- Печать

Страницы: 1 … 14 15 [16] 17 18 19 Вниз

Тема: BLT контроллер MPK708C (Прочитано 77592 раз)

0 Пользователей и 1 Гость просматривают эту тему.

хуже не будет

Вы главное определите момент, когда она «зависает». А потом смотреть, что в этот момент включается/отключается

Записан

Уважай лифты: они делают твою жизнь комфортнее

Такая проблема, с пустого места. MPK708C частный привод UNIDRIVE ES2403. В ревизии ходит отлично в оба направления. Вверх на скорости без проблем, но вниз как только стартует, тормоз отходит на частотнике сразу ошибка t071. Провода протянули, разъёмы шевелить. В чем проблема, можете подсказать?

Записан

Проблема с модулем SM-Applications, который устанавливается на частотник. Попробуй заменить с заведомо исправного частотника.

Плюс еще одна информация: вверх лебедка работает в генераторном режиме. Мощность рассеивается на тормозном резисторе. Смотри силовую часть к тормознику (проверь само тормозное сопротивление).

Записан

Уважай лифты: они делают твою жизнь комфортнее

У меня стоят sm-universal encoder plus, sm-i/o plus . Поменяли 3 платы, такая же ерунда.

Сопротивление тормозной 30ом, сразу в частник идет, вроде все норм по нему.

Оказывается он и в ревизии так же t071 кажет.

Во общем в ревизии и нормальной работе ошибка t071, НО когда корректируется вниз то нормально!!!

И еще вопрос, есть у кого документация на Unidrive ES? Может надо револьвер настроить просто. Лебедев безредукторная

« Последнее редактирование: Ноябрь 12, 2019, 11:47:54 от smesharik »

Записан

« Последнее редактирование: Ноябрь 12, 2019, 13:19:06 от alex-chlm »

Записан

Уважай лифты: они делают твою жизнь комфортнее

Можно ее получить?

povsakoi@mail.ru

Записан

Записан

Уважай лифты: они делают твою жизнь комфортнее

Доброго времени суток!

Проблема такая: лифт в нормальной работе ездит хорошо, но стоит перевести в МП начинаются кульбиты, при движении вверх лифт пролетает несколько метров. Такое же происходит при движении на ревизии. Если изначально проехать сначала вниз, а потом вверх то на ревизии не летает. На МП летает постоянно. Надеюсь понятно описал проблему.

Лебедка безредукторная, двигатель синхронный, грузоподъемность 1000кг, остановок 8.

Это происходит с монтажа лифта, специалистов которые могли бы устранить это нет. Если есть прошивка для частотника или какие-нибудь предположения по этому поводу жду вашего ответа. Вопрос очень серьезный.

Записан

«Это происходит с монтажа лифта, специалистов которые могли бы устранить это нет.»

Как можно устранять проблемы на лифте без специалистов? Полное отсутствие страха… Печально

По существу: частотник тут не причем, коль в нормальной работе у вас проблемы нет.

В нормальной работе частотники и система управления «отрабатывает» процедуру остановки лифта: переход с большой скорости на малую, дотягивание до точной остановки, удержание кабины на точной остановке, наложение тормоза, снятие усилия с частотника на лебедку.

В режиме ревизия и управления с машинного помещения удержание частотником «на месте» не производится: остановка происходит только путем снятия усилия по перемещению кабины на скорости ревизии с частотника на лебедку с одновременным наложением тормоза. У вас просто тормоз лебедки не работает должным образом. Причину должен искать специалист.

Эксплуатация такого лифта запрещена.

« Последнее редактирование: Ноябрь 20, 2019, 10:06:13 от alex-chlm »

Записан

Уважай лифты: они делают твою жизнь комфортнее

спасибо

Я как электромеханик, свои обязанности по обслуживанию лифта исполняю. Наладчики, кои у нас имеются в количестве 2-х штук от этого объекта открещиваются, аргументируя это тем, что тут нужно менять все узлы, чуть ли не до лебедки(а по факту они просто не могут выполнить наладку). Начальство также открещивается, т.к. замена лебедки, ПЧ, и контроллера(опять же информация из доклада наладчиков) обойдется в круглую сумму.

Выходит лифт в нормальной работе отрабатывает, и слава богу, никому он не нужен, кроме электромеханика(меня).

В итоге мне остается устранить это своими силами. Либо я мог бы предложить начальству пригласить специалиста со стороны, но таких в нашей области не имеется.

Надеюсь на понимание, сломя голову с молотком и болгаркой наперевес на лифт нападать не собираюсь, просто коль вышла такая ситуация прошу у вас совета, куда копать и что искать.

Удалено цитирование предыдущего сообщения.

« Последнее редактирование: Ноябрь 20, 2019, 13:35:39 от Мишаня »

Записан

Михаил Воскресенский,

Если в норме ездит, то лебедка и пч здесь ни при чем. Менять их точно смысла нет.

Записан

Я понимаю, такую информацию дают начальству наладчики. Они как один из вариантов предлагают заменить ПЧ на unidrive, т.к. есть соседние лифты с таким частотником, соответственно параметры можно было бы скопировать оттуда. Но, начальство отказывается т.к. это дорого

Удалено цитирование предыдущего сообщения.

« Последнее редактирование: Ноябрь 20, 2019, 13:36:25 от Мишаня »

Записан

Какой трындец, «специалисты» на букву х (от слова хреновые) одинаковы с лица. Михаил Воскресенский, из рассказанного вами очевидно, что описанная проблема к преобразователю частоты отношения не имеет. Вы бы хоть указали о каком лифте идёт речь.

alex-chlm, дал вам правильное направление для понимания проблемы. И писали об этом на страницах форума уже не один раз. В ревизии при отпускании кнопки происходит немедленное отключение пускателей привода и тормоза.

Возможные причины протягивания, подскока в режиме ревизии (инспекции):

1) С большой вероятностью катушка тормоза шунтирована диод. За счет протекания тока само ЭДС катушки тормоза через диод, происходит подлипание тормозов на ~ 1 с;

2) катушка тормоза подмагничивает сама по себе (были случаи с китайскими лебедками — приходилось переделывать мостовой выпрямитель на однополупериодный с шунтирующим диодом);

3) тормоза заедают или неправильно отрегулированы.

В результате происходит подскок, так как момента на валу уже нет. В нормальной работе время удержания преобразователем частоты больше чем 1 с и тормоза накладываются раньше чем снимается момент с электродвигателя, поэтому все нормально.

Если шунтирующий диод есть, для уменьшения подмагничивания последовательно с диодом устанавливается мощный резистор ~ 100 -300 Ом, либо диод подключается не непосредственно к катушке, а через блок контакты пускателей привода.

Записан

спасибо

В тему: лифт с частотником но без тормозов

Добавлен тэг youtube. Как вставлять в сообщение видеоролики YouTube

От видео волосы встают «дыбом». А ведь в такой лифт можешь попасть обыкновенным пассажиром. И вспоминается спор на форуме «Может ли лифт ехать с открытыми дверями?». И судя по вопросам таких лифтов не единицы. И сразу в тему вопрос к производителям: почему в заводских инструкциях (на монтаж, наладку, эксплуатацию) отсутствует информация по регулировке тормозов и контрольных размерах. А у обслуги и монтажников принцип такой: лебедка пришла в сборе с завода — трогать/проверять не надо.

« Последнее редактирование: Ноябрь 21, 2019, 17:08:48 от alex-chlm »

Записан

Уважай лифты: они делают твою жизнь комфортнее

Лифт BLT, грузоподъемность 1000кг, 8 остановок, контроллер MPK708C.

Попробую найти диод, он должен быть расположен непосредственно на катушке? Что если попробовать убрать его ради теста, дабы убедиться что дело в нем?

Спасибо за дельные советы, поймите меня правильно, я единственное лицо, которое реально хочет устранить эту проблему, т.к. понимаю что это грубое нарушение и так быть не должно. Даже если я откажусь от объекта(что самое простое в моем случае) его попросту отдадут другому механику, который также ничего с этим не сделает. Поэтому раз так вышло, попытаюсь своими силами, или хотя бы теперь привлеку наших наладчиков с идеей про диод.

P.S: Прилагаю фото тормоза лебедки, который стоит на соседнем лифте

Удалил пустую цитату.

И вот еще схема, не этот ли диод? Если он, то как я понимаю, у меня он установлен на плате вместе с диодным мостом, которая расположена в станции.

« Последнее редактирование: Ноябрь 21, 2019, 22:02:31 от Михаил Воскресенский »

Записан

- Печать

Страницы: 1 … 14 15 [16] 17 18 19 Вверх

Trip Indications

Understanding trip codes is an important part of keeping your equipment running smoothly. Below are some of the more common codes you may come across when using your Control Techniques Unidrive M700 series drive:

| Trip | Diagnosis |

|---|---|

| Over Volts | DC bus voltage has exceeded the peak level or maximum continuous level for 15 seconds |

| Trip 2 | The Over Volts trip indicates that the DC bus voltage has exceeded the VM_DC_VOLTAGE[MAX] or VM_DC_VOLTAGE_SET[MAX] for 15 s. The trip threshold varies depending on voltage rating of the drive as shown below  Recommended actions: • Increase deceleration ramp (Pr 00.004) • Decrease the braking resistor value (staying above the minimum value) • Check nominal AC supply level • Check for supply disturbances which could cause the DC bus to rise • Check motor insulation using an insulation tester |

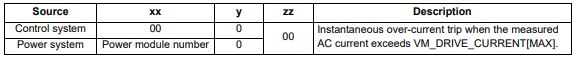

| OI ac | OI ac Instantaneous output over current detected |

| Trip 3 | The instantaneous drive output current has exceeded VM_DRIVE_CURRENT[MAX]. This trip cannot be reset until 10 s after the trip was initiated. Recommended actions: • Acceleration/deceleration rate is too short • If seen during auto-tune reduce the voltage boost • Check for short circuit on the output cabling • Check integrity of the motor insulation using an insulation tester • Check feedback device wiring • Check feedback device mechanical coupling • Check feedback signals are free from noise • Is motor cable length within limits for the frame size • Reduce the values in the speed loop gain parameters — (Pr 03.010, 03.011, 03.012) or (Pr 03.013, 03.014, 03.015) • Has the phase angle autotune been completed? (RFC-S mode only) • Reduce the values in current loop gain parameters (RFC-A, RFC-S modes only) |

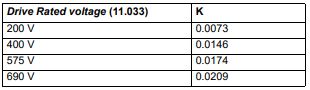

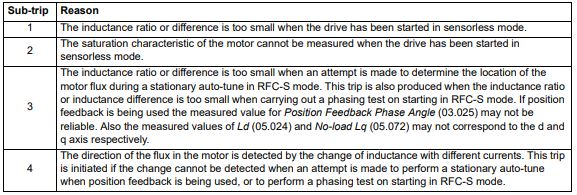

| Inductance | Inductance measurement out of range or motor saturation not detected |

| Trip 8 | This trip occurs in RFC-S mode when the drive has detected that the motor inductances are not suitable for the operation being attempted. The trip is either caused because the ratio or difference between Ld and Lq is too small or because the saturation characteristic of the motor cannot be measured. If the inductance ratio or difference is too small this is because one of the following conditions is true: (No-load Lq (05.072)- Ld (05.024)) / Ld (05.024) < 0.1 (No-load Lq (05.072) — Ld (05.024)) < (K / Full Scale Current Kc (11.061))H where:  If the saturation characteristic of the motor cannot be measured this is because when the flux in the motor is changed the measured value of Ld does change sufficiently due to saturation to be measured. When half of Rated Current (05.007) is applied in the d axis of the motor in each direction the inductance must fall change at least (K / (2 x Full Scale Current Kc (11.061)). The specific reasons for each of the sub-trips are given in the table below:  Recommended actions for sub-trip 1: • Ensure that RFC Low Speed Mode (05.064) is set to Non-salient (1), Current (2) or Current No test (3). Recommended actions for sub-trip 2: • Ensure that RFC Low Speed Mode (05.064) is set to Non-salient (1), Current (2) or Current No test (3). Recommended actions for sub-trip 3: • None. The trip acts as a warning. Recommended actions for sub-trip 4: • Stationary autotune is not possible. Perform a minimal movement or rotating autotune. • Phasing test on starting is not possible. Use a position feedback device with commutation signals or absolute position |

| Motor Too Hot | Output current overload timed out (I2t) |

| Trip 20 | The Motor Too Hot trip indicates a motor thermal overload based on the Rated Current (Pr 05.007) and Motor Thermal Time Constant (Pr 04.015). Pr 04.019 displays the motor temperature as a percentage of the maximum value. The drive will trip on Motor Too Hot when Pr 04.019 gets to 100 %. Recommended actions: • Ensure the load is not jammed / sticking • Check the load on the motor has not changed • If seen during an auto-tune test in RFC-S mode, ensure the motor Rated Current in Pr 05.007 is ≤ Heavy duty current rating of the drive • Tune the Rated Speed (Pr 05.008) (RFC-A mode only) • Check feedback signal for noise • Ensure the motor rated current is not zero • This trip can be disabled and current limiting activated on the motor overload by setting thermal protection mode Pr 04.016 to 1. |

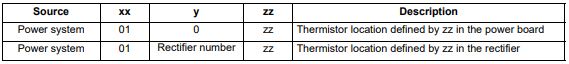

| OHt Power | Power stage over temperature |

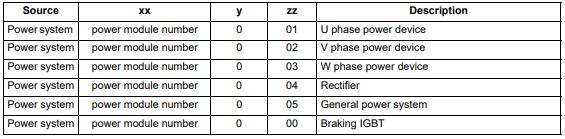

| Trip 22 | This trip indicates that a power stage over-temperature has been detected. From the sub-trip ‘xxyzz’, the Thermistor location which is indicating the over-temperature is identified by ‘zz’.The thermistor numbering is different for a single module type drive (i.e. no parallel board fitted) and a multi-module type drive (i.e. parallel board fitted with one or more power modules) as shown below: Single module type drive:  Multi-module type system:  Note that the power module that has caused the trip cannot be identified except for the braking IGBT temperature measurement Recommended actions: • Check enclosure / drive fans are still functioning correctly • Force the heatsink fans to run at maximum speed • Check enclosure ventilation paths • Check enclosure door filters • Increase ventilation • Reduce the drive switching frequency • Reduce duty cycle • Increase acceleration / deceleration rates • Use S ramp (Pr 02.006) • Reduce motor load • Check the derating tables and confirm the drive is correctly sized for the application. • Use a drive with larger current / power rating |

| An Input 1 Loss | Analog input 1 current loss (Unidrive M700 / M701) |

| Trip 28 | An Input 1 Loss trip indicates that a current loss was detected in current mode on Analog input 1 (Terminal 5, 6). In 4-20 mA and 20-4 mA modes loss of input is detected if the current falls below 3 mA. Recommended actions: • Check control wiring is correct • Check control wiring is undamaged • Check the Analog Input 1 Mode (07.007) • Current signal is present and greater than 3 mA |

| Phase Loss | Supply phase loss |

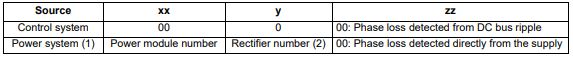

| Trip 32 | The Phase Loss trip indicates that the drive has detected an input phase loss or large supply imbalance. Phase loss can be detected directly from the supply where the drive has a thyristor base charge system (Frame size 8 and above). If phase loss is detected using this method the drive trips immediately and the xx part of the sub-trip is set to 01. In all sizes of drive phase loss is also detected by monitoring the ripple in the DC bus voltage in which case the drive attempts to stop the drive before tripping unless bit 2 of Action On Trip Detection (10.037) is set to one. When phase loss is detected by monitoring the ripple in the DC bus voltage the xx part of the sub-trip is zero.  (1) Input phase loss detection can be disabled when the drive required to operate from the DC supply or from a single phase supply in Input Phase Loss Detection Mode (06.047). (2) For a parallel power-module system the rectifier number will be one as it is not possible to determine which rectifier has detected the fault. This trip does not occur in regen mode. Recommended actions: • Check the AC supply voltage balance and level at full load • Check the DC bus ripple level with an isolated oscilloscope • Check the output current stability • Check for mechanical resonance with the load • Reduce the duty cycle • Reduce the motor load • Disable the phase loss detection, set Pr 06.047 to 2. |

| Out Phase Loss | Output phase loss detected |

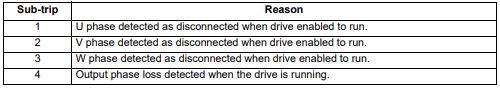

| Trip 98 | The Out Phase Loss trip indicates that phase loss has been detected at the drive output.  NOTE: If Pr 05.042 = 1 the physical output phases are reversed, and so sub-trip 3 refers to physical output phase V and sub-trip 2 refers to physical output phase W. Recommended actions: • Check motor and drive connections • To disable the trip set Output Phase Loss Detection Enable (06.059) = 0 |

| OI dc | Power module over current detected from IGBT on state voltage monitoring |

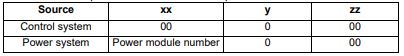

| Trip 109 | The OI dc trip indicates that the short circuit protection for the drive output stage has been activated. The table below shows where the trip has been detected. This trip cannot be reset until 10 s after the trip was initiated.  Recommended actions: • Disconnect the motor cable at the drive end and check the motor and cable insulation with an insulation tester • Replace the drive |

| Configuration | The number of power modules installed is different from the modules expected |

| Trip 111 | The Configuration trip indicates that the Number Of Power Modules Detected (11.071) does not match the previous value stored. The sub-trip value indicates the number of power modules expected. Recommended actions: • Ensure that all the power modules are correctly connected • Ensure all the power modules have powered up correctly • Ensure that the value in Pr 11.071 is set to the number of power modules connected • Set Pr 11.035 to 0 to disable the trip if it is not required This trip is also initiated if the number of external rectifiers connected to each power module is less than the number defined by Number Of Rectifiers Expected (11.096). If this is the reason for the trip the sub-trip is 10x where x is the number of external rectifiers that should be connected. Recommended actions: • Ensure that all the external rectifiers are connected correctly • Ensure that the value in Number Of Rectifiers Expected (11.096) is correct |

Alarm Indications

In any mode, an alarm is an indication given on the display by alternating the alarm string with the drive status string on the first row and showing the alarm symbol in the last character in the first row. If an action is not taken to eliminate any alarm except «Auto Tune and Limit Switch» the drive may eventually trip. Alarms are not displayed when a parameter is being edited, but the user will still see the alarm character on the upper row.

| Alarm string | Description |

|---|---|

| Brake Resistor | Brake resistor overload. Braking Resistor Thermal Accumulator (10.039) in the drive has reached 75.0 % of the value at which the drive will trip. |

| Motor Overload | Motor Protection Accumulator (04.019) in the drive has reached 75.0 % of the value at which the drive will trip and the load on the drive is >100 %. |

| Ind Overload | Regen inductor overload. Inductor Protection Accumulator (04.019) in the drive has reached 75.0 % of the value at which the drive will trip and the load on the drive is >100 %. |

| Drive Overload | Drive over temperature. Percentage Of Drive Thermal Trip Level (07.036) in the drive is greater than 90 %. |

| Auto Tune | The autotune procedure has been initialized and an autotune in progress. |

| Limit Switch | Limit switch active. Indicates that a limit switch is active and that is causing the motor to be stopped. |

Status Indications

| Upper row string | Description | Drive output stage |

|---|---|---|

| Inhibit | The drive is inhibited and cannot be run. The Safe Torque Off signal is not applied to Safe Torque Off terminals or Pr 06.015 is set to 0 | Disabled |

| Ready | The drive is ready to run. The drive enable is active, but the drive inverter is not active because the final drive run is not active | Disabled |

| Stop | The drive is stopped / holding zero speed. | Enabled |

| Run | The drive is active and running | Enabled |

| Scan | The drive is enabled in Regen mode and is trying to synchronize to the supply | Enabled |

| Supply Loss | Supply loss condition has been detected | Enabled |

| Deceleration | The motor is being decelerated to zero speed / frequency because the final drive run has been deactivated. | Enabled |

| dc injection | The drive is applying dc injection braking | Enabled |

| Position | Positioning / position control is active during an orientation stop | Enabled |

| Trip | The drive has tripped and no longer controlling the motor. The trip code appears in the lower display | Disabled |

| Active | The regen unit is enabled and synchronized to the supply | Enabled |

| Under Voltage |

The drive is in the under voltage state either in low voltage or high voltage mode | Disabled |

| Heat | The motor pre-heat function is active | Enabled |

| Phasing | The drive is performing a ‘phasing test on enable’ | Enabled |

Option module and NV Media Card and other status indications at power-up

| First row string | Second row string | Status |

|---|---|---|

| Booting | Parameters | Parameters are being loaded |

| Drive parameters are being loaded from a NV Media Card | ||

| Booting | User Program | User program being loaded |

| User program is being loaded from a NV Media Card to the drive | ||

| Booting | Option Program | User program being loaded |

| User program is being loaded from a NV Media Card to the option module in slot X | ||

| Writing To | NV Card | Data being written to NV Media Card |

| Data is being written to a NV Media Card to ensure that its copy of the drive parameters is correct because the drive is in Auto or Boot mode | ||

| Waiting For | Power System | Waiting for power stage |

| The drive is waiting for the processor in the power stage to respond after power-up | ||

| Waiting For | Options | Waiting for an option module |

| The drive is waiting for the Options Modules to respond after power-up | ||

| Uploading From |

Options | Loading parameter database |

| At power-up it may be necessary to update the parameter database held by the drive because an option module has changed or because an applications module has requested changes to the parameter structure. This may involve data transfer between the drive an option modules. During this period ‘Uploading From Options’ is displayed |

Programming error indications

Following are the error message displayed on the drive keypad when an error occurs during programming of drive firmware.

| Error String | Reason | Solution |

|---|---|---|

| Error 1 | There is not enough drive memory requested by all the option modules. | Power down drive and remove some of the option modules until the message disappears. |

| Error 2 | At least one option module did not acknowledge the reset request. | Power cycle drive |

| Error 3 | The boot loader failed to erase the processor flash | Power cycle drive and try again. If problem persists, return drive |

| Error 4 | The boot loader failed to program the processor flash | Power cycle drive and try again. If problem persists, return drive |

| Error 5 | One option module did not initialize correctly. Option module did not set Ready to Run flag. | Remove faulty option module |

Need further help?

If you have an AC / DC drive module breakdown or stability issue our engineers are able to analyse the whole machine to identify where the control issues lie. Our extensive experience in retrofit and new projects means we have the knowledge to look deep into the control system where we commonly find the peripheral devices are faulty rather than the drive module.

Our team of engineers are able to offer on site service and breakdown support throughout the UK to get you up and running again quickly.

Высокопроизводительный привод переменного тока M700

Руководство по вводу в эксплуатацию

с Unidrive M700, M701, M702 без обратной связи по положению

Двигатели от 11 до 240 кВт взаимозаменяемые версии серий 1,500 и 3,000 с приводом

Артикул: 6069 эн – 2022.06/с

ВВЕДЕНИЕ

1 — ВВЕДЕНИЕ

Перед настройкой привода следуйте инструкциям по безопасности и установке для двигателей Dyneo+ и приводов Unidrive M70x, описанным в соответствующих руководствах. Двигатели Dyneo+: http://www.leroy-somer.com/documentation_pdf/5411_en.pdf Привод Unidrive M70x: см. Руководство по началу работы и соответствующее Руководство по установке питания (доступно в Control Techniques). webсайт).

· Установка и ввод в эксплуатацию должны выполняться квалифицированным, компетентным и уполномоченным персоналом.

Затем выполните быстрый ввод в эксплуатацию, описанный в пункте 2, с заводскими настройками.

Требования: · Убедитесь, что на приводе установлена версия микропрограммы, равная или выше V01.20.00.00. · Не включайте процедуру автонастройки. · Параметры, указанные в таблицах данных двигателя из приложения, применимы только к номинальной мощности привода Unidrive M70x, указанной для

каждую строку данных. Если используется привод с другим номиналом, то коэффициент усиления Kp регулятора тока (Pr 04.013) и коэффициент усиления Ki регулятора тока (Pr 04.014) необходимо масштабировать, как описано ниже:

Новое значение = значение приложения x (KC новый привод / KC дополнительный привод) Значения для KC можно найти в Справочном руководстве по параметрам, в разделе «Текущие номиналы» или в интерактивной справке программного обеспечения Control Techniques Connect.

Dyneo+ с Unidrive M70x без обратной связи по положению Руководство по вводу в эксплуатацию

3

6069 эн – 2022.06/с

ВВОД В ЭКСПЛУАТАЦИЮ UNIDRIVE M70X БЕЗ ОБРАТНОЙ СВЯЗИ ПО ПОЛОЖЕНИЮ

2 – ВВОД В ЭКСПЛУАТАЦИЮ С UNIDRIVE M70x БЕЗ ОБРАТНОЙ СВЯЗИ ПО ПОЛОЖЕНИЮ

Режим RFC-S для взаимозаменяемых двигателей Dyneo+ с постоянными магнитами без обратной связи по положению (без датчиков)

Действие

Описание

Перед включением

Убедитесь, что: · Сигнал включения привода не подается (клемма 31 на Unidrive M700/M701 и клеммы 11 и 13 на Unidrive M702) · Сигнал «Работа» не подается · Двигатель подключен

Если при включении привода отображается режим Open Loop или RFC-A:

· Установите Pr 00.048 = RFC-S (3). · Если частота сети 60 Гц, установите Pr 00.000 = 1254, иначе, если частота сети 50 Гц, установите Pr 00.000 = 1253.

Включите привод

Если при включении привода отображается режим RFC-S:

· Если частота сети 60 Гц, установите Pr 00.000 = 1244, иначе, если частота сети 50 Гц, установите Pr 00.000 = 1233.

Доступ к расширенному меню с клавиатуры Установка максимальной скорости

Установите коэффициенты ускорения и замедления

Настройка термистора двигателя

Нажмите красную кнопку сброса или переключите логический вход сброса. Эти действия оставят диск в режиме RFC-S с параметрами по умолчанию. Привод будет находиться в отключенном состоянии, но соответствующие отключения регулируются настройками в рамках этой процедуры.

Чтобы получить доступ ко всем меню, необходимым для ввода в эксплуатацию, установите Pr 00.0049 = Все меню (1).

Напоминание: выберите меню с помощью стрелок влево и вправо. Параметры выбираются стрелками вверх и вниз.

Установите максимальную скорость в Pr 01.006 (об/мин).

Задайте: · Скорость ускорения в Pr 02.011 (с до Pr 01.006) — значение 20 с подходит для большинства приложений. · Скорость замедления в Pr 02.021 (с до Pr 01.006) – значение 20 с подходит для большинства приложений. · Рamp Единицы скорости Pr 02.039 = Вкл. (1)

Если тормозной резистор установлен, установите Pr 02.004 = Fast (0). Также убедитесь, что Pr 10.030, Pr 10.031 и Pr 10.061 установлены правильно, в противном случае могут наблюдаться постоянные отключения «Brake R Too Hot».

Термистор PTC двигателя должен быть подключен к приводу: · M700/M701: Подключите термистор к аналоговому входу 3 (клеммы 8 и 11). · M702 (с кодом даты 1710 или более поздней): Подключите термистор к цифровому входу 5 / аналоговому входу 3 (клеммы 8 и 10).

Чтобы привод управлял термистором: · Установите режим аналогового входа 3 Pr 07.015 = Therm short Cct (7).

Если при подключении термистора недостаточно входов, может потребоваться установка модуля SI-I/O.

4

Dyneo+ с Unidrive M70x без обратной связи по положению Руководство по вводу в эксплуатацию

6069 эн – 2022.06/с

ВВОД В ЭКСПЛУАТАЦИЮ UNIDRIVE M70X БЕЗ ОБРАТНОЙ СВЯЗИ ПО ПОЛОЖЕНИЮ

Действие

Введите данные паспортной таблички двигателя

Описание См. таблицы двигателей Dyneo+ в Приложении. Выберите таблицу, соответствующую диапазону скорости двигателя (1500 или 3000 об/мин). Затем в зависимости от типа двигателя и его мощности выберите строку, которая соответствует объему.tage, частота питания и номинальная скорость приложения. Из этой строки задайте в накопителе значения всех параметров, перечисленных в таблице. Если нагрузка имеет большую инерцию, может потребоваться увеличить Pr 03.010.

ПРИМЕЧАНИЕ. Если тип двигателя не указан в таблице, значит, он принадлежит к компактной серии. В этом случае обратитесь в службу технической поддержки Control Techniques.

Example: Для двигателя серии 1500, ЛШРМ 160МР1 – 11 кВт 400 В – 50 Гц с номинальной скоростью 1500 об/мин, значения параметров, которые необходимо установить в приводе, соответствуют значениям зеленой линии, как показано ниже:

Тип МОТОР

ЛШРМ 160 МР1

ГАММЕ 1500 мин-1

ВАРИАТОР

НАСТРОЙКИ

Муфта

#03.010 #03.011 #04.013 #04.014 #04.015 #05.007 #05.008 #05.009 #05.017 #05.024 #05.033 #05.069 #05.072 #05.075 #05.078 #05.082 #05.084 #05.087

кВт М700

Гц Усиление Усиление Усиление Усиление Константе Курант

Сопротивление

Витесс Напряжение

Ld

Vitesse Vitesse Courant Courant thermoque номинальный (мин-1) (В)

Кр Ки Кр Ки

(S)

(A)

Статор ()

(М)

БЭМП (В/

кммин-1)

Куран де Дефо

(%)

Lq @0A (мГн)

IQ (%)

Lq @ Iq Id (мГн) (%)

Угол

Lq @ Id (мГн)

пара (°)

11 44-00172 У 50 0,005 0,05 152 269 800 21,0 1500 400 0,31582 7,626 72,1 236 68,540 73 44,845 -108 68,540 56

11 44-00172 У 60 0,005 0,05 152 269 800 20,3 1800 400 0,31582 7,626 72,1 244 68,540 73 44,845 -108 68,540 56

12,7 44-00172 У 60 0,005 0,05 152 269 800 21,2 1800 460 0,31582 7,626 72,1 233 68,540 73 44,845 -108 68,540 56

19,1 64-00420 Д 87 0,005 0,05 124 219 800 38,2 2600 400 0,10527 2,542 41,6 218 22,847 73 14,948 -108 22,850 56

Дополнительные настройки

Сохранить параметры

ПРИМЕЧАНИЕ. При настройке Pr 05.069 может потребоваться увеличить введенное значение, чтобы фактическое значение отключения, отображаемое в Pr 05.068, было близко (но не больше) к требуемому значению.

Задавать :

· Режим обратной связи RFC (Pr 03.024) = Без датчика · Уровень обнаружения ошибки P1 (Pr 03.040) = 0 · Обнаружение ошибки термистора P1 (Pr 03.123) = Нет (0) · Ограничение тока двигателя (Pr 04.005) = 120% макс. · Ток рекуперации Предел (Pr 04.006) = 120 % макс · Предел симметричного тока (Pr 04.007) = 120 % макс · Постоянная времени фильтра опорного тока 1 (Pr 04.012) = 1 мс ]

· Режим тепловой защиты (Pr 04.016) = Отключен (4) · Максимальное масштабирование пользовательского тока (Pr 04.024) = макс. 120 % · Количество пар полюсов двигателя (Pr 05.011) = 2 · Максимальная частота коммутации (Pr 05.018) = 3 кГц (1) ) · Включить высокоскоростной режим (Pr 05.022) = Включить (2) · Коэффициент усиления управления потоком (Pr 05.027) = 0.1 · Минимальная частота переключения (Pr 05.038) = 3 кГц (1) · Voltage Запас Pr 05.041 = 5 %. [Не устанавливайте меньшее значение. Увеличьте это значение до 10 %, если двигатель нестабилен в области ослабления поля] · Режим низкой скорости RFC (Pr 05.064) = впрыск · Управление крутящим моментом Saliency Выберите Pr 05.065 = Авто (3) [Убедитесь, что Pr 05.066 = Высокий (2) ) в противном случае проверьте значение, введенное для Pr 05.087 из таблицы] · Инверсная характеристика насыщения (Pr 05.070) = Вкл. (1) · Ток в бессенсорном режиме на низкой скорости (Pr 05.071) = 60 % [Примечание. скорость и 20% от номинальной скорости двигателя]

· Режим остановки (Pr 06.001) = Ramp (1) · Удержание нулевой скорости (Pr 06.008) = отключено (0)

Выберите «Сохранить параметры» в Pr mm.000 и нажмите красную кнопку сброса или переключите цифровой вход сброса.

Привод готов к запуску.

Dyneo+ с Unidrive M70x без обратной связи по положению Руководство по вводу в эксплуатацию

5

6069 эн – 2022.06/с

ВВОД В ЭКСПЛУАТАЦИЮ С UNIDRIAVPEPME7N0DXIX БЕЗ ОБРАТНОЙ СВЯЗИ ПО ПОЛОЖЕНИЮ

Тип двигателя

ПРИВОД кВт

M70x

Связь

1500 об/мин ДИАПАЗОН ПАРАМЕТРОВ

#03.010 #03.011 #04.013 #04.014 #04.015 #05.007 #05.008 #05.009 #05.017 #05.024 #05.033 #05.069 #05.072 #05.075

#05.078

#05.082

# 05.084 # 05.087

Hz

Увеличение скорости Кр

Скорость Ток Ток Тепловой Номинал

Усиление Усиление Усиление постоянный ток

Ки Кр Ки

(S)

(A)

Номинальная скорость (об / мин)

Номинальный статор

обtagе Сопротивление

(V)

()

Ld (мГн)

OverBEMF текущий Lq @0A

(В/об/мин) уровень срабатывания (мГн) (%)

IQ (%)

Lq @ Iq (мГн)

Идентификатор (%)

Lq @ Id (мГн)

Угол крутящего момента

(°)

11 44-00172 Д 50 0.005 0.05 152 269 800 21.0 1500 400 0.31582 7.626 72.1 236 68.540 73

ЛШРМ 160 МР1

11 12.7

44-00172 44-00172

Д 60 0.005 Д 60 0.005

0.05 0.05

152 152

269 269

800 800

20.3 1800 400 0.31582 7.626 72.1 21.2 1800 460 0.31582 7.626 72.1

244 68.540 233 68.540

73 73

19.1 64-00420 Д 87 0.005 0.05 124 219 800 38.2 2600 400 0.10527 2.542 41.6 218 22.847 73

15 54-00300 Д 50 0.005 0.05 304 493 800 27.5 1500 400 0.28454 7.478 78.7 199 67.889 69

ЛШРМ 160 ЛР1

15 17.3

54-00270 54-00270

Д 60 0.005 Д 60 0.005

0.05 0.05

234 234

381 381

800 800

26.8 1800 400 0.28454 7.478 78.7 26.7 1800 460 0.28454 7.478 78.7

204 67.889 204 67.889

69 69

26.0 64-00470 Д 87 0.005 0.05 136 221 800 48.6 2600 400 0.09485 2.493 45.4 189 22.630 69

18.5 64-00420 Д 50 0.03 0.1 277 444 1000 35.9 1500 400 0.2133 5.676 73.1 181 43.301 71

ЛШРМ 180 М1

18.5 21.3

64-00420 64-00420

Д 60 0.03 Д 60 0.03

0.1 0.1

277 444 1000 35.1 1800 400 0.2133 5.676 73.1 277 444 1000 35.5 1800 460 0.2133 5.676 73.1

185 43.301 183 43.301

71 71

32.1 74-00660 Д 87 0.03 0.1 145 232 1000 62.9 2600 400 0.0711 1.892 42.2 174 14.434 71

22 64-00420 Д 50 0.03 0.1 207 281 1000 42.2 1500 400 0.13516 4.253 71.6 196 33.058 73

ЛШРМ 180 Л1

22 25.4

64-00420 64-00420

Д 60 0.03 Д 60 0.03

0.1 0.1

207 281 1000 40.1 1800 400 0.13516 4.253 71.6 207 281 1000 41.1 1800 460 0.13516 4.253 71.6

207 33.058 202 33.058

73 73

38.1 74-00770 Д 87 0.03 0.1 127 172 1000 73.5 2600 400 0.04505 1.418 41.3 189 11.019 73

30 64-00470 Д 50 0.03 0.1 190 252 1000 57.0 1500 400 0.10831 3.492 71.6 174 27.497 69

LSHRM 200 LQ1 30 64-00470 Y 60 0.03 0.1 190 252 1000 54.9 1800 400 0.10831 3.492 71.6 181 27.497 69 34.6 64-00470 Y 60 0.03 0.1 190 252 1000 56.1 1800 460 0.10831 3.492 71.6 177 27.497 69

52 74-01000 Д 87 0.03 0.1 135 179 1000 99.3 2600 400 0.03611 1.164 41.3 168 9.166 69

37 74-00660 Д 50 0.03 0.1 232 290 1000 70.1 1500 400 0.08873 3.028 72.3 164 24.063 69

ЛШРМ 225 СЗ1

37 42.7

74-00660 74-00660

Д 60 0.03 Д 60 0.03

0.1 0.1

232 290 1000 68.4 1800 400 0.08873 3.028 72.3 232 290 1000 69.2 1800 460 0.08873 3.028 72.3

168 24.063 166 24.063

69 69

64.2 84-01340 Д 87 0.03 0.1 157 196 1000 122 2600 400 0.02958 1.009 41.8 157 8.021 69

45 74-00770 Д 50 0.005 0.1 220 172 1200 82.1 1500 400 0.04505 2.467 76.6 201 23.645 67

ЛШРМ 225 МГ

45 54.3

74-00770 74-00770

Д 60 0.005 Д 60 0.005

0.1 0.1

220 172 1200 79.6 1800 400 0.04505 2.467 76.6 220 172 1200 83.1 1800 460 0.04505 2.467 76.6

207 23.645 198 23.645

67 67

79.2 84-01570 Д 87 0.005 0.1 150 117 1200 142 2600 400 0.01502 0.822 44.2 195 7.882 67

55 74-01000 Д 50 0.005 0.1 234 168 1200 99.4 1500 400 0.03388 2.015 76.6 199 19.664 67

LSHRM 250 ME 55 74-01000 y 60 0.005 0.1 234 168 1200 94.7 1800 400 0.03388 2.015 76.6 208 19.664 67 64 74-01000 y 60 0.005 0.1 234 168 1200 97.8 1800 460 0.03388 2.015 76.6 202 19.664 67 XNUMX XNUMX XNUMX XNUMX XNUMX XNUMX XNUMX XNUMX XNUMX XNUMX XNUMX XNUMX XNUMX XNUMX XNUMX XNUMX XNUMX XNUMX XNUMX XNUMX XNUMX XNUMX XNUMX XNUMX XNUMX XNUMX

95 94-02000 Д 87 0.005 0.1 136 98 1200 176 2600 400 0.01129 0.672 44.2 189 6.555 67

75 84-01340 Д 50 0.005 0.1 261 163 1200 134 1500 400 0.02461 1.677 81.7 185 16.736 63

ЛШРМ 280 СД

75 86.4

84-01340 84-01340

Д 60 0.005 Д 60 0.005

0.1 0.1

261 163 1200 130 1800 400 0.02461 1.677 81.7 261 163 1200 131 1800 460 0.02461 1.677 81.7

190 16.736 189 16.736

63 63

131 94-02240 Д 87 0.005 0.1 127 159 1200 231 2600 400 0.00821 0.559 47.2 180 5.579 63

90 84-01570 Д 50 0.005 0.1 261 154 1200 163 1500 400 0.01982 1.432 80.4 174 14.403 63

ЛШРМ 280 МД

90 104

84-01570 84-01570

Д 60 0.005 Д 60 0.005

0.1 0.1

261 154 1200 158 1800 400 0.01982 1.432 80.4 261 154 1200 155 1800 460 0.01982 1.432 80.4

179 14.403 182 14.403

63 63

156 104-02700 Д 87 0.005 0.1 149 177 1200 279 2600 400 0.00661 0.477 46.4 171 4.801 63

110 94-02000 Д 50 0.005 0.1 236 133 1200 199 1500 400 0.01534 1.161 76.6 165 11.750 61

ЛШРМ 315 СН1

110 132

94-02000 94-02240

Д 60 0.005 Д 60 0.005

0.1 0.1

236 133 1200 195 1800 400 0.01534 1.161 76.6 264 149 1200 202 1800 460 0.01534 1.161 76.6

168 11.750 163 11.750

61 61

192 114-04170 Д 87 0.005 0.1 164 185 1200 342 2600 400 0.00511 0.387 44.2 161 3.917 61

132 94-02240 Д 50 0.005 0.1 240 92 1400 235 1500 400 0.00952 1.057 86 194 9.591 59

ЛШРМ 315 МП

132 152

94-02240 94-02240

Д 60 0.005 Д 60 0.005

0.1 0.1

240 240

92 92

1400 234 1800 400 0.00952 1.057 1400 233 1800 460 0.00952 1.057

86 86

195 9.591 196 9.591

59 59

229 114-04170 Д 87 0.005 0.1 149 115 1400 415 2600 400 0.00317 0.352 49.6 186 3.197 59

160 104-03770 Д 50 0.005 0.1 264 96 1400 304 1500 400 0.00604 0.712 75.2 192 6.520 59

ЛШРМ 315 МП 160 104-02700 Y 60 0.005 0.1 223 81 1400 280 1800 400 0.00604 0.712 75.2 209 6.520 59

184 104-03770 Д 60 0.005 0.1 264 96 1400 294 1800 460 0.00604 0.712 75.2 198 6.520 59

200 114-04170 Д 50 0.005 0.1 247 82 1400 377 1500 400 0.00454 0.583 75.8 188 5.413 59

ЛШРМ 315 МР 200 114-04170 Д 60 0.005 0.1 247 82 1400 319 1800 400 0.00454 0.583 75.8 203 5.413 59

230 114-04170 Д 60 0.005 0.1 247 82 1400 366 1800 460 0.00454 0.583 75.8 193 5.413 59

75 84-01340 Д 50 0.005 0.1 261 163 1400 134 1500 400 0.02461 1.677 81.7 185 16.736 63

ФЛШРМ 280 СБ

75 86.4

84-01340 84-01340

Д 60 0.005 Д 60 0.005

0.1 0.1

261 163 1400 130 1800 400 0.02461 1.677 81.7 261 163 1400 131 1800 460 0.02461 1.677 81.7

190 16.736 189 16.736

63 63

131 94-02240 Д 87 0.005 0.1 127 80 1400 231 2600 400 0.0082 0.559 47.2 180 5.579 63

90 84-01570 Д 50 0.005 0.1 261 154 1500 163 1500 400 0.01982 1.432 80.4 174 14.403 63

ФЛШРМ 280 МД

90 104

84-01570 84-01570

Д 60 0.005 Д 60 0.005

0.1 0.1

261 154 1500 158 1800 400 0.01982 1.432 80.4 261 154 1500 155 1800 460 0.01982 1.432 80.4

179 14.403 182 14.403

63 63

156 104-02700 Д 87 0.005 0.1 149 95 1500 279 2600 400 0.00661 0.477 46.4 171 4.801 63

110 94-02000 Д 50 0.005 0.1 236 133 1500 199 1500 400 0.01534 1.161 76.6 165 11.750 61

FLSHRM 315 STB 110 94-02000 Y 60 0.005 0.1 236 133 1500 195 1800 400 0.01534 1.161 76.6 168 11.750 61 131 94-02240 Y 60 0.005 0.1 264 149 1500 202 1800 460 0.01534 1.161 76.6 163 11.750 61

192 114-04170 Д 87 0.005 0.1 164 92 1500 342 2600 400 0.00511 0.387 44.2 161 3.917 61

132 94-02240 Д 50 0.005 0.1 240 92 1600 236 1500 400 0.00952 1.057 86 194 9.591 59

ФЛШРМ 315 М

132 152

94-02240 94-02240

Д 60 0.005 Д 60 0.005

0.1 0.1

240 240

92 92

1600 234 1800 400 0.00952 1.057 1600 233 1800 460 0.00952 1.057

86 86

195 9.591 196 9.591

59 59

229 114-04170 Д 87 0.005 0.1 149 57 1600 415 2600 400 0.00317 0.352 49.6 186 3.197 59

160 104-03770 Д 50 0.005 0.1 264 96 1600 304 1500 400 0.00604 0.712 75.2 192 6.520 59

ФЛШРМ 315 ЛА 160 104-02700 Y 60 0.005 0.1 223 81 1600 280 1800 400 0.00604 0.712 75.2 209 6.520 59

184 104-03770 Д 60 0.005 0.1 264 96 1600 294 1800 460 0.00604 0.712 75.2 198 6.520 59

200 114-04170 Д 50 0.005 0.1 247 82 1600 377 1500 400 0.00454 0.583 75.8 188 5.413 59

ФЛШРМ 315 ЛБ 200 114-04170 Д 60 0.005 0.1 247 82 1600 349 1800 400 0.00454 0.583 75.8 203 5.413 59

230 114-04170 Д 60 0.005 0.1 247 82 1600 366 1800 460 0.00454 0.583 75.8 193 5.413 59

240 114-04800 Д 50 0.005 0.1 241 78 1600 457 1500 400 0.00385 0.512 74.5 172 4.780 59

ФЛШРМ 315 ЛЦ 240 114-04170 Д 60 0.005 0.1 217 70 1600 429 1800 400 0.00385 0.512 74.5 183 4.780 59

276 114-04800 Д 60 0.005 0.1 241 78 1600 443 1800 460 0.00385 0.512 74.5 177 4.780 59

44.845 -108 68.540 56 44.845 -108 68.540 56 44.845 -108 68.540 56 14.948 -108 22.850 56 40.485 -110 67.890 58 40.485 -110 67.890 58 40.485 -110 67.890 58 13.495 -110 22.630 58 31.534 -109 43.300 57 31.534 -109 43.300 57 31.534 -109 43.300 57 10.511 -109 14.430 57 25.019 -108 33.060 56 25.019 -108 33.060 56 25.019 -108 33.060 56 8.340 -108 11.020 56 19.675 -110 27.500 58 19.675 -110 27.500 58 19.675 -110 27.500 58 6.558 -110 9.170 58 16.697 -110 24.060 58 16.697 -110 24.060 58 16.697 -110 24.060 58 5.566 -110 8.020 58 13.172 -111 23.640 59 13.172 -111 23.640 59 13.172 -111 23.640Р59Р4.391Р111Р7.880Р59Р10.923А 111, 19.660 -59 10.923 111 19.660 -59 10.923 111 19.660 -59 3.641 111 6.550 -59 8.988 114 16.740 -61 8.988 114 16.740 -61 8.988 114 16.740 -61 2.996 114 5.580 -61 7.519 114 14.400 -61 7.519 114 14.400 -61 7.519 114 14.400 -61 -2.506 114 -4.800 -61 -6.646 -115 -11.750. 62 -6.646 115 11.750 62 -6.646 115 11.750 62 -2.215 115 3.920 62 -5.620 116 9.590 63 -5.620 116 9.590 63 -5.620 116 9.590 63 -1.873 116 -3.200 63 3.800 116 -6.520 63 3.800 116 -6.520 63 3.800 116 -6.520 63 3.096 116 -5.410 63 3.096 116 -5.410 63 3.096 116 5.410 63

8.988 -114 16.740 61 8.988 -114 16.740 61 8.988 -114 16.740 61 2.996 -114 5.580 61 7.519 -114 14.400 61 7.519 -114 14.400 61 7.519 -114 14.400 61 2.506 -114 4.800 61 6.646. 115 -11.750 62 6.646 115 -11.750 62 6.646 115 -11.750 62 2.215 115 -3.920 62 5.620 116 -9.590 63 5.620 116 -9.590 63 5.620 116 -9.590 63 1.873 116 -3.200 63 3.800 116 -6.520 63 3.800 116 -6.520 63 3.800 116 -6.520 63 3.096 116 -5.410 63 3.096 116 -5.410 63 3.096 116 -5.410 63 2.550 116 -4.780 63 2.550

6

Dyneo+ с Unidrive M70x без обратной связи по положению Руководство по вводу в эксплуатацию

6069 эн – 2022.06/с

ВВОД В ЭКСПЛУАТАЦИЮ С ПОМОЩЬЮ UNIDRIVAEPPME7N0DXIX БЕЗ ОБРАТНОЙ СВЯЗИ ПО ПОЛОЖЕНИЮ

Тип двигателя

ПРИВОД кВт

M70x

Связь

3000 об/мин ДИАПАЗОН ПАРАМЕТРОВ

#03.010 #03.011 #04.013 #04.014 #04.015 #05.007 #05.008 #05.009 #05.017 #05.024 #05.033 #05.069 #05.072 #05.075

#05.078

#05.082

# 05.084 # 05.087

Hz

Увеличение скорости Кр

Скорость Ток Ток Тепловой Номинал

Усиление Усиление Усиление постоянный ток

Ки Кр Ки

(S)

(A)

Номинальная скорость (об / мин)

Номинальный статор

обtagе Сопротивление

(V)

()

Ld (мГн)

OverBEMF текущий Lq @0A

(В/об/мин) уровень срабатывания (мГн) (%)

IQ (%)

Lq @ Iq (мГн)

Идентификатор (%)

Lq @ Id (мГн)

Угол крутящего момента

(°)

11 44-00172 Д 100 0.005 0.05 95 213 800 20.3 3000 400 0.25015 4.781 43.3 238 41.329 73

ЛШРМ 160 МР1

11 12.7

44-00172 44-00172

Д 120 0.005 0.05 Д 120 0.005 0.05

95 95

213 213

800 800

19.8 3600 400 0.25015 4.781 43.3 19.9 3600 460 0.25015 4.781 43.3

244 41.329 243 41.329

73 73

19.1 64-00420 Д 173 0.005 0.05 78 173 800 35.8 5200 400 0.08338 1.594 25 223 13.776 73

15 54-00300 Д 100 0.005 0.05 117 223 800 27.7 3000 400 0.12877 2.884 39.3 254 25.538 75

ЛШРМ 160 МР1

15 17.3

54-00270 64-00350

Д 120 0.005 0.05 Д 120 0.005 0.05

90 117

172 223

800 800

27.1 3600 400 0.12877 2.884 39.3 28.2 3600 460 0.12877 2.884 39.3

259 25.538 249 25.538

75 75

26.0 64-00470 Д 173 0.005 0.05 52 100 800 50.9 5200 400 0.04292 0.961 22.7 226 8.513 75

18.5 64-00350 Д 100 0.005 0.05 117 223 800 33.7 3000 400 0.12877 2.884 39.3 209 25.538 71

ЛШРМ 160 ЛР1

18.5 21.3

64-00350 64-00350

Д 120 0.005 0.05 Д 120 0.005 0.05

117 117

223 223

800 800

32.9 3600 400 0.12877 2.884 39.3 33.1 3600 460 0.12877 2.884 39.3

214 25.538 212 25.538

71 71

32.1 74-00660 Д 173 0.005 0.05 74 140 800 61.8 5200 400 0.0429 0.961 22.7 186 8.513 71

22 64-00420 Д 100 0.03 0.1 104 192 800 41.8 3000 400 0.0925 2.134 38.2 216 15.79 76

ЛШРМ 180 М1

22 25.5

64-00420 64-00420

Д 120 0.03 Д 120 0.03

0.1 0.1

104 104

192 192

800 800

40.2 3600 400 0.0925 2.134 38.2 41.4 3600 460 0.0925 2.134 38.2

224 15.79 218 15.79

76 76

38.1 74-00770 Д 173 0.03 0.1 64 118 800 73.6 5200 400 0.0308 0.711 22 200 5.263 76

30 64-00470 Д 100 0.03 0.1 116 215 800 56.7 3000 400 0.0925 2.134 38.2 159 15.79 69

ЛШРМ 200 LQ1 30 64-00470 Y 120 0.03 0.1 116 215 800 57.1 3600 400 0.0925 2.134 38.2 158 15.79 69

34.7 64-00470 Д 120 0.03 0.1 116 215 800 56.5 3600 460 0.0925 2.134 38.2 160 15.79 69

37 74-00660 Д 100 0.03 0.1 109 174 800 69.9 3000 400 0.05333 1.419 36.6 178 10.825 71

ЛШРМ 200 LQ1 37 74-00660 Y 120 0.03 0.1 109 174 800 68.8 3600 400 0.05333 1.419 36.6 181 10.825 71

42.9 74-00660 Д 120 0.03 0.1 109 174 800 69 3600 460 0.05333 1.419 36.6 181 10.825 71

45 74-00770 Д 100 0.03 0.1 106 142 800 84.1 3000 400 0.03715 1.185 37.8 180 9.208 71

ЛШРМ 225 МГ1 45 74-00770 Y 120 0.03 0.1 106 142 800 82 3600 400 0.03715 1.185 37.8 184 9.208 71

52 74-00770 Д 120 0.03 0.1 106 142 800 83.4 3600 460 0.03715 1.185 37.8 181 9.208 71

55 74-01000 Y 100 0.005 0.1 118 104 1100 100 3000 400 0.02106 1.019 43.4 226 9.52

71

ЛШРМ 250 МЭ 55 74-01000 Y 120 0.005 0.1 118 104 1100 101 3600 400 0.02106 1.019 43.4 225 9.52

71

63.7 74-01000 Y 120 0.005 0.1 118 104 1100 100 3600 460 0.02106 1.019 43.4 226 9.52

71

75 84-01340 Д 100 0.005 0.1 123 109 1100 138 3000 400 0.01637 0.794 38.3 185 7.412 65

ЛШРМ 280 СК 75 84-01340 Д 120 0.005 0.1 123 109 1100 136 3600 400 0.01637 0.794 38.3 187 7.412 65

86.3 84-01340 Д 120 0.005 0.1 123 109 1100 135 3600 460 0.01637 0.794 38.3 189 7.412 65

90 84-01570 Д 100 0.005 0.1 112 88 1100 167 3000 400 0.01125 0.617 38.3 190 5.911 65

ЛШРМ 280 МС 90 84-01570 Y 120 0.005 0.1 112 88 1100 160 3600 400 0.01125 0.617 38.3 198 5.911 65

104 94-02000 Д 120 0.005 0.1 125 98 1100 168 3600 460 0.01125 0.617 38.3 189 5.911 65

110 94-02000 Д 100 0.005 0.1 102 72 1100 201 3000 400 0.00836 0.504 38.3 189 4.916 69

ЛШРМ 315 СН1 110 94-02000 Д 120 0.005 0.1 102 72 1100 195 3600 400 0.00836 0.504 38.3 195 4.916 69

127 94-02000 Д 120 0.005 0.1 102 72 1100 197 3600 460 0.00836 0.504 38.3 193 4.916 69

132 94-02240 Д 100 0.005 0.1 107 70 1100 237 3000 400 0.00722 0.469 40.2 178 4.639 69

ЛШРМ 315 МН1 132 94-02240 Д 120 0.005 0.1 107 70 1100 234 3600 400 0.00722 0.469 40.2 181 4.639 69

152 94-02240 Д 120 0.005 0.1 107 70 1100 232 3600 460 0.00722 0.469 40.2 182 4.639 69

160 104-02700 Д 100 0.005 0.1 112 66 1100 289 3000 400 0.00495 0.358 40.2 188 3.601 65

ЛШРМ 315 МН1 160 104-02700 Д 120 0.005 0.1 112 66 1100 273 3600 400 0.00495 0.358 40.2 199 3.601 65

184 104-02700 Д 120 0.005 0.1 112 66 1100 283 3600 460 0.00495 0.358 40.2 192 3.601 65

200 114-04170 Д 100 0.005 0.1 123 69 1100 366 3000 400 0.00383 0.29 38.3 172 2.937 63

ЛШРМ 315 МН1 200 114-04170 Д 120 0.005 0.1 123 69 1100 365 3600 400 0.00383 0.29 38.3 173 2.937 63

233 114-04170 Д 120 0.005 0.1 123 69 1100 359 3600 460 0.00383 0.29 38.3 175 2.937 63

75 84-01340 y 100 0.005 0.1 123 109 1800 138 3000 400 0.01637 0.794 38.3 185 7.412 65 FLSHRM 280 SA 75 84-01340 Y 120 0.005 0.1 123 109 1800 136 3600 400 0.01637 0.794 38.3 187 7.412 65 XNUMX XNUMX XNUMX XNUMX XNUMX XNUMX XNUMX XNUMX XNUMX XNUMX XNUMX XNUMX XNUMX XNUMX XNUMX XNUMX XNUMX XNUMX XNUMX XNUMX XNUMX XNUMX XNUMX XNUMX XNUMX. XNUMX XNUMX XNUMX XNUMX XNUMX XNUMX XNUMX XNUMX XNUMX XNUMX XNUMX XNUMX XNUMX XNUMX.

86.3 84-01340 y 120 0.005 0.1 123 109 1800 135 3600 460 0.01637 0.794 38.3 189 7.412 65 90 84-01570 y 100 0.005 0.1 112 88 1800 167 3000 400 0.01125 0.617 38.3 190. 5.911 65 280 90 84 01570 120 0.005 0.1 112 88 1800 160 3600 400-0.01125 Y 0.617 38.3 198 5.911 65 108 94 02000 120 0.005 0.1 125 98 1800 168 3600 460-0.01125 Y 0.617 38.3 189 5.911 65 110 94 02000 100 0.005 0.1 102 72 1800 201 FLSHRM 3000 STA 400 0.00836-0.504 Y 38.3 189 4.916 69 315 110 94 02000 120 0.005 0.1 102 72 1800 195 3600 400-0.00836 Y 0.504 38.3 195 4.916 69 127 94 02000 120 0.005 0.1 102 72 1800 197 3600 460-0.00836 Y 0.504 38.3 193 4.916 69 132 94 02240 100 0.005 0.1 107 70 1800 237 FLSHRM 3000 MT 400 0.00722-0.469 Y 40.2 178 4.639 69 315 132 94 02240 120 0.005 0.1 107 70 1800 234 3600 400-0.00722 0.469 40.2. 181 4.639 69 152 94 02240 120 0.005 0.1 107 70 1800 232 3600. 460 0.00722 0.469 40.2 182 4.639 69 160 104 02700 100-0.005 Д 0.1 112 66 1800 289 3000 400 0.00495 0.358 40.2 188 3.601 65ШМ 315 160LTA 104 02700-120 y 0.005 0.1 112 66 1800 273 3600 400 0.00495 0.358 40.2 199 3.601 65 184 104 02700-120 Y 0.005 0.1 112 66 1800 283 3600 460 0.00495 0.358 40.2 192 3.601 65 200 114 04170 100 0.005 0.1 123 69 1800 366-3000 400 0.00383 0.29 38.3 172 2.937 63 315 200 114 04170 120 0.005 0.1 123. 69 1800 365 3600 400 0.00383 0.29 38.3 173 2.937 63 FLSHRM 233 LTB 114 04170-120 y 0.005 0.1 123 69 1800 359 3600 460 0.00383 0.29 38.3 175 2.937 63 XNUMX XNUMX XNUMX-XNUMX y XNUMX XNUMX XNUMX XNUMX-XNUMX y XNUMX XNUMX XNUMX XNUMX XNUMX XNUMX XNUMX XNUMX

27.751 -108 41.329 56

27.751 -108 41.329 56

27.751 -108 41.329 56

9.25 -108 13.776 56

17.72 -106 25.538 55

17.72 -106 25.538 55

17.72 -106 25.538 55

5.907 -106 8.513 55

17.009 -109 25.538 57

17.009 -109 25.538 57

17.009 -109 25.538 57

5.70 -109 8.513 57

12.578 -105 15.79 54

12.578 -105 15.79 54

12.578 -105 15.79 54

4.20 -105 5.263 54

11.032 -110 15.79 58

11.032 -110 15.79 58

11.032 -110 15.79 58

7.982 -109 10.825 57

7.982 -109 10.825 57

7.982 -109 10.825 57

6.802 -109 9.208 57

6.802 -109 9.208 57

6.802 -109 9.208 57

5.657-109

9.52

57

5.657-109

9.52

57

5.657-109

9.52

57

4.063 -113 7.412 60

4.063 -113 7.412 60

4.063 -113 7.412 60

3.648 -113 5.911 60

3.648 -113 5.911 60

3.648 -113 5.911 60

2.56 -110 4.916 58

2.56 -110 4.916 58

2.56 -110 4.916 58

2.28 -110 4.639 58

2.28 -110 4.639 58

2.28 -110 4.639 58

1.989 -113 3.601 60

1.989 -113 3.601 60

1.989 -113 3.601 60

1.734 -114 2.937 61

1.734 -114 2.937 61

1.734 -114 2.937 61

4.063 -113 7.412 60 4.063 -113 7.412 60 4.063 -113 7.412 60 3.648 -113 5.911 60 3.648 -113 5.911 60 3.648 -113 5.911 60 2.56 -110 4.916 58 2.56 -110 4.916 58 2.56 -110 4.916 58 2.28 -110 4.639 58 2.28 -110 4.639 58 2.28 -110 4.639 58 2.21 -113 3.601 60 2.21 -113 3.601 60 2.21 -113 3.601 60 1.734 -114 2.937 61 1.734 -114 2.937 61 1.734

Dyneo+ с Unidrive M70x без обратной связи по положению Руководство по вводу в эксплуатацию

7

6069 эн – 2022.06/с

Штаб-квартира Moteurs Leroy-Somer: бульвар Марселлен Леруа — CS 10015

16915 АНГУЛЕМ Cedex 9

Компания с ограниченной ответственностью с капиталом 38,679,664 338 567 RCS Angoulême 258 XNUMX XNUMX

www.leroy-somer.com

Документы / Ресурсы

|

Высокопроизводительный привод переменного тока Nidec M700 [pdf] Руководство пользователя Высокопроизводительный привод переменного тока M700, M700, Высокопроизводительный привод переменного тока, Высокопроизводительный привод переменного тока, Привод переменного тока, Высокопроизводительный привод переменного тока M700 |

10

This section of the manual provides basic diagnostic information intended to enable

resolution of the most common problems encountered when setting up the Ethernet

interface on an Ethernet network.

A high percentage of problems reported are basic setup problems that can be avoided

by using the following pages. Start by using the Diagnostic flow chart on page 188 to

determine the possible cause of a problem. If after following the flow chart you are still

experiencing problems please contact your supplier or local drive supplier for support.

Please note that support will be limited to the setting up and networking of the drive and

NOTE

not network infrastructure design.

10.1

LED diagnostics

Each Ethernet connection has an associated LED to aid diagnostics, in the case of the

onboard Ethernet interface, this LED is mounted below the associated RJ45 connector;

the SI-Ethernet option module has two LEDs mounted on the topside of the module

(Figure 2-1 SI-Ethernet on page 8).

The connection status for the first port (nearest the grounding tab) is indicated by LED

«A», and the second port is indicated by LED «B».

The function of these LEDs are described in table 10.1 LED functionality below.

Table 10.1 LED functionality

LED State

Steady green

Flashing green

10.2

Drive trip display codes

If the Ethernet interface detects an error during operation, it will force a trip on the

drive. However, the trip string displayed on the drive will only indicate which slot

initiated the trip, if the error originated from the onboard Ethernet interface then the

default slot will be 4, however, if the SI-Ethernet option module generated the trip then

the slot number will be the slot number the SI-Ethernet option module is fitted to. The

exact reason for the trip will be indicated in the drive trip code parameters (Pr 0.10.020

and Pr 0.10.070).

Table 10.2 Drive trip indications on page 184 following shows the possible trips that will

be displayed on the drive when a problem is detected or the Ethernet interface initiates

a trip.

SI-Ethernet User Guide

Issue: 1

Description

Off

Ethernet connection not detected.

Ethernet connection detected but no data.

Ethernet communication detected and data flow.

183

-

Page 1

User Guide Free Standing Model sizes 6 to 9 Universal Variable Speed AC Drive for induction and servo motors Part Number: 0471-0122-01 Issue: 1 www.controltechniques.com… -

Page 2

General Information The manufacturer accepts no liability for any consequences resulting from inappropriate, negligent or incorrect installation or adjustment of the optional operating parameters of the equipment or from mismatching the variable speed drive with the motor. The contents of this guide are believed to be correct at the time of printing. In the interests of a commitment to a policy of continuous development and improvement, the manufacturer reserves the right to change the specification of the product or its performance, or the contents of the guide, without notice. -

Page 3

How to use this guide This user guide provides complete information for installing and operating the drive from start to finish. The information is in logical order, taking the reader from receiving the drive through to fine tuning the performance. NOTE There are specific safety warnings throughout this guide, located in the relevant sections. -

Page 4: Table Of Contents

4.13 SAFE TORQUE OFF (SECURE DISABLE) ..69 10.4 Getting started ……….126 10.5 Onboard PLC parameters …….. 126 10.6 Onboard PLC trips ……….. 127 10.7 Onboard PLC and the SMARTCARD ….127 Unidrive SP Free Standing User Guide www.controltechniques.com Issue Number: 1…

-

Page 5: Table 2-1 400V Standard (Ip21) Free Standing Drive Table

14.3 AC supply specification ……..260 14.4 Maximum continuous output current ….260 14.5 Safety label …………260 14.6 UL listed accessories ……..260 List of figures ……..261 List of tables ……..263 Index ………..265 Unidrive SP Free Standing User Guide Issue Number: 1 www.controltechniques.com…

-

Page 6

*Clause 5.2.3.8 of EN 61800-5-1:2003 (breakdown of components test) has been amended to eliminate the 30A ground (earth) fuse, in accordance with the draft edition 2 of IEC 61800-5-1 Unidrive SP Free Standing User Guide www.controltechniques.com Issue Number: 1… -

Page 7: Safety Information

The system designer is responsible for ensuring that the complete system is safe and designed correctly according to the relevant safety standards. Independent approval by BGIA has been given. Unidrive SP Free Standing User Guide Issue Number: 1 www.controltechniques.com…

-

Page 8: Product Information

Information Product information Unidrive SP Free Standing cubicles are made up to one or more SPM modules (SPMA / SPM), depending on size and current ratings. Model number The way in which the model numbers for the Unidrive SP range are formed is illustrated below.

-

Page 9: Ratings

Data Information Ratings The Unidrive SP is dual rated. Available output The setting of the motor rated current determines which rating applies — Overload limit — current Heavy Duty Heavy Duty or Normal Duty. Maximum The two ratings are compatible with motors designed to IEC60034.

-

Page 10

690V 575V current current 690V 575V current current 66X1 66X2 76X1 76X2 5 6 5 7 5 8 86X1 86X2 86X3 86X4 96X1 96X3 96X4 96X5 Unidrive SP Free Standing User Guide www.controltechniques.com Issue Number: 1… -

Page 11: Table 2-3 400V Ip23 Free Standing Drive Ratings At

76X2-E23 5 6 5 7 5 8 86X1-E23 86X2-E23 86X3-E23 86X4-E23 96X1-E23 96X3-E23 96X4-E23* 96X5-E23* * Ratings for SP96X4 E23 and SP96X5 E23 are for an ambient temperature of 30°C Unidrive SP Free Standing User Guide Issue Number: 1 www.controltechniques.com…

-

Page 12: Operating Modes

2.3.4 Servo For use with permanent magnet brushless motors with a feedback The Unidrive SP is designed to operate in any of the following modes: device installed. 1. Open loop mode The drive directly controls the speed of the motor using the feedback Open loop vector mode device to ensure the rotor speed is exactly as demanded.

-

Page 13: Drive Features

3 Control terminals Encoder connection Relay terminals Braking terminals (optional) Motor Motor connections connections Ground connections Ground connections Braking terminals (optional) AC supply connections Internal fuse location Internal fuse location Unidrive SP Free Standing User Guide Issue Number: 1 www.controltechniques.com…

-

Page 14: Figure 2-5 Features Of The Size 8 And 9 Free Standing

Relay terminals Brake connections (optional) Brake connections (optional) Motor connections Motor connections 24V power supply Ground connections AC supply connections AC supply connections Internal fuse Internal fuse location location Unidrive SP Free Standing User Guide www.controltechniques.com Issue Number: 1…

-

Page 15: Nameplate Description

Heavy Duty / No. of phases & frequency Normal Duty Typical input current for rating output current Normal Duty rating Options Figure 2-7 Options available with Unidrive SP SMARTCARD* Keypad Feedback Automation Fieldbus CT Comms cable * A SMARTCARD is provided as standard. For further information, refer to Chapter 9 SMARTCARD operation on page 119.

-

Page 16: Table 2-7 Solutions Module Identification

Additional I/O with overvoltage protection up to 48V SM-I/O 24V Cobalt Blue 2 x Analog outputs (current modes) Protected 4 x Digital input / outputs, 3 x Digital inputs, 2 x Relay outputs Unidrive SP Free Standing User Guide www.controltechniques.com Issue Number: 1…

-

Page 17

Pale Green SM-LON LonWorks adapter for communications with the drive SLM interface The SM-SLM allows SLM feedback to be connected directly to the Unidrive SP drive and allows operation in either of the Orange SM-SLM following modes: • Encoder only mode •… -

Page 18: Items Supplied With The Drive

The drive is supplied with a printed manual, a SMARTCARD, a safety information booklet, the Certificate of Quality, and a CD ROM containing all related product documentation and software tools. All accessories (e.g. control connectors) are supplied installed to the drive. Unidrive SP Free Standing User Guide www.controltechniques.com Issue Number: 1…

-

Page 19: Mechanical Installation

Lift the drive by the method detailed in Figure 3-2 on page 20. Do not tilt the drive. The centre of gravity of the unit is high. An overturning unit can cause physical injury. Unidrive SP Free Standing User Guide Issue Number: 1 www.controltechniques.com…

-

Page 20: Planning The Installation

0.5 metres must be maintained between drives. Certain Unidrive SP size 6 and 7 Free Standing drives are fitted with smaller roof fans, baffling should also be fitted if installed side by side Unidrive SP Free Standing User Guide www.controltechniques.com…

-

Page 21: Figure 3-3 Location And Identification Of Terminal Covers For Free Standing Drives

Data Information Figure 3-3 Location and identification of terminal covers for Free Standing drives Control Control Input / output Input / output Input / output Unidrive SP Free Standing User Guide Issue Number: 1 www.controltechniques.com…

-

Page 22: Figure 3-4 Removing The Size 6, 7 And 8 Terminal Covers From The Free Standing Drive

Started parameters the motor operation parameters Data Information Figure 3-4 Removing the size 6, 7 and 8 terminal covers from the Free Standing drive Pozi Pz4 Pozi Pz2 Pozi Pz4 Unidrive SP Free Standing User Guide www.controltechniques.com Issue Number: 1…

-

Page 23: Figure 3-5 Removing The Size 9 Terminal Covers From The Free Standing Drive

Installation Started parameters the motor operation parameters Data Information Figure 3-5 Removing the size 9 terminal covers from the Free Standing drive Pozi Pz4 Pozi Pz2 Pozi Pz4 Pozi Pz4 Unidrive SP Free Standing User Guide Issue Number: 1 www.controltechniques.com…

-

Page 24: Installing Fuses In A Free Standing Drive

3.4.2 Size 8 & 9 (with date code S18 or later) Secure fuse to upper Unidrive SP size 8 and 9 Free Standing with date code of S18 or later mounting stud with M10 nut can accept type DIN80 or type DIN110 fuses.

-

Page 25: Figure 3-10 Preparation For Baying The Incomer/Applications Shell

Data Information Figure 3-10 Preparation for baying the incomer/applications shell An incomer shell is supplied with no side panels. Figure 3-11 Preparation for baying the size 8 Free Standing drive Unidrive SP Free Standing User Guide Issue Number: 1 www.controltechniques.com…

-

Page 26: Figure 3-12 Preparation For Baying The Size 9 Free Standing Drive (Slave And Master)

Lift the drive by the method detailed in Figure 3-2 on page 20. Do not tilt the drive. The centre of gravity of the unit is high. WARNING An overturning unit can cause physical injury. Unidrive SP Free Standing User Guide www.controltechniques.com Issue Number: 1…

-

Page 27: Figure 3-13 Location Of The Rectifier Status Connectors For Size 9 Free Standing Drive

2. M6 star lock washer 3. In comer frame Free Standing drive frame 5. M6 screw Once the Free Standing drive and incomer are in position they must be bolted to the floor Unidrive SP Free Standing User Guide Issue Number: 1 www.controltechniques.com…

-

Page 28: Figure 3-15 Installing The Parallel Cable From A Size 9 Master To Slave

1. Remove size 9 slave interface cover 2. Connect the paralleling cable to the size 9 slave input slot 3. Replace size 9 slave interface cover 4. Replace all size 9 Free Standing drive panels Unidrive SP Free Standing User Guide www.controltechniques.com Issue Number: 1…

-

Page 29: Figure 3-16 Input Busbar Connections Between The

Fit the input parallel busbar with (M8 x 20 screws) (torque 17Nm [12.5 lb ft]); and M6 x 30 insulating spacer with (M6 x 12 screws) (torque 12Nm [8.85 lb ft]) Fit the input parallel busbar with (M8 x 20 screws) (torque 17Nm [12.5 lb ft]) Unidrive SP Free Standing User Guide Issue Number: 1 www.controltechniques.com…

-

Page 30: Figure 3-17 Input Busbar Connections Between The

4. Fit: 2 x 12 pulse busbars, 4 x 30mm insulator, 6 x M6x16 screws, 4 x M8x20 screws, L1(A) terminal marker NOTE Pre-fit insulators to busbars before fitting to cubicle. Unidrive SP Free Standing User Guide www.controltechniques.com Issue Number: 1…

-

Page 31: Figure 3-18 Baying A 6 Pulse Incomer To A 6 Pulse Free Standing Drive (Size 8 Shown)

The images below shows how to remove the gland plate from a Free Standing drive. Figure 3-19 Removing the cable gland plate from the Free Standing drive for «glanding off» the cable Unidrive SP Free Standing User Guide Issue Number: 1…

-

Page 32: Free Standing Drive Dimensions

Data Information Free standing drive dimensions Figure 3-20 Incomer/applications shell dimensions 400mm 600mm (15.748in) (23.622in) ∅20mm (0.787in) 520mm 600mm (20.472in) (23.622in) 315mm (12.402in) 404.6mm (15.929in) Unidrive SP Free Standing User Guide www.controltechniques.com Issue Number: 1…

-

Page 33: Figure 3-21 Size 6 And 7 Drives With Integral Line Side

Started parameters the motor operation parameters Data Information Figure 3-21 Size 6 and 7 drives with integral line side options 400mm 630mm (15.75in) (24.80in) ∅20mm (0.79in) 315mm (12.40in) 404.6mm (15.93in) Unidrive SP Free Standing User Guide Issue Number: 1 www.controltechniques.com…

-

Page 34: Figure 3-22 Size 6, 7 And 8 Free Standing Drive Dimensions

Dimensions for IP23 drives are:- H — 2248.5 mm (88.521 in) D — 653 mm (25.70 in) W =- 404.6 mm (15.929 in) 520mm 600mm (20.472in) (23.622in) 315mm (12.402in) 404.6mm (15.929in) Unidrive SP Free Standing User Guide www.controltechniques.com Issue Number: 1…

-

Page 35: Figure 3-23 Size 9 Free Standing Drive Dimensions

Dimensions for IP23 drives are:- H — 2248.5 mm (88.521 in) D — 653 mm (25.70 in) W — 809.2 mm (31.85 in) 520mm 600mm (20.472in) (23.622in) 89.60mm (3.528in) 719.60mm (28.331in) 809.20mm (31.858in) Unidrive SP Free Standing User Guide Issue Number: 1 www.controltechniques.com…

-

Page 36: External Emc Filter

28 kg (61.7 lb) SP96X5 4200-6814 18 kg (39.7 lb) 4200-6807 28 kg (61.7 lb) NOTE Contact the supplier of the drive for information on EMC filters for 12 pulse drives. Unidrive SP Free Standing User Guide www.controltechniques.com Issue Number: 1…

-

Page 37: Figure 3-24 Size 6 , 7, 8 And 9 Epcos External Emc Filter

42±3 mm 4200 — 6806 260 mm 116 mm 434±3 mm Ø11 350 mm 145±0.5 mm 4200 — 6807 80 mm 275 mm 3 mm 52±3 mm 454±3 mm Ø14 Unidrive SP Free Standing User Guide Issue Number: 1 www.controltechniques.com…

-

Page 38: Figure 3-25 Size 8 And 9 Schaffner External Emc Filter

145±1 mm 280±1 mm 255 mm 50 mm 177 mm 450 mm 4200-6814 3 mm Ø14 4200-6810 400±1 mm 170±1 mm 300±1 mm 275 mm 90 mm 160 mm 580 mm Unidrive SP Free Standing User Guide www.controltechniques.com Issue Number: 1…

-

Page 39: Electrical Terminals

Input terminals M10 nut Internal fuse 17mm AF location M10 nut Internal fuse 17mm AF location M10 nut Input terminals 17mm AF M10 nut 17mm AF Unidrive SP Free Standing User Guide Issue Number: 1 www.controltechniques.com…

-

Page 40: Figure 3-27 Locations Of The Power And Ground Terminals

17mm AF terminals M10 nut 17mm AF Ground stud Ground stud Input busbar 10.5mm Input busbar 10.5mm Internal fuse location M10 nut Internal fuse 17mm AF location M10 nut 17mm AF Unidrive SP Free Standing User Guide www.controltechniques.com Issue Number: 1…

-

Page 41: Table 3-5 Drive Control And Relay Terminal Data

Max torque 4200-6808 48 N m 4200-6811 48 N m 4200-6812 48 N m 4200-6813 48 N m 4200-6809 83 N m 4200-6814 83 N m 4200-6810 83 N m Unidrive SP Free Standing User Guide Issue Number: 1 www.controltechniques.com…

-

Page 42: Solutions Module Installation / Removal

To remove, while pressing the tabs inwards (A), gently lift the keypad in the direction indicated (B). NOTE The keypad can be installed / removed while the drive is powered up and running a motor, providing that the drive is not operating in keypad mode. Unidrive SP Free Standing User Guide www.controltechniques.com Issue Number: 1…

-

Page 43: Routine Maintenance

Ensure all screw terminals remain tight Ensure all crimp terminals remains tight – check for any discoloration which could indicate Crimp terminals overheating Cables Check all cables for signs of damage Unidrive SP Free Standing User Guide Issue Number: 1 www.controltechniques.com…

-

Page 44: Electrical Installation

If the motor load is capable of rotating the motor when the supply is disconnected, then the motor must be isolated from the drive before gaining access to any live parts. Unidrive SP Free Standing User Guide www.controltechniques.com Issue Number: 1…

-

Page 45: Power Connections

Started parameters the motor operation parameters Data Information Power connections 4.1.1 AC and DC connections Figure 4-1 Unidrive SP size 6 Free Standing drive power connections Optional (SPxx1x brake versions only) Thermal overload protection device Motor Optional ground connection Output connections…

-

Page 46: Figure 4-2 Unidrive Sp Size 7 Free Standing Drive Power Connections

Information information Installation Installation Started parameters the motor operation parameters Data Information Figure 4-2 Unidrive SP size 7 Free Standing drive power connections Optional (SP7x1x brake versions only) Thermal overload protection device Motor Optional ground connection Output connections Input connections…

-

Page 47: Figure 4-3 Unidrive Sp Size 8 Free Standing Drive Power Connections

Information information Installation Installation Started parameters the motor operation parameters Data Information Figure 4-3 Unidrive SP size 8 Free Standing drive power connections Per cubicle (SP8x1x brake versions only) Thermal Thermal overload overload protection protection device device Motor Optional ground…

-

Page 48: Figure 4-4 Unidrive Sp Size 9 Free Standing Drive Power Connections

Installation Installation Started parameters the motor operation parameters Data Information Figure 4-4 Unidrive SP size 9 Free Standing drive power connections Per cubicle (SP9x1x brake versions only) Thermal Thermal overload overload protection protection device device Both motor cables must be the same length.

-

Page 49: Figure 4-5 Unidrive Sp Size 6 And 7 Free Standing Drive Ground Connections

Data Information 4.1.2 Ground connections Figure 4-6 Unidrive SP size 8 and 9 Free Standing drive ground connections Figure 4-5 Unidrive SP size 6 and 7 Free Standing drive ground connections Ground Ground connections connections The ground loop impedance must conform to the requirements of local safety regulations.

-

Page 50: Ac Supply Requirements

3.5% negative phase sequence (equivalent to 5% voltage imbalance between phases). Severe disturbances may be caused by the following factors, for example: • Power factor correction equipment connected close to the drive. Unidrive SP Free Standing User Guide www.controltechniques.com Issue Number: 1…

-

Page 51: Auxiliary Power Supply

For all size 6 & 7, and size 8 & 9 units that have a date code of R48 and later, a mains transformer has been introduced for Unidrive SP 8XXX and 9XXX Free Standing drives. The new transformer eliminates the requirement for a separate external 230V power source.

-

Page 52: Figure 4-9 Location Of Size 8 And 9 Free Standing Drive Mains Transformer

Until the cable is moved from the parked position to the terminals identified above, the drive will not power up using the three phase supply. The ground and 0V wires are also pre-fitted and must not be changed. Unidrive SP Free Standing User Guide www.controltechniques.com…

-

Page 53: Control 24Vdc Supply

Data Information Control 24Vdc supply The 24Vdc input on the Unidrive SP has three main functions. • It can be used to supplement the drive’s own internal 24V when multiple SM-Universal Encoder Plus, SM-Encoder Output Plus or SM-I/O Plus or SM-I/O32 modules are being used, and the current drawn by these modules is greater than the drive can supply.

-

Page 54: Table 4-3 400V Free Standing Drive Input Current, Fuse And Cable Size Rating

The Semiconductor IEC class aR fuses for sizes 6, 7, 8 and 9 drives must be installed within the enclosure, see Figure on page 24. These parts may be purchased from Control Techniques, see Table 4-5. Unidrive SP Free Standing User Guide www.controltechniques.com Issue Number: 1…

-

Page 55: Table 4-5 Fuses

To ensure that the motor and cable are protected against overload, the drive must be programmed with the correct motor rated current. Unidrive SP Free Standing User Guide Issue Number: 1 www.controltechniques.com…

-

Page 56: Output Circuit And Motor Protection

This is because of the high rate of change of voltage, in conjunction with the impedance of the motor cable and the distributed nature of the motor winding. Unidrive SP Free Standing User Guide www.controltechniques.com Issue Number: 1…

-

Page 57: Figure 4-11 Preferred Chain Connection For Multiple Motors

The Drive Enable terminal (T31) when opened provides a SECURE DISABLE function. This can in many cases replace output contactors. For further information see section 4.13 SAFE TORQUE OFF (SECURE DISABLE) on page 69. Unidrive SP Free Standing User Guide Issue Number: 1 www.controltechniques.com…

-

Page 58: Braking

Optimization of the braking resistor requires a careful consideration of the braking duty. Unidrive SP Free Standing User Guide www.controltechniques.com Issue Number: 1…

-

Page 59: Ground Leakage

Braking resistor software overload protection WARNING The Unidrive SP software contains an overload protection function for a If an external EMC filter is used, a delay of at least 50ms should be braking resistor. In order to enable and set-up this function, it is incorporated to ensure spurious trips are not seen.

-

Page 60: Figure 4-14 Installation Of Grounding Bracket (Master/Slave)

In these cases all the shields should be connected to ground and 0V at both ends. Unidrive SP Free Standing User Guide www.controltechniques.com Issue Number: 1…

-

Page 61: Figure 4-15 Feedback Cable, Twisted Pair

4.9.3 Compliance with EN 61800-3 (standard for Power Drive Systems) Meeting the requirements of this standard depends on the environment that the drive is intended to operate in, as follows: Unidrive SP Free Standing User Guide Issue Number: 1 www.controltechniques.com…

-

Page 62: Figure 4-17 Connecting The Motor Cable To An Isolator / Disconnect Switch

Figure 4-18 Surge suppression for digital and unipolar inputs and outputs Signal from plant Signal to drive 30V zener diode e.g. 2xBZW50-15 Figure 4-19 Surge suppression for analog and bipolar inputs and Unidrive SP Free Standing User Guide www.controltechniques.com Issue Number: 1…

-

Page 63: Serial Communications Connections

Serial communications connections 4.10.2 Multi-drop network The Unidrive SP can be used on a 2 wire EIA485 multi-drop network The Unidrive SP has a serial communications port (serial port) as using the drive’s serial communications port when the following standard supporting 2 wire EIA485 communications. Please see Table guidelines are adhered to.

-

Page 64: Figure 4-21 Default Terminal Functions

Ensure the logic sense is correct for the control circuit to be Connections for used. Incorrect logic sense could cause the motor to be differential input signal started unexpectedly. Positive logic is the default state for Unidrive SP. CAUTION Analog frequency/speed NOTE reference 2 Any signal cables which are carried inside the motor cable (i.e.

-

Page 65

T8 analog input 3 has a parallel connection to terminal 15 of the drive encoder connector. Unidrive SP Free Standing User Guide Issue Number: 1 www.controltechniques.com… -

Page 66

Maximum output current 240mA (including all digital I/O) 0V common Protection Current limit and trip Common connection for all external Function devices 0V common Common connection for all external Function devices Unidrive SP Free Standing User Guide www.controltechniques.com Issue Number: 1… -

Page 67: Encoder Connections

The UVW commutation signals are used to define the motor position during the first 120° electrical rotation after the drive is powered-up or the encoder is initialized. Unidrive SP Free Standing User Guide Issue Number: 1 www.controltechniques.com…

-

Page 68: Table 4-14 Drive Encoder Connector Details

Line loading <2 unit loads Ω Line termination components (switchable) Working common mode range +12V to –7V Absolute maximum applied voltage ±25V relative to 0V Absolute maximum applied differential ±25V voltage Unidrive SP Free Standing User Guide www.controltechniques.com Issue Number: 1…

-

Page 69: Safe Torque Off (Secure Disable)

±4V ±14V and common mode voltage range relative to 0V For the SinCos encoder to be compatible with Unidrive SP, the output Absolute maximum applied differential ±14V voltage signals from the encoder must be a 1V peak to peak differential voltage (across Sin to Sinref and Cos to Cosref).

-

Page 70: Figure 4-23 Start / Stop Control En954-1 Category