Сам с подобной проблемой не сталкивался, может поможет описание ошибок. Думаю, имеет смысл проверить значения ускорений. Удачи!

25000 Ось %1 Сбой аппаратуры активного датчика

Объяснение:

%1 = Название оси, номер шпинделя

Сигналы активного в данный момент датчика фактического положения

(интерфейсный сигнал V 380×0001.5) отсутствуют, не являются синфазными

или обнаруживают замыкание на корпус/короткое замыкание.

Реакция:

ЧПУ не готово к работе.

Блокировка запуска ЧПУ.

Останов ЧПУ при аварийном сигнале.

ЧПУ переключается в следящий режим.

Индикация аварийного сигнала.

Устанавливаются сигналы интерфейса.

Оси больше не синхронизированы с фактическим значением станка (точка

отсчета).

Устранение:

Проверьте штекер измерительной цепи на правильность замыкания

контактов. Проверьте сигналы датчика, в случае ошибок замените

измерительный датчик.

Продолжение программы Выключить-включить систему управления.

25050 Ось %1 Контроль контура

Объяснение:

%1 = Название оси, номер шпинделя

ЧПУ рассчитывает для каждой опорной точки интерполяции в оси (заданное

значение) действительное значение, которое должно получаться на

основании внутренней модели. Если это расчетное действительное значение

и фактическое значение станка отличаются друг от друга на величину,

превышающую значение параметра станка 36400 CONTOUR_TOL, то

происходит прерывание программы с выдачей аварийного сигнала.

Реакция:

ЧПУ не готово к работе.

При известных условиях возможность переключения в канале через MD.

Канал не готов к работе.

Блокировка запуска ЧПУ.

Останов ЧПУ при аварийном сигнале.

ЧПУ переключается в следящий режим.

Индикация аварийного сигнала.

Устанавливаются сигналы интерфейса.

Устранение:

• Проверьте значение допуска в MD 36400 CONTOUR_TOL, возможно,

было предусмотрено слишком малое значение.

• Проверьте оптимальность позиционного регулятора (Kv-

коэффициент в параметре станка 32200 POSCTRL_GAIN), следует ли

ось установке заданного значения без перерегулирования. В противном

случае нужно улучшить оптимальность регулятора частоты вращения

или уменьшить Kv-коэффициент.

• Проверьте ускорение в MD 32300 MAX_AX_ACCEL. Если вследствие

слишком высокого ускорения достигаются пределы тока, то из-за этого

отключается позиционное регулирование. “Пропавшее“ фактическое

значение нагоняется снова в форме выброса при перерегулировании, как

только контур регулирования опять замкнется.

• Улучшение оптимальности регулятора частоты вращения.

• Проверьте механику (легкость хода, инерционная масса).

Продолжение программы Удалить сообщение с помощью клавиши RESET. Снова запустить программу

обработки деталей.

25060 Ось %1 Ограничение заданного значения частоты вращения

Объяснение:

%1 = Название оси, номер шпинделя

Заданное значение частоты вращения превысило свой верхний предел

дольше допустимого времени.

Максимальное заданное значение частоты вращения ограничивается

специфическим для осей параметром станка 36210 CTRLOUT_LIMIT в

процентах. Вводимое значение 100% соответствует номинальной частоте

вращения электродвигателя и тем самым скорости быстрого хода.

Кратковременные превышения допускаются, если они длятся не дольше,

разрешено значением параметра MD 36220 CTRLOUT_LIMIT_TIME,

специфического для осей. В течение этого времени заданное значение

ограничивается до установленного максимального значения (MD 36210

CTRLOUT_LIMIT).

Реакция:

ЧПУ не готово к работе.

При известных условиях возможность переключения в канале через MD.

Блокировка запуска ЧПУ.

Останов ЧПУ при аварийном сигнале.

ЧПУ переключается в следящий режим.

Индикация аварийного сигнала.

Устанавливаются сигналы интерфейса.

Устранение:

Этот аварийный сигнал не должен появляться в случае правильно

настроенного регулятора привода и обычных соотношений обработки.

• Проверьте фактические значения: локальное затруднение хода

салазок [суппорта], возмущение частоты вращения из-за выброса

момента при контакте с заготовкой/инструментом, наезд на жесткое

препятствие и др.

• Проверьте направление регулирования: Ось проходит бесконтрольно?

• Проверьте кабель заданного значения частоты вращения.

Продолжение программы Удалить сообщение с помощью клавиши RESET.

Sinumerik Alarm 25000 Axis %1 hardware fault of active encoder

Parameters:

%1 = Axis name, spindle number

Definitions:

The signals of the currently active position actual value encoder (interface signal DB 31 – 48, DBX 1.5 = 1 or DBX 1.6 = 1) are missing, do not have the same phase, or exhibit grounding/short-circuit. The alarm can be reprogrammed in the MD ALARM_REACTION_CHAN_NOREADY (channel not ready).

Reactions:

– Mode group not ready.

– Channel not ready.

– If the axis is a single axis when this alarm is triggered, the alarm is only effective for this axis (not effective for e.g. the channel or mode group)

– Channel not ready.

– NC Start disable in this channel.

– NC Stop on alarm.

– The NC switches to follow-up mode.

– Alarm display.

– Interface signals are set.

– Axes of this channel must be re-referenced.

Remedy:

Please inform the authorized personnel/service department. Check measuring circuit connectors for correct contacting. Check encoder signals and replace the encoder if faults are found.

Program Continuation:

Switch control OFF – ON.

References

- Siemens Diagnostics Guide by Siemens

Sinumerik Alarm 25000 Axis %1 hardware fault of active encoder

- 24 Авг 2016

andreieinav сказал(а):

Добрый день!

На станке с Sinumerik 840d проблема — ошибка 25000 — энкодер или связь с энкодером

Но может ли быть проблема в том что ремень двигатель-ось был растянут и ослаб, произошла рассинхронизация линейного и кругового перемещения?

Где хранятся данные с линеек и энкодеров в ЧПУ?

Хочу попробовать восстановить из архива.

Спасибо!

Если это линейная ось,то такая неисправность говорит об отсутствии фидбека(обратной связи) с ведущим энкодером Если в комплект входит оптическая линейка,то ,как правило,-это она!Оборванный ремень движка к таким сбоям привести не может т к при референсе оси,ведомый энкодер обнуляется Ищи проблему в линейке,-могут быть следующие варианты:

1 Убитые подшипники оси —>увеличенный зазор между головкой линейки и корпусом

2 Оборванный коннектор энкодера на линейке,или в шкафу

3 Проблема в плате драйвера энкодера (см по книжке его адрес,но не перепутай с ведомым!)

В общем,-кусок работы у тебя есть! Удачи!

Дело оказалось в отсутствующем болте на головке линейки… из-за этого был перекос….как болтик выкрутился?…может рабочие выкрутили ибо то провод в станке выпадет самозажимной колодки, то плк слетит в ноль, то вот это

Спасибо!

- 25 Авг 2016

andreieinav, Siemens 840C Сделал сброс ,ввод в эксплуатацию ,пролил все файлы.Машина включается ,загружается,подключаются привода,включается гидравлика.

Светится кнопка оси X ,другие не выбираются и ни одна ось не двигается.Все сигналы на контроллер приходят конечники,гидравлики и т.д.Что ей не хватает для движения??

- 26 Авг 2016

san-vai сказал(а):

andreieinav, Siemens 840C Сделал сброс ,ввод в эксплуатацию ,пролил все файлы.Машина включается ,загружается,подключаются привода,включается гидравлика.

Светится кнопка оси X ,другие не выбираются и ни одна ось не двигается.Все сигналы на контроллер приходят конечники,гидравлики и т.д.Что ей не хватает для движения??

А ошибок никаких не выдаёт?

Я не эксперт, но попробовать другой архив PLC залить, если нет других, то снова этот же перезалить. Думаю обработка кнопок и команд идет от PLC.

- 28 Авг 2016

san-vai сказал(а):

andreieinav, Siemens 840C Сделал сброс ,ввод в эксплуатацию ,пролил все файлы.Машина включается ,загружается,подключаются привода,включается гидравлика.

Светится кнопка оси X ,другие не выбираются и ни одна ось не двигается.Все сигналы на контроллер приходят конечники,гидравлики и т.д.Что ей не хватает для движения??

Проверь,-реагирует ли машина на переключение скорости подачи,-на пульте это должно быть видно в правом верхнем углу экрана!

- 29 Авг 2016

Добрый день!

На станке с Sinumerik 840d проблема — ошибка 400260

Machine control panel (MCP) at machine control panel interface 1 has failed. Timer of FB1 parameter MCP1Timeout has expired.Reactions:- Alarm display.Remedy:Check the connection with the MCP. Do not use timer T0 through T9 in the user program. Increase the value of timer parameter MCP1Timeout. Set MCP1Cycl to the default value.

Как следует из описания, что-то не в порядке с тайм-аутом при работе со станочной панелью. При этом панель подвешивается намертво и не реагирует не на одну кнопку.

После перезагрузки станка или выдергивания разъёма питания на панели работоспособность восстанавливается. За день работы выскакивает раз 5-6, абсолютно непредсказуемо. Подсоединение разъёмов проверяли. Подскажите что еще надо проверить.

- 30 Авг 2016

Лежат на стеллаже 2 шт. — дефект тот же. Одна ещё реагировала на охлаждение снегом в районе МС контроллера — помогает только замена — увы ((((

- 30 Авг 2016

anatoly_k_57, Спасибо.

Будем заказывать.

- 30 Авг 2016

andreieinav, Частично разобрался с выносного пульта управляются все оси ,а с панели нет ,также горит ось X другие не выбираются.Может что не прописано ?

- 2 Сен 2016

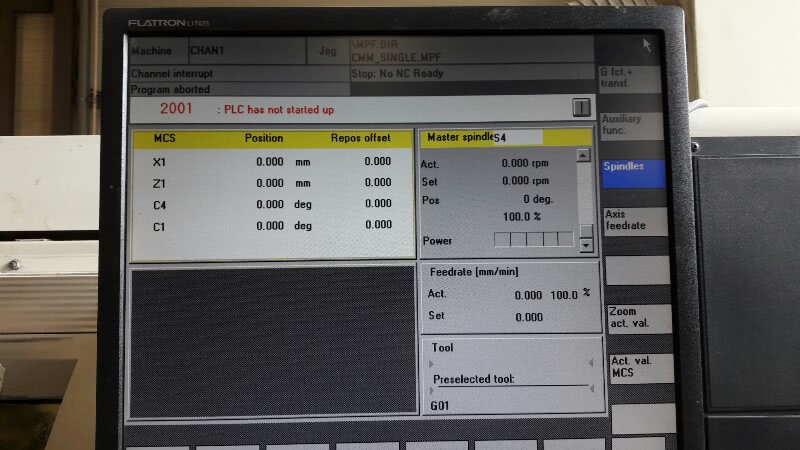

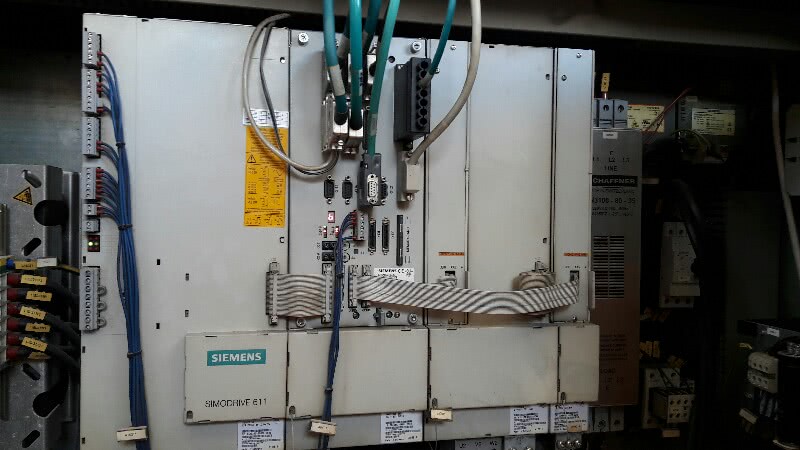

Доброго дня

Станок gildemeister ctx400serie2

Sinumerik 810d

Небольшая предистория

Работал нормально, пол дня стоял включеным без работы, появилась ошибка «plc нет связи, ждите». Выключил машину на пару минут, включил- все ок, проработал неделю, потом неделя простоя.

Включаю опять ошибка «plc не стартовал», перезагрузка больше не помогает, все кнопки пульта мигают. Батарейку меняли 2 месяца назад.

На мой взгляд нестандартная ситуация, когда во время работы теряется plc, потом опять находится после перезагрузки, а потом теряется напрочь.

Где в первую очередь искать причину? Может контакт гденибудь в электроавтоматике теряется. Помогите кто чем может. Заранее благодарен

- 5 Сен 2016

Добрый день,есть турецкий станок для резки стекла CMSmachine FLC 3225 на базе sinumerik 810d, на блоке CCU горит индикатор «6» светодиод 5+, SF , PR, на HMI пишет ошибка 120202 STOP:No NC Ready,при нажатии сброса NCK CCU щелкает реле и горит желтая надпись NC Communication failed. Батарейка 3,07 вольта. Шпиндели обесточены,при перемещении каретки руками,на главном экране стоят нули,система не видит где находится каретка,на пульт не реагирует Прошу помощи.Есть два архива,е ли полазить через MMC но содержимое не знаю,как можно сделать бекап того что сейчас есть и опробовать эти архивы?

- 7 Сен 2016

СашаМ сказал(а):

Доброго дня

Станок gildemeister ctx400serie2

Sinumerik 810d

Небольшая предистория

Работал нормально, пол дня стоял включеным без работы, появилась ошибка «plc нет связи, ждите». Выключил машину на пару минут, включил- все ок, проработал неделю, потом неделя простоя.

Включаю опять ошибка «plc не стартовал», перезагрузка больше не помогает, все кнопки пульта мигают. Батарейку меняли 2 месяца назад.

На мой взгляд нестандартная ситуация, когда во время работы теряется plc, потом опять находится после перезагрузки, а потом теряется напрочь.

Где в первую очередь искать причину? Может контакт гденибудь в электроавтоматике теряется. Помогите кто чем может. Заранее благодарен

Значит так,

1Причиной падения интерфейсов не всегда является батарейка,-это могут быть

а)плохо сдящая в коннекторе заглушка

б)остановка одного из перефкрийных осцилляторов

с)плохой контакт на батарейке поддержки протоколов интерфейса

д)наводки от неисправного контура заземления ,или реактора приводов

2 Так как интерфейсы у тебя упали и бояться больше нечего ,сделай следуюшее,

а)пробегись по всему кабелю,проверь коннекторы и заглушки

б)под высоковольтными шинами,под CPU,должна находиться батарейка и вентилятор охлаждения Надо это все аккуратно вытащить и проверить!Учти,-коннекторы хлипкие,действуй осторожно!

с)Когда все проверки закончишь,-внимательно почитай темку,проверь наличие архивов ,и,обязательно выполни процедуру полной чистки регистров!Не экономь время,делай все пошагово,не торопясь!

Удачи тебе!

Добавлено 07-09-2016 14:35

AntonovA сказал(а):

Добрый день,есть турецкий станок для резки стекла CMSmachine FLC 3225 на базе sinumerik 810d, на блоке CCU горит индикатор «6» светодиод 5+, SF , PR, на HMI пишет ошибка 120202 STOP:No NC Ready,при нажатии сброса NCK CCU щелкает реле и горит желтая надпись NC Communication failed. Батарейка 3,07 вольта. Шпиндели обесточены,при перемещении каретки руками,на главном экране стоят нули,система не видит где находится каретка,на пульт не реагирует Прошу помощи.Есть два архива,е ли полазить через MMC но содержимое не знаю,как можно сделать бекап того что сейчас есть и опробовать эти архивы?

Все это уже обсуждалось много раз,в разных вариациях!

Завари себе кофейку,закури сигаретку и,потрать часик,-почитай эту темку!Найдешь ответ в куче вариантов!

- 7 Сен 2016

Сейчас пишет 300701,300739,при ручном движении стола руками,по трем осям пишет 0.0000мм,PLC в составе блока работает. До этого через адаптер CP5512 Profibus и step-7 был слит проект трехсотого,и через программу SinuCom NC создан архив. Уровень доступа manufacturing. Пароль не вводился.В созданном архиве две папки NC и PLC.Вес архива 200кб.Не знаю достаточно этого или нет.Все ли данные выгрузил.

- 12 Сен 2016

andreieinav, Андрей добрый день.Давно читаю эту тему.много полезного.спасибо вам за это большое.Сейчас возникла конкретная проблема.

Имеем станок лазерной резки TRUMPF 3050 2000 г.в. SIMENS 840D. Есть острая необходимость опустить ось z на 3-4 мм. При попытке это сделать требует пароль второго уровня.Нужно бы поскорей.стоим. если можете то позвоните 8 916 681 09 61. С уважением Юрий.

- 12 Сен 2016

yura262 сказал(а):

.Давно читаю эту тему.много полезного.спасибо вам за это большое.Сейчас возникла конкретная проблема.

Имеем станок лазерной резки TRUMPF 3050 2000 г.в. SIMENS 840D. Есть острая необходимость опустить ось z на 3-4 мм. При попытке это сделать требует пароль второго уровня.Нужно бы поскорей.стоим. если можете то позвоните 8 916 681 09 61. С уважением Юрий.

Добрый день. Попробуйте SUNRISE. Это пароль производителя. Должен подойти ко всем уровням.

- 12 Сен 2016

Это пароль второго уровня?

Добавлено 12-09-2016 11:54

Дело в том что есть первый пароль.он позволяет менять референт оси x и y.а вот чтобы изменить этот параметр оси z требует пароль второго уровня.

Добавлено 12-09-2016 12:01

Похоже общие пароли не подходят.здесь какие то свои. Проблема.

- 12 Сен 2016

У нас 2 шт. 7020, но оболочка для 3010, 7040 — ни какого пароля не спрашивает. Может имеется в виду положение ключа? У наших своя панель, не Сименс…

- 14 Сен 2016

yura262 сказал(а):

Это пароль второго уровня?

Добавлено 12-09-2016 11:54

Дело в том что есть первый пароль.он позволяет менять референт оси x и y.а вот чтобы изменить этот параметр оси z требует пароль второго уровня.

Добавлено 12-09-2016 12:01

Похоже общие пароли не подходят.здесь какие то свои. Проблема.

Значит так,-SUNRISE ты уже пробовал,-теперь попробуй эту парочку;

1 EVENING

2 CUCTOMER

Может еще какие-то пароли есть,-надо поспрашивать!

И еще,-при вводе пароля,попробуй постоянно удерживать кнопку переключения регистров ^!

- 14 Сен 2016

Спасибо за ответ.попробуем.Актуальность пропала правда.ремонтируем ось.Есть надежда что сможем отремонтировать мотор линейного привода.простоим несколько дней.но все равно рано или поздно это нужно было делать.

- 15 Сен 2016

Здравствуйте, у нас siemens sinumerik 810m, заменили севшие батарейки, не могу разобраться с файлами на диске, там их 6 штук:

F5FC14.CMP

F5FJ70.01

F5FJ7001.KD

F5FJ7001.NC -T E A 1

F5FJ7001.PLC -T E A 2

F5FJ7001.PRG -P C P

Подскажите какие из них мне нужны? и что есть что?)

Заранее, благодарен…

► F5FJ7001.rar

- 20 Сен 2016

DJPuma сказал(а):

Здравствуйте, у нас siemens sinumerik 810m, заменили севшие батарейки, не могу разобраться с файлами на диске, там их 6 штук:

F5FC14.CMP

F5FJ70.01

F5FJ7001.KD

F5FJ7001.NC -T E A 1

F5FJ7001.PLC -T E A 2

F5FJ7001.PRG -P C P

Подскажите какие из них мне нужны? и что есть что?)

Заранее, благодарен…

Я не могу распокавать твой rar!Но,судя по расширениям,тебе нужны

1 ТЕА 1

2 ТЕА 2

3 РСР

и именно в такой последовательности!Проверь эти файлы обычными текстовыми редакторами NOTEPAD ,или WORDPAD!Остальное + инструкции есть в теме .Удачи!

- 30 Сен 2016

Добрый день, друзья!

Подскажите пожалуйста какая батарейка ставится на sinumerik 810d. Стояла 6в сименс, когда вылезла ошибка «слабая батарейка» поменял на аналогичную, но не сименс, хватило на два месяца- поменял, через два месяца ситуация повторилась. Может батарейка должна быть 3.6в?

Заранее благодарен!

- 30 Сен 2016

Батарейка SAFT- 3,6в, они отличаются малым током саморазряда, большой ёмкостью и НЕ ПРИЕМЛЮТ короткое! Дорогие, сцуко — 25 евро два года назад — сейчас не знаю….

- 2 Окт 2016

День добрый.

Много искал, но кроме как переустановка, не чего не нашёл. Возможно я плохо искал.Проблема такая. Я по невнимательности нажал кнопку подтверждения вместо отмены и по менял bus note с 13 на 6. Теперь пишет ошибку 120202 Wait for connection to NC/PLC. Есть ли возможность его поменять обратно. Без переустановки? Есть кабеля под сименс 200 300 400 серий, но чувствую, что они не подойдут. Сам станок chiron sinumerik 840d. Mmc 103. В загрузочном окне написано mmc 101/102 Regie.

С ув. Руслан.

П.с. Синумерик ново для меня. Если что извиняюсь за глупый вопрос.

- 6 Окт 2016

СашаМ сказал(а):

Добрый день, друзья!

Подскажите пожалуйста какая батарейка ставится на sinumerik 810d. Стояла 6в сименс, когда вылезла ошибка «слабая батарейка» поменял на аналогичную, но не сименс, хватило на два месяца- поменял, через два месяца ситуация повторилась. Может батарейка должна быть 3.6в?

Заранее благодарен!

Оно без «может»!3.6v и только литевая!

Добавлено 06-10-2016 14:20

Tehnikvg сказал(а):

День добрый.

Много искал, но кроме как переустановка, не чего не нашёл. Возможно я плохо искал.Проблема такая. Я по невнимательности нажал кнопку подтверждения вместо отмены и по менял bus note с 13 на 6. Теперь пишет ошибку 120202 Wait for connection to NC/PLC. Есть ли возможность его поменять обратно. Без переустановки? Есть кабеля под сименс 200 300 400 серий, но чувствую, что они не подойдут. Сам станок chiron sinumerik 840d. Mmc 103. В загрузочном окне написано mmc 101/102 Regie.

С ув. Руслан.П.с. Синумерик ново для меня. Если что извиняюсь за глупый вопрос.

Скажи,а какой PLC у тебя?Если в комплекте PCU-50,то вернуть можно быстро ,за счет архивов

P S Извиняюсь коллеги за задержку с ответами,-праздники+ модернизация завода!

- 13 Окт 2016

Спасибо за ответ. Сам контроллер я не нашел. В зависимости, что имеется ввиду для синумерика. Блоки входов выходов 300 — сименса и блоки связи. ПСУ нигде такого не обнаружил. Но машина старая 96(97)- 2002 года выпуска. Если надо, могу выложить полный фото-отчет по машине.

п.с. Праздники хорошо! Отдыхать тоже надо. А модернизация сама по себе приятна). У самого такая работа) Но синумерик это мой личный станок). и с ним не сталкивался.

- Manuals

- Brands

- Siemens Manuals

- Control Unit

- SINUMERIK 808D

- Diagnostic manual

-

Contents

-

Table of Contents

-

Bookmarks

Quick Links

T able of contents

Tables

Figures

SINUMERIK

SINUMERIK 808D ADVANCED

Diagnostics Manual

Diagnostics Manual

08/2013

6FC5398-6DP10-0BA1

Preface

Introduction

Operating in the «SYSTEM»

area

SINUMERIK 808D

ADVANCED alarms

System responses

SINAMICS V70 alarms

Data backup

Updating software

Appendix A

1

2

3

4

5

6

7

A

Related Manuals for Siemens SINUMERIK 808D ADVANCED

Summary of Contents for Siemens SINUMERIK 808D ADVANCED

-

Page 1

T able of contents Tables Figures 1 Introduction Operating in the «SYSTEM» 2 SINUMERIK area SINUMERIK 808D 3 SINUMERIK 808D ADVANCED ADVANCED alarms Diagnostics Manual 4 System responses 5 SINAMICS V70 alarms Diagnostics Manual 6 Data backup 7 Updating software A … -

Page 2

Note the following: WARNING Siemens products may only be used for the applications described in the catalog and in the relevant technical documentation. If products and components from other manufacturers are used, these must be recommended or approved by Siemens. Proper transport, storage, installation, assembly, commissioning, operation and maintenance are required to ensure that the products operate safely and without any problems. -

Page 3: Table Of Contents

Configuring the Ethernet connection ………………46 2.12 Defining the maintenance planner………………… 52 2.13 Alarm display ……………………..53 SINUMERIK 808D ADVANCED alarms ………………..55 System error alarms ……………………55 NCK alarms ……………………..55 Drive alarms ……………………..333 PLC alarms……………………..342 Cycle alarms……………………..346…

-

Page 4

Table of contents PLC user alarms ……………………434 System responses ………………………435 System reactions to SINUMERIK alarms …………….435 Cancel criteria for alarms………………….438 SINAMICS V70 alarms ……………………..439 Overview of alarms ……………………439 Common faults and alarms…………………. 441 Data backup ……………………….453 Overview of internal/external data backup……………. -

Page 5: Preface

Preface Applicable products This manual is applicable to the following control systems: Control system Software version SINUMERIK 808D ADVANCED T (Turning) V4.6 SINUMERIK 808D ADVANCED M (Milling) V4.6 Documentation components and target groups Component Recommended target group User documentation Programming and Operating Manual (Turning)

-

Page 6

EC Declaration of Conformity The EC Declaration of Conformity for the EMC Directive can be found on the Internet at http:/ /support.automation.siemens.com Here, enter the number 15257461 as the search term or contact your local Siemens office. Diagnostics Manual Diagnostics Manual, 08/2013, 6FC5398-6DP10-0BA1… -

Page 7: Introduction

Introduction Structure of the Diagnostics Manual NCK / PLC alarms The descriptions for the alarms can be found in the chapters: • NCK alarms (Page 55) • Drive alarms (Page 333) • PLC alarms (Page 342) • Cycle alarms (Page 346) •…

-

Page 8: Alarm Number Ranges

Introduction 1.2 Alarm number ranges Action list The actions described in the NCK alarm texts («Action %…») are explained in the following Chapter: See Chapter: Cancel criteria for alarms (Page 438) Specification «%» The specification «%» represents variables for an online parameter that is replaced on the control with a corresponding value.

-

Page 9: Operating In The «System» Area

Operating in the «SYSTEM» area Operating area overview Softkey functions Press the keys on the PPU to enter the following operating area. This operating area includes functions required for parameterizing and analyzing the NCK, the PLC and the drive. The start screen displays the machine configuration data and softkeys available.

-

Page 10: Setting Start-Up Function

Operating in the «SYSTEM» area 2.2 Setting start-up function An extended horizontal softkey bar can be accessed via this key on the PPU. Two extended horizontal softkeys are provided: Views the service information Defines the maintenance planner Setting start-up function Functionality This softkey allows you to choose the NC, PLC, and drive start-up modes.

-

Page 11

Operating in the «SYSTEM» area 2.2 Setting start-up function Selecting a PLC restart mode Proceed through the following steps to select a PLC restart mode: Select the desired operating area. Press this softkey. Press this softkey to open the window for selecting the PLC start-up mode. -

Page 12: Setting System Machine Data

Operating in the «SYSTEM» area 2.3 Setting system machine data Select all drives or one specific drive using the cursor keys. Press this softkey to confirm your selection. The selected drive(s) will restart in the mode selected. Setting system machine data Machine data structure Any changes in the machine data have a substantial influence on the machine.

-

Page 13

2.3 Setting system machine data Setting basic machine data The SINUMERIK 808D ADVANCED provides two easy-to-use data lists for beginner users. You can use the basic data list for quick access of common NC data and drive data. Setting basic NC data In the basic NC data list, the general, axis, and channel MD are integrated in one screen. -

Page 14

Operating in the «SYSTEM» area 2.3 Setting system machine data Setting basic drive data Several common drive parameters are provided in the basic drive data list. Proceed through the following steps to set the basic drive data: Select the desired operating area. Enter the window of basic drive data through the following softkey operations: →… -

Page 15

Operating in the «SYSTEM» area 2.3 Setting system machine data Setting machine data in expert list All machine data are divided into five groups described as follows. Setting general machine data Select the desired operating area. Enter the window of general machine data through the following softkey operations: →… -

Page 16

Operating in the «SYSTEM» area 2.3 Setting system machine data Setting channel-specific machine data Select the desired operating area. Enter the window of channel-specific machine data through the following softkey operations: → → Locate the machine data which you desire to set. You can also search for an MD using the following softkeys: Searches for the desired number or the name (or a part of the name) of the machine data… -

Page 17

Operating in the «SYSTEM» area 2.3 Setting system machine data Setting axis-specific machine data Select the desired operating area. Enter the window of axis-specific machine data through the following softkey operations: → → Locate the machine data which you desire to set. You can also search for an MD using the following softkeys: Searches for the desired number or the name (or a part of the name) of the machine data… -

Page 18

Operating in the «SYSTEM» area 2.3 Setting system machine data Setting drive machine data Select the desired operating area. Enter the window of drive machine data through the following softkey operations: → → Locate the machine data which you desire to set. You can also search for an MD using the following softkeys: Searches for the desired number or the name (or a part of the name) of the machine data… -

Page 19

To learn more functions regarding the servo trace, refer to the Section «Servo trace (Page 40)». References You can find a description of the machine data in the following manufacturers’ documents: SINUMERIK 808D ADVANCED Parameter Manual SINUMERIK 808D ADVANCED Function Manual Diagnostics Manual Diagnostics Manual, 08/2013, 6FC5398-6DP10-0BA1… -

Page 20: Configuring The Drive System

Operating in the «SYSTEM» area 2.4 Configuring the drive system Configuring the drive system Pressing this softkey opens the drive system configuration window where you can configure the connected drives and motors. Before starting the drive and motor configuration, you must ensure the Drive Bus addresses are properly set (p0918) via the drive BOPs according to the instructions in the window above.

-

Page 21

Operating in the «SYSTEM» area 2.4 Configuring the drive system Press this softkey to enter the motor configuration window. Select the right motor ID according to the motor rating plate with the cursor keys. Press this softkey to confirm your selection. The selected motor information then displays in the drive list. -

Page 22: Plc Diagnostics

Operating in the «SYSTEM» area 2.5 PLC diagnostics PLC diagnostics Functionality A PLC user program consists to a large degree of logical operations to realize safety functions and to support process sequences. These logical operations include the linking of various contacts and relays. As a rule, the failure of a single contact or relay results in a failure of the whole system/installation.

-

Page 23: Screen Layout

Operating in the «SYSTEM» area 2.5 PLC diagnostics ⑥ ⑬ Displays the list of cross references Displays all symbolic identifiers used in the selected network ⑦ Displays the logic and graphic information of the selected program block 2.5.1 Screen layout Legend Display Meaning…

-

Page 24: Operating Options

Operating in the «SYSTEM» area 2.5 PLC diagnostics 2.5.2 Operating options In addition to the softkeys and the navigation keys, this area provides still further key combinations. Hot keys The cursor keys move the focus over the PLC user program. When reaching the window borders, it is scrolled automatically.

-

Page 25

Operating in the «SYSTEM» area 2.5 PLC diagnostics Key combination Action To the last field of the subroutine Opens the previous program block in the same window Opens the next program block in the same window The function of the Select key depends on the position of the input focus. -

Page 26

Operating in the «SYSTEM» area 2.5 PLC diagnostics Searching for operands In big programs, you can use the search function to quickly reach the desired positions. To search for operands, follow these steps: Use this softkey to switch between the absolute and symbolic representation of the operands. -

Page 27: Displaying Information On The Program Blocks

Operating in the «SYSTEM» area 2.5 PLC diagnostics 2.5.3 Displaying information on the program blocks Functionality You can display any logical and graphical information of a program block in the program windows. The program block is one of the components of the PLC user program. Logic information The logics in the ladder diagram (LAD) display the following: •…

-

Page 28: Displaying Cross-References

Operating in the «SYSTEM» area 2.5 PLC diagnostics Select the desired program block and press this softkey to open it. After the selected program block is opened, you can press the following softkeys to switch the display information. Further softkeys are available in the program block window as follows: Displays additional information of the selected program block Displays the table of local variables of the selected…

-

Page 29: Setting The Hmi Display

Operating in the «SYSTEM» area 2.6 Setting the HMI display Setting the HMI display 2.6.1 Setting the date and time At delivery, the system date and time remain at the factory settings, and thus you must manually modify the date and time in the window as follows. Operating sequence Select the desired operating area on the PPU.

-

Page 30: Adjusting The Screen Brightness

Operating in the «SYSTEM» area 2.6 Setting the HMI display 2.6.2 Adjusting the screen brightness You can open the window for adjusting the brightness of the HMI screen through the following operations: → → Press this softkey to increase the brightness of the HMI screen. Press this softkey to decrease the brightness of the HMI screen.

-

Page 31: Managing The System Data

Operating in the «SYSTEM» area 2.7 Managing the system data Managing the system data Overview By pressing this softkey in the system data management operating area, you can enter the window as follows: Three folders and one file are available in this window. You can import/export the subfolders or single files in this window for backup or other customized purposes.

-

Page 32

You can import/export the subfolders or single files in this window for backup or other customized purposes. For more information, refer to the SINUMERIK 808D ADVANCED Function Manual and SINUMERIK 808D ADVANCED Commissioning Manual. Managing the NCK/PLC data Select this folder and press the key to enter. -

Page 33: Creating Commissioning Archives

Operating in the «SYSTEM» area 2.8 Creating commissioning archives Creating commissioning archives Functionality Pressing this softkey allows you to create or restore a start-up or series start-up archive in the following window. Operating sequence Select the desired operating area on the PPU. Press this horizontal softkey to open the start-up archive window.

-

Page 34: Optimizing Drive Performance

Operating in the «SYSTEM» area 2.9 Optimizing drive performance Press this softkey to confirm and the archive information dialog opens. Specify the properties of the archive and press this softkey to start creating the archive file in the selected folder. Optimizing drive performance The control system provides facilities to optimize the performance of each connected drive by automatically modifying the control loop parameters.

-

Page 35

Operating in the «SYSTEM» area 2.9 Optimizing drive performance Press this softkey to return to the main screen of drive optimization. Press this softkey to enter the preparation screen before the optimization. Switch to «JOG» mode, and use the axis traversing keys to move the axis to a safe position. -

Page 36: Viewing The Service Info

Operating in the «SYSTEM» area 2.10 Viewing the service info Views the optimization results of the previous axis Returns to the main screen of drive optimization. In this case, you may optimize the drive again with either new measurements or last measurement results. 2.10 Viewing the service info You can view the service information through the following operations:…

-

Page 37: Action Log

Operating in the «SYSTEM» area 2.10 Viewing the service info 2.10.1 Action log Overview The action log function is provided for service events. The contents of the action log file can only be accessed through a system password on the HMI. Viewing the action log Select the desired operating area.

-

Page 38

Operating in the «SYSTEM» area 2.10 Viewing the service info Settings for the message sending Proceed through the following steps to configure the settings for the message sending: Select the desired operating area. Press this key to view the extended softkeys. Open the service message window through the following softkey operations: →… -

Page 39: Data Backup

Operating in the «SYSTEM» area 2.10 Viewing the service info Press this softkey to save the settings and return to the service message main screen. Press this softkey to cancel and return to the service message main screen. Note To transfer messages via the RS232 interface, the communication settings from the following are used: →…

-

Page 40: Servo Trace

Operating in the «SYSTEM» area 2.10 Viewing the service info 2.10.3 Servo trace Overview An oscilloscope function is provided for the purpose of optimizing the drives. This enables the following graphical representations: • velocity setpoint • contour violation • following error •…

-

Page 41

Operating in the «SYSTEM» area 2.10 Viewing the service info To analyze the result, you can perform the following operations: • Changing and scaling the abscissa and ordinate values • Measuring a value using the horizontal or vertical marker • Measuring the abscissa and ordinate values as a difference between two markers •… -

Page 42: Version/Hmi Details

Operating in the «SYSTEM» area 2.10 Viewing the service info Press this softkey to return after you set the desired marker steps. If the trace exceeds the current screen, press + cursor movement. When a marker reaches the margin of the diagram, the grid automatically appears in the horizontal or vertical direction.

-

Page 43

Operating in the «SYSTEM» area 2.10 Viewing the service info This window displays the version numbers and the date of creation of the individual CNC components. ① ③ Displays the operator programs with the Activates the licensed optional functions version numbers ②… -

Page 44

Press this softkey to open the dialog for entering the license key Enter the license key in the following dialog: Press this softkey to confirm. Activating the options The following optional functions can be purchased for the SINUMERIK 808D ADVANCED control system. • Additional axes •… -

Page 45

For the other options, press the following key to select: Press this softkey to restart the NCK, so that the licensed options are activated. Reference SINUMERIK 808D ADVANCED Function Manual SINUMERIK 808D ADVANCED Commissioning Manual Diagnostics Manual Diagnostics Manual, 08/2013, 6FC5398-6DP10-0BA1… -

Page 46: Configuring The Ethernet Connection

With the tool Access MyMachine P2P (AMM) installed on your PC/PG, you can enable the Ethernet connection between a SINUMERIK 808D ADVANCED control system and a PC/PG. This tool is available in the SINUMERIK 808D ADVANCED Toolbox and is supported by Windows XP/Vista/Win 7.

-

Page 47

Operating in the «SYSTEM» area 2.11 Configuring the Ethernet connection Select the direct connection option in the following dialog and then click this button. An attempt is made to establish a direct connection. If you have not established any authentication data, the following dialog appears: Select the log-on details and enter the corresponding password or alternatively select a key file in the dialog. -

Page 48

Operating in the «SYSTEM» area 2.11 Configuring the Ethernet connection Enter the main screen of the service control options through the following softkey operations: → Press this softkey to enter the window for the network configuration. Note: make sure the following vertical softkey is not selected: Configure the network as required in the following window: You can configure the DHCP with the following key: Note: if you select «No»… -

Page 49

Operating in the «SYSTEM» area 2.11 Configuring the Ethernet connection Select the new network connection option in the following dialog: This dialog can also be called with the button from the toolbar. The dialog for setting the new network connection appears. Assign the parameters for a new network connection in this dialog: Select the following button to save the settings: Select the following button and the AMM tool connects to the control… -

Page 50

Operating in the «SYSTEM» area 2.11 Configuring the Ethernet connection Creating and connecting a network drive Proceed as follows to create and connect a network drive: Share a directory on your local disk on your PC/PG. Select the desired operating area on the PPU. Press this key to view the extended softkeys. -

Page 51

Operating in the «SYSTEM» area 2.11 Configuring the Ethernet connection Press this softkey to establish the server connection and assign the local shared directory to the network drive. You can disconnect a selected network drive using the following softkey: After you connect a network drive successfully, you may open it directly on the PPU using the following softkey either in the system data management operating area or in the program management operating area:… -

Page 52: Defining The Maintenance Planner

Operating in the «SYSTEM» area 2.12 Defining the maintenance planner 2.12 Defining the maintenance planner Overview This part introduces how to define the maintenance planner. You can enter the maintenance planner main screen through the following operations: → → The maintenance planner window displays the position, task description, interval, first warning time, number of warnings, etc.

-

Page 53: Alarm Display

Operating in the «SYSTEM» area 2.13 Alarm display 2.13 Alarm display Softkey functions Press this key on the PPU to open the alarm window. You can check the NC and drive alarms using the softkeys. PLC alarms are not sorted. ①…

-

Page 54

Operating in the «SYSTEM» area 2.13 Alarm display Diagnostics Manual Diagnostics Manual, 08/2013, 6FC5398-6DP10-0BA1… -

Page 55: Sinumerik 808D Advanced Alarms

This alarm is also caused by PLC stop. (PLC stop with programming tool, PLC stop by commissioning switch, PLC stop by alarm) If none of these cases applies, place a support request with the error text under: http://www.siemens.com/automation/ support-request Program Switch control OFF — ON.

-

Page 56

$MN_PLC_RUNNINGUP_TIMEOUT must be checked and adapted to the first OB1 cycle. — Determine the cause of error in the PLC (loop or stop in the user program) and eliminate it. Place a support request with the error text under: http://www.siemens.com/automation/support-request Program Switch control OFF — ON. -

Page 57

SINUMERIK 808D ADVANCED alarms 3.2 NCK alarms 2900 Reboot is delayed Definitions: This alarm indicates a delayed reboot. This alarm only occurs when reboot was carried out by the HMI and MD10088 $MN_REBOOT_DELAY_TIME was set greater than zero. The alarm can be suppressed with MD11410 $MN_SUPPRESS_ALARM_MASK Bit 20. -

Page 58

SINUMERIK 808D ADVANCED alarms 3.2 NCK alarms Definitions: Only axes that have been activated in the channel by MD20070 $MC_AXCONF_MACHAX_USED [kx]=m may be declared as geometry axes, transformation axes or orientation axes in MD20050 $MC_AXCONF_GEOAX_ASSIGN_TAB [gx]=k. This also applies to MD22420 $MC_FGROUP_DEFAULT_AXES (gx: Geometry axis index, kx: Channel axis index, k: Channel axis no., m: Machine axis no.). -

Page 59

SINUMERIK 808D ADVANCED alarms 3.2 NCK alarms Example: — CHANDATA(2) — $MC_AXCONF_MACHAX_USED[0] = 7 — $MC_AXCONF_MACHAX_USED[1] = 8 — $MC_AXCONF_MACHAX_USED[2] = 0 — $MC_AXCONF_MACHAX_USED[3] = 3 — $MC_AXCONF_MACHAX_USED[4] = 2 — $MC_AXCONF_MACHAX_USED[5] = 0 — $MC_AXCONF_MACHAX_USED[6] = 1 — $MC_AXCONF_MACHAX_USED[7] = 0 This channel uses the five machine axes 1, 2, 3, 8, 7, i.e. -

Page 60

SINUMERIK 808D ADVANCED alarms 3.2 NCK alarms Definitions: When determining a name in the NCK tables (arrays) for: machine axes, Euler angles, direction vectors, normal vectors, interpolation parameters and intermediate point coordinates, one of the following syntax rules for the identifier… -

Page 61

SINUMERIK 808D ADVANCED alarms 3.2 NCK alarms Program Switch control OFF — ON. Continuation: 4020 Identifier %1 used several times in machine data %2 Parameters: %1 = String: Name of identifier %2 = String: MD identifier Definitions: When determining a name in the NCK tables (arrays) for: machine axes, Euler angles, direction vectors, normal vectors, interpolation parameters and intermediate point coordinates, an identifier has been used that already exists in the control. -

Page 62

SINUMERIK 808D ADVANCED alarms 3.2 NCK alarms 4032 [Channel %1: ] Wrong identifier for facing axis in %2 Parameters: %1 = Channel number %2 = String: MD identifier Definitions: According to the axis configuration in MD20150 $MC_GCODE_RESET_VALUES or MD20100 $MC_DIAMETER_AX_DEF, a facing axis identifier is expected at the specified location. -

Page 63

SINUMERIK 808D ADVANCED alarms 3.2 NCK alarms Definitions: Renaming of an NC code was not possible for one of the following reasons: — The old identifier does not exist — The new identifier lies in another type range. NC codes/keywords can be reconfigured via machine data as long as the type range is not abandoned. -

Page 64

SINUMERIK 808D ADVANCED alarms 3.2 NCK alarms Remedy: Restart the control. Program Switch control OFF — ON. Continuation: 4070 Normalizing machine data has been changed Definitions: The control uses internal physical units (mm, degrees, s, for paths, velocities, acceleration, etc.). During programming or data storage, some of these values are input and output using different units (rev./min, m/s2, etc.). -

Page 65

SINUMERIK 808D ADVANCED alarms 3.2 NCK alarms Definitions: On executing a TOA file or when writing data from the part program an attempt has been made to write data with a higher protection level than the access authorization currently set in the control. The data in question have not been written and program execution is continued without hindrance. -

Page 66

SINUMERIK 808D ADVANCED alarms 3.2 NCK alarms 2. MD10910 $MN_INDEX_AX_POS_TAB_1 or MD10930 $MN_INDEX_AX_POS_TAB_2: the contents of the displayed tables are incorrect. — The entered positions must be arranged in increasing size. — A particular position must not be set more than once. -

Page 67

SINUMERIK 808D ADVANCED alarms 3.2 NCK alarms 4112 Servo cycle changed to %1 ms Parameters: %1 = String (new servo cycle time) Definitions: For PROFIBUS/PROFINET only: MD10060 $POSCTRL_SYSCLOCK_TIME_RATIO has been modified because of the modified DP cycle in the SDB (MD10050 $SYSCLOCK_CYCLE_TIME). -

Page 68

SINUMERIK 808D ADVANCED alarms 3.2 NCK alarms MD10718 $MN_M_NO_FCT_CYCLE_PAR contains an invalid array index of MD10715 $MN_M_NO_FCT_CYCLE[n]. Currently, the values 0 to 9 are permissible. The affected machine data is reset to the default value -1. This deactivates the function. -

Page 69

SINUMERIK 808D ADVANCED alarms 3.2 NCK alarms 4180 Invalid M function number assigned to enable ASUP Definitions: An invalid M function number has been assigned for activation of ASUP. An illegal M number has been assigned in MD10804 $MN_EXTERN_M_NO_SET_INT or MD10806 $MN_EXTERN_M_NO_DISABLE_INT for the configuration of the M number range for activation/deactivation of the interrupt program. -

Page 70

SINUMERIK 808D ADVANCED alarms 3.2 NCK alarms NC Start disable in this channel. Interface signals are set. Alarm display. NC Stop on alarm. Remedy: Check the specified machine data and create a unique assignment of M auxiliary function numbers. Program Switch control OFF — ON. -

Page 71

SINUMERIK 808D ADVANCED alarms 3.2 NCK alarms Remedy: Please inform the authorized personnel/service department. Remove rotary axis declaration for this machine axis. For this purpose, the geometry axis index for the displayed geometry axis must be determined by means of MD20060 $MC_AXCONF_GEOAX_NAME_TAB. -

Page 72

SINUMERIK 808D ADVANCED alarms 3.2 NCK alarms 4225 [Channel %1: ] Axis %2 declaration as rotary axis missing Parameters: %1 = Channel number %2 = Axis name, axis number Definitions: The modulo functionality requires a rotary axis (positions in [deg]). -

Page 73

SINUMERIK 808D ADVANCED alarms 3.2 NCK alarms Interface signals are set. Alarm display. NC Stop on alarm. Remedy: Please inform the authorized personnel/service department. Correct machine data. Activate required inputs/outputs via MDs: MD10350 $MN_FASTIO_DIG_NUM_INPUTS MD10360 $MN_FASTIO_DIG_NUM_OUTPUTS MD10300 $MN_FASTIO_ANA_NUM_INPUTS MD10310 $MN_FASTIO_ANA_NUM_OUTPUTS Activation of fast inputs/outputs does not require the corresponding hardware configuration to be available at the control. -

Page 74

SINUMERIK 808D ADVANCED alarms 3.2 NCK alarms 4282 Hardware of external NCK outputs assigned repeatedly Definitions: Several outputs have been configured on the same hardware byte. Reaction: NC not ready. Channel not ready. NC Start disable in this channel. Interface signals are set. -

Page 75

SINUMERIK 808D ADVANCED alarms 3.2 NCK alarms 4340 [Channel %1: ] Block %2 invalid transformation type in transformation no. %3 Parameters: %1 = Channel number %2 = Block number, label %3 = Transformation number Definitions: An invalid, i.e. undefined number was entered in one of the machine data $MC_TRAFO_TYPE_..This alarm also occurs if a certain type of transformation is only impossible on the type of control used (e.g. -

Page 76

SINUMERIK 808D ADVANCED alarms 3.2 NCK alarms Reaction: Correction block is reorganized. Interface signals are set. Alarm display. NC Stop on alarm at block end. Remedy: Set valid machine data. Program Clear alarm with the RESET key. Restart part program… -

Page 77

SINUMERIK 808D ADVANCED alarms 3.2 NCK alarms Definitions: MD2..$MC_TRAFO_AXIS_IN_… contains an invalid entry. The following causes for the error are possible: — The entry refers to a channel axis which does not exist. — The entry is zero (no axis) but the transformation needs the relevant axis as a channel axis. -

Page 78

SINUMERIK 808D ADVANCED alarms 3.2 NCK alarms 77. The 3rd linear axis is not perpendicular to the rotary axis and the first geometry axis. 78. More than one additional linear axis was defined. 79. Illegal kinematic chain element type (e.g. manual rotary axis). -

Page 79

SINUMERIK 808D ADVANCED alarms 3.2 NCK alarms Definitions: A machine data has been altered that configures the buffered memory. If the NCK powers up with the altered data, this will lead to reorganization of the buffered memory and thus to the loss of all buffered user data (part programs, tool data, GUD, leadscrew error compensation, …) -

Page 80

SINUMERIK 808D ADVANCED alarms 3.2 NCK alarms Remedy: H numbers must be assigned only once in a TO unit. Then, MD10890, $MN_EXTERN_TOOLPROG_MODE, bit 3 can be set = 0 and a restart can be performed. Program Clear alarm with the Delete key or NC START. -

Page 81

SINUMERIK 808D ADVANCED alarms 3.2 NCK alarms Definitions: The handwheel input for handwheel %1 requested through MD11352 $MN_HANDWHEEL_INPUT is not available for 802D sl, 828D sl, 808D systems. A maximum of 2 handwheels can be directly linked to 802D sl, 828D sl, 808D systems. -

Page 82

SINUMERIK 808D ADVANCED alarms 3.2 NCK alarms Reaction: Interface signals are set. Alarm display. Remedy: Set machine date MD11351 $MN_HANDWHEEL_MODULE = 1 for the corresponding handwheel. Program Switch control OFF — ON. Continuation: 4641 Invalid handwheel input for handwheel %1… -

Page 83

SINUMERIK 808D ADVANCED alarms 3.2 NCK alarms Definitions: Data management has detected an error during ramp-up. The specified data block may not have been created. The error number specifies the type of error. An error number >100000 indicates a fatal system error. Other error numbers indicate that the user memory area provided is too small. -

Page 84

SINUMERIK 808D ADVANCED alarms 3.2 NCK alarms Reaction: NC not ready. Channel not ready. NC Start disable in this channel. Interface signals are set. Alarm display. NC Stop on alarm. Remedy: Correct the machine data or undo the changes made. -

Page 85

There is no interference with any NCK functions. It shows that the NCK has less free user memory available than specified by Siemens for this control variant. The value of the actually available free user memory can also be taken from the MD18050 $MN_INFO_FREE_MEM_DYNAMIC, MD18060 $MN_INFO_FREE_MEMS_STATIC. -

Page 86

SINUMERIK 808D ADVANCED alarms 3.2 NCK alarms 6437 [Channel %1: ] Block %2 Command ‘%3’ cannot be programmed. Function ‘%4’ is activated. Parameters: %1 = Channel number %2 = Block number, label %3 = Programmed command %4 = Function identifier Definitions: The command cannot be programmed as the specified function is active. -

Page 87

SINUMERIK 808D ADVANCED alarms 3.2 NCK alarms 6520 The value of the machine data %1%2 is too low Parameters: %1 = String: MD identifier %2 = If required, index: MD array Definitions: The MD18370 $MN_MM_PROTOC_NUM_FILES specifies the number of protocol files for the protocol users. -

Page 88

Clear alarm with the Delete key or NC START. Continuation: 6583 NC system memory full Definitions: The DRAM file system of the system area (Siemens) is full. The order cannot be executed. Reaction: Alarm display. Remedy: Delete or unload files (e.g. parts programs) Program Clear alarm with the Delete key or NC START. -

Page 89

Alarm display. Remedy: Modify definition files /_N_DEF_DIR/_N_MACCESS_DEF or /_N_DEF_DIR/_N_UACCESS_DEF-CESS_ DEF. Please see the Siemens Programming Guide or the OEM documentation for the language commands permissible for the relevant system configurations. Program Clear alarm with the RESET key. Restart part program… -

Page 90

SINUMERIK 808D ADVANCED alarms 3.2 NCK alarms Remedy: Please inform the authorized personnel/service department. Do not use rapid interrupt inputs or contact the machine manufacturer with a view to retrofitting this option! Program Clear alarm with the RESET key. Restart part program… -

Page 91

SINUMERIK 808D ADVANCED alarms 3.2 NCK alarms Remedy: Please inform the authorized personnel/service department. — Purchase option — Reset the activation of ‘Advanced Surface’ functionality (MD20606 $MC_PREPDYN_SMOOTHING_ON and/or MD20443 $MC_LOOKAH_FFORM) Program Switch control OFF — ON. Continuation: 8030 [Channel %1: ] Block %2 option ‘interpolation of more than %3 axes’ not set… -

Page 92

3.2 NCK alarms Remedy: Please inform the authorized personnel/service department. For retrofitting the option, please refer to your machine manufacturer or to a sales representative of SIEMENS AG, A&D MC. Program Clear alarm with the Delete key or NC START. -

Page 93

One ore more options were activated, that are not licensed by the license key entered. Reaction: Alarm display. Remedy: Generate a new license key on the internet at http://www.siemens.com/automation/licence and enter it in the operating area «Setup», function (HSK) «Licenses».. Program Clear alarm with the Delete key or NC START. -

Page 94

Reaction: Alarm display. Remedy: Generate a new license key via the Internet at http://www.siemens.com/automation/license and enter in the operating area «Startup», function (HSK) «Licenses». Enter a valid license key in the operating area «Startup», function (HSK) «Licenses». Activate an additional test period… -

Page 95

SINUMERIK 808D ADVANCED alarms 3.2 NCK alarms Reaction: Interpreter stop NC Start disable in this channel. Interface signals are set. Alarm display. NC Stop on alarm. Remedy: Modify part program. Program Clear alarm with the RESET key. Restart part program… -

Page 96

SINUMERIK 808D ADVANCED alarms 3.2 NCK alarms Program Clear alarm with NC START or RESET key and continue the program. Continuation: 10204 [Channel %1: ] User action not possible without reference point (internal action=%2<ALNX>) Parameters: %1 = Channel number %2 = internal action number/internal action name… -

Page 97

SINUMERIK 808D ADVANCED alarms 3.2 NCK alarms Remedy: NC-Start Program Clear alarm with NC START or RESET key and continue the program. Continuation: 10225 [Channel %1: ] command denied Parameters: %1 = Channel number Definitions: The channel has received a command that cannot be executed. -

Page 98

SINUMERIK 808D ADVANCED alarms 3.2 NCK alarms Definitions: This alarm occurs only when several blocks with G33 follow in succession. The block end velocity in the specified block is zero, although a further thread cutting block follows. The reasons for this can be, for instance:… -

Page 99

SINUMERIK 808D ADVANCED alarms 3.2 NCK alarms Remedy: Check and correct the part program (analyze whether motion beyond block boundaries is appropriate here). Prevent block change by means of the keyword WAITP for axes or WAITS for spindles until the positioning axes or positioning spindles have also reached their target position. -

Page 100

SINUMERIK 808D ADVANCED alarms 3.2 NCK alarms 10630 [Channel %1: ] Block %2 axis %3 at working area limit %4 Parameters: %1 = Channel number %2 = Block number, label %3 = Axis, spindle number %4 = String (+ or -) Definitions: The specified axis violates the working area limitation. -

Page 101

SINUMERIK 808D ADVANCED alarms 3.2 NCK alarms Program Alarm display showing cause of alarm disappears. No further operator action necessary. Continuation: 10634 [Channel %1: ] Axis %2, tool radius compensation is inactive for type %3 working area limitation, reason: The tool is not oriented parallel to the axis. -

Page 102

SINUMERIK 808D ADVANCED alarms 3.2 NCK alarms Remedy: The tool radius compensation for working area limitations in JOG mode cannot be taken into account wihout an active tool. Program Clear alarm with the Delete key or NC START. Continuation: 10650… -

Page 103

SINUMERIK 808D ADVANCED alarms 3.2 NCK alarms 13: Slave axis grouping 3 Program Switch control OFF — ON. Continuation: 10652 [Channel %1: ] Axis %2 gantry warning threshold exceeded Parameters: %1 = Channel number %2 = Axis Definitions: The gantry following axis has exceeded the warning limit specified in MD37110 $MA_GANTRY_POS_TOL_WARNING. -

Page 104

SINUMERIK 808D ADVANCED alarms 3.2 NCK alarms Program Alarm display showing cause of alarm disappears. No further operator action necessary. Continuation: 10656 [Channel %1: ] Axis %2 gantry slave axis dynamically overloaded Parameters: %1 = Channel number %2 = Axis Definitions: The indicated gantry slave axis is dynamically overloaded, i.e. -

Page 105

SINUMERIK 808D ADVANCED alarms 3.2 NCK alarms Remedy: Error ID: — 30XX => assign all gantry axes to the current channel, for example via axis exchange. — 40XX => set all axes of the gantry group to the same axis state, for example assign all axes to the NC program, or assign all axes to the PLC. -

Page 106

SINUMERIK 808D ADVANCED alarms 3.2 NCK alarms 10703 [Channel %1: ] Channel-specific protection zone %2 violated during manual mode Parameters: %1 = Channel number %2 = Protection zone number Definitions: The workpiece-related channel-specific protection zone has been violated. Note that another tool-related protection zone is still active. -

Page 107

SINUMERIK 808D ADVANCED alarms 3.2 NCK alarms 10720 [Channel %1: ] Block %3 axis %2 software limit switch %4 Parameters: %1 = Channel number %2 = Axis name, spindle number %3 = Block number, label %4 = String (+ or -) Definitions: The path programmed for the axis violates the currently valid software limit switch. -

Page 108

SINUMERIK 808D ADVANCED alarms 3.2 NCK alarms Definitions: The path programmed for the axis violates the currently valid software limit switch. The alarm is activated when preparing the part program block. This alarm is issued instead of alarm 10720 if bit 11=1 in the MD11411 $MN_ENABLE_ALARM_MASK. Alarm 10722 offers an expanded diagnostics option for the software limit switch violation. -

Page 109

SINUMERIK 808D ADVANCED alarms 3.2 NCK alarms Definitions: This alarm is generated if it is determined during block preparation that the programmed path of the axis violates the working area limitation. If bit 11=0 in machine data MD11411$MN_ENABLE_ALARM_MASK, this alarm is issued instead of alarm 10732. If bit 11 is set in machine dataMD11411 $MN_ENABLE_ALARM_MASK, an expanded diagnostics option is offered for the software limit switch violation. -

Page 110

SINUMERIK 808D ADVANCED alarms 3.2 NCK alarms 10733 [Channel %1: ] Block %5 axis %2 working area limitation violated, residual distance: %6 %3<ALUN> Parameters: %1 = Channel number %2 = Axis name, spindle number %3 = Unit of distance %4 = Block number, label|residual distance Definitions: The motion planned for the axis violates the currently active working area limitation. -

Page 111

SINUMERIK 808D ADVANCED alarms 3.2 NCK alarms Remedy: Determine the cause of the offset from the initial or target position. The REPOS command is executed at the end of an ASUB or system ASUB. See also cross reference from ASUBs. -

Page 112

SINUMERIK 808D ADVANCED alarms 3.2 NCK alarms Definitions: An attempt has been made to activate a WAB motion before a previously activated WAB motion was terminated. Reaction: Correction block is reorganized. Local alarm reaction. Interface signals are set. Alarm display. -

Page 113

SINUMERIK 808D ADVANCED alarms 3.2 NCK alarms 10747 [Channel %1: ] Block %2 retraction direction not defined for WAB Parameters: %1 = Channel number %2 = Block number, label Definitions: In a WAB retraction block with quarter circle or semi-circle (G248 or G348), the end point in the machining plane was not programmed, and either G143 or G140 without tool radius compensation is active. -

Page 114

SINUMERIK 808D ADVANCED alarms 3.2 NCK alarms Definitions: The «Bottleneck detection» (calculation of intersection for the following compensated traversing blocks) has not been able to calculate a point of intersection for the reviewed number of traversing blocks. It is therefore possible that one of the equidistant paths violates the workpiece contour. -

Page 115

SINUMERIK 808D ADVANCED alarms 3.2 NCK alarms 10754 [Channel %1: ] Block %2 deselection of the tool radius compensation only possible in linear block Parameters: %1 = Channel number %2 = Block number, label Definitions: Deselection of tool radius compensation with G40 can only be performed in blocks where the G function G00 (rapid traverse) or G01 (feed) is active. -

Page 116

SINUMERIK 808D ADVANCED alarms 3.2 NCK alarms NC Stop on alarm at block end. Remedy: Place deselection of the CRC such that the programmed end point comes to rest outside the compensation circle around the last active compensation point. The following possibilities are available:… -

Page 117

SINUMERIK 808D ADVANCED alarms 3.2 NCK alarms Reaction: Correction block is reorganized. Local alarm reaction. Interface signals are set. Alarm display. NC Stop on alarm at block end. Remedy: Do not use splines or polynomials when writing the contour section, but straight lines and circles instead. Divide up the tool piece geometry and deselect the cutter radius compensation between the various sections. -

Page 118

SINUMERIK 808D ADVANCED alarms 3.2 NCK alarms Remedy: — Modify part program — Modify machine data — Check whether SBL2 is activated. With SBL2, a block is generated from each part program line which can lead to exceeding the maximum permissible number of empty blocks between two traversing blocks. -

Page 119

SINUMERIK 808D ADVANCED alarms 3.2 NCK alarms 10770 [Channel %1: ] Block %2 change of corner type due to change of orientation with active tool radius compensation Parameters: %1 = Channel number %2 = Block number, label Definitions: The type of a corner (inside or outside corner) depends not only on the programmed path but also on the tool orientation. -

Page 120

SINUMERIK 808D ADVANCED alarms 3.2 NCK alarms 10778 [Channel %1: ] Block %2 preprocessing stop with active tool radius compensation Parameters: %1 = Channel number %2 = Block number, label Definitions: If a preprocessing stop is detected with active tool radius compensation (either programmed by the user or generated… -

Page 121

SINUMERIK 808D ADVANCED alarms 3.2 NCK alarms Alarm display. NC Stop on alarm at block end. Remedy: Modify part program. Program Clear alarm with NC START or RESET key and continue the program. Continuation: 10784 [Channel %1: ] Block %2 illegal tool for tool radius compensation with constraint… -

Page 122

SINUMERIK 808D ADVANCED alarms 3.2 NCK alarms 10792 [Channel %1: ] Block %2 illegal interpolation type during linear programming with angles Parameters: %1 = Channel number %2 = Block number, label Definitions: Only spline or linear interpolation is permitted for programming two straight lines with angle specification. Circular or polynomial interpolation is not allowed. -

Page 123

SINUMERIK 808D ADVANCED alarms 3.2 NCK alarms Definitions: During programming of a straight line, both positions of the active plane and an angle were specified (the position of the end point is over-specified), or the position of the programmed coordinate cannot be reached with the specified angle. -

Page 124

SINUMERIK 808D ADVANCED alarms 3.2 NCK alarms For the definition the MD 20090 $MC_SPIND_DEF_MASTER_SPIND is available for the default or the keyword SETMS in the part program, thus allowing each spindle of the channel to be redefined as master spindle. -

Page 125

SINUMERIK 808D ADVANCED alarms 3.2 NCK alarms 10861 [Channel %1: ] Block %3 velocity of positioning axis %2 is zero Parameters: %1 = Channel number %2 = Axis %3 = Block number, label Definitions: No axis velocity has been programmed and the positioning velocity set in the machine data is zero. -

Page 126

SINUMERIK 808D ADVANCED alarms 3.2 NCK alarms Reaction: Correction block is reorganized. Local alarm reaction. Interface signals are set. Alarm display. NC Stop on alarm. Remedy: Check the NC program for correct tool selection and correct it, if required; then continue the NC program with NC start. -

Page 127

SINUMERIK 808D ADVANCED alarms 3.2 NCK alarms Local alarm reaction. Interface signals are set. Alarm display. Remedy: Modify part program such that the number of dummy blocks is reduced. Program Clear alarm with NC START or RESET key and continue the program. -

Page 128

SINUMERIK 808D ADVANCED alarms 3.2 NCK alarms 10891 [Channel %1: ] Block %2 multiplicity of node is greater than its order Parameters: %1 = Channel number %2 = Block number, label Definitions: In the B spline the distance between nodes PL (node = point on spline at which 2 polynomials meet) has been programmed with zero too often in succession (i.e. -

Page 129

SINUMERIK 808D ADVANCED alarms 3.2 NCK alarms Local alarm reaction. NC Start disable in this channel. Interface signals are set. Alarm display. Remedy: Modify part program. Program Clear alarm with the RESET key. Restart part program Continuation: 10912 [Channel %1: ] Block %2 preprocessing and main run might not be synchronized… -

Page 130

SINUMERIK 808D ADVANCED alarms 3.2 NCK alarms 10915 [Channel %1: ] Block %2 Preparation problem in LookAhead (Identifier %3, Details %4) Parameters: %1 = Channel number %2 = Block number, label %3 = Error code %4 = Error details Definitions: The NCK was incorrectly parameterized (under certain circumstances, the parameterized memory is not sufficient), which is why LookAhead can no longer be operated in the expansion mode. -

Page 131

SINUMERIK 808D ADVANCED alarms 3.2 NCK alarms NC Start disable in this channel. Interface signals are set. Alarm display. Remedy: The errors listed above must be corrected in the subroutine for the stock removal contour. Program Clear alarm with the RESET key. Restart part program… -

Page 132

SINUMERIK 808D ADVANCED alarms 3.2 NCK alarms Definitions: The calculation of the arc length function could not be performed to the required accuracy. Reaction: Alarm display. Warning display. Remedy: The calculation of the arc length function could not be performed to the required accuracy during active polynomial interpolation. -

Page 133

SINUMERIK 808D ADVANCED alarms 3.2 NCK alarms 12000 [Channel %1: ] Block %2 address %3 programmed repeatedly Parameters: %1 = Channel number %2 = Block number, label %3 = Source string of the address Definitions: Most addresses (address types) may only be programmed once in an NC block, so that the block information remains unambiguous (e.g. -

Page 134

SINUMERIK 808D ADVANCED alarms 3.2 NCK alarms Definitions: In polynomial interpolation, polynomials must not be greater than the 3rd degree (refer to Programming Guide). f(p) = a0 + a1 p + a2 p2 + a3 p3 The coefficients a0 (the starting points) are identical to the end points of the preceding block and need not be programmed. -

Page 135

SINUMERIK 808D ADVANCED alarms 3.2 NCK alarms Definitions: The G functions that can be used in the part program are divided into groups that are syntax defining or non-syntax defining. Only one G function may be programmed from each G group. The functions within a group are mutually preclusive. -

Page 136

SINUMERIK 808D ADVANCED alarms 3.2 NCK alarms 12090 [Channel %1: ] Block %2 unexpected parameter %3 Parameters: %1 = Channel number %2 = Block number, label %3 = Disallowed parameters in the text Definitions: The programmed function has been predefined; no parameters are allowed in its call. The first unexpected parameter is displayed. -

Page 137

SINUMERIK 808D ADVANCED alarms 3.2 NCK alarms G92: Spindle speed limitation with v constant STARTFIFO, STOPFIFO: Control of preprocessing buffer E.g. G4 F1000 M100: no M function allowed in the G4 block. Reaction: Correction block is reorganized. Interface signals are set. -

Page 138

SINUMERIK 808D ADVANCED alarms 3.2 NCK alarms Reaction: Correction block is reorganized. Interface signals are set. Alarm display. Remedy: Press the NC Stop key and select the function «Correction block» with the softkey PROGRAM CORRECT. The correction pointer positions on the incorrect block. -

Page 139

SINUMERIK 808D ADVANCED alarms 3.2 NCK alarms 22 Frequency [Hz] 23 Voltage [V] 24 Current [A] 25 Temperature [degrees Celsius] 26 Angle [degrees] 27 KV [ 1000/min ] 28 Linear or angluar position [mm|deg or inch|deg] 29 Cutting velocity [m/min; feet/min] 30 Peripheral velocity [m/s;… -

Page 140

SINUMERIK 808D ADVANCED alarms 3.2 NCK alarms Reaction: Correction block is reorganized. Interface signals are set. Alarm display. Remedy: If access protection in the part program and on the OPI needs to be set to diffferent levels, only the language commands APWP, APWB, APRP and APRB may be used. -

Page 141

SINUMERIK 808D ADVANCED alarms 3.2 NCK alarms 12190 [Channel %1: ] Block %2 variable of type ARRAY has too many dimensions Parameters: %1 = Channel number %2 = Block number, label Definitions: Array with variables of type STRING may be no more than 1-dimensional, and with all other variables no more than 2-dimensional. -

Page 142

SINUMERIK 808D ADVANCED alarms 3.2 NCK alarms Definitions: — In the definition of a STRING type variable, an attempt has been made to initialize more than 200 characters. — In an allocation, it has been found that the string does not fit the given variable. -

Page 143

SINUMERIK 808D ADVANCED alarms 3.2 NCK alarms Definitions: Only 1 tool orientation can be programmed per DIN block. This can either be defined via the 3 Euler angles, or the end points of the axes, or through direction vectors. Reaction: Correction block is reorganized. -

Page 144

SINUMERIK 808D ADVANCED alarms 3.2 NCK alarms Reaction: Correction block is reorganized. Interface signals are set. Alarm display. Remedy: IPerform initialization in separate block in the execution part of the program: DEF FRAME LOCFRAME LOCFRAME = CTRANS(X,200) When using for axis variables:… -

Page 145

SINUMERIK 808D ADVANCED alarms 3.2 NCK alarms Remedy: Press the NC Stop key and select the function «Correction block» with the softkey PROGRAM CORRECT. The correction pointer positions on the incorrect block. Define the required variable in the definition part of the program (possibly in the calling program if it is to be a global variable). -

Page 146

SINUMERIK 808D ADVANCED alarms 3.2 NCK alarms Reaction: Correction block is reorganized. Interface signals are set. Alarm display. Remedy: Press the NC Stop key and select the function «Correction block» with the softkey PROGRAM CORRECT. The correction pointer positions on the incorrect block. -

Page 147

SINUMERIK 808D ADVANCED alarms 3.2 NCK alarms 12340 [Channel %1: ] Block %2 number of parameters too high %3 Parameters: %1 = Channel number %2 = Block number, label %3 = Source string Definitions: When calling a function or a procedure (predefined or user-defined) more parameters were transferred than defined. -

Page 148

SINUMERIK 808D ADVANCED alarms 3.2 NCK alarms 12370 [Channel %1: ] Block %2 range of values %3 not permissible Parameters: %1 = Channel number %2 = Block number, label %3 = Source string Definitions: A variable has been initialized with a value range outside an initialization block. The definition of program-global variables is allowed only in special initialization blocks. -

Page 149

SINUMERIK 808D ADVANCED alarms 3.2 NCK alarms Reaction: Correction block is reorganized. Interface signals are set. Alarm display. Remedy: Press the NC Stop key and select the function «Correction block» with the softkey PROGRAM CORRECT. The correction pointer positions on the incorrect block. -

Page 150

SINUMERIK 808D ADVANCED alarms 3.2 NCK alarms Alarm display. Remedy: Press the NC Stop key and select the function «Correction block» with the softkey PROGRAM CORRECT. The correction pointer positions on the incorrect block. The symbol to be created or the target of program jumps (label) must conform to the system specifications, that means the name must begin with 2 letters (but the 1st sign must not be «$») and may be up to a maximum of 32 characters. -

Page 151

SINUMERIK 808D ADVANCED alarms 3.2 NCK alarms 12460 [Channel %1: ] Block %2 maximum number of symbols exceeded with %3 Parameters: %1 = Channel number %2 = Block number, label %3 = Source string Definitions: The max. number of variable definitions (GUD, LUD), macro definitions, cycle programs and/or cycle parameters (PROC instruction) that the controller’s data management system is able to handle has been exceeded. -

Page 152

SINUMERIK 808D ADVANCED alarms 3.2 NCK alarms Definitions: A non-allowed G function number (parameter 3) has been programmed for a G group with indirect G code programming. Only the G function numbers indicated in the Programming Guide «Fundamentals», Section 12.3 «List of G functions/Path conditions»… -

Page 153

SINUMERIK 808D ADVANCED alarms 3.2 NCK alarms Remedy: Press the NC Stop key and select the function «Correction block» with the softkey PROGRAM CORRECT. The correction pointer positions on the incorrect block. — Use the REDEF instruction only in the INITIAL_INI block… -

Page 154

SINUMERIK 808D ADVANCED alarms 3.2 NCK alarms N … Reaction: Correction block is reorganized. Interface signals are set. Alarm display. Remedy: Press the NC Stop key and select the function «Correction block» with the softkey PROGRAM CORRECT. The correction pointer positions on the incorrect block. -

Page 155

SINUMERIK 808D ADVANCED alarms 3.2 NCK alarms Definitions: The maximum internal block length after translator processing must not exceed 256 characters. After editing, for example, several macros in the block or a multiple nesting, this limit can be exceeded. Reaction: Correction block is reorganized. -

Page 156

SINUMERIK 808D ADVANCED alarms 3.2 NCK alarms 12553 [Channel %1: ] Block %2 name %3 option/function is not active Parameters: %1 = Channel number %2 = Block number, label %3 = Source symbol Definitions: The option (if MD10711 $MN_NC_LANGUAGE_CONFIGURATION = 1) or the NC function (if MD10711 $MN_NC_LANGUAGE_CONFIGURATION = 3) related to this language command is not active. -

Page 157

SINUMERIK 808D ADVANCED alarms 3.2 NCK alarms 12556 [Channel %1: ] Block %2 name %3 Name is already known Parameters: %1 = Channel number %2 = Block number, label %3 = Source symbol Definitions: The name of the symbol to be created is part of the NC language scope and therefore already known. Although the NC function is not active, this name can no longer be used for GUDs, macros and PROC definitions. -

Page 158

SINUMERIK 808D ADVANCED alarms 3.2 NCK alarms 12571 [Channel %1: ] Block %2 %3 not permissible for motion synchronous action Parameters: %1 = Channel number %2 = Block number, label %3 = Source symbol Definitions: The predefined subprogram %3 specified here is not allowed in a block with motion synchronous action. It may only be contained in a «normal»… -

Page 159

SINUMERIK 808D ADVANCED alarms 3.2 NCK alarms 12581 [Channel %1: ] Block %2 invalid read access to %3 while in motion synchronous action Parameters: %1 = Channel number %2 = Block number, label %3 = Source symbol Definitions: In a motion synchronous action, the displayed variable must not be entered as a variable that is to be read online, i.e. -

Page 160

SINUMERIK 808D ADVANCED alarms 3.2 NCK alarms 12584 [Channel %1: ] Block %2 variable %3 cannot be read synchronously with motion Parameters: %1 = Channel number %2 = Block number, label %3 = Source symbol Definitions: In motion synchronous actions on the left side of the compare operation, only special variables are allowed as input variables of SYNFCT and as input variables for PUTFTOCF. -

Page 161

SINUMERIK 808D ADVANCED alarms 3.2 NCK alarms 12587 [Channel %1: ] Block %2 motion synchronous action: operation/function %3 not allowed Parameters: %1 = Channel number %2 = Block number %3 = Operator/function Definitions: The specified function / operator is not permissible for logic operations of real-time variables in motion synchronous actions. -

Page 162

SINUMERIK 808D ADVANCED alarms 3.2 NCK alarms Definitions: The number of global user data blocks is defined in MD18118 $MN_MM_NUM_GUD_MODULES. Here, _N_SGUD_DEF corresponds to block 1, _N_MGUD_DEF corresponds to block 2, _N_UGUD_DEF corresponds to block 3, _N_GUD4_DEF corresponds to block 4 etc. -

Page 163

SINUMERIK 808D ADVANCED alarms 3.2 NCK alarms 12630 [Channel %1: ] Block %2 skip ID/label in control structure not allowed Parameters: %1 = Channel number %2 = Block number Definitions: Blocks with control structures (FOR, ENDIF, etc.) cannot be concealed and must not contain any labels. -

Page 164

The programmed language element is not allowed or unknown in external language mode. Only the language elements from Siemens mode which are used for subprogram calls (except for Lxx) and the language constructs for program repetition with REPEAT (UNTIL) are allowed. -

Page 165

SINUMERIK 808D ADVANCED alarms 3.2 NCK alarms 12722 [Channel %1: ] Block %2 multiple ISO_2/3 macro or cycle calls in the block Parameters: %1 = Channel number %2 = Block number, label Definitions: A mixture of cycle and macro calls are programmed in a block, e.g. cycle calls with G81 — G89 together with an M macro in the block or a G65/G66 macro call together with M macros in the block. -

Page 166