RAP Argument Failure (UI-Control panel).

123-390 ERROR — RAP Job Parameter Failure (UI-Control panel).

123-391 ERROR — RAP Job Actual Parameter Failure (UI-Control panel).

123-392 ERROR — RAP Auditron Failure (UI-Control panel).

123-393 ERROR — RAP EP Failure (UI-Control panel).

123-394 ERROR — RAP File Access Failure (UI-Control panel).

123-395 ERROR — RAP NVM Failure (UI-Control panel).

123-396 ERROR — RAP FF Failure (UI-Control panel).

123-397 ERROR — RAP MGR Failure (UI-Control panel).

123-398 ERROR — RAP Delay Release Queue Full (UI-Control panel).

123-399 ERROR — RAP Internal Failure (UI-Control panel).

123-400 ERROR — RAP Internal Failure (UI-Control panel).

124-310 ERROR — RAP DC132 11 — The product number was not specified.

124-311 ERROR — RAP DC132 09 — The serial number registration field failed.

124-312 ERROR — RAP DC132 12 — Product numbers did not agree.

124-313 ERROR — RAP DC132 10 — Serial numbers did not agree.

124-314 ERROR — RAP DC 132-01 — IOT Speed Failure.

124-315 ERROR — RAP DC 132-02 — IOT Speed Mismatch.

124-316 ERROR — RAP DC 132-04 — Product a/f Model Failure.

124-317 ERROR — RAP DC 132-04 — Product a/f All Product Model Mismatch.

124-318 ERROR — RAP Product Type for S/W Key Failure.

124-319 ERROR — RAP DC 132-08 — All Product Type For S/W Key Mismatch.

124-320 ERROR — RAP EEP ROM Failure.

124-321 ERROR — RAP Backup SRAM Failure. An NVM ROM write problem occurred on the ESS PWB.

124-322 ERROR — RAP DC 132-05 — Copy/Scan/Print S/W Key by PWE Failure.

124-323 ERROR — RAP DC 132-06 — Copy/Scan/Print S/W Key 1 Failure.

124-324 ERROR — RAP All Billings Mismatch.

124-325 ERROR — RAP Billing Restoration Failure.

124-333 ERROR — RAP ASIC Failure (Panther).

124-334 ERROR — RAP Standard Font ROM Error.

124-335 ERROR — RAP Font ROM Not Found.

124-337 ERROR — RAP ESS Standard RAM Error.

124-338 ERROR — RAP Same Font ROMs Found.

124-339 ERROR — RAP ROM DIMM of another product found.

124-340 ERROR — RAP The three CRUM market destination values are not set up (0 or different).

124-341 ERROR — RAP One CRUM market destination value is different (IOT).

124-342 ERROR — RAP One CRUM market destination value is different (SYS 1).

124-343 ERROR — RAP One CRUM market destination value is different (SYS 2).

124-350 ERROR — RAP The three CRUM OEM destination values are not set up (0 or different).

124-351 ERROR — RAP One CRUM OEM destination value is different (IOT).

124-352 ERROR — RAP One CRUM OEM destination value is different (SYS 1).

124-353 ERROR — RAP One CRUM OEM destination value is different (SYS 2).

124-360 ERROR — RAP CRUM Valid/Invalid is not set up at the three locations (0 or different values).

124-361 ERROR — RAP CRUM Validation Failure MCU.

124-362 ERROR — RAP CRUM Validation Failure SYS 1.

124-363 ERROR — RAP CRUM Validation Failure SYS 2.

124-372 ERROR — RAP IOT sc Soft Failure.

124-373 ERROR — RAP IOT Manager SW Failure.

124-374 ERROR — RAP IOT IM Device Driver SW Failure.

124-380 ERROR — RAP CRUM Market fail ALL (2).

124-381 ERROR — RAP CRUM Market fail MCU (2).

124-382 ERROR — RAP CRUM Market fail SYS 1 (2).

124-383 ERROR — RAP CRUM Market fail SYS 2 (2).

124-390 ERROR — RAP CRUM OEM fail ALL (2).

124-391 ERROR — RAP CRUM OEM fail MCU (2).

124-392 ERROR — RAP CRUM OEM fail SYS 1 (2).

124-393 ERROR — RAP CRUM OEM fail SYS 2 (2).

124-701 ERROR — RAP Side Tray to Center Tray.

124-704 ERROR — RAP The output tray was changed from the Folder Tray to the Center Tray and printing continued.

124-705 ERROR — RAP Punching Cancelled.

124-706 ERROR — RAP Folding Cancelled.

124-708 ERROR — RAP The output tray has been changed to the Sub Tray because a failure was detected in the specified output tray.

124-709 ERROR — RAP Stapler Sheet Count is too high.

125-311 ERROR — RAP PSWcont Unexpected Failure.

127-210 ERROR — RAP DFE Communication Failure.

127-211 ERROR — RAP DFE Parameter Error.

127-212 ERROR — RAP ExtPrint Check Mode Error.

127-213 ERROR — RAP External Print IF Mismatch.

127-220 ERROR — RAP Communication Error (video) detected by the DFE.

127-221 ERROR — RAP Communication Error (Command) detected by the DFE.

127-310 ERROR — RAP ESR Task Fatal Error.

127-311 ERROR — RAP ExtPRT.

127-320 ERROR — RAP DFE Critical Failure.

127-337 ERROR — RAP Job Template HDD Write Error.

127-342 ERROR — RAP Job Template Monitor Failure.

127-353 ERROR — RAP LPD Soft Fatal Error.

127-354 ERROR — RAP FTP Server Software Failure.

127-396 ERROR — RAP Mail I/O Soft Fatal error.

127-398 ERROR — RAP IPP Soft Fatal Error.

127-399 ERROR — RAP JME Soft Fatal Error.

202-399 ERROR — RAP Timer Internal Fail.

WorkCentre 5021/5019

Service Documentation

WC 5021/5019 Service Documentation

702P00886

Initial Issue

08/2012

***Xerox Private Data***

All service documentation is supplied to Xerox external customers for informational purposes only. Xerox service documentation is intended for use by certified, product-trained service personnel only. Xerox does not warrant or represent that it will notify or provide to such customer any future change to this documentation. Customer performed service of equipment, or modules, components, or parts of such equipment may affect whether Xerox is responsible to fix machine defects under the warranty offered by Xerox with respect to such equipment. You should consult the applicable warranty for its terms regarding customer or third-party provided service.

If the customer services such equipment, modules, components or parts thereof, the customer releases Xerox from any and all liability for the customer actions, and the customer agrees to indemnify, defend and hold xerox harmless from any third party claims which arise directly or indirectly for such service.

While Xerox has tried to make the documentation accurate, Xerox will have no liability arising out of any inaccuracies or omissions. Changes are periodically made to this document. Changes, technical inaccuracies, and typographical errors will be corrected in subsequent editions.

Prepared by Creative and Technical Communications – North America

800 Phillips Road, Building 218-01A

Webster, New York 14580

ISO9001 and ISO27001 Certified

©2012 by Xerox Corporation. All rights reserved.

XEROX® and XEROX and design® are trademarks of Xerox Corporation in the US and/or other countries.

Changes are periodically made to this document. Changes, technical inaccuracies, and typographic errors will be corrected in subsequent editions.

CAUTION

This equipment generates, uses and can radiate radio frequency energy, and if not installed and used in accordance with the instructions documentation, may cause interference to radio communications. It has been tested and found to comply with the limits for a Class A computing device pursuant to subpart B of part 15 of FCC rules, which are designed to provide reasonable protection against such interference when operated in a commercial environment. Operation of this equipment in a residential area is likely to cause interference in which case the user, at his own expense, will be required to correct the interference.

|

Initial Issue |

08/2012 |

Front Matter |

|

WorkCentre 5021/5019 |

0-1 |

0 Introduction

|

0.1 |

Getting to know this Service Manual……………………………………………………………… |

0-3 |

|

0.2 |

How to use the Service Manual ……………………………………………………………………. |

0-3 |

|

0.3 |

Description for Terminology And Symbols ……………………………………………………… |

0-4 |

|

Initial Issue |

08/2012 |

Introduction |

|

WorkCentre 5021/5019 |

0-1 |

|

0.1 Getting to know this Service Manual |

0.2 How to use the Service Manual |

This manual is used as the standard service manual for WorkCentre 5021/ 5019.

This manual describes the standard procedures for the servicing this product. Refer to Chapter 1 Service Call Procedure for efficient and effective servicing during maintenance calls.

For more information on the options, refer to the options manual.

2.1 Contents of Manual

This manual is divided into 10 chapters as described below.

•Chapter 1 Service Call Procedure

This chapter describes the general work and servicing procedures for the maintenance of this product.

•Chapter 2 Troubleshooting

This chapter describes the troubleshooting procedures other than image quality troubleshooting for this product.

•Chapter 3 Image Quality Troubleshooting

This chapter describes the image quality troubleshooting procedures for this product.

•Chapter 4 Disassembly/Assembly and Adjustment

This chapter describes the disassembly, assembly, adjustment and replacement procedures for components of this product.

•Chapter 5 Parts List

This chapter contains the spare parts information for this product.

•Chapter 6 General

This chapter contains the following information.

6.1Specifications

6.2Tools/Service Consumables/Consumables

6.3Service Data

6.4Service Mode

6.6KO PROGRAM# LIST

•Chapter 7 Wiring Data

This chapter contains the information about the Wiring Connector List/Locations, the Wiring Data, and the BSD for this machine.

•Chapter 8 Accessories (not yet issued)

•Chapter 9 Installation/Removal

This chapter contains the installation and removal procedures for this product and the options that are specific to it.

•Chapter 10 Mechanism & Functions Overview (not yet issued)

Initial Issue

WorkCentre 5021/5019

2.2 Information on Updating

This manual will be sent to each Service Center as specified below. Revisions must be incorporated correctly to keep the manual up-to-date.

Updating Procedure:

•When the manual is updated, the issue number ‘Ver. 1’ will be changed to Ver. 1.1, Ver. 1.2, and so on.

|

08/2012 |

Introduction |

|

|

0.1, 0.2 |

||

|

0-3 |

0.3 Description for Terminology And Symbols

The terms and symbols used throughout this manual are explained here.

•The terms and symbols used at the beginning of a text are defined as follows:

DANGER

Indicates an imminently hazardous situation, such as death or serious injury if operators do not handle the machine correctly by disregarding the statement.

WARNING

Indicates a potentially hazardous situation, such as death or serious injury if operators do not handle the machine correctly by disregarding the statement.

CAUTION

Purpose

Used to describe the purposes of Adjustment and Troubleshooting.

REP: Indicates the disassembly/assembly procedure for reference.

ADJ: Indicates the adjustment procedure for reference.

PL: Indicates the parts list for reference.

Terminology

Indicates a potentially hazardous situation, such as injury or property damage if operators do not handle the machine correctly by disregarding the statement.

Instruction: Used to alert you to a procedure which, if not strictly observed, could result in damage to the machine or equipment.

|

Table 1 Terminology |

|

|

Terminology |

Description |

|

Assy |

Means Assembly. |

|

TEC Value |

Abbreviation of Typical Electricity Consumption, which means the standard |

|

power consumption. Read as ‘tec’. |

|

|

Introduction |

08/2012 |

Initial Issue |

|

0.2, 0.3 |

||

|

0-4 |

WorkCentre 5021/5019 |

1 Service Call Procedures

|

1.1 |

Before Starting the Servicing ……………………………………………………………………….. |

1-3 |

|

1.2 |

Service Call Procedure ……………………………………………………………………………….. |

1-5 |

|

1.3 |

Detailed Contents of the Service Call ……………………………………………………………. |

1-6 |

|

1.4 |

TRIM Check List…………………………………………………………………………………………. |

1-7 |

|

1.5 |

Periodic Replacement Parts/Consumables List ………………………………………………. |

1-7 |

|

Initial Issue |

08/2012 |

Service Call Procedures |

|

WorkCentre 5021/5019 |

1-1 |

1.1 Before Starting the Servicing

1.1.1 Safety

To prevent any accident that may occur during a maintenance service, any warning or any caution regarding the servicing must be strictly observed. Do not perform any hazardous operation.

1.Power Supply

To prevent electrical shocks, burns, or injury, etc., be sure to switch OFF the machine and disconnect the plug before starting the maintenance service. If the machine has to be switched ON, such as when measuring the voltage, take extra care not to get an electrical shock.

2.Drive Area

Never inspect, clear or lubricate the drive area such as chain belts, chain wheel or gears during the machine operation.

3.Heavy Parts

Position your hip lower when removing or installing heavy parts.

4.Safety Device

See that safety devices for preventing mechanical accidents, such as fuses, circuit breakers, interlock switches, etc., and those for protecting customers from injury, such as panels and covers, function properly. Modifications that hinder the function of any safety devices are strictly prohibited.

5.Installing and Removing Parts

The edge of parts and covers may be sharp, take care not to touch them. Be careful not to touch those parts, and wipe off any oil that may have adhered to your fingers or hands before servicing. When removing parts, cables, and etc. do not pull them out by force but remove them slowly.

6.Specified Tools

Follow the instruction when a tool is specified.

7.Cleaning the Toner and Developer

As the toner can be explosive, sweep or brush the spilled toner into a container for collecting the sweepings.

Clean away the remaining toner with a damp cloth or use a standard vacuum cleaner that is toner-tolerant. Never use the customer’s vacuum cleaner.’

Do the same when cleaning the Developer because it also contains some toner.

8.Organic Solvents

When using an organic solvent such as the Drum Cleaner or Machine Cleaner, pay attention to the following:

•Ensure good ventilation in the room to prevent too much inhalation of solvent fumes.

•Do not use heated solvent.

•Keep it away from fire.

•Wash your hands thoroughly after use.

9.Harmful Laser

The customer or service personnel would not be exposed to any harmful laser during the usual copying or scanning of documents. However, if a customer finds that the lamp that is used for exposing documents is too bright when performing platen copy or scan, it is possible to block the light from the platen glass by covering the portion of the platen document area that is usually not used for copying or scanning documents.

|

Initial Issue |

08/2012 |

Service Call Procedure |

|

1.1 |

||

|

WorkCentre 5021/5019 |

1-3 |

1.1.2 Things to Take Note When Handling Customer Information

1.Handling of customer’s electronic information — samples of copy/print (paper data), log files (Activity Report), and etc.

Before you bring back any samples for the purpose of investigation/analysis, always obtain permission from the customer. Make sure to assure them that the data will not be used for any other purpose.

2.Handling of a PWB, etc. that contains customer information.

Data such as Fax Address Numbers and URLs that are registered in the customer’s machine are all important customer information. These types of information are stored in the PWB, etc. within the machine. Take extra care when handling them.

(1)In case of replacements, transfer the data to the new PWB and make sure that all data in the old parts is thoroughly erased before disposing it. Make sure that no important customer information gets leaked. (For details, refer to the preface in Chapters 4 and 5)

(2)If a component was replaced and it was not found to be the cause of the malfunction, return it to the machine it came from. (For components that were temporarily installed/removed for troubleshooting, etc. clear the data using the CE Mode, etc.)

1.1.3 Other Precautions

Pay attention to the following when performing maintenance service to avoid wrong or redundant servicing:

1.Reference Materials

Before performing maintenance servicing, read all relevant technical materials to make a systematic approach.

2.Disassembling

Make sure to check the assembled condition before removing parts or disassembling the machine.

3.Installation/Adjustment

After the installation or adjustment is complete, check that no parts or tools are left inside or on the assemblies before using the machine.

4.Handling of replaced parts/consumables

Make sure that the replaced parts or consumables as well as their packaging materials are collected back to the Service Center.

For the separation and processing methods for the collected items, refer to the Common Technical Information No. 2-027 for all machines.

• Drum Cleaner

WARNING

Never discard the Drum Cleaner into a fire. Always keep it away from open flames to prevent it from catching and causing a fire. Always dispose of the Drum Cleaner after it is completely used up. For recyclable parts, fill the necessary items in the [U-TAG] and perform collection.

5.General Precautions

•Take care not to disturb the customer’s daily work.

•Place a drop cloth or paper on the floor of the service area to keep the site clean.

•Throw any trash generated during the maintenance service into a trash bag and bring them back to the Service Center.

•Record clearly the service details and the consumables and parts replaced at visit in the Machine Service Log.

|

Service Call Procedure |

08/2012 |

Initial Issue |

|

1.1, 1.2 |

||

|

1-4 |

WorkCentre 5021/5019 |

1.2 Service Call Procedure

1.2.1 Initial Actions

1.Ask the operator(s) about the machine condition.

2.Record the billing meter readings.

3.Inspect any error copies, then check the machine.

4.Check the Service Log.

1.2.2 When UM is requested, perform the following:

1.Check the problem status by performing the Level 1 Troubleshooting in [Chapter 2 Troubleshooting].

2.Perform the applicable Level 2 Troubleshooting FIP in [Chapter 2 Troubleshooting].

3.If there are no applicable items, troubleshoot by referring to [Chapter 7 BSD].

4.Check the copy quality.

Make several sheets of copies using the Test Chart (499T 00247), then check the quality of the copies for problems.

5.Output the following [Error History Report] and check the [System Fail History] and [Paper Jam History] in order to understand the machine status.

(1)Enter the System Administrator Mode.

i.Press the [Log In / Out] button and hold it down for 4 s or longer until the following screen is displayed.

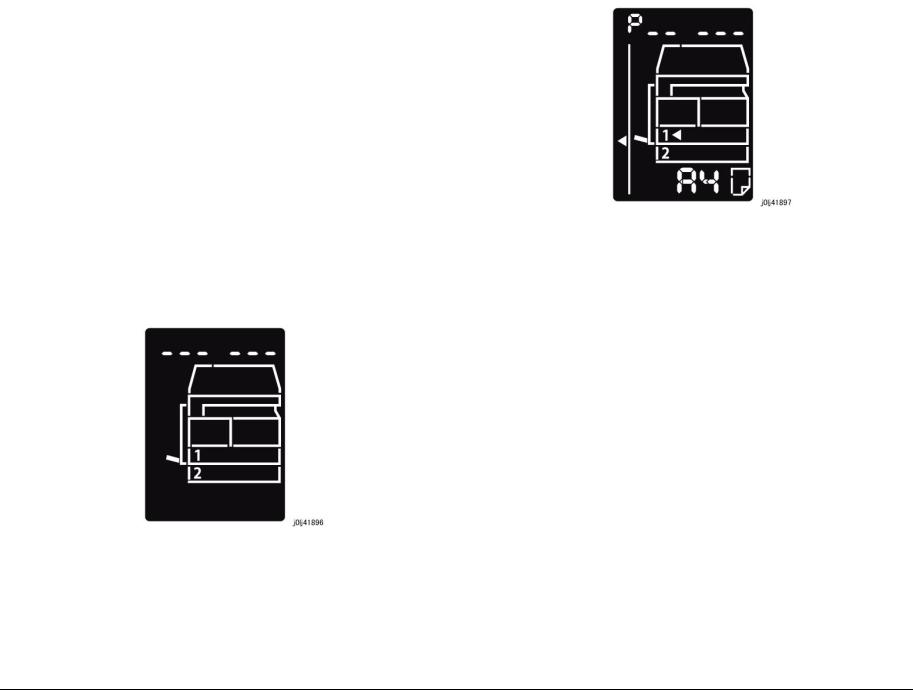

Figure 1 j0lj41896

ii.Use the keypad to enter the Passcode [11111]*1 (5 ‘1’ digits) and press the [Start] button.

NOTE: *1: Default Value

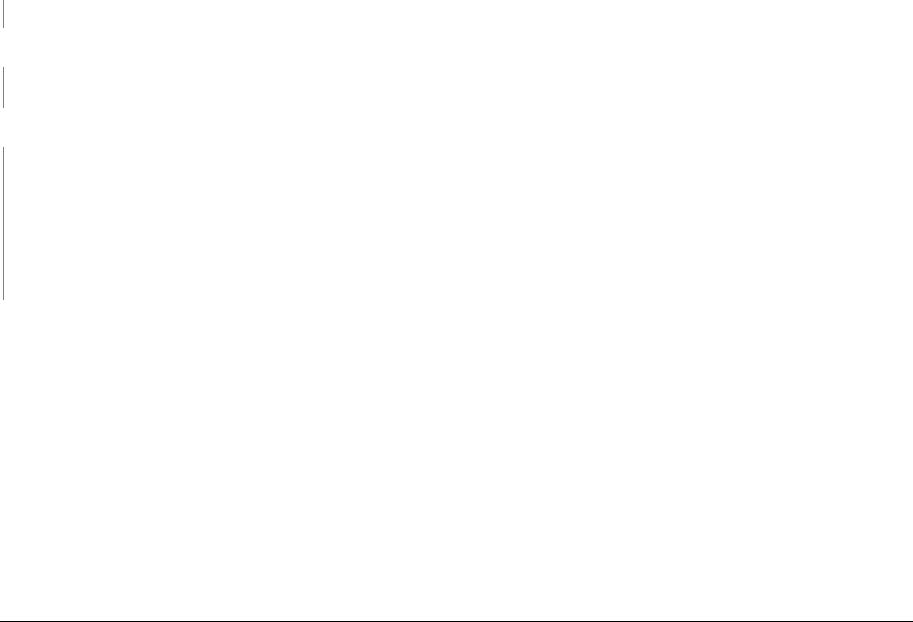

iii.The Program Number input screen is displayed.

Figure 2 j0lj41897

(2)Load any one of A4 SEF, A4 LEF, Letter SEF, or Letter LEF into the Tray.

(3)Enter ‘202’ at the Program Number and press the [Start] button.

(4)Enter ‘4’ for [Error History Report] and press the [Start] button.

(5)Once printing has completed, press the [Log In / Out] button to exit from the System Administrator Mode.

NOTE: When replacing parts that will incur cost to the customer, obtain the customer’s agreement before performing the replacement.

6.Repair all the secondary problems.

7.Perform TRIM Service.

1.2.3 When SM is requested, perform the following:

1.Check the copy quality.

Make several sheets of copies using the Test Chart (499T 00247), then check the quality of the copies for problems.

2.Output the [Error History Report] and check the [System Fail History] and [Paper Jam History] in order to understand the machine status.

•For how to output the [Error History Report], refer to [1.2.2 When UM is requested, perform the following:].

NOTE: When replacing parts that will incur cost to the customer, obtain the customer’s agreement before performing the replacement.

3.Perform TRIM Service.

1.2.4 Final Actions

1.Check overall operation/features.

2.Check the machine exterior and consumables.

3.Train the operator as required.

4.Complete the Service Log and Service Report.

|

Initial Issue |

08/2012 |

Service Call Procedure |

|

1.2 |

||

|

WorkCentre 5021/5019 |

1-5 |

5.Keep the copy samples with the Service Log.

1.3 Detailed Contents of the Service Call

1.3.1 Initial Actions

1. Ask the operator(s) about the machine condition.

• How often and where do paper jams have been occurring recently

• How is the copy quality

2. Record the copy meter readings.

3. Inspect any error copies, then check the machine.

4. Check the print samples from previous service calls and the Service Log.

1.3.2 Checking Reproducibility of Problem

1. Check the problem status by performing the Level 1 Troubleshooting in [Chapter 2 Troubleshooting].

2. Perform the applicable Level 2 Troubleshooting FIP in [Chapter 2 Troubleshooting].

3. If there are no applicable items, troubleshoot by referring to [Chapter 7 BSD].

1.3.3 Checking Copy Quality

1. Make several sheets of copies using the Test Chart (499T 00247), then check the quality of the copies.

1.3.4 TRIM Servicing

Perform TRIM servicing during a service call to maintain the machine performance.

1. Follow the TRIM Check List to perform the required TRIM items.

2. Check for parts that require periodical cleaning/replacement (consumables, parts) by referring to the TRIM Chec List, the Periodic Replacement Parts/Consumables List, and the Maintenance Report, and clean them if necessary. After a replacement, make sure that you enter the CE Mode and use [HFSI Read / Clear] to clear the applicable counter(s).

|

Service Call Procedure |

08/2012 |

Initial Issue |

|

1.3, 1.4 |

||

|

1-6 |

WorkCentre 5021/5019 |

1.4TRIM Check List

C:Perform checking. Clean, replace, or feed if necessary.

O:Always perform cleaning and checking.

*: Always perform replacement service at the specified interval.

|

Table 1 |

||||

|

Every |

||||

|

No. |

Servicing Items |

time |

Service Details |

|

|

1.1 |

Pre-servicing Check |

C |

• |

Activate the machine and check that abnormal |

|

(Check the machine |

noise is not heard. |

|||

|

operation sound) |

||||

|

1.2 |

Pre-servicing Check |

C |

• |

Make several sheets of copies using the Test |

|

(Copy and print the |

Chart (499T 00247), then check the quality of |

|||

|

Test Chart) |

the copies. |

|||

|

2 |

Clean the interior of the |

C |

• |

Clean any paper dust and toner residue in the |

|

machine |

paper path and on the jam sensor. |

|||

|

(Clean the paper trans- |

• |

Especially, clean the operation section of the |

||

|

port system) |

operator carefully. |

|||

|

3 |

Cleaning the IIT |

C |

• |

Clean the Platen Glass surface and the Platen |

|

Cushion with the optical cleaning cloth. |

||||

|

• |

Clean the Reflector, back of the Platen Glass, |

|||

|

mirrors and lens with the optical cleaning cloth. |

||||

|

4 |

Clean the DADF |

C |

• |

Clean the Feed Roll, Nudger Roll, and Retard |

|

Roll with a cloth that has been wrung dry. |

||||

|

• |

Clean the DADF Platen Glass with the optical |

|||

|

cleaning cloth. |

||||

|

5 |

Safety Check |

O |

• |

Make sure that the power plug is plugged in |

|

properly. |

||||

|

• |

Make sure that the power cords are not |

|||

|

cracked and no wires are exposed. |

||||

|

• |

Make sure that no extension cord with insuffi- |

|||

|

cient length or power cord outside the specifi- |

||||

|

cation, such as an off-the-shelf power strip, is |

||||

|

being used. |

||||

|

• |

Make sure that a single socket does not have |

|||

|

multiple power plugs plugged into it. |

||||

|

6.1 |

Post-servicing check |

C |

• |

Make several sheets of copies using the Test |

|

(Copy Quality Check) |

Chart (499T 00247), then check if the quality |

|||

|

satisfies the specification. |

||||

|

6.2 |

Post-servicing check |

C |

• |

Check the paper feed and abnormal noise. |

|

(Check the machine |

||||

|

operation) |

||||

|

6.3 |

Post-servicing check |

C |

• |

Create the Service Log and Service Report. |

|

(Check the meter) |

||||

1.5 Periodic Replacement Parts/Consumables List

When servicing, check the number of copies and number of fed sheets for the consumables and parts that require periodical cleaning/replacement. Clean or replace them if necessary. The history can be checked by printing the Maintenance Report or by checking the approriate counter in [HFSI Read / Clear] in CE Mode (6.4.2.9 HFSI Read / Clear).

For the items that cannot be checked in CE Mode, clean or replace them according to the replacement intervals (standard PV).

CAUTION

Do not place the imaging materials, such as the Toner and the Drum, in the car for a long time.

NOTE: Clean the Platen Glass with a Platen Wax Cleaner 499D 00194 (194D) every 10K Feeds.

Table 1

|

HFSI |

||||

|

Parts/Consumables |

[Chain- |

Replacement |

||

|

No |

Name/PL No. |

Link] |

Interval |

Check the counter |

|

1 |

Tray 1 Feed No. |

950-803 |

50,000PV |

1 Feed = 1 Count Up. |

|

Tray 1 Feed Roll / Retard |

Replace both at the same |

|||

|

Pad |

time. |

|||

|

(PL 9.2) |

||||

|

2 |

Tray 2 Feed No. |

950-804 |

300,000PV |

1 Feed = 1 Count Up. |

|

Tray 2 Feed Roll/Nudger |

Replace all 3 at the same |

|||

|

Roll/Retard Roll |

time. |

|||

|

(PL 10.3) |

||||

|

3 |

MSI Feed Count |

950-802 |

50,000PV |

1 Feed = 1 Count Up. |

|

MSI Feed Roll/MSI Nudger |

Replace all 3 at the same |

|||

|

Roll/MSI Retard Pad |

time. |

|||

|

(PL 13.3) |

||||

|

4 |

Fusing Unit |

950-801 |

175,000PV |

1 pass through the Fusing Unit |

|

(PL 7.1) |

Exit Sensor = 1 Count Up. |

|||

|

5 |

BTR Unit |

950-800 |

100,000PV |

1 pass through the Fusing Unit |

|

(PL 6.1) |

Exit Sensor = 1 Count Up. |

|||

|

6 |

Document Feed No. |

955-806 |

200,000PV |

Replace the Feed Roll, |

|

DADF Feed Roll/Nudger |

Nudger Roll, and Retard Pad |

|||

|

Roll |

at the same time. |

|||

|

(PL 56.5) |

NOTE: Clean the Platen Glass |

|||

|

DADF Retard Pad |

||||

|

with a Platen Wax Cleaner |

||||

|

(PL 56.13) |

||||

|

499D 00914 (194D) every 10K |

||||

|

Feeds. |

||||

|

7 |

Toner Cartridge |

— |

9,000PV |

|

|

(PL 8.1) |

||||

|

8 |

Drum Cartridge *1 |

950-807 |

343k cycle |

<Refer- |

|

(PL 8.1) |

ence>75KPV*1@18PPM / |

|||

|

80KPV*1@20PPM |

||||

|

Initial Issue |

08/2012 |

Service Call Procedure |

|

1.5 |

||

|

WorkCentre 5021/5019 |

1-7 |

*1: The maximum number of prints is a reference value under the condition of A4 LEF and simplex printing. Some specific conditions such as paper size, number of copies for a print job, etc. might cause a serious deterioration of image quality before the time to replace the drum cartridge comes.

|

Service Call Procedure |

08/2012 |

Initial Issue |

|

1.5 |

||

|

1-8 |

WorkCentre 5021/5019 |

2 Status Indicator RAPs

|

2.1 Introduction |

010-327 |

Fusing Unit On Time Fail ……………………………………………………………………… |

2-17 |

||

|

2.1.1 |

How to Troubleshoot ………………………………………………………………………………… |

2-3 |

010-379 |

Fusing Unit Hot Not Ready Return Time Fail…………………………………………… |

2-18 |

|

2.1.2 How to Switch the Error Code Display ………………………………………………………… |

2-3 |

010-392 |

NOHAD Fan Defect……………………………………………………………………………… |

2-18 |

|

|

2.1.3 |

Glossary …………………………………………………………………………………………………. |

2-4 |

010-602 |

Over Temp Cooling Mode …………………………………………………………………….. |

2-18 |

2.2 Product FIP

2.2.1 Level 1 FIP

|

2.2.1.1 Level 1 FIP …………………………………………………………………………………………… |

2-7 |

|

|

2.2.2 Level 2 FIP |

||

|

CHAIN 3 |

||

|

003-500/795 N-Up NG Out Of Range/ AMS NG Out Of Range………………………………. |

2-9 |

|

|

003-754 IPS Overrun ……………………………………………………………………………………….. |

2-9 |

|

|

003-942 Not-Supported Doc Size ………………………………………………………………………. |

2-9 |

|

|

003-951 1Job Max Page Over …………………………………………………………………………… |

2-9 |

|

|

003-963 APS NG Out Of Range ………………………………………………………………………… |

2-9 |

|

|

003-972 EPC Memory Full………………………………………………………………………………… |

2-9 |

|

|

003-973 Auto Rotation NG Out Of Range……………………………………………………………. |

2-9 |

|

|

CHAIN 4 |

||

|

004-345 HVPS Communication Error …………………………………………………………………. |

2-11 |

|

|

CHAIN 5 |

||

|

005-122 DADF Simplex/Side 1 Pre Regi Sensor On Jam ……………………………………… |

2-13 |

|

|

005-123 DADF Simplex/Side 1 Regi Sensor On Jam……………………………………………. |

2-13 |

|

|

005-125/145 DADF Regi Sensor Off Jam/ DADF Regi Sensor Off Jam on Inverting…. |

2-13 |

|

|

005-131/132 DADF Invert Sensor On Jam on Inverting/ DADF Invert Sensor On Jam. |

2-13 |

|

|

005-134/139 DADF Invert Sensor Off Jam on Inverting/ DADF Invert Sensor Off Jam. |

2-14 |

|

|

005-135 DADF Side 2 Pre Regi Sensor On Jam ………………………………………………….. |

2-14 |

|

|

005-136 DADF Side 2 Regi Sensor On Jam………………………………………………………… |

2-14 |

|

|

005-147 DADF Pre Regi Sensor Off Jam on Inverting ………………………………………….. |

2-15 |

|

|

005-196 Size Mismatch Jam on No Mix-Size ………………………………………………………. |

2-15 |

|

|

005-197 Prohibit Combine Size Jam…………………………………………………………………… |

2-15 |

|

|

005-198/199 Too Short Size Jam/ Too Long Size Jam …………………………………………. |

2-15 |

|

|

005-210 DADF Download Fail …………………………………………………………………………… |

2-15 |

|

|

005-275/280 DADF RAM Fail/ DADF EEPROM Fail …………………………………………….. |

2-15 |

|

|

005-305 DADF Feeder Cover Interlock Open………………………………………………………. |

2-16 |

|

|

005-500 DADF Download Flash Write Error ………………………………………………………… |

2-16 |

|

|

005-907/908/913 DADF Pre Regi Sensor/DADF Regi Sensor/DADF Invert Sensor Static Jam |

||

|

2-16 |

||

|

005-940 |

DADF No Original Fail …………………………………………………………………………. |

2-16 |

|

005-948 SS-Size Mismatch Jam on No Mix-size ………………………………………………….. |

2-16 |

|

|

CHAIN 10 |

||

|

010-311 |

Fusing Unit Center Thermistor Defect ……………………………………………………. |

2-17 |

|

010-312 |

Fusing Unit Rear Thermistor Defect ………………………………………………………. |

2-17 |

|

010-320 |

Over Heat Temperature Fail …………………………………………………………………. |

2-17 |

CHAIN 16

|

016-500 |

Controller Download Flash Write Error …………………………………………………… |

2-19 |

|

|

016-501 |

Controller Boot Flash Write Error …………………………………………………………… |

2-19 |

|

|

016-502 |

UI Panel Download Flash Write Error …………………………………………………….. |

2-19 |

|

|

016-570 No Response from USB-Host for Scan Job …………………………………………….. |

2-19 |

||

|

016-571 No Response from USB-Host for Print Job……………………………………………… |

2-19 |

||

|

016-742/744 |

Download File Error/ Download File Check Sum Error ……………………….. |

2-19 |

|

|

016-749/799 |

HBPL or XPJL Syntax Error/ Print Instruction Fail ……………………………… |

2-20 |

|

|

016-759 |

Copy Counter Full ……………………………………………………………………………….. |

2-20 |

|

|

016-776 |

Marker Code Detection Fail ………………………………………………………………….. |

2-20 |

CHAIN 23

|

023-600 Held Down key Error (UI Panel)…………………………………………………………….. |

2-21 |

CHAIN 24

|

024-910/911/915 |

Tray 1/Tray 2/MSI Paper Length Mismatch ………………………………… |

2-23 |

|

024-950/951/954 Tray 1/Tray 2/MSI No Paper …………………………………………………….. |

2-23 |

|

|

024-958/959/960 |

MSI/Tray 1/Tray 2 Paper Size Mismatch ……………………………………. |

2-23 |

|

024-965 APS NG Unselected…………………………………………………………………………….. |

2-23 |

CHAIN 41

|

041-210/211 STM NVM Out-Of-Order/ STM NVM R/W Error…………………………………. |

2-25 |

CHAIN 42

|

042-325/614 Main Motor Rotation Error/ Main Motor Rotation Warning …………………… |

2-27 |

CHAIN 45

|

045-310 |

Image Ready Error………………………………………………………………………………. |

2-29 |

|

045-313 |

IOT Logic Fail……………………………………………………………………………………… |

2-29 |

CHAIN 61

|

061-321 |

ROS Motor Fail …………………………………………………………………………………… |

2-31 |

|

061-325 |

No SOS Fail ……………………………………………………………………………………….. |

2-31 |

CHAIN 62

|

062-277 DADF Communication Fail……………………………………………………………………. |

2-33 |

|

|

062-311 |

IIT Software Logic Fail …………………………………………………………………………. |

2-33 |

|

062-360 |

Carriage Position Fail…………………………………………………………………………… |

2-33 |

|

062-371/380 Lamp Illumination Fail/ AGC Fail……………………………………………………… |

2-33 |

|

|

062-386 AOC Fail…………………………………………………………………………………………….. |

2-34 |

|

|

062-389 |

Carriage Over Run Fail (Scan End Side) ………………………………………………… |

2-34 |

|

062-396 |

CCD Cable Connection Fail ………………………………………………………………….. |

2-34 |

CHAIN 71

|

071-105 Regi Sensor On Jam (Tray 1) ……………………………………………………………….. |

2-35 |

|

Initial Issue |

08/2012 |

Status Indicator RAPs |

|

WorkCentre 5021/5019 |

2-1 |

CHAIN 72

|

072-102 Feed Out Sensor 2 On Jam ………………………………………………………………….. |

2-37 |

||

|

072-105 |

Regi Sensor On Jam (Tray 2) ……………………………………………………………….. |

2-37 |

|

|

072-210 |

Tray 2 |

Lift Up Fail………………………………………………………………………………… |

2-37 |

|

072-212 |

Tray 2 |

Size Sensor Broken …………………………………………………………………… |

2-37 |

|

072-215 |

MCU-STM Communication Fail …………………………………………………………….. |

2-37 |

CHAIN 75

|

075-135 Regi Sensor On Jam (MSI)…………………………………………………………………… |

2-39 |

CHAIN 77

|

077-101 Regi Sensor Off Jam……………………………………………………………………………. |

2-41 |

|

|

077-103 |

Fusing Unit Exit Sensor Off Jam (Long) …………………………………………………. |

2-41 |

|

077-104 |

Fusing Unit Exit Sensor Off Jam (Short)…………………………………………………. |

2-41 |

|

077-106 Fusing Unit Exit Sensor On Jam……………………………………………………………. |

2-41 |

|

|

077-129 |

Regi Sensor On Jam (Duplex Wait)……………………………………………………….. |

2-42 |

|

077-212 |

Tray Module Reset Fail………………………………………………………………………… |

2-42 |

|

077-300/301/305 Front Cover/Left Hand Cover/STM Cover Open………………………….. |

2-42 |

|

|

077-900/901/904 Regi Sensor/Fusing Unit Exit Sensor/Feed Out Sensor 2 Static Jam |

2-42 |

CHAIN 91

|

091-313 CRUM ASIC Communication Fail ………………………………………………………….. |

2-43 |

||

|

091-401/402 |

Drum Cartridge Quality Life Over/ Drum Cartridge Life Over ………………. |

2-43 |

|

|

091-406/424 |

Drum Cartridge Normal Life Over/ Drum Cartridge Abnormal Life Over… |

2-43 |

|

|

091-430 |

Drum Cartridge Life End ………………………………………………………………………. |

2-43 |

|

|

091-440 |

Drum Cartridge Pre Near End……………………………………………………………….. |

2-43 |

|

|

091-441 |

Drum Cartridge Near End …………………………………………………………………….. |

2-44 |

|

|

091-914 |

Drum CRUM Communication Fail………………………………………………………….. |

2-44 |

|

|

091-915/916 Drum CRUM ID Error/ Drum CRUM Market Identity Mismatch ……………. |

2-44 |

|

117-326 Controller Backup NVM Data Defect………………………………………………………. |

2-53 |

CHAIN 123

|

123-314 UI Panel Communication Fail………………………………………………………………… |

2-55 |

2.2.3 Other Failure FIP

|

2.2.3.1 AC Power FIP……………………………………………………………………………………….. |

2-57 |

|

|

2.2.3.2 |

+5VDC Power FIP…………………………………………………………………………………. |

2-57 |

|

2.2.3.3 |

+24VDC Power FIP……………………………………………………………………………….. |

2-58 |

2.2.4 Generic FIP

|

2.2.4.1 |

Reflective Sensor Failure FIP………………………………………………………………….. |

2-59 |

|

2.2.4.2 |

Permeable Sensor Failure FIP ………………………………………………………………… |

2-59 |

|

2.2.4.3 |

Switch (Normal/Open) Failure FIP …………………………………………………………… |

2-60 |

|

2.2.4.4 |

Solenoid/Clutch Not Energized Failure FIP……………………………………………….. |

2-60 |

|

2.2.4.5 |

Solenoid/Clutch Left Energized Failure FIP ………………………………………………. |

2-61 |

|

2.2.4.6 |

Motor Does Not Rotate Failure FIP ………………………………………………………….. |

2-61 |

|

2.2.4.7 |

Motor Left Running Failure FIP ……………………………………………………………….. |

2-62 |

|

2.2.4.8 NIP/RELEASE SOLENOID Not Energized Failure FIP……………………………….. |

2-62 |

2.3 NET System Fault Check

|

2.3.1 |

No output is available, no data is printed …………………………………………………….. |

2-65 |

|

2.3.2 |

Printing can be performed but abnormally …………………………………………………… |

2-65 |

CHAIN 92

|

092-660/668 ATC Amplitude Fail/ ATC Average Fail…………………………………………….. |

2-45 |

|

|

092-661 |

Temperature Sensor Fail ……………………………………………………………………… |

2-45 |

|

092-910 |

ATC Sensor Fail………………………………………………………………………………….. |

2-45 |

CHAIN 93

|

093-312 |

Toner Dispense Motor Rotation Fail ………………………………………………………. |

2-47 |

|

093-400 Toner Near Empty……………………………………………………………………………….. |

2-47 |

|

|

093-406 Toner Pre Near Empty …………………………………………………………………………. |

2-47 |

|

|

093-912 |

Toner Empty ………………………………………………………………………………………. |

2-47 |

|

093-956 |

Drum New CRU Installation Fail ……………………………………………………………. |

2-47 |

|

093-959 |

Drum New CRU Installation Fail Exceeds Thresholding Times………………….. |

2-47 |

CHAIN 95

|

095-910 No Drum Cartridge………………………………………………………………………………. |

2-49 |

CHAIN 116

|

116-321 |

Controller Logic Fail …………………………………………………………………………….. |

2-51 |

|

116-323 |

Controller NVM Data Defect …………………………………………………………………. |

2-51 |

|

116-334 NVM Data Mismatch ……………………………………………………………………………. |

2-51 |

|

|

116-377 |

IIT Interrupt Time out …………………………………………………………………………… |

2-51 |

|

116-747 |

Invalid Page Margin …………………………………………………………………………….. |

2-51 |

CHAIN 117

|

Status Indicator RAPs |

08/2012 |

Initial Issue |

|

2-2 |

WorkCentre 5021/5019 |

2.1.1 How to Troubleshoot

Level 1 Troubleshooting:

•Level 1 Troubleshooting (Level 1 FIP) is the first step to diagnose a problem. Level 1 FIP asks you whether any Fault Code and other problematic symptoms exist, guiding you to Level 2 Troubleshooting or BSD to resolve the problem.

Level 2 Troubleshooting:

•Level 2 Troubleshooting is a diagnostic procedure of separating a problem by Fault Code, document/paper jam and other problematic symptoms. Performing a FIP or an appropriate procedure in the Check Procedure enables you to discover causes of a problem in a short period of time.

How to proceed with troubleshooting and Cautions:

•First, perform Level 1 FIP to categorize a problem. Second, proceed to an appropriate Level 2 FIP or BSD to resolve the problem. To find the causes of the problem using FIP or Check Procedure etc., thoroughly read the instructions and follow the procedure properly. Sometimes, when two or more causes exist, they cannot be identified at once, so the same FIP should be repeated. In this case, pay attention to a different judgment made in the process of the same FIP.

•For source voltage related problems, such as being unable to power up the machine, refer to ‘Other Failure FIP’ to proceed with the troubleshooting.

•The Check Procedure for general electrical parts (Motor, Solenoid/Clutch, Switch, Sensor etc.) may not be shown in each troubleshooting for some cases. In such cases, proceed to troubleshoot by referring to ‘Generic FIP’.

2.1.2 How to Switch the Error Code Display

When a problem has occurred in the machine, an Error Code or a Fault Code (Chain-Link) will be displayed on the UI screen. When an Error Code is being displayed, you can perform the following operation to switch the display to the Chain-Link number that correspond to that Error Code. To repair, check the Chain-Link number and proceed with the appropriate FIP.

How to switch to the Chain-Link number

1.When a problem has occurred, the displayed Error Code will be flashing.

Figure 1 j0lj21201

2.With the Error Code being displayed, press and hold down the [ID Card Copy] button on the Control Panel.

•As long as the button is being pressed, the Chain-Link number will be displayed and flashing.

|

Figure 2 |

j0lj21202 |

|

|

Initial Issue |

08/2012 |

Status Indicator RAPs |

|

2.1.1, 2.1.2 |

||

|

WorkCentre 5021/5019 |

2-3 |

3.Releasing the [ID Card Copy] button returns the display to the Error Code.

2.1.3 Glossary

The following terminology are used throughout the troubleshooting section. The meaning of these terminology must be fully understood when performing problem analysis.

Common terms:

Status Indicator RAPs

2.1.2, 2.1.3

•Fault Code

This 6-digit code appears when the machine has found problems.

•Actuate (Deactuate)

To mechanically push (release) the Actuator of the switch or the connected mechanical linkage.

•Block

To place a sheet of document or paper on the photo sensor surface for detection.

•Check

To visually check for operation failure of parts such as relay or mechanical linkage, and the failure status of the parts.

•Enter the CE Mode

To enter the CE Mode by following the procedure described in ‘How to Enter/Exit the CE Mode’ of Chapter 6.

•Check the connection for short circuit

Turn the power OFF. Measure the resistance between the wire and the frame using the ohm range of a tester.

•Check the connection for open circuit

Turn the power OFF. Measure the resistance between both ends of the wire using the ohm range of a tester.

•Input Check [xxx-xxx]/Output Check [xxx-xxx]

To enter the Component Check by following the procedure described in ‘How to Use the CE Mode’ of Chapter 6.

•Analog Monitor [xxx-xxx]

To enter the Analog Monitor by following the procedure described in ‘How to Use the CE Mode’ of Chapter 6.

•Check the voltage level

|

Table 1 |

||

|

Voltage |

Level |

Range |

|

+3.3VDC |

(H) |

+3.2 to +3.6VDC |

|

(L) |

0.0 to +1.0VDC |

|

|

+5VDC |

(H) |

+4.8 to +5.4VDC |

|

(L) |

0.0 to +1.0VDC |

|

|

+24VDC |

(H) |

+23.3 to +25.7VDC |

|

(L) |

0.0 to +3.0VDC |

|

•PL 4.2

Refer to PL 4.2 in Chapter 5 Parts List.

•CH 6.2 Zone J4

|

08/2012 |

Initial Issue |

|

2-4 |

WorkCentre 5021/5019 |

Refer to Chain 6.2 Zone J4 in Chapter 7 BSD.

•REP 4.1.3