Итак, нужно произвести чтение кода ошибок при невозможности произвести полноценную компьютерную диагностику.

Автомобиль HINO-300 евро 4, хотя под эту методологию попадает большинство японских двигателей, так-как на большинстве из них

установлена топливная система COMMON RAIL от производителя DENSO

! ПЕРЕД НАЧАЛОМ ДИАГНОСТИКИ ПОВЕРНИТЕ КЛЮЧ ЗАЖИГАНИЯ В ПОЛОЖЕНИЕ (ON) И УБЕДИТЕСЬ ЧТО ЛАМПОЧКА «CHECK ENGINE»

НА ПАНЕЛИ ПРИБОРОВ ЗАГОРЕЛАСЬ (ЕСЛИ НЕ ГОРИТ, ТО НЕИСПРАВНА ЛАМПА ИЛИ НЕТ ПИТАНИЯ НА БЛОК УПРАВЛЕНИЯ)

ВЫКЛЮЧИТЕ ЗАЖИГАНИЕ

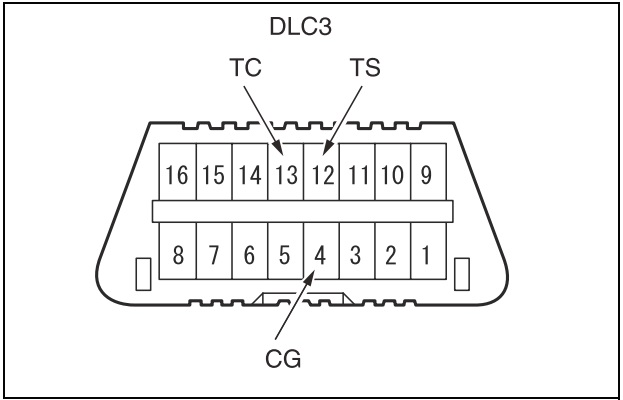

1) Находим диагностический разъем, на этих автомобилях он находится со стороны водителя снизу

2) Берем качественную одножильную перемычку (чтобы исключить замыкание соседних контактов)

Замыкаем контакты (13 и 4) для диагностирования двигатиеля

Замыкаем контакты (12 и 4) для тестирования прочих бортовых систем (ABS например)

3) Переводим ключ зажигания в положение (ON) и по вспыхиванию лампы индикации неисправности двигателя (CHECK ENGINE)

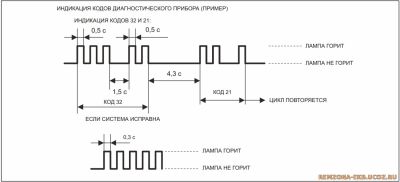

ОПРЕДЕЛЕНИЕ КОДА ОШИБОК ПРОИЗВОДИТСЯ ПО СЛЕДУЮЩЕМУ АЛГОРИТМУ:

Код диагностического прибора можно определить при помощи

диагностического прибора и лампы индикации неисправностей

двигателя. Ниже в качестве примера приведен случай определения

кодов диагностического прибора 32 и 21. Код диагностического

прибора определяется интервалами между вспышками лампы.

В случае первого кода первая цифра кода «3» отображается

тремя вспышками продолжительностью 0,5 секунды, за которыми

следует интервал продолжительностью 1,5 секунды. Затем

следуют две вспышки. В случае второго кода после интервала

продолжительностью 4.3 секунды следуют сначала две вспышки

и затем еще одна вспышка по аналогии с первым кодом. Эта

последовательность вспышек повторяется. Если нарушения в

системе не обнаружены, лампа будет давать последовательность

вспышек продолжительностью 0,3 секунды. (см.рисунок)

| Код DTC | Мигающий код | Диагностируемый элемент |

| B2799 | 99 | Система иммобилайзера |

| B279A | 99 | Линия обмена данными с иммобилайзером [высокий уровень] |

| B279C | 99 | Отклонение от нормы при обнаружении присутствия/отсутствия иммобилайзера |

| P0045 | 34 | Система турбокомпрессора с изменяемой геометрией турбины (VN) |

| P0069 | A5 | Несоответствие норме разности давлений [атмосферного давления и давления поступающего воздуха] |

| P0087 | 49 | Несоответствие норме давления в топливной системе Common Rail [низкое давление в топливном аккумуляторе] |

| P0088 | 78 | Неисправность клапана регулирования подачи топлива [высокое давление в топливном аккумуляторе] |

| P0093 | 78 | Несоответствие норме утечки топлива |

| P0095 | 23 | Система датчика температуры поступающего воздуха [впускной коллектор] |

| P0096 | 23 | Система датчика температуры поступающего воздуха [впускной коллектор] [выход за пределы диапазона] |

| P0097 | 23 | Система датчика температуры поступающего воздуха [низкий уровень] |

| P0098 | 23 | Система датчика температуры поступающего воздуха [высокий уровень] |

| P0101 | 31 | Система датчика расхода воздуха [выход за пределы диапазона] |

| P0102 | 31 | Система датчика расхода воздуха [низкий уровень] |

| P0103 | 31 | Система датчика расхода воздуха [высокий уровень] |

| P0106 | 35 | Система датчика давления [выход за пределы диапазона] |

| P0107 | 35 | Система датчика давления [низкий уровень] |

| P0108 | 35 | Система датчика давления [высокий уровень] |

| P0112 | 24 | Система датчика температуры поступающего воздуха [низкий уровень] |

| P0113 | 24 | Система датчика температуры поступающего воздуха [высокий уровень] |

| P0115 | 22 | Система датчика температуры охлаждающей жидкости |

| P0116 | 22 | Система датчика температуры охлаждающей жидкости [выход за пределы диапазона] |

| P0117 | 22 | Система датчика температуры охлаждающей жидкости [низкий уровень] |

| P0118 | 22 | Система датчика температуры охлаждающей жидкости [высокий уровень] |

| P0122 | 41 | Обрыв цепи датчика заслонки [низкий уровень] |

| P0123 | 41 | Обрыв цепи датчика заслонки [высокий уровень] |

| P0168 | 39 | Несоответствие норме температуры топлива высокого давления |

| P0180 | 39 | Система датчика температуры топлива |

| P0182 | 39 | Система датчика температуры топлива [низкий уровень] |

| P0183 | 39 | Система датчика температуры топлива [высокий уровень] |

| P0190 | 49 | Система датчика давления в топливном аккумуляторе Common Rail |

| P0191 | 49 | Система датчика давления в топливном аккумуляторе Common Rail [выход за пределы диапазона] |

| P0192 | 49 | Система датчика давления в топливном аккумуляторе Common Rail [низкий уровень] |

| P0193 | 49 | Система датчика давления в топливном аккумуляторе Common Rail [высокий уровень] |

| P0201 | 97 | Неисправность форсунки [EDU] цилиндра № 1 |

| P0202 | 97 | Неисправность форсунки [EDU] цилиндра № 2 |

| P0203 | 97 | Неисправность форсунки [EDU] цилиндра № 3 |

| P0204 | 97 | Неисправность форсунки [EDU] цилиндра № 4 |

| P0217 | — | Перегрев |

| P0219 | — | Чрезмерная частота вращения двигателя |

| P0234 | 34 | Заклинивание в закрытом положении лопаток турбокомпрессора с изменяемой геометрией турбины (VN) |

| P0263 | 78 | Неисправность форсунки [коррекция подачи] цилиндра № 1 |

| P0266 | 78 | Неисправность форсунки [коррекция подачи] цилиндра № 2 |

| P0269 | 78 | Неисправность форсунки [коррекция подачи] цилиндра № 3 |

| P0272 | 78 | Неисправность форсунки [коррекция подачи] цилиндра № 4 |

| P0299 | 34 | Заклинивание в открытом положении лопаток турбокомпрессора с изменяемой геометрией турбины (VN) |

| P0335 | 12,13 | Система датчика положения коленчатого вала |

| P0339 | 13 | Кратковременное исчезновение сигнала датчика положения коленчатого вала (Ne) |

| P0340 | 12 | Система датчика положения распределительного вала |

| P0488 | 15 | Система воздушной заслонки двигателя |

| P0500 | 42 | Система датчика скорости автомобиля |

| P0504 | 51 | Система выключателя стоп-сигнала |

| P0524 | — | Падение давления масла в двигателе |

| P0545 | A3 | Обрыв цепи датчика температуры отработавших газов 1 [низкий уровень] |

| P0546 | A3 | Обрыв цепи датчика температуры отработавших газов 1 [высокий уровень] |

| P0560 | 96 | Неисправность аккумуляторной батареи |

| P0606 | 89 | Внутренняя неисправность 1 ЭБУ |

| P060A | 89 | Внутренняя неисправность 2 ЭБУ |

| P060B | 89 | Внутренняя неисправность 3 ЭБУ |

| P0610 | 89 | Несоответствие идентификационного кода автомобиля |

| P0617 | 43 | Несоответствие норме сигнала управления стартером (STA) [высокий уровень] |

| P0627 | 78 | Неисправность клапана регулирования подачи топлива [обрыв цепи/ короткое замыкание] |

| P062D | 97 | Неисправность форсунки [EDU] |

| P062F | 89 | Несоответствие норме/незарегистрированный идентификационный код |

| P0630 | 89 | Незаписанный идентификационный номер автомобиля |

| P0704 | 95 | Концевой выключатель педали сцепления [обрыв цепи] |

| P0724 | 95 | Выключатель стоп-сигнала [обрыв цепи] |

| P081A | 43 | Система реле остановки стартера [низкий уровень] |

| P081B | 43 | Система реле остановки стартера [высокий уровень] |

| P0850 | 95 | Концевой выключатель нейтрального положения |

| P1133 | 00 | Датчик рабочего акселератора [высокий уровень] |

| P1143 | 19 | Ручка регулирования оборотов холостого хода [высокий уровень] |

| P1229 | 78 | Неисправность клапана управления подачей топлива [чрезмерная подача] |

| P1251 | 34 | Система турбокомпрессора с изменяемой геометрией турбины (VN) [кратковременное исчезновение высокого давления наддува] |

| P1266 | 78 | Несоответствие норме давления подачи ТНВД |

| P1426 | A4 | Система датчика разности давлений [неисправность трубопровода] |

| P1427 | A4 | Система датчика разности давлений [низкий уровень] |

| P1428 | A4 | Система датчика разности давлений [высокий уровень] |

| P1458 | 71 | Неисправность клапана РОГ [незначительная неисправность] |

| P1459 | 71 | Неисправность клапана РОГ [серьезная неисправность] |

| P1530 | 92 | Система выключателя аварийного останова |

| P1603 | — | Обнаружение самопроизвольного останова двигателя |

| P1604 | — | Обнаружение отказа запуска двигателя |

| P1608 | — | Недостаточная выходная мощность |

| P1609 | — | Избыточный впрыск топлива |

| P1674 | 36 | Система клапана VSV тормоза-замедлителя |

| P200C | 94 | Слишком высокая температура отработавших газов |

| P2032 | A3 | Обрыв цепи датчика температуры отработавших газов 2 [низкий уровень] |

| P2033 | A3 | Обрыв цепи датчика температуры отработавших газов 2 [высокий уровень] |

| P2120 | 19 | Обрыв цепи датчика положения педали акселератора |

| P2121 | 19 | Датчик положения педали акселератора [выход за пределы диапазона] |

| P2122 | 19 | Обрыв цепи датчика положения педали акселератора № 1 [низкий уровень] |

| P2123 | 19 | Обрыв цепи датчика положения педали акселератора № 1 [высокий уровень] |

| P2125 | 19 | Обрыв цепи датчика положения педали акселератора № 2 |

| P2127 | 19 | Обрыв цепи датчика положения педали акселератора № 2 [низкий уровень] |

| P2128 | 19 | Обрыв цепи датчика положения педали акселератора № 2 [высокий уровень] |

| P2138 | 19 | Обрыв цепи датчика положения педали акселератора |

| P2226 | A5 | Система датчика атмосферного давления |

| P2228 | A5 | Система датчика атмосферного давления [низкий уровень] |

| P2229 | A5 | Система датчика атмосферного давления [высокий уровень] |

| P2269 | 78 | Обнаружение попадания воды в топливо |

| P244A | 94 | Неисправность сажевого фильтра [слишком низкая разность давлений] |

| P244B | 94 | Неисправность сажевого фильтра [слишком высокая разность давлений] |

| P244D | 94 | Неисправность сажевого фильтра [слишком высокая температура] |

| P2458 | 94 | Отказ регенерации сажевого фильтра [не происходит повышения температуры] |

| P2463 | 94 | Неисправность сажевого фильтра [засорение сажей] |

| P24A2 | 94 | Завышенная скорость ввода топлива |

| U0101 | A2 | Нарушение связи по шине CAN с ЭБУ коробки передач |

| U0129 | A2 | Нарушение связи по шине CAN с ЭБУ тормозной системы |

| U0155 | A2 | Нарушение связи по шине CAN с ЭБУ щитка приборов |

| U110A | A2 | Нарушение связи по шине CAN с ЭБУ автомобиля |

| U1122 | A2 | Нарушение связи по шине CAN с системой РОГ |

| U1123 | A2 | Нарушение связи по шине CAN с турбокомпрессором с изменяемой геометрией турбины |

_____________________________________________________________________________________

БОНУС ДЛЯ ДОЧИТАВШИХ ДО КОНЦА — АЛГОРИТМ ПОИСКА НЕИСПРАВНОСТИ ПО КАЖДОЙ ОШИБКЕ ЗА 300р пишем на WHATS APP 89826514323

_____________________________________________________________________________________

И как обычно в конце только для благодарных ребят (со временем деньги возвращаются х100 кратно «ПРОВЕРЕНО»)

Счета для вашей благодарности:

Яндекс-деньги 41001327031715

Карта сбербанка РФ 639002169074388980 (Красноперов Дмитрий Сергеевич)

Партнерка от Donation Alert http://www.donationalerts.ru/r/dmitrij_krasnoperov

HINO E13C Type Engine 2.pdf

Adobe Acrobat Document

968.4 KB

HINO Dutro Fault Codes list (PDF).pdf

Adobe Acrobat Document

188.0 KB

Hino J05dJ08e Engine ECU Fault Codes Lis

Adobe Acrobat Document

344.2 KB

Wiring diagrams for HINO 300 models

(WU300, 302, 340, 410, 412, 420, 422 series / XZU303, 306, 307, 343, 347, 405, 407, 413, 415, 417, 423, 425, 427, 435, 437 series)

A / C = Air conditioner

A / T = Automatic transmission

DC = Direct current

DLC3 = Data Connector 3

DPR (DPF) = Diesel Particulate Emission Reduction System

ECU = Electronic control unit

EDU = Electronic drive

EGR = Exhaust Gas Recirculation

FL = Fuse

ISC = Idle speed control

J / B = C connection block

LCD = Liquid Crystal Display

LH = Left hand

LHD = Left hand drive

M / T = Mechanical transmission

PTO = Power Take Off

R / B = Relay box

RH = Right-handed

RHD = Right Hand Drive

SW = Switch

TEMP. = Temperature

vsv = Vacuum cut-off valve

w / = c

w / o = without

A1 Magnetic clutch of the air conditioner (W04D-TN, N04C-TT) 90980-11069

Air conditioner magnetic clutch (W04D-TM, N04C-TU) 90980-11271

A2 ABS speed sensor 90980-11073

A4 Accelerator pedal position sensor (for operation) 90980-11930

A6 Alternator 90980-09213

A7 Alternator 90980-11349

A8 Air conditioner amplifier 90980-10801

A9 Air conditioner switch 90980-11280

A10 Accelerator pedal switch 90980-10825

Air conditioner thermistor 90980-10825

A11 Accelerator pedal position sensor 90980-11858

A13 Electronic airbag control unit 90980-11872

A15 ABS speed sensor 90980-11073

A16 ABS speed sensor 90980-11773

A17 ABS sensor 90980-10845

A18 Front safety subuppsi sensor 90980-11856

A19 Airbag igniter 90980-11884

A20 Air flow sensor 90980-11317

A21 Electronic control unit ABS 90980-11638

A22 Electronic control unit ABS 90980-11637

A23 Electronic control unit ABS 90980-11476

A24 Electronic control unit ABS 90980-11421

A25 ABS actuator 90980-11893

B1 Reverse light switch (N04C) 90980-11003

Reversing light switch (except N04C) 90980-10576

B2 Brake vacuum signal switch 90980-11252

VZ Electric blower motor 90980-10214

B4 Blower resistor 90980-10171

B5 Switch signal level brake fluid 90980-10214

B6 Beep brake vacuum 90980-10825

B7 Seat belt latch switch (driver’s side) 90980-11212

B8 Accelerator sensor 90980-10845

B9 Brake vacuum signal sensor 90980-11011

C1 Camshaft position sensor 90980-11143

C2 Condenser fan motor and resistor 90980-10841

SZ Crankshaft Position Sensor (N04C) 90980-11162

Crankshaft position sensor (W04D) 90980-10923

C4 Cigarette lighter 90980-10760

C5 Combined sensor 90980-12557

C6 Combined sensor 90980-12554

C7 Combined switch 90980-10803

C8 Combined switch 90980-11913

C9 CAN DLC (controller local area network data transmission connector) 90980-12355

С10 CAN ECD (electronic detector of the local network of connectors) 90980-12355

С11 Cooler relay 90980-10713

С12 Cooler switch 90980-10795

C13 Grounding of the local network of connectors 90980-10871

C14 Clutch travel sensor 90980-11349

С16 Cab tilt switch 90980-10841

С17 Cab tilt switch 90980-11075

D1 Diode (brake light) 90980-11608

D2 Data connector 3 82824-36150

D3 Data connector 3 90980-11665

D4 Plug, door striker 90980-10806

D5 Light switch when the door is open 90980-10871

D6 Door striker switch 90980-11245

D7 Electric door striker 90980-11019

D8 DC / DC Converter 90980-11362

D9 Diode (air conditioner No. 2) 90980-11608

D10 Diode (0 / D) 90980-10962

D11 Diode (Diesel particulate matter reduction system) 90980-11071

Diode (parking brake) 90980-11071

Diode (vacuum) 90980-10962

Diode (cabin tilt) 90980-10962

D12 Ceiling light switch 90980-10795

D13 Switch for updating the particulate matter reduction system 90980-10799

D14 Differential pressure sensor 90980-10845

D15 Door catch 90980-11150

E1 Electronic horn 90980-10214

E2 Switch of the electronic switch 90980-11529

EZ Exhaust gas vacuum shut-off valve 90980-10923

E8 Air brake accelerator pedal switch 90980-10825

E9 Air brake clutch switch 90980-10935

E16 ECT SOL2 (12P) 90980-11151

E17 Exhaust gas recirculation valve sensor 90980-11317

E18 EST SOLI (YUR) 90980-11658

E19 Electronic control unit ECT (31P) 90980-11421

E20 Electronic control unit ECT (17P) 90980-11586

E21 Electronic control unit ECT (24P) 90980-11476

E22 Electronic engine control unit (34P) 90980-12527

E23 Electronic engine control unit (35P) 90980-12528

E24 Electronic engine control unit (35P) 90980-12529

E25 Electronic engine control unit (31P) 90980-12525

E2b Electronic drive 1 90980-11592

E27 Electronic drive 2 90980-11593

E28 Exhaust gas temperature sensor 90980-10898

F1 Front parking light left 90980-11020

F2 Front marker lamp right 90980-11020

F3 Left fog light (except for standard W04D cab) 90980-11019

Left fog light (standard cab W04D) 82824-37070

F4 Right fog lamp (except for standard cab W04D) 90980-11019

Right fog light (standard cab W04D) 82824-37070

F5 Front turn signal left 90980-11003

F6 Front turn signal right 90980-11003

F7 Fuel Sump Switch (N04C) 90980-11003

Fuel Sump Switch (W04D) 90980-10737

F8 Fuel pressure sensor 90980-10845

F9 Fuel supercharger 90980-10834

F10 Fuel temperature sensor 90980-11062

F11 Relay switching turn signals 90980-10173

F12 Front side turn signal left 90980-11019

F13 Front side turn signal right 90980-11019

F14 Fuel heater 90980-10928

F15 Four-wheel drive switch 90980-10795

F16 Front fog lamp switch 90980-10795

F17 Fuel Sump Switch 90980-11003

G3 Glow plug 90980-11161

G4 Glow plug 90980-11045

G5 Glow plug 90980-11184

H1 Actuator high beam left 90980-11016

H2 Actuator high beam right 90980-11016

NZ Headlight left 90980-11314

H4 Headlamp right 90980-11314

H5 Heater blower electric motor 90980-10795

H6 Sound signal (low) 90980-10619

H7 Alarm switch 90980-10801

H8 High beam switch 90980-11296

H9 Heater switch 90980-10714

H10 Headlamp left 90980-10942

H11 Headlight right 90980-10942

12 Injector No. 1 90980-11875

13 Injector No. 2

14 Injector No. 3

15 Injector No. 4

16 Ignition switch 90980-11537

17 Interior lighting (road map lighting) 90980-11804

18 Interior lighting (road map lighting) 90980-11369

19 Intake air temperature sensor 90980-11025

110 Vacuum shut-off valve inlet flap 90980-11149

111 Relay integrator 90980-10819

112 Idle control valve 90980-10695

113 Volume increase idle 90980-10908

114 Signal increase idle 90980-10871

115 Ignition switch 90980-10988

J1 Connector 90980-10830

J4 Connector 90980-10807

J5 Connector 90980-10807

J8 Connection connector

J13 Connector 90980-10803

J16 Connection connector

J28 Joint connector 90980-11542

J29 Connecting connector

J30 Connector 90980-10807

J31 Connector

J32 Connector 90980-11915

J33 Junction connector

J34 Junction connector

J35 Connector 90980-10803

J36 Connector 90980-11542

J37 Junction connector

J38 Connector 90980-10803

J39, 40 Connection connector

J41 Joint connector 90980-11915

J43, 44 Connector 90980-11661

J47 Connector 90980-10807

J48 Connector 90980-11398

K1 Keyless entry 90980-10807

L1 License plate light, left

L2 License plate light on the right 90980-10498

L3 License plate lighting 90980-11075

Ml Monitor Display 90980-10795

N1 Neutral switch 90980-11075

N2 Neutral gear sensor 90980-10923

N3 Start switch in neutral 90980-11658

01 Oil pressure switch 90980-11363

02 Oil pressure sensor 90980-10845

03 Oil temperature sensor 90980-11025

P1 Pressure switch 90980-11149

P2 Solenoid valve of power take-off 90980-10923

RZ Power take-off neutral position switch (electric) 90980-11002

Power take-off neutral position switch (W04D) 90980-10887

Power take-off neutral switch (wide cab N04C) 90980-11250

Short contact (wide cab except mechanical lever N04C)

P4 Power socket 90980-10171

P5 Power take-off clutch switch 90980-10860

P6 Power take-off switch 90980-10997

P7 Parking brake switch (left side) 90980-10795

Parking brake switch (right side) 90980-10359

P8 Rear power window switch 90980-11090

P9 Power window switch (passenger side) 90980-10631

P10 Universal power window switch 90980-10799

P11 Power window motor (driver’s side) (passenger’s side) 90980-11900

P12 Power window motor (driver’s side) (passenger’s side) 90980-11900

P13 Window regulator sensor 90980-11003

P14 Parking light switch 90980-10045

P15 Preheat timer 90980-11915

P16 Pre-tensioner 90980-11862

P17 Passenger seat switch 90980-10860

P18 Power take-off controller No. 2 90980-11607

P19 Power take-off controller No. 1 90980-10988

P20 Power take-off position switch 90980-10935

P21 Passenger seat belt latch switch 90980-10906

P22 Power take-off switch 90980-11015

P23 Parking sensor 90980-11918

P24 Power socket 4 90980-11178

P25 Power window switch 90980-10789

P26 Power window switch right-left 90980-11013

R1 Radio receiver and turntable 825 80-8810А

R2 Switch for rear fog lights 90980-11533

R3 Combination of taillights left 90980-11290

R4 Combination rear lights right 90980-11290

R5 Rear fog lamp 90980-10556

R6 Reverse sound signal 90980-11156

R7 Rear heater switch 90980-11399

R8 Rearview mirror 90980-11172

R9 Rear light combination 90980-10173

R10 Interior lighting 1 90980-11436

R11 Interior lighting 2 90980-10121

R12 Rear cooler resistor 90980-10171

R13 Rear cooler motor 90980-10214

R14 Rear heater relay 90980-10171

S2 Side direction indicator right 90980-11019

S3 Speed sensor 90980-11020

Speed sensor 2 90980-11143

Signal output 90980-10216

S4 Starter 90980-09508

Starter 90980-09507

S5 Starter 90980-11183

Starter 99141-13006

S6 Starter 99141-13006

S7 Starter relay 99141-13006

S8 Starter relay 90980-11299

S9 Suction Control Valve No. 1 90980-10720

S10 Electronic control unit for gearshift lock 90980-10322

S11 Gear shift lever 90980-11011

S14 Stop light switch 90980-10916

S15 Brake light switch (W04D) 90980-10916

Brake light switch (N04C) 90980-11118

S16 Speaker left

S17 Speaker right 90980-10935

S18 Protective arc switch 90980-11075

T1 Switch for cab tilt control 90980-11075

T2 Turbo pressure sensor 90980-10845

TZ Tachometer 82580-7000A

T4 Tachometer 90980-11529

Т5 Switch for the cabin tilt lock 90980-10841

TB Cab tilt pump 90980-10839

T7 Throttle position sensor 90980-11261

T8 Turbocharger actuator 90980-11194

T9 Tilt Vacuum Shut-Off Valve Motor 90980-10959

T10 Sound signal for cab tilt 90980-11156

T11 Cabin tilt relay 1 90980-11410

T12 Cab tilt relay 2 90980-10923

T13 Cab tilt control switch 90980-10494

T14 Turbine sensor 90980-10572

VI Vacuum signal switch 90980-10893

V2 Vacuum sensor 90980-10845

V3 Vacuum shut-off valve (intake flap) 90980-11149

V6 Vacuum cut-off valve (pneumatic brake) 90980-10923

W1 Water temperature switch 90980-10892

W2 Wiper motor 90980-11599

W3 Windscreen washer motor 90980-10214

W5 Water temperature sensor 90980-11451

W6 Warm-up switch 90980-10799

W7 Warm-up switch 90980-10321

Electronic engine management system S05C, S05D, S05C-TB

Panel indicator

Error code

Possible cause of the malfunction

(lamp)

Yes

P0335

The main sensor of the speed of rotation of the internal combustion engine or its wiring

Yes

P0335

Main and additional engine speed sensor or its wiring

Yes

P0336

Invalid signal from the main engine speed sensor

Yes

P0606

Defective ECU

Yes

P0629

Feed pump check valve (Power wire short)

Yes

P0200

ECU supply voltage above normal

Yes

P0611

ECU supply voltage below normal

No

P2120

Accelerator Pedal Position Sensor

No

P0217

Overheating of the internal combustion engine

Yes

P0088

Excess pressure in the first stage of the common fuel line

Yes

P0088

Excess pressure in the second stage of the common fuel line

Yes

P0088

Excessive pressure in the fuel line, excess in the supply of the feed pump

Yes

P0087

Lack of flow of the feed pump

Yes

P0108

Charge air pressure sensor, assignment above normal

Yes

P0117

Coolant temperature sensor, assignment below normal

Yes

P0118

Coolant temperature sensor, assignment above normal

Yes

P0191

Common rail pressure sensor, mechanical failure

Yes

P0192

Common rail pressure sensor, value below normal

Yes

P0193

Common rail pressure sensor, value above normal

Yes

P0201

First cylinder injector

Yes

P0202

Second cylinder injector

Yes

P0203

Third cylinder injector

Yes

P0204

Fourth cylinder injector

Yes

P0205

Fifth cylinder injector

Yes

P0206

Sixth cylinder injector

Yes

P0237

Charge air pressure sensor, assignment below normal

Yes

P0605

Error in ECU memory

Yes

P0607

Defective ECU

Yes

P0628

Feed pump check valve

Yes

P1211

Short circuit of the common ground line of 1 injector

Yes

P1212

Short circuit of the common line of the source 1 of the injector

Yes

P2112

Injector line 1 rupture

Yes

P1214

Short circuit of the common ground line 2 of the injector

Yes

P1215

Short circuit of the common line of the source 2 of the injector

Yes

P1215

Injector line 1 rupture

No

P1601

Injector correction data matching error

No

P2228

Atmospheric pressure sensor, low power input

Yes

P2229

Ambient pressure sensor, high power input

Yes

P2635

Feed pump suction check valve, mechanical failure

Yes

P0182

Fuel temperature sensor, low power input

Yes

P0183

Fuel temperature sensor, high input power

Yes

P0340

Additional engine speed sensor, circuit malfunction

Yes

P0500

Truck speed sensor , circuit low power input

Yes

P0501

Truck speed sensor , circuit high input power

Yes

P0686

Malfunction of the main relay

Yes

P2121

Accelerator sensor 1, stuck open

Yes

P2121

Accelerator sensor 1, stuck closed

Yes

P2122

Accelerator sensor 1, low voltage

Yes

P2123

Accelerator sensor 1, high voltage

Yes

P2126

Accelerator sensor 2, stuck open

Yes

P2126

Accelerator sensor 2, stuck closed

Yes

P2127

Accelerator sensor 2, low voltage

Yes

P2128

Accelerator sensor 1, high voltage

No

P0540

Boost Pressure Sensor Circuit Low Power Input

No

P0341

Flash ROM error

No

P0219

Circuit malfunction in the central processing unit

No

P0263

Imbalance of the 1st cylinder

No

P0266

Imbalance of the 2nd cylinder

No

P0269

Imbalance of the 3rd cylinder

No

P0272

Violation of balancing of the 4th cylinder

No

P0275

Violation of balancing of the 5th cylinder

No

P0278

Violation of balancing of the 6th cylinder

No

P0510

Faulty accelerator switch

No

P0617

Starter switch malfunction

No

P0704

Faulty clutch switch

No

P0850

Neutral switch malfunction

No

P1142

Idle speed controller, low voltage

No

P1143

Open circuit controller, high voltage

No

P1681

Retarder solenoid valve, short circuit, open circuit in the ground line

No

P1682

Retarder solenoid valve, short circuit, power supply lines

No

P2635

Abnormally high pressure of the feed pump

No

U0155

Meter data bus communication error

No

U1001

Chassis data bus communication error

No

U0121

ABS data bus communication error

No

P1132

PTO accelerator sensor, circuit low voltage

No

P1133

PTO accelerator sensor, circuit high voltage

Electronic engine management system S05C, S05D, S05C-TB

Reading fault codes

Normal check mode

1. Warm up the engine to operating temperature.

2. Turn off dcc accessories.

3. Switch on the ignition.

4. Install a jumper on the terminals «TE1» and «E1» of the diagnostic socket DLC1 or ‘Тс «(13) and» GG «(4) of the diagnostic socket DLC3.

5. The malfunction code is determined by a series of flashes «tens-one» of the control lamp.

6. For example, the lamp flashes 1 time, then a pause of 1.5 seconds, then flashes 3 times. This means code 13.

7. If two or more fault codes are stored in the memory of the electronic unit, the codes will be separated by a pause of 2.5 seconds.

8. If there are no malfunctions, the control lamp should flash with an interval of 0.26 seconds.

After all the codes are displayed, there is a pause of 4.5 s, and then they are all repeated until the terminals «TE1» and «E1» of the diagnostic connector are short-circuited.

Note: in the case of several codes of malfunctions, their indication starts with a smaller code and continues in ascending order.

Test check mode

Note:

— On models with DLC3 diagnostic connector, self-diagnosis in test mode is carried out using special testers.

— This self-diagnosis mode can be carried out on models with a DLC1 diagnostic connector, without the use of special testers.

— The self-diagnostic system allows a more detailed check of the control system by jumpering the terminals «TE2» and «E1» of the diagnostic connector. This test mode for specialists and some of

the fault codes given in the table appear only in this test mode.

— This test, in comparison with the usual one, has a higher sensitivity (you can diagnose individual circuits in real time). This is especially useful if constantly disappearing faults occur

during the movement).

1.Conditions of verification:

— the engine is warmed up to operating temperature;

— the battery is fully charged (voltage is not less than 24 V);

— the throttle valve is closed (the contacts of the limit switch pslnssgyu of the closed position of the throttle valve are closed);

— all additional equipment is turned off.

2. Switch off the «ignition».

3. Place a jumper on the terminals «TE2» and «E1» of the diagnostic socket.

4. Switch on the ignition.

Note: The flashing of the «CHECK ENGINE» lamp confirms the start of the test check.

5. Start the engine and drive at a speed over 5 km / h.

6. Create fault conditions (according to owner).

7. After the test check, jumper the leads «TE1» and «E1» of the diagnostic socket.

Note: «ignition» must be turned off when jumpering the leads.

8. Read the trouble codes.

Test mode with a tester

When using a proprietary TOYOTA tester to check the engine management system, a malfunction code is displayed in the event of a malfunction. The tester is connected to the «DLC3» diagnostic

connector.

Erasing fault codes

1. Switch off the ignition.

2. Remove the «ECD» electronic control unit fuse or disconnect the negative battery cable for one minute or more (at low temperatures). For models with a DLC3 diagnostic connector, the DTCs can

be cleared using a tester.

Note: disconnecting the battery erases the memory of other electronic devices (watches, etc.).

3. Road test the vehicle.

A. Repeat the diagnostic procedure and verify that there are no DTCs.

Diagnostic codes of malfunctions of the engine management system S05C, S05D

Code Sensor or system Condition Location of fault

12

Crankshaft Position Sensor [TDC]

No transmission of the «TDC» signal to the electronic control unit at a crankshaft speed of 400 rpm or more

1. Open or short circuit of the crankshaft position sensor circuit.

2. Crankshaft position sensor.

3. Electronic control unit.

13

Pump shaft speed sensor [NE + NE-]

1. There is no transmission of the «NE» signal to the electronic control unit for 0.5 seconds at a speed of 630 rpm and above.

2. There is no transmission of the «NE» signal to the electronic control unit for 2 seconds or more when cranking the crankshaft with the starter.

1. Break or short circuit in the pump shaft speed sensor circuit.

2. The sensor of the frequency of rotation of the injection pump shaft.

3. Electronic control unit.

14 Injection timing control solenoid valve [TCV]

On a warm engine, the readings of the solenoid valve for adjusting the injection timing do not match with the data in the memory of the electronic control unit for 20 seconds.

1. Break or short circuit of the z-circuit of the solenoid valve for adjusting the injection timing.

2. Fuel filter (clogged).

3. Fuel is frozen or air is trapped.

4. High pressure fuel pump (internal pressure and solenoid valve of the injection timing).

5. Electronic control unit.

19 (1)

Throttle position sensor [VA, VAS, E2C]

Open or short circuit in the accelerator pedal position sensor circuit for 1.0 seconds

and more

1. Open or short circuit in the accelerator pedal position sensor circuit.

2. Accelerator pedal position sensor.

3. Electronic control unit.

19 (2)

Throttle position sensor [IDL, E2C]

1. State (a) or (b) for 0.5 seconds or more:

a) Limit switch of idling in position «ON ‘(IDL» ON «) and voltage at the output

«VA»> 1.4 V;

b) Limit switch of idling in the «ON» position (IDL «ON») and voltage at the output

«VAS»> 1.4 V.

2. State (a) or (b) lasts 0.05 seconds or more:

a) Limit switch of idling in the «OFF» position (IDL «OFF») and the voltage at the output

«VA» <0.6V;

b) Limit switch of idling in the «OFF» position (IDL «OFF») and the voltage at the output

and «VAS» <0.6 V.

3. State (a) or (b) lasts 0.05 seconds or more:

a) 0.6 V <«VA» <4.4 V and 0.6 V <«VAS» <4.4 V;

b) «VA» — «VAS»> 0.5 V.

1. Open or short circuit in the accelerator pedal position sensor circuit.

2. Accelerator pedal position sensor.

3. Electronic control unit.

19 (3)

Throttle position sensor [PDL]

State (a), (b) or (c) lasts 0.5 seconds or more:

a) The accelerator pedal is depressed «ON»;

b) Voltage at terminal «VA»> voltage fully closed + 0.41 V.

1. Short circuit in the idle speed limit switch circuit.

2. Limit switch of idling.

3. Electronic control unit.

19 (4)

Throttle position sensor [PDL]

The PDL signal is received even when the vehicle is moving.

Note: A two-stage troubleshooting algorithm is used.

States (a) and (b) last for 5 seconds or more:

a) Accelerator pedal not depressed (PDL «OFF»);

b) Limit switch of idle speed in the «ON» position

1. Open circuit in the idle speed limit switch.

2. Limit switch of idling.

3. Electronic control unit.

22

Coolant temperature sensor signal [THW, E2]

Open or short circuit in the coolant temperature sensor («THW») circuit for 1.0 s or more

1. Circuit of the coolant temperature sensor.

2. Coolant temperature sensor.

3. Electronic control unit.

25

Electro-pneumatic damper valve

Open or short circuit in the electric pneumatic valve circuit of the noise suppressor for 1.0 s or

more

1. Open or short circuit in the electric pneumatic valve circuit of the noise suppressor.

2. Electronic control unit.

28

Mountain brake solenoid valve

Rupture or short circuit in the solenoid valve of the mountain brake for 1.0 s

or more

1. Open or short circuit in the mountain brake solenoid valve circuit.

2. Electronic control unit.

32

Correction resistor block [DATA, CLK, E2]

High-pressure pump correction resistor circuit

1. Open or short circuit in the correction resistor circuit,

2. Block of correcting resistors.

3. Electronic control unit.

33

Electrically actuated throttle valve

Rupture or short circuit in a chain of an electro-pneumatic valve of management of a throttle valve

1. Open or short circuit in the electric pneumatic valve circuit of the throttle actuator.

2. Electro-pneumatic valve.

3. Electronic control unit.

39

Fuel temperature sensor

Open or short circuit in the fuel temperature sensor circuit for 1.0 s or more

1. Open or short circuit in the fuel temperature sensor circuit.

2. Fuel temperature sensor.

3. Electronic control unit.

42

Vehicle speed sensor [SP1]

The signal does not go to the electronic control unit when the car is moving for 8 or more

seconds under the following conditions:

— speed signal 0 km / h;

— crankshaft rotation speed 2400 — 4000 rpm;

— coolant temperature 60 ° C or more;

— the accelerator pedal is depressed 29% or more.

1. Circuit of the vehicle speed sensor.

2. Vehicle speed sensor.

3. A combination of devices.

4. Electronic control unit.

95

Electronic control unit

Internal error of the electronic control unit

1. Open or short circuit in the mountain brake electro-pneumatic valve circuit.

2. Electronic control unit.

95

Electronic control unit

Internal error of the electronic control unit

1. Open or short circuit in the mountain brake electro-pneumatic valve circuit.

2. Electronic control unit.

96

EGR valve

There is no signal «EGLS» in the ECU for 1.0 seconds or more

1. Open or short circuit in the exhaust gas recirculation valve circuit.

2. Position sensor of the exhaust gas recirculation valve.

3. Electronic control unit.

97

Electronic control unit signal

Although the «SPVD» signal comes from the electronic control unit at a frequency

engine speed of 500 rpm and more, the «SPVF» signal is not sent to the electronic control unit in

for 5 times or more

1. Open or short circuit in the circuit of the electronic control unit.

2. Electronic control unit.

3. Electromagnetic bypass valve.

Engine Control System Diagnostic Trouble Codes S05C-TB

Code Sensor or system Condition Location of fault

12

Engine speed sensor [TDC or G1J

No transmission of the «G1» signal when the «NE» signal is present at 3600 rpm

1. Open or short circuit of the camshaft position sensor circuit.

2. Camshaft position sensor.

3. Camshaft pulley.

4. Electronic control unit.

13

Pump shaft speed sensor [NE + NE-]

There is no signal transmission «NE» when the engine is rotating, there is a signal «G l» at 525 rpm

1. Open or short circuit in the crankshaft speed sensor circuit.

2. Crankshaft speed sensor.

3. Rotor of the crankshaft position sensor.

4. Electronic control unit.

17

Electronic control unit

There is no normal signal at the output of the electronic control unit j or the central processor

Electronic control unit

19 (1)

Accelerator pedal position sensor (open / short circuit)

1. State (a) or (b) continues for 0.5 seconds or more:

a) «ASSR1 <or = 0.6 V;

b) «ASSR1»> or = 4.6 V.

2. State (a) or (b) continues for 0.5 seconds or more:

a) «ASSR2» <or = 0.6 V;

b) «ASSR2»> or = 4.6 V.

1. Open or short circuit in the accelerator pedal position sensor circuit.

2. Accelerator pedal position sensor.

3. Electronic control unit.

19 (2)

Accelerator Pedal Position Sensor

1. Any of the following conditions takes place:

a) The engine is idling (ACC off);

b) There is no wrong voltage at sensor # 1 or # 2;

c) 0.65 V <or = «ASCP2» <or = 1.05 V;

d) «ASSR1»> or = 1.5 V.

2. Any of the following conditions takes place:

a) The engine is idling (ACC off);

b) There is no wrong voltage at sensor # 1 or # 2;

c) 0.65 V <or = «ASCP2» <or = 1.05 V;

d) «ASSR2»> or = 1.5 V.

1. Open or short circuit in the accelerator pedal position sensor circuit.

2. Accelerator pedal position sensor.

3. Electronic control unit.

19 (3)

Accelerator pedal limit switch (short circuit)

Short circuit in the limit switch of the accelerator pedal

1. Short circuit in the limit switch circuit.

2. Accelerator pedal position sensor.

3. Electronic control unit.

19 (4)

Accelerator pedal limit switch (open circuit)

Gap in the limit switch of the accelerator pedal

1. Open circuit in the limit switch.

2. Accelerator pedal position sensor.

3. Electronic control unit.

22

Coolant temperature sensor signal

Rupture or short circuit in the coolant temperature sensor circuit for 3.0 s

or more

1. Circuit Danica coolant temperature.

2. Coolant temperature sensor.

3. Electronic control unit.

28

Mountain brake solenoid valve

Rupture or short circuit in the solenoid valve of the mountain brake for 1.0 s

or more

1. Open or short circuit in the mountain brake solenoid valve circuit.

2. Mountain brake system.

3. Electronic control unit.

32

Correcting resistor block

High-pressure pump correction resistor circuit

1. Open or short circuit in the correction resistor circuit.

2. Block of correcting resistors.

3. Electronic control unit.

35

Boost pressure sensor

Rupture or short circuit in the boost pressure sensor circuit for 1.0 s or more

1. Open or short circuit in the boost pressure sensor circuit or in the electric pneumatic valve circuit.

2. Boost pressure sensor.

3. Electro-pneumatic valve.

4. Turbocharging system.

5. Electronic control unit.

39

Fuel temperature sensor

Open or short circuit in the fuel temperature sensor circuit for 3.0 s or more

1. Open or short circuit in the fuel temperature sensor circuit.

2. Fuel temperature sensor.

3. Electronic control unit.

42

Vehicle speed sensor [SPD]

The signal does not go to the electronic control unit when the vehicle is moving at a speed of 30 km / h under the following conditions:

a) speed signal 0 km / h;

b) the frequency of rotation of the crankshaft is 2400 — 4000 rpm;

c) coolant temperature 60 ° C or more;

d) the accelerator pedal is depressed 29% or more.

1. Circuit of the vehicle speed sensor.

2. Vehicle speed sensor.

3. A combination of devices.

4. Electronic control unit.

49/83

Pressure sensor in the «Common Rail» system

Rupture or short circuit in the pressure sensor of the «Common Rail» system

1. Open or short circuit in the pressure sensor of the «Common Rail» system.

2. Fuel pressure sensor in the «Common Rail» system.

3. Electronic control unit.

78 (1)

Malfunction of the fuel line «Common Rail»

States «a», «b» and «c» are determined in the absence of fault codes 78 (2), (3), 49 and 83, frequency

engine rotation more than 650 rpm, and the coolant temperature is more than 60 ° C:

a) when the malfunction code 81 is determined, the design pressure is 5 MPa less than required;

b) when the difference between the design pressure and the required pressure is about 5 MPa at idle,

the power supply of the injection pump is higher than usual at idle, and this condition continues for some time;

c) when the injection volume is 0 and the difference between the design and required pressure is about 5 MPa, the fuel injection pump power supply is greater, and this state continues for some

time.

1. Leaks in the fuel line.

2. Blockage in the fuel supply line.

3. High pressure fuel pump.

78 (2)

Malfunction in the fuel pump system (short circuit)

Short circuit in the PCV2 circuit

1. Short circuit in the PCV2 circuit.

2. Fuel control valve (built into the fuel pump).

3. Electronic control unit.

78 (3)

Malfunction in the fuel pump system (high pressure)

The change in the pressure of the «Common Rail» system does not correspond to the change in the pressure of the fuel supply

pump

1. Open or short circuit in the fuel pressure sensor circuit.

2. Fuel pressure sensor.

3. Engine speed sensor.

4. Fuel pump.

5. Angle of advance of injection.

6. Electronic control unit.

78 (4)

Malfunction in the fuel pump system (short circuit)

Short circuit in the PCV1 circuit

1. Short circuit in the PCV1 circuit.

2. Fuel control valve (built into the fuel pump).

3. Electronic control unit.

79 (1)

79 (2)

79 (3)

79 (4)

Error in the control system of fuel supply to the cylinders (cylinder No. 1, No. 2, No. 3 or No. 4)

Difference in compensation of fuel volume (cylinder # 1, # 2, # 3 or # 4)

1. Fuel pipe from common rail to injector).

2. Nozzle.

3. Damper (on a common line).

4. Electronic control unit

81

Malfunction of the fuel pump system (no pressure / pressure limiter triggered)

The maximum pressure in the «Common Rail» system is maintained when there are no DTCs

78 (2), (4) and 83

1. Safety valve (on «Common Rail»).

2. Injection pump.

82

Engine spacing

Engine speed 3900 rpm and above

1. Camshaft position sensor.

2. Crankshaft position sensor.

3. Electronic control unit.

84

Malfunction in the «Common Rail» system (pressure does not change)

The pressure in the «Common Rail» system does not change when the engine is running

1. Circuit of the fuel pressure sensor.

2. Fuel pressure sensor.

3. Electronic control unit.

85

Relay bypass valve (PCV)

Malfunction in a relay circuit of the bypass valve (PCV)

1. Open or short circuit in the relay circuit of the bypass valve.

2. Relay bypass valve.

3. Electronic control unit.

86 (1)

86 (2)

86 (3)

86 (4)

Malfunction of injector no. 1, no. 2, no. 3 or no. 4

Break in a chain of a nozzle # 1, # 2, # 3 or # 4

1. Open or short circuit in the injector circuit.

2. Nozzle.

3. Wiring.

4. Electronic control unit.

86 (5) / 86 (6)

Injector malfunction (short circuit)

Short circuit in the «+ B» or «GND» circuits of the injector

1. Open or short circuit in the injector circuit.

2. Nozzle No. 1.

3. Nozzle No. 2.

4. Electronic control unit.

92

Engine stop switch malfunction

Engine stop switch

1. Open or short circuit in the engine stop switch circuit.

2. Engine stop switch.

3. Wiring.

4. Electronic control unit

Location Offline

Junior Member

Reputation:

10

Thanks Given: 21

Thanks Received: 66 (19 Posts)

Posts:

27

Threads:

1

Joined: Aug 2015

1

01-30-2016, 05:27 AM

HI friends, please elp with this: i have a hino dutro 300 series N04 engine 2015, and cranck but doesn start, and give me p1604, and show every ting as possible error, what can i do???

Thanks given by:

whallab

Location Offline

Senior Member

Reputation:

263

Thanks Given: 2167

Thanks Received: 785 (126 Posts)

Posts:

307

Threads:

19

Joined: Jul 2011

2

01-30-2016, 08:38 AM

What does the code say. Startabilty malfunction

Long live MHHAUTO. COM

Thanks given by:

el_mikino

Location Offline

Junior Member

Reputation:

15

Thanks Given: 75

Thanks Received: 80 (9 Posts)

Posts:

39

Threads:

1

Joined: Feb 2012

3

05-05-2016, 10:51 PM

hello, you try the test the ckp?, just for beging inyection you need the ckp signal, also check the cmp, is both are unsincronized the engine will not start, even if you have diesel, you can check with a led if you have pulse on the inyectors the cmp send the signal to ecu to start the inyectors.

i have a weichai with the same problem, i disconect the cmp and the engine start, but the scanner say that the cmp and the ckp are unsincronized.

how i check

1) i try with all conectect the engine crank but dont star

2) i change the ckp with all conected and nothing the engine dont start

3) i disconect the cmp and try again, the engine start but with low power and shutoff when i try to move the car

4) i use an osciloscope to check the signal an note that the cmp and ckp are unsincronized (dont send code i have a kts570)

5) i move the fuel pump to sincronized the cmp, this sensor is on the side of the fuel pump, bosch cpn/cp2 (this take me a week, i dont have manual of this engine)

6) the engine start and the cmp and ckp are sincronized now have power to move the truck and dont shutoff

Thanks given by:

2018 TOYOTA RAV4 with 8940.0 miles

My 2018 Toyota Rav4 has stalled 5 times while driving on city streets in moving traffic, first time in feb 2019 while driving home from work, in april three times while driving to work and one time while driving home from work(rush hour). All documented with Toyota. Occurs when i take my foot off the gas while driving, and difficulty restarting after it stalls with loss of power and sputtering. ‘charging system malfunction’ warning msg appeared on dashboard(i took photo and emailed to Toyota). I followed instructions in 2018 Toyotal Rav4 owner’s manual «stop the car immediately…Continuing to drive the vehicle may be dangerous». Had car towed to Toyota immediately. 3 trouble codes were recorded P1603(engine stall), P1604 startability malfunction, and P1605(rough idling), however they were unable to determine root cause of stalling and refused to keep my car to do further analysis despite the fact that i told them i did not feel safe driving vehicle, and my car is still under comprehensive warranty coverage. I contacted corporate, and they restated dealer conclusions and would not allow me to speak to a field tech specialist. I then emailed and wrote a letter to vp sales of Toyota, andrew gilleland. Rep from executive office called me. I asked for Toyota to provide me with either transportation assistance and a no cost-to-me extended comprehensive warranty until the underlying cause is determined and without further stalling incidences, or a replacement vehicle. He refused, despite all the significant potentially dangerous safety issues in a vehicle with less than 9,200 miles. Toyota does not appear to be concerned with reliability, peace of mind, and most of all safety. I have a case # with Toyota. I recently discovered there are several other reports on this site with same stalling issues as my car.

ELECTRICAL SYSTEM, POWER TRAIN

2018 TOYOTA RAV4 with 8940.0 miles

My 2018 Toyota Rav4 has stalled 5 times while driving on city streets in moving traffic, first time in feb 2019 while driving home from work, in april three times while driving to work and one time while driving home from work(rush hour). All documented with Toyota. Occurs when i take my foot off the gas while driving, and difficulty restarting after it stalls with loss of power and sputtering. ‘charging system malfunction’ warning msg appeared on dashboard(i took photo and emailed to Toyota). I followed instructions in 2018 Toyotal Rav4 owner’s manual «stop the car immediately…Continuing to drive the vehicle may be dangerous». Had car towed to Toyota immediately. 3 trouble codes were recorded P1603(engine stall), P1604 startability malfunction, and P1605(rough idling), however they were unable to determine root cause of stalling and refused to keep my car to do further analysis despite the fact that i told them i did not feel safe driving vehicle, and my car is still under comprehensive warranty coverage. I contacted corporate, and they restated dealer conclusions and would not allow me to speak to a field tech specialist. I then emailed and wrote a letter to vp sales of Toyota, andrew gilleland. Rep from executive office called me. I asked for Toyota to provide me with either transportation assistance and a no cost-to-me extended comprehensive warranty until the underlying cause is determined and without further stalling incidences, or a replacement vehicle. He refused, despite all the significant potentially dangerous safety issues in a vehicle with less than 9,200 miles. Toyota does not appear to be concerned with reliability, peace of mind, and most of all safety. I have a case # with Toyota. I recently discovered there are several other reports on this site with same stalling issues as my car.

POWER TRAIN, ELECTRICAL SYSTEM

2018 TOYOTA RAV4 with 8940.0 miles

My 2018 Toyota Rav4 has stalled 5 times while driving on city streets in moving traffic, first time in feb 2019 while driving home from work, in april three times while driving to work and one time while driving home from work(rush hour). All documented with Toyota. Occurs when i take my foot off the gas while driving, and difficulty restarting after it stalls with loss of power and sputtering. ‘charging system malfunction’ warning msg appeared on dashboard(i took photo and emailed to Toyota). I followed instructions in 2018 Toyotal Rav4 owner’s manual «stop the car immediately…Continuing to drive the vehicle may be dangerous». Had car towed to Toyota immediately. 3 trouble codes were recorded P1603(engine stall), P1604 startability malfunction, and P1605(rough idling), however they were unable to determine root cause of stalling and refused to keep my car to do further analysis despite the fact that i told them i did not feel safe driving vehicle, and my car is still under comprehensive warranty coverage. I contacted corporate, and they restated dealer conclusions and would not allow me to speak to a field tech specialist. I then emailed and wrote a letter to vp sales of Toyota, andrew gilleland. Rep from executive office called me. I asked for Toyota to provide me with either transportation assistance and a no cost-to-me extended comprehensive warranty until the underlying cause is determined and without further stalling incidences, or a replacement vehicle. He refused, despite all the significant potentially dangerous safety issues in a vehicle with less than 9,200 miles. Toyota does not appear to be concerned with reliability, peace of mind, and most of all safety. I have a case # with Toyota. I recently discovered there are several other reports on this site with same stalling issues as my car.

POWER TRAIN, ELECTRICAL SYSTEM

2018 TOYOTA RAV4 with 8940.0 miles

My 2018 Toyota Rav4 has stalled 5 times while driving on city streets in moving traffic, first time in feb 2019 while driving home from work, in april three times while driving to work and one time while driving home from work(rush hour). All documented with Toyota. Occurs when i take my foot off the gas while driving, and difficulty restarting after it stalls with loss of power and sputtering. ‘charging system malfunction’ warning msg appeared on dashboard(i took photo and emailed to Toyota). I followed instructions in 2018 Toyotal Rav4 owner’s manual «stop the car immediately…Continuing to drive the vehicle may be dangerous». Had car towed to Toyota immediately. 3 trouble codes were recorded P1603(engine stall), P1604 startability malfunction, and P1605(rough idling), however they were unable to determine root cause of stalling and refused to keep my car to do further analysis despite the fact that i told them i did not feel safe driving vehicle, and my car is still under comprehensive warranty coverage. I contacted corporate, and they restated dealer conclusions and would not allow me to speak to a field tech specialist. I then emailed and wrote a letter to vp sales of Toyota, andrew gilleland. Rep from executive office called me. I asked for Toyota to provide me with either transportation assistance and a no cost-to-me extended comprehensive warranty until the underlying cause is determined and without further stalling incidences, or a replacement vehicle. He refused, despite all the significant potentially dangerous safety issues in a vehicle with less than 9,200 miles. Toyota does not appear to be concerned with reliability, peace of mind, and most of all safety. I have a case # with Toyota. I recently discovered there are several other reports on this site with same stalling issues as my car.

POWER TRAIN, ELECTRICAL SYSTEM

2017 SUBARU OUTBACK with 13777 miles

Battery appears to drain over a relatively short period of time resulting in: P1604 startability malfunction, B2320 back &side radar low voltage, C1413 antilock brakes voltage malfunction, B2500 power lift gate voltage malfunction, B2A07 telematics battery charge history fault, B1011 battery power supply control malfunction, B1013 ignition power supply failure, and B1014 accessory power supply failure. All is taking place while vehicle is parked in heated garage.

ELECTRICAL SYSTEM, ELECTRICAL SYSTEM

2016 TOYOTA CAMRY with 19289.0 miles

Update to nhtsa id — 10937419 my 2016 Toyota Camry se has since been back in and out of the shop with the same since the original complaint my car has been at the dealership 5 times. Each time was simply told «normal operation» or «could not duplicate»…It is intermittent had received a call from my service advisor that they pulled codes showing the following; P1604 — startability malfunction P2610 — ecm/pcm internal engine off timer performance B1507 — vehicle speed control and idle control related he informed me it was likely a bad ecm and was waiting on Toyota to approve the repair. Shortly after i was informed Toyota denied the repair stating driver error… And the service invoice says no codes? I have report showing otherwise!!! In april, my car accelerated pulling into a driveway and ran into the back of truck at approximately 5 mph causing damage to the hood, grill and bumper of my vehicle. I reported this incident and Toyota took my vehicle in for 20 days for an investigation and brought in a «3rd party» to pull the edr box info. When the 3rd party sent me their readings…All codes including freeze codes were non-existent? However i demanded the diagnostic report from daytona Toyota and have that to prove they were indeed there to begin with. Where did they go? I spoke with wendy olsen the victim and witness coordinator of the us attorneys office southern district of new york regarding this matter. Honorable william h. Pauley iii us district judge for the southern district of new york arranged a deferred prosecution of fraud charges on Toyota for this same issue in 2014 and upon completion of monitoring for several years the case was to be nullified, however that was changed and was not…There must be a reason why!!! I have attached documents to show service records with obvious personal information blocked for privacy reasons!

VEHICLE SPEED CONTROL, POWER TRAIN ENGINE

2015 TOYOTA RAV4 with 50493 miles

Ongoing issues with my fuel system. Car will display one of these many symptoms: -misfire, hard start, stall or shutoff. Other symptoms include car stuttering and stalling out while driving. This last symptom is very dangerous as it often comes with no warning. When the car stalls out, the car is driving up straight up a medium grade hill. I have experienced this on several different dates and times along w 24th st. Austin, tx near 1106 w 24th st. This will happen if i’m either stopping at a light or while in motion. I don’t have the exact mph i am driving, but it would be around 20 — 40 mph when this occurs. Ive taken the care to both round rock Toyota and christian auto brothers to address the issue. So far, neither have been able to diagnose the problem. On 5/22/20, christian auto brothers replaced the evaporative emissions system leak detection unit r&r, the fuel evaporative canister r&r, the evaporative emissions system leak detection pump, and the vapor canister purge solenoid. This did not resolve the issue. Current codes: P0441, P0455, P1604, P1605, P0171. While no diagnostic proof has been established, it is hypothesized by the mechanics that there is an issue with either the fuel pump or the fuel line. After reading about the 2020 Toyota fuel pump recall, i believe my 2015 Rav4 has been experiencing similar issues. However, it is not part of the recall. Therefore i am submitting this incident info to document the current situation. If i learn more, i will try to update.

UNKNOWN OR OTHER, FUEL/PROPULSION SYSTEM

2013 TOYOTA TUNDRA with 58000.0 miles

On two different occasions i was driving my Tundra on the freeway at approx. 70 mph. My truck lost power and i almost caused accidents on both instances since i could not accelerate past 40 mph. I had to manage my way out of the freeway to a safe place. 2two diagnostics were performed and i received codes P0418, P1604, C1241, P2445, P2441. I was told by the Toyota dealership that there was a problem with a faulty secondary air injection system pump and other components related to the system and i was provided a repair cost of over $3,000 dollars. I was later informed, and i discovered through research, that Toyota had installed faulty/defective air pumps in thousands of Tundras 2013’s like the one that i own. I reached out to corporate office but they stated that my vin number somehow did not «qualify» as one of the affected pickups. My Tundra only has 60k miles and i use it to commute from and to work basically. I perform routine maintenance. There is obviously a problem with a defective secondary air pump system that Toyota refuses to fix. My truck is a liability on the road and this is my only means of transportation. It looses power and the check engine light activates. Toyota recalled thousands of vehicles like mine and fixed them after they acknowledged that they had placed faulty air pump systems. My truck is a potential possible cause for an accident since it unpredictably looses power on the freeway. I have not received a solution from headquarters/corporate office to repair my truck at no price since it is affected by their faulty pumps. They did offer $750 dollars towards the cost of parts, meaning that i have to come out with over $2000k out of pocket. I need Toyota to take responsibility and fix my truck.

ENGINE, ELECTRICAL SYSTEM ELECTRICAL SYSTEM ENGINE FUEL/PROPULSION SYSTEM FUEL/PROPULSION SYSTEM

2012 TOYOTA TUNDRA with 78000 miles

My truck has been having hard start issues since winter 2017. I figured it was my battery so i replaced it, but it didnt help. The hard start wasn’t consistent so i chose take some time to see if any other problems surfaced. Got through winter 2018 and spring/summer 2019 with it still starting rough on occasion. By october 2019 my truck reached approx 78k miles, and one day it didn’t start at all. Took three tries to get it going. I had the battery checked once again. It tested bad but it was under warranty so i had i lt swapped out. The problem persisted. This time it gave me an engine light. Mechanic said it was an ‘evap code’ and recommended i replace the gas cap to start. Code didnt return but still hard starting. Took almost two months and engine light came back on. This time P1604 startability malfunction. Was told i had to take it to Toyota to get a reflash. I decided to do some research and came across the problems Tundra owners were having with this ffv density sensor malfunction. Printed the old service bulletins and went to Toyota to talk to service dept about it. They said Toyota just put out a new service bulletin in december 2019 for the reflash but now also replacing the fuel pump (Toyota told me density sensor attached to the pump). Unfortunately Toyota also told me they won’t cover the cost since my truck had just gone over 80k miles, and they are not flexible with that at all, even though i told them it started before 80k. T-sb-0166-19. So i got prices. The reflash is about $140 and just the cost of the pump itself is $600, not including labor. I have spoken to the Toyota usa customer care team and they said they cant help me since i didnt take it to the dealer to diagnose it. Apparently it doesnt matter if you have service records from another shop. This is my 3rd Toyota, and i love my truck so this breaks my heart.

ENGINE, FUEL/PROPULSION SYSTEM FUEL/PROPULSION SYSTEM ENGINE

2011 TOYOTA COROLLA with 35740.0 miles

Vehicle fails to start. Found codes P0606 (ecm/pcm processor error) and P0303 (random misfire) on obd 2 computer. Vehicle towed to Toyota dealership where they cleaned spark plugs and cylinders due to engine flooding. Upon return of vehicle drove it home were it sputtered on the drive (afraid vehicle would shut down during drive). Ran obd 2 tester on it again and found a Toyota code P1604 ecm error. Returned to dealership were they did test on fuel samples and had the car for a couple of days. Computer was deemed faulty and replaced by Toyota. Toyota replaced original computer under manufactures warranty. Have had the car for two days after new computer and 5 new codes are on under readiness codes. P0606 (ecm/pcm processor error), P0303 (random misfire), P0171 (system too lean bank 1), P0172 (system too rich (bank 1), and P0125 (insufficient collanbd temp for closed loop fuel control). Car continues to idle and rev uncontrollably while driving. Concerned vehicle may shut off while driving and or not start.

ENGINE, VEHICLE SPEED CONTROL

Лень было ставить в гараж(, раз выдержала -37, подумал я, так и выдержит — 26, ага щас. -37 ( по ощущениям -44) было критичным для авто.

В кратции, если замёрзла машина и не заводится, и после отогрева пушкой тоже, и на сканере появилась ошибка р1604, ничего не мудрите и тащите авто в тёплое помещение как минимум на 12 часов. Пришлось воспользоваться Демкой и тащить замерзшего насмерть крокодила — иначе не назовёшь т.к. перед сном он начал жрать бенз на бык помои.

Описание ошибки р1604

P1604 TOYOTA — неисправность пускового устройства P1604 TOYOTA Возможные причины

— Низкий заряд батареи

— Пусковая система

— Низкокачественное топливо

— Засорен топливный фильтр

— Неисправный модуль управления двигателем (ECM)

Как исправить код P1604 TOYOTA

Проверьте «Возможные причины», перечисленные выше. Визуально осмотрите соответствующий жгут проводов и разъемы. Проверьте, не повреждены ли компоненты, и проверьте, не сломаны ли, изогнуты ли, вытолкнуты или разъедены контакты разъема.

P1604 TOYOTA Возможные симптомы.

Подсветка двигателя включена (или предупреждающая лампа обслуживания двигателя).

P1604 Toyota Описание.

Код P1604 сохраняется, если двигатель не запускается или продолжает вращаться без запуска в течение определенного периода времени. Код P1604 также сохраняется, если в автомобиле заканчивается топливо. Перед проверкой необходимо проверить, достаточно ли топлива в топливном баке.

Цена вопроса: 0 ₽