WorkCentre 5021/5019

Service Documentation

WC 5021/5019 Service Documentation

702P00886

Initial Issue

08/2012

***Xerox Private Data***

All service documentation is supplied to Xerox external customers for informational purposes only. Xerox service documentation is intended for use by certified, product-trained service personnel only. Xerox does not warrant or represent that it will notify or provide to such customer any future change to this documentation. Customer performed service of equipment, or modules, components, or parts of such equipment may affect whether Xerox is responsible to fix machine defects under the warranty offered by Xerox with respect to such equipment. You should consult the applicable warranty for its terms regarding customer or third-party provided service.

If the customer services such equipment, modules, components or parts thereof, the customer releases Xerox from any and all liability for the customer actions, and the customer agrees to indemnify, defend and hold xerox harmless from any third party claims which arise directly or indirectly for such service.

While Xerox has tried to make the documentation accurate, Xerox will have no liability arising out of any inaccuracies or omissions. Changes are periodically made to this document. Changes, technical inaccuracies, and typographical errors will be corrected in subsequent editions.

Prepared by Creative and Technical Communications – North America

800 Phillips Road, Building 218-01A

Webster, New York 14580

ISO9001 and ISO27001 Certified

©2012 by Xerox Corporation. All rights reserved.

XEROX® and XEROX and design® are trademarks of Xerox Corporation in the US and/or other countries.

Changes are periodically made to this document. Changes, technical inaccuracies, and typographic errors will be corrected in subsequent editions.

CAUTION

This equipment generates, uses and can radiate radio frequency energy, and if not installed and used in accordance with the instructions documentation, may cause interference to radio communications. It has been tested and found to comply with the limits for a Class A computing device pursuant to subpart B of part 15 of FCC rules, which are designed to provide reasonable protection against such interference when operated in a commercial environment. Operation of this equipment in a residential area is likely to cause interference in which case the user, at his own expense, will be required to correct the interference.

|

Initial Issue |

08/2012 |

Front Matter |

|

WorkCentre 5021/5019 |

0-1 |

0 Introduction

|

0.1 |

Getting to know this Service Manual……………………………………………………………… |

0-3 |

|

0.2 |

How to use the Service Manual ……………………………………………………………………. |

0-3 |

|

0.3 |

Description for Terminology And Symbols ……………………………………………………… |

0-4 |

|

Initial Issue |

08/2012 |

Introduction |

|

WorkCentre 5021/5019 |

0-1 |

|

0.1 Getting to know this Service Manual |

0.2 How to use the Service Manual |

This manual is used as the standard service manual for WorkCentre 5021/ 5019.

This manual describes the standard procedures for the servicing this product. Refer to Chapter 1 Service Call Procedure for efficient and effective servicing during maintenance calls.

For more information on the options, refer to the options manual.

2.1 Contents of Manual

This manual is divided into 10 chapters as described below.

•Chapter 1 Service Call Procedure

This chapter describes the general work and servicing procedures for the maintenance of this product.

•Chapter 2 Troubleshooting

This chapter describes the troubleshooting procedures other than image quality troubleshooting for this product.

•Chapter 3 Image Quality Troubleshooting

This chapter describes the image quality troubleshooting procedures for this product.

•Chapter 4 Disassembly/Assembly and Adjustment

This chapter describes the disassembly, assembly, adjustment and replacement procedures for components of this product.

•Chapter 5 Parts List

This chapter contains the spare parts information for this product.

•Chapter 6 General

This chapter contains the following information.

6.1Specifications

6.2Tools/Service Consumables/Consumables

6.3Service Data

6.4Service Mode

6.6KO PROGRAM# LIST

•Chapter 7 Wiring Data

This chapter contains the information about the Wiring Connector List/Locations, the Wiring Data, and the BSD for this machine.

•Chapter 8 Accessories (not yet issued)

•Chapter 9 Installation/Removal

This chapter contains the installation and removal procedures for this product and the options that are specific to it.

•Chapter 10 Mechanism & Functions Overview (not yet issued)

Initial Issue

WorkCentre 5021/5019

2.2 Information on Updating

This manual will be sent to each Service Center as specified below. Revisions must be incorporated correctly to keep the manual up-to-date.

Updating Procedure:

•When the manual is updated, the issue number ‘Ver. 1’ will be changed to Ver. 1.1, Ver. 1.2, and so on.

|

08/2012 |

Introduction |

|

|

0.1, 0.2 |

||

|

0-3 |

0.3 Description for Terminology And Symbols

The terms and symbols used throughout this manual are explained here.

•The terms and symbols used at the beginning of a text are defined as follows:

DANGER

Indicates an imminently hazardous situation, such as death or serious injury if operators do not handle the machine correctly by disregarding the statement.

WARNING

Indicates a potentially hazardous situation, such as death or serious injury if operators do not handle the machine correctly by disregarding the statement.

CAUTION

Purpose

Used to describe the purposes of Adjustment and Troubleshooting.

REP: Indicates the disassembly/assembly procedure for reference.

ADJ: Indicates the adjustment procedure for reference.

PL: Indicates the parts list for reference.

Terminology

Indicates a potentially hazardous situation, such as injury or property damage if operators do not handle the machine correctly by disregarding the statement.

Instruction: Used to alert you to a procedure which, if not strictly observed, could result in damage to the machine or equipment.

|

Table 1 Terminology |

|

|

Terminology |

Description |

|

Assy |

Means Assembly. |

|

TEC Value |

Abbreviation of Typical Electricity Consumption, which means the standard |

|

power consumption. Read as ‘tec’. |

|

|

Introduction |

08/2012 |

Initial Issue |

|

0.2, 0.3 |

||

|

0-4 |

WorkCentre 5021/5019 |

1 Service Call Procedures

|

1.1 |

Before Starting the Servicing ……………………………………………………………………….. |

1-3 |

|

1.2 |

Service Call Procedure ……………………………………………………………………………….. |

1-5 |

|

1.3 |

Detailed Contents of the Service Call ……………………………………………………………. |

1-6 |

|

1.4 |

TRIM Check List…………………………………………………………………………………………. |

1-7 |

|

1.5 |

Periodic Replacement Parts/Consumables List ………………………………………………. |

1-7 |

|

Initial Issue |

08/2012 |

Service Call Procedures |

|

WorkCentre 5021/5019 |

1-1 |

1.1 Before Starting the Servicing

1.1.1 Safety

To prevent any accident that may occur during a maintenance service, any warning or any caution regarding the servicing must be strictly observed. Do not perform any hazardous operation.

1.Power Supply

To prevent electrical shocks, burns, or injury, etc., be sure to switch OFF the machine and disconnect the plug before starting the maintenance service. If the machine has to be switched ON, such as when measuring the voltage, take extra care not to get an electrical shock.

2.Drive Area

Never inspect, clear or lubricate the drive area such as chain belts, chain wheel or gears during the machine operation.

3.Heavy Parts

Position your hip lower when removing or installing heavy parts.

4.Safety Device

See that safety devices for preventing mechanical accidents, such as fuses, circuit breakers, interlock switches, etc., and those for protecting customers from injury, such as panels and covers, function properly. Modifications that hinder the function of any safety devices are strictly prohibited.

5.Installing and Removing Parts

The edge of parts and covers may be sharp, take care not to touch them. Be careful not to touch those parts, and wipe off any oil that may have adhered to your fingers or hands before servicing. When removing parts, cables, and etc. do not pull them out by force but remove them slowly.

6.Specified Tools

Follow the instruction when a tool is specified.

7.Cleaning the Toner and Developer

As the toner can be explosive, sweep or brush the spilled toner into a container for collecting the sweepings.

Clean away the remaining toner with a damp cloth or use a standard vacuum cleaner that is toner-tolerant. Never use the customer’s vacuum cleaner.’

Do the same when cleaning the Developer because it also contains some toner.

8.Organic Solvents

When using an organic solvent such as the Drum Cleaner or Machine Cleaner, pay attention to the following:

•Ensure good ventilation in the room to prevent too much inhalation of solvent fumes.

•Do not use heated solvent.

•Keep it away from fire.

•Wash your hands thoroughly after use.

9.Harmful Laser

The customer or service personnel would not be exposed to any harmful laser during the usual copying or scanning of documents. However, if a customer finds that the lamp that is used for exposing documents is too bright when performing platen copy or scan, it is possible to block the light from the platen glass by covering the portion of the platen document area that is usually not used for copying or scanning documents.

|

Initial Issue |

08/2012 |

Service Call Procedure |

|

1.1 |

||

|

WorkCentre 5021/5019 |

1-3 |

1.1.2 Things to Take Note When Handling Customer Information

1.Handling of customer’s electronic information — samples of copy/print (paper data), log files (Activity Report), and etc.

Before you bring back any samples for the purpose of investigation/analysis, always obtain permission from the customer. Make sure to assure them that the data will not be used for any other purpose.

2.Handling of a PWB, etc. that contains customer information.

Data such as Fax Address Numbers and URLs that are registered in the customer’s machine are all important customer information. These types of information are stored in the PWB, etc. within the machine. Take extra care when handling them.

(1)In case of replacements, transfer the data to the new PWB and make sure that all data in the old parts is thoroughly erased before disposing it. Make sure that no important customer information gets leaked. (For details, refer to the preface in Chapters 4 and 5)

(2)If a component was replaced and it was not found to be the cause of the malfunction, return it to the machine it came from. (For components that were temporarily installed/removed for troubleshooting, etc. clear the data using the CE Mode, etc.)

1.1.3 Other Precautions

Pay attention to the following when performing maintenance service to avoid wrong or redundant servicing:

1.Reference Materials

Before performing maintenance servicing, read all relevant technical materials to make a systematic approach.

2.Disassembling

Make sure to check the assembled condition before removing parts or disassembling the machine.

3.Installation/Adjustment

After the installation or adjustment is complete, check that no parts or tools are left inside or on the assemblies before using the machine.

4.Handling of replaced parts/consumables

Make sure that the replaced parts or consumables as well as their packaging materials are collected back to the Service Center.

For the separation and processing methods for the collected items, refer to the Common Technical Information No. 2-027 for all machines.

• Drum Cleaner

WARNING

Never discard the Drum Cleaner into a fire. Always keep it away from open flames to prevent it from catching and causing a fire. Always dispose of the Drum Cleaner after it is completely used up. For recyclable parts, fill the necessary items in the [U-TAG] and perform collection.

5.General Precautions

•Take care not to disturb the customer’s daily work.

•Place a drop cloth or paper on the floor of the service area to keep the site clean.

•Throw any trash generated during the maintenance service into a trash bag and bring them back to the Service Center.

•Record clearly the service details and the consumables and parts replaced at visit in the Machine Service Log.

|

Service Call Procedure |

08/2012 |

Initial Issue |

|

1.1, 1.2 |

||

|

1-4 |

WorkCentre 5021/5019 |

1.2 Service Call Procedure

1.2.1 Initial Actions

1.Ask the operator(s) about the machine condition.

2.Record the billing meter readings.

3.Inspect any error copies, then check the machine.

4.Check the Service Log.

1.2.2 When UM is requested, perform the following:

1.Check the problem status by performing the Level 1 Troubleshooting in [Chapter 2 Troubleshooting].

2.Perform the applicable Level 2 Troubleshooting FIP in [Chapter 2 Troubleshooting].

3.If there are no applicable items, troubleshoot by referring to [Chapter 7 BSD].

4.Check the copy quality.

Make several sheets of copies using the Test Chart (499T 00247), then check the quality of the copies for problems.

5.Output the following [Error History Report] and check the [System Fail History] and [Paper Jam History] in order to understand the machine status.

(1)Enter the System Administrator Mode.

i.Press the [Log In / Out] button and hold it down for 4 s or longer until the following screen is displayed.

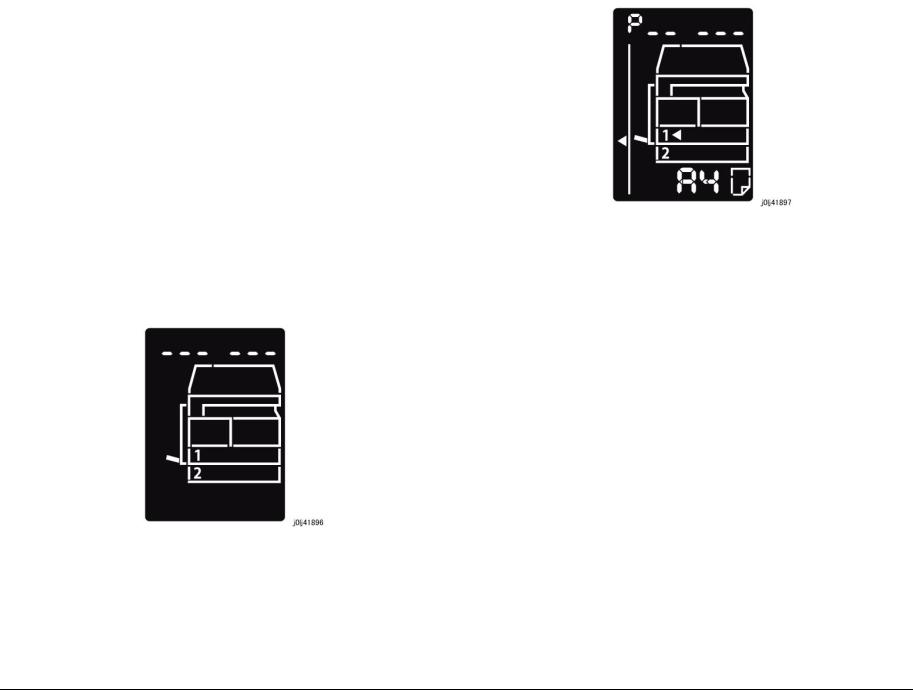

Figure 1 j0lj41896

ii.Use the keypad to enter the Passcode [11111]*1 (5 ‘1’ digits) and press the [Start] button.

NOTE: *1: Default Value

iii.The Program Number input screen is displayed.

Figure 2 j0lj41897

(2)Load any one of A4 SEF, A4 LEF, Letter SEF, or Letter LEF into the Tray.

(3)Enter ‘202’ at the Program Number and press the [Start] button.

(4)Enter ‘4’ for [Error History Report] and press the [Start] button.

(5)Once printing has completed, press the [Log In / Out] button to exit from the System Administrator Mode.

NOTE: When replacing parts that will incur cost to the customer, obtain the customer’s agreement before performing the replacement.

6.Repair all the secondary problems.

7.Perform TRIM Service.

1.2.3 When SM is requested, perform the following:

1.Check the copy quality.

Make several sheets of copies using the Test Chart (499T 00247), then check the quality of the copies for problems.

2.Output the [Error History Report] and check the [System Fail History] and [Paper Jam History] in order to understand the machine status.

•For how to output the [Error History Report], refer to [1.2.2 When UM is requested, perform the following:].

NOTE: When replacing parts that will incur cost to the customer, obtain the customer’s agreement before performing the replacement.

3.Perform TRIM Service.

1.2.4 Final Actions

1.Check overall operation/features.

2.Check the machine exterior and consumables.

3.Train the operator as required.

4.Complete the Service Log and Service Report.

|

Initial Issue |

08/2012 |

Service Call Procedure |

|

1.2 |

||

|

WorkCentre 5021/5019 |

1-5 |

5.Keep the copy samples with the Service Log.

1.3 Detailed Contents of the Service Call

1.3.1 Initial Actions

1. Ask the operator(s) about the machine condition.

• How often and where do paper jams have been occurring recently

• How is the copy quality

2. Record the copy meter readings.

3. Inspect any error copies, then check the machine.

4. Check the print samples from previous service calls and the Service Log.

1.3.2 Checking Reproducibility of Problem

1. Check the problem status by performing the Level 1 Troubleshooting in [Chapter 2 Troubleshooting].

2. Perform the applicable Level 2 Troubleshooting FIP in [Chapter 2 Troubleshooting].

3. If there are no applicable items, troubleshoot by referring to [Chapter 7 BSD].

1.3.3 Checking Copy Quality

1. Make several sheets of copies using the Test Chart (499T 00247), then check the quality of the copies.

1.3.4 TRIM Servicing

Perform TRIM servicing during a service call to maintain the machine performance.

1. Follow the TRIM Check List to perform the required TRIM items.

2. Check for parts that require periodical cleaning/replacement (consumables, parts) by referring to the TRIM Chec List, the Periodic Replacement Parts/Consumables List, and the Maintenance Report, and clean them if necessary. After a replacement, make sure that you enter the CE Mode and use [HFSI Read / Clear] to clear the applicable counter(s).

|

Service Call Procedure |

08/2012 |

Initial Issue |

|

1.3, 1.4 |

||

|

1-6 |

WorkCentre 5021/5019 |

1.4TRIM Check List

C:Perform checking. Clean, replace, or feed if necessary.

O:Always perform cleaning and checking.

*: Always perform replacement service at the specified interval.

|

Table 1 |

||||

|

Every |

||||

|

No. |

Servicing Items |

time |

Service Details |

|

|

1.1 |

Pre-servicing Check |

C |

• |

Activate the machine and check that abnormal |

|

(Check the machine |

noise is not heard. |

|||

|

operation sound) |

||||

|

1.2 |

Pre-servicing Check |

C |

• |

Make several sheets of copies using the Test |

|

(Copy and print the |

Chart (499T 00247), then check the quality of |

|||

|

Test Chart) |

the copies. |

|||

|

2 |

Clean the interior of the |

C |

• |

Clean any paper dust and toner residue in the |

|

machine |

paper path and on the jam sensor. |

|||

|

(Clean the paper trans- |

• |

Especially, clean the operation section of the |

||

|

port system) |

operator carefully. |

|||

|

3 |

Cleaning the IIT |

C |

• |

Clean the Platen Glass surface and the Platen |

|

Cushion with the optical cleaning cloth. |

||||

|

• |

Clean the Reflector, back of the Platen Glass, |

|||

|

mirrors and lens with the optical cleaning cloth. |

||||

|

4 |

Clean the DADF |

C |

• |

Clean the Feed Roll, Nudger Roll, and Retard |

|

Roll with a cloth that has been wrung dry. |

||||

|

• |

Clean the DADF Platen Glass with the optical |

|||

|

cleaning cloth. |

||||

|

5 |

Safety Check |

O |

• |

Make sure that the power plug is plugged in |

|

properly. |

||||

|

• |

Make sure that the power cords are not |

|||

|

cracked and no wires are exposed. |

||||

|

• |

Make sure that no extension cord with insuffi- |

|||

|

cient length or power cord outside the specifi- |

||||

|

cation, such as an off-the-shelf power strip, is |

||||

|

being used. |

||||

|

• |

Make sure that a single socket does not have |

|||

|

multiple power plugs plugged into it. |

||||

|

6.1 |

Post-servicing check |

C |

• |

Make several sheets of copies using the Test |

|

(Copy Quality Check) |

Chart (499T 00247), then check if the quality |

|||

|

satisfies the specification. |

||||

|

6.2 |

Post-servicing check |

C |

• |

Check the paper feed and abnormal noise. |

|

(Check the machine |

||||

|

operation) |

||||

|

6.3 |

Post-servicing check |

C |

• |

Create the Service Log and Service Report. |

|

(Check the meter) |

||||

1.5 Periodic Replacement Parts/Consumables List

When servicing, check the number of copies and number of fed sheets for the consumables and parts that require periodical cleaning/replacement. Clean or replace them if necessary. The history can be checked by printing the Maintenance Report or by checking the approriate counter in [HFSI Read / Clear] in CE Mode (6.4.2.9 HFSI Read / Clear).

For the items that cannot be checked in CE Mode, clean or replace them according to the replacement intervals (standard PV).

CAUTION

Do not place the imaging materials, such as the Toner and the Drum, in the car for a long time.

NOTE: Clean the Platen Glass with a Platen Wax Cleaner 499D 00194 (194D) every 10K Feeds.

Table 1

|

HFSI |

||||

|

Parts/Consumables |

[Chain- |

Replacement |

||

|

No |

Name/PL No. |

Link] |

Interval |

Check the counter |

|

1 |

Tray 1 Feed No. |

950-803 |

50,000PV |

1 Feed = 1 Count Up. |

|

Tray 1 Feed Roll / Retard |

Replace both at the same |

|||

|

Pad |

time. |

|||

|

(PL 9.2) |

||||

|

2 |

Tray 2 Feed No. |

950-804 |

300,000PV |

1 Feed = 1 Count Up. |

|

Tray 2 Feed Roll/Nudger |

Replace all 3 at the same |

|||

|

Roll/Retard Roll |

time. |

|||

|

(PL 10.3) |

||||

|

3 |

MSI Feed Count |

950-802 |

50,000PV |

1 Feed = 1 Count Up. |

|

MSI Feed Roll/MSI Nudger |

Replace all 3 at the same |

|||

|

Roll/MSI Retard Pad |

time. |

|||

|

(PL 13.3) |

||||

|

4 |

Fusing Unit |

950-801 |

175,000PV |

1 pass through the Fusing Unit |

|

(PL 7.1) |

Exit Sensor = 1 Count Up. |

|||

|

5 |

BTR Unit |

950-800 |

100,000PV |

1 pass through the Fusing Unit |

|

(PL 6.1) |

Exit Sensor = 1 Count Up. |

|||

|

6 |

Document Feed No. |

955-806 |

200,000PV |

Replace the Feed Roll, |

|

DADF Feed Roll/Nudger |

Nudger Roll, and Retard Pad |

|||

|

Roll |

at the same time. |

|||

|

(PL 56.5) |

NOTE: Clean the Platen Glass |

|||

|

DADF Retard Pad |

||||

|

with a Platen Wax Cleaner |

||||

|

(PL 56.13) |

||||

|

499D 00914 (194D) every 10K |

||||

|

Feeds. |

||||

|

7 |

Toner Cartridge |

— |

9,000PV |

|

|

(PL 8.1) |

||||

|

8 |

Drum Cartridge *1 |

950-807 |

343k cycle |

<Refer- |

|

(PL 8.1) |

ence>75KPV*1@18PPM / |

|||

|

80KPV*1@20PPM |

||||

|

Initial Issue |

08/2012 |

Service Call Procedure |

|

1.5 |

||

|

WorkCentre 5021/5019 |

1-7 |

*1: The maximum number of prints is a reference value under the condition of A4 LEF and simplex printing. Some specific conditions such as paper size, number of copies for a print job, etc. might cause a serious deterioration of image quality before the time to replace the drum cartridge comes.

|

Service Call Procedure |

08/2012 |

Initial Issue |

|

1.5 |

||

|

1-8 |

WorkCentre 5021/5019 |

2 Status Indicator RAPs

|

2.1 Introduction |

010-327 |

Fusing Unit On Time Fail ……………………………………………………………………… |

2-17 |

||

|

2.1.1 |

How to Troubleshoot ………………………………………………………………………………… |

2-3 |

010-379 |

Fusing Unit Hot Not Ready Return Time Fail…………………………………………… |

2-18 |

|

2.1.2 How to Switch the Error Code Display ………………………………………………………… |

2-3 |

010-392 |

NOHAD Fan Defect……………………………………………………………………………… |

2-18 |

|

|

2.1.3 |

Glossary …………………………………………………………………………………………………. |

2-4 |

010-602 |

Over Temp Cooling Mode …………………………………………………………………….. |

2-18 |

2.2 Product FIP

2.2.1 Level 1 FIP

|

2.2.1.1 Level 1 FIP …………………………………………………………………………………………… |

2-7 |

|

|

2.2.2 Level 2 FIP |

||

|

CHAIN 3 |

||

|

003-500/795 N-Up NG Out Of Range/ AMS NG Out Of Range………………………………. |

2-9 |

|

|

003-754 IPS Overrun ……………………………………………………………………………………….. |

2-9 |

|

|

003-942 Not-Supported Doc Size ………………………………………………………………………. |

2-9 |

|

|

003-951 1Job Max Page Over …………………………………………………………………………… |

2-9 |

|

|

003-963 APS NG Out Of Range ………………………………………………………………………… |

2-9 |

|

|

003-972 EPC Memory Full………………………………………………………………………………… |

2-9 |

|

|

003-973 Auto Rotation NG Out Of Range……………………………………………………………. |

2-9 |

|

|

CHAIN 4 |

||

|

004-345 HVPS Communication Error …………………………………………………………………. |

2-11 |

|

|

CHAIN 5 |

||

|

005-122 DADF Simplex/Side 1 Pre Regi Sensor On Jam ……………………………………… |

2-13 |

|

|

005-123 DADF Simplex/Side 1 Regi Sensor On Jam……………………………………………. |

2-13 |

|

|

005-125/145 DADF Regi Sensor Off Jam/ DADF Regi Sensor Off Jam on Inverting…. |

2-13 |

|

|

005-131/132 DADF Invert Sensor On Jam on Inverting/ DADF Invert Sensor On Jam. |

2-13 |

|

|

005-134/139 DADF Invert Sensor Off Jam on Inverting/ DADF Invert Sensor Off Jam. |

2-14 |

|

|

005-135 DADF Side 2 Pre Regi Sensor On Jam ………………………………………………….. |

2-14 |

|

|

005-136 DADF Side 2 Regi Sensor On Jam………………………………………………………… |

2-14 |

|

|

005-147 DADF Pre Regi Sensor Off Jam on Inverting ………………………………………….. |

2-15 |

|

|

005-196 Size Mismatch Jam on No Mix-Size ………………………………………………………. |

2-15 |

|

|

005-197 Prohibit Combine Size Jam…………………………………………………………………… |

2-15 |

|

|

005-198/199 Too Short Size Jam/ Too Long Size Jam …………………………………………. |

2-15 |

|

|

005-210 DADF Download Fail …………………………………………………………………………… |

2-15 |

|

|

005-275/280 DADF RAM Fail/ DADF EEPROM Fail …………………………………………….. |

2-15 |

|

|

005-305 DADF Feeder Cover Interlock Open………………………………………………………. |

2-16 |

|

|

005-500 DADF Download Flash Write Error ………………………………………………………… |

2-16 |

|

|

005-907/908/913 DADF Pre Regi Sensor/DADF Regi Sensor/DADF Invert Sensor Static Jam |

||

|

2-16 |

||

|

005-940 |

DADF No Original Fail …………………………………………………………………………. |

2-16 |

|

005-948 SS-Size Mismatch Jam on No Mix-size ………………………………………………….. |

2-16 |

|

|

CHAIN 10 |

||

|

010-311 |

Fusing Unit Center Thermistor Defect ……………………………………………………. |

2-17 |

|

010-312 |

Fusing Unit Rear Thermistor Defect ………………………………………………………. |

2-17 |

|

010-320 |

Over Heat Temperature Fail …………………………………………………………………. |

2-17 |

CHAIN 16

|

016-500 |

Controller Download Flash Write Error …………………………………………………… |

2-19 |

|

|

016-501 |

Controller Boot Flash Write Error …………………………………………………………… |

2-19 |

|

|

016-502 |

UI Panel Download Flash Write Error …………………………………………………….. |

2-19 |

|

|

016-570 No Response from USB-Host for Scan Job …………………………………………….. |

2-19 |

||

|

016-571 No Response from USB-Host for Print Job……………………………………………… |

2-19 |

||

|

016-742/744 |

Download File Error/ Download File Check Sum Error ……………………….. |

2-19 |

|

|

016-749/799 |

HBPL or XPJL Syntax Error/ Print Instruction Fail ……………………………… |

2-20 |

|

|

016-759 |

Copy Counter Full ……………………………………………………………………………….. |

2-20 |

|

|

016-776 |

Marker Code Detection Fail ………………………………………………………………….. |

2-20 |

CHAIN 23

|

023-600 Held Down key Error (UI Panel)…………………………………………………………….. |

2-21 |

CHAIN 24

|

024-910/911/915 |

Tray 1/Tray 2/MSI Paper Length Mismatch ………………………………… |

2-23 |

|

024-950/951/954 Tray 1/Tray 2/MSI No Paper …………………………………………………….. |

2-23 |

|

|

024-958/959/960 |

MSI/Tray 1/Tray 2 Paper Size Mismatch ……………………………………. |

2-23 |

|

024-965 APS NG Unselected…………………………………………………………………………….. |

2-23 |

CHAIN 41

|

041-210/211 STM NVM Out-Of-Order/ STM NVM R/W Error…………………………………. |

2-25 |

CHAIN 42

|

042-325/614 Main Motor Rotation Error/ Main Motor Rotation Warning …………………… |

2-27 |

CHAIN 45

|

045-310 |

Image Ready Error………………………………………………………………………………. |

2-29 |

|

045-313 |

IOT Logic Fail……………………………………………………………………………………… |

2-29 |

CHAIN 61

|

061-321 |

ROS Motor Fail …………………………………………………………………………………… |

2-31 |

|

061-325 |

No SOS Fail ……………………………………………………………………………………….. |

2-31 |

CHAIN 62

|

062-277 DADF Communication Fail……………………………………………………………………. |

2-33 |

|

|

062-311 |

IIT Software Logic Fail …………………………………………………………………………. |

2-33 |

|

062-360 |

Carriage Position Fail…………………………………………………………………………… |

2-33 |

|

062-371/380 Lamp Illumination Fail/ AGC Fail……………………………………………………… |

2-33 |

|

|

062-386 AOC Fail…………………………………………………………………………………………….. |

2-34 |

|

|

062-389 |

Carriage Over Run Fail (Scan End Side) ………………………………………………… |

2-34 |

|

062-396 |

CCD Cable Connection Fail ………………………………………………………………….. |

2-34 |

CHAIN 71

|

071-105 Regi Sensor On Jam (Tray 1) ……………………………………………………………….. |

2-35 |

|

Initial Issue |

08/2012 |

Status Indicator RAPs |

|

WorkCentre 5021/5019 |

2-1 |

CHAIN 72

|

072-102 Feed Out Sensor 2 On Jam ………………………………………………………………….. |

2-37 |

||

|

072-105 |

Regi Sensor On Jam (Tray 2) ……………………………………………………………….. |

2-37 |

|

|

072-210 |

Tray 2 |

Lift Up Fail………………………………………………………………………………… |

2-37 |

|

072-212 |

Tray 2 |

Size Sensor Broken …………………………………………………………………… |

2-37 |

|

072-215 |

MCU-STM Communication Fail …………………………………………………………….. |

2-37 |

CHAIN 75

|

075-135 Regi Sensor On Jam (MSI)…………………………………………………………………… |

2-39 |

CHAIN 77

|

077-101 Regi Sensor Off Jam……………………………………………………………………………. |

2-41 |

|

|

077-103 |

Fusing Unit Exit Sensor Off Jam (Long) …………………………………………………. |

2-41 |

|

077-104 |

Fusing Unit Exit Sensor Off Jam (Short)…………………………………………………. |

2-41 |

|

077-106 Fusing Unit Exit Sensor On Jam……………………………………………………………. |

2-41 |

|

|

077-129 |

Regi Sensor On Jam (Duplex Wait)……………………………………………………….. |

2-42 |

|

077-212 |

Tray Module Reset Fail………………………………………………………………………… |

2-42 |

|

077-300/301/305 Front Cover/Left Hand Cover/STM Cover Open………………………….. |

2-42 |

|

|

077-900/901/904 Regi Sensor/Fusing Unit Exit Sensor/Feed Out Sensor 2 Static Jam |

2-42 |

CHAIN 91

|

091-313 CRUM ASIC Communication Fail ………………………………………………………….. |

2-43 |

||

|

091-401/402 |

Drum Cartridge Quality Life Over/ Drum Cartridge Life Over ………………. |

2-43 |

|

|

091-406/424 |

Drum Cartridge Normal Life Over/ Drum Cartridge Abnormal Life Over… |

2-43 |

|

|

091-430 |

Drum Cartridge Life End ………………………………………………………………………. |

2-43 |

|

|

091-440 |

Drum Cartridge Pre Near End……………………………………………………………….. |

2-43 |

|

|

091-441 |

Drum Cartridge Near End …………………………………………………………………….. |

2-44 |

|

|

091-914 |

Drum CRUM Communication Fail………………………………………………………….. |

2-44 |

|

|

091-915/916 Drum CRUM ID Error/ Drum CRUM Market Identity Mismatch ……………. |

2-44 |

|

117-326 Controller Backup NVM Data Defect………………………………………………………. |

2-53 |

CHAIN 123

|

123-314 UI Panel Communication Fail………………………………………………………………… |

2-55 |

2.2.3 Other Failure FIP

|

2.2.3.1 AC Power FIP……………………………………………………………………………………….. |

2-57 |

|

|

2.2.3.2 |

+5VDC Power FIP…………………………………………………………………………………. |

2-57 |

|

2.2.3.3 |

+24VDC Power FIP……………………………………………………………………………….. |

2-58 |

2.2.4 Generic FIP

|

2.2.4.1 |

Reflective Sensor Failure FIP………………………………………………………………….. |

2-59 |

|

2.2.4.2 |

Permeable Sensor Failure FIP ………………………………………………………………… |

2-59 |

|

2.2.4.3 |

Switch (Normal/Open) Failure FIP …………………………………………………………… |

2-60 |

|

2.2.4.4 |

Solenoid/Clutch Not Energized Failure FIP……………………………………………….. |

2-60 |

|

2.2.4.5 |

Solenoid/Clutch Left Energized Failure FIP ………………………………………………. |

2-61 |

|

2.2.4.6 |

Motor Does Not Rotate Failure FIP ………………………………………………………….. |

2-61 |

|

2.2.4.7 |

Motor Left Running Failure FIP ……………………………………………………………….. |

2-62 |

|

2.2.4.8 NIP/RELEASE SOLENOID Not Energized Failure FIP……………………………….. |

2-62 |

2.3 NET System Fault Check

|

2.3.1 |

No output is available, no data is printed …………………………………………………….. |

2-65 |

|

2.3.2 |

Printing can be performed but abnormally …………………………………………………… |

2-65 |

CHAIN 92

|

092-660/668 ATC Amplitude Fail/ ATC Average Fail…………………………………………….. |

2-45 |

|

|

092-661 |

Temperature Sensor Fail ……………………………………………………………………… |

2-45 |

|

092-910 |

ATC Sensor Fail………………………………………………………………………………….. |

2-45 |

CHAIN 93

|

093-312 |

Toner Dispense Motor Rotation Fail ………………………………………………………. |

2-47 |

|

093-400 Toner Near Empty……………………………………………………………………………….. |

2-47 |

|

|

093-406 Toner Pre Near Empty …………………………………………………………………………. |

2-47 |

|

|

093-912 |

Toner Empty ………………………………………………………………………………………. |

2-47 |

|

093-956 |

Drum New CRU Installation Fail ……………………………………………………………. |

2-47 |

|

093-959 |

Drum New CRU Installation Fail Exceeds Thresholding Times………………….. |

2-47 |

CHAIN 95

|

095-910 No Drum Cartridge………………………………………………………………………………. |

2-49 |

CHAIN 116

|

116-321 |

Controller Logic Fail …………………………………………………………………………….. |

2-51 |

|

116-323 |

Controller NVM Data Defect …………………………………………………………………. |

2-51 |

|

116-334 NVM Data Mismatch ……………………………………………………………………………. |

2-51 |

|

|

116-377 |

IIT Interrupt Time out …………………………………………………………………………… |

2-51 |

|

116-747 |

Invalid Page Margin …………………………………………………………………………….. |

2-51 |

CHAIN 117

|

Status Indicator RAPs |

08/2012 |

Initial Issue |

|

2-2 |

WorkCentre 5021/5019 |

2.1.1 How to Troubleshoot

Level 1 Troubleshooting:

•Level 1 Troubleshooting (Level 1 FIP) is the first step to diagnose a problem. Level 1 FIP asks you whether any Fault Code and other problematic symptoms exist, guiding you to Level 2 Troubleshooting or BSD to resolve the problem.

Level 2 Troubleshooting:

•Level 2 Troubleshooting is a diagnostic procedure of separating a problem by Fault Code, document/paper jam and other problematic symptoms. Performing a FIP or an appropriate procedure in the Check Procedure enables you to discover causes of a problem in a short period of time.

How to proceed with troubleshooting and Cautions:

•First, perform Level 1 FIP to categorize a problem. Second, proceed to an appropriate Level 2 FIP or BSD to resolve the problem. To find the causes of the problem using FIP or Check Procedure etc., thoroughly read the instructions and follow the procedure properly. Sometimes, when two or more causes exist, they cannot be identified at once, so the same FIP should be repeated. In this case, pay attention to a different judgment made in the process of the same FIP.

•For source voltage related problems, such as being unable to power up the machine, refer to ‘Other Failure FIP’ to proceed with the troubleshooting.

•The Check Procedure for general electrical parts (Motor, Solenoid/Clutch, Switch, Sensor etc.) may not be shown in each troubleshooting for some cases. In such cases, proceed to troubleshoot by referring to ‘Generic FIP’.

2.1.2 How to Switch the Error Code Display

When a problem has occurred in the machine, an Error Code or a Fault Code (Chain-Link) will be displayed on the UI screen. When an Error Code is being displayed, you can perform the following operation to switch the display to the Chain-Link number that correspond to that Error Code. To repair, check the Chain-Link number and proceed with the appropriate FIP.

How to switch to the Chain-Link number

1.When a problem has occurred, the displayed Error Code will be flashing.

Figure 1 j0lj21201

2.With the Error Code being displayed, press and hold down the [ID Card Copy] button on the Control Panel.

•As long as the button is being pressed, the Chain-Link number will be displayed and flashing.

|

Figure 2 |

j0lj21202 |

|

|

Initial Issue |

08/2012 |

Status Indicator RAPs |

|

2.1.1, 2.1.2 |

||

|

WorkCentre 5021/5019 |

2-3 |

3.Releasing the [ID Card Copy] button returns the display to the Error Code.

2.1.3 Glossary

The following terminology are used throughout the troubleshooting section. The meaning of these terminology must be fully understood when performing problem analysis.

Common terms:

Status Indicator RAPs

2.1.2, 2.1.3

•Fault Code

This 6-digit code appears when the machine has found problems.

•Actuate (Deactuate)

To mechanically push (release) the Actuator of the switch or the connected mechanical linkage.

•Block

To place a sheet of document or paper on the photo sensor surface for detection.

•Check

To visually check for operation failure of parts such as relay or mechanical linkage, and the failure status of the parts.

•Enter the CE Mode

To enter the CE Mode by following the procedure described in ‘How to Enter/Exit the CE Mode’ of Chapter 6.

•Check the connection for short circuit

Turn the power OFF. Measure the resistance between the wire and the frame using the ohm range of a tester.

•Check the connection for open circuit

Turn the power OFF. Measure the resistance between both ends of the wire using the ohm range of a tester.

•Input Check [xxx-xxx]/Output Check [xxx-xxx]

To enter the Component Check by following the procedure described in ‘How to Use the CE Mode’ of Chapter 6.

•Analog Monitor [xxx-xxx]

To enter the Analog Monitor by following the procedure described in ‘How to Use the CE Mode’ of Chapter 6.

•Check the voltage level

|

Table 1 |

||

|

Voltage |

Level |

Range |

|

+3.3VDC |

(H) |

+3.2 to +3.6VDC |

|

(L) |

0.0 to +1.0VDC |

|

|

+5VDC |

(H) |

+4.8 to +5.4VDC |

|

(L) |

0.0 to +1.0VDC |

|

|

+24VDC |

(H) |

+23.3 to +25.7VDC |

|

(L) |

0.0 to +3.0VDC |

|

•PL 4.2

Refer to PL 4.2 in Chapter 5 Parts List.

•CH 6.2 Zone J4

|

08/2012 |

Initial Issue |

|

2-4 |

WorkCentre 5021/5019 |

Refer to Chain 6.2 Zone J4 in Chapter 7 BSD.

•REP 4.1.3

Refer to REP 4.1.3 in Chapter 4.

•ADJ 4.1.3

Refer to ADJ 4.1.3 in Chapter 4.

•Replace the parts in sequence

When it is impossible to analyze causes of a problem further, replace the parts in sequence. The part with a higher replacement frequency or higher possibility of causing a problem is listed first for replacement.

|

Initial Issue |

08/2012 |

|

WorkCentre 5021/5019 |

2-5 |

Status Indicator RAPs

2.1.3

|

Status Indicator RAPs |

08/2012 |

Initial Issue |

|

2.1.3 |

||

|

2-6 |

WorkCentre 5021/5019 |

2.2.1.1 Level 1 FIP

Procedure

Ask the operator about the problem. Did the operator operate the machine correctly?

YN

Explain the correct way to operate the machine to the operator.

Output all jobs that are stored in the memory. Turn the power OFF and ON. Is the UI display normal?

YN

Refer to [BSD (CH2.1)] and [2.2.3 Other Failure FIP] to repair the malfunction in UI display.

Check the Shutdown History. Refer to [6.4.2.1 Shutdown History] to display the Fault Code on the UI. Is the Fault Code displayed on the UI?

YN

Refer to [Troubleshooting] in the User guide and repair the following errors.

•Problems With Hardware

•Problems With Image Quality

•Problems With Copy

•Problems With Printer

•Problems With Scanner

•Problems With Network

•In Case of Paper Jam

•In Case of Document Jam

Proceed to Level 2 Troubleshooting and perform the applicable FIP.

|

Initial Issue |

08/2012 |

|

WorkCentre 5021/5019 |

2-7 |

Status Indicator RAPs

2.2.1.1

|

Status Indicator RAPs |

08/2012 |

Initial Issue |

|

2.2.1.1 |

||

|

2-8 |

WorkCentre 5021/5019 |

003-500/795 N-Up NG Out Of Range/ AMS NG Out Of

Range

BSD-ON:-

[N-Up NG Out Of Range]

During 2-Up or 4-Up, the reduce/enlarge ration was not within the range of 25 to 400%.

[AMS NG Out Of Range]

During AMS (Auto Magnification Selection), the reduce/enlarge ration was not within the range of 25 to 400%

Cause/Action

Press [Stop] on the UI Panel and change the settings.

003-951 1Job Max Page Over

BSD-ON:-

During Copy Job, the number of pages that can be scanned has been exceeded.

Cause/Action

Press [Stop] on the UI Panel and reduce the number of document pages.

003-963 APS NG Out Of Range

BSD-ON:-

During Copy Job, when APS is selected, the image size obtained from document size x reduce/enlarge ratio was detected to be larger than the largest Standard Paper Size.

003-754 IPS Overrun

BSD-ON:-

The IPS processing has overtook the Scan processing.

Cause/Action

This might be avoided by setting the R/E ratio to 99% or 101%. If this occurs frequently, obtain the document from the User and contact the Support Department for assistance.

003-942 Not-Supported Doc Size

BSD-ON:-

During DADF Scan of a Copy Job, an unsupported document size was detected.

Cause/Action

1.Press [Stop] on the UI Panel.

2.Check the setting of the document size group.

3.Check whether the document size is a supported size.

4.If the document size is a supported size, the DADF might have malfunctioned. Refer to following FIP to check the DADF.

•005-196 (Size Mismatch Jam on No Mix-size)

•005-948 (SS-Size Mismatch Jam on No Mix-size)

Cause/Action

Press [Stop] on the UI Panel and change the settings.

003-972 EPC Memory Full

BSD-ON:-

During Copy Job, the EPC memory is filled up.

Cause/Action

Print out all the images that had been successfully scanned by the DADF so far and then perform the copy again for the documents (images) that were unable to be scanned.

003-973 Auto Rotation NG Out Of Range

BSD-ON:-

During Copy Job, the following conditions were met.

•Rotation is required.

•The length of the image obtained by document x reduce/enlarge ratio is longer than 297 mm.

Cause/Action

Press [Stop] on the UI Panel and change the reduce/enlarge ratio.

|

Initial Issue |

08/2012 |

Status Indicator RAPs |

|

003-500/795, 003-951 |

||

|

WorkCentre 5021/5019 |

2-9 |

|

Status Indicator RAPs |

08/2012 |

Initial Issue |

|

003-500/795, 003-951 |

||

|

2-10 |

WorkCentre 5021/5019 |

004-345 HVPS Communication Error

BSD-ON:CH9.2

Communication failure between the ESS/MCU PWB and the HVPS was detected.

Cause/Action

1.Turn the power OFF and ON.

2.Turn OFF the power and check the connection between the HVPS J500 and the ESS/ MCU PWB J402 for open circuit, short circuit, and poor contact.

3.If no problem is found, replace the following parts in sequence:

•HVPS (PL 18.1)

•ESS/MCU PWB (PL 18.1)

|

Initial Issue |

08/2012 |

|

WorkCentre 5021/5019 |

2-11 |

Status Indicator RAPs

004-345

|

Status Indicator RAPs |

08/2012 |

Initial Issue |

|

004-345 |

||

|

2-12 |

WorkCentre 5021/5019 |

005-122 DADF Simplex/Side 1 Pre Regi Sensor On Jam

BSD-ON:CH5.4

•After Pre-Feed started for the first sheet (DADF Feed Motor On (CW)) in Simplex and Duplex, the DADF Pre Regi Sensor did not turn ON within the specified time.

•After Pre-Feed started for the second sheet onwards (DADF Feed Motor On (CW)) in Duplex, the DADF Pre Regi Sensor did not turn ON within the specified time.

005-125/145 DADF Regi Sensor Off Jam/ DADF Regi Sensor Off Jam on Inverting

BSD-ON:CH5.5, CH5.4

[DADF Regi Sensor Off Jam]

After the DADF Pre Regi Sensor turned OFF at Scan operation, the DADF Regi Sensor did not turn OFF within the specified time.

Cause/Action

Check the following:

•Transportation failure due to foreign substance on the document path.

•The surface of the Feed Roll and Nudger Roll for foreign substances.

•The surface of the Feed Roll and Nudger Roll for wear.

•The DADF Pre Regi Sensor (Input Check [005-206]) for operation failure. (PL 56.14)

•The DADF Feed Clutch (Output Check [005-062]) for operation failure. (PL 56.7)

•The DADF Feed Motor (Output Check [005-008]) for operation failure. (PL 56.6)

•The Drive Gear for wear and damage.

If no problem is found, replace the DADF PWB. (PL 56.2)

005-123 DADF Simplex/Side 1 Regi Sensor On Jam

BSD-ON:CH5.5, CH5.4

The DADF Regi Sensor does not turn ON within the specified time after the DADF Pre Regi Sensor On.

[DADF Regi Sensor Off Jam on Inverting]

After the DADF Pre Regi Sensor turned OFF at Invert operation, the DADF Regi Sensor did not turn OFF within the specified time.

Cause/Action

Check the following:

•Transportation failure due to foreign substance on the document path.

•The surface of the Regi Roll, Out Roll, and Exit Roll for foreign substances.

•The surface of the Regi Roll, Out Roll, and Exit Roll for wear.

•The DADF Regi Sensor (Input Check [005-110]) for operation failure. (PL 56.14)

•The DADF Pre Regi Sensor (Input Check [005-206]) for operation failure. (PL 56.14)

•The DADF Feed Motor (Output Check [005-008]) for operation failure. (PL 56.6)

•The Drive Gear for wear and damage.

If no problem is found, replace the DADF PWB. (PL 56.2)

Cause/Action

Check the following:

•Transportation failure due to foreign substance on the document path.

•The surface of the Takeaway Roll and Regi Roll for foreign substances.

•The surface of the Takeaway Roll and Regi Roll for wear.

•The DADF Regi Sensor (Input Check [005-110]) for operation failure. (PL 56.14)

•The DADF Pre Regi Sensor (Input Check [005-206]) for operation failure. (PL 56.14)

•The DADF T/A Clutch (Output Check [005-098]) for operation failure. (PL 56.7)

•The DADF Feed Motor (Output Check [005-008]) for operation failure. (PL 56.6)

•The Drive Gear for wear and damage.

If no problem is found, replace the DADF PWB. (PL 56.2)

005-131/132 DADF Invert Sensor On Jam on Inverting/ DADF Invert Sensor On Jam

BSD-ON:CH5.5, CH5.4

[DADF Invert Sensor On Jam on Inverting]

After the DADF Regi Sensor turned ON at Invert operation, the DADF Invert Sensor did not turn ON within the specified time.

[DADF Invert Sensor On Jam]

After the DADF Regi Sensor turned ON in the Scan operation, the DADF Invert Sensor did not turn ON within the specified time.

Cause/Action

Check the following:

•Transportation failure due to foreign substance on the document path.

|

Initial Issue |

08/2012 |

Status Indicator RAPs |

|

005-122, 005-125/145 |

||

|

WorkCentre 5021/5019 |

2-13 |

•The surface of the Out Roll for foreign substances.

•The surface of the Out Roll for wear.

•The DADF Invert Sensor (Input Check [005-211]) for operation failure. (PL 56.10)

•The DADF Regi Sensor (Input Check [005-110]) for operation failure. (PL 56.14)

•The DADF Feed Motor (Output Check [005-008]) for operation failure. (PL 56.6)

•The Drive Gear for wear and damage.

If no problem is found, replace the DADF PWB. (PL 56.2)

005-134/139 DADF Invert Sensor Off Jam on Inverting/ DADF Invert Sensor Off Jam

BSD-ON:CH5.5, CH5.4

[DADF Invert Sensor Off Jam on Inverting]

During the Invert operation where there is a next document, after the DADF Regi Sensor turned OFF, the DADF Invert Sensor did not turn OFF within the specified time.

[DADF Invert Sensor Off Jam]

During the Simplex and Duplex Scan operation, after the DADF Regi Sensor turned OFF, the DADF Invert Sensor did not turn OFF within the specified time.

Cause/Action

Check the following:

•Transportation failure due to foreign substance on the document path.

•The surface of the Out Roll and Exit Roll for foreign substances.

•The surface of the Out Roll and Exit Roll for wear.

•The DADF Invert Sensor (Input Check [005-211]) for operation failure. (PL 56.10)

•The DADF Regi Sensor (Input Check [005-110]) for operation failure. (PL 56.14)

•The DADF Feed Motor (Output Check [005-008]) for operation failure. (PL 56.6)

•The Exit Pinch Roll for operation failure (including for the operation failure of the Exit Nip Release Solenoid (Output Check [005-072])). (PL 56.7)

•The Drive Gear for wear and damage.

If no problem is found, replace the DADF PWB. (PL 56.2)

005-135 DADF Side 2 Pre Regi Sensor On Jam

BSD-ON:CH5.4, CH5.5

After the DADF Feed Motor started the reverse rotation at Invert operation, the DADF Pre Regi Sensor did not turn ON within the specified time.

Cause/Action

Check the following:

•Transportation failure due to foreign substance on the document path.

•The surface of the Exit Roll for foreign substances.

•The surface of the Exit Roll for wear

•The DADF Pre Regi Sensor (Input Check [005-206]) for operation failure. (PL 56.14)

•The DADF Feed Motor (Output Check [005-048]) for operation failure. (PL 56.6)

•The Exit Pinch Roll for operation failure (including for the operation failure of the Exit Nip Release Solenoid (Output Check [005-072])). (PL 56.7)

•The Drive Gear for wear and damage.

If no problem is found, replace the DADF PWB. (PL 56.2)

005-136 DADF Side 2 Regi Sensor On Jam

BSD-ON:CH5.5, CH5.4

After the DADF Pre Regi Sensor turned ON at Invert operation, the DADF Regi Sensor did not turn ON within the specified time.

Cause/Action

Check the following:

•Transportation failure due to foreign substance on the document path.

•The surface of the Exit Roll, Takeaway Roll, and Regi Roll for foreign substances.

•The surface of the Exit Roll, Takeaway Roll, and Regi Roll for wear.

•The DADF Regi Sensor (Input Check [005-110]) for operation failure. (PL 56.14)

•The DADF Pre Regi Sensor (Input Check [005-206]) for operation failure. (PL 56.14)

•The DADF Feed Motor (Output Check [005-008]) for operation failure. (PL 56.6)

•The DADF T/A Clutch (Output Check [005-098]) for operation failure. (PL 56.7)

•The Exit Pinch Roll for operation failure (including for the operation failure of the Exit Nip Release Solenoid (Output Check [005-072])). (PL 56.7)

•The Drive Gear for wear and damage.

If no problem is found, replace the DADF PWB. (PL 56.2)

|

Status Indicator RAPs |

08/2012 |

Initial Issue |

|

005-131/132, 005-135 |

||

|

2-14 |

WorkCentre 5021/5019 |

005-147 DADF Pre Regi Sensor Off Jam on Inverting

BSD-ON:CH5.4, CH5.5

After the DADF Feed Motor started the reverse rotation at Invert operation, the DADF Pre Regi Sensor did not turn OFF within the specified time.

Cause/Action

Check the following:

•Transportation failure due to foreign substance on the document path.

•The surface of the Exit Roll, Takeaway Roll, Regi Roll, and Out Roll for foreign substances.

•The surface of the Exit Roll, Takeaway Roll, Regi Roll, and Out Roll for wear.

•The DADF Pre Regi Sensor (Input Check [005-206]) for operation failure. (PL 56.14)

•The DADF Feed Motor (Output Check [005-048/008] (CCW/CW)) for operation failure. (PL 56.6)

•The Exit Pinch Roll for operation failure (including for the operation failure of the Exit Nip Release Solenoid (Output Check [005-072])). (PL 56.7)

•The Drive Gear for wear and damage.

If no problem is found, replace the DADF PWB. (PL 56.2)

005-196 Size Mismatch Jam on No Mix-Size

BSD-ON:CH5.4, CH5.2

The 2nd sheet or later of the document was detected to be of a different size conpared to the 1st sheet (the length of the document’s 2nd sheet or later in SS direction is longer).

Cause/Action

1.Check the size of the document that was fed by the User.

2.If the error is not cleared, check the following:

Cause/Action

Explain to the User that Mixed Size is not supported.

005-198/199 Too Short Size Jam/ Too Long Size Jam

BSD-ON:CH5.4, CH5.2

[Too Short Size Jam]

It was detected that the document length in Slow Scan direction is shorter than the specifications (Simpex: 85 mm, Duplex: 110 mm).

[Too Long Size Jam]

It was detected that the document length in Slow Scan direction is at the specifications (Simpex: 1275 mm, Duplex: 480.1 mm) or longer.

Cause/Action

Check the size of the document that was fed by the user. If it is within the permitted length for DADF transport, check the following:

•The DADF Pre Regi Sensor (Input Check [005-206]) for operation failure. (PL 56.14)

•The Document Tray Size Sensor 1/2 (Input Check [005-221/222]) for operation failure. (PL 56.11)

If no problem is found, replace the DADF PWB. (PL 56.2)

005-210 DADF Download Fail

BSD-ON:CH3.1

When the IISS starts up (including at Power ON/Sleep recovery), it was detected that the DADF is in Download Mode.

•The DADF Pre Regi Sensor (Input Check [005-206]) for operation failure. (PL 56.14)

•The Document Tray Size Sensor 1/2 (Input Check [005-221/222]) for operation failure.

(PL 56.11)

3.If no problem is found, replace the DADF PWB. (PL 56.2)

Cause/Action

Perform the DADF software download.

005-275/280 DADF RAM Fail/ DADF EEPROM Fail

BSD-ON:CH3.1

|

005-197 Prohibit Combine Size Jam |

[DADF RAM Fail] |

||

|

BSD-ON:CH5.4 |

|||

|

A Mixed Size document was detected. |

The DADF PWB RAM failed during the Read/Write operation. (At Power ON) |

||

|

[DADF EEPROM Fail] |

|||

|

Initial Issue |

08/2012 |

Status Indicator RAPs |

|

|

005-147, 005-198/199 |

|||

|

WorkCentre 5021/5019 |

2-15 |

Write failure to DADF EEPROM or communication failure with EEPROM was detected.

Cause/Action

1.Turn the power OFF and ON.

2.If the problem persists, replace the DADF PWB. (PL 56.2)

005-305 DADF Feeder Cover Interlock Open

BSD-ON:CH5.1

The DADF Feeder Cover Interlock Switch was opened during DADF operation.

• DADF Invert Sensor (Input Check[005-211]) (PL 56.10)

3.If no problem is found, replace the DADF PWB. (PL 56.2)

005-940 DADF No Original Fail

BSD-ON:CH5.1

It was detected that the document was pulled out during document feed.

Cause/Action

Reload the document.

Cause/Action

1.Check the DADF Feeder Cover for mismatch.

2.Check the DADF Feeder Cover Interlock Switch (Input Check [005-212]) for operation failure.

(PL 56.6)

3.If no problem is found, replace the DADF PWB. (PL 56.2)

005-500 DADF Download Flash Write Error

BSD-ON:CH3.1

Failed to write into the Flash ROM during DAFD Download.

Cause/Action

1.Turn the power OFF and ON.

2.If the problem persists, replace the following parts in sequence:

•DADF PWB (PL 56.2)

•ESS/MCU PWB (PL 18.1)

005-948 SS-Size Mismatch Jam on No Mix-size

BSD-ON:CH5.4, CH5.2

In No Mix mode, it was detected that a document with a shorter size in Slow Scan (SS) direction was transported from the DADF.

Cause/Action

1.Check the size of the document that was fed by the User.

2.If the error is not cleared, check the following:

•The DADF Pre Regi Sensor (Input Check [005-206]) for operation failure. (PL 56.14)

•The Document Tray Size Sensor 1/2 (Input Check [005-221/222]) for operation failure.

(PL 56.11)

3.If no problem is found, replace the DADF PWB. (PL 56.2)

005-907/908/913 DADF Pre Regi Sensor/DADF Regi Sensor/DADF Invert Sensor Static Jam

BSD-ON:CH5.4, CH5.5

Paper was detected by the applicable sensor at Power ON, Feeder Cover Interlock Close, or DADF Open Sensor Close.

Cause/Action

1.Check the applicable sensor for remaining paper, the Actuator for return failure, contamination on sensor, and etc.

2.Check the applicable sensor for operation failure.

•DADF Pre Regi Sensor (Input Check[005-206]) (PL 56.14)

•DADF Regi Sensor (Input Check[005-110]) (PL 56.14)

|

Status Indicator RAPs |

08/2012 |

|

|

005-275/280, 005-940 |

||

|

2-16 |

Initial Issue

WorkCentre 5021/5019

010-311 Fusing Unit Center Thermistor Defect

BSD-ON:CH10.2

An open circuit abnormality (the AD value of the STS is equivalent to the open circuit value) of the Heat Roll Center Thermistor was detected.

Procedure

Turn OFF the power and disconnect the Heat Roll Center Thermistor connector P/J600. Measure the resistance between the Heat Roll Center Thermistor J600 pin-1 and J600 pin-2. Is the resistance infinite?

YN

Reconnect the connector P/J600 and measure the resistance between the ESS/MCU PWB J403 pin-1 and J403 pin-2. Is the resistance infinite?

Y N

Replace the ESS/MCU PWB. (PL 18.1)

Check the following connections for open circuits and poor contacts.

• Between ESS/MCU PWB J403-1 and Heat Roll Center Thermistor P600-4

• Between ESS/MCU PWB J403-2 and Heat Roll Center Thermistor P600-3

Replace the Fusing Unit. (PL 7.1)

010-312 Fusing Unit Rear Thermistor Defect

BSD-ON:CH10.2

An open circuit abnormality (the AD value of the STS is equivalent to the open circuit value) of the Heat Roll Rear Thermistor was detected.

010-320 Over Heat Temperature Fail

BSD-ON:CH10.2, CH10.1

A high temperature error was detected at the Center Thermistor (245 degrees C or higher) or the Rear Thermistor (270 degrees C or higher).

NOTE: To clear this Fail, first remove the cause, next clear the value of NVM [744-040] (Over Heat Temp Fail) to ‘0’, and then turn the power OFF then ON. The relationship between the displayed value and the Thermistor that detected the high temperature error is as follows:

•0: Normal

•1: High Temperature Error of Heat Roll Center Thermistor

•2: High Temperature Error of Heat Roll Rear Thermistor

Cause/Action

Check the following:

•The Center Thermistor or the Rear Thermistor for dropped parts, sensor contamination, and foreign substances blocking the sensor.

•The Heat Roll for wound up, stuck paper.

•The Heat Roll Center Thermistor (Analog Monitor [010-050]) for operation failure.

•The Heat Roll Rear Thermistor (Analog Monitor [010-051]) for operation failure.

•The Heater Rod for operation failure.

If no problem is found, replace the following parts in sequence:

•Fusing Unit (PL 7.1)

•LVPS (PL 18.1)

•ESS/MCU PWB (PL 18.1)

Procedure

Turn OFF the power and disconnect the Heat Roll Rear Thermistor connector P/J600. Measure the resistance between the Heat Roll Rear Thermistor J600 pin-3 and J600 pin-4. Is the resistance infinite?

YN

Reconnect the connector P/J600 and measure the resistance between the ESS/MCU PWB J403 pin-3 and J403 pin-4. Is the resistance infinite?

Y N

Replace the ESS/MCU PWB. (PL 18.1)

Check the following connections for open circuits and poor contacts.

• Between ESS/MCU PWB J403-3 and Heat Roll Rear Thermistor P600-2

• Between ESS/MCU PWB J403-4 and Heat Roll Rear Thermistor P600-1

Replace the Fusing Unit. (PL 7.1)

010-327 Fusing Unit On Time Fail

BSD-ON:CH10.2, CH10.1

Any of the following was detected:

•The Heater Rod did not turn OFF within the specified time after the Heater Rod On.

•After power ON, the temperature of the Fusing Unit does not reach the specified value within the specified time.

Cause/Action

Check the following:

•The Heater Rod for operation failure.

•The connection between the LVPS J511 and the Fusing Unit P10 for open circuit and poor contact

•The Center Thermistor for dropped parts, sensor contamination, and foreign substances blocking the sensor.

•The Heat Roll for wound up, stuck paper.

|

Initial Issue |

08/2012 |

Status Indicator RAPs |

|

010-311, 010-320 |

||

|

WorkCentre 5021/5019 |

2-17 |

If no problem is found, replace the following parts in sequence:

•Fusing Unit (PL 7.1)

•LVPS (PL 18.1)

•ESS/MCU PWB (PL 18.1)

010-379 Fusing Unit Hot Not Ready Return Time Fail

BSD-ON:CH10.2, CH10.1

The time taken to recover from High Temperature Not Ready state has exceeded the specified time.

Cause/Action

1.Turn the power OFF and ON.

2.Turn OFF the power and check the following:

•The Fusing Unit for improper installation.

•The connection between the Fusing Unit P10 and the LVPS J511 for open circuit, short circuit, and poor contact.

•The connection between the Fusing Unit P600 and the ESS/MCU PWB J403 for open circuit, short circuit, and poor contact.

•The connection between the ESS/MCU PWB J401 and the LVPS J513 for open circuit, short circuit, and poor contact.

•The Heat Roll for wound up, stuck paper.

3.If the problem persists, replace the following parts in sequence:

•Fusing Unit (PL 7.1)

•LVPS (PL 18.1)

•ESS/MCU PWB (PL 18.1)

010-602 Over Temp Cooling Mode

BSD-ON:CH10.2

Unable to print because the temperature in the machine has risen above the specification value.

Cause/Action

Wait until the temperature in the machine has dropped.

010-392 NOHAD Fan Defect

BSD-ON:CH10.3

NOHAD Fan failure was detected. When the NOHAD Fan Fail signal indicating an abnormality of the Fan was monitored at the specified time interval, it was found to have failed the specified number of times or higher in a row.

Cause/Action

1.Check the NOHAD Fan (Output Check [042-002]) for operation failure. (PL 4.1)

2.Check the NOHAD Fan for foreign substances.

3.If no problem is found, replace the ESS/MCU PWB. (PL 18.1)

|

Status Indicator RAPs |

08/2012 |

Initial Issue |

|

010-327, 010-602 |

||

|

2-18 |

WorkCentre 5021/5019 |

016-500 Controller Download Flash Write Error

BSD-ON:-

Unable to write the Download File of Controller Main into the Flash ROM.

Cause/Action

1.Press [Stop] on the UI Panel.

2.Check the connection of the USB Cable between this machine and the PC.

3.Check the status (is it powered OFF, frozen, etc.) of the PC.

Cause/Action

1.Turn the power OFF and ON.

(If the contents of the Flash ROM is corrupted, the machine will boot up in Emergency Boot Download mode after Power ON.)

2.If the problem persists, replace the ESS/MCU PWB. (PL 18.1)

016-501 Controller Boot Flash Write Error

BSD-ON:-

Unable to write the Download File of Controller Boot into the Flash ROM.

Cause/Action

1.Turn the power OFF and ON.

2.If the problem persists, replace the ESS/MCU PWB. (PL 18.1)

016-571 No Response from USB-Host for Print Job

BSD-ON:CH3.2

When any of the following has occurred as USB Print or Download data interpretation is in progress.

•The command from the PC was disrupted for 2 minutes.

•The machine has detected a communication error with the USB Device.

•The sending of commands to the PC remained unsuccessful even when 500 ms has passed.

NOTE: This Fault will clear automatically. (It will not be displayed on the UI Panel)

Cause/Action

1.Check the connection of the USB Cable between this machine and the PC.

2.Check the status (is it powered OFF, frozen, etc.) of the PC.

016-502 UI Panel Download Flash Write Error

BSD-ON:CH2.1

Unable to write the Download File of UI Panel into the Flash ROM.

Cause/Action

1.Turn the power OFF and ON.

2.If the problem persists, replace the following parts in sequence:

•ESS/MCU PWB (PL 18.1)

•UI PWB (PL 1.6)

016-570 No Response from USB-Host for Scan Job

BSD-ON:CH3.2

When any of the following has occurred as Scan to PC (USB) is in progress.

•The command from the PC was disrupted for 5 seconds.

•The machine has detected a communication error with the USB Device.

•The sending of commands to the PC remained unsuccessful even when 500 ms has passed.

(The timeout time is the time calculated from the size of the data being sent only when sending image data.)

016-742/744 Download File Error/ Download File Check

Sum Error

BSD-ON:-

[Download File Error]

It was detected that there is an error with either the file format of the Download File, the Device Identifier, the Device Serial Number, or the Target Device Character String.

[Download File Check Sum Error]

The Download File checksum error was detected.

Cause/Action

1.Turn the power OFF and ON.

2.Install a firmware with the correct version.

|

Initial Issue |

08/2012 |

Status Indicator RAPs |

|

016-500, 016-570 |

||

|

WorkCentre 5021/5019 |

2-19 |

016-749/799 HBPL or XPJL Syntax Error/ Print Instruction Fail

BSD-ON:-

[HBPL or XPJL Syntax Error]

When the Print Job data interpretation is in progress, an illegal command that cannot be ignored was received from the Client driver.

[Print Instruction Fail]

During the Print Job, the Job cannot be executed with the specified combination of print parameters (Stored File Size, Paper Size, Paper Tray, Duplex Settings, Output Tray, and etc.).

NOTE: During Continuous Print, this error will not occur until the paper that immediately precedes the paper where the applicable image is supposed to be printed on has been output successfully.

Cause/Action

1.Press [Stop] on the UI Panel.

2.Check whether the Printer Driver that is being used is the correct one.

3.Check whether the specified print parameters are correct.

016-759 Copy Counter Full

BSD-ON:-

During Multi Account Mode, any of the following has occurred:

•The general user that is logged in has reached the alotted maximum print count.

•A general user that has reached the alotted maximum print count has logged in.

Cause/Action

1.Press [Stop] on the UI Panel.

2.Clear the count for the user.

016-776 Marker Code Detection Fail

BSD-ON:-

During Copy Job or Print Job, when expanding only up to the size that was specified at the expansion, the End Code cannot be found in the compressed data.

NOTE: Before the occurrence of this fail, there are cases where [045-310 Image Ready Error] would occur first.

NOTE: During Continuous Print, this error will not occur until the paper that immediately precedes the paper where the applicable image is supposed to be printed on has been output successfully.

Cause/Action

1.Turn the power OFF and ON.

2.If the problem reoccurs, determine whether it is caused by the Copy document or the Print data and contact the Support Department for assistance.

|

Status Indicator RAPs |

08/2012 |

Initial Issue |

|

016-749/799, 016-776 |

||

|

2-20 |

WorkCentre 5021/5019 |

023-600 Held Down key Error (UI Panel)

BSD-ON:CH2.1

Any key on the UI Panel has been pressed and held down for 1 minute or longer.

Cause/Action

Check whether any key on the UI Panel is pressed and held down.

|

Initial Issue |

08/2012 |

Status Indicator RAPs |

|

023-600 |

||

|

WorkCentre 5021/5019 |

2-21 |

|

Status Indicator RAPs |

08/2012 |

Initial Issue |

|

023-600 |

||

|

2-22 |

WorkCentre 5021/5019 |

024-910/911/915 Tray 1/Tray 2/MSI Paper Length Mismatch

BSD-ON:CH8.3, CH8.1

The Paper Size for the applicable Tray is longer by 10.1 mm or more, or shorter by 13.1 mm or more than the setting.

Cause/Action

Check the following:

•Transportation failure due to foreign substance on the document path.

•The surface of the Feed Roll, T/A Roll 2 (Tray 2), Regi. Roll, and Idler Roll of the applicable Tray for foreign substances.

•The surface of the Feed Roll, T/A Roll 2 (Tray 2), Regi. Roll, and Idler Roll of the applicable Tray for wear.

•The Regi Sensor (Input Check [071-105]) for operation failure. (PL 15.1)

•The Regi Clutch (Output Check [071-001]) for operation failure. (PL 15.1)

•The MSI Feed Clutch (Output Check [072-006]) for operation failure. (MSI) (PL 13.3)

•The BTR for contamination, wear, and transportation failure due to deterioration.

•The Drive Gear for wear and damage.

•Usage of out of spec paper.

If no problems are found, replace the ESS/MCU PWB. (PL 18.1)

•ESS/MCU PWB (Tray 1/MSI) (PL 18.1)

•STM PWB (Tray 2) (PL 10.6)

024-958/959/960 MSI/Tray 1/Tray 2 Paper Size Mismatch

BSD-ON:-

During Print Job, the paper size settings of the selected Tray is different from the paper size specified for the Job.

Cause/Action

Change the paper settings of the selected Tray to the appropriate one.

024-965 APS NG Unselected

BSD-ON:-

During Copy Job, Print Job, and Report Job with APS settings, the Paper Size and paper orientation (SEF/LEF) settings specified by the Job are different from the settings at Tray 1 and Tray 2.

Cause/Action

Change the paper settings of the Tray to the appropriate one.

024-950/951/954 Tray 1/Tray 2/MSI No Paper

BSD-ON:CH7.2, CH7.3, CH7.4

Any of the following was detected:

•The paper in the applicable Tray has ran out.

(When the APS function of Tray 1 and Tray 2 is disabled)

•Although the paper in the applicable Tray was detected to have ran out, paper is not supplied from another Tray. (When the APS function of Tray 1 and Tray 2 is enabled)

Cause/Action

1.Load paper into the applicable Tray. (If this had occurred during APS of Tray 1 or Tray 2, load paper with the same settings as for the aplicable Tray into other than MSI.)

2.If the problem persists, check the following:

•The paper supply mechanism of the applicable Tray for damage and foreign substances.

•The No Paper Sensor of the applicable Tray (Input Check [072-100/101/102]) for operation failure. (PL 9.1, PL 10.3, PL 13.3)

•The No Paper Sensor of the applicable Tray for contamination, improper installation, and Actuator operation failure.

3.If no problem is found, replace the following parts:

|

Initial Issue |

08/2012 |

Status Indicator RAPs |

|

024-910/911/915 , 024-950/951/954 |

||

|

WorkCentre 5021/5019 |

2-23 |

|

Status Indicator RAPs |

08/2012 |

Initial Issue |

|

024-910/911/915 , 024-950/951/954 |

||

|

2-24 |

WorkCentre 5021/5019 |

041-210/211 STM NVM Out-Of-Order/ STM NVM R/W Error

BSD-ON:CH3.2

[STM NVM Out-Of-Order]

The NVM of the STM is malfunctioning.

[STM NVM R/W Error]

Unable to perform NVM Read / Write for the STM.

Cause/Action

1.Turn the power OFF and ON.

2.If the problem persists, replace the STM PWB. (PL 10.6)

|

Initial Issue |

08/2012 |

Status Indicator RAPs |

|

041-210/211 |

||

|

WorkCentre 5021/5019 |

2-25 |

|

Status Indicator RAPs |

08/2012 |

Initial Issue |

|

041-210/211 |

||

|

2-26 |

WorkCentre 5021/5019 |

042-325/614 Main Motor Rotation Error/ Main Motor

Rotation Warning

BSD-ON:CH4.1

[Main Motor Rotation Error]

The Main Drive Motor revolution failure was detected. When the Lock Up (Main Drive Motor Fail) signal of the Motor Drive output was monitored at the specified time interval after a certain time has passed since the Main Drive Motor operation had started, it was found to have failed 5 times in a row.

[Main Motor Rotation Warning]

The Main Drive Motor revolution failure was detected. When the Lock Up (Main Drive Motor Fail) signal of the Motor Drive output was monitored at the specified time interval after a certain time has passed since the Main Drive Motor operation had started, it was found to have failed 2 times in a row.

Procedure

|

Enter the CE Mode and turn ON the Output Check [042-001] (Main Drive Motor). Does |

the |

|

|

Main Drive Motor rotate? |

||

|

Y N |

||

|

Check the power supply line (+24VDC, +5VDC) of the Main Drive Motor. Is the |

power |

|

|

supply of the Main Drive Motor normal? |

||

|

Y N |

||

|

Check the power supply circuit to the Main Drive Motor. |

||

Turn OFF the power and check the following:

•The connection between the Main Drive Motor J202 and the ESS/MCU PWB J403 for open circuit, short circuit, and poor contact.

•The Drive Gear for wear, damage, and bearing blockage.

•The Main Drive Motor for loading.

If no problem is found, replace the following parts in sequence:

•Main Drive Motor (PL 3.1)

•ESS/MCU PWB (PL 18.1)