-

Contents

-

Table of Contents

-

Bookmarks

Quick Links

Catálogos

Levante Sistemas de

Automatización y Control S.L.

LSA Control S.L. — Bosch Rexroth Sales Partner

Ronda Narciso Monturiol y Estarriol, 7-9

Edificio TecnoParQ Planta 1ª Derecha, Oficina 14

(Parque Tecnológico de Paterna)

46980 Paterna (Valencia)

Telf. (+34) 960 62 43 01

comercial@lsa-control.com

www.lsa-control.com

www.boschrexroth.es

Distribuidor oficial Bosch Rexroth, Indramat, Bosch y Aventics.

www.lsa-control.com

Summary of Contents for Bosch Rexroth IndraDrive

|

|

Ремонт двигателей BOSCH REXROTH INDRAMAT

Электродвигатели данного производителя имеют высокие параметры по перегрузкам, а также динамике и широким диапазоном крутящего момента.

Двигатели BOSCH REXROTH INDRAMAT отличаются классом защиты, встроенным стояночного тормозом и т. п. Двигатели BOSCH REXROTH INDRAMAT, часто встречаются автоматизированных производственных площадках на больших и малых производствах.

В процессе работы рано или поздно (зависит то эксплуатационных режимов) промышленное оборудование выходит из строя, в этой ситуации ремонт двигателя BOSCH REXROTH INDRAMAT единственное экономически выгодное решение.

Самыми распространенными сериями электродвигателей BOSCH REXROTH INDRAMAT ремонт которых предлагает наша компания являются:

|

|

|

Специалисты сервисного центра «Кернел» более 20 лет проводят качественный ремонт электродвигателей BOSCH REXROTH INDRAMAT. Для максимально быстрого, а главное качественного ремонта, перемотки электродвигателей потребуется специализированное помещение, оборудованное необходимым оборудованием расходные материалы и компоненты для восстановления подобного промышленного оборудования и конечно же квалифицированный персонал.

Благодаря вышеперечисленному ремонт двигателей BOSCH REXROTH INDRAMAT в Дяневе проводится согласно всем техническим требованиям, в сжатые сроки. Каждый ремонт электродвигателей BOSCH REXROTH INDRAMAT завершается проверкой на специализированном стенде с блоками управления в условиях максимально приближенных к реальным.

Что входит в ремонт электродвигателей BOSCH REXROTH INDRAMAT

- Внутренняя и внешняя очистка двигателя

- Изоляция обмоток электродвигателя

- Перемотка силовых обмоток электродвигателя

- Пролачивание и сушка обмоток электродвигателя

- Токарные работы (восстановление посадочного места подшипника)

- Замена подшипника электродвигателя

- Замена клеммников, силовых и сигнальных разъёмов

- Ремонт датчиков обратной связи (энкодера, резольвера)

- Изготовление и замена муфты энкодера

- Юстировка положения датчиков обратной связи (энкодера / резольвера)

И в тоже время каждый отдельно взятый ремонт электродвигателей BOSCH REXROTH INDRAMAT уникален. Они отличаются схемами силовых обмоток количеством витков, сечением провода и т.д.

Ошибки и неисправности двигателей BOSCH REXROTH INDRAMAT

Неисправности электродвигателей BOSCH REXROTH INDRAMAT

- Неисправность датчиков обратной связи (энкодер, резольвер, тахогенератор);

- Сбито юстировочное положение энкодера двигателя;

- Неисправность обмоток статора. (межвитковое замыкание, пробой изоляции на корпус и обрыв);

- Износ подшипников их заклинивание;

- Износ посадочных мест подшипников на фланцах серводвигателя;

- Износ сальников;

- Износ тормозной системы;

- Размагничивание магнитов на роторе, потеря магнитных свойств;

- Разрушение корпуса двигателя (механические повреждения или из-за работы в агрессивной среде) разъёмов;

- Выход из строя термодатчика.

Ошибки двигателей BOSCH REXROTH INDRAMAT зависят от привода (частотного преобразователя) в связке с которым работают.

Ошибки привода электродвигателя BOSCH REXROTH INDRAMAT EFC x610

- Ошибка 1 (OC-1): Сверхток при постоянной скорости;

- Ошибка 2 (OC-2): Сверхток в ходе ускорения;

- Ошибка 3 (OC-3): Сверхток в ходе замедления;

- Ошибка 4 (OE-1): Перегрузка по напряжению при постоянной скорости;

- Ошибка 5 (OE-2): Скачок напряжения при ускорении;

- Ошибка 6 (OE-3): Скачок напряжения при замедлении;

- Ошибка 9 (SC): Сверхток или ток короткого замыкания;

- Ошибка 30 (OL-2): Перегрузка двигателя;

- Ошибка 31 (Ot): Перегрев двигателя;

- Ошибка 32 (t-Er): Ошибка настройки параметров двигателя;

- Ошибка 33 (AdE-): Ошибка обнаружения угла синхронного двигателя.

Ошибки BOSCH REXROTH серии EFC x610 – расшифровка, скачать руководство пользователя PDF

Перемотка электродвигателей BOSCH REXROTH INDRAMAT

Нет смысла перечислять все возможные сферы промышленности где работает данное промышленное оборудование, мы просто не найдем ни чего подобного. Электродвигатели BOSCH REXROTH INDRAMAT работают как в нормальных условиях, так и в крайне агрессивных средах, что приводит к частому выходу из строя оборудования, это может быть короткое межвитковое замыкание в результате попадания скажем охлаждающей жидкости на обмотки электродвигателя либо это может быть вызвано механическим износом, когда подшипник вырабатывает свой ресурс.

- Чистка внешнего корпуса электродвигателя;

- Ремонт смазочной системы, замена смазки;

- Ремонт протяжка и замена рефлекторных крепежных соединений;

- Проверка крепления вентилятора;

- Перемотка статора электродвигателя;

- Перемотка ротора электродвигателя;

- Покрытие лаком лобовых обмоточных частей

- Ремонт якоря электродвигателя;

- Ремонт статора электродвигателя;

- Восстановление вала и посадочных мест;

- Замена подшипников и сальников;

- Токарные и фрезерные работы;

- Проверка электродвигателя без нагрузки и с нагрузкой.

Ремонт и настройка энкодера и резольвера BOSCH REXROTH INDRAMAT

- Грязное кодирующие стекло или диск;

- Поломка, неисправность сигнального разъема;

- Не правильная форма сигналов или их отсутствие;

- Наличие внутренней ошибки (для абсолютных энкодеров);

- Замыкание в электросхеме энкодера.

Также влечет за собой ремонт энкодера.

Ремонт резольвера необходим в следующих случаях:

- Обрыв одной из статорных (неподвижная часть) обмоток резольвера;

- Обрыв одной из обмоток ротора (вращающаяся часть) резольвера;

- Межвитковое замыкание одной из обмоток. Обычно происходит в части обмоток;

- Сбита позиция резольвера на двигателе.

Мы предлагаем не просто квалифицированный ремонт энкодера и резольвера в сжатые сроки, а также дополнительную экономию бюджета 60%-80% от стоимости нового датчика обратной связи. На все виды ремонта мы даем 6-и месячную гарантию

Ремонтом энкодера, на данный момент занимаются далеко не все организации предлагающие услуги по ремонту промышленного оборудования, в связи с крайне сложным процессом ремонта и последующей настройки энкодера.

Сервисный центр «Кернел» предоставляет услуги по ремонту подобного сложного промышленного оборудования как энкодеры и резольверы.

Ремонт распространенных двигателей BOSCH REXROTH INDRAMAT

Ремонт двигателей BOSCH REXROTH INDRAMAT MKD

|

mkd025a, mkd025a-144-kp0-kn |

mkd025b, mkd025b-144-gg0-un |

|

mkd041b, mkd041b-058-gg1-kn, mkd041b-144-gp0-kn |

mkd071b, mkd071b-024-gg1-kn, mkd071b-035-gg0-kn |

|

mkd090b, mkd090b-035-gp0-kn, mkd090b-035-gp0-kn |

mkd112a, mkd112a-024-gg0-bn, mkd112a-058-gg1-b1 |

|

mkd112b, mkd112b-024-gg0-an, mkd112b-048-gg0-an |

mkd112c, mkd112c-024-gg3-an, mkd112c-058-gg0-an |

Ремонт электродвигателей BOSCH REXROTH INDRAMAT MDD

|

mdd025a, mdd025a-n-100-n2g-040ga0 |

mdd025a, mdd025a-n-100-n2g-040ga0 |

|

mdd025b, mdd025b-n-100-n2g-040pb0 |

mdd025b, mdd025b-n-100-n2g-040pb0 |

|

mdd025c, mdd025c-n-100-n2g-040mb1 |

mdd025c, mdd025c-n-100-n2g-040mb1 |

|

mdd041c, mdd041c-n-100-n2g-050pb0 |

mdd041c, mdd041c-n-100-n2g-050pb0 |

|

mdd065a, mdd065a-n-040-n2l-095ga0 |

mdd065a, mdd065a-n-040-n2l-095ga0 |

|

mdd065b, mdd065b-n-040-n2l-095ga0 |

mdd065b, mdd065b-n-040-n2l-095ga0 |

|

mdd065c, mdd065c-n-040-n2l-095pb0 |

mdd065c, mdd065c-n-040-n2l-095pb0 |

|

mdd065d, mdd065d-n-040-n2l-095pa1 |

mdd065d, mdd065d-n-040-n2l-095pa1 |

Ремонт двигателей BOSCH REXROTH INDRAMAT MHD

|

mhd041b, mhd041b-144-ng0-un |

mhd071b, mhd071b-035-ng1-un, mhd071b-061-np0-un |

|

mhd071a, mhd071a-061-np0-un |

mhd090b, mhd090b-058-pp1-un, mhd090b-035-np1-un, mhd090b-047-pp1-un |

|

mhd093c, mhd093c-035-ng0-an |

mhd093b, mhd093b-035-pg0-an, mhd093b-058-pg0-an, mhd093b-024-np0-la |

|

mhd093c, mhd093c-058-pg1-an, mhd093c-035-ng0-bn, mhd093a-024-pp0-ba |

mhd093a, mhd093a-024-np0-aa, mhd093a-035-pg1-ba, mhd093a-058-ng0-ba |

|

mhd112d, mhd112d-024-np0-0n, mhd112d-027-pp0-bn, mhd112b-048-np0-bn |

mhd112c, mhd112c-024-pg0-an, mhd112c-058-pp3-bn, mhd112c-035-ng0-bn |

|

mhd112b, mhd112b-058-pg0-рн, mhd112b-024-pg0-рн, mhd112b-048-pg1-bn |

mhd112a, mhd112a-024-pg1-an, mhd112a-058-pp0-bn, mhd112a-035-pg0-bn |

|

mhd115c, mhd115c-024-pp0-bn, mhd115c-058-pp0-bn, mhd115c-035-pg1-aa |

mhd115b, mhd115b-024-ng0-bn, mhd115b-058-ng0-an, mhd115b-035-pg1-ba |

|

mhd115a, mhd115a-024-np0-aa, mhd115a-058-pp1-bn, mhd115a-035-pg1-aa |

mhd131d, mhd131d-024-pg2-an |

|

mhd131b, mhd131b-024-np0-an |

Ремонт электродвигателей BOSCH REXROTH INDRAMAT MSK

|

msk030b, msk030b-0900-nn-m1-ug1-nsnn |

msk030c, msk030c-0900-nn-s3-up1-nnnn |

|

msk040b, msk040b-0450-nn-m1-up0-nnnn |

msk040c, msk040c-0450-nn-s1-ug0-nsnn |

|

msk050b, msk050b-0300-nn-m1-up1-nnnn |

msk050c, msk050c-0450-nn-s1-ug1-nnnn |

|

msk060b, msk060b-0300-nn-s1-up0-nnnn |

msk060c, msk060c-0300-nn-s2-up1-rnnn |

|

msk061c, msk061c-0600-nn-m1-up1-nsnn |

msk070c, msk070c-0150-nn-s1-ug1-nnnn |

|

msk070d, msk070d-0300-nn-s1-ug1-nnnn |

msk070e, msk070e-0300-nn-s2-ug1-rnnn |

|

msk071c, msk071c-0200-nn-m1-up0-nnnn |

msk071d, msk071d-0450-nn-s1-bg0-nnan |

|

msk071e, msk071e-0202-nn-s3-ug0-nnnn |

msk100b, msk100b-0300-nn-s1-bg0-nnnn |

|

msk100c, msk100c-0450-nn-s1-bg0-nnnn |

msk100d, msk100d-0300-nn-s1-bg0-nnnn |

|

msk101c, msk101c-0200-nn-m1-ag2-nnnn |

msk101d, msk101d-0200-nn-m1-ag2-nnnn |

|

msk101e, msk101e-0300-nn-s3-ag0-nnnn |

Ремонт двигателей BOSCH REXROTH INDRAMAT MAC

|

mac025a, mac025a-0-ws-2-e, mac025a-0-ws-3-e, mac025a-0-ws-4-e |

mac025a, mac025a-0-ws-2-e, mac025a-0-ws-3-e, mac025a-0-ws-4-e |

|

mac025b, mac025b-0-zs-2-e, mac025b-0-zs-3-e, mac025b-0-zs-4-e |

mac025b, mac025b-0-zs-2-e, mac025b-0-zs-3-e, mac025b-0-zs-4-e |

|

mac025c, mac025c-0-qs-3-e, mac025c-0-qs-2-e, mac025c-0-qs-4-e |

mac025c, mac025c-0-qs-3-e, mac025c-0-qs-2-e, mac025c-0-qs-4-e |

|

mac041a, mac041a-0-fs-4-e, mac041a-0-fs-3-e, mac041a-0-fs-4-e |

mac041a, mac041a-0-fs-4-e, mac041a-0-fs-3-e, mac041a-0-fs-4-e |

|

mac041b, mac041b-0-bs-2-e, mac041b-0-bs-3-e, mac041b-0-bs-4-e |

mac041b, mac041b-0-bs-2-e, mac041b-0-bs-3-e, mac041b-0-bs-4-e |

|

mac041c, mac041c-0-ls-2-e, mac041c-0-ts-2-e, mac041c-0-ts-3-e |

mac041c, mac041c-0-ls-2-e, mac041c-0-ts-2-e, mac041c-0-ts-3-e |

|

mac063a, mac063a-0-es-2-f, mac063a-0-es-4-c, mac063a-0-es-2-c |

mac063a, mac063a-0-es-2-f, mac063a-0-es-4-c, mac063a-0-es-2-c |

|

MAC063B, MAC063B-0-GS-2-C, mac063b-0-gs-4-c, mac063b-0-js-1-c |

mac063b, mac063b-0-gs-2-c, mac063b-0-gs-4-c, mac063b-0-js-1-c |

|

mac063c, mac063c-0-gs-2-c, mac063c-0-h5-4-c, mac063c-0-hs-4-c |

mac063c, mac063c-0-gs-2-c, mac063c-0-h5-4-c, mac063c-0-hs-4-c |

Ремонт электродвигателей BOSCH REXROTH INDRAMAT IndraDyn S MKE

|

mke037b, mke037b-144, mke037b-144-ap0-benn |

MKE037B, MKE037B-144, mke037b-144-ap0-benn |

|

mke047b, mke047b-144, mke047b-144-kg1-bunn |

MKE047B, MKE047B-144, mke047b-144-kg1-bunn |

|

mke098b, mke098b-047, mke098b-058, mke098b-058-bg0-benn |

Ремонт двигателей BOSCH REXROTH INDRAMAT IndraDrive Cs MSM

|

msm019, msm019b, msm019a-0300, msm019b-0300, msm019b-r300 |

msm019, msm019b, msm019a-0300, msm019b-0300, msm019b-r300 |

|

msm020b-0300, msm020b-0300-nn-m0-cc0 |

msm020b-0300, msm020b-0300-nn-m0-cc0 |

|

msm030b, msm030b-0300, msm030b-0300-nn-m0-cg0 |

msm030b, msm030b-0300, msm030b-0300-nn-m0-cg0 |

|

msm030c, msm030c-0300, msm030c-0300-nn-m0-cc0 |

Ремонт электродвигателей BOSCH REXROTH INDRAMAT MAD

|

mad100b, mad100b-0150-sa-s2-hh0-05-n1 |

mad100c, mad100c-0150-sa-s2-ap0-05-n3 |

|

mad100d, mad100d-0100-sa-s2-bp0-05-a1 |

mad130b, mad130b-0100-sa-s2-fh0-05-n1 |

|

mad130c, mad130c-0200-sa-m2-ap0-05-n1 |

mad130d, mad130d-0100-sa-m2-bq0-05-v1 |

|

mad160b,mad160b-0200-sa-s2-rg0-35-v3 |

mad160c, mad160c-0200-sa-m2-ah0-05-h1 |

|

mad180c, mad180c-0100-sa-m2-ep2-35-n1 |

mad180d, mad180d-0150-sa-c0-kp0-35-a1 |

|

mad225c, mad225c-0100-sa-s2-dh0-35-n1 |

Ремонт двигателей BOSCH REXROTH INDRAMAT MAF

|

maf100, maf100c, maf100c-0150, maf100c-0250 |

maf100d, maf100d-0150, maf100d-0200, maf100d-0250 |

|

maf100b, maf100b-0200, maf100b-0250 |

maf130b, maf130b-0050, maf130b-0200, maf130b-0250 |

|

maf130d, maf130d-0100, maf130d-0150, maf130d-0200, maf130d-0250 |

maf130c, maf130c-0150, maf130c-0250, maf130c-0200 |

|

maf160b, maf160b-0100, maf160b-0200 |

maf160c, maf160c-0100, maf160c-0150, maf160c-0200 |

|

maf180d, maf180d-0100, maf180d-0150, maf180d-0200 |

maf180c, maf180c-0150 |

|

maf225c, maf225c-0100 |

Ремонт электродвигателей BOSCH REXROTH INDRAMAT 2AD и ADF

|

BOSCH REXROTH INDRAMAT 2AD |

BOSCH REXROTH INDRAMAT ADF |

|

|

Выше представлены далеко не все типы электродвигателей BOSCH REXROTH INDRAMAT ремонт которых предлагает сервисный центр «Кернел»

Оставить заявку на ремонт двигателей BOSCH REXROTH INDRAMAT

Оставить заявку на ремонт или перемотку двигателей BOSCH REXROTH INDRAMAT в Дяневе можно с помощью специальной формы, которая вызывается нажатием одноименной кнопки в верхней части страницы. Все вопросы, связанные с ремонтом электродвигателей BOSCH REXROTH INDRAMAT в Дяневе вы можете задать нашим менеджерам. Связаться с ними можно несколькими способами:

- Заказав обратный звонок (кнопка в правом нижнем углу сайта)

- Посредством чата (кнопка расположена с левой стороны сайта)

- Позвонив по номеру телефона:

- +7(8482) 79-78-54;

- +7(8482) 55-96-39;

- +7(917) 121-53-01

- Написав на электронную почту: 89171215301@mail.ru

Вот далеко не полный список производителей промышленной электроники и оборудования, ремонтируемой в нашей компании.

IndraDrive C Error Codes fall into eight classes:

- F2xxx: non-fatal error

- F3xxx: non-fatal safety technology error

- F4xxx: interface error

- F6xxx: travel range error

- F7xxx: safety technology error

- F8xxx: fatal error

- F9xxx: fatal system error

- E-xxxx: fatal system error “processor exception”

You can tell which kind of error you’re looking at by the first two characters in the 5-character error code.

When an error flashes on the control panel, you can clear the error message by resetting or using the Esc button. However, if the error state still exists, the error message will immediately begin flashing again. If, for example, you see error code F2190, Incorrect Ethernet configuration, you will have to correct the ethernet configuration before you can continue using your IndraDrive C.

You can check the most recent 50 error messages for your unit with the IndraWorks D software.

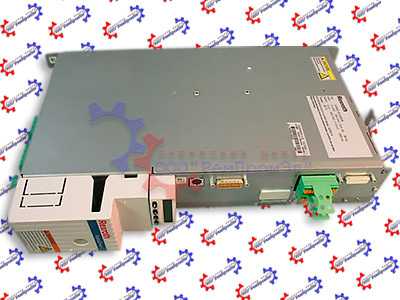

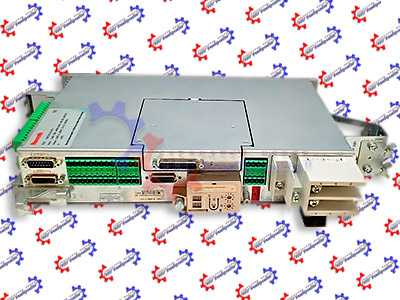

Thr IndraDrive C is a current model.

IndraDrive C uses Ethernet-based communications with multi-protocol support: Sercos III, Profi Net IO, EtherNet/IP and EtherCa.t. The intelligent operating panel has a programming function which supports device swap without a PC. Digital inputs and outputs as well as analog input on board.

In line with newer Rexroth lines, the IndraDrive C is energy efficient and features drive-integrated safety technology.

We can provide a manual for IndraDrive C. Just use our Manual Request form.

Need more than a manual? We offer phone and field support, factory repair, and factory reman. We also have the nation’s largest inventory of emergency repair units, with charter planes standing by for the fastest possible delivery. Our goal is always to get you up and running with minimal downtime. Call 479-422-0390 for immediate assistance.

|

|

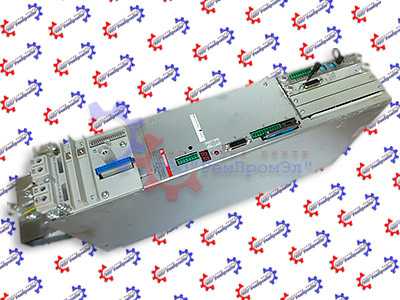

Ремонт сервоприводов REXROTH INDRAMAT indradrive в Тольятти

Сервопривода достаточно распространенное промышленное оборудование, и как все подвержены износу. В зависимости от интенсивности использования, нагрузки, среды в которой работает оборудования сервопривода выходят из строя останавливая рабочий процесс.

В целях сомнительной «экономии» некоторые пытаются провести ремонт сервоусилителя BOSCH REXROTH INDRAMAT indradrive самостоятельно на территории производства. Зачастую данные действия приводят к значительному удорожанию ремонта а при самом неблагоприятном исходе могут привести к не ремонтопригодности сервопривода.

В виду вышесказанного, настоятельно рекомендуем, не пытайтесь проводить ремонт сервоприводов BOSCH REXROTH своими силами, обратитесь за помощью к специалистам. Современный специализированный сервисный центр имеет в наличии весь необходимый инструмент, включая специальное диагностическое оборудование, а компетентный персонал проведет качественный ремонт сервоприводов BOSCH REXROTH INDRAMAT indradrive в Тольятти, дополнительно сервисные центры дают гарантию на проведенные ремонтные работы.

Ремонт сервоприводов BOSCH REXROTH в СЦ «РемПромЭл»

В 2013-ом году специалистами компании был проведен первый ремонт сервопривода BOSCH REXROTH положивший начало дальнейшему развитию в данном направлении. За прошедшее время были отремонтированы сотни единиц промышленного оборудования и накоплен колоссальный, бесценный опыт в ремонте сервоприводов различных производителей.

Сервисный центр «РемПромЭл» оснащен самым современным диагностическим и ремонтным оборудованием, имеются в наличии расходные материалы, а так же на складе компании богатый выбор оригинальных запасных частей, что дает возможность провести качественный ремонт сервоприводов BOSCH REXROTH INDRAMAT indradrive.

Обратившись в СЦ за ремонтом сервоприводов вы получите:

- Глубокую диагностику с выявлением неисправного компонента;

- Чистку неисправного блока;

- Ремонт сервопривода BOSCH REXROTH в кратчайшие сроки;

- Настройка сервоусилителя;

- Проверку отремонтированного блока на специальном стенде в условиях максимально приближенных к реальным;

- Видео проверки отремонтированного сервопривода.

Отдельное внимание мы уделяем качеству проведения ремонта и даем гарантию на ремонт сервоприводов BOSCH REXROTH INDRAMAT indradrive, а так же на замененные в процессе ремонта запасные части и расходные материалы 6 месяцев.

Настройка сервоусилителей BOSCH REXROTH INDRAMAT indradrive в Тольятти

Настройка сервоусилителей или как еще называют программирование сервоприводов, неотъемлемая часть процесса реанимирования, ввиду того, что ремонт силовой части это только половина мероприятий направленных на восстановление работоспособности сервоприводов.

В некоторых случаях возникает необходимость провести программирование сервоусилителя без его ремонта. Причин по которым может возникнуть подобная необходимость масса.

Настройка сервоуслилтелей в Тольятти может быть и отдельной услугой предоставляемой сервисным центром «РемПромЭл». Инженеры компании проведут необходимую настройку сервоприводов как на территории сервисного центра так и с выездом на территорию заказчика (по предварительной договоренности).

От качественной настройки сервоусилителя зависит правильная и безаварийная работа связки сервопривода и серводвигателя, а для этого требуется не много, просто программирование сервопривода должен проводить компетентный персонал с богатым опытом по настройке сервоуслилтелей.

Подключение сервопривода BOSCH REXROTH

При необходимости специалист центра выполнит подключение сервоприводаBOSCH REXROTH INDRAMAT indradrive с выездом на территорию заказчика.

В некоторых случаях на производстве может быть дефицит квалифицированны кадров которые могли бы произвести качественное подключение сервопривода, именно по этому мы предлагаем услуги нашего сервисного центра.

Свяжитесь с нашими менеджерами, закажите выезд специалиста, и подключением сервопривода BOSCH REXROTH займется инженер сервисного центра. В случае заказа на подключение сервопривода BOSCH REXROTH INDRAMAT indradrive силами наших специалистов вы получаете гарантию качества и работоспособности вашего оборудования.

Доверяя работу по подключению сервопривода BOSCH REXROTH профессионалам, вы избавляетесь от головной боли и гарантированно получаете работающее оборудование в кратчайшие сроки и за разумную цену.

Ошибки сервопривода Bosch Rexroth

У каждого производителя разные коды ошибок у кого то это могут быть цифровые обозначения у кого то буквенные, но вся прелесть заключается в том, что открыв документацию и расшифровав код ошибки сервопривода мы с большой долей вероятности можем исправить эту ошибку на месте, сбросить ее на сервоприводе и запустить оборудование заново.

К сожалению не все ошибки сервоприводов можно исправить и сбросить самостоятельно, в некоторых случаях придется обращаться к специалистам сервисного центра.

Самые распространенные ошибки сервоприводов:

- Превышение тока;

- Перенапряжение или недостаточное напряжение;

- Перегрузка;

- Ошибка сигнала энкодера;

- Превышение температуры IGBT-модуля ;

- Ошибка связи;

- Обрыв фазы питания;

- Короткое замыкание.

Это не полный список распространенных ошибок сервоприводов которые можно сбросить самостоятельно без обращения к специалистам.

Коды ошибок сервопривода Bosch Rexroth IndraDrive MPx-02 to MPx-08

Дисплеи F8030 и F8135

|

Дисплей |

E-код канал 1 (P3219 [0]) |

E-код канал 2 (P3219 [1]) |

Описание ошибки |

|---|---|---|---|

| F8030 | 113 | Разрешение привода установлено в состоянии внутренней ошибки. Ошибка «Безопасный останов 1». | |

| 114 | 637, 642 | Разрешение привода настраивается в функции техники безопасности «Безопасный останов 1». | |

| 115 | 638, 641 | Разрешение привода задается в функции техники безопасности «Безопасный останов 1 (Аварийный останов)». | |

| 303 | 639 | Разрешение движения устанавливается с помощью «парковочной оси». | |

| 669 | Разрешение привода все еще установлено при переходе к «Безопасный останов 1 (SS1)». | ||

| 670 | Разрешение привода все еще установлено при переходе к «Безопасный останов 1 (Аварийный останов) (SS1ES)». | ||

| F8134 | 273 | При переходе к ошибке «Безопасная остановка 1» рампа замедления упала ниже установленного значения в P-0-3282. |

|

| 405 | Безопасная система торможения и удержания: отсутствие обратной связи или тормоз управляемый приводом, включить отсутствующий. | ||

| 406 | Безопасная система торможения и удержания: Отсутствует управление резервным удерживающим тормозом без разрешения привода в состоянии покоя. | ||

| 408 | Безопасная система торможения и удержания: Отсутствует управление стояночным тормозом двигателя («P-0-3307, Техника безопасности — время задержки выключения «работает). | ||

| 235, 542 | Тормоз двигателя или резервный стояночный тормоз отпущен, хотя выходной каскад не активен. Устранение: Проверить управление тормозом. |

||

| F8135 | 205 | В функции техники безопасности «Безопасный останов 1» рампа замедления упала ниже установленного значения, для надежно контролируемого замедления (P-0-3282). |

|

| 207 | В функции техники безопасности «Безопасный останов 1 (Аварийный останов)» замедление рампа упала ниже значения, установленного для надежно контролируемого замедления (P-0-3282). |

||

| 272 | 566, 567, 586 |

При переходе к ошибке «Безопасная остановка 1» рампа замедления упала ниже установленного значения в P-0-3282. |

|

| 273 | Реакция на ошибку F7: При переходе к ошибке «Безопасный останов 1» рампа замедления упало ниже значения, установленного в P-0-3282. |

||

| 407 | Безопасная система торможения и удержания: Отсутствует управление резервным удерживающим тормозом. Причина: задержки из-за стояночного тормоза двигателя. |

||

| 410 | Превышено время безопасного останова, в результате реакции на ошибку, не удалось удалить привод, включить в течение времени P-0-3220 / P-0-3225 Устранение: Проверить параметрирование в P ‑ 0‑3220 / P ‑ 0‑3225 и S ‑ 0‑0207. |

||

| 412, 413 | 546, 623 | Безопасная система торможения и удержания: при замедлении с «значением команды скорости. сброс », темп замедления упал ниже значения, установленного в P-0-3282. |

|

| 619, 620 | В случае ошибки привод не может во время остановки, управляемой приводом, остановится в параметризованных пределах контроля. Ошибка генерируется до P-0-3226 закончился. |

Диагностический дисплей от MPB-07V12 / MPx-08VRS

|

Светодиод |

Значение | Устранение |

|---|---|---|

|

Off |

|

|

|

Мигает зеленый |

|

|

|

Горит зеленый |

|

|

|

Мигает зеленый-желтый |

|

|

|

Мигает желтый |

|

|

|

Горит желтый |

|

|

|

Мигает красный-желтый |

|

|

|

Мигает красный-зеленый |

|

|

|

Мигает красный |

Ошибка (F2xxx, F3xxx, F6xxx, F7xxx, F8xxx). | Прочтите точный статус через «S ‑ 0‑0095», (диагностическое сообщение). Обратитесь в сервисный центр. |

|

Горит красный |

|

|

Все возможные ошибки сервопривода Bosch Rexroth IndraDrive MPx-02 to MPx-08 — Скачать в формате DDF

Типы сервоприводов Bosch Rexroth

| Сервопривод | Тип сервопривода |

|---|---|

|

BOSCH REXROTH INDRAMAT indradrive |

HCS02.1E-W0070-A-03-NNNN; HMD01.1N-W0036; HCS01.1E-W0008-A-03; DKC02.3-018-3-MGP-01VRS; DKCXX.3-100-7; HCS01.1E-W0028-A-03; HMS01.1N-W0020; HMD01.1N-W0020 |

Указанные в таблице типы сервоприводов BOSCH REXROTH INDRAMAT это далеко не все, мы предлагаем качественный ремонт сервоприводов в Тольятти абсолютно любых производителей и года выпуска.

Оставить заявку на ремонт сервопривода BOSCH REXROTH INDRAMAT indradrive

У вас есть проблемы с сервоприводом? Вам нужен срочный ремонт сервопривода BOSCH REXROTH INDRAMAT indradrive или его настройка? Оставьте заявку на ремонт сервопривода BOSCH REXROTH в Тольятти воспользовавшись одноименной кнопкой на сайте либо обратитесь к нашим менеджерам. Связаться с ними можно несколькими способами:

- Заказав обратный звонок (кнопка в правом верхнем углу сайта)

- Посредством чата (кнопка расположена с левой стороны сайта)

- Позвонив по номеру телефона: +7(927)610-78-70; +7(848)255-80-30

- Написав на электронную почту: Адрес электронной почты защищен от спам-ботов. Для просмотра адреса в вашем браузере должен быть включен Javascript.

- Перейти в начало статьи

Rexroth IndraDrive

7.8

Error code

0x1001

0x1009

0x2001

0x2002

0x2003

0x2004

0x2005

0x3002

0x3003

0x3004

0x3005

0x4001

0x4002

0x4003

0x4004

0x4005

0x5001

0x5002

0x5003

0x5004

0x5005

0x6001

0x6002

0x6003

0x6004

DOK-INDRV*-GEN-**VRS**-WA01-EN-P

LSA Control S.L. www.lsa-control.com comercial@lsa-control.com (+34) 960 62 43 01

The error codes defined in the SERCOS interface specification are used.

(See SERCOS Interface specification, sec. 4.3.2.3 «Error messages in

service channel»). These codes are also used with faulty accessing of

control and systems parameters.

Explanation

IDN not available

element 1 incorrectly accessed

name not available

name transmission too short

name transmission too long

name cannot be changed

name presently write protected

attribute transmission too short

attribute transmission too long

attribute cannot be changed

attribute presently write protected

unit not available

unit transmission too short

unit transmission too long

unit cannot be changed

unit presently write protected

minimum input value not available

minimum input value transmission too short

minimum input value transmission too long

minimum input value cannot be changed

minimum input value presently write protected

maximum input value not available

maximum input value transmission too short

maximum input value transmission too long

maximum input value cannot be changed

-> continuation…

7-129

Error Messages

Rexroth error messages are made up of a diagnostic code and a diagnostic text. For error F2028, “F2” and “28” alternate on the H1 display. In the diagnostic message, it shows as F2028. F2028 is one of the “excessive” — error codes that tell you there’s too much of something. In this case, it’s too much deviation.

There are lots of error codes for various conditions and various components.

One group of error codes includes the word “excessive.” Sometimes too much of a good thing is just too much.

Excessives error codes

- F2027 Excessive oscillation in DC bus

The DC bus voltage fluctuates too much. The oscillation might not be visible in the machine, so be sure to check the command torque. Check the settings on the velocity control loop and the position control loop.

- F2028 Excessive deviation

When the actual position exceeds the expected parameters, this error is generated. This can be caused by errors in the parameters, if the axis is blocked, or when the power supply was turned off while the controller enable signal was applied. Check both the mechanical system to correct axis jamming, and the parameters to make sure they’re correct.

- F2036 Excessive position feedback difference

This error code means that the difference between actual position value 1 and position value 2 is greater than the monitoring window.

- F2037 Excessive position command difference

F2037 is the error shown when the position difference between two successive position command values is the same as the value in the bipolar velocity limit value — or larger.

Can we help?

Error codes can be caused by too much, too little, or just the wrong things. But any error code is more error codes than you really want to deal with.

Call us at 479-422-0390 for any Rexroth electric motion control issues. We specialize in Rexroth electric industrial motion control. We offer phone support, field support, and factory repair and reman. We also maintain the nation’s largest inventory of Rexroth electric drive and control components.

Bosch Rexroth IndraDrive Troubleshooting Manual

Title: Rexroth IndraDrive

Type of Documentation: Troubleshooting Guide

Document Type code: DOK-INDRV*-GEN-**VRS**-WA01-EN-P

Internal File Reference: Document Number 120-2400-B307-01/EN

Purpose of Documentation: This document is designed to assist maintanenance personnel in

identifying errors with the machinery.

It serves to:

• help in understanding error messages

• help in finding the cause of errors

• describe the procedure for trouble shooting

Record of Revisions:

Description Release Date Notes

DOK-INDRV*-GEN-**VRS**-WA01-EN-P 03.2004 First edition

Copyright: 2004 Bosch Rexroth AG

Copying this document, giving it to others and the use or communication of the contents thereof without express authority, are forbidden. Offenders are liable for the payment of damages. All rights are reserved in the event of the grant of a patent or the registration of a utility model or design (DIN 34-1).

Validity: The specified data is for product description purposes only and may not be deemed to be guaranteed unless expressly confirmed in the contract. All rights are reserved with respect to the content of this documentation and the availability of the product.

Published by:

Bosch Rexroth AG

Bgm.-Dr.-Nebel-Str. 2 • D-97816 Lohr a. Main

Telephone +49 (0)93 52/40-0

• Tx 68 94 21

• Fax +49 (0)93 52/40-48 85

http://www.boschrexroth.com/ Dept. ED

NOTE: This document has been printed on chlorine-free bleached paper.

Basics on Device Diagnosis

Diagnostic System

Coded Diagnostic Drive Messages:

Brief Description

The drive provides a diagnostic system including different possibilities that are basically divided into two groups:

• recognizing and displaying the current drive status by means of drive internal, priority-dependent generation of diagnostic messages

• collective messages for diverse status messages

Additionally, there are parameters for all important operating data the values of which can be transmitted both via master communication (e.g. SERCOS) and a parameterization interface (RS-232/485 in the ASCII protocol or SIS protocol; see “Serial Communication”). Pertinent Parameters

• S-0-0030, Manufacturer version

• S-0-0095, Diagnostic message

• S-0-0140, Controller type

• S-0-0142, Application type

• S-0-0375, List of diagnostic numbers

• S-0-0390, Diagnostic message number

• P-0-0009, Error number

• P-0-0478, Logbook event

• P-0-0479, Logbook time stamp

Drive-Internal Generation of Diagnostic Messages

Operating states, activities and reactions of the drive controller are detected by drive-internal generation of diagnostic messages and appear in coded form on the display of the control panel. In addition, these diagnostic messages can be transmitted to the master (control unit or commissioning software, e.g. Drive Top).

The following categories of diagnostic messages are differentiated (kinds of diagnostic messages):

• errors

• warnings

• commands/command errors

• status displays/operating states

Generally, the current diagnostic message with the highest priority is displayed or stored at the following locations in the drive:

• Display of the control panel

The diagnostic message number appears on the 8-digit display of the standard control panel.

• S-0-0095, Diagnostic message

This parameter contains the operating status of the drive at present relevant in the form of a plain text. Preceding the text is the respective content of parameter S-0-0390.

• S-0-0390, Diagnostic message number

The diagnostic message number shown on the display is stored in this parameter.

When a diagnostic message of the “error” category occurs, the corresponding diagnostic message number is stored in the P-0-0009,

Error number parameter. When there isn’t any error present, the value of parameter P-0-0009 equals zero.

In the S-0-0375, List of diagnostic numbers parameter the last 50 diagnostic message numbers of parameter S-0-0390 are recorded in

chronological order. When reading this list, the number of the diagnostic message that last occurred is displayed as parameter element 1.

Priorities of Display

The following priorities apply for displaying the current diagnostic message:

Structure of a Diagnostic Message

Every diagnostic message consists of

• diagnostic message number and

• diagnostic text.

The diagnostic message for the non-fatal error “Excessive deviation”, for example, has the following structure:

“F2028” flashes on the display of the control panel. The diagnostic message number is contained in the S-0-0390, Diagnostic message

number parameter in hexadecimal form (for this example: 0x00F2028).

The diagnostic message number and the diagnostic text are contained as string F2028 Excessive deviation in the S-0-0095, Diagnostic message parameter. “2028” (dec) is written to the P-0-0009, Error number parameter because it is an error diagnosis.

Diagnostic Message on the Control Panel Display

The diagnostic message number appears on the 8-digit display of the standard control panel. This allows recognizing the current operating status of the drive quickly and without using a communication interface.

As a matter of principle, the following applies:

• status displays (P0, Ab, AF …) are displayed in right-aligned form

• warnings, command errors and other error messages are flashing

Diagnostic Messages in Plain Text

The diagnostic message in plain text contains the diagnostic message number followed by the diagnostic text. It can be read via the S-0-0095,

Diagnostic message parameter and directly displayed on an operator interface as a language-dependent description of the drive status.

The diagnostic message in plain text is switched to the selected language via the S-0-0265, Language selection parameter.

Diagnostic Message Number

The diagnostic message number contains only the diagnostic number without the diagnostic text. It can be read with the S-0-0390, Diagnostic message number parameter and is a language-independent possibility of determining and displaying the drive status on an operator interface.

Error Number

The error number contains only the error number without the diagnostic text. It can be read with the P-0-0009, Error number parameter and is a language-independent possibility of determining and displaying an error condition on an operator interface. This parameter only contains a value unequal zero when an error is present in the drive.

The error number is generated from the lowest 4 digits of the diagnostic message number. For example, the F2028 Excessive deviation error with the diagnostic message number “(0x)F2028” would produce the error number “2028.”

List of Diagnostic Numbers

The last 50 diagnostic message numbers displayed are stored in chronological order in the S-0-0375, List of diagnostic numbers parameter. Every change in the content of S-0-0390, Diagnostic message number means that the old content is transferred to S-0-0375.

When reading S-0-0375 the last transferred diagnostic message number appears in the first element of the parameter, the diagnostic message number transferred before from S-0-0390 in the second element etc.

Language Selection

Via parameter S-0-0265, Language selection it is possible to define or switch the language of diagnostic message texts.

Status Classes, Status Displays, Control Parameters:

In the drive there are many parameters with important status information

(bit lists). Some of the bits contained in these lists can be used for

configuring real-time status bits and additionally can be assigned to digital

outputs or to the configurable signal status word.

See “Digital Inputs/Outputs” in chapter “Extended Drive Functions” and

“Configurable Signal Status Word” in chapter “Master Communication”

Status Classes:

Brief Description

The drive differentiates between 3 states (error, warning and message) for which there is status information. To make the status information available there are so-called status class parameters (S-0-0011, S-0-0012, S-0-0013) that contain the respective status bits.

In addition to these status class parameters there are change bits contained in the status word of the field bus (e.g. S-0-0135 in the case of SERCOS) that display changes in one of the above-mentioned status class parameters (collective information).

Features:

• status class parameter for errors (cf. S-0-0011)

• status class parameter for warnings (cf. S-0-0012)

• status class parameter for messages (cf. S-0-0013)

• change bits in status word of master communication (e.g. S-0-0135 in the case of SERCOS)

• change bits of class 2 and 3 diagnostics (S-0-0097 and S-0-0098) can be masked in status word of master communication (e.g.

S-0-0135 in the case of SERCOS) to suppress individual bits or status messages

Pertinent Parameters:

• S-0-0011, Class 1 diagnostics

• S-0-0012, Class 2 diagnostics

• S-0-0013, Class 3 diagnostics

• S-0-0097, Mask class 2 diagnostics

• S-0-0098, Mask class 3 diagnostics

• S-0-0135, Drive status word

Functional Description:

Status Class Parameters

– S-0-0011, Class 1 diagnostics (status parameter for drive errors)

• In case a drive error occurs, the bit assigned to the error is set in parameter S-0-0011. A separate bit is assigned in S-0-0011 to errors defined according to SERCOS.

Manufacturer-specific errors cause bit 15 to be set in S-0-0011.

• In case a drive error occurs, bit 13 (drive interlock; error in class 1 diagnostics) is simultaneously set in the status word of the field bus (S-0-0135 in the case of SERCOS).

Note: All bits in class 1 diagnostics are cleared by executing the command C0500 (reset class 1 diagnostics).

See also Parameter Description “S-0-0099, C0500 Reset class 1 diagnostics”

– S-0-0012, Class 2 diagnostics (status parameter for drive warnings)

• In case a drive warning occurs, the bit assigned to the warning is set in parameter S-0-0012. A separate bit is assigned in S-0-0012 to warnings defined according to SERCOS.

Manufacturer-specific warnings cause bit 15 to be set in S-0-0012.

• In case a drive warning occurs, bit 12 (change bit class 2 diagnostics) is simultaneously set in the status word of the field bus (S-0-0135 in the case of SERCOS) when the content of S-0-0012 changes (i.e. at least one bit toggles).

• The bits in parameter S-0-0012 are automatically cleared when the warning disappears. The change bit in the status word of the master communication (S-0-0135 in the case of SERCOS) remains set, however, until parameter S-0-0012 has been read once.

Note: Via parameter S-0-0097, Mask class 2 diagnostics warnings can be masked in terms of their effect on the change bit.

– S-0-0013, Class 3 diagnostics (status parameter for drive messages)

• Messages of the drive are listed in parameter S-0-0013. A separate bit is assigned in S-0-0013 to messages defined according to SERCOS.

• In the case of a drive message, bit 11 (change bit class 3 diagnostics) is simultaneously set in the status word of the field bus (S-0-0135 in the case of SERCOS).

Note: Each of these messages is stored in a separate parameter (S-0-0330 to S-0-0342).

• The bits in parameter S-0-0013 are automatically cleared when the message disappears. The change bit in the status word of the master communication (S-0-0135 in the case of SERCOS) remains set, however, until parameter S-0-0013 has at least been read once.

Change Bits in Drive Status Word:

If the status of a bit in S-0-0012, Class 2 diagnostics or S-0-0013, Class 3 diagnostics changes, the change bit for class 2 or 3 diagnostics is set in the field bus status word (e.g. S-0-0135 in the case of SERCOS).

A change bit in the status word (bit 11 or 12) is always set due to a change of the parameter content of S-0-0012 or S-0-0013. This enables the master to recognize very quickly whether a change occurred in S-0-0012 or S-0-0013.

A read access to one of the two parameters clears the respective change bit again.

Masking the Change Bit:

By means of the parameters S-0-0097, Mask class 2 diagnostics and S-0-0098, Mask class 3 diagnostics it is possible to mask out certain bits in terms of their effect on the change bit of the status word (bit 12 or bit 11).

The figure below illustrates the principle of masking by means of an example:

The figure below illustrates the handling of the change bits in the status word and of the status class parameters:

Fixed Status Displays:

Function-Related Status Parameters

In the drive there are parameters the content of which has a direct relation to the status of the sequence of different drive functions. These parameters are used to display the current status information of the assigned function.

The following parameters are available for function-related status display:

• S-0-0014, Interface status

This parameter displays the status of the communication phase

transition and the cyclic communication.

• S-0-0135, Drive status word

This is the status word of the master communication (SERCOS) and

contains all essential status information for the master.

• S-0-0403, Position feedback value status

This parameter contains status bits for the position data reference of

the individual measuring systems.

• S-0-0419, Positioning command acknowledge

This status information is used for acknowledgment in the “drivecontrolled

positioning” mode.

• P-0-0046, Status word of current controller

This parameter contains status bits of the internal motor control (e.g.

overvoltage in DC bus).

• P-0-0115, Status word of system control

This parameter contains status bits of device control (see also “Device

Control”).

• P-0-0188, Status word positioning generator

This parameter contains status bits for the positioning behavior of the

drive (e.g. “In target position”).

• P-0-0222, Travel range limit inputs

This parameter displays the status of the travel range limit switch

inputs (see also “Travel Range Limit Switches”).

• P-0-0223, E-Stop input

This parameter displays the status of the E-Stop input (see also “EStop Function”).

• P-0-0445, Status word torque/current limit

This parameter contains status bits to display the activation of

torque/current limitation (see also “Torque/Current Limit”).

• P-0-0539, Holding brake status word

This parameter contains status bits for the status of the motor holding brake (see also “Motor Holding Brake”).

• P-0-0555, Controller status word

This parameter displays messages with regard to velocity and limits that have been reached.

• P-0-4029, SCSB diagnostics

Parameter for reading master communication settings and states (with SERCOS interface).

• P-0-4086, Master communication status

This parameter displays control information of the master communication for handling phase switch, drive enable etc., defined during initialization.

Status Parameters for Real-Time Status Bits

The following list contains status parameters that only contain one bit and can therefore be used for configuring real-time status bits (see “Master Communication: SERCOS interface”):

• S-0-0330, Message ’n_actual = n_command’

• S-0-0331, Status ’n_feedback = 0’

• S-0-0332, Message ’nactual < nx’

• S-0-0333, Message ’T >= Tx’

• S-0-0334, Message ’T >= Tlimit’

• S-0-0335, Message ’n command > n limit’

• S-0-0336, Message In position

• S-0-0337, Message ’P >= Px’

• S-0-0341, In-Position coarse message

• S-0-0342, Target position reached

• S-0-0343, Status “Interpolator halted”

• S-0-0409, Probe 1 positive latched

• S-0-0410, Probe 1 negative latched

• S-0-0411, Probe 2 positive latched

• S-0-0412, Probe 2 negative latched

Control Parameters

Apart from the parameters for status display, there are parameters available in the drive that are used to control the drive functions (see also

corresponding parameter description):

• P-0-0045, Control word of current controller

• P-0-0427, Control parameter of analog output

• P-0-0522, Commutation setting control word

• P-0-0556, Control word of axis controller

• P-0-0612, Control word for setting absolute measuring

• P-0-4028, Device control word

Control Panel of the IndraDrive Controllers

Brief Description:

The standard design of IndraDrive controllers includes a control panel with an 8-digit display and four buttons located underneath it.

The display shows operating states, command and error diagnoses, as well as present warnings.

Using the four buttons, the commissioning engineer or service technician can opt to display extended diagnostic messages at the drive controller and to activate simple commands (in addition to master communication using the commissioning tool or NC control unit).

Functional Description:

Standard Displays:

The display of the IndraDrive controller automatically shows:

• status of the master communication

• operating status

• activated commands and command diagnoses

• warnings and error diagnoses

The displays have priorities because it is impossible to have various displays at the same time.

Priorities of Display:

The current drive status is displayed with highest priority.

Activating Extended Display and Command Input:

By simultaneously pressing the “Enter” and “Esc” buttons (for 8 s!) you can call up extended displays; subsequently pressing the “Up” button activates the command input.

Extended Displays:

By means of the extended displays it is possible to additionally call up the contents of certain parameters:

• error memory

• diagnostic message memory

• operating hours counter control section

• operating hours counter power section

• type designation of the firmware active in the device

• safety technology code, if safety technology option available

Command Inputs:

Starting from the extended display it is possible to activate commands and make settings:

• set the drive address (drive number in the bus system of the master communication)

• set the length of the fiber optic cable

• activate the “analog mode” master communication

• C07_x load defaults procedure command (loading controller parameters resp. base parameters)

• other commands like

• C2200 Backup working memory procedure command

• C2300 Load working memory command

• C2500 Copy IDN from optional memory to internal memory

• C2600 Copy IDN from internal memory to optional memory

• C2900 Firmware update from MMC

Notes on Commissioning:

Extended Diagnostic Possibilities

The firmware provides further possibilities of diagnosis. For the description please see the Functional Description of the Firmware.

Kinds of Diagnostic Messages

Error:

Depending on the operating mode that is used and some parameter settings, the drive controller carries out monitoring functions. An error

message is generated by the drive controller, if a status is detected that no longer allows correct operation.

Error Classes:

Errors can be divided into several error classes. The error class is represented by the first two digits of the diagnostic message number.

Drive Error Reaction:

If the drive controller is in control (drive enable was set) and an error occurs, the drive controller automatically starts a drive error reaction.

The reaction to errors of certain classes can be influenced by the P-0-0119, Best possible deceleration parameter.

At the end of each error reaction, the drive is torque-free.

Clearing Errors:

Errors are not automatically cleared; they have to be cleared by:

• the control unit by activating the S-0-0099, C0500 Reset class 1 diagnostics command or

• by the user via the control panel

Note: Some errors can only be cleared in communication phase 2. If the error status persists the drive controller generates the error message again.

Booting and Firmware Download Errors:

Note: Apart from the mentioned error classes that can occur during operation, errors can occur when the devices are booted and during firmware download. These errors are not displayed at the control panel with a diagnostic message number of the “Fxxxx” pattern, but with a short text. Booting and firmware download errors are described separately.

Warnings:

While in operation the drive controller carries out monitoring functions. Some monitoring functions depend on the operating mode that is used and/or parameter settings. If a status is detected that still allows correct operation but persists, which would then cause an error to be generated, a warning is generated.

Note: Some warnings won’t result in an error if they are ignored.

Warning Classes:

Warnings can be divided into two classes:

• without drive reaction (E1xxx ..E7xxx)

• with drive reaction (E8xxx)

Warnings cannot be cleared externally.

Commands:

Commands are used to control complex functions in the drive. The command execution is displayed in a diagnostic message.

By means of the respective parameter that is assigned to the command, a higher-level control unit can start, interrupt and clear commands. In addition, some selected commands can be directly started via the control panel of the drive controller.

There are 3 command types:

Drive Control Commands: Drive control commands can only be started when drive enable was set. They might possibly cause automatic drive motion and deactivate the active operating mode during its execution.

Monitoring Commands: Executing monitoring commands activates or deactivates monitors and functions.

Administration Commands: Administration commands execute administration tasks. They cannot be interrupted.

Note: Command errors are displayed with a diagnostic message, too. By means of the first three digits (Cxx) of the diagnostic message number it is possible to recognize which command caused the command error.

States/Operating States:

The diagnostic status messages display the phases of communication build-up and initialization (boot phase), operating states or the currently active operating mode.

Note: In the case of some diagnostic status messages the diagnostic message number contained in parameter S-0-0390, Diagnostic message number differs from the display at the drive controller (see also “Operating States”).

Important directions for use

Appropriate use

Introduction:

Rexroth products represent state-of-the-art developments and manufacturing. They are tested prior to delivery to ensure operating safety

and reliability.

The products may only be used in the manner that is defined as appropriate. If they are used in an inappropriate manner, then situations

can develop that may lead to property damage or injury to personnel.

Note: Bosch Rexroth, as manufacturer, is not liable for any damages resulting from inappropriate use. In such cases, the guarantee and the right to payment of damages resulting from inappropriate use are forfeited. The user alone carries all responsibility of the risks.

Before using Rexroth products, make sure that all the pre-requisites for an appropriate use of the products are satisfied:

• Personnel that in any way, shape or form uses our products must first read and understand the relevant safety instructions and be familiar with appropriate use.

• If the product takes the form of hardware, then they must remain in their original state, in other words, no structural changes are permitted.

It is not permitted to decompile software products or alter source codes.

• Do not mount damaged or faulty products or use them in operation.

• Make sure that the products have been installed in the manner described in the relevant documentation.

Areas of use and application:

Drive controllers made by Bosch Rexroth are designed to control electrical motors and monitor their operation. Control and monitoring of the motors may require additional sensors and actors.

Note: The drive controllers may only be used with the accessories and parts specified in this document. If a component has not been specifically named, then it may not be either mounted or connected. The same applies to cables and lines.

Operation is only permitted in the specified configurations and combinations of components using the software and firmware as specified in the relevant function descriptions.

Every drive controller has to be programmed before starting it up, making it possible for the motor to execute the specific functions of an application. The drive controllers of the IndraDrive family are designed for use in single or multiple-axis drive and control applications.

To ensure an application-specific use, the drive controllers are available with differing drive power and different interfaces.

Typical applications of drive controllers belonging to the IndraDrive family are:

• handling and mounting systems,

• packaging and foodstuff machines,

• printing and paper processing machines and

• machine tools.

The drive controllers may only be operated under the assembly, installation and ambient conditions as described here (temperature, system of protection, humidity, EMC requirements, etc.) and in the position specified.

Inappropriate use

Using the drive controllers outside of the above-referenced areas of application or under operating conditions other than described in the document and the technical data specified is defined as “inappropriate use”.

Drive controllers may not be used if

• they are subject to operating conditions that do not meet the above specified ambient conditions. This includes, for example, operation under water, in the case of extreme temperature fluctuations or extremely high maximum temperatures or if

• Rexroth has not specifically released them for that intended purpose.

Please note the specifications outlined in the general safety instructions!

Safety Instructions for Electric Drives and Controls

Introduction

Read these instructions before the initial startup of the equipment in order to eliminate the risk of bodily harm or material damage. Follow these safety instructions at all times.

Do not attempt to install or start up this equipment without first reading all documentation provided with the product. Read and understand these safety instructions and all user documentation of the equipment prior to working with the equipment at any time. If you do not have the user documentation for your equipment, contact your local Bosch Rexroth representative to send this documentation immediately to the person or persons responsible for the safe operation of this equipment.

If the equipment is resold, rented or transferred or passed on to others, then these safety instructions must be delivered with the equipment.

Improper use of this equipment, failure to follow the safety instructions in this document or tampering with the product, including disabling of safety devices, may result in material damage, bodily harm, electric shock or even death!

Explanations

The safety instructions describe the following degrees of hazard seriousness in compliance with ANSI Z535. The degree of hazard seriousness informs about the consequences resulting from noncompliance with the safety instructions.

Hazards by Improper Use

General Information

• Bosch Rexroth AG is not liable for damages resulting from failure to observe the warnings provided in this documentation.

• Read the operating, maintenance and safety instructions in your language before starting up the machine. If you find that you cannot completely understand the documentation for your product, please ask your supplier to clarify.

• Proper and correct transport, storage, assembly and installation as well as care in operation and maintenance are prerequisites for optimal and safe operation of this equipment.

• Only persons who are trained and qualified for the use and operation of the equipment may work on this equipment or within its proximity.

• The persons are qualified if they have sufficient knowledge of the assembly, installation and operation of the equipment as well as an understanding of all warnings and precautionary measures noted in these instructions.

• Furthermore, they must be trained, instructed and qualified to switch electrical circuits and equipment on and off in accordance with technical safety regulations, to ground them and to mark them according to the requirements of safe work practices. They must

have adequate safety equipment and be trained in first aid.

• Only use spare parts and accessories approved by the manufacturer.

• Follow all safety regulations and requirements for the specific application as practiced in the country of use.

• The equipment is designed for installation in industrial machinery.

• The ambient conditions given in the product documentation must be observed.

• Use only safety features and applications that are clearly and explicitly approved in the Project Planning Manual.

For example, the following areas of use are not permitted: construction cranes, elevators used for people or freight, devices and vehicles to transport people, medical applications, refinery plants, transport of hazardous goods, nuclear applications, applications sensitive to high frequency, mining, food processing, control of protection equipment (also in a machine).

• The information given in the documentation of the product with regard to the use of the delivered components contains only examples of

applications and suggestions.

The machine and installation manufacturer must

• make sure that the delivered components are suited for his individual application and check the information given in this documentation with regard to the use of the components,

• make sure that his application complies with the applicable safety regulations and standards and carry out the required measures, modifications and complements.

• Startup of the delivered components is only permitted once it is sure that the machine or installation in which they are installed complies with the national regulations, safety specifications and standards of the application.

• Operation is only permitted if the national EMC regulations for the application are met.

The instructions for installation in accordance with EMC requirements can be found in the documentation “EMC in Drive and Control Systems”.

The machine or installation manufacturer is responsible for compliance with the limiting values as prescribed in the national regulations.

• Technical data, connections and operational conditions are specified in the product documentation and must be followed at all times.

Protection Against Contact with Electrical Parts

Note: This section refers to equipment and drive components with voltages above 50 Volts.

Touching live parts with voltages of 50 Volts and more with bare hands or conductive tools or touching ungrounded housings can be dangerous and cause electric shock. In order to operate electrical equipment, certain parts must unavoidably have dangerous voltages applied to them.

High electrical voltage! Danger to life, severe bodily harm by electric shock!

⇒ Only those trained and qualified to work with or on electrical equipment are permitted to operate, maintain or repair this equipment.

⇒ Follow general construction and safety regulations when working on high voltage installations.

⇒ Before switching on power the ground wire must be permanently connected to all electrical units according to the connection diagram.

⇒ Do not operate electrical equipment at any time, even for brief measurements or tests, if the ground wire is not permanently connected to the points of the components provided for this purpose.

⇒ Before working with electrical parts with voltage higher than 50 V, the equipment must be disconnected from the mains voltage or power supply. Make sure the equipment cannot be switched on again unintended.

⇒ The following should be observed with electrical drive and filter components:

⇒ Wait five (5) minutes after switching off power to allow capacitors to discharge before beginning to work.

Measure the voltage on the capacitors before beginning to work to make sure that the equipment is safe to touch.

⇒ Never touch the electrical connection points of a component while power is turned on.

⇒ Install the covers and guards provided with the equipment properly before switching the equipment on.

Prevent contact with live parts at any time.

⇒ A residual-current-operated protective device (RCD) must not be used on electric drives! Indirect contact must be prevented by other means, for example, by an overcurrent protective device.

⇒ Electrical components with exposed live parts and uncovered high voltage terminals must be installed in a protective housing, for example, in a control cabinet.

To be observed with electrical drive and filter components:

High electrical voltage on the housing! High leakage current! Danger to life, danger of injury by electric shock!

⇒ Connect the electrical equipment, the housings of all electrical units and motors permanently with the safety conductor at the ground points before power is switched on. Look at the connection diagram. This is even necessary for brief tests.

⇒ Connect the safety conductor of the electrical equipment always permanently and firmly to the supply mains. Leakage current exceeds 3.5 mA in normal operation.

⇒ Use a copper conductor with at least 10 mm² cross section over its entire course for this safety conductor connection!

⇒ Prior to startups, even for brief tests, always connect the protective conductor or connect with ground wire.

Otherwise, high voltages can occur on the housing that lead to electric shock.

Protection Against Electric Shock by Protective Low Voltage (PELV)

All connections and terminals with voltages between 0 and 50 Volts on Rexroth products are protective low voltages designed in accordance with international standards on electrical safety.

High electrical voltage due to wrong connections! Danger to life, bodily harm by electric shock!

⇒ Only connect equipment, electrical components and cables of the protective low voltage type (PELV = Protective Extra Low Voltage) to all terminals and clamps with voltages of 0 to 50 Volts.

⇒ Only electrical circuits may be connected which are safely isolated against high voltage circuits. Safe isolation is achieved, for example, with an isolating transformer, an opto-electronic coupler or when battery-operated.

Protection Against Dangerous Movements

Dangerous movements can be caused by faulty control of the connected motors. Some common examples are:

• improper or wrong wiring of cable connections

• incorrect operation of the equipment components

• wrong input of parameters before operation

• malfunction of sensors, encoders and monitoring devices

• defective components

• software or firmware errors

Dangerous movements can occur immediately after equipment is switched on or even after an unspecified time of trouble-free operation.

The monitoring in the drive components will normally be sufficient to avoid faulty operation in the connected drives. Regarding personal safety, especially the danger of bodily injury and material damage, this alone cannot be relied upon to ensure complete safety. Until the integrated monitoring functions become effective, it must be assumed in any case that faulty drive movements will occur. The extent of faulty drive movements depends upon the type of control and the state of operation.

Dangerous movements! Danger to life, risk of injury, severe bodily harm or material damage!

⇒ Ensure personal safety by means of qualified and tested higher-level monitoring devices or measures integrated in the installation. Unintended machine motion is possible if monitoring devices are disabled, bypassed or not activated.

⇒ Pay attention to unintended machine motion or other malfunction in any mode of operation.

⇒ Keep free and clear of the machine’s range of motion and moving parts. Possible measures to prevent people from accidentally entering the machine’s range of motion:

– use safety fences

– use safety guards

– use protective coverings

– install light curtains or light barriers

⇒ Fences and coverings must be strong enough to resist maximum possible momentum, especially if there is a possibility of loose parts flying off.

⇒ Mount the emergency stop switch in the immediate reach of the operator. Verify that the emergency stop works before startup. Don’t operate the machine if the emergency stop is not working.

⇒ Isolate the drive power connection by means of an emergency stop circuit or use a starting lockout to prevent unintentional start.

⇒ Make sure that the drives are brought to a safe standstill before accessing or entering the danger zone. Safe standstill can be achieved by switching off the power supply contactor or by safe mechanical locking of moving parts.

⇒ Secure vertical axes against falling or dropping after switching off the motor power by, for example:

– mechanically securing the vertical axes

– adding an external braking/ arrester/ clamping mechanism

– ensuring sufficient equilibration of the vertical axes

The standard equipment motor brake or an external brake controlled directly by the drive controller are not sufficient to guarantee personal safety!

⇒ Disconnect electrical power to the equipment using a master switch and secure the switch against reconnection for:

– maintenance and repair work

– cleaning of equipment

– long periods of discontinued equipment use

⇒ Prevent the operation of high-frequency, remote control and radio equipment near electronics circuits and supply leads. If the use of such equipment cannot be avoided, verify the system and the installation for possible malfunctions in all possible positions of normal use before initial startup. If necessary, perform a special electromagnetic compatibility (EMC) test on the installation.

Protection Against Magnetic and Electromagnetic Fields During Operation and Mounting

Magnetic and electromagnetic fields generated near current-carrying conductors and permanent magnets in motors represent a serious health hazard to persons with heart pacemakers, metal implants and hearing aids.

Health hazard for persons with heart pacemakers, metal implants and hearing aids in proximity to electrical equipment!

⇒ Persons with heart pacemakers, hearing aids and metal implants are not permitted to enter the following areas:

– Areas in which electrical equipment and parts are mounted, being operated or started up.

– Areas in which parts of motors with permanent magnets are being stored, operated, repaired or mounted.

⇒ If it is necessary for a person with a heart pacemaker to enter such an area, then a doctor must be consulted prior to doing so. Heart pacemakers that are already implanted or will be implanted in the future, have a considerable variation in their electrical noise immunity. Therefore there are no rules with general validity.

⇒ Persons with hearing aids, metal implants or metal pieces must consult a doctor before they enter the areas described above. Otherwise, health hazards will occur.

Protection Against Contact with Hot Parts

Housing surfaces could be extremely hot!

Danger of injury! Danger of burns!

⇒ Do not touch housing surfaces near sources of heat!

Danger of burns!

⇒ After switching the equipment off, wait at least ten (10) minutes to allow it to cool down before touching it.

⇒ Do not touch hot parts of the equipment, such as housings with integrated heat sinks and resistors.

Danger of burns!

Protection During Handling and Mounting

Under certain conditions, incorrect handling and mounting of parts and components may cause injuries.

Risk of injury by incorrect handling! Bodily harm caused by crushing, shearing, cutting and mechanical shock!

⇒ Observe general installation and safety instructions with regard to handling and mounting.

⇒ Use appropriate mounting and transport equipment.

⇒ Take precautions to avoid pinching and crushing.

⇒ Use only appropriate tools. If specified by the product documentation, special tools must be used.

⇒ Use lifting devices and tools correctly and safely.

⇒ For safe protection wear appropriate protective clothing, e.g. safety glasses, safety shoes and safety gloves.

⇒ Never stand under suspended loads.

⇒ Clean up liquids from the floor immediately to prevent slipping.

Battery Safety

Batteries contain reactive chemicals in a solid housing. Inappropriate handling may result in injuries or material damage.

Risk of injury by incorrect handling!

⇒ Do not attempt to reactivate discharged batteries by heating or other methods (danger of explosion and cauterization).

⇒ Never charge non-chargeable batteries (danger of leakage and explosion).

⇒ Never throw batteries into a fire.

⇒ Do not dismantle batteries.

⇒ Do not damage electrical components installed in the equipment.

Note: Be aware of environmental protection and disposal! The batteries contained in the product should be considered as hazardous material for land, air and sea transport in the sense of the legal requirements (danger of explosion). Dispose batteries separately from other waste. Observe the legal requirements in the country of installation.

Protection Against Pressurized Systems

Certain motors and drive controllers, corresponding to the information in the respective Project Planning Manual, must be provided with pressurized media, such as compressed air, hydraulic oil, cooling fluid and cooling lubricant supplied by external systems. Incorrect handling of the supply and connections of pressurized systems can lead to injuries or accidents. In these cases, improper handling of external supply systems, supply lines or connections can cause injuries or material damage.

Danger of injury by incorrect handling of pressurized systems !

⇒ Do not attempt to disassemble, to open or to cut a pressurized system (danger of explosion).

⇒ Observe the operation instructions of the respective manufacturer.

⇒ Before disassembling pressurized systems, release pressure and drain off the fluid or gas.

⇒ Use suitable protective clothing (for example safety glasses, safety shoes and safety gloves)

⇒ Remove any fluid that has leaked out onto the floor immediately.

Note: Environmental protection and disposal! The media used in the operation of the pressurized system equipment may not be environmentally compatible. Media that are damaging the environment must be disposed separately from normal waste.

Observe the legal requirements in the country of installation.

Diagnostic Messages when Booting the Devices

Devices with Valid Firmware

When a valid firmware is available in the control section, the texts

800T1.1

800T1.2

800T1.3

are displayed on the control section display after the control voltage is

switched on (“booting”). The controller first goes through the boot phases

in which the basic initialization of the processor takes place.

In the following boot phases the basic initialization of the hardware

configuration, the peripherals, the parameters, the master communication

etc. takes place:

800T2.2

….

800T2.9

Finally, the initialization results are controlled. If initialization errors

occurred they are output via the display. After initialization without errors

the controller goes through the communication phases and, where

required, switches to “ready for operation” (“bb”):

800T3.0

800T3.1

Devices without Valid Firmware

In case the device does not detect valid firmware, neither in the nonvolatile memory (flash) nor in the MultiMediaCard (MMC), the so-called

“loader” is started. The “loader” is an auxiliary program used to load firmware to the flash memory. When the “loader” is activated the controller goes through several initialization phases:

LOAD1

LOAD2

LOAD3

LOAD4

The LOADER display signals that the auxiliary program for loading (“download”) firmware is ready for operation.

Error Messages when Booting the Devices

PLC ?

Brief Description: PLC start dialog

Before “Boot 2.9” was displayed on the control panel the buttons “ESC” and “ENTER” had been simultaneously pressed and kept pressed on the control panel.

As the functional package “Motion Logic” (drive PLC and technology functions) has been enabled, the display reads “PLC ?”. The automatic start of a PLC boot project was prevented.

By pressing the arrow buttons (arrow down or arrow up) the display changes between “Run PLC” and “Stop PLC”.

Stop PLC

Brief Description: Do not start PLC after booting

Pressing the “ENTER” button on the control panel prevents the start of a PLC boot project.

Run PLC

Brief Description: Start PLC after booting

When the “ENTER” button is pressed on the control panel, the drive PLC and a possibly available boot project are started after the booting process.

No IDN on MMC !

Brief Description: MMC was not formatted correctly

Load new Param. ?

Brief Description: MMC plugged, changed or removed => different parameter file

End C29

Brief Description: Command C29 successfully completed

The command C2900 Command Firmware update from MMC was successfully completed. The firmware was copied from the MultiMediaCard (MMC) to the drive-internal memory.

MMC not correct!

Brief Description: MMC incorrectly formatted.

IBF not correct!

Brief Description: Content of IBF file not correct

Firmware update ?