HP Designjet Entry-Level Printers Service

Manual

Version: September 2010

For HP Internal Use Only

©Copyright Hewlett-Packard Company 2010

This document contains proprietary

information that is protected by copyright. All

rights are reserved. No part of this document

may be photocopied, reproduced, or

translated to another language without the

prior written consent of Hewlett-Packard

Company.

Edition,

September 2010.

Notices

Warranty

The information contained in this

document is subject to change without

notice.

Hewlett-Packard makes no

warranty of any kind with regard to

this material, including, but not

limited to, the implied warranties of

merchantability and fitness for a

particular purpose.

Hewlett-Packard shall not be liable for

errors contained herein or for

incidental or consequential damages

in connection with the furnishing,

performance, or use of this material.

WARNING

The procedures described in this manual are

to be performed by HP-qualified service

personnel only.

Electrical Shock Hazard

Serious shock hazard leading to death or

injury may result if you do not take the

following precautions:

●

Ensure that the ac power outlet (mains)

has a protective earth (ground)

terminal.

●

Disconnect the Printer from the power

source prior to performing any

maintenance.

●

Prevent water or any other liquids from

running onto electrical components or

circuits, or through openings in the

enclosure.

Electrostatic Discharge

Refer to the beginning of Chapter 4

Utilities on page 53 of this manual, for

precautions you should take to prevent

damage to the Printer circuits from

electrostatic discharge.

Safety Symbols

General definitions of safety symbols are

given immediately after the table of contents.

WARNING

The Warning symbol calls attention to a

procedure, practice, or the like, which,

if not correctly performed or adhered to,

could result in personal injury. Do not

proceed beyond a Warning symbol until

the indicated conditions are fully

understood and met.

CAUTION

The Caution symbol calls attention to

an operating procedure, practice, or the

like, which, if not correctly performed or

adhered to, could result in damage to or

destruction of part or all of the product.

Do not proceed beyond a Caution

symbol until the indicated conditions

are fully understood and met.

Content Management Department,

Barcelona Division,

Hewlett-Packard Espanola, S.A.

Avda. Graells, 501

08190 Sant Cugat del Valles

Spain

ENWW iii

iv Notices ENWW

Using this Manual

Purpose

This Service Manual contains information necessary to test, calibrate and service:

●

HP Designjet 30 Printer (Model C7790D)

●

HP Designjet 30n Printer (Model C7790E)

●

HP Designjet 70 Printer (Model Q6655A)

●

HP Designjet 90 Printer (Model Q6656A)

●

HP Designjet 90r Printer (Model Q6656B)

●

HP Designjet 100+ Printer (Model C7796C)

●

HP Designjet 110+ Printer (Model C7796D)

●

HP Designjet 110+nr Printer (Model C7796E)

●

HP Designjet 130 Printer (Model C7791C)

●

HP Designjet 130nr Printer (Model C7791D)

●

HP Designjet 110+r Printer (Model C7796H)

●

HP Designjet 130r Printer (Model C7791H)

●

HP Designjet 111 Printer with Roll (Model CQ532A)

●

HP Designjet 111 Printer with tray (Model CQ533A)

For information about using these printers, refer to the corresponding User and Quick Reference Guides.

Readership

The procedures described in this Service Manual are to be performed by HP Certified service personnel

only.

Part Numbers

Part Numbers for Printer options, accessories and service parts are located in Chapter 7

Removal

and Installation on page 95.

Conventions

A small arrow

is used to indicate other parts of the Service Manual where you can find information

related to the topic you are consulting.

ENWW v

vi Using this Manual ENWW

Table of contents

1 Test Prints

Usage Report Page ………………………..……………………………………………………………………..……….……. 2

Information Page ……………………..…………………..…………………………………………..………..……………….. 3

NVM Contents Page ………………………………..…………………………………………………………..………………. 5

2 System Error Codes

Introduction ……………………………..…………………………….……………………………………………………………. 8

Errors and Warnings ………………………………………..………………………………………………………………….. 9

System Error Codes ………………………………………..…………………..………………………………..…………… 10

Warnings ……………………………..…………………….………………………………………..………..…………………. 17

Startup track mode …………………….………………………………………….…………………………….…………….. 25

Emergency Firmware Upgrade ……………………………………………….……………………………..……….…… 33

System Error Codes — Explanation ………………………….…………………..………………….……………………. 34

3 System Maintenance Utility

Introduction ……………………………..…………………………….………………………………………………………….. 38

Launching the System Maintenance Utility …………………….……………………………………………………... 38

System Maintenance Utility (Designjet 30, 30n, 70, 90, 90r, 110plus, 111, 130, 130nr) ……………….. 40

Main Menu — Printer Front Panel Replication ………………………………………..…………………. 40

Color Calibration .…………………….…………………..………………….…………………….………….… 40

Align Printheads ……………………………………………………………….…………………………..…..… 45

Clean Printheads …………………………….………………………………………………………………….. 46

Check Image Quality …………………………………..…………………………………..………………….. 47

Calibrate Paper Feed ……………………………..………………………………………………………..….. 48

Get Printer Information ………………………….…………………………………….………………………. 50

Update Firmware ……………………………………………………………………………….……………….. 51

Reset Jetdirect Network Card …………………………..……………..……………………..…………….. 52

4 Utilities

Utilities ………………………………………………..………………………………………………….………………………… 53

How to Access Restricted Access Utilities …………..…………………………..……………………… 54

Enable/Disable Buzzer ………………………..………………………………………………………………. 54

Transport Position ………………………………….……………………………..…………………………..... 54

Printhead Recovery …………………….………………………..………………………….…………………. 55

Network Card Reset ……………………………..………………………………..…………………………… 56

Set to Factory Defaults ……………..………………………..………………………..……………………… 56

Hard EEPROM reset …………………………..……………………………..…………….…………..…….. 57

ENWW vii

Set Flag to Prime Tubes ……………….…………………………………………..…………………..…….. 57

5 Calibrations

PRS Adjustment ………………….………………………………………….…………………..…………………………..… 60

When Required …………………………..…………………….……………………..…………………………. 60

Manual PRS Adjustment …………………………….……………………..……………………….……………..……….. 60

Factory Accuracy Calibration ……….……………………………….…………………………………………………….. 70

Parts replacement and associated calibrations …………………….……………………………………………..…. 72

6 Parts and Diagrams

Cover Assemblies .………………………..…………………………..………………………..……………….……………. 75

Cover Assemblies .………………………..…………………………..………………………..……………….……………. 76

Printer Labels …………………..…………………..…………………..……………………..……………..………………… 78

Right Hand Assemblies ……………………………………….…………………..…………………..………….…………. 79

Left Hand Assemblies ….………………………..……………………………………………………….………………….. 81

Scan-Axis Assemblies ………………………….……………………………………………..………………….………….. 82

Top Paper Path Assemblies (1 of 2) ……..……………………………….………………………………..…………… 84

Top Paper Path Assemblies (2 of 2) ……..……………………………….………………………………..…………… 85

Rear Paper Path Assemblies …………….………………………………………………..……………………....……… 87

Paper Feed Assemblies .…………………….……………………….…………………….……………………..………… 88

Cable Harnesses ………………………..……………………….………………………………………………………….…. 90

Ink Supplies and Accessories (1 of 2) ..…………………..…………………..…………………….…………….……. 91

Ink Supplies & Accessories (2 of 2) ……………..…………..…………………………………………………………… 92

Rollfeed Components …………………………..………………………..……………………………………….………….. 93

Printer Stand and Basket ……………………………………………….…………………………….………….…………. 94

7 Removal and Installation

Introduction ………………………..…………………………….……………………………….…………..………………….. 96

Top Cover ……………………………..……………………………..…………………………….………….…………………. 98

Front Cover (Applicability: 30, 30n, 50ps) ……………………….…………..…………………..……….…………… 98

Center Cover ………………………..…………………….…………………..……………………………….……………….. 99

Right End Cover ………………….……………………..………………………………………………………………….… 101

Left End Cover ..………………………….………………………..……………………….………………….…………….. 103

Ink Supply Station Cover (Applicability: 70, 100, 100plus, 110plus, 111) …………………………………. 105

Ink Supply Station …………………….…………………………………………………..…………………………………. 106

Electronics Module ……………………….…………………..…………………..…………………….…………………… 109

Power Supply Unit ……………………….……………………………………………………………………………..……. 112

Service Station ..……………………………………………………………………………………..………..……………… 114

Front Panel ……………………….………………………………………………….……………………….………………… 117

Encoder Strip …………………………………..…………………………….……………………………..…………………. 118

Carriage Motor ………………………………….………………………..………………………..…………..…………….. 119

Cleanout Assembly …………………………..…………………………………………………………………..…………. 120

Ink Supply Tubes ………………………..…………………………………………………………….………..……………. 121

Carriage Assembly (Applicability: 70, 100+, 110+, 111) ………………………………………………………… 123

Carriage Assembly (Applicability: 30, 30nr, 90, 90r, 130, 130nr) …………………………………………..… 125

Carriage Belt …………………………………..……………………….……………………………………..……….……… 128

viii ENWW

Starwheel Assembly (Applicability: 30, 30n) ……………………………………………………..…………………. 129

Starwheel Assembly …………………..……………………..…………………….……………………..……..…………. 130

Print Platen Assembly ……………………………………….……………………….…………………….………………. 131

Output Separator (Applicability: 30, 30n) ..…………….………………..………………………………………..…. 133

Ramp Motor Assembly .………………………………………………………..………………………….……….………. 134

Output Mechanism Assembly (Applicability: 30, 30n) ……………………………………..…………………….. 135

Spittoon (If Installed in the Printer) …………………………………..………………………………………..……….. 137

Pivot Assembly …..…………………….…………………………………………..…………………….…….……….……. 138

Feed Roller Assembly (Applicability: 30, 30n) …..………………………………………………………………….. 13 9

Feed Roller Assembly …………………..……………………..……………………………………………..….………… 141

Pick Assembly (Applicability: 30, 30n) ..……………………..……………………..…………………………….…… 145

Pick Assembly ..………………………..……………………….…………………………..………………….…………….. 146

Pinch Assembly (Applicability: 30, 30n) …….……………………………..…………….………………………..…. 152

Lower Paper Guide (Applicability: 30, 30n) ……………………………..……………………………..………….... 153

Inner Paper Guide (Applicability: 30, 30n) .…………………………..………………………………………………. 154

Inner Paper Guide .………………………..…………………………..………………………………………..……….….. 155

OOPS Sensor ……………………….…………………..………………………………………….…………………………. 156

Paper-Axis Motor Drive Assembly (Applicable only to 30, 30n) ………………………………………………. 158

Paper-Axis Motor Assembly (Applicability: 90, 90r, 130, 130nr) ……………………………………………… 159

Bypass Platen (Applicability: 90, 90r, 130, 130nr) ……………..………………………….………………………. 160

Bypass Platen Actuator (Applicability: 90, 90r, 130, 130nr) ………..…………………………………….……. 163

Output Platen (HP Designjet 111 with Roll) ……………………………….………………………………………... 165

8 Maintenance

Maintenance ………………………………………………………..…………………..……………………………………… 168

Cleaning Information ..………………………………………….…………………..………………………… 168

Lubrication Information …………..………………………..………………………………………………… 170

About this Edition ………………………….………………………………………………….……………….. 17 0

What’s in this Service Manual ……………….…………………….…………………….………………… 170

ENWW ix

x ENWW

1Test Prints

●

Usage Report Page

●

Information Page

●

NVM Contents Page

ENWW 1

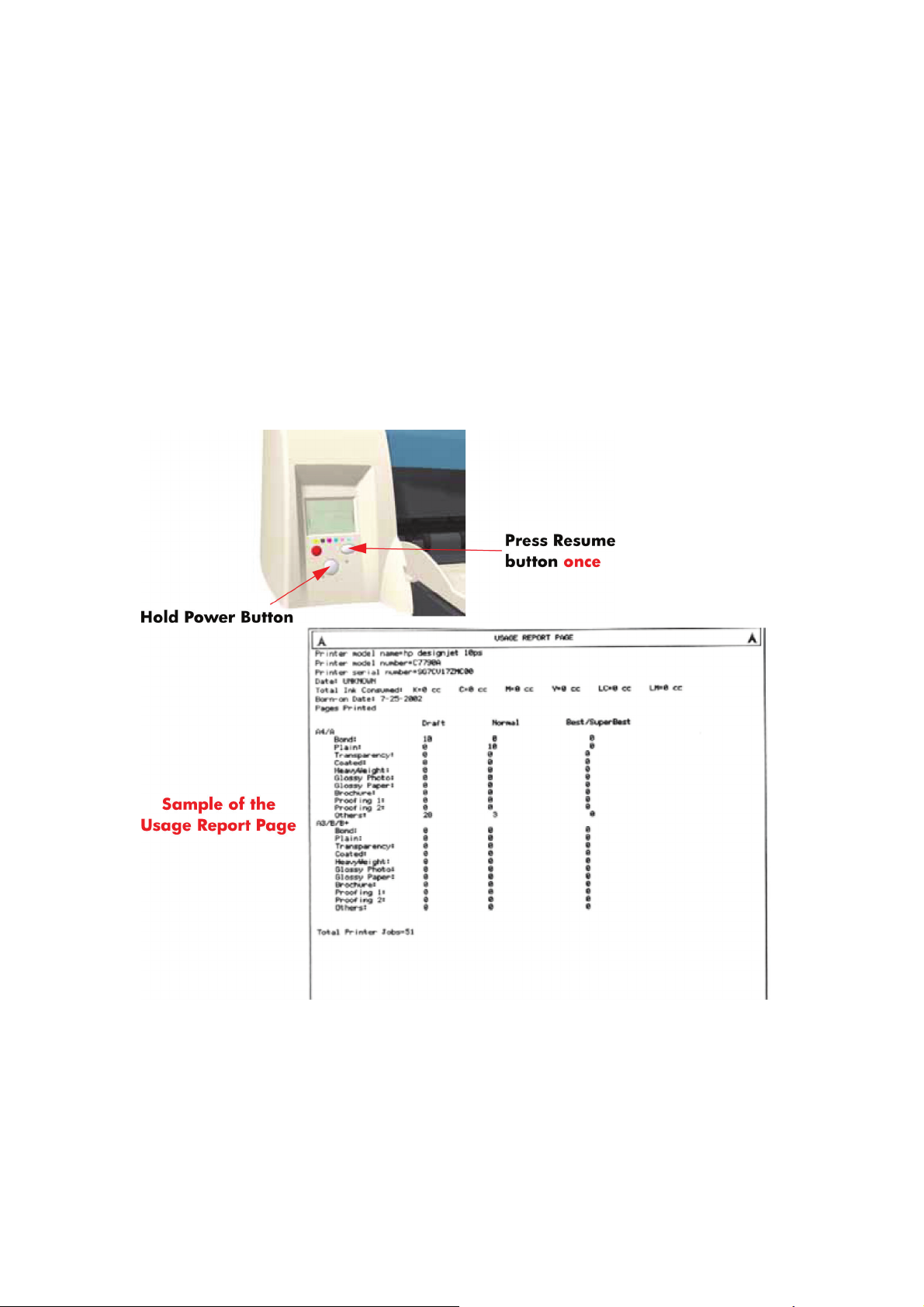

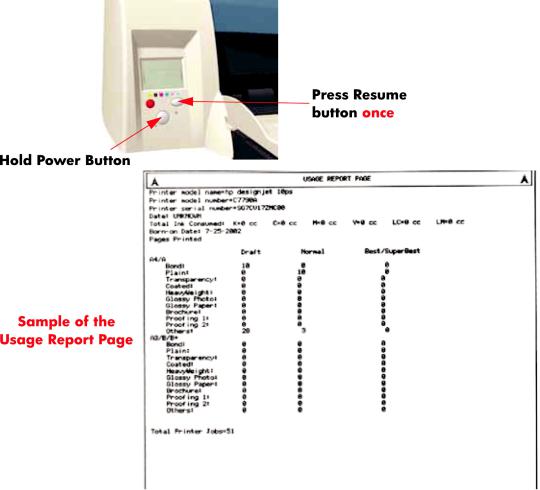

Usage Report Page

The Usage Report Page contains the following information:

●

Printer Model Name.

●

Printer Model Number.

●

Printer Serial Number.

●

Date of last print job received.

●

Total ink consumed.

●

Date of first print job received.

●

Number of pages printer (media size/media type/print quality setting).

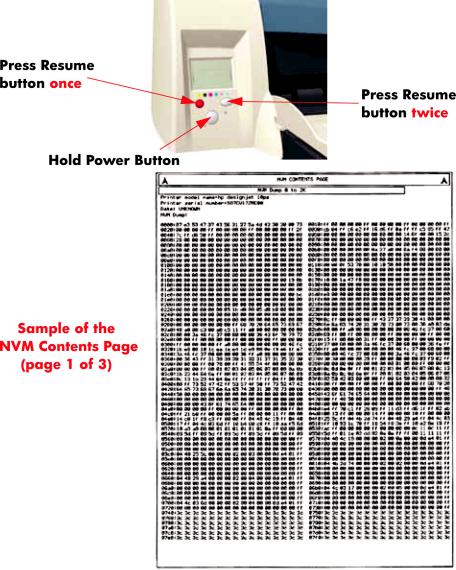

To print the Usage Report Page, hold the power button down and press the resume button once.

2 Chapter 1 Test Prints ENWW

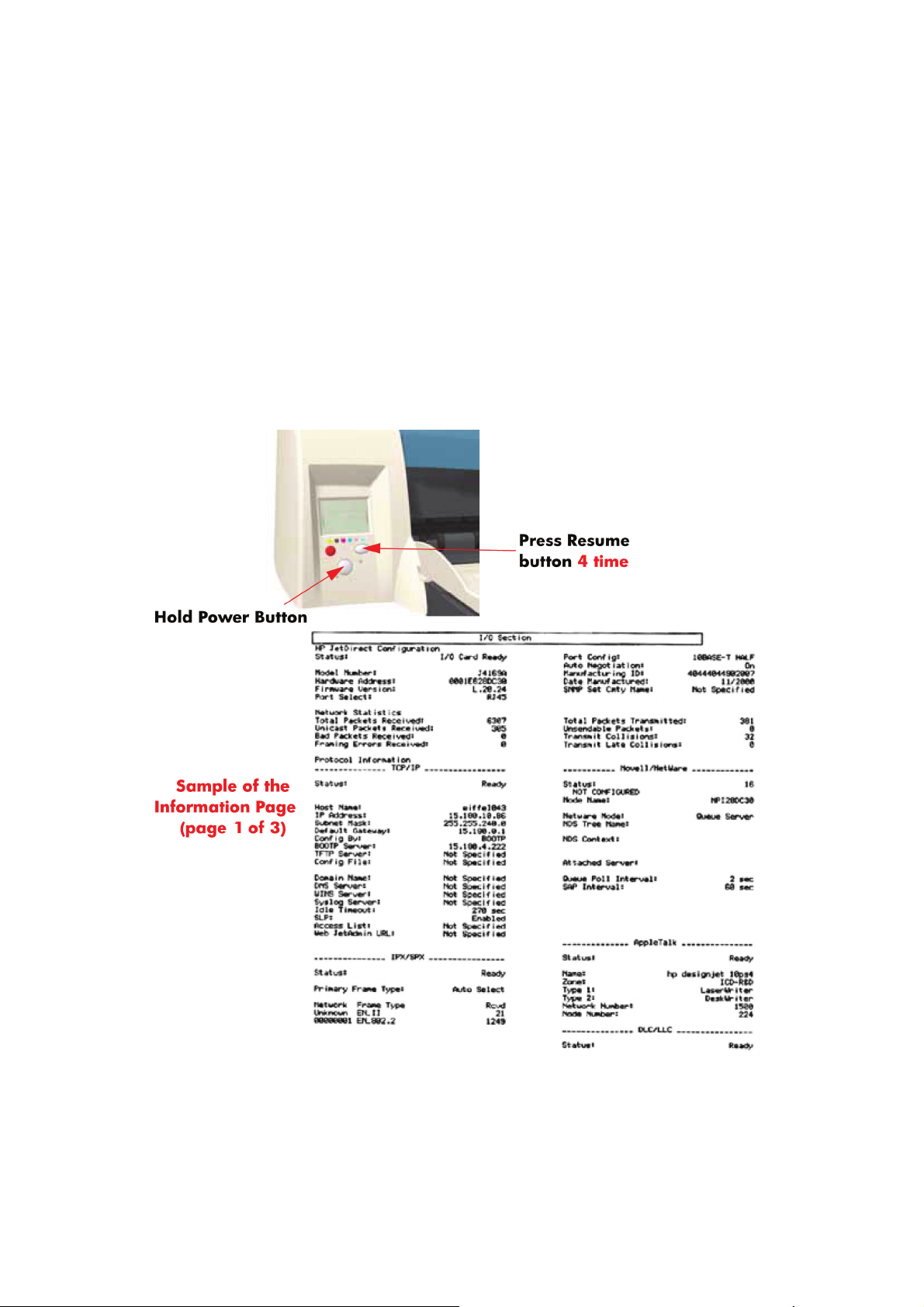

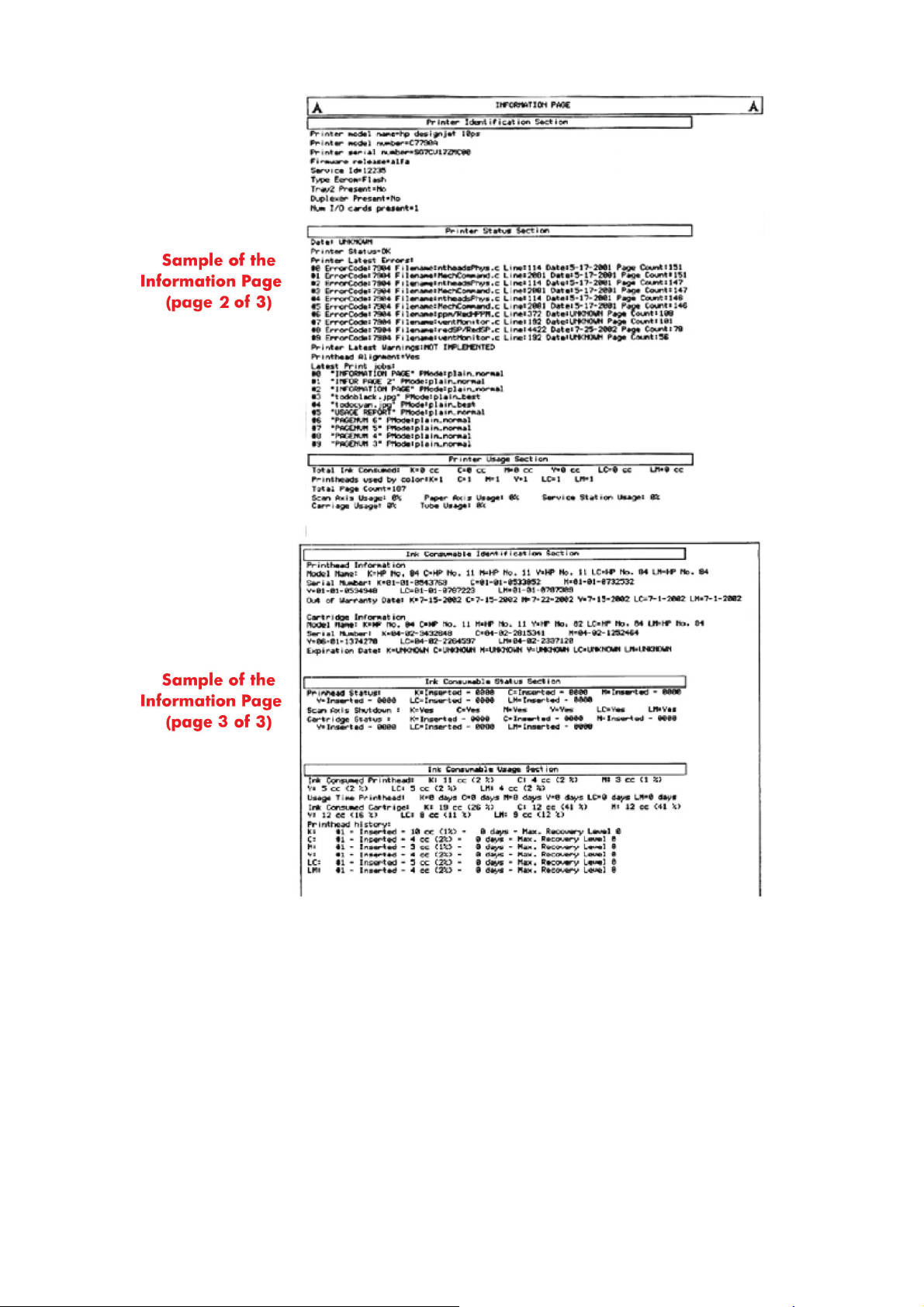

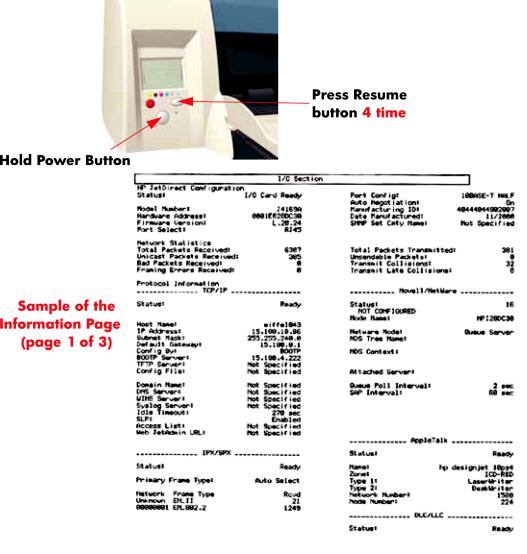

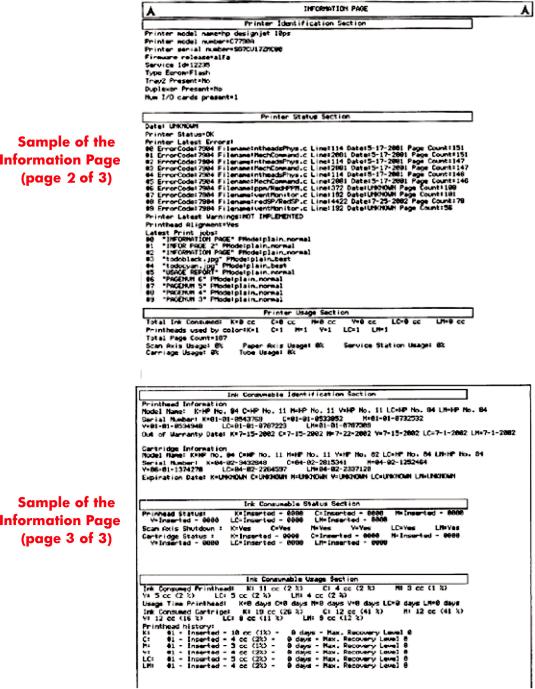

Information Page

The Information Page contains the following information:

●

Printer Identification.

●

Printer Status.

●

Printer Usage.

●

Ink Consumable Identification.

●

Ink Consumable Status.

●

Ink Consumable Usage.

●

Network Card Information.

To print the Information Page, hold the power button down and press the resume button four times.

ENWW Information Page 3

4 Chapter 1 Test Prints ENWW

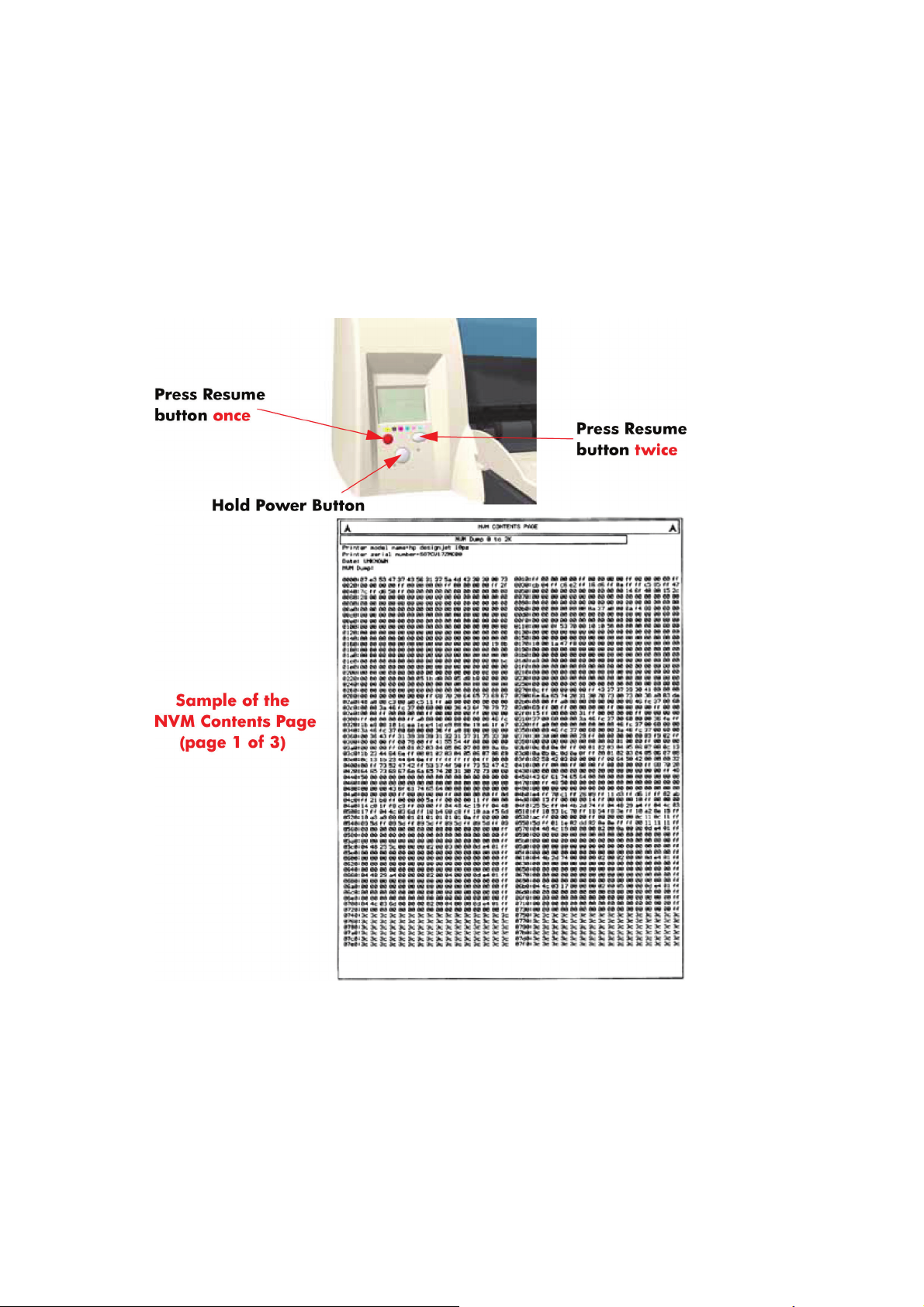

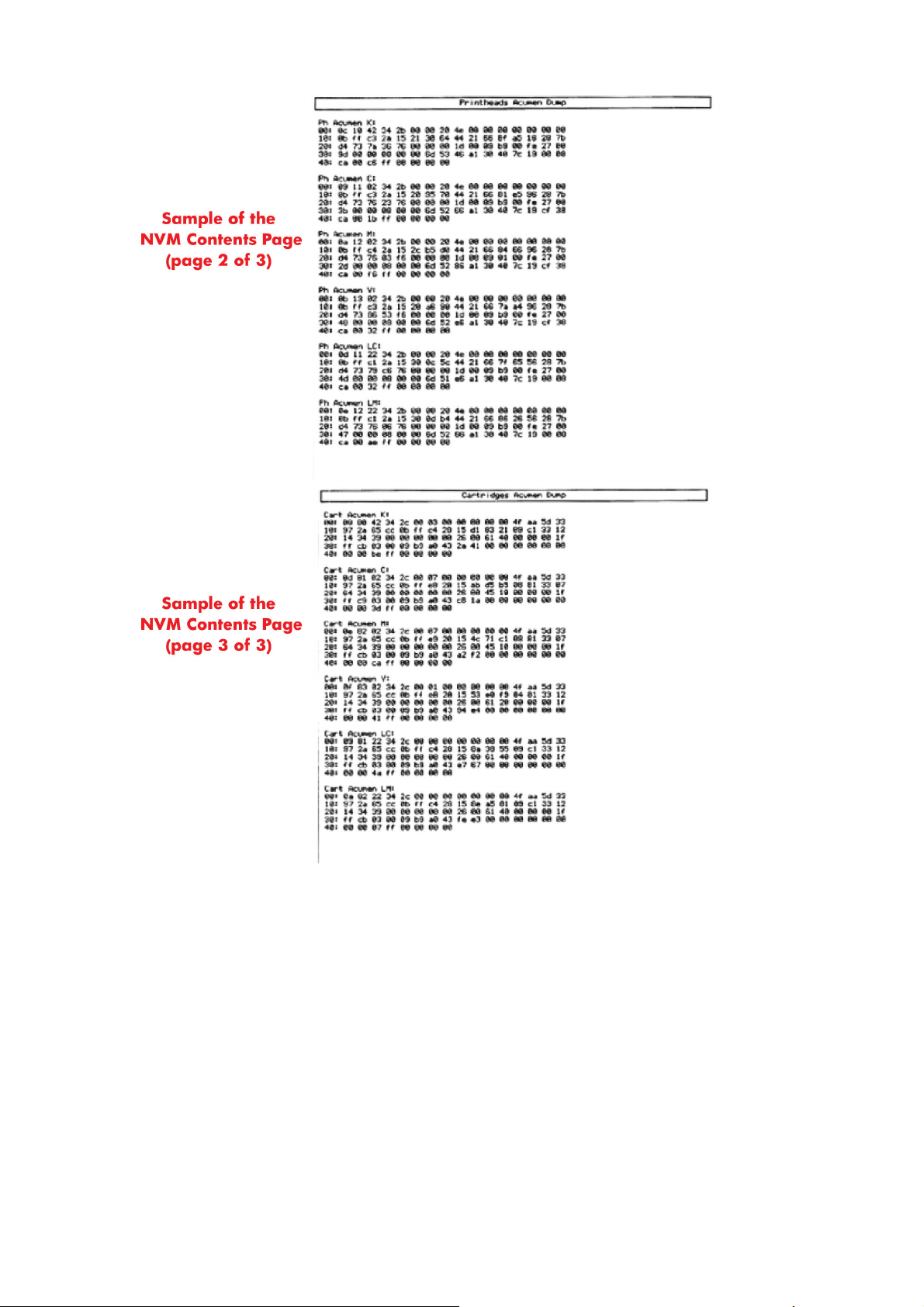

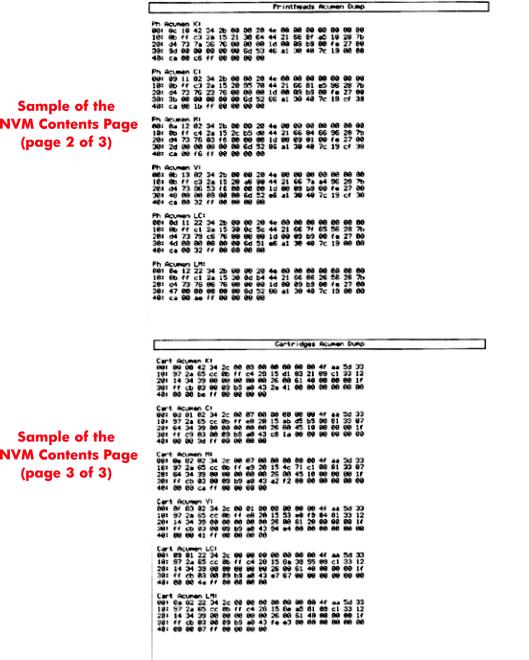

NVM Contents Page

The NVM Contents Page contains the following information:

●

EEROM values dump containing all the values stored in the EEROM (Calibration, etc.)

●

Printheads Acumen dump

●

Cartridges Acumen dump.

To print the NVM Contents Page, hold the power button down and press the cancel button once and

the resume button twice.

ENWW NVM Contents Page 5

6 Chapter 1 Test Prints ENWW

2 System Error Codes

●

Introduction

●

Errors and Warnings

●

System Error Codes

●

Warnings

●

Startup track mode

●

Emergency Firmware Upgrade

●

System Error Codes — Explanation

ENWW 7

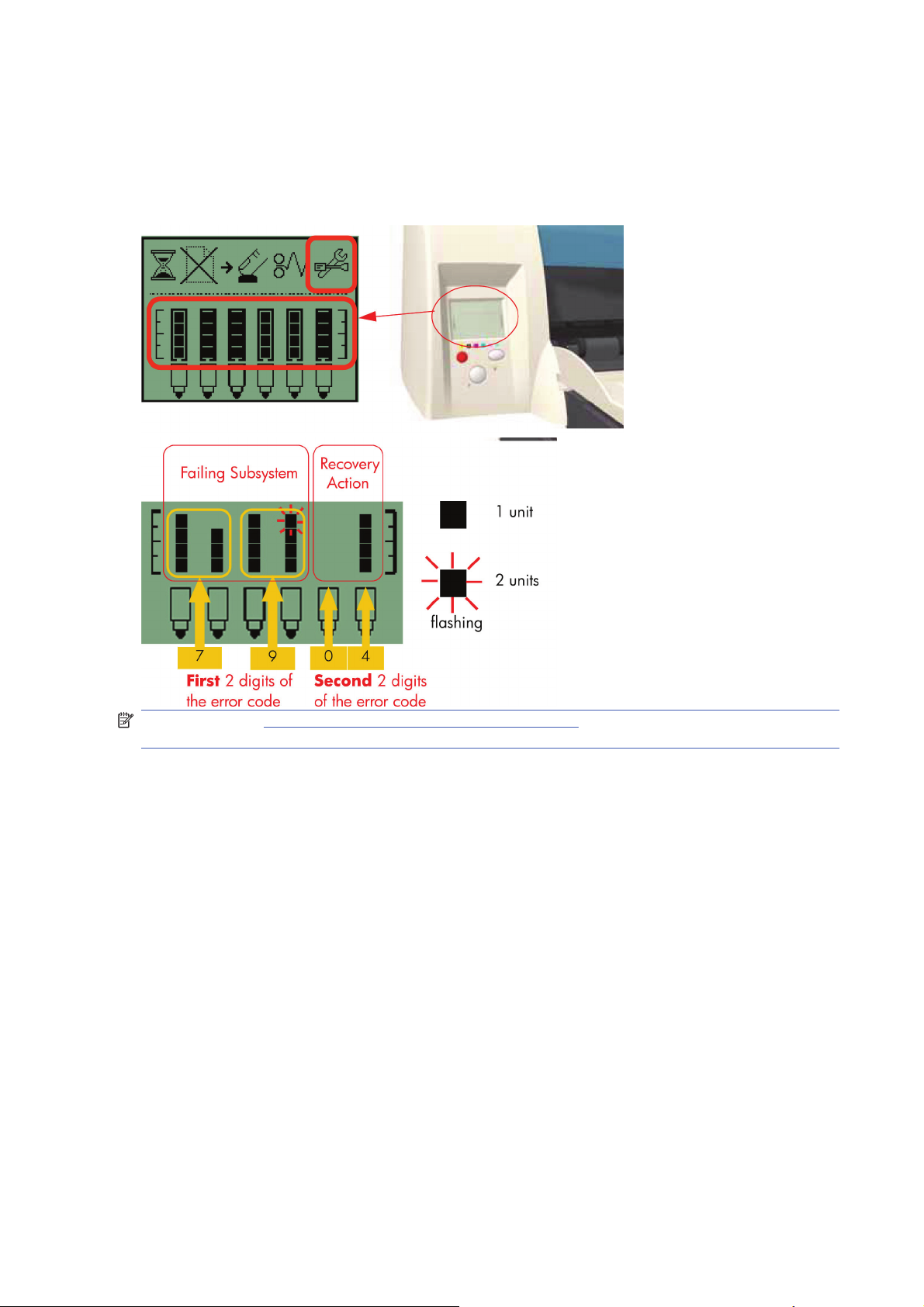

Introduction

The following pages contain a list of system error codes and their respective descriptions and

recommended corrective actions. Only try one recommended action at a time and check if the error

code has disappeared. Since the front panel can only display graphics, the error code needs to be

determined by counting the bars on the front panel (as shown below).

NOTE: Refer to System Error Codes — Explanation on page 34 for an explanation on the construction

of the Error Codes and Warnings.

8 Chapter 2 System Error Codes ENWW

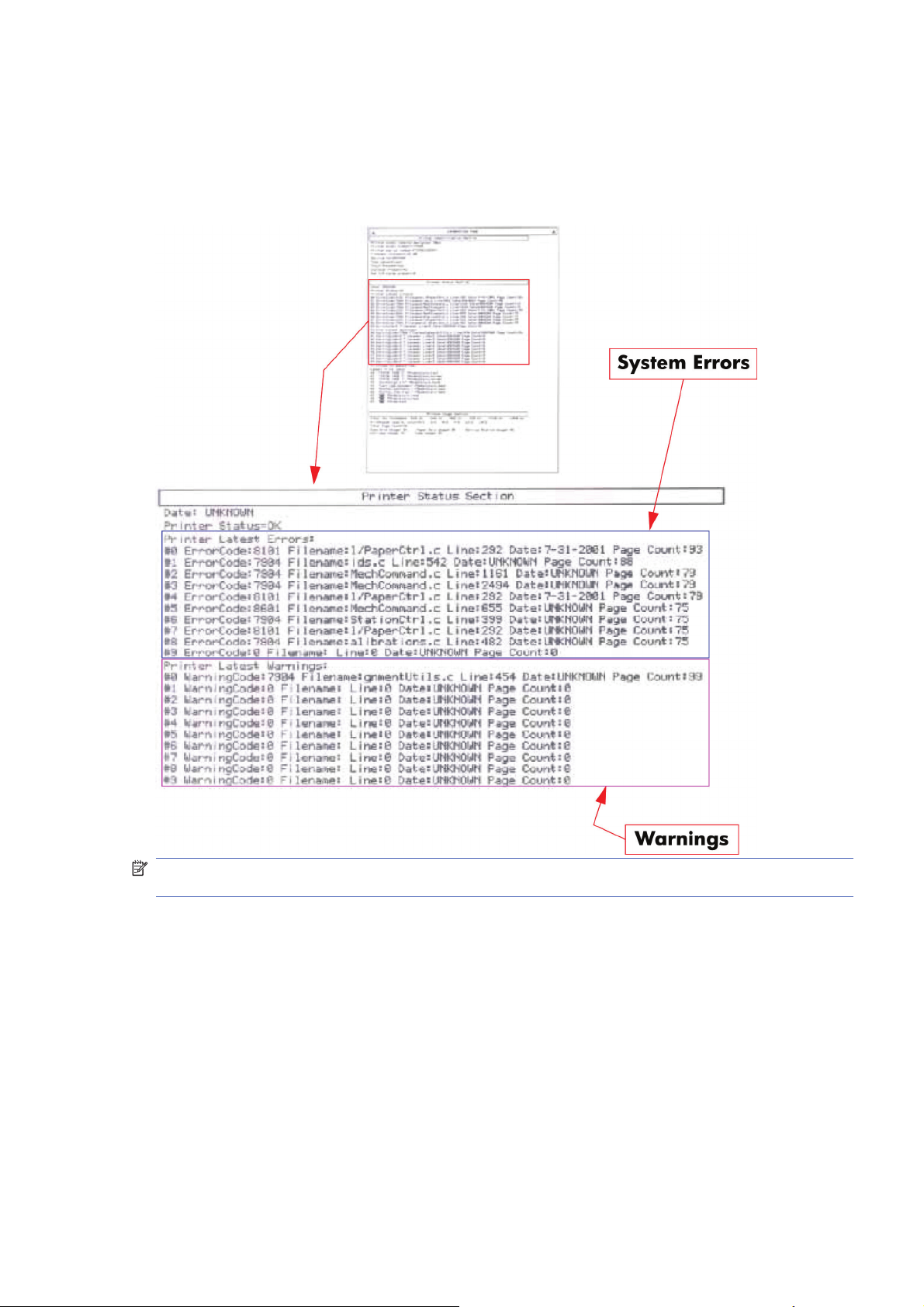

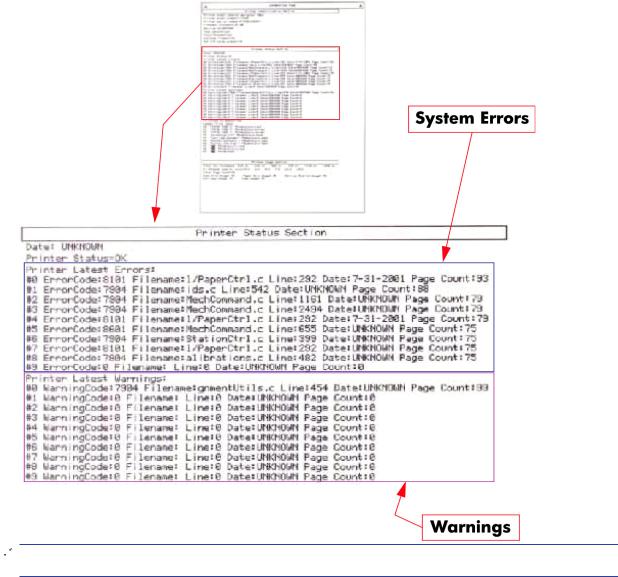

Errors and Warnings

Error Codes will normally be displayed directly on the front panel (but can also be seen on the

Information Page) and will require some kind of intervention to resolve the problem. Warnings will

not be displayed on the front panel, but will instead only appear on the Information Page, therefore

allowing the user to continue operating the printer without the need of an intervention.

NOTE: You can also obtain report of the System Error and Warnings through the DesignJet System

Maintenance Tool.

ENWW Errors and Warnings 9

System Error Codes

NOTE: Applicable for 111 only: The printer has a MROM module and it is not possible to perform a

firmware upgrade, and in fact not required as the printer already has the latest version.

01:10

Cause

Solution

Electronics Module failure.

Replace the Electronics Module

Electronics Module

on page 109.

01:12

Cause

Solution

Electronics Module failed during the firmware upgrade OR the

Electronics Module failed during initialization.

Try the following:

●

If the Electronics Module failed during the firmware

upgrade, first perform an emergency firmware upgrade

(

Emergency Firmware Upgrade on page 33).

●

If an emergency firmware upgrade is NOT possible or it

didn’t work, replace the Electronics Module

Electronics Module on page 109.

02:10

Cause

Solution

Carriage failure.

Replace the Carriage Assembly

Carriage Assembly

(Applicability: 70, 100+, 110+, 111) on page 123.

04:13

Cause

Solution

Generic Firmware Error (Network Card). Unplug the power cable from the printer and wait a few

seconds. Plug in the power cable again and check if the Error

Code has disappeared. If the error code continues, refer to the

Jetdirect Card Service Manual and Service Notes.

08:11

Cause

Solution

Front Panel cannot be detected. Try the following:

●

Check the connections and cables of the Font Panel,

check they have not been damaged and are correctly

connected, disconnect and reconnect the front panel.

●

Replace the Front Panel if the problem persists

Front

Panel on page 117.

10 Chapter 2 System Error Codes ENWW

11:10

Cause

Solution

Trailing Cable Failure. Try the following:

●

Replace the Carriage Assembly

Carriage Assembly

(Applicability: 70, 100+, 110+, 111) on page 123.

●

If the Error Code continues, replace the Electronics

Module

Electronics Module on page 109.

NOTE: Only replace one component at a time and check if

the error has gone before replacing another component. Using

this procedure you will be able to determine exactly which

component failed.

11:11

Cause

Solution

Trailing Cable is badly connected. Try the following:

●

Reconnect the Trailing Cable correctly to the Electronics

Module.

●

If the Error Code continues, replace the Carriage

Assembly

Carriage Assembly (Applicability: 70, 100

+, 110+, 111) on page 123.

21:10

Cause

Solution

Service Station failure.

Replace the Service Station Assembly

Service Station

on page 114.

22:10

Cause

Solution

Ink Supply Station failure.

Replace the Ink Supply Station

Ink Supply Station

on page 106.

ENWW System Error Codes 11

35:01

Cause

Solution

No Cleanout Assembly detected while loading media. Try the following:

●

Remove the Cleanout Assembly and install it again

correctly.

●

Replace the Cleanout Interconnect PCA.

●

If the Error Code continues, replace the Cleanout

Assembly.

NOTE: Only replace one component at a time and check if

the error has gone before replacing another component. Using

this procedure you will be able to determine exactly which

component failed.

37:01

Cause

Solution

Automatic roll motor shutdown. Try the following:

●

If this error code was caused by a paper jam, unplug the

power cable from the printer and clear the blockage. Plug

in the power cable again and check if the Error Code has

disappeared.

●

If there is no paper jam or if recovering the paper jam does

not resolve the problem, then replace the Automatic Roll

System (the error could be caused by anything that stalls

the motor).

37:10

Cause

Solution

Automatic roll home position error. Replace the Automatic Roll System (the error could be caused

by anything that causes the home position not to be detected

or not to be the correct one — electrical sensors, internal

mechanical problems, etc.).

42:10

Cause

Solution

Carriage Motor failure (short-circuit).

Replace the Carriage Motor Assembly

Carriage Motor

on page 119.

12 Chapter 2 System Error Codes ENWW

56:10

Cause

Solution

Error during the calibration of the motor encoder system or a

problem finding the zero position on the Encoder Disc.

Try the following:

●

Replace the Paper-Axis Motor Drive Assembly

Paper-

Axis Motor Drive Assembly (Applicable only to 30, 30n)

on page 158.

●

Replace the Encoder Disc.

NOTE: Make sure you recalibrate the Paper-Axis after

replacing the Paper-Axis Motor Drive Assembly or the Encoder

Disc.

Only replace one component at a time and check if the error

has gone before replacing another component. Using this

procedure you will be able to determine exactly which

component failed.

56:13

Cause

Solution

Error during the calibration of the Line-feed Motor/Encoder

system.

Unplug the power cable from the printer and wait a few

seconds. Plug in the power cable again.

61:05

Cause

Solution

Firmware Upgrade or Color Calibration was rejected because

the file was sent in the wrong format.

Upgrade the RIP software or the Designjet System

Maintenance Tool.

62:04, 63:04, 64:04 and 65:04

Cause

Solution

I/O module error (62 = parallel; 63 = Network; 64 = USB). Try the following:

●

Unplug the power cable from the printer and wait a few

seconds. Plug in the power cable again and check if the

Error Code has disappeared.

●

If the Error Code reappears, upgrade the firmware.

71:03

Cause

Solution

Generic Firmware Error (Out of memory). Try the following:

●

Unplug the power cable from the printer and wait a few

seconds. Plug in the power cable again and check if the

Error Code has disappeared.

●

If the Error Code reappears, check for a new Firmware

release.

ENWW System Error Codes 13

71:14

Cause

Solution

Memory Management Error (Out of memory during firmware

upgrade).

Try the following:

●

Unplug the power cable from the printer and wait a few

seconds. Plug in the power cable again and check if the

Error Code has disappeared.

●

If the Error Code reappears, perform an emergency

firmware upgrade (

Emergency Firmware Upgrade

on page 33).

72:04

Cause

Solution

Generic Firmware Error (expected). Try the following:

●

Unplug the power cable from the printer and wait a few

seconds. Plug in the power cable again and check if the

Error Code has disappeared.

●

If the Error Code reappears, check for a new Firmware

release.

●

If possible, request the user to provide the following

information which can be found on the information

page:

◦

Firmware Release.

◦

Filename.

◦

Line.

74:12

Cause

Solution

Firmware Upgrade Error (Memory size check failed during

firmware upgrade).

Try the following:

●

Perform the automatic troubleshooting procedure

(requires a special firmware upgrade file that must be

provided by the manufacturing division).

74:14

Cause

Solution

The printer is unavailable to upgrade the firmware.. Try the following:

●

Turn off and on the printer.

●

Print the Service Page

●

Check that the firmware is the latest available.:

◦

Applicable for 110+,110+r,130,130r: If the

firmware version is D.05.04, this would indicate that

the printer has a MROM module and it is not possible

to perform a firmware upgrade, and in fact not

required as the printer already has the latest version.

14 Chapter 2 System Error Codes ENWW

74:14

Cause

Solution

◦

Applicable for 111 only: The printer has a MROM

module and it is not possible to perform a firmware

upgrade, and in fact not required as the printer

already has the latest version.

79:04

Cause

Solution

Generic Firmware Error (unexpected). Try the following:

●

Unplug the power cable from the printer and wait a few

seconds. Plug in the power cable again and check if the

Error Code has disappeared.

●

If the Error Code reappears, check for a new Firmware

release.

●

If possible, request the user to provide the following

information which can be found on the information

page:

◦

Firmware Release.

◦

Filename.

◦

Line.

81:01

Cause Solution

Paper-Axis shutdown — usually a paper-jam caused by a

blockage of the Paper-axis System.

Try the following:

●

If this error code was caused by a paper-jam, unplug the

power cable from the printer and clear the blockage. Plug

in the power cable again and check if the Error Code has

disappeared

●

If this error code appeared but was NOT caused by a

paper jam, replace the Paper-Axis Motor Drive Assembly

Paper-Axis Motor Drive Assembly (Applicable only to

30, 30n) on page 158.

81:12

Cause

Solution

Media Advance error. This error usually appears during the paper-advance

calibration — Retry the paper-advance calibration.

ENWW System Error Codes 15

83:10

Cause

Solution

Sheet feeding failure. Try the following:

●

Replace the Out-Of-paper Sensor.

●

Replace the Electronics Module

Electronics Module

on page 109.

85:10

Cause

Solution

Paper-Axis Encoder error. Try the following:

●

Make sure that the Encoder Sensor cable is connected

correctly.

●

Replace the Paper-Axis Motor Drive Assembly

Paper-

Axis Motor Drive Assembly (Applicable only to 30, 30n)

on page 158.

●

Replace the Electronics Module

Electronics Module

on page 109.

86:01

Cause Solution

Scan-axis shutdown — usually a paper-jam caused by a

blockage of the Scan-axis System.

Try the following:

●

Check that there are no obstacles in the Scan-Axis which

stops the Carriage from moving freely.

●

Too much friction in the Slider Rod, try lubricating the

Slider Rod.

●

The Carriage is bumping into the Service Station. If the

Carriage is stuck at the right hand side of the Printer and

cannot be moved out to the center of the Print Platen it is

because the Service Station cannot uncap the

printheads. In this case replace the Service Station

Assembly

Service Station on page 114.

●

Check that the belt is correctly installed and not damaged.

●

Check that the Turnaround Pulley is correctly installed.

●

Replace the Carriage Motor Assembly

Carriage

Motor on page 119.

16 Chapter 2 System Error Codes ENWW

86:11

Cause

Solution

Scan-axis shutdown during initialization. Typically, this error

occurs when the printer detects an incorrect length.

Try the following:

●

Unplug the power cable from the printer and wait a few

seconds. Plug in the power cable again and check if the

Error Code has disappeared.

●

Check that the Paper-Axis Drive Motor Assembly is

correctly installed and that the bushing is correctly locked

into position.

●

Check that the Carriage moves freely and DOES NOT

bump into the Service Station.

●

If the Printheads are not installed, maybe the carriage

cover is not closed completely.

●

If the Error Code continues, replace the Carriage

Assembly

Carriage Assembly (Applicability: 70, 100+,

110+, 111) on page 123.

Warnings

01:11

Cause

Solution

The Electronics Module is incorrectly positioned. Reseat the Electronics Module by Removing it from the Printer

Electronics Module on page 109 and installing it again in

the correct position.

01:12

Cause

Solution

Electronics Module Error. The Electronics Module EEPROM is flagged as empty and

must be upgraded with the contents of the Carriage EEPROM,

but the Carriage is also flagged as empty. The backup is not

performed. This is the result of an error during the

manufacturing or the repair process. Therefore the Electronics

Module must be reconfigured.

02:10

Cause

Solution

Carriage failure.

Replace the Carriage Assembly

Carriage Assembly

(Applicability: 70, 100+, 110+, 111) on page 123.

ENWW Warnings 17

270:00

Cause

Solution

Black Color Calibration Failure — Black Color Calibration

cancelled.

Try the following:

●

Clean the electrical contacts on the black printhead.

●

If the error code continues, replace the black printhead.

271:00

Cause

Solution

Cyan Color Calibration Failure — Cyan Color Calibration

cancelled.

Try the following:

●

Clean the electrical contacts on the cyan printhead.

●

If the error code continues, replace the cyan printhead.

272:00

Cause

Solution

Magenta Color Calibration Failure — Magenta Color Calibration

cancelled.

Try the following:

●

Clean the electrical contacts on the magenta printhead.

●

If the error code continues, replace the magenta

printhead.

273:00

Cause

Solution

Yellow Color Calibration Failure — Yellow Color Calibration

cancelled.

Try the following:

●

Clean the electrical contacts on the yellow printhead.

●

If the error code continues, replace the yellow printhead.

274:00 (Not applicable to HP DesignJet 70, 100, 100+, 110+)

Cause

Solution

Light Cyan Color Calibration Failure — Light Cayan Color

Calibration cancelled.

Try the following:

●

Clean the electrical contacts on the light cyan printhead.

●

If the error code continues, replace the light cyan

printhead.

18 Chapter 2 System Error Codes ENWW

275:00 (Not applicable to HP DesignJet 70, 100, 100+, 110+)

Cause

Solution

Light Magenta Color Calibration Failure — Light Magenta Color

Calibration cancelled.

Try the following:

●

Clean the electrical contacts on the light magenta

printhead.

●

If the error code continues, replace the light magenta

printhead.

35:01

Cause

Solution

No Cleanout Assembly (or Duplexer, if installed) detected

while loading media.

Try the following:

●

Remove the Cleanout Assembly (

Cleanout

Assembly on page 120) (or Duplexer, if installed) and

install it again correctly.

●

Replace the Duplexer Interconnect PCA.

●

If the Error Code continues, replace the Cleanout

Assembly

Cleanout Assembly on page 120.

58:10

Cause

Solution

Problem detected in the color sensor system.

Replace the Carriage Assembly

Carriage Assembly

(Applicability: 70, 100+, 110+, 111) on page 123.

61:05

Cause

Solution

Language interpreting error. This is usually and error produced

while parsing a file. There is probably an incompatibility

between the driver and the firmware.

Upgrade the RIP software or the Designjet System

Maintenance Tool.

65:01

Cause

Solution

Communication Failure. Try the following:

●

Unplug the power cable from the printer and check the

cable connections (Parallel, USB and Network cables).

Plug in the power cable again and check if the Error Code

has disappeared.

ENWW Warnings 19

66:02:1 (Only applicable to HP DesignJet 30, 30n, 90, 90r, 130, 130nr)

Cause

Solution

Horizontal clipping. May happen when the roll ends in the

middle of printing an image. Could also happen when multi-

pick occurs and two sheets are loaded together and they do

not completely overlap.

Make sure the image size is within the selected WIDTH of the

sheet.

66:02:2 (Only applicable to HP DesignJet 30, 30n, 90, 90r, 130, 130nr)

Cause

Solution

Vertical clipping. May happen when the roll ends in the middle

of printing an image. Could also happen when multi-pick

occurs and two sheets are loaded together and they do not

completely overlap.

Make sure the image size is within the selected LENGTH of

the sheet.

71:14

Cause

Solution

Out-of-memory while trying to process the firmware upgrade

file. Probably this is a firmware bug, because the firmware

should free up enough memory to perform the firmware

upgrade process correctly.

Perform an emergency firmware upgrade (

Emergency

Firmware Upgrade on page 33) .

74:12

Cause

Solution

Firmware bug in the firmware upgrade process Try the following:

●

Download the special file in order to update the bootlog.

●

If possible, request the user to provide the following

information which can be found on the information

page:

◦

Firmware Release.

◦

Printer Serial Number.

74:14

Cause

Solution

The printer is unavailable to upgrade the firmware.. Try the following:

●

Turn off and on the printer.

●

Print the Service Page

●

Check that the firmware is the latest available.:

◦

Applicable for 110+,110+r,130,130r: If the

firmware version is D.05.04, this would indicate that

the printer has a MROM module and it is not possible

20 Chapter 2 System Error Codes ENWW

74:14

Cause

Solution

to perform a firmware upgrade, and in fact not

required as the printer already has the latest version.

◦

Applicable for 111 only: The printer has a MROM

module and it is not possible to perform a firmware

upgrade, and in fact not required as the printer

already has the latest version.

81:01

Cause Solution

Paper-Axis shutdown — usually a paper-jam caused by a

blockage of the Paper-axis System.

Try the following:

●

If this error code was caused by a paper-jam, unplug the

power cable from the printer and clear the blockage. Plug

in the power cable again and check if the Error Code has

disappeared.

●

If this error code appeared but was NOT caused by a

paper jam, replace the Paper-Axis Motor Drive Assembly

Paper-Axis Motor Drive Assembly (Applicable only to

30, 30n) on page 158.

83:01:1 (Only applicable to HP DesignJet 30, 30n, 70, 100+, 110+, 111, 90, 90r,, 130, 130nr)

Cause

Solution

The paper is rejected from the Bypass due to skew. When manually loading paper from the front of the paper, make

sure that it is loaded straight.

83:01:3 (Only applicable to HP DesignJet 70/100plus/110plus, 111 with Roll)

Cause

Solution

The paper is rejected from the roll due to skew. When loading paper from the roll, make sure that it is loaded

straight.

94:02:1 (Only applicable to HP DesignJet 30, 30n, 90, 90r, 130, 130nr, 111)

Cause

Solution

User selected Coated Paper and Best mode, but the Color

Calibration profile was obsolete or missing for Coated Paper

and the selected print quality setting.

Using the System Maintenance Tool, perform Color Calibration

for Coated Paper and the selected print quality setting.

94:02:3 (Only applicable to HP DesignJet 30, 30n, 90, 90r, 130, 130nr, 111)

Cause

Solution

User selected Photo Paper and Best mode, but the Color

Calibration profile was obsolete or missing for Photo Paper and

the selected print quality setting.

Using the System Maintenance Tool, perform Color Calibration

for Photo Paper and the selected print quality setting.

ENWW Warnings 21

94:02:4 (Only applicable to HP DesignJet 30, 30n, 90, 90r, 130, 130nr)

Cause

Solution

User selected Heavy-Weight Coated Paper and Best mode,

but the Color Calibration profile was obsolete or missing for

Heavy-Weight Coated Paper and the selected print quality

setting.

Using the System Maintenance Tool, perform Color Calibration

for Heavy- Weight Coated Paper and the selected print quality

setting.

94:02:5 (Only applicable to HP DesignJet 30, 30n, 90, 90r, 130, 130nr)

Cause

Solution

User selected Proofing Semi-Gloss Paper and Best mode, but

the Color Calibration profile was obsolete or missing for

Proofing Semi-Gloss Paper and the selected print quality

setting

Using the System Maintenance Tool, perform Color Calibration

for Proofing Semi-Gloss Paper and the selected print quality

setting.

94:02:6 (Only applicable to HP DesignJet 30, 30n, 90, 90r, 130, 130nr)

Cause

Solution

User selected Photo Matte Paper and Best mode, but the Color

Calibration profile was obsolete or missing for Photo Matte

Paper and the selected print quality setting.

Using the System Maintenance Tool, perform Color Calibration

for Photo Matte Paper and the selected print quality setting.

94:02:7 (Only applicable to HP DesignJet 30, 30n, 90, 90r, 130, 130nr)

Cause

Solution

User selected Photo Satin Paper and Best mode, but the Color

Calibration profile was obsolete or missing for Photo Satin

Paper and the selected print quality setting.

Using the System Maintenance Tool, perform Color Calibration

for Photo Satin Paper and the selected print quality setting.

94:02:8 (Only applicable to HP DesignJet 30, 30n, 90, 90r, 130, 130nr)

Cause

Solution

User selected Coated Paper and Max dpi, but the Color

Calibration profile was obsolete or missing for Coated Paper

and the selected print quality setting.

Using the System Maintenance Tool, perform Color Calibration

for Coated Paper and the selected print quality setting.

941:02:1 (Only applicable to HP DesignJet 30, 30n, 90, 90r, 130, 130nr)

Cause

Solution

User selected Photo Paper and Max dpi, but the Color

Calibration profile was obsolete or missing for Photo Paper and

the selected print quality setting.

Using the System Maintenance Tool, perform Color Calibration

for Photo Paper and the selected print quality setting.

22 Chapter 2 System Error Codes ENWW

941:02:2 (Only applicable to HP DesignJet 30, 30n, 90, 90r, 130, 130nr)

Cause

Solution

User selected Heavy-Weight Coated Paper and Max dpi, but

the Color Calibration profile was obsolete or missing for Heavy-

Weight Coated Paper and the selected print quality setting.

Using the System Maintenance Tool, perform Color Calibration

for Heavy- Weight Coated Paper and the selected print quality

setting.

941:02:3 (Only applicable to HP DesignJet 30, 30n, 90, 90r, 130, 130nr)

Cause

Solution

User selected Proofing Semi-Gloss Paper and Max dpi mode,

but the Color Calibration profile was obsolete or missing for

Proofing Semi-Gloss Paper and the selected print quality

setting.

Using the System Maintenance Tool, perform Color Calibration

for Proofing Semi-Gloss Paper and the selected print quality

setting.

941:02:4 (Only applicable to HP DesignJet 30, 30n, 90, 90r, 130, 130nr)

Cause

Solution

User selected Photo Matte Paper and Max dpi mode, but the

Color Calibration profile was obsolete or missing for Photo

Matte Paper and the selected print quality setting.

Using the System Maintenance Tool, perform Color Calibration

for Photo Matte Paper and the selected print quality setting.

941:02:5 (Only applicable to HP DesignJet 30, 30n, 90, 90r, 130, 130nr)

Cause

Solution

User selected Photo Satin Paper and Max dpi mode, but the

Color Calibration profile was obsolete or missing for Photo

Satin Paper and the selected print quality setting.

Using the System Maintenance Tool, perform Color Calibration

for Photo Satin Paper and the selected print quality setting.

94:04

Cause

Solution

Firmware Error (during color calibration). Try the following:

●

Unplug the power cable from the printer and wait a few

seconds. Plug in the power cable again and check if the

Error Code has disappeared.

●

If the Error Code reappears, check for a new Firmware

release.

94:08

Cause

Solution

Color Calibration Warning — Color Calibration not cancelled but

Color Calibration values are likely to be incorrect.

Try the Color Calibration again, but this time using a different

type of media (preferably HP media).

ENWW Warnings 23

94:10

Cause

Solution

Color Calibration Failure — Color Calibration cancelled. Try the following:

●

Unplug the power cable from the printer and wait a few

seconds. Plug in the power cable again and try the Color

Calibration again.

●

If this error code appears again, check the Color

Calibration print:

◦

If the Color Calibration was printed correctly without

any print defects, then check that the media is

moving freely (backwards and forwards) while the

printer is scanning it.

◦

If the Color Calibration was printed incorrectly, with

some print defects, replace the faulty Printhead of

the color where the defects were noticeable.

◦

If the Error Code continues, replace the Carriage

Assembly

Carriage Assembly (Applicability: 70,

100+, 110+, 111) on page 123.

95:00

Cause

Solution

Printhead Alignment Failure — Printhead Alignment cancelled. Try the following:

●

Clean the printhead indicated by the printer.

●

If the error code continues, replace the faulty printhead.

95:02

Cause

Solution

Printhead Alignment Failure — Printhead Alignment cancelled. Try the following:

●

Unplug the power cable from the printer and wait a few

seconds. Plug in the power cable again and try the

Printhead Alignment again.

●

If this error code appears again, check the Printhead

Alignment print:

◦

If the Printhead Alignment was printed correctly

without any print defects, then check that the media

is moving freely (backwards and forwards) while the

printer is scanning it.

◦

If the Printhead Alignment was printed incorrectly,

with some print defects, replace the faulty Printhead

of the color where the defects were noticeable.

95:04

Cause

Solution

Firmware Error (during Printhead Alignment). Upgrade the printer to the latest firmware release.

24 Chapter 2 System Error Codes ENWW

Startup track mode

Introduction

The startup track mode is designed to enable you to identify a failing subsystems while the printer is

initializing. Startup track mode provides a specific indication of which particular subsystem is failing.

This mode is not intended for use by end-users.

Initializing the printer in Startup track mode

To initialize the printer in Startup track mode:

1. Hold the ’Continue’ button while connecting the printer to the power supply.

2. During the initialization of the printer, the front panel will display a range of code numbers in the

form of squares, these code numbers added together represent the various subsystems about to

be initialized.

3. Once the printer comes to initializing the failing subsystem, the front panel will hang, and all that

will be displayed is the failing subsystem.

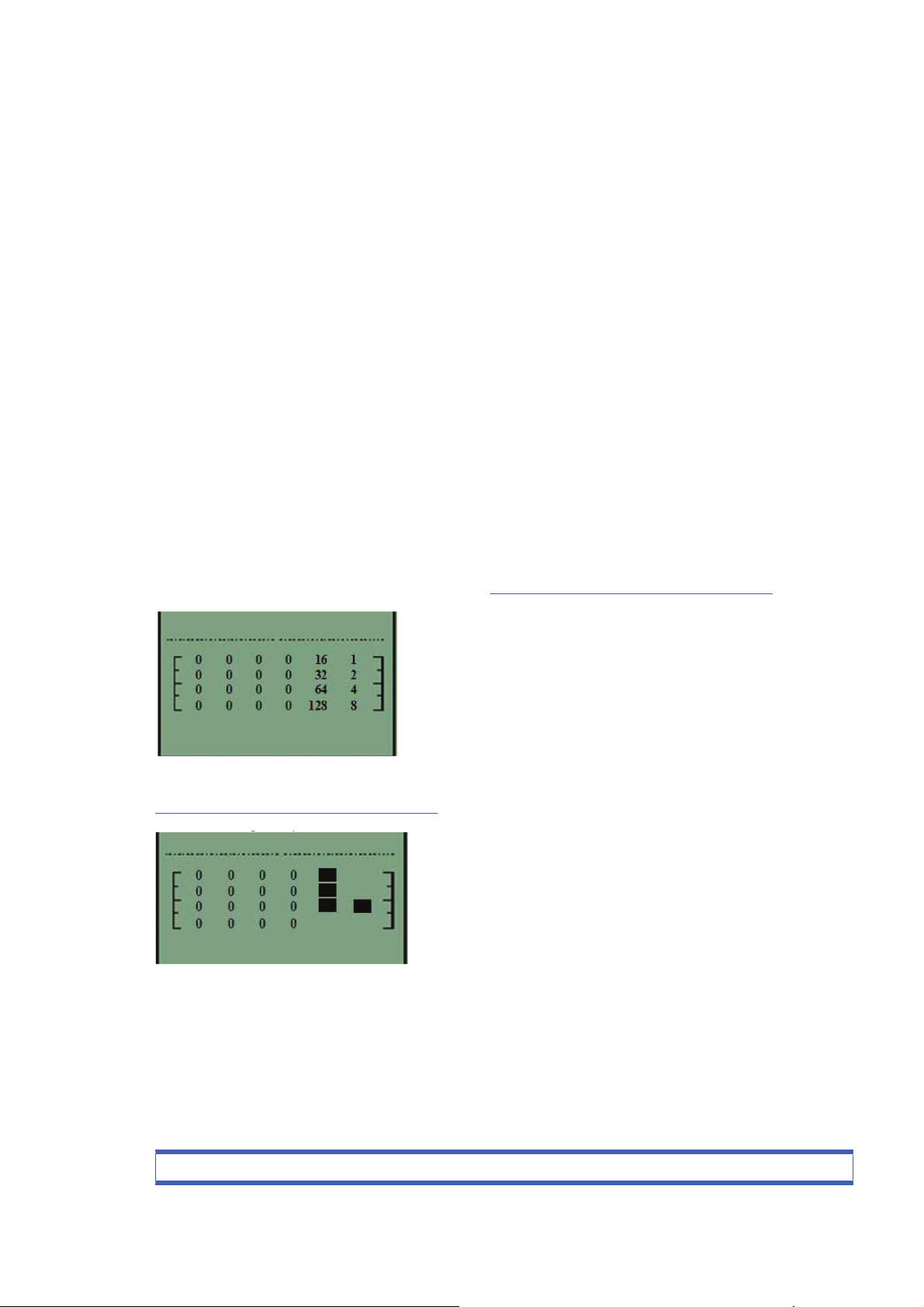

Interpreting the numbered code system

While the printer is initializing, the front panel will display a sequence of squares in the last two columns.

Each position in the last two columns represents a number, all the numbers represented are shown

below. To find the failing subsystem, add the numbers together that have a square and refer to the list

of numbers with their associated subsystems on

Subsystem Code Description on page 25.

In the example below the printer is initializing and the front panel has stopped and is displaying squares

in positions 16, 32, 64, and 4. Add these four values together and you get 116, refer to the list on

Subsystem Code Description on page 25, and we can see the failing subsystem is the Trailing Cable.

If the display reaches 191, you will need to turn On the printer from the power button. If all the subsystems

pass the initialization, the printer will initialize normally and go to the ready status.

Subsystem Code Description

This is the list of the subsystems and their associated Startup Track Numbers. Many of the descriptions

of the Subsystems will not be immediately obvious, when this is the case contact the lfp help desk and

they can assist you.

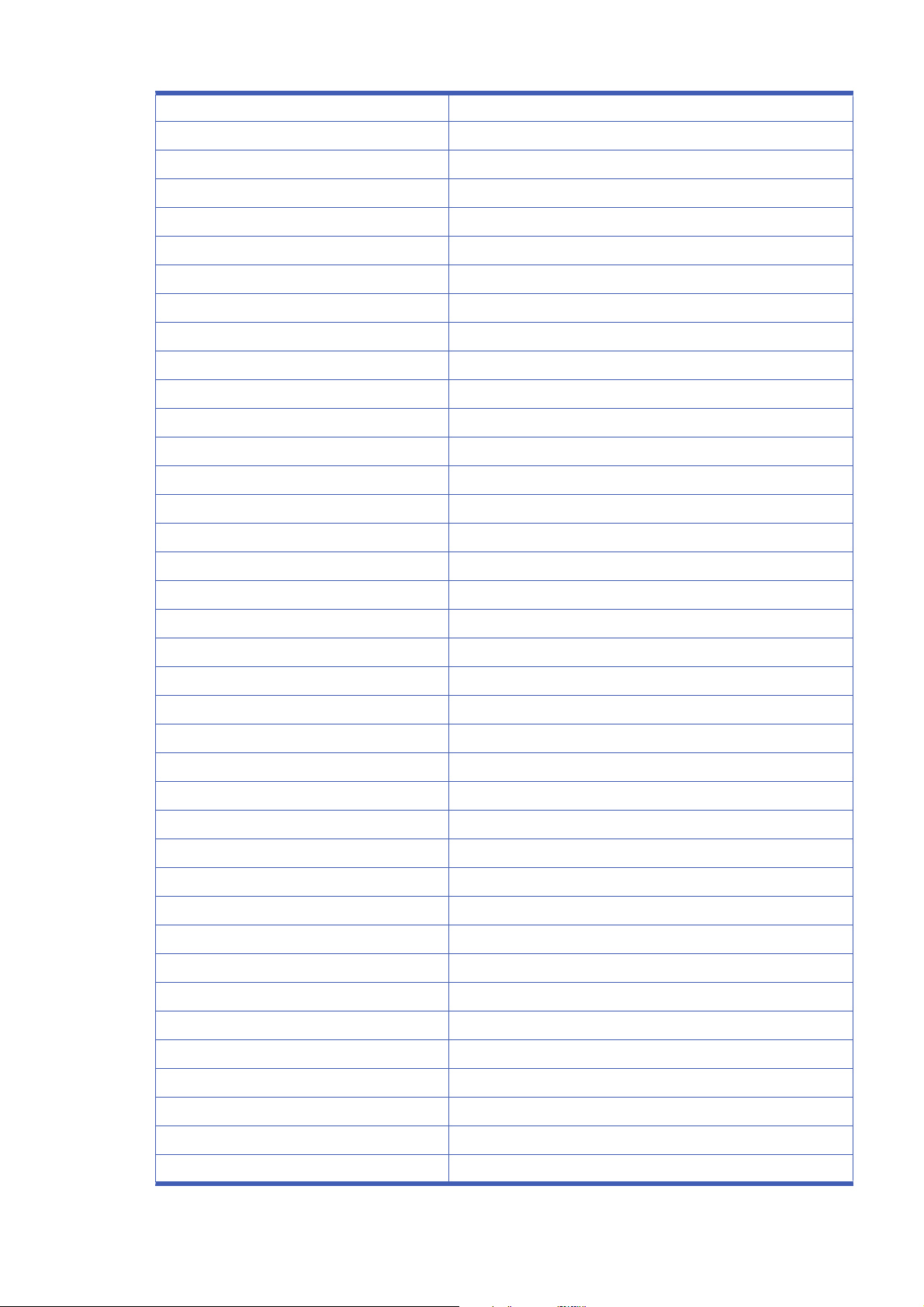

Table 2-1 Subsystem code description

Startup track number: Associated Subsystem

ENWW Startup track mode 25

Startup Track 004: Calling EiffelMain

Startup Track 005: Initializing Classes

Startup Track 006: Initializing SM

Startup Track 007: Initializing Memory

Startup Track 008: Initializing MemoryVolatile

Startup Track 009: Initializing MemoryEndian

Startup Track 010: Initializing MemoryVolatileEndian

Startup Track 011: Initializing Impala

Startup Track 012: Initializing ColdFire

Startup Track 013: Initializing ImpalaInterruptController

Startup Track 014: Initializing MechProcTaskHiIntA

Startup Track 015: Initializing IsardInterruptA

Startup Track 016: Initializing Watchdog

Startup Track 017: Initializing Chronometer

Startup Track 018: Initializing EddTimer

Startup Track 019: Initializing IsardInterruptB

Startup Track 020: Initializing PciSlot2Interrupt

Startup Track 021: Initializing PciSlot3Interrupt

Startup Track 022: Initializing PciSlot4Interrupt

Startup Track 023: Initializing PciSlot5Interrupt

Startup Track 024: Initializing MagentaFireLow

Startup Track 025: Initializing BongoGpio

Startup Track 026: Initializing SecondTraySensor

Startup Track 027: Initializing CleanoutSensor

Startup Track 028: Initializing RearPathPaperSensor

Startup Track 029: Initializing BlackCartridgeSensor

Startup Track 030: Initializing CyanCartridgeSensor

Startup Track 031: Initializing MagentaCartridgeSensor

Startup Track 032: Initializing YellowCartridgeSensor

Startup Track 033: Initializing LightMagentaCartridgeSensor

Startup Track 034: Initializing LightCyanCartridgeSensor

Startup Track 035: Initializing SynergyReset

Startup Track 036: Initializing FrontPanelReset

Startup Track 037: Initializing PowerFan

Startup Track 038: Initializing FrontPanelInterrupt

Startup Track 039: Initializing CoverWindowSensor

Startup Track 040: Initializing nUSB_ENABLE

Startup Track 041: Initializing USB_CONNECT

Table 2-1 Subsystem code description (continued)

26 Chapter 2 System Error Codes ENWW

Startup Track 042: Initializing TrailingCable3Sensor

Startup Track 043: Initializing TrailingCable12Sensor

Startup Track 044: Initializing PrintheadSensor

Startup Track 045: Initializing BongoBrake

Startup Track 046: Initializing Dma

Startup Track 047: Initializing BongoEncoder

Startup Track 048: Initializing ServiceStationEncoder

Startup Track 049: Initializing SSPwm

Startup Track 050: Initializing PaperPwm

Startup Track 051: Initializing RampPwm

Startup Track 052: Initializing CarriagePwmForward

Startup Track 052: Initializing CarriagePwmForward

Startup Track 054: Initializing BomboPwm

Startup Track 055: Initializing EddPwm

Startup Track 056: Initializing ImpalaCarriagePosition

Startup Track 057: Initializing I2c0

Startup Track 058: Initializing I2c1

Startup Track 059: Initializing I2c2

Startup Track 060: Initializing I2c3

Startup Track 061: Initializing Darwin

Startup Track 062: Initializing PciCtrl

Startup Track 063: Initializing PciDma

Startup Track 064: Initializing MBandToPixel

Startup Track 065: Initializing PixelData

Startup Track 066: Initializing BlackCSData

Startup Track 067: Initializing CyanCSData

Startup Track 068: Initializing MagentaCSData

Startup Track 069: Initializing YellowCSData

Startup Track 070: Initializing LightCyanCSData

Startup Track 071: Initializing LightMagentaCSData

Startup Track 072: Initializing BlackPrintHead

Startup Track 073: Initializing CyanPrintHead

Startup Track 074: Initializing MagentaPrintHead

Startup Track 075: Initializing YellowPrintHead

Startup Track 076: Initializing LightCyanPrintHead

Startup Track 077: Initializing LightMagentaPrintHead

Startup Track 078: Initializing BlockBlack

Startup Track 079: Initializing BlockColor

Table 2-1 Subsystem code description (continued)

ENWW Startup track mode 27

Startup Track 080: Initializing ContoneToRaster

Startup Track 081: Initializing Enhancer

Startup Track 082: Initializing RasterToMband

Startup Track 083: Initializing MechProcA

Startup Track 084: Initializing MemoryUncached

Startup Track 085: Initializing Isard

Startup Track 086: Initializing IsardInterruptController

Startup Track 087: Initializing PaperInterrupt

Startup Track 088: Initializing IsardPMTimer

Startup Track 089: Initializing IsardKFort

Startup Track 090: Initializing IsardCarriagePosition

Startup Track 091: Initializing IsardPaperPosition

Startup Track 092: Initializing MediaPosition

Startup Track 093: Initializing PaperEncoderPosition

Startup Track 094: Initializing IsardMotorShortcut

Startup Track 095: Initializing Eridani

Startup Track 096: Initializing EddOn

Startup Track 097: Initializing ServiceStationLed

Startup Track 098: Initializing FetRegulator

Startup Track 099: Initializing EddOut

Startup Track 100: Initializing DuplexerConversor

Startup Track 101: Initializing EridaniConversorAuto

Startup Track 102: Initializing EridaniConversorAB

Startup Track 103: Initializing EridaniConversorAnA

Startup Track 104: Initializing EridaniConversorBnB

Startup Track 105: Initializing PaperDriver

Startup Track 106: Initializing ServiceStationDriver

Startup Track 107: Initializing RampDriver

Startup Track 108: Initializing DuplexerSensor

Startup Track 109: Initializing PaperMotorHw

Startup Track 110: Initializing CarriageMotorHw

Startup Track 111: Initializing ServiceStationMotorHw

Startup Track 112: Initializing BongoEncoderWindowHw

Startup Track 113: Initializing BongoMotorHw

Startup Track 114: Initializing RampMotorHw

Startup Track 115: Initializing FrontPanelHw

Startup Track 116: Initializing TrailingCable

Startup Track 117: Initializing CarriageBoardHw

Table 2-1 Subsystem code description (continued)

28 Chapter 2 System Error Codes ENWW

Startup Track 118: Initializing SynergyA

Startup Track 119: Initializing VPPA

Startup Track 120: Initializing VPPB

Startup Track 121: Initializing SynergyInternalRegulatorA

Startup Track 122: Initializing Led1Voltage

Startup Track 123: Initializing EndeavourA

Startup Track 124: Initializing EndeavourAcumenA

Startup Track 125: Initializing CLC_Channel0

Startup Track 126: Initializing CLC_Channel1

Startup Track 127: Initializing CLC_Channel2

Startup Track 128: Initializing EndeavourVRefConversor

Startup Track 129: Initializing CLC_ChannelDACConversor

Startup Track 130: Initializing IS_Channel3Conversor_A

Startup Track 131: Initializing CLC_Channel0Conversor

Startup Track 132: Initializing CLC_Channel1Conversor

Startup Track 133: Initializing CLC_Channel2Conversor

Startup Track 134: Initializing Led2Voltage

Startup Track 135: Initializing Black5V

Startup Track 136: Initializing Yellow5V

Startup Track 137: Initializing Magenta5V

Startup Track 138: Initializing Cyan5V

Startup Track 139: Initializing Black12V

Startup Track 140: Initializing Yellow12V

Startup Track 141: Initializing Magenta12V

Startup Track 142: Initializing Cyan12V

Startup Track 143: Initializing VPen_Current_Sense_A

Startup Track 144: Initializing VPen_OV_Latch_A

Startup Track 145: Initializing VPen_OV_Clear_Latch_A

Startup Track 146: Initializing VPen_UV_Latch_A

Startup Track 147: Initializing VPen_UV_Clear_Latch_A

Startup Track 148: Initializing VPen_OV_Present_A

Startup Track 149: Initializing VPen_UV_Present_A

Startup Track 150: Initializing EndeavourB

Startup Track 151: Initializing EndeavourAcumenB

Startup Track 152: Initializing IS_Channel3Conversor_B

Startup Track 153: Initializing Led3Voltage

Startup Track 154: Initializing LightMagenta5V

Startup Track 155: Initializing LightCyan5V

Table 2-1 Subsystem code description (continued)

ENWW Startup track mode 29

Startup Track 156: Initializing LightMagenta12V

Startup Track 157: Initializing LightCyan12V

Startup Track 158: Initializing VPen_Current_Sense_B

Startup Track 159: Initializing VPen_OV_Latch_B

Startup Track 160: Initializing VPen_OV_Clear_Latch_B

Startup Track 161: Initializing VPen_UV_Latch_B

Startup Track 162: Initializing VPen_UV_Clear_Latch_B

Startup Track 163: Initializing VPen_OV_Present_B

Startup Track 164: Initializing VPen_UV_Present_B

Startup Track 165: Initializing Eerom

Startup Track 166: Initializing EeromCarriage

Startup Track 167: Initializing PrintheadControl

Startup Track 168: Initializing BlackPrintheadAcumen

Startup Track 169: Initializing CyanPrintheadAcumen

Startup Track 170: Initializing MagentaPrintheadAcumen

Startup Track 171: Initializing YellowPrintheadAcumen

Startup Track 172: Initializing LightCyanPrintheadAcumen

Startup Track 173: Initializing LightMagentaPrintheadAcumen

Startup Track 174: Initializing BlackCartridgeAcumen

Startup Track 175: Initializing CyanCartridgeAcumen

Startup Track 176: Initializing MagentaCartridgeAcumen

Startup Track 177: Initializing YellowCartridgeAcumen

Startup Track 178: Initializing LightCyanCartridgeAcumen

Startup Track 179: Initializing LightMagentaCartridgeAcumen

Startup Track 180: Initializing ColorSensor

Startup Track 181: Initializing ColorSensorLed1

Startup Track 182: Initializing ColorSensorLed2

Startup Track 183: Initializing ColorSensorLed3

Startup Track 184: Initializing ColorSensorConverso

Startup Track 185: Initializing ColorSensorConversorB

Startup Track 186: Initializing ColorSensorConversorC

Startup Track 187: Initializing V5_V12_ISDetection

Startup Track 188: Initializing VPP_ISDetection

Startup Track 189: Initializing InterruptController

Startup Track 190: SM Initialized

Startup Track 191: Back from EiffelMain!!!

PRESS POWER BUTTON HERE!!

Startup Track 192: Initializing VPPA

Table 2-1 Subsystem code description (continued)

30 Chapter 2 System Error Codes ENWW

Startup Track 193: Initializing VPPB

Startup Track 194: Initializing SynergyInternalRegulatorA

Startup Track 195: Initializing Led1Voltage

Startup Track 196: Initializing EndeavourAcumenA

Startup Track 197: Initializing CLC_Channel0

Startup Track 198: Initializing CLC_Channel1

Startup Track 199: Initializing CLC_Channel2

Startup Track 200: Initializing EndeavourVRefConversor

Startup Track 201: Initializing CLC_ChannelDACConversor

Startup Track 202: Initializing IS_Channel3Conversor_A

Startup Track 203: Initializing CLC_Channel0Conversor

Startup Track 204: Initializing CLC_Channel1Conversor

Startup Track 205: Initializing CLC_Channel2Conversor

Startup Track 206: Initializing Led2Voltage

Startup Track 207: Initializing Black5V

Startup Track 208: Initializing Yellow5V

Startup Track 209: Initializing Magenta5V

Startup Track 210: Initializing Cyan5V

Startup Track 211: Initializing Black12V

Startup Track 212: Initializing Yellow12V

Startup Track 213: Initializing Magenta12V

Startup Track 214: Initializing Cyan12V

Startup Track 215: Initializing VPen_Current_Sense_A

Startup Track 216: Initializing VPen_OV_Latch_A

Startup Track 217: Initializing VPen_OV_Clear_Latch_A

Startup Track 218: Initializing VPen_UV_Latch_A

Startup Track 219: Initializing VPen_UV_Clear_Latch_A

Startup Track 220: Initializing VPen_OV_Present_A

Startup Track 221: Initializing VPen_UV_Present_A

Startup Track 222: Initializing EndeavourAcumenB

Startup Track 223: Initializing IS_Channel3Conversor_B

Startup Track 224: Initializing Led3Voltage

Startup Track 225: Initializing LightMagenta5V

Startup Track 226: Initializing LightCyan5V

Startup Track 227: Initializing LightMagenta12V

Startup Track 228: Initializing LightCyan12V

Startup Track 229: Initializing VPen_Current_Sense_B

Startup Track 230: Initializing VPen_OV_Latch_B

Table 2-1 Subsystem code description (continued)

ENWW Startup track mode 31

Startup Track 231: Initializing VPen_OV_Clear_Latch_B

Startup Track 232: Initializing VPen_UV_Latch_B

Startup Track 233: Initializing VPen_UV_Clear_Latch_B

Startup Track 234: Initializing VPen_OV_Present_B

Startup Track 235: Initializing VPen_UV_Present_B

Table 2-1 Subsystem code description (continued)

32 Chapter 2 System Error Codes ENWW

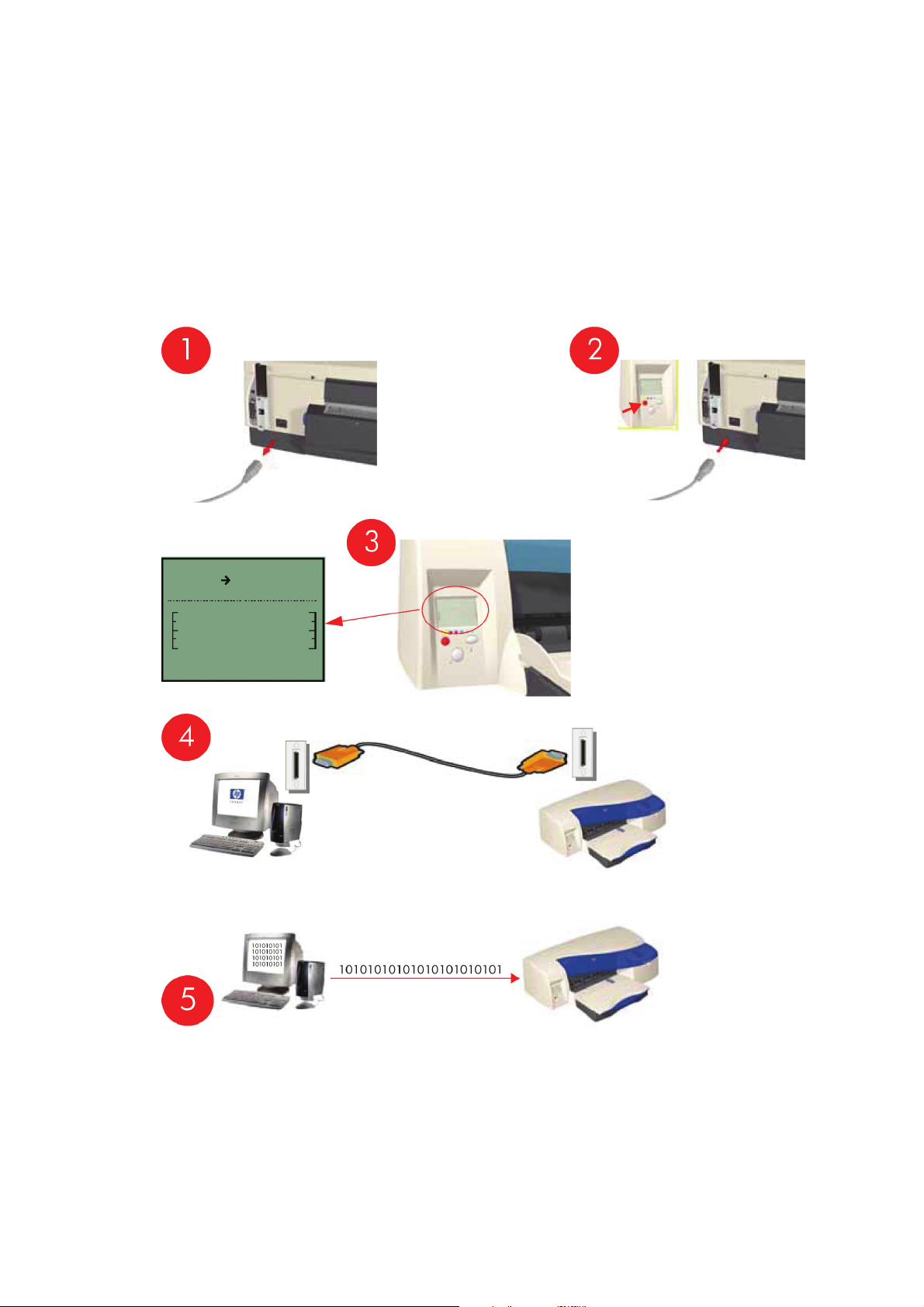

Emergency Firmware Upgrade

1. Unplug the power cord from the printer and wait a few seconds.

2. Press and hold the Cancel (red) button while plugging in the power cord.

3. The printer will initialize in emergency mode (the front panel will display just the arrow icon).

4. Connect the printer to the computer with a parallel cable.

5. Send the firmware file through the parallel port from the DOS command prompt. Type: copy /b

firmware_file lpt1: and then press ENTER.

ENWW Emergency Firmware Upgrade 33

System Error Codes — Explanation

System Error Codes explain which component/system is failing and what action should be taken to

resolve the problem.

System Error Codes are displayed directly on the front panel (but can also be seen on the Information

Page) and have been defined in the format XX.YZ.

Warnings will not be displayed on the front panel, but will instead only appear on the Information Page

and have been defined in the format XXn.YZ.m.

●

XX: Service Part (2 digits).

●

n: Service Part Index (if more than one used in the product) — Optional.

◦

e.g. Identify the Ink Supply (color and number).

●

Y: Who should perform the action (1 digit) — (User or Service Engineer).

●

Z: Action to perform (1 digit).

●

m: additional actions/information to consider (1 digit) — Optional.

◦

e.g. Non-authorized ink was detected, PM was triggered or Printhead in/out of Warranty.

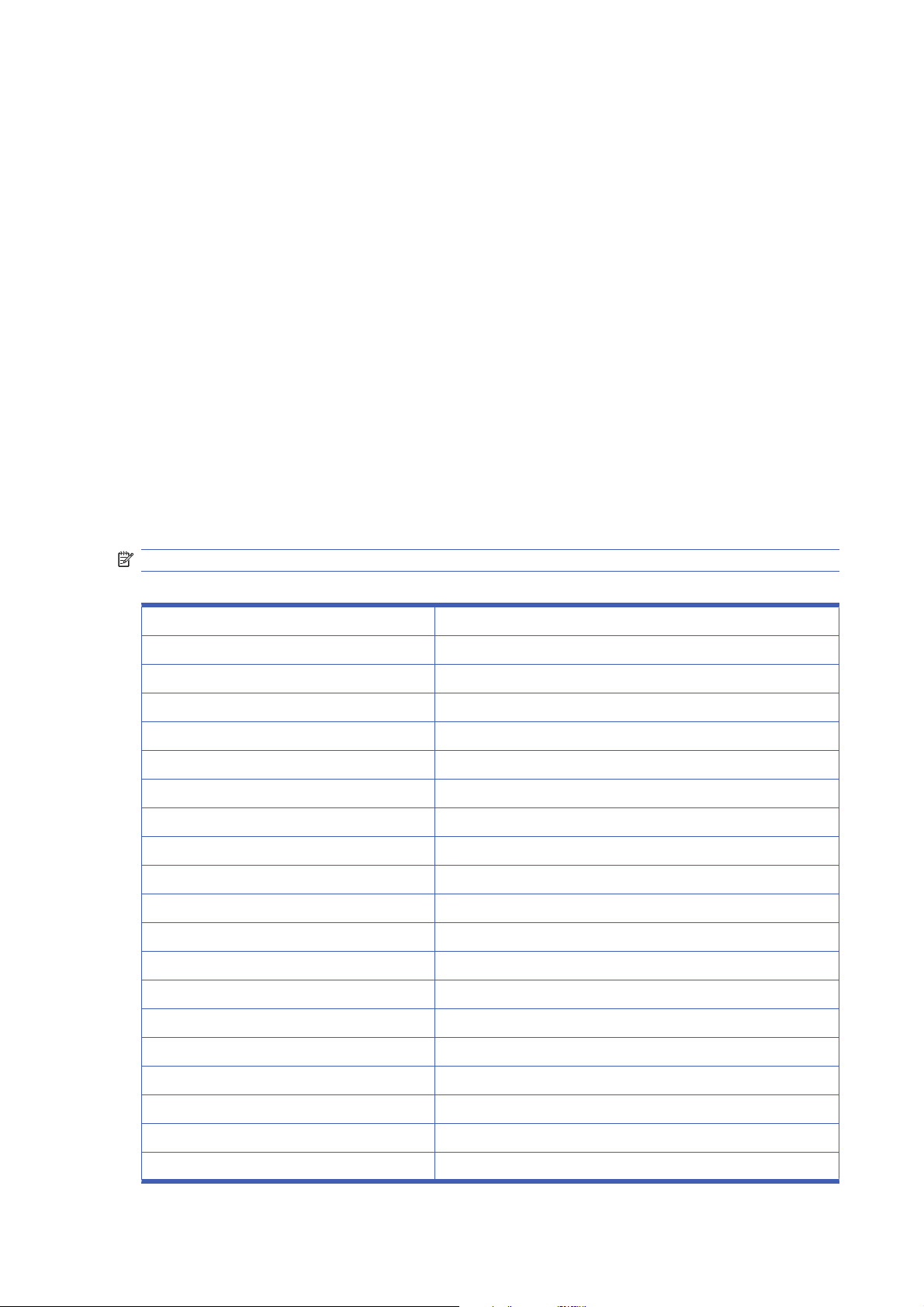

The following table explains the XX part of the System Error Code or Warning:

NOTE: Items denoting * (Asterisk) are not applicable to the printers.

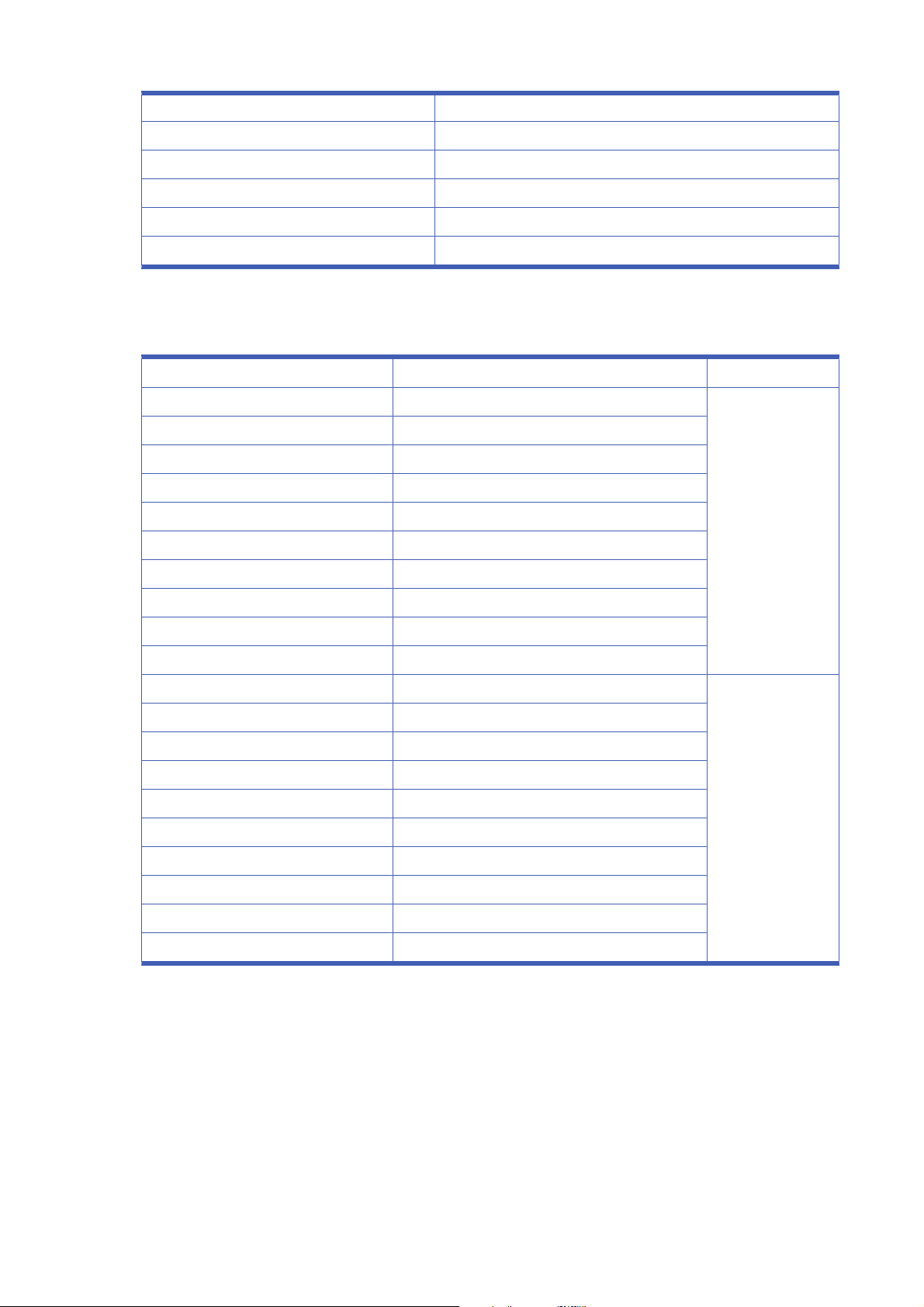

Table 2-2 System error codes

Code Component/System

01 Main PCA/Electronics Module

02 Carriage/Carriage PCA

03 Power Supply Unit

04 Network Card

05 Formatter *

06 Hard Disk Drive *

07 Interconnect PCA

08 Front Panel

11 Trailing Cable

12 Carriage Flex Circuit

17 Interconnect Cable

21 Service Station

22 Ink Supply Station

23 Pressure System (APS) *

24 Ink Delivery Tubes

25 Spittoon *

26n Ink Cartridge (color n)

26n Printhead (color n)

31 Cutter

34 Chapter 2 System Error Codes ENWW

32 Take-up Reel *

33 Sheet Feeder

34 Dryer/Blower *

35 Cleanout Assembly

36 Duplexer

37 ARSS/Rollfeed

38 Output Tray

41 Paper-Axis Motor

42 Scan-Axis Motor

43 Vacuum Fan *

44 Aerosol fan *

51 Window Sensor

52 Drop Detector *

53 Media Sensor

54 Pinch-Arm Sensor

55 Line Sensor

56 Drive Roller Encoder Sensor

57 Ink Leak Detector *

58 Color Sensor *

59 Media Type Sensor *

61 Language Interpreting

62 Input/Output through Parallel Port

63 Input/Output through Network Card

64 Input/Output through USB Port

65 Input/Output (not know what port)

66 Print Job Configuration

71 Print Job Configuration

72 Generic Firmware

73 Motor Control Functions

74 Motor Control Functions 74 Firmware Upgrade

79 Firmware Crash

81 Media Advance

82 Media Cut *

83 Single-Sheet Feeding

84 Roll Feeding *

85 Media-Axis Encoder Reading

86 Carriage Movement

87 Scan-Axis Encoder Reading

Table 2-2 System error codes (continued)

ENWW System Error Codes — Explanation 35

91 Printhead Firing

92 Servicing

93 Ink Pumping

94 Ink Pumping

95 Printhead Alignment

96 Image Quality Troubleshooting

The following table explains the YZ part of the System Error Code or Warning:

Table 2-3 System error codes

Code Response Response

00 Replace

Possible for customer

to perform action

01 Reseat/Reconnect/Clean/Adjust (manually)

02 Calibrate/Adjust (using Automatic Process)

03 Power OFF

04 Upgrade System Firmware

05 Upgrade Driver

06 Add Accessory

07 Escalate

08 Send Plot Again

09 Wrong Part Installed

10 Replace

HP qualified

personnel assistance

required

11

Reseat/Reconnect/Clean/Adjust (manually)

12 Calibrate/Adjust (using Automatic Process)

13 Power OFF

14 Upgrade System Firmware

15 Upgrade Driver

16 Add Accessory

17 Escalate

18 Send Plot Again

19 Wrong Part Installed

Table 2-2 System error codes (continued)

36 Chapter 2 System Error Codes ENWW

3 System Maintenance Utility

●

Introduction

●

Launching the System Maintenance Utility

●

System Maintenance Utility (Designjet 30, 30n, 70, 90, 90r, 110plus, 111, 130, 130nr)

ENWW 37

Introduction

The System Maintenance Utility is designed to assist the customer with common maintenance tasks for

the printer and also to resolve common problems that they may encounter.

NOTE: Print jobs must not be sent to the printer while the system maintenance utility is in use.

Since the design of the System Maintenance Tool is different between the Designjet 120/120nr and

Designjet 130/130, this chapter will explain how to use the tool for each product separately:

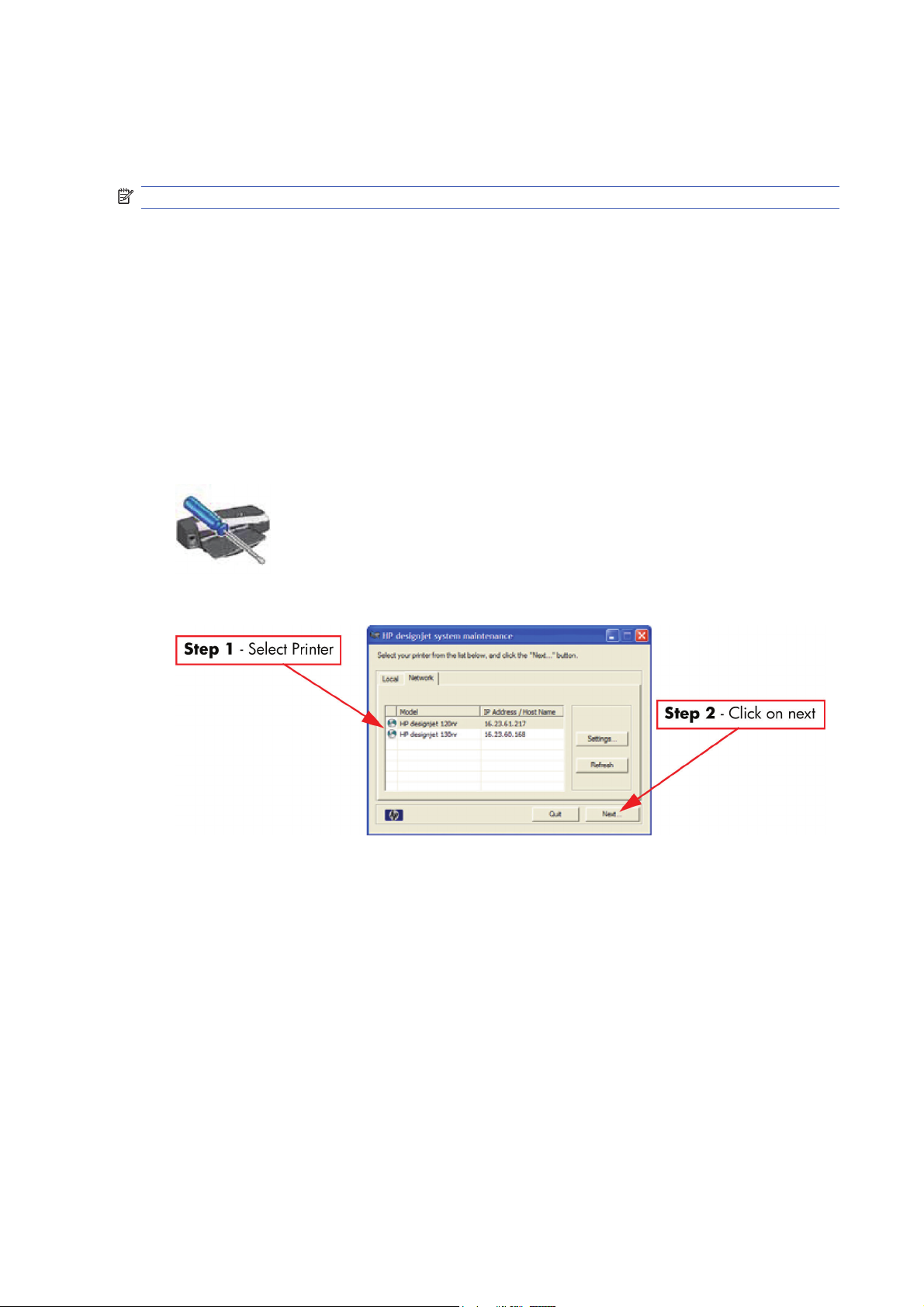

Launching the System Maintenance Utility

The procedures described here are applicable to the following printers: HP Designjet 30, 30n, 70, 90,

90r, 100+, 110+r, 110+nr, 111 with roll, 111 with tray, 130, 130r, 130nr:

There are two ways of launching the System Maintenance Utility.

From your computer’s desktop (Windows, Mac OS 9 and X)

1. Double click the hp designjet system maintenance icon on the desktop.

2. A printer selector window opens — select your printer from the list.

3. Click Next (in Windows) or Configure (in Mac OS).

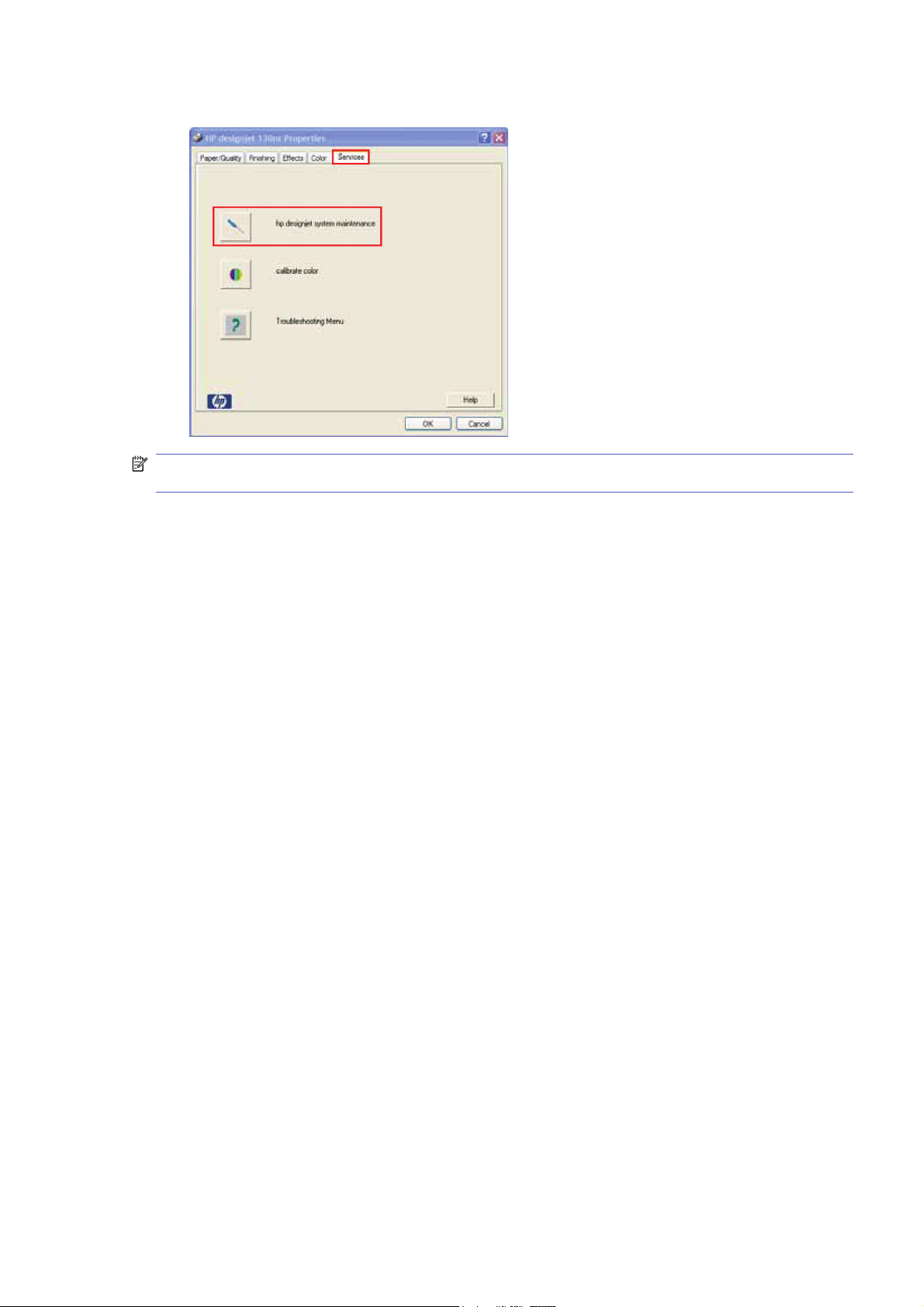

From the Printer Driver (Windows, Mac OS X)

●

In the Windows driver click the hp designjet system maintenance icon in the Services tab.

38 Chapter 3 System Maintenance Utility ENWW

●

In Mac OS X, select the Printer in the Print Center or Print Setup Utility and click configure.

NOTE: When you finish using the System Maintenance Utility, you must click on exit on the left hand

column before closing the browser.

ENWW Launching the System Maintenance Utility 39

System Maintenance Utility (Designjet 30, 30n, 70, 90, 90r,

110plus, 111, 130, 130nr)

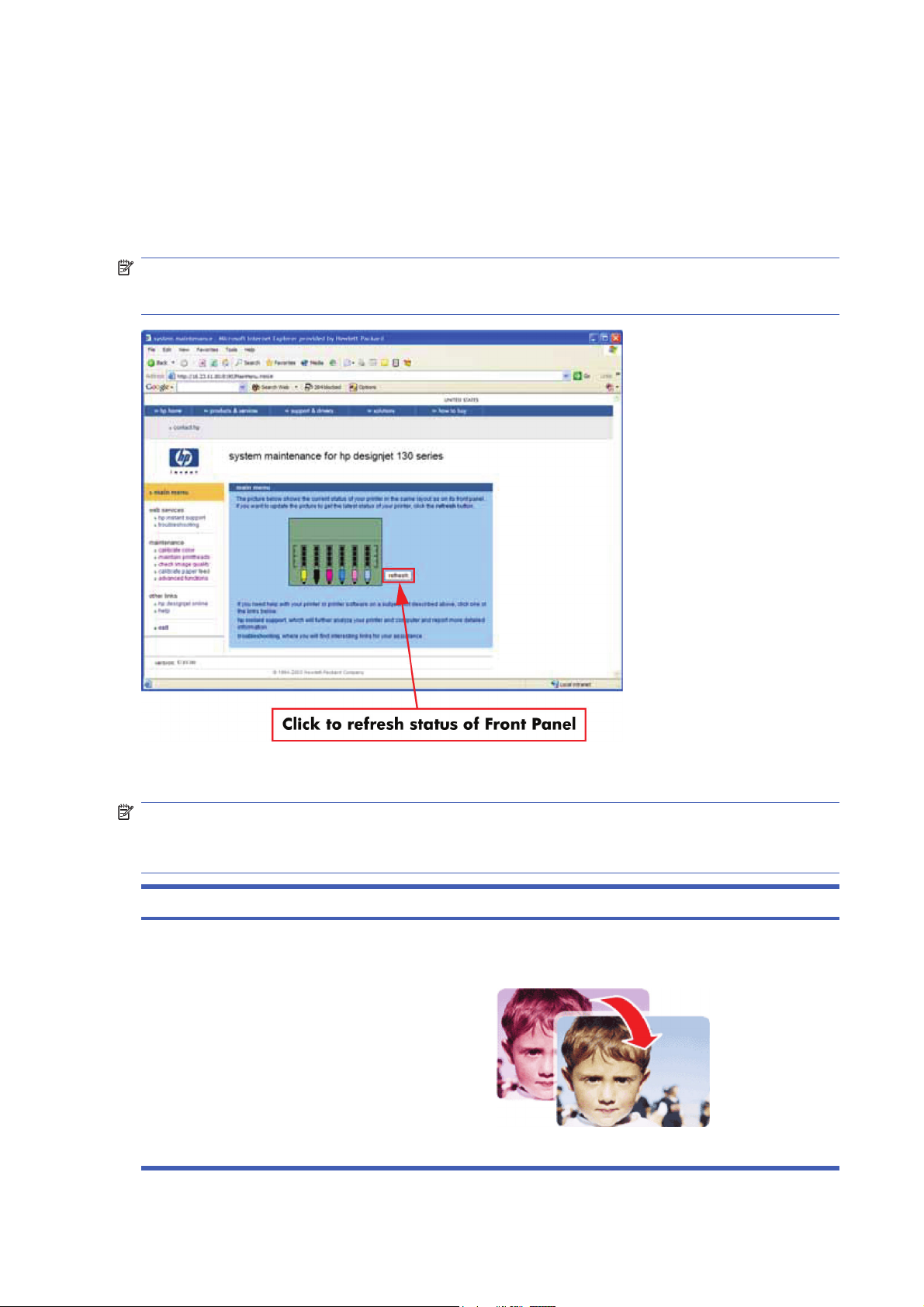

Main Menu — Printer Front Panel Replication

The main page of the System Maintenance Utility includes a replica of the Printer’s Front Panel showing

the status of the Printer.

NOTE: The replica Front Panel does not show the real-time status. It is a snapshot which can be

refreshed by pressing the refresh button either on the web browser toolbar or in the actual replica

window.

Color Calibration

NOTE: The Color Calibration is only available for the following printers: HP Designjets 30, 30n, 90,

90r, 130, 130nr. It is not available for the HP Designjets 70, 110plus, 111.

NOTE: The Color Calibration should ONLY be performed by the user when required.

Question Answer

Why calibrate color? Calibrate color performs a maintenance function to ensure

color consistency. If you calibrate correctly, the colors printed

on printers with different printheads will look very similar.

This picture shows an exaggerated example of how a printout

could look like before and after color calibration.

40 Chapter 3 System Maintenance Utility ENWW

* 01:10

Electronics Module failure.

Requires Service Engineer

* 01:12 Warning/Error Code

Electronics Module Error. Warning information indicates:- Electronics Module failed during the firmware upgrade OR the Electronics Module failed during initialization.

The Electronics Module EEPROM is flagged as empty and must be upgraded with the contents of the Carriage EEPROM, but the Carriage is also flagged as empty. The backup is not performed. This is the result of an error during the manufacturing or the repair process. Therefore the Electronics Module must be reconfigured. Call service engineer

* 02:10

Carriage failure.

Call service engineer

* 04:13

Generic Firmware Error (Network Card).

Unplug the power cable from the printer and wait a few seconds. Plug in the power cable again and check if the Error Code has disappeared.

If the error code continues Requires a Service Engineer

* 08:11

Problem with the Front Panel/Front Panel cannot be detected.

• Switch the Power OFF from the back of the Printer and disconnect the Power cord. Reconnect the power cord and power ON the Printer.

• If the System Error continues requires a Service Engineer.

* 11:10

Trailing Cable does not seem to be detected.

Try the following:

- Switch the Power OFF from the back of the Printer and disconnect the Power cord.

- Check that the Trailing Cable is not damaged.

- Reconnect the power cord and power ON the Printer.

If problem continues — requires Service Engineer.

* 11:11

Trailing Cable is badly connected.

Requires Service Engineer.

* 1:11 Warning

The Electronics Module is incorrectly positioned

Call service engineer to reseat module

* 21:10

Service Station failure.

Requires a Service Engineer.

* 22:10

Ink Supply Station failure.

Requires Service Engineer

* 270:00 Warning

Black Color Calibration Failure — Black Color Calibration cancelled.

Try the following: Clean the electrical contacts on the black printhead. If the error code continues, replace the black printhead.

* 271:00 Warning

Cyan Color Calibration Failure — Cyan Color Calibration cancelled.

Try the following: Clean the electrical contacts on the cyan printhead. If the error code continues, replace the cyan printhead

* 272:00 Warning

Magenta Color Calibration Failure — Magenta Color Calibration cancelled.

Try the following: Clean the electrical contacts on the magenta printhead. If the error code continues, replace the magenta printhead.

* 273:00 Warning

Yellow Color Calibration Failure — Yellow Color Calibration cancelled.

Try the following: Clean the electrical contacts on the yellow printhead. If the error code continues, replace the yellow printhead.

* 274:00 Warning

Light Cyan Color Calibration Failure — Light Cayan Color Calibration cancelled.

Try the following: Clean the electrical contacts on the light cyan printhead. If the error code continues, replace the light cyan printhead.

(Not applicable to HP DesignJet 70, 100, 100+, 110+)

* 275:00 Warning

Light Magenta Color Calibration Failure — Light Magenta Color Calibration cancelled.

Try the following:Clean the electrical contacts on the light magenta printhead. If the error code continues, replace the light magenta printhead.

(Not applicable to HP DesignJet 70, 100, 100+, 110+)

* 35:01 Warning/Error Code

No Cleanout Assembly (or Duplexer, if installed) detected while loading media.

Call service engineer

* 37:01

Automatic roll motor shutdown.

If this error code was caused by a paper jam, unplug the power cable from the printer and clear the blockage. Plug in the power cable again and check if the Error Code has disappeared.

If there is no paper jam or if recovering the paper jam does not resolve the problem, Requires Sevice Engineer.

* 37:10

Automatic roll home position error.

Requires Service Engineer.

* 42:10

Carriage Motor failure (short-circuit).

Requires Service Engineer.

* 56:10

Error during the calibration of the motor encoder system or a problem finding the zero position on the Encoder Disc.

Requires Service Engineer.

* 56:13

Error during the calibration of the Line-feed Motor/Encoder system.

Unplug the power cable from the printer and wait a few seconds. Plug in the power cable again and check if the Error Code has disappeared.

If Error Code remains,Requires Sevice Engineer.

* 58:10

Problem detected in the colour sensor system.

Call service engineer

* 61:05 Warning/Error Code

Language interpreting error. This is usually an error produced while parsing a file.

There is probably an incompatibility between the driver and the firmware.

Warning info indicates:- Firmware Upgrade or Colour Calibration was rejected because the file was sent in the wrong format. Upgrade the RIP software or the Designjet System Maintenance Tool. Requires Service Engineer

* 62:04

I/O module error (62 = parallel).

Unplug the power cable from the printer and wait a few seconds. Plug in the power cable again and check if the Error Code has disappeared.

If the Error Code reappears, the firmware requires an upgrade. Requires Service Engineer

* 63:04

I/O module error (63 = Network).

Try the following: Unplug the power cable from the printer and wait a few seconds. Plug in the power cable again and check if the Error Code has disappeared. If the Error Code reappears, upgrade the firmware.

Requires a Service Engineer.

* 64:04

I/O module error (64 = USB).

Try the following: Unplug the power cable from the printer and wait a few seconds. Plug in the power cable again and check if the Error Code has disappeared. If the Error Code reappears, upgrade the firmware.

Requires a Service Engineer.

* 65:01 Warning

Communication Failure.

Try the following: Unplug the power cable from the printer and check the cable connections (Parallel, USB and Network cables). Plug in the power cable again and check if the Error Code has disappeared.

* 65:04

I/O module error (62 = parallel; 63 = Network; 64 = USB = Unknown Port; 65).

Try the following: Unplug the power cable from the printer and wait a few seconds. Plug in the power cable again and check if the Error Code has disappeared.

If the Error Code reappears, upgrade the firmware. Call service engineer

* 71:03

Generic Firmware Error (Out of memory).

Unplug the power cable from the printer and wait a few seconds. Plug in the power cable again and check if the Error Code has disappeared.

If the Error Code reappears, check for a new Firmware release. Requires a Service Engineer.

* 71:14 Warning/Error Code

Out-of-memory while trying to process the firmware upgrade file.

Probably this is a firmware bug, because the firmware should free up enough memory to perform the firmware upgrade process correctly. Requires a Service Engineer.

* 72:04

Generic Firmware error.

• Switch the Power OFF from the back of the Printer and disconnect the Power cord. Reconnect the power cord and power ON the Printer.

• Check that the Printer has the latest Firmware version. If not requires a Service Engineer to update the Firmware to the latest version.

* 74:12 Warning/Error Code

Firmware Upgrade Error (Memory size check failed during firmware upgrade).

Call service engineer to Perform the automatic troubleshooting procedure — If possible, provide the following information which can be found on the information page:– Firmware Release.– Printer Serial Number.

* 79:04

Generic Firmware error.

• Switch the Power OFF from the back of the Printer and disconnect the Power cord. Reconnect the power cord and power ON the Printer.

• Check that the Printer has the latest Firmware version.

If error persists, requires a Service Engineer

* 81:01

Paper-Axis shutdown/ Paper Servo shutdown — usually a paper-jam caused by a blockage of the Paper-axis System.

If this error code was caused by a paper-jam, unplug the power cable from the printer and clear the blockage. Plug in the power cable again and check if the Error Code has disappeared.

If this error code appeared but was NOT caused by a paper jam — requires a Service Engineer.

* 81:12

Media Advance error.

This error usually appears during the paper-advance calibration — Retry the paper-advance calibration.

* 83:10

Sheet feeding failure.

Call service engineer

* 85:10

Paper-Axis Encoder error. The Drive Roller Encoder Sensor cannot find the zero position of the Encoder Disk.

Requires Service Engineer

* 86:01

Scan-axis shutdown/Carriage Servo shutdown — caused by problem moving the carriage, most likely due to a paper jam.

Try the following:

- Switch the Power OFF from the back of the Printer and disconnect the Power cord.

- Open the Window and check for any visible obstacles restricting the movement of the carriage. If there is a wrinkled mass of media inside the paper path, lift the Pinch wheels (using the Media Lever) and clear the obstruction.

- Reconnect the power cord and power ON the Printer.

If problem persists — Requires Service Engineer

* 86:11

Scan-axis shutdown during initialization. Typically, this error occurs when the printer detects an incorrect length.

- Unplug the power cable from the printer and wait a few seconds.

- Plug in the power cable again and check if the Error Code has disappeared.

- Check that the Carriage moves freely and DOES NOT bump into the Service Station.

- If the Printheads are not installed, maybe the carriage cover is not closed completely.

If the Error Code continues, Requires a Service Engineer

* 94:08 Warning

Color Calibration Warning — Color Calibration not cancelled but Color Calibration values are likely to be incorrect.

Try the Color Calibration again, but this time using a different type of media (preferably HP media).

* 94:10 Warning

Color Calibration Failure — Color Calibration cancelled.

Try the following: Unplug the power cable from the printer and wait a few seconds. Plug in the power cable again and try the Color Calibration again. If this error code appears again, check the Color Calibration print:– If the Color Calibration was printed correctly without any print defects, then check that the media is moving freely (backwards and forwards) while the printer is scanning it.– If the Color Calibration was printed incorrectly,with some print defects replace the faulty Printhead of the color where the defects were noticeable. If the Error Code continues, call service engineer

* 95:00 Warning

Printhead Alignment Failure — Printhead Alignment cancelled.

Try the following: Clean the printhead indicated by the printer. If the error code continues, replace the faulty printhead.

* 95:02 Warning

Printhead Alignment Failure — Printhead Alignment cancelled.

Try the following: Unplug the power cable from the printer and wait a few seconds. Plug in the power cable again and try the Printhead Alignment again. If this error code appears again, check the Printhead Alignment print:– If the Printhead Alignment was printed correctly without any print defects, then check that the media is moving freely (backwards and forwards) while the printer is scanning it. – If the Printhead Alignment was printed incorrectly, with some print defects, replace the faulty Printhead of the color where the defects were noticeable.

* 95:04 Warning

Firmware Error (during Printhead Alignment)

Upgrade the printer to the latest firmware release. — Call service engineer

HP Designjet Entry-Level Printers Service

Manual

Version: September 2010

For HP Internal Use Only

©Copyright Hewlett-Packard Company 2010

This document contains proprietary

information that is protected by copyright. All

rights are reserved. No part of this document

may be photocopied, reproduced, or

translated to another language without the