15

Errors occurring during the operation of the virtual encoder are shown as «Error 38: Error

in one technology function» (main error). The sub error code offers more information on

the cause of the error.

Suber-

ror

Problem

code

Electronic cam

3

Incorrect flow control block type.

4

Incorrect flow table block type.

5

Incorrect profile generator block type.

6

Incorrect derivative generator block type.

7

Incorrect motor management block type.

8

Flow control block version is newer than

that of the firmware.

9

Flow table block version is newer than

that of the firmware.

10

Profile generator block version is newer

than that of the firmware.

11

Derivative generator block version is

newer than that of the firmware.

12

Motor management block version is

newer than that of the firmware.

13

Start address of CAMFlow table block not

within DDB.

14

The denominator of a mathematical curve

must not be zero.

15

Invalid start curve type.

16

This curve type is not permitted.

17

–

18

The master cycle of a curve defined by

control points must be greater than zero.

19

A sequence of transition functions is not

permitted.

20

A transition function may not be con-

nected to speed control.

21

A mathematic curve may not precede

speed control.

22

Absolute position control may not precede

speed control.

23

Relative position control may not precede

speed control.

24

Start curve number is negative (not initial-

ized).

25

A negative curve number is not permitted

(not initialized).

Technology Functions Manual – MOVIAXIS® Multi-Axis Servo Inverter

Response

Stop at application limit

Stop at application limit

Stop at application limit

Stop at application limit

Stop at application limit

Stop at application limit

Stop at application limit

Stop at application limit

Stop at application limit

Stop at application limit

Stop at application limit

Stop at application limit

Stop at application limit

Stop at application limit

–

Stop at application limit

Stop at application limit

Stop at application limit

Stop at application limit

Stop at application limit

Stop at application limit

Stop at application limit

Stop at application limit

Error description

Remedy

Check structure in the DDB.

Download the project again, if necessary.

Make sure that the Output and Reverse

output are connected in all curve blocks.

Check structure in the DDB.

Download the project again, if necessary.

Check structure in the DDB.

Download the project again, if necessary.

Check structure in the DDB.

Download the project again, if necessary.

Check structure in the DDB.

Download the project again, if necessary.

Check structure in the DDB.

Download the project again, if necessary.

Update firmware.

Update firmware.

Update firmware.

Check structure in the DDB.

Download the project again, if necessary.

The parameter CFT Denominator factor is

zero for one or several mathematical

curves (control-point-based curves).

Start curves may not be transition func-

tions.

The value of the CFT Curve type parame-

ter of a curve is not permitted.

–

The parameter CFT Master cycle of a

mathematical curve (control-point-based

curve) must be set > 5.

Transition functions must not be con-

nected in sequence. You must always

connect another curve type in between.

A transition function must not follow or

precede the curve type «absolute speed

control».

The curve type «speed control» must not

follow a «mathematic curve».

The curve type «speed control» must not

follow «absolute position control».

The curve type «speed control» must not

follow «relative position control».

The «Start» output of the system block is

not connected to a start curve.

The value of the CFT Curve type parame-

ter of a curve is not permitted.

n

n

kVA

kVA

15

f

f

i

i

P

Hz

P

Hz

217

- Manuals

- Brands

- SEW-Eurodrive Manuals

- Inverter

- MOVIAXIS MXP81A 503-00 Series

Manuals and User Guides for SEW-Eurodrive MOVIAXIS MXP81A 503-00 Series. We have 1 SEW-Eurodrive MOVIAXIS MXP81A 503-00 Series manual available for free PDF download: System Manual

-

Page 1

Gearmotors Industrial Gear Units Drive Electronics Drive Automation Services ® MOVIAXIS MX Multi-Axis Servo Inverter Edition 07/2007 perating nstructions 11508213 / EN… -

Page 2

SEW-EURODRIVE – Driving the world… -

Page 3: Table Of Contents

Contents General Information ………………6 Structure of the safety notes …………..6 Right to claim under warranty …………..6 Exclusion of liability………………. 6 Safety Notes …………………. 7 General information ……………… 7 Target group ………………… 7 Designated use ………………7 Transportation, storage…………….8 Installation………………..

-

Page 4

………………70 Signal bus connection cable for several axis systems – EtherCAT-based…………. 71 Signal bus cables to other SEW units — EtherCAT-based system bus..72 Covers and touch guards……………. 73 Electrical Installation …………….74 4.10 Wiring diagrams ………………78 4.11 Terminal assignment……………. -

Page 5

Contents Service ………………….179 General information …………….179 Removing / installing a module …………. 180 Extended storage……………… 186 Waste disposal………………186 Technical Data………………..187 CE marking and approvals…………..187 General technical data …………….188 Technical data for the supply module ……….. 189 Technical data for the axis module ………… -

Page 6: General Information

MOVIAXIS multi-axis servo inverter and to achieve the spec- ified product characteristics and performance requirements. SEW-EURODRIVE as- sumes no liability for injury to persons or damage to equipment or property resulting from non-observance of these operating instructions. In such cases, any liability for defects is excluded.

-

Page 7: Safety Notes

If you are unclear about any of the information in this documentation, or if you require further information, please contact SEW-EURO- DRIVE.

-

Page 8: Transportation, Storage

Safety Notes Transportation, storage Startup (i.e. start of designated operation) is only permitted with adherence to EMC (89/336/EEC) guideline. The multi-axis servo inverters meet the requirements stipulated in the low voltage guide- line 2006/95/EC. The harmonized standards of the EN 61800-5-1 DIN VDE/T105 series in connection with EN 60439-1 VDE 0660 part 500 and EN 60146 VDE/0558 are applied to the multi-axis servo inverters.

-

Page 9: Electrical Connection

Safety Notes Electrical connection Electrical connection Observe the applicable national accident prevention guidelines when working on live multi-axis servo inverters (for example, BGV A3). Perform electrical installation according to the pertinent regulations (e.g. cable cross sections, fusing, protective conductor connection). Additional information is contained in the documentation.

-

Page 10: Unit Temperature

Safety Notes Unit temperature Unit temperature ® MOVIAXIS multi-axis servo inverters are usually operated with braking resistors. The braking resistors can also be installed in the housing of the supply modules. The braking resistors can reach surface temperatures ranging from 70 °C to 250 °C. ®…

-

Page 11: Unit Design

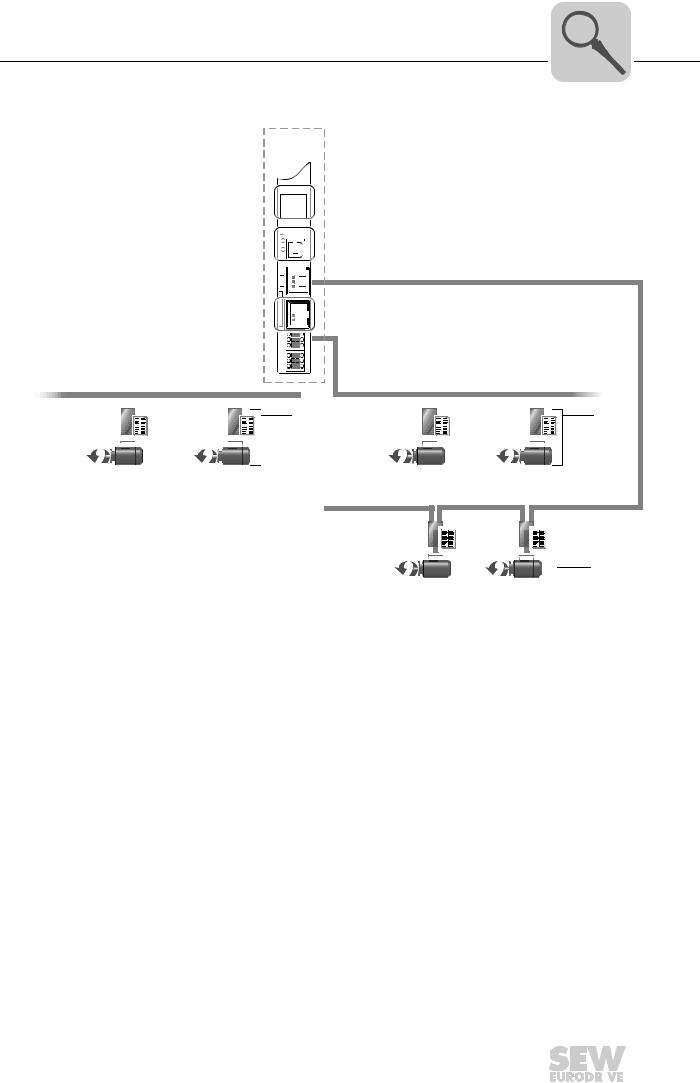

Unit Design Axis system with CAN-based system bus Unit Design Axis system with CAN-based system bus [10] 61523axx ® Figure 1: Sample structure of a MOVIAXIS axis system Master module Axis module size 4 Capacitor or buffer module Axis module size 3 Supply module size 3 Axis module size 2 Axis module size 6…

-

Page 12: Axis System With Ethercat-Based System Bus

Unit Design Axis system with EtherCAT-based system bus Axis system with EtherCAT-based system bus [10] [11] 62072axx ® Figure 2: Sample structure of a MOVIAXIS axis system Master module Axis module size 4 Capacitor or buffer module Axis module size 3 Supply module size 3 Axis module size 2 Option card for EtherCAT-based system…

-

Page 13: Important Notes

Unit Design Important notes Important notes Protective measures and protective equipment have to meet the respective national regulations in force. Required preventive measures: Protective grounding (protection class I) Required protection devices: The overcurrent protection devices have to be designed to protect the lines at the cus- tomer’s site.

-

Page 14: Nameplates And Unit Designations

Unit Design Nameplates and unit designations Nameplates and unit designations The nameplate is divided into up to three parts depending on the module. • Part «I»of the nameplate indicates the unit designation, production number and sta- tus. • Part «II» of the nameplate indicates the factory installed options and the version sta- tus.

-

Page 15

Unit Design Nameplates and unit designations Axis module nameplate XFA11A XIO11A XFP11A XIA11A XIA11A 10 11 10 10 11 11 11 10 61847axx ® Figure 4: Example: MOVIAXIS MX axis module nameplate Part «I» of the nameplate: Located on the Unit designation, see page 17 upper fastening plate of the module Part «II»… -

Page 16

Unit Design Nameplates and unit designations Nameplate of the 24 V switched mode power supply additional module 61849axx Figure 6: Example: Nameplate of a 24 V switched-mode power supply module Part «I» of the nameplate: Located on the Unit designation upper fastening plate of the module Part «III»… -

Page 17

Unit Design Nameplates and unit designations ® Example: Unit designation for MOVIAXIS basic units -004 — 00 00 = Standard design XX = Special design 3-phase connection type 50 = U = AC 380 — 500 V connection voltage Versions: 004 = For axis modules the rated current, such as 004 = 4 A 050 =… -

Page 18

Unit Design Nameplates and unit designations Unit designation for the supply module: MXP80A-010-503-00 10 kW supply module MXR80A-025-503-00 25 kW supply module with regeneration (in preparation) Unit designation for the 24 V switched-mode power supply module component MXS80A-060-503-00 24 V switched-mode power supply module Unit designation DC link discharge module component: DC link discharge module with a dissipatable energy quantity of MXZ80A-050-503-00… -

Page 19: Standard Accessories

Unit Design Standard accessories Standard accessories Standard accessories are included with the basic unit at delivery. [15] [16] [17] [18] [19] [10] [20] [11] [21] [22] [12] [23] [24] [25] [26] [27] [13] [28] [29] [14] [30] 61637axx Figure 8: Standard accessories The corresponding mating connectors for all connectors are installed at the factory.

-

Page 20

Unit Design Standard accessories Standard accessory assignment table MXP [kW] MXA [A] Dimen- sions Touch guard DC link connection [2] 76 mm [3] 106 mm [4] 136 mm [5] 160 mm [6] 226 mm Electronics shield clamp [7] 60 mm [8] 90 mm [9] 120 mm [10] 150 mm… -

Page 21: Optional Accessories

Figure 9: Optional accessories Optional accessory assignment table Dimension / Designation / Connector type System bus connection cable for CAN-based system bus (axis system with other SEW units) 750 mm RJ45 / open end 3,000 mm RJ45 / open end Connection cable EtherCAT –…

-

Page 22: Overview Of An Axis System

Unit Design Overview of an axis system Overview of an axis system The units are displayed without cover in the following figure. 61507axx Figure 10: Exemplary representation of the energy supply in the axis system X4: DC link connection X5a, X5b: 24 V voltage supply Master module Capacitor / buffer module Supply module BG 3…

-

Page 23: Unit Design Of Moviaxis® Mxp Power Supply Module

Unit Design Unit design of MOVIAXIS® MXP power supply module ® Unit design of MOVIAXIS MXP power supply module The following figures show the units without cover. ® MOVIAXIS MXP supply module size 1 [13] [14] [10] [12] [11] 61524axx ®…

-

Page 24

Unit Design Unit design of MOVIAXIS® MXP power supply module ® MOVIAXIS MXP supply module size 2 [13] [14] [10] [11] [12] 64525axx ® Figure 12: Unit design of MOVIAXIS MXP power supply module size 2 View from top View from front View from bottom Signaling bus Electronics shield clamps… -

Page 25

Unit Design Unit design of MOVIAXIS® MXP power supply module ® MOVIAXIS MXP supply module size 3 [10] [11] [14] [12] [13] 55468AXX ® Figure 13: Unit design of MOVIAXIS MXP power supply module size 3 View from top View from front Signaling bus Electronics shield clamps X9a: Input, green plug on cable… -

Page 26: Unit Design Of Moviaxis® Mxa Axis Modules

Unit Design Unit design of MOVIAXIS® MXA axis modules ® Unit design of MOVIAXIS MXA axis modules The following figures show the units without cover. ® MOVIAXIS MXP axis module size 1 [11] [12] [13] [10] 61544axx ® Figure 14: Unit design of MOVIAXIS MXA axis module size 1 View from top View from front…

-

Page 27

Unit Design Unit design of MOVIAXIS® MXA axis modules ® MOVIAXIS MXP axis module size 2 [11] [12] [13] [10] 61545axx ® Figure 15: Unit design of MOVIAXIS MXA axis module size 2 View from top View from front View from bottom Signaling bus Electronics shield clamps [11]… -

Page 28

Unit Design Unit design of MOVIAXIS® MXA axis modules ® MOVIAXIS MXP axis module size 3 [11] [12] [13] [10] 61546axx ® Figure 16: Unit design of MOVIAXIS MXA axis module size 3 View from top View from front View from bottom Signaling bus Electronics shield clamps [11]… -

Page 29

Unit Design Unit design of MOVIAXIS® MXA axis modules ® MOVIAXIS MXP axis module size 4 [12] [13] [10] [11] 61547axx ® Figure 17: Unit design of MOVIAXIS MXA axis module size 4 View from top View from front View from bottom Signaling bus Electronics shield clamps [12]… -

Page 30

Unit Design Unit design of MOVIAXIS® MXA axis modules ® MOVIAXIS MXP axis module size 5 [12] [13] [10] [11] 61548axx ® Figure 18: Unit design of MOVIAXIS MXA axis module size 5 View from top View from front View from bottom Signaling bus Electronics shield clamps [12]… -

Page 31

Unit Design Unit design of MOVIAXIS® MXA axis modules ® MOVIAXIS MXP axis module size 6 [12] [13] [10] [11] 61549axx ® Figure 19: Unit design of MOVIAXIS MXA axis module size 6 View from top View from front View from bottom Signaling bus Electronics shield clamps [12]… -

Page 32: System Bus In Ethercat- Or Can-Based Version

Unit Design System bus in EtherCAT- or CAN-based version 3.10 System bus in EtherCAT- or CAN-based version Axis modules can be equipped with different system bus versions: • CAN-based system bus, • EtherCAT-based system bus. The figures displayed on page 26… page 31 show the axis modules with CAN-based system bus.

-

Page 33: Unit Design Of The Moviaxis® Mxm Master Module Component

Unit Design Unit design of the MOVIAXIS® MXM master module component ® 3.11 Unit design of the MOVIAXIS MXM master module component The following figure shows the unit without cover. ® MOVIAXIS MXM master module in MOVI-PLC basic version master module shown here…

-

Page 34

Unit Design Unit design of the MOVIAXIS® MXM master module component ® MOVIAXIS MXM master module in MOVI-PLC advanced version master module shown here following designation: MXM80A-000-000-00/DHE41B. 62207axx ® Figure 22: Unit design of the master module, MOVI-PLC Advanced version View from front ®… -

Page 35: Unit Design Of The Moviaxis Mxc Capacitor Module Component

Unit Design Unit design of the MOVIAXIS® MXC capacitor module component ® 3.12 Unit design of the MOVIAXIS MXC capacitor module component The following figure shows the unit without protective cover. Capacitor module MXC 60433AXX ® Figure 23: Unit design of the MOVIAXIS MXC capacitor module View from front Standby display (Power)

-

Page 36: Unit Design Of The Moviaxis Mxb Buffer Module Component

Unit Design Unit design of the MOVIAXIS® MXB buffer module component ® 3.13 Unit design of the MOVIAXIS MXB buffer module component The following figure shows the unit without protective cover. Buffer module 60433AXX ® Figure 24: Unit design of the MOVIAXIS MXB buffer module View from front No function…

-

Page 37: Unit Design Of The Moviaxis ® Mxs 24 V Switched-Mode

Unit Design Unit design of the MOVIAXIS® MXS 24 V switched-mode power supply ® 3.14 Unit design of the MOVIAXIS MXS 24 V switched-mode power supply module component The following figure shows the unit without protective cover. 24 V switched-mode power supply module 57583axx Figure 25: Units design of the 24 V switched-mode power supply module View from top…

-

Page 38: Unit Design Of The Moviaxis Mxz Dc Link Discharge Module Component

Unit Design Unit design of the MOVIAXIS® MXZ DC link discharge module component ® 3.15 Unit design of the MOVIAXIS MXZ DC link discharge module component The following figure shows the unit without protective cover. ® DC link discharge module MOVIAXIS 54427BXX ®…

-

Page 39: Option Combinations On Delivery

Unit Design Option combinations on delivery 3.16 Option combinations on delivery The axis modules include an expansion system for up to three options. 56598axx Figure 27: Slot combinations [1 — 3] Slots 1 — 3, assignment see following table [4] Control board — Basic unit components EtherCAT- The following table shows the possible combinations and the fixed assignment of cards capable units…

-

Page 40

Unit Design Option combinations on delivery CAN version of The following tables show the possible combinations and the fixed assignment of cards the units to the slots. Fieldbus The fieldbus options can be plugged in the following combinations: combinations Combination Slot 1 Slot 2 Slot 3… -

Page 41

Unit Design Option combinations on delivery Combinations with The following option card combinations are possible: Combination Slot 1 Slot 2 Slot 3 XIA11A XIA11A Combinations with The following option card combinations are possible: XGH, XGS only Combination Slot 1 Slot 2 Slot 3 Combinations with The following option card combinations are possible:… -

Page 42: Multi-Encoder Card Option Xgh11A, Xgs11A

Unit Design Multi-encoder card option XGH11A, XGS11A 3.17 Multi-encoder card option XGH11A, XGS11A ® The multi-encoder card expands the MOVIAXIS system for evaluation of additional en- coders. Two different multi-encoder cards are available. Their selection is based on the encoder type that is to be evaluated, see table on page 44.

-

Page 43

Analog input Optional 24 V voltage supply Resolver • Please contact SEW-EURODRIVE before installing HTL encoders. • You need 15-pole SUB-D connectors for all encoders that are to be connected to the multi-encoder card. Operating Instructions – MOVIAXIS® MX Multi-Axis Servo Inverter… -

Page 44

Unit Design Multi-encoder card option XGH11A, XGS11A Suitable The encoders listed in the following tables are evaluated by the multi-encoder card. encoders SEW encoder desig- Manufacturer designation / Voltage Encoder system nation manufacturer AL1H Hiperface linear encoder L230 / SICK-Stegmann… -

Page 45

Unit Design Multi-encoder card option XGH11A, XGS11A Manufacturer designation / Encoder system Voltage manufacturer Laser encoder DME5000 / SICK-Stegmann 24 V Laser encoder DME4000 / SICK-Stegmann Hiperface single-turn absolute encoder SRS60 / SICK-Stegmann Hiperface multi-turn absolute encoder SRM60 / SICK-Stegmann 12 V Single-turn absolute encoder ECN1313 / Heidenhain… -

Page 46

Unit Design Multi-encoder card option XGH11A, XGS11A Restrictions for the evaluation of inputs for axis modules equipped with I / O and multi-encoder cards NOTE If the axis module is equipped with two I / O and one multi-encoder card or with one I / O and two multi-encoder cards (see following table), the following restrictions apply for the evaluation of inputs and outputs: Evaluation is only possible for the inputs and outputs (if applicable) of two cards. -

Page 47

Unit Design Multi-encoder card option XGH11A, XGS11A (DGND) 3 +24 V / +12 V (+24 V) 4 X63 / X64 X63 / X64 62358axx Figure 30: Wiring diagram with two multi-encoder cards Voltage source Multi-encoder card Encoders PIN assignment X62 encoder emu- Terminal Assignment Brief description Type of connector… -

Page 48

Unit Design Multi-encoder card option XGH11A, XGS11A PIN assignment X63 XGH X64 Terminal Function for TTL encoder, sin/cos encoder Type of XGS with TTL connector encoder, sin/cos X63 (XGH) encoder 1 Signal track A (cos+) 2 Signal track B (sin+) 3 Signal track C 4 n.c. -

Page 49

Unit Design Multi-encoder card option XGH11A, XGS11A PIN assignment X63 XGH Terminal Function for EnDat 2.1 Type of X64 XGS with connector EnDat 2.1 X63 (XGH) 1 Signal track A 2 Signal track B 3 Cycle + 4 DATA + 5 n.c. -

Page 50

Unit Design Multi-encoder card option XGH11A, XGS11A PIN assignment X64 XGS with SSI Terminal Function for SSI (AV1Y) Type of (AV1Y) connector X64 (XGS) 1 Signal track A (cos+) 2 Signal track B (sin+) 3 Cycle + 4 DATA + 5 n.c. -

Page 51: Profibus Xfp11A Fieldbus Interface Option

Unit Design PROFIBUS XFP11A fieldbus interface option 3.18 PROFIBUS XFP11A fieldbus interface option Terminal assignment Front view of XFP11A Description switches Function Terminal 56596AXX RUN: PROFIBUS operation Indicates that the bus electronics are operating cor- LED (green) rectly. BUS FAULT: PROFIBUS error Indicates PROFIBUS-DP error.

-

Page 52

Unit Design PROFIBUS XFP11A fieldbus interface option The PROFIBUS interface sends a TTL control signal for a repeater or fiber optic adapter (reference = pin 9) via pin 4 (CNTR-P). NOTE If long bus cables are used, the bus stations must have a «hard» common reference potential. -

Page 53: K-Net Xfa11A Fieldbus Interface Option

Unit Design K-Net XFA11A fieldbus interface option 3.19 K-Net XFA11A fieldbus interface option The XFA11A (K-Net) fieldbus interface is a slave module for connection to a serial bus system for high-speed data transfer. Install no more than one XF11A fieldbus interface per axis module.

-

Page 54: Ethercat Xfe24A Fieldbus Interface Option

Unit Design EtherCAT XFE24A fieldbus interface option 3.20 EtherCAT XFE24A fieldbus interface option The XFE24A fieldbus interface is a slave module for connection to EtherCAT networks. Only one XFE24A fieldbus interface can be installed per axis module. The XFE24A field- ®…

-

Page 55: Xse24A Ethercat-Based System Bus Option

MOVIAXIS . The XSE24A option module is no fieldbus card. It cannot be used for communication with non-SEW EtherCAT masters. Analogously to the wiring of the CAN system bus, the system is connected using the RJ- 45 plug connection on the top of the unit included in the standard scope of delivery. The CAN system bus is not available when XSE24A is used.

-

Page 56: Terminal Expansion Board Type Xio11A Option

Unit Design Terminal expansion board type XIO11A option 3.22 Terminal expansion board type XIO11A option NOTE For information on the ground designations used in the following diagrams, refer to sec. «Terminal assignment» on page 89. STOP There is electrical isolation between servo drive and analog inputs and outputs on the XIO card.

-

Page 57

Unit Design Terminal expansion board type XIO11A option +24V XIO11A +24V Load Logic GND_EXT GND_EXT 58750aen Figure 32: Block diagram for using a free-wheeling diode at the binary output Free-wheeling diode Parallel connection Connecting two binary outputs in parallel doubles the rated current. of binary outputs This module has •… -

Page 58

Unit Design Terminal expansion board type XIO11A option Connection diagram +24V XIO11A Voltage +24V supply GND_EXT Logic GND_EXT GND_EXT 56935aen Figure 33: Block diagram of a binary input +24V XIO11A +24V Load Logic GND_EXT GND_EXT 56936aen Figure 34: Block diagram of a binary output NOTE It the 24 V supply for the outputs is disconnected, the inputs will not function any longer. -

Page 59: Terminal Expansion Board Type Xia11A Option

Unit Design Terminal expansion board type XIA11A option 3.23 Terminal expansion board type XIA11A option NOTE For information on the ground designations used in the following diagrams, refer to sec. «Terminal assignment» on page 89. STOP There is no electrical isolation between servo drive and analog inputs and outputs on the XIA card.

-

Page 60

Unit Design Terminal expansion board type XIA11A option +24V XIA11A +24V Load GND_EXT Logic GND_EXT 56942aen Figure 35: Block diagram for using a free-wheeling diode at the binary output Free-wheeling diode Parallel connection Connecting two binary outputs in parallel doubles the rated current. of binary outputs This module has •… -

Page 61

Unit Design Terminal expansion board type XIA11A option Connection diagram +24V XIA11A Voltage +24V supply GND_EXT Logic GND_EXT GND_EXT 58752aen Figure 36: Block diagram of a binary input +24V XIA11A +24V Load Logic GND_EXT GND_EXT 58753aen Figure 37: Block diagram of a binary output NOTE The XIA11A analog / binary hybrid module has no internal free-wheeling diodes. -

Page 62

Unit Design Terminal expansion board type XIA11A option XIA11A Sensor -10V<U<10V Logic Ground bar 56937aen Figure 38: Block diagram of an analog input XIA11A Actuator Logic Ground bar 56940aen Figure 39: Block diagram of an analog output Operating Instructions – MOVIAXIS® MX Multi-Axis Servo Inverter… -

Page 63: Installation

Installation Mechanical installation Installation Mechanical installation CAUTION ® Do not install defective or damaged modules of the MOVIAXIS MX multi-axis servo inverter; they can possibly result in injuries or damage parts of the production system. ® • Check the MOVIAXIS MX multi-axis servo inverter modules prior to installing them for external damage and replace any damaged modules.

-

Page 64

Installation Mechanical installation ® Rear view of MOVIAXIS MX axis and supply module housing 06695AXX Figure 40: Drilling template Position of tapped hole Table with dimensions, see page 63 Operating Instructions – MOVIAXIS® MX Multi-Axis Servo Inverter… -

Page 65

Installation Mechanical installation ® Rear view of MOVIAXIS MX DC link discharge module housing 06696AXX Figure 41: Drilling template Position of tapped hole Operating Instructions – MOVIAXIS® MX Multi-Axis Servo Inverter… -

Page 66

Installation Mechanical installation Minimum clear- • Leave 100 mm (4 in) clearance at the top and bottom for optimum cooling. Make ance and mount- sure air circulation in the clearance is not impaired by cables or other installation ing position equipment. -

Page 67: Connection Cable For Can-Based System Bus With Optional Master Module

Installation Connection cable for CAN-based system bus with optional master module Connection cable for CAN-based system bus with optional master module The following describes how the signal bus cables of the CAN system bus must be con- nected in the axis system. •…

-

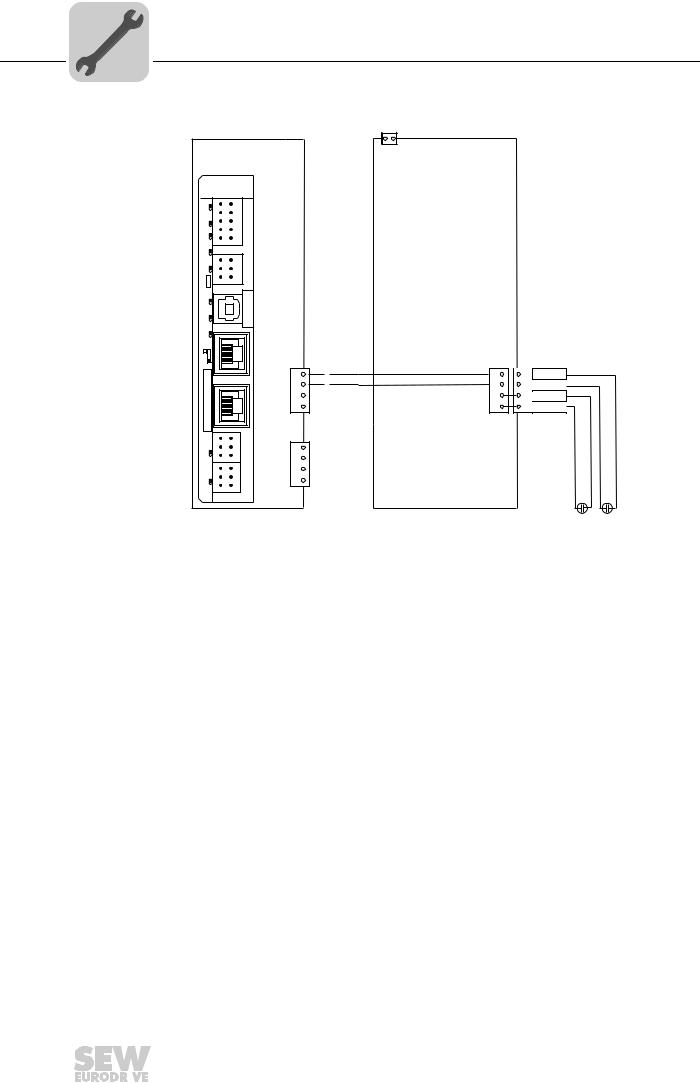

Page 68: System Bus Connection Cable For Several Axis Systems — Can-Based

Installation System bus connection cable for several axis systems – CAN-based System bus connection cable for several axis systems – CAN-based • The individual axis systems are connected as described on page 67. • The CAN connection cable [1] is routed from the red output (X9b) of the last axis module in one axis system to the green input (X9a) of the first axis module of the sub- sequent system.

-

Page 69: System Bus Connection Cable To Other Sew Units — Can-Based

Installation System bus connection cable to other SEW units – CAN-based System bus connection cable to other SEW units – CAN-based System bus connection cable CAN H orange-white Output plug black Terminating resistor CAN L orange Contact shield connection NOTE Establish a common ground potential, e.g.

-

Page 70: Connection Cable Ethercat-Based System Bus — Optional Master Module

Installation Connection cable EtherCAT-based system bus – optional master module Connection cable EtherCAT-based system bus – optional master module The following describes how the signal bus cables of the EtherCAT-based system bus must be connected in the axis system. • Insert the signal bus plugs [1] as described in the following (X9a, X9b): •…

-

Page 71: Signal Bus Connection Cable For Several Axis Systems — Ethercat-Based

Installation Signal bus connection cable for several axis systems – EtherCAT-based Signal bus connection cable for several axis systems – EtherCAT-based • The individual axis systems are connected as described on page 70. • The connection cable [1] is routed from the yellow output (b) of the last axis module in one axis system to the black input (a) of the first axis module of the subsequent system.

-

Page 72: Signal Bus Cables To Other Sew Units — Ethercat-Based System Bus

Installation Signal bus cables to other SEW units — EtherCAT-based system bus Signal bus cables to other SEW units — EtherCAT-based system bus System bus connection cable SEW stations with SEW EtherCAT interface Output plug yellow LAM switch • Switch setting 0: All axis modules except the last one •…

-

Page 73: Covers And Touch Guards

Installation Covers and touch guards Covers and touch guards Cover The following units come equipped with a cover: • Master module (not shown), • Capacitor module (not shown), • Buffer module (not shown), • Supply module; all sizes, • Axis module; all sizes. •…

-

Page 74: Electrical Installation

Installation Electrical Installation Electrical Installation HAZARD Dangerous voltage levels may still be present inside the unit and at the terminal strips up to 10 minutes after the complete axis system has been disconnected from the mains. Severe or fatal injuries from electric shock. To prevent electric shocks: •…

-

Page 75

Installation Electrical Installation Temperature sen- sor in the motor WARNING Dangerous contact voltages at the unit terminals when connecting the wrong temper- ature sensors. Severe or fatal injuries from electric shock. • Connect only temperature sensors with reliable isolation from the motor winding to the temperature evaluation. -

Page 76

199. • SEW-EURODRIVE recommends to connect the braking resistor as shown in figure 46. Install switch F16 close to the unit system. If an unshielded cable is used for con- necting switch F16 with the supply module, keep the length as short as possible. -

Page 77

Installation Electrical Installation ® Electrical • Connect the supply terminals of all units in the MOVIAXIS MX axis system accord- installation ing to the wiring diagrams in section «Wiring diagrams» page 78 ff. • Check to see that the assignment of multi-axis servo drive and motor is correct ac- cording to project planning specification. -

Page 78: Wiring Diagrams

Installation Wiring diagrams 4.10 Wiring diagrams General notes on the wiring diagrams • You will find more information on the connection of power electronics and control electronics in section «Technical Data», page 187. • All units within the axis group will have to be connected to each other via the DC link bus connection (PE, + U , — U ), the 24 V bus (X5a, X5b) and the signaling bus (X9a,…

-

Page 79: Wiring Of Power Terminals

Installation Wiring diagrams Connection of supply module, axis module and capacitor or buffer module Wiring of power terminals L1 L2 L3 Line filter L1´ L2´ L3´ Cable length < 600 mm L2 L3 Capacitor Supply module Axis module Axis module Axis module module PE U…

-

Page 80

** Make sure to provide separate isolation for the brake lines when controlling the brakes with 24 V. We recommend using SEW hybrid cables that offer complete shielding with shielding supports as well as separate shielding for the brake line. -

Page 81

Installation Wiring diagrams Brake control BMK brake control BMK brake control Terminal box connection variant Plug connector connection variant PE U PE U Brake Brake control control Motor Motor Brake Brake Terminal box Brake connector BME brake control Terminal box connection variant Directly controlled motor brake PE U PE U… -

Page 82

Installation Wiring diagrams Connection of supply module Wiring of control electronics X9a X9b Not assigned DGND CAN_L CAN_H DGND CAN_H CAN_L Internal bus terminating resistor 2 x 7-segment displays Supply modules size 1-3 DGND BGND DGND 24 V for 24 V supply brake supply for control electronics* 53664AEN… -

Page 83

Installation Wiring diagrams Connection of axis modules Wiring of control electronics X9a X9b Electronics Input Output signal bus signal bus shield clamps not assigned DGND CAN_L CAN_H DGND Higher-level CAN_H CAN_L not assigned controller not assigned Fixed assignment with DI∅∅ Output stage enable User programmable DI∅1… -

Page 84

Installation Wiring diagrams Connection diagram of binary inputs and outputs +24V DGND DI0 1 .. 8 Logik DCOM 60888axx Figure 50: Block diagram of a binary input +24V DGND Logik D00 1 .. 4 DGND 60889axx Figure 51: Block diagram of a binary output Operating Instructions –… -

Page 85

Installation Wiring diagrams Connection of master module component Wiring DGND BGND DGND 24 V for 24 V supply brake supply* for control electronics* PE (housing grounding point) 62224AEN ® Figure 52: Wiring diagram of MOVIAXIS MXM master module Connection via supplied pre-fabricated cables. STOP The housing grounding point of the master module must be connected to PE, e.g. -

Page 86

Installation Wiring diagrams Connection of capacitor module component Wiring of control electronics DGND BGND DGND 24 V for 24 V supply brake control* for control electronics* 60438AEN ® Figure 53: Wiring diagram control electronics MOVIAXIS MXC capacitor module Connection via supplied pre-fabricated cables. Operating Instructions –… -

Page 87

Installation Wiring diagrams Connection of buffer module component Wiring of control electronics DGND BGND DGND 24 V for 24 V supply brake control* for control electronics* 60438AEN ® Figure 54: Wiring diagram control electronics MOVIAXIS MXB buffer module Connection via supplied pre-fabricated cables. Operating Instructions –… -

Page 88

Installation Wiring diagrams Connection of 24 V switched-mode power supply module component Wiring 24 V external DGND BGND 24 V for 24 V supply 24 V supply for brake supply for control electronics* (channel 1) control electronics (2) 57165aen Figure 55: Wiring of the 24 V switched-mode power supply module Connection via supplied pre-fabricated cables. -

Page 89: Terminal Assignment

Installation Terminal assignment 4.11 Terminal assignment NOTES Reference potentials inside the unit: The designation of the reference potentials is listed in the following table: Designation Meaning DGND General reference potential of control electronics. There is a metallic connection to PE. BGND Reference potential for brake connection RGND…

-

Page 90

Installation Terminal assignment Terminal assignment of the MXP supply modules (10 kW, 25 kW, 50 kW, 75 kW) NOTES The technical data for the connections of power electronics and control electronics are listed in section 9 «Technical Data». Terminal Assignment Brief description X1:1 X1:2… -

Page 91

Installation Terminal assignment Terminal Assignment Brief description X12:1 n.c. X12:2 CAN_L CAN bus low X12:3 DGND Reference potential CAN bus X12:4 CAN_L CAN bus low X12:5 Unit internal SBus terminating resistor termination X12:6 DGND Reference potential CAN bus X12:7 CAN_H CAN bus high X12:8 CAN_H… -

Page 92

Installation Terminal assignment Terminal Assignment Brief description Unit design with one safety relay, optional Safety relay I (sizes 1-6) X7:1 +24 V X7:2 RGND Safety relay I (size 1-6), common contact X7:3 Safety relay I (sizes 1-6), NC contact X7:4 The connector comes equipped with a coding nose. -

Page 93

Installation Terminal assignment Terminal Assignment Brief description X13:1 Signal track A (COS +) X13:2 Signal track B (SIN +) X13:3 Signal track C X13:4 n.c. X13:5 n.c. X13:6 TF / TH / KTY — X13:7 n.c. X13:8 DGND Connection of motor encoders: sin/cos encoder, TTL encoder X13:9 Signal track A_N (COS -) X13:10… -

Page 94

Installation Terminal assignment Terminal assignment of the MXC capacitor module Terminal Assignment Brief description X4:PE X4:1 DC link bar X4:2 X5a:1 +24 V Voltage supply for electronics X5a:2 DGND X5a:3 +24 V Voltage supply for brake supply X5a:4 BGND X5b:1 +24 V Voltage supply for electronics X5b:2… -

Page 95: Connecting Encoders To The Basic Unit

The core colors specified in the wiring diagrams are in accordance with IEC 757 and correspond to the core colors used in the pre-fabricated cables from SEW- EURODRIVE. You will find detailed information in the «SEW encoder systems» manual. The manual is available from SEW-EURODRIVE. Example…

-

Page 96

For drives with a plug connector, connect the shield on the encoder plug. Prefabricated SEW-EURODRIVE offers prefabricated cables for connecting encoders. SEW- cables EURODRIVE recommends to use these prefabricated cables. ® You can find details on prefabricated cables in the «MOVIAXIS MX Multi-Axis Servo Inverter»… -

Page 97: Notes On Electromagnetic Compatibility

Installation Notes on electromagnetic compatibility 4.13 Notes on electromagnetic compatibility Separate cable • Route power cables and electronics leads in separate cable ducts. ducts Shielding and • Only use shielded control cables. grounding • Apply the shield by the shortest possible route and make sure it is grounded over a wide area at both ends.

-

Page 98

Installation Notes on electromagnetic compatibility Interference SEW-EURODRIVE recommends the following EMC measures to limit interference emission emission: • On the supply end: – Select line filters according to the assignment tables of braking resistors and line ® filters in the MOVIAXIS catalog. -

Page 99: Ul Compliant Installation

Installation UL compliant installation 4.14 UL compliant installation Note the following points for UL-compliant installation: • Use only copper cables with the temperature range 60 / 75 °C as connection ca- bles. ® • The permitted tightening torques for MOVIAXIS power terminals are: Tightening torque Power supply module…

-

Page 100

Installation UL compliant installation • The maximum permitted value of the input fuse is: MXP power supply module 10 kW 25 kW 50 kW 75 kW Input fuse 20 A 40 A 80 A 125 A • Only use melting fuses as input fuses. •… -

Page 101: Startup

Startup General information Startup General information HAZARD Uncovered power connections. Severe or fatal injuries from electric shock. • Install the covers at the modules, see page 73. • Install the touch guards according to the regulations, see page 73. ® •…

-

Page 102: Supply Module Settings For A Can-Based System Bus

Startup Supply module settings for a CAN-based system bus Supply module settings for a CAN-based system bus The following settings are necessary: • The CAN baud rate is set using the two DIP switches S1 and S2 on the supply mod- ule, see sec.

-

Page 103

Startup Supply module settings for a CAN-based system bus Setting the CAN baud rate The two DIP switches S1 and S2 have been installed in the supply module for setting the CAN baud rate, see figure 58. 125 kBit/s 250 kBit/s 500 kBit/s 1 MBit/s NOTES… -

Page 104

Startup Supply module settings for a CAN-based system bus The addresses within the axis system are assigned as follows: Signal bus Terminating resistor* a / b a / b a / b a / b a / b a / b a / b a / b a / b… -

Page 105

Startup Supply module settings for a CAN-based system bus Connections and PC diagnostics NOTES CAN connections should only be implemented in the control cabinet to avoid any dif- ference of potential. max. 5 m CAN1 59095axx Figure 60: CAN cable length Connection cable between PC and CAN interface on the supply module. -

Page 106

Startup Supply module settings for a CAN-based system bus Connecting CAN cables to the supply module: Connection assignment of connection and extension cables The connecting and extension cables between the CAN adapter (see page 111) and the axis system comes equipped with a 9 pin D-sub socket on both ends. The pin assign- ment of the connection cable with the 9 pin D-sub CAN connector is shown in the follow- ing figure. -

Page 107

Startup Supply module settings for a CAN-based system bus Bus terminating resistors for CAN / signal bus connection: The signal bus connection includes the CAN1 connection between supply module and axis module. The CAN bus requires a terminating resistor. The following figures show the diagram of possible combinations for CAN communica- tion and the respective position of the terminating resistor (supply module option). -

Page 108: Can2 Bus Information And Settings

The maximum permitted cable length between terminating resistor and the first axis module is 5 m. NOTES For the connection between the axis systems, please use pre-fabricated cables from SEW-EURODRIVE. ® For more information on communication between PC and the MOVIAXIS system, refer to page 111.

-

Page 109

Startup CAN2 bus information and settings Connecting CAN2 cables to the axis modules: Connection assignment of connection and extension cables The connecting and extension cables between the CAN adapter (see page 111) and the axis system comes equipped with a 9 pin D-sub socket on both ends. The pin assign- ment of the connection cable with the 9 pin D-sub CAN connector is shown in the follow- ing figure. -

Page 110

Startup CAN2 bus information and settings Bus terminating resistors for CAN2 bus connection: The signal bus connection includes the CAN2 connection between supply module and axis module. The CAN2 bus requires a terminating resistor. The following figure shows the diagram of possible combinations for CAN communica- tion and the respective position of the terminating resistor (supply module accessory). -

Page 111: Communication Via Can Adapter

For communication between a PC and a MOVIAXIS system, we recommend using the CAN adapter from SEW-EURODRIVE, which is supplied with a pre-fabricated cable and a terminating resistor. The part no. of the CAN adapter is 18210597. As an alternative, the CAN adapter «USB Port PCAN-USB ISO (IPEH 002022)» from Peak can be used.

-

Page 112: Settings For Ethercat-Based System Bus

Startup Settings for EtherCAT-based system bus Settings for EtherCAT-based system bus Please note the following when using an EtherCAT-based system bus: • Set the 4 DIP switches on the supply module to setting «E», see Figure 68. • Switches S1, S2, S3 and S4 plus X12 on the supply modules have no function in this version.

-

Page 113: Description Of The Startup Software

Description of the startup software ® The MOVITOOLS MotionStudio software package is the SEW engineering tool that ® you can use to access all SEW drive units. For the MOVIAXIS series, you can use ® MOVITOOLS MotionStudio for startup, parameter setting and diagnostics.

-

Page 114: Communication Selection

Figure 70: Communication access PC-CAN to CAN Master module with CAN- / EtherCAT-based system bus PC-CAN to CAN2 SEW-EURODRIVE recommends the following communication paths: • Unit system without master module: CAN • Unit system with master module + DHP: CAN •…

-

Page 115: Sequence In Case Of New Startup

Startup Sequence in case of new startup Sequence in case of new startup There are two different variants for new startup: • New startup without master module ® • New startup with master module and MOVI-PLC New startup without master module 1.

-

Page 116: Moviaxis ® Startup — Single-Motor Operation

Startup MOVIAXIS® startup — Single-motor operation ® MOVIAXIS startup — Single-motor operation • Start the motor startup by selecting the respective unit in the hardware tree with the right mouse button. • Double-click on the «Startup» entry. • Click on «Next» to continue with the startup sequence. 11796aen Figure 71: Commencing startup Operating Instructions –…

-

Page 117

Startup MOVIAXIS® startup — Single-motor operation NOTES There are 3 parameter records available for startup, which can be assigned to 3 differ- ent motors. The parameter record that is to be used for startup can be selected by clicking on it, see figure 72. -

Page 118

Startup MOVIAXIS® startup — Single-motor operation Current settings The figure below shows the current settings. 11798aen Figure 73: Overview of current settings The card types of option cards inserted into the card slots are shown in this figure. In this example: •… -

Page 119

11833aen Figure 74: Encoder with electronic nameplate When using encoders with a SEW nameplate (electronic nameplate), i. e. encoders which were programmed according to SEW specifications, you can select one of the fol- lowing options for data transfer: • Accept data: The motor data stored in the encoder is read out from the encoder and used for startup. -

Page 120

Startup MOVIAXIS® startup — Single-motor operation Encoder management 11799aen Figure 75: Encoder management Encoder management allows you to assign the yellow-marked encoders offered in the encoder pool to the individual parameter records or motors. If several motors are to be operated on one axis module, you need additional multi-encoder cards (option). -

Page 121

SEW designation Double-click on an encoder symbol to open the «Encoder selection» submenu. of encoders In this menu, the SEW designations of the encoders are listed. They are necessary for selecting the encoders. 11800aen Figure 76: SEW designation of the encoders •… -

Page 122

Startup MOVIAXIS® startup — Single-motor operation Encoder data You can enter encoder data in this menu. However, you cannot enter data if the encoder is defined as «motor encoder». 11801aen Figure 77: Encoder data Operating Instructions – MOVIAXIS® MX Multi-Axis Servo Inverter… -

Page 123

Startup MOVIAXIS® startup — Single-motor operation Approved You can view the list of approved encoders by selecting «Approved encoders». encoders 11802aen Figure 78: Approved encoders Operating Instructions – MOVIAXIS® MX Multi-Axis Servo Inverter… -

Page 124

Startup MOVIAXIS® startup — Single-motor operation Encoder management for non-SEW encoders 11803aen Figure 79: Encoder management / non-SEW encoder Input data Description • Rotational Mechanically • Linear • Hiperface • Resolver Electrical • • • sin/cos There are two counting directions: •… -

Page 125

Input data Description This factor determines the encoder resolution. The value that has to be entered depends on the encoder type. • Non-SEW TTL, non-SEW sin/cos, non-SEW Hiperface Factor numerator encod.1 = Encoder resolution Factor denominator encod.1 Revolution Example: sin / cos encoder:… -

Page 126

Startup MOVIAXIS® startup — Single-motor operation Selection menu 11804aen Figure 80: Startup options You have three options for startup in the selection menu: • Complete startup: This is the setting option for the initial startup. This part of the program stores the in- formation for motor, speed controller as well as machine and system data. -

Page 127

One drive is equipped with encoder feedback. The other motors are running in the same rotating field. When synchronous motors are used, the two rotors have to be aligned in addition. Please also refer to the SEW documentation «10509011 / EN Multi-Motor Drives» manual. -

Page 128

In this menu, you can set the motor to which the MOVIAXIS is connected. The motor type of SEW motors is indicated on the nameplate. If the motor is a non-SEW motor, activate the radio button «Non-SEW motor.» The next menu view will prompt you to load an XML file created by SEW-EURODRIVE. -

Page 129

You will need a file created by SEW-EURODRIVE with the motor spec- ifications to use this option. If the function «Non-SEW motor» is selected, you will see the «Load motor file» button. Select the non-SEW motor from the motor database. -

Page 130

The KTY only provides an initial value. Afterwards, the calculation model is responsible for motor protection. If the motor with KTY is a non-SEW motor and the XML file of the non-SEW motor does not contain any thermal data, then a KTY limit temperature shut- down is activated. -

Page 131

Startup MOVIAXIS® startup — Single-motor operation Monitoring 11808aen Figure 84: Menu setting for monitoring NOTES The value in the left column of the input menu is a recommendation, while the value in ® the right column is the current value of the MOVIAXIS MX multi-axis servo drive. -

Page 132

• If you increase the stiffness value, you will also increase the control rate. SEW-EURODRIVE recommends to increase the value during startup in small increments (0.05) until the control loop starts oscillating (motor noise). You will then have to lower the value. This approach ensures an optimum setting. -

Page 133

Startup MOVIAXIS® startup — Single-motor operation Block diagram speed controller 11810aen Figure 86: Block diagram speed controller Speed control parameters In addition, you can set the speed controller parameters to «Classic». 11811aen Figure 87: Parameter speed control menu Operating Instructions – MOVIAXIS® MX Multi-Axis Servo Inverter… -

Page 134

Startup MOVIAXIS® startup — Single-motor operation NOTES The value in the left column of the input menu is a recommendation, while the value in ® the right column is the current value of the MOVIAXIS MX multi-axis servo drive. Click on →… -

Page 135

Startup MOVIAXIS® startup — Single-motor operation «Basic configuration» button • Travel distance Unit: Rotations (of the motor), 4 decimal positions Example: Setpoint Traveled distance Display in MotionStudio 10000 1 motor revolution 1.0000 15000 1.5 motor revolutions 1.5000 Once motor startup has been executed, the following values are written to the axis module (conversion 16-bit increments / rotation): •… -

Page 136

Startup MOVIAXIS® startup — Single-motor operation Example Proceed as follows to set user-defined units other than the basic configuration. Specification × • Position in (mm 1E-01) • Velocity in 1/min × • Acceleration in (m/s 1E-02) The rotary motion is turned into a linear motion with a spindle (pitch = 5 mm). Spindle pitch 5 mm are traveled per reference revolution of s = 1… -

Page 137

Startup MOVIAXIS® startup — Single-motor operation Application and system limits 11813aen Figure 90: Application and system limits menu The application and machine limit values refer to the set user-specified units, see figure 89. The user-specified units selected previously are shown in the illustration and cannot be altered. -

Page 138

Startup MOVIAXIS® startup — Single-motor operation Download 11814aen Figure 91: Download menu • Press the «Finish» button to download the settings to the axis module. • Close the window to finish startup. Operating Instructions – MOVIAXIS® MX Multi-Axis Servo Inverter… -

Page 139

Startup MOVIAXIS® startup — Single-motor operation Pxxx controller parameters Pxxx speed control Speed control only parameter set 1. The setting of all parameters important for speed control is supported by the startup functions of the startup manager. Direct alterations to individual controller parameters are reserved for optimization by specialists. -

Page 140: Moviaxis ® Startup — Multi-Motor Operation

Positioning, either directly using the external encoder or with the motor encoder. • Multi-motor operation (max. 3 motors). • SSI absolute encoder evaluation. • Operation of non-SEW motors that are equipped with EnDat encoders. • Systems with slip. • Compensation of rope and belt elongation. •…

-

Page 141

Startup MOVIAXIS® startup — Multi-motor operation Current settings The figure below shows the current settings. 11815aen Figure 93: Overview of current settings The card types of option cards inserted into the card slots are shown in this menu. In this example: •… -

Page 142

Startup MOVIAXIS® startup — Multi-motor operation Encoder management 11818aen Figure 94: Encoder management Encoder management allows you to assign the yellow-marked encoders offered in the encoder pool to the individual parameter records or motors. If several motors are to be operated on one axis module, you need additional multi-encoder cards (option). -

Page 143

Startup MOVIAXIS® startup — Multi-motor operation Encoder signal processing when using encoder emulation Encoder emulation can be used to make encoder signals available to a higher-level con- troller via the emulation output terminals. Encoder emulation is independent of the connected encoder type. 11817aen Figure 95: Encoder signal processing Emulation source direct is without delay. -

Page 144: Application Examples

Startup Application examples Emulation source direct The signals of the connected encoder are looped through to emulation directly. NOTES If a resolver is connected to the encoder input of the basic unit, this cannot be used as «emulation source direct». This is possible in connection with software emulation only. With signal fan-out, increments per motor revolution This selection uses software emulation.

-

Page 145

Startup Application examples Settings: Encoder 2 must be set as «Source actual position». Selection and settings of the encoder type. Operating Instructions – MOVIAXIS® MX Multi-Axis Servo Inverter… -

Page 146

Startup Application examples Setting the ratio between encoder revolutions and motor revolutions directly, i.e. by cal- cuation or moving the system. Example 2: Linear encoder as position encoder Applications: E.g. storage and retrieval units (because of the slip of the carrying wheels), for systems with backlash. -

Page 147

Startup Application examples Settings: Selection and settings of the encoder type using the example of the linear encoder AL1H. Encoder 2 must be set as «Source actual position». Selection and settings of the used AL1H encoder. Operating Instructions – MOVIAXIS® MX Multi-Axis Servo Inverter… -

Page 148

Startup Application examples «Travel distance on encoder per motor revolution» can be entered here directly after cal- culating it manually, or be determined by moving the system. «Determined automatically» can only be selected under the menu item «Axis configura- tion», see next figure. Configuration of the axis. -

Page 149

Startup Application examples Double-click on encoder 2 «AL1H» to enter the «Travel distance on encoder per motor revolution». It is possible to enter the travel distance by clicking on the «Direct entry» but- ton after calculating it manually, or to determine it by clicking on «Move the system» or by selecting «Determined automatically». -

Page 150

Startup Application examples Example 3: Multi-motor operation Application: In applications with several axes, which have the same output torque and which are not operated at the same time. Up to 3 motors can be connected to one axis module. For this purpose, 2 additional multi-encoder cards must be inserted into the axis module, see following figure. -

Page 151

Startup Application examples Encoder 1 must be set as «Actual position source» for parameter record 1. Encoder 2 must be set as «Actual position source» for parameter record 2. Encoder 3 must be set as «Actual position source» for parameter record 3. The individual parameter records can only be started up one after another and only once the startup process has been completed. -

Page 152: Pdo Editor

Startup PDO Editor 5.12 PDO Editor Use the PDO Editor to set the process data. Structure and You can write setpoints, such as velocity or position, as 16-bit process data into the PD- ® data flow IN buffer of MOVIAXIS via a bus system, e.g.

-

Page 153

Startup PDO Editor Parameter set- This example shows how to set the parameters of a PROFIBUS connection for speed ting example control. Setting the fieldbus A mouse-click on an IN buffer opens its configuration interface. The communication op- interface parame- tion is selected as data source for a PROFIBUS connection. -

Page 154

Startup PDO Editor Setting the para- A single click on one of the control words, in the example control word 1, opens the con- meters of the con- figuration interface and selects the FCB / instance layout. The IN process data trol word and the channel 0 is assigned the system variable «velocity», and channel 1 the system variable IN process data… -

Page 155

Startup PDO Editor Assigning the input Next, the words of the IN buffer must be assigned to the control word 1 and the IN pro- buffer to the sys- cess data. tem variables In the example, the first word of the IN buffer is assigned the FCB number, the second word is assigned the speed, and the third word the ramp. -

Page 156: Parameter List

Startup Parameter list Testing the The configuration is now complete and can be tested. You can change the words in the configurations detail view using the keyboard as long as IN buffer update is disabled. 11832aen Figure 101: Testing the configuration Once buffer update is enabled, see figure 97, the words are automatically updated with the values of the bus.

-

Page 157: Operation

Operation General information Operation General information HAZARD Dangerous voltages at cables and motor terminals Severe or fatal injuries from electric shock. • When the unit switch is in the ON position, dangerous voltages are present at the output terminals as well as any connected cables and motor terminals. This also ap- plies even when the unit is inhibited and the motor is at standstill.

-

Page 158: Displays Of The Supply And Axis Modules

Operation Displays of the supply and axis modules Displays of the supply and axis modules Operating display of the 7-segment display • The two 7-segment displays indicate the operating status of the supply modules and axis modules. • All settings and functions relating to startup of the axis system are located in the axis module.

-

Page 159

Operation Displays of the supply and axis modules Error list Explanation of terms in the error lists Terms and Meaning abbreviations Programmable error response Default error response set at the factory Power supply module Axis module DC link Hardware Software User-defined unit The final error status determines which reset type will be executed in case of an error reset, see following table. -

Page 160

Operation Displays of the supply and axis modules Responses to error acknow- ledgement CPU reset A true restart of the microcontroller and the firmware will take place in case of a CPU reset. The firmware system is started as though a new axis module has been connected to the network. -

Page 161: Operating Displays And Errors Of The Mxp Supply Module

Operation Operating displays and errors of the MXP supply module Operating displays and errors of the MXP supply module Table of displays Display on Description State Comment / action the axis module Displays during standard operation Ready for operation (ready) No error/Warning.

-

Page 162: Operating Displays And Errors Of Mxa Axis Module

Operation Operating displays and errors of MXA axis module Operating displays and errors of MXA axis module Table of displays Description State Comment / action Displays during boot process Unit passes through several • Status: not ready. states when loading the firm- •…

-

Page 163

Operation Operating displays and errors of MXA axis module Description State Comment / action Displays during standard operation The drive is not actuated by the output stage. The brake is applied; without brake the motor Output stage inhibit • Output stage is blocked. coasts to a halt. -

Page 164

NOTES Errors or sub-error codes, which are not included in the following list, can be displayed within the framework of displayed error codes. In this case, contact SEW-EURO- DRIVE. A «P» in the column «Error response» indicates that the response is programmable. The factory set error response appears in the «Error response»… -

Page 165

Operation Operating displays and errors of MXA axis module Error Error message Possible reason for error Error response Final error Save Message code error (P = programma- status / binary out- code ble, Reset type History puts (valid D = default for default response) response) -

Page 166

Operation Operating displays and errors of MXA axis module Error Error message Possible reason for error Error response Final error Save Message code error (P = programma- status / binary out- code ble, Reset type History puts (valid D = default for default response) response) -

Page 167

Operation Operating displays and errors of MXA axis module Error Error message Possible reason for error Error response Final error Save Message code error (P = programma- status / binary out- code ble, Reset type History puts (valid D = default for default response) response) -

Page 168

Operation Operating displays and errors of MXA axis module Error Error message Possible reason for error Error response Final error Save Message code error (P = programma- status / binary out- code ble, Reset type History puts (valid D = default for default response) response) -

Page 169

Operation Operating displays and errors of MXA axis module Error Error message Possible reason for error Error response Final error Save Message code error (P = programma- status / binary out- code ble, Reset type History puts (valid D = default for default response) response) -

Page 170

Operation Operating displays and errors of MXA axis module Error Error message Possible reason for error Error response Final error Save Message code error (P = programma- status / binary out- code ble, Reset type History puts (valid D = default for default response) response) -

Page 171

Operation Operating displays and errors of MXA axis module Error Error message Possible reason for error Error response Final error Save Message code error (P = programma- status / binary out- code ble, Reset type History puts (valid D = default for default response) response) -

Page 172

Operation Operating displays and errors of MXA axis module Error Error message Possible reason for error Error response Final error Save Message code error (P = programma- status / binary out- code ble, Reset type History puts (valid D = default for default response) response) -

Page 173

Operation Operating displays and errors of MXA axis module Error Error message Possible reason for error Error response Final error Save Message code error (P = programma- status / binary out- code ble, Reset type History puts (valid D = default for default response) response) -

Page 174

Operation Operating displays and errors of MXA axis module Error Error message Possible reason for error Error response Final error Save Message code error (P = programma- status / binary out- code ble, Reset type History puts (valid D = default for default response) response) -

Page 175

Operation Operating displays and errors of MXA axis module Error Error message Possible reason for error Error response Final error Save Message code error (P = programma- status / binary out- code ble, Reset type History puts (valid D = default for default response) response) -

Page 176

Operation Operating displays and errors of MXA axis module Error Error message Possible reason for error Error response Final error Save Message code error (P = programma- status / binary out- code ble, Reset type History puts (valid D = default for default response) response) -

Page 177

Operation Operating displays and errors of MXA axis module Error Error message Possible reason for error Error response Final error Save Message code error (P = programma- status / binary out- code ble, Reset type History puts (valid D = default for default response) response) -

Page 178: Operating Displays Of Mxc Capacitor Module Component

Operation Operating displays of MXC capacitor module component Operating displays of MXC capacitor module component The operating statuses are indicated by a two-color LED at the front of the housing, see page 35. • LED lights up green: – Capacitor module is ready for operation. •…

-

Page 179: Service

«Customer and spare parts service»). → When contacting the SEW electronics service, please always quote the production num- ber and order number, so that our service personnel can assist you more effectively. You find the production number on the nameplate, see page 15.

-

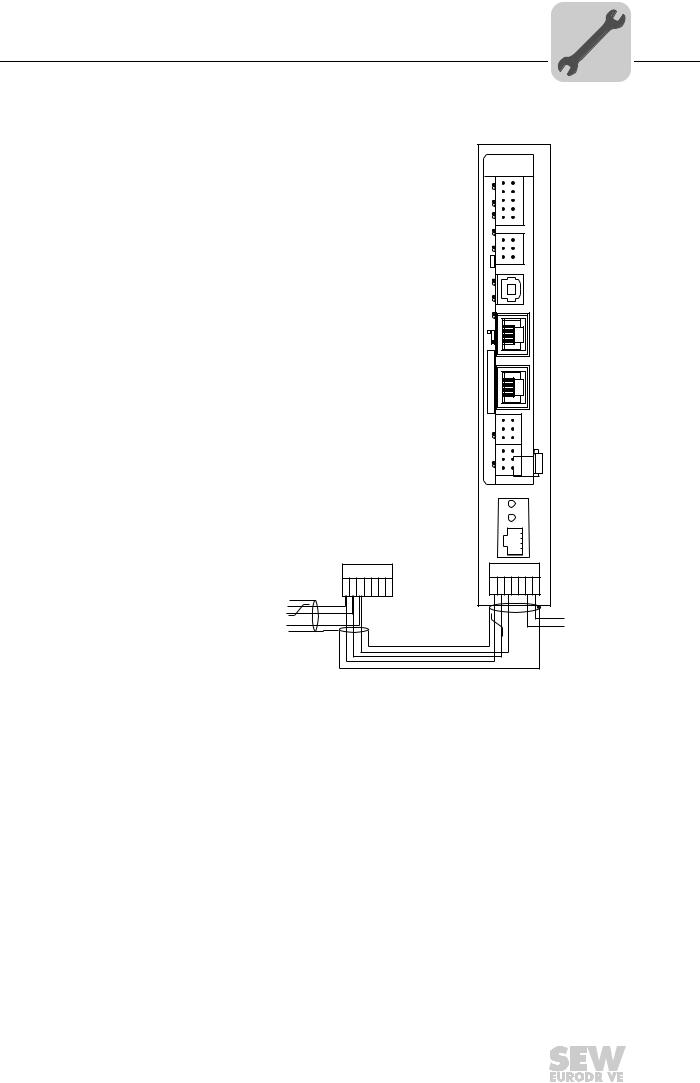

Page 180: Removing / Installing A Module

Service Removing / installing a module Removing / installing a module This chapter describes how to replace an axis module in the axis system. The master module, capacitor module, buffer module, supply module, DC link discharge module and the 24 V switched mode power supply unit are all installed / removed in the same way. Safety notes Always adhere to the following safety instructions.

-

Page 181

Service Removing / installing a module Removing an axis module Remove an axis module in the following sequence: Disconnecting the • Disconnect the entire axis system from the power supply. Follow the safety notes on axis system from page 180. the power supply Shield clamps •… -

Page 182

Service Removing / installing a module 24 V cables • Remove 24 V cable plugs [8] (electronics and brake supply) (X5a, X5b). DC link bars • Remove DC link bars [13] of the respective units (X4). Shield plate • Remove shield plate on the power terminal [10]: •… -

Page 183

Service Removing / installing a module Removing the axis • Slightly raise the axis module, tilt it to the front and remove it in upward direction. module Operating Instructions – MOVIAXIS® MX Multi-Axis Servo Inverter… -

Page 184

Service Removing / installing a module Installing an axis module Installing an axis • Insert the axis module from top into the lower retaining screws, press the axis module module backward and then lower it. Operating Instructions – MOVIAXIS® MX Multi-Axis Servo Inverter… -

Page 185

Service Removing / installing a module Retaining screws • Tighten upper retaining screws [7]. • Tighten bottom retaining screws [9]. Brake control • Insert brake control plug [11] (X6). system Motor lines • Insert motor line plug [12] (X2). Shield plate •… -

Page 186: Extended Storage

This effect can damage the capacitors if the unit is connected using the rated voltage after a longer period of storage. If you have not performed maintenance regularly, SEW-EURODRIVE recommends that you increase the supply voltage slowly up to the maximum voltage. This can be done, for example, by using a variable transformer for which the output voltage has been set according to the following overview.

-

Page 187: Technical Data

SEW-EURODRIVE can provide detailed information on request. The CE mark on the nameplate indicates conformity with the Low Voltage Directive 2006/95/EC and the EMC Directive 89/336/EEC. SEW-EURODRIVE can provide a dec- laration of conformity on request. ®…

-

Page 188: General Technical Data

Technical Data General technical data General technical data ® The technical data in the following tables is valid for all MOVIAXIS MX multi-axis servo inverters, regardless of type, version, size and performance. ® MOVIAXIS Interference resistance Conforms to EN 61800-3 Interference emission with Category «C2″…

-

Page 189: Technical Data For The Supply Module

Technical Data Technical data for the supply module Technical data for the supply module Power component supply module Size ® MOVIAXIS supply module MXP80A-…-503-00 Type INPUT 3 × 380 V … 3 × 500 V Supply voltage AC V mains Rated supply current AC I mains…

-

Page 190

Technical Data Technical data for the supply module Size ® MOVIAXIS supply module MXP80A-…-503-00 GENERAL INFORMATION Power loss at nominal capacity No. of times power may be < 1/min switched on/off Minimum switch-off time for > 10 mains off Weight 10.2 10.7 12.1… -

Page 191: Technical Data For The Axis Module

Technical Data Technical data for the axis module Technical data for the axis module Axis module power section Size ® MOVIAXIS axis module MXA80A-…-503-00 Type INPUT (DC link) Rated DC link voltage U DC 560 Rated DC link current I Cross section and con- CU rails 3 ×…

-

Page 192

Technical Data Technical data for the axis module Size ® MOVIAXIS axis module MXA80A-…-503-00 GENERAL INFORMATION Power loss at nominal 1100 capacity Weight 15.6 15.6 Dimensions: 1) Nameplate information 2) Unit 3) With simplification: I (typical motor application) 4) Material strength [mm] × width [mm] 5) Indicated values apply to motor operation. -

Page 193

Technical Data Technical data for the axis module Control section axis module ® MOVIAXIS MX axis module General electronics data DC 24 V ± 25 % (EN 61131) COMBICON 5.08 DC 24 V voltage supply One conductor per terminal: 0.20…2.5 mm Two conductors per terminal: 0.25…1 mm X10:1 and X10:10 binary inputs Isolated (optocoupler), PLC compatible (EN 61131), sampling interval 1 ms… -

Page 194: Technical Data For Master Module Component

Technical Data Technical data for master module component Technical data for master module component ® MOVIAXIS MX master module Size 1 MXM80A-…-000-00 Type Supply voltage U DC 24 V ± 25 % to EN 61131 COMBICON 5.08 Cross section and contacts (X5a) One conductor per terminal: 0.20…2.5 mm Two conductors per terminal: 0.25…1 mm COMBICON 5.08…

-

Page 195: Technical Data For Capacitor Module Component

Technical Data Technical data for capacitor module component Technical data for capacitor module component ® MOVIAXIS capacitor module MXC80A-050-503-00 Type INPUT Rated DC link voltage DC 560 Storable energy 1000 Peak power capacity CU rails 3 × 14 mm, M6 screw fitting Cross section and contacts GENERAL INFORMATION Capacity…

-

Page 196: Technical Data For Buffer Module Component

Technical Data Technical data for buffer module component Technical data for buffer module component ® MOVIAXIS buffer module MXB80A-050-503-00 Type INPUT Rated DC link voltage DC 560 CU rails 3 × 14 mm, M6 screw fitting Cross section and contacts GENERAL INFORMATION Capacity µF…

-

Page 197: Technical Data For 24 V Switched-Mode Power Supply Module Component

Technical Data Technical data for 24 V switched-mode power supply module component Technical data for 24 V switched-mode power supply module component ® MOVIAXIS 24 V switched-mode power supply module MXS80A-…-503-00 Type INPUT via DC link Rated DC link voltage U DC 560 CU rails 3 ×…

-

Page 198: Technical Data For The Dc Link Discharge Module Component

Convertible energy E 5000 OUTPUT Ω Braking resistor R Discharge connection Specific screw fitting by SEW M6 screw bolts, max. 4 × 16 Cross section and contacts max. 4 × 16 Connection to power shield clamp GENERAL INFORMATION Ready for operation once mains ≤…

-

Page 199: Technical Data For 24 V Current Consumption

Type BW… braking resistors are UL and cUL approved in conjunction with the ® approval MOVIAXIS multi-axis servo inverter. SEW-EURODRIVE will provide a certificate upon request. ® The following braking resistors have cRUus approval independent of the MOVIAXIS multi-axis servo inverter: •…

-

Page 200

Technical Data Technical data for the braking resistors BW012-015- Braking resistor type BW012-015 BW012-025 BW012-050 BW012-100 BW915 Part number 821 679 7 1 820 010 9 821 680 0 821 681 9 821 682 7 821 260 0 Power class of the supply 25, 50, 75 module Load capacity at… -

Page 201: Technical Data For Line Filter And Line Chokes

–25 … +40 Degree of protection IP20 (EN 60529) Connections L1-L3/L1’-L3’ M5 stud M5/M6 stud NF…type line filter 1) Unit 2) SEW-EURODRIVE will provide a certificate upon request. Line choke Line choke type ND020-013 ND045-013 ND085-013 ND150-013 Part number 826 012 5…

-

Page 202: Appendix

Appendix Cable dimensions to AWG Appendix Cable dimensions to AWG AWG stands for American Wire Gauge and refers to the size of the wires. This number specifies the diameter or cross section of a wire in code. This type of cable designation is usually only used in the USA.

-

Page 203: List Of Abbreviations

Appendix List of abbreviations List of abbreviations Abbreviation Definition Meaning Controller Area Network Digital In Deutsches Institut für Normung e.V. (German institute for standardization) EN European Standard whose German version DIN EN has the status of a German standard. ISO standard that has been made a European DIN EN ISO standard and has been adopted into the German book of standards.

-

Page 204: Definition Of Terms

Appendix Definition of terms Definition of terms Serial bus system for the automotive industry and industrial control CAN bus system devices. The bus medium is a twisted conductor pair with excellent trans- mission characteristics in the short-distance range of less than 40 m. PROFIBUS (Process Field Bus) is a standard for fieldbus communication PROFIBUS used in automation engineering.

-

Page 205

Index Line filter …………97 Separate cable ducts ……..97 Accessory assignment table ……20 Shielding and grounding ……97 Axis module nameplate ……..15 Error display of the 7-segment display ….. 158 Error in the supply module ……158 Bending space note ……….66 Error message with two 7-segment Binary inputs / binary outputs ……76 displays ………… -

Page 206

Encoder management for Assigning the input buffer to the system non-SEW encoders ……..124 variables ………….155 Encoder management of SEW encoders .. 119 Parameter setting example ……153 Encoder selection ……120 Setting the FCB parameters …….155 Encoder signal processing when Setting the fieldbus interface parameters …153… -

Page 207

Index Technical data for Brake control ……….81 the DC link discharge module component Buffer module — Control section ………..198 Wiring of control electronics ……87 Power section ……….198 Capacitor module — Technical data for the supply module Wiring of control electronics ……86 Control section ………..190 General notes ………. -

Page 208

Sales Avenue Eiffel 5 Fax +32 10 231-336 Service B-1300 Wavre http://www.caron-vector.be info@caron-vector.be Italy Assembly Milano SEW-EURODRIVE di R. Blickle & Co.s.a.s. Tel. +39 02 96 9801 Sales Via Bernini,14 Fax +39 02 96 799781 Service I-20020 Solaro (Milano) sewit@sew-eurodrive.it… -

Page 209

Fax +31 10 4155-552 Service NL-3044 AS Rotterdam http://www.vector.nu Postbus 10085 info@vector.nu NL-3004 AB Rotterdam Switzerland Assembly Basel Alfred lmhof A.G. Tel. +41 61 417 1717 Sales Jurastrasse 10 Fax +41 61 417 1700 Service CH-4142 Münchenstein bei Basel http://www.imhof-sew.ch info@imhof-sew.ch… -

Page 211

SEW-EURODRIVE – Driving the world… -

Page 212

Internet, available Anywhere. today. around the clock. SEW-EURODRIVE GmbH & Co KG P.O. Box 3023 · D-76642 Bruchsal / Germany Phone +49 7251 75-0 · Fax +49 7251 75-1970 sew@sew-eurodrive.com www.sew-eurodrive.com…

File Specifications:1698/1698846-moviaxis_series.pdf file (13 Mar 2023) |

Accompanying Data:

SEW-Eurodrive MOVIAXIS Series Inverter PDF System Manual (Updated: Monday 13th of March 2023 12:19:28 AM)

Rating: 4.6 (rated by 83 users)

Compatible devices: MOVITRAC 31C005-233-4-21, Movidrive MDX61B, MOVIDRIVE B, MOVIDRIVE compact Series, MOVIAXIS, MOVIDRIVE MDX60/61B, MOVIDRIVE modular, MOVITRAC 07.

Recommended Documentation:

System Manual (Text Version):

(Ocr-Read Summary of Contents of some pages of the SEW-Eurodrive MOVIAXIS Series Document (Main Content), UPD: 13 March 2023)

-

SEW-Eurodrive MOVIAXIS Series User Manual

-

SEW-Eurodrive MOVIAXIS Series User Guide

-

SEW-Eurodrive MOVIAXIS Series PDF Manual

-

SEW-Eurodrive MOVIAXIS Series Owner’s Manuals

Recommended: TC SERIES, Pliko X-Lite, CBA750B, DC-SLIM3000

Links & Tools

-

Air-ConditionersIndoor unitPKA-RP·HALPCA-RP·KAQPCA-RP·HAQISTRUZIONI DI FUNZIONAMENTOLeggere attentamente questi istruzioni di funzionamento prima di avviare l’unità, per un uso corretto e sicuro della stessa.BEDIENUNGSHANDBUCHZum sicheren und einwandfreien Gebrauch der Klimaanlage dieses Bedienungshandbuch vor …

PKA-RP·HAL 28

-

Safety Instructions & Operator’s ManualThank you for buying a SENCI Power Product! Before operating your generator, read this manual carefully and pay particular attention to the “IMPORTANT SAFETY INSTRUCTIONS” on Pages 2 & 3. Remember that all power equipment can be dangerous if used impr …

SC13000 14

-

Fronius prints on elemental chlorine free paper (ECF) sourced from certified sustainable forests (FSC)./ Perfect Charging / Perfect Welding / Solar EnergyFronius Symo GEN243.0 / 3.0 Plus / 4.0 / 4.0 Plus5.0 / 5.0 PlusENOperating instructions42,0426,0388,EN 011-10112021 …

Symo GEN24 3.0 144

-

OPERATOR’S MANUALMANUEL D’UTILISATIONMANUAL DEL OPERADOR7,500 WATT GENERATORGÉNÉRATRICE DE 7 500 WATTS GENERADOR 7 500 WATTSAR907511PWARNING: To reduce the risk of injury, the user must read and understand the operator’s manual before using this product.TABLE OF CONTENTS Important Safety Instructions …

AR907511P 68

Operating Impressions, Questions and Answers:

Drive Technology \ Drive Automation \ System Integration \ Services

Manual

Controllers

DHE21B / DHF21B / DHR21B (standard)

DHE41B / DHF41B / DHR41B (advanced)

|

Edition 03/2010 |

16897226 / EN |