Модератор: vetal

То, что другие люди говорят обо мне, никак не характеризует меня. Зато отлично характеризует их.

-

Andreyak777

- Избран тонером

-

kvg » Чт июн 20, 2019 8:56 am

Выключите принтер. Откройте левую дверь и нажмите на барабан, пока он не защелкнется на месте. Снова включите принтер, аппарат войдет в готовность.

-

kvg

- Администратор сайта и форума

-

- Сайт

- Персональный альбом

Andreyak777 » Чт июн 20, 2019 1:08 pm

То, что другие люди говорят обо мне, никак не характеризует меня. Зато отлично характеризует их.

-

Andreyak777

- Избран тонером

-

Andreyak777 » Чт июн 20, 2019 1:12 pm

То, что другие люди говорят обо мне, никак не характеризует меня. Зато отлично характеризует их.

-

Andreyak777

- Избран тонером

-

Andreyak777 » Чт июн 20, 2019 2:47 pm

То, что другие люди говорят обо мне, никак не характеризует меня. Зато отлично характеризует их.

-

Andreyak777

- Избран тонером

-

pc-porta » Чт июн 20, 2019 3:24 pm

Andreyak777 писал(а):Если была бы проблема в контактах, грязь там и все такое, почему он тогда нормально печатает когда загружается с открытой крышкой??

люфтит у Вас драм (шатает его) при закрывании крышки …

Драм совместимка или оригинал ?

Контакты чють подвытянуть в драме или принтаке … для лучшего и надёжного контакта :))

-

pc-porta

- Тонерный автобот

-

- Персональный альбом

dviz » Чт июн 20, 2019 7:14 pm

Andreyak777 писал(а):DK3130 изначально стоял, с ним все работало

Оно конечно, хорошо, но это ж не родной — может глюк какой — там в нём плата сопряжения маленькая с микрухой(кто-то на форуме уже писал, что они иногда дохнут) и датчик регистрации лишний (можно попробовать его отключить).

Плюс ещё по 0180 — проверить в U004 не сбойнули ли серийные номера.

-

dviz

- Эксперт по тонеру

-

- Персональный альбом

dviz » Пт июн 21, 2019 10:54 am

Надо бы для начала узнать с каких аппаратов и какие модели драмов ставились..

- За это сообщение автора dviz поблагодарил:

- admdep33

-

dviz

- Эксперт по тонеру

-

- Персональный альбом

dviz » Пт июн 21, 2019 2:57 pm

Вытащил из включенного m3040dn dk-3100, установил dk-3130 — работает. Выключил-включил — ошибка c7410. Вернул dk-3100 обратно — всё норм.

В fs-4100 вместо dk-3130 установил dk-3100 — ошибка замятия бумаги — ожидаемо — ведь в dk-3100 нет датчика регистрации и в аппарате нет..

- За это сообщение автора dviz поблагодарил:

- Andreyak777

-

dviz

- Эксперт по тонеру

-

- Персональный альбом

dviz » Пт июн 21, 2019 3:51 pm

В аппаратах со скоростью 40-45 стр/мин — fs 2100, m3040, p3045 и т.п. — два датчика регистрации в самом аппарате, поэтому датчик в драме не требуется. Во всех остальных — в самом аппарате один датчик и один в драме.

Тут поправлюсь — в fs2100, m3040, p3045 не два, а только один датчик регистрации — до валов регистрации, а в остальных аппаратах два: один — после валов регистрации, и один — в драме.

Последний раз редактировалось dviz Сб июн 22, 2019 3:42 pm, всего редактировалось 1 раз.

- За это сообщение автора dviz поблагодарил:

- admdep33

-

dviz

- Эксперт по тонеру

-

- Персональный альбом

-

-

Kyocera FS-1120d индикатор «Нет бумаги»

vs-dos в форуме Принтеры, МФУ, факсы, копиры формата A4

- 11

- 15430

СТРОНЦИЙ

Вт ноя 02, 2021 2:24 pm

-

Kyocera FS-1120d индикатор «Нет бумаги»

-

-

[SCANNER ERROR] Lamp Error Kyocera FS-1016

мастерчип в форуме Принтеры, МФУ, факсы, копиры формата A4

- 3

- 6738

Усатый Полосатый

Вс окт 28, 2018 11:08 pm

-

[SCANNER ERROR] Lamp Error Kyocera FS-1016

-

-

Kyocera 1035 «бледная» печать

srMax в форуме Принтеры, МФУ, факсы, копиры формата A4

- 2

- 14199

srMax

Пт янв 23, 2015 2:49 pm

-

Kyocera 1035 «бледная» печать

-

-

Taskalfa 180 ошибка «Е» и «Встряхните картр. с тонером»

manik.76 в форуме Принтеры, МФУ, копиры формата A3

- 3

- 9944

dviz

Пн фев 20, 2017 1:35 pm

-

Taskalfa 180 ошибка «Е» и «Встряхните картр. с тонером»

-

-

Kyocera Ecosys M2635dn «поворот» изображения

Искатель в форуме Принтеры, МФУ, факсы, копиры формата A4

- 10

- 6312

MatrixAgent

Ср апр 08, 2020 5:18 am

-

Kyocera Ecosys M2635dn «поворот» изображения

Вернуться в Принтеры, МФУ, факсы, копиры формата A4

Кто сейчас на форуме

Сейчас этот форум просматривают: нет зарегистрированных пользователей и гости: 33

Правила форума

Картинки и фотографии (если они нужны в сообщении) надо загружать только как вложения к своему сообщению (через кнопку Добавить файлы). Тогда картинки будут автоматически отображаться в сообщении.

-

lamac0

- Сообщения: 4

- Стаж: 11 месяцев

KYOCERA P3145DN код ошибки 7410:0035148

Сообщение

lamac0 »

Всем по привету, при включении данный аппарат говорит обратиться к сервисникам с кодом ошибки 7410:0035148, понимая, что дело где-то в драме зарыто полез копать гуглы, там сказали, что бывает крякает плата на драме, нашел донора, подкинул плату и результата нет, НО! если выдеруть питалово, открыть крышку переднюю, подать питалово, то он работает как ни в чем не бывало, до ребута

-

dviz

- Сообщения: 238

- Стаж: 1 год 9 месяцев

- Откуда: Ярославль

- Благодарил (а): 21 раз

- Поблагодарили: 29 раз

-

Репутация:

KYOCERA P3145DN код ошибки 7410:0035148

Сообщение

dviz »

Если есть донор — то ставьте донора и проверяйте работоспособность. Только хорошо бы конечно быть уверенным, что донор действительно рабочий. Если с открытой крышкой включается, то вероятно он при инициализации не проверяет работоспособность всех компонентов драма, а с закрытой проверяет и что-то его не устраивает — проверьте всё что там подключено к этой платке — датчик тонера, движок подмеса, засветку фотика.

-

- 4 Ответы

- 775 Просмотры

-

Последнее сообщение

-

- 2 Ответы

- 934 Просмотры

-

Последнее сообщение

-

- 1 Ответы

- 205 Просмотры

-

Последнее сообщение

-

- 21 Ответы

- 276 Просмотры

-

Последнее сообщение

-

- 0 Ответы

- 172 Просмотры

-

Последнее сообщение

Перейти к контенту

Модератор: vetal

То, что другие люди говорят обо мне, никак не характеризует меня. Зато отлично характеризует их.

-

Andreyak777

- Избран тонером

-

kvg » Чт июн 20, 2019 8:56 am

Выключите принтер. Откройте левую дверь и нажмите на барабан, пока он не защелкнется на месте. Снова включите принтер, аппарат войдет в готовность.

-

kvg

- Администратор сайта и форума

-

- Сайт

- Персональный альбом

Andreyak777 » Чт июн 20, 2019 1:08 pm

То, что другие люди говорят обо мне, никак не характеризует меня. Зато отлично характеризует их.

-

Andreyak777

- Избран тонером

-

Andreyak777 » Чт июн 20, 2019 1:12 pm

То, что другие люди говорят обо мне, никак не характеризует меня. Зато отлично характеризует их.

-

Andreyak777

- Избран тонером

-

Andreyak777 » Чт июн 20, 2019 2:47 pm

То, что другие люди говорят обо мне, никак не характеризует меня. Зато отлично характеризует их.

-

Andreyak777

- Избран тонером

-

pc-porta » Чт июн 20, 2019 3:24 pm

Andreyak777 писал(а):Если была бы проблема в контактах, грязь там и все такое, почему он тогда нормально печатает когда загружается с открытой крышкой??

люфтит у Вас драм (шатает его) при закрывании крышки …

Драм совместимка или оригинал ?

Контакты чють подвытянуть в драме или принтаке … для лучшего и надёжного контакта :))

-

pc-porta

- Форумный оракул

-

- Персональный альбом

dviz » Чт июн 20, 2019 7:14 pm

Andreyak777 писал(а):DK3130 изначально стоял, с ним все работало

Оно конечно, хорошо, но это ж не родной — может глюк какой — там в нём плата сопряжения маленькая с микрухой(кто-то на форуме уже писал, что они иногда дохнут) и датчик регистрации лишний (можно попробовать его отключить).

Плюс ещё по 0180 — проверить в U004 не сбойнули ли серийные номера.

-

dviz

- Блуждающий заряд

-

- Персональный альбом

dviz » Пт июн 21, 2019 10:54 am

Надо бы для начала узнать с каких аппаратов и какие модели драмов ставились..

-

dviz

- Блуждающий заряд

-

- Персональный альбом

dviz » Пт июн 21, 2019 2:57 pm

Вытащил из включенного m3040dn dk-3100, установил dk-3130 — работает. Выключил-включил — ошибка c7410. Вернул dk-3100 обратно — всё норм.

В fs-4100 вместо dk-3130 установил dk-3100 — ошибка замятия бумаги — ожидаемо — ведь в dk-3100 нет датчика регистрации и в аппарате нет..

- За это сообщение автора dviz поблагодарил:

- Andreyak777

-

dviz

- Блуждающий заряд

-

- Персональный альбом

dviz » Пт июн 21, 2019 3:51 pm

В аппаратах со скоростью 40-45 стр/мин — fs 2100, m3040, p3045 и т.п. — два датчика регистрации в самом аппарате, поэтому датчик в драме не требуется. Во всех остальных — в самом аппарате один датчик и один в драме.

Тут поправлюсь — в fs2100, m3040, p3045 не два, а только один датчик регистрации — до валов регистрации, а в остальных аппаратах два: один — после валов регистрации, и один — в драме.

Последний раз редактировалось dviz Сб июн 22, 2019 3:42 pm, всего редактировалось 1 раз.

-

dviz

- Блуждающий заряд

-

- Персональный альбом

-

-

[SCANNER ERROR] Lamp Error Kyocera FS-1016

мастерчип в форуме Принтеры, МФУ, факсы, копиры формата A4

- 3

- 6431

Усатый Полосатый

Вс окт 28, 2018 11:08 pm

-

[SCANNER ERROR] Lamp Error Kyocera FS-1016

-

-

Kyocera FS-1120d индикатор «Нет бумаги»

vs-dos в форуме Принтеры, МФУ, факсы, копиры формата A4

- 11

- 14579

СТРОНЦИЙ

Вт ноя 02, 2021 2:24 pm

-

Kyocera FS-1120d индикатор «Нет бумаги»

-

-

Kyocera 1035 «бледная» печать

srMax в форуме Принтеры, МФУ, факсы, копиры формата A4

- 2

- 13541

srMax

Пт янв 23, 2015 2:49 pm

-

Kyocera 1035 «бледная» печать

-

-

Taskalfa 180 ошибка «Е» и «Встряхните картр. с тонером»

manik.76 в форуме Принтеры, МФУ, копиры формата A3

- 3

- 9184

dviz

Пн фев 20, 2017 1:35 pm

-

Taskalfa 180 ошибка «Е» и «Встряхните картр. с тонером»

-

-

Kyocera Ecosys M2635dn «поворот» изображения

Искатель в форуме Принтеры, МФУ, факсы, копиры формата A4

- 10

- 5742

MatrixAgent

Ср апр 08, 2020 5:18 am

-

Kyocera Ecosys M2635dn «поворот» изображения

Вернуться в Принтеры, МФУ, факсы, копиры формата A4

Кто сейчас на форуме

Сейчас этот форум просматривают: нет зарегистрированных пользователей и гости: 96

Правила форума

Картинки и фотографии (если они нужны в сообщении) надо загружать только как вложения к своему сообщению (через кнопку Добавить файлы). Тогда картинки будут автоматически отображаться в сообщении.

-

lamac0

- Сообщения: 4

- Стаж: 3 месяца

KYOCERA P3145DN код ошибки 7410:0035148

Сообщение

lamac0 » 12 окт 2022, 08:49

Всем по привету, при включении данный аппарат говорит обратиться к сервисникам с кодом ошибки 7410:0035148, понимая, что дело где-то в драме зарыто полез копать гуглы, там сказали, что бывает крякает плата на драме, нашел донора, подкинул плату и результата нет, НО! если выдеруть питалово, открыть крышку переднюю, подать питалово, то он работает как ни в чем не бывало, до ребута

-

dviz

- Сообщения: 178

- Стаж: 1 год 1 месяц

- Откуда: Ярославль

- Благодарил (а): 11 раз

- Поблагодарили: 22 раза

-

Репутация:

KYOCERA P3145DN код ошибки 7410:0035148

Сообщение

dviz » 15 окт 2022, 03:41

Если есть донор — то ставьте донора и проверяйте работоспособность. Только хорошо бы конечно быть уверенным, что донор действительно рабочий. Если с открытой крышкой включается, то вероятно он при инициализации не проверяет работоспособность всех компонентов драма, а с закрытой проверяет и что-то его не устраивает — проверьте всё что там подключено к этой платке — датчик тонера, движок подмеса, засветку фотика.

-

- 4 Ответы

- 152 Просмотры

-

Последнее сообщение

22 окт 2022, 21:22

-

- 1 Ответы

- 93 Просмотры

-

Последнее сообщение

19 сен 2022, 07:48

-

- 0 Ответы

- 53 Просмотры

-

Последнее сообщение

13 дек 2022, 19:30

-

- 13 Ответы

- 2616 Просмотры

-

Последнее сообщение

03 фев 2022, 15:54

-

- 6 Ответы

- 2001 Просмотры

-

Последнее сообщение

02 фев 2022, 11:07

Все современные копировальные аппараты, мфу и принтеры Kyocera имеют возможность диагностировать все узлы устройства в режиме запуска и во время работы аппарата. По этому, если во время включения или во время работы произошел сбой, то техника Kyocera сможет сообщить о наличии ошибки.

В большинстве случаев у аппаратов Kyocera код ошибки отображается на дисплее, в остальных случаях тип ошибки зависит от последовательности и количества миганий индикаторов.

Если Ваш копировальный аппарат, МФУ или принтер Kyocera выдал на дисплее некий код, то узнать причину, описание возникновения ошибки, а так же в каком узле аппарата стоит искать проблему, Вы можете в этом разделе выбрав интересующую модель из списка.

Но диагностика не решит проблему сбоя аппарата, для этого лучше обратиться к профессиональным и опытным сервисным специалистам компании Kyomart! Позвоните нам по телефону

8 (343) 288-23-45 или отправьте запрос на электронную почту: sales@kyomart.ru , и мы обязательно свяжемся с Вами в кратчайшие сроки.

Код ошибки

Описание ошибки

Причина ошибки

0030

FAX control PWB system error

Processing with the fax software was disabled due to a hardware problem.

Defective FAX PWB.

0070

FAX PWB incompatible detection Error

Abnormal detection of FAX PWB incompatibility In the initial communication with the FAX PWB, any normal communication command is not transmitted.

Defective fax software. Defective FAX PWB.

0100

Backup memory device error

Defective flash memory. Defective main PWB.

0120

MAC address data error

For data in which the MAC address is invalid.

Defective flash memory. Defective engine PWB.

0130

Backup memory read/write error

Defective flash memory. Defective control PWB.

0140

Backup memory data error

Defective flash memory. Defective control PWB.

0150

Control PWB EEPROM error

Detecting control PWB EEPROM (U17) communication error.

Improper installation control PWB EEPROM (U17). Defective control PWB. Data damage of control PWB EEPROM (U17).

0170

Billing counting error

Defective control PWB. Data damage of control PWB EEPROM (U17).

0180

Machine number mismatch

Machine number of main and engine does not match.

Data damage of control PWB EEPROM (U17).

0420

Paper feeder communication error

Communication error between control PWB and optional paper feeder.

Improper installation paper feeder. Defective harness between control PWB (YC30) and paper feeder interface connector, or improper connector insertion. Defective control PWB. Defective harness between PF main PWB (YC5) and paper feeder interface connector, or improper connector insertion.

0830

FAX PWB flash program area checksum error

A checksum error occurred with the program of the FAX PWB.

Defective fax software. Defective FAX PWB.

0840

Faults of RTC

The time is judged to go back based on the comparison of the RTC time and the current time or five years or more have passed.

Defective control PWB. The battery is disconnected from the control PWB.

0870

FAX PWB to control PWB high capacity data transfer problem

High-capacity data transfer between the FAX PWB and the control PWB of the machine was not normally performed even if the data transfer was retried the specified times.

Improper installation FAX PWB. Defective FAX PWB or control PWB.

0920

Fax file system error

The backup data is not retained for file system abnormality of flash memory of the FAX PWB.

Defective FAX PWB. Defective PF paper feed motor drive transmission system. Defective PF main motor. Defective control PWB.

1010

Lift motor error

During driving the lift motor, a motor overcurrent signal is detected for 5 s. This error is detected five times successively.

Defective bottom plate elevation mechanism in the cassette. Defective connector cable or poor contact in the connector. Defective drive transmission system of the lift motor. Defective lift motor. Defective engine PWB or connect-R PWB.

2000

Main motor error

The main motor ready input is not given for 2 s during the main motor is ON.

Defective harness between main motor (CN1) and control PWB (YC17), or improper connector insertion. Defective drive transmission system of the main motor. Defective main motor. Defective control PWB.

2200

Drum motor steady-state error

The drum motor ready input is not given for 2 s during the drum motor is ON.

Defective connector cable or poor contact in the connector. Defective drive transmission system of the drum motor. Defective drum motor. Defective engine PWB.

3100

ISU home position error

Defective FFC between CCD PWB (YC1) and control PWB (YC8). Defective FFC between control PWB (YC6) and scanner PWB (YC103), or improper FFC insertion. Defective home position sensor. Defective harness between ISU motor and scanner PWB (YC104), or improper connector insertion. Defective ISU motor.

3200

Exposure lamp error

The exposure lamp is not turned on.

Defective FFC between scanner PWB (YC103) and control PWB (YC6), or improper FFC insertion. Defective FFC between CCD PWB (YC1) and control PWB (YC8). Defective harness between CCD PWB (YC3) and inverter PWB (YC101), or improper connector insertion. Defective harness between inverter PWB (YC102) and exposure lamp, or improper connector insertion. Defective exposure lamp. Defective inverter PWB. Defective control PWB.

3300

AGC error

After AGC, correct input is not obtained at CCD.

Defective FFC between CCD PWB (YC1) and control PWB (YC8). Defective exposure lamp. Defective CCD PWB. Defective control PWB.

3500

Communication error between scanner and ASIC

An error code is detected.

Defective connector cable or poor contact in the connector. Defective CCD PWB. Defective main PWB.

4000

Polygon motor (laser scanner unit) error

The polygon motor ready input is not given for 6 s during the polygon motor is ON.

Defective harness between polygon motor and control PWB (YC10), or improper connector insertion. Defective laser scanner unit. Defective control PWB.

4200

BD error (laser scanner unit) error

BD sensor does not detect laser beam due to condensation on the polygon mirror. Defective laser scanner unit. Defective control PWB.

4700

VIDEO ASIC device error

Mismatch of reading data from two locations occurs eight times successively. Mismatch between writing data and reading data occurs eight times successively.

Defective connector cable or poor contact in the connector. Defective main PWB or engine PWB.

4700

VIDEO ASIC device error

Mismatch of reading data from two locations occurs eight times successively. Mismatch between writing data and reading data occurs eight times successively.

Defective connector cable or poor contact in the connector. Defective main PWB or engine PWB.

5100

Main charger high-voltage error

Five pages have been printed with the main charger output short-circuited.

Drum unit installed incorrectly. Engine PWB installed incorrectly. Defective engine PWB.

6000

Broken fuser heater wire

The temperature does not reach 100°C/212°F after the fuser heater has been turned on continuously for 30 s. The temperature does not rise by 1°C/1.8°F after the fuser heater lamp has been turned on continuously for 15 s during warm-up or at standby.(Only when the detection temperature is less than 200°C.)

Defective connector cable or poor contact in the connector. Fuser thermostat triggered. Broken fuser heater wire.

6020

Abnormally high fuser thermistor temperature

Fuser thermistor detects abnormally temperature.

Shorted fuser thermistor. Defective control PWB.

6030

Broken fuser thermistor wire

Input from fuser thermistor is 0 (A/D value).

Poor contact in the fuser thermistor connector terminals. Broken fuser thermistor wire. Fuser thermistor installed incorrectly. Fuser thermal cutout triggered. Fuser heater lamp installed incorrectly. Broken fuser heater lamp wire.

6220

Abnormally high fuser thermistor 1 temperature

The temperature of the fuser thermistor 1 detects 255°C/491°F or more continuously for 3 s.

Shorted fuser thermistor 1. Defective engine PWB.

6230

Broken fuser thermistor 1 wire

average AD value input from fuser thermistor 1 for 1.8 seconds is less than one.

Defective connector cable or poor contact in the connector. Broken fuser thermistor 1 wire. Fuser thermostat triggered. Broken fuser heater wire.

6400

Zero cross signal error

The zero cross signal does not reach the control PWB for specified time.

Defective harness between high voltage PWB (YC202) and control PWB (YC23), or improper connector insertion. Defective connection between power source PWB (YC103) and high voltage PWB (YC201). Defective power source PWB. Defective control PWB.

7000

Toner motor lock error

During driving the toner motor, a motor overcurrent signal is detected for 5 s.

Lump of toner inside toner container. Defective drive transmission system of the toner motor. Defective toner motor. Defective engine PWB.

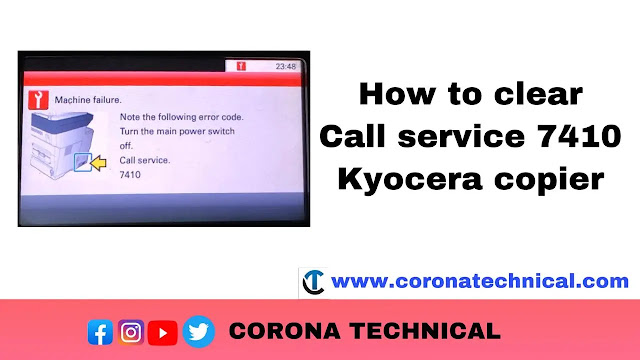

7410

Drum unit non- installing error The drum unit is not installed or not installed properly. The drum PWB EEPROM does not communicate normally.

The drum unit is not installed. Defective connector cable or poor contact in the connector. Defective drum PWB EEPROM. Defective engine PWB.

9500

BRU communication error

IPU PWB error

9510

BRU PWB error

IPU PWB error

9520

BRU PWB data error

IPU PWB error

F000

Main PWB — operation panel PWB communication error

Defective main PWB. Defective operation panel PWB.

F010

Main PWB checksum error

Defective main PWB.

F020

Main PWB RAM checksum error

Defective main memory (RAM) on the main PWB. Defective expanded memory (DIMM).

F040

Main PWB — engine PWB communication error

Defective main PWB. Defective engine PWB.

F041

Main PWB — scanner communication error

Defective main PWB.

F050

Engine ROM checksum error

Defective engine PWB.

F051

Scan engine ROM checksum error

Defective engine PWB.

how to clear call service 7410 in Kyocera fs3540mfp The error displays when you not inserted a drum unit in your printer or the Drum unit not insert.

|

| how to clear call service 7410 in Kyocera fs3540mfp |

The Kyocera fs3540mfp is a B/W printer that has key features

like a large control panel with a touch screen and a speed of 30ppm. It has the

facility for secure id card access. Also, it needs very low maintenance.

Solutions for the call service 7410 in Kyocera fs3540mfp

In this article, we are explaining the solutions for the call for service 7410 in Kyocera FS3040MFP, FS3540, FS3140MFP, and FS1130MFP printer. We will tell you the

solution and the causes behind this error code. You can easily solve it through

the following methods. I hope it will help you to get rid of the error code

easily.

What does the call service 7410 indicates?

The error code call

for service 7410 in Kyocera fs3540mfp printer stands for Drum unit non-

installing error. The error displays when you not inserted a drum unit in your

printer or the Drum unit is not inserted properly. It also occurs if the drum

PWB EEPROM is not done communicating properly. There may be some causes behind

this error,

- If the drum unit is

not inserted or the drum unit is not properly inserted. - Damaged drum PWB

EEPROM. - Damaged connector cable.

- lack of or poor contact in the connector.

- Damaged engine PWB.

How it can be solved?

- Install the drum unit properly.

- Check the connectors

drum PWB (YC1) and Connect-L PWB (YC3). - Reinstall the connector. Check the connector cable and

check the continuity within the connector cable. Replace it if necessary. - Check the drum PWB EEPROM.

- Check the engine PWB, replace it if necessary.

I hope this helps you.

If the error persists after doing the above solutions, you should

contact the Kyocera Customer Service Team for the assistance of an expert.

Share your experience with us through the comment section.

- Code: 0100

- Description: Backup memory device error

- Causes: Defective flash memory.

Defective main PWB. - Remedy: Replace the main PWB and check for correct operation.

- Code: 0120

- Description: MAC address data error

For data in which the MAC address is invalid. - Causes:

- Remedy: Defective flash memory. Replace the main PWB and check for correct operation.

Defective main PWB. Replace the main PWB and check for correct operation.

- Code: 0130

- Description: Backup memory read/write error (main PWB)

- Causes: Defective flash memory.

Defective main PWB. - Remedy: Replace the main PWB and check for correct operation.

- Code: 0140

- Description: Backup memory data error (main PWB)

- Causes: Defective flash memory.

Defective main PWB. - Remedy: Replace the main PWB and check for correct operation.

- Code: 0150

- Description: Backup memory read/write error (engine PWB)

Detecting engine PWB EEPROM communication error. - Causes:

- Remedy: Improper installation engine PWB EEPROM. Check the installation of the EEPROM and remedy if necessary.

Defective engine PWB. Replace the engine PWB and check for correct operation.

Device damage of EEPROM. Contact the Service Administrative Division.

- Code: 0160

- Description: Backup memory data error (engine PWB)

- Causes: Defective EEPROM.

Defective engine PWB. - Remedy: Replace the main PWB and check for correct operation.

- Code: 0170

- Description: Billing counting error

A checksum error is detected in the main and engine backup memories for the billing counters. - Causes:

- Remedy: Data damage of EEPROM. Contact the Service Administrative Division.

Defective PWB. Replace the main PWB or the engine PWB and check for correct operation.

- Code: 0190

- Description: Backup memory device error (engine PWB)

- Causes: Defective engine PWB.

- Remedy: Replace the engine PWB and check for correct operation.

- Code: 0800

- Description: Image processing error

JAM010x is detected twice. - Causes:

- Remedy: Defective connector cable or poor contact in the connector. Reinsert the connector. Also check for continuity within the connector cable. If none, replace the cable. Fuser thermistor 1/2 and fuser thermistor connect PWB(YC1/2) Fuser thermistor connect PWB(YC3) and engine PWB (YC21)

Defective fuser thermistor. Replace the fuser thermistor connect PWB. Replace the fuser unit.

Defective engine PWB. Replace the engine PWB and check for correct operation.

Defective main PWB. Replace the main PWB and check for correct operations.

- Code: 0840

- Description: Faults of RTC

Unable to communicate with the RTC device normally. The RTC data is mismatched due to dead battery or short-circuit with the metal part. - Causes:

- Remedy: Other RTC device failure due to dead battery or short-circuit with the metal part. Restart the main unit and set the correct time from the operation panel. Repair it if the battery comes off from the main PWB.

Defective main PWB. Replace the main PWB and check for correct operation.

- Code: 1010

- Description: Lift motor error

After cassette 1 is inserted, lift sensor does not turn on within 10 s. This error is detected five times successively. - Causes:

- Remedy: Defective bottom plate elevation mechanism in the cassette. Check to see if the bottom plate can move smoothly and repair it if any problem is found.

Defective connector cable or poor contact in the connector. Reinsert the connector. Also check for continuity within the connector cable. If none, replace the cable. Lift motor and engine PWB (YC13)

Defective drive transmission system of the lift motor. Check if the gears rotate smoothly. If not, grease the bushes and gears. Check for broken gears and replace if any.

Defective lift motor. Replace the lift motor.

Defective engine PWB. Replace the engine PWB and check for correct operation.

- Code: 1020

- Description: PF lift motor 1 error (paper feeder)

After cassette 2 is inserted, PF lift sensor 1 does not turn on. This error is detected four times successively. - Causes:

- Remedy: Defective bottom plate elevation mechanism in the cassette. Check to see if the bottom plate can move smoothly and repair it if any problem is found.

Defective connector cable or poor contact in the connector. Reinsert the connector. Also check for continuity within the connector cable. If none, replace the cable. PF lift motor 1 and PF main PWB (YC7)

Defective drive transmission system of the PF lift motor. Check if the gears rotate smoothly. If not, grease the bushes and gears. Check for broken gears and replace if any.

Defective PF lift motor. Replace the PF lift motor 1.

Defective PF main PWB. Replace the PF main PWB.

- Code: 1030

- Description: PF lift motor 2 error (paper feeder)

After cassette 3 is inserted, PF lift sensor 2 does not turn on. This error is detected four times successively. - Causes:

- Remedy: Defective bottom plate elevation mechanism in the cassette. Check to see if the bottom plate can move smoothly and repair it if any problem is found.

Defective connector cable or poor contact in the connector. Reinsert the connector. Also check for continuity within the connector cable. If none, replace the cable. PF lift motor 2 and PF main PWB (YC7)

Defective drive transmission system of the PF lift motor. Check if the gears rotate smoothly. If not, grease the bushes and gears. Check for broken gears and replace if any.

Defective PF lift motor. Replace the PF lift motor 2.

Defective PF main PWB. Replace the PF main PWB.

- Code: 1040

- Description: PF lift motor 3 error (paper feeder)

After cassette 4 is inserted, PF lift sensor 3 does not turn on. This error is detected four times successively. - Causes:

- Remedy: Defective bottom plate elevation mechanism in the cassette. Check to see if the bottom plate can move smoothly and repair it if any problem is found.

Defective connector cable or poor contact in the connector. Reinsert the connector. Also check for continuity within the connector cable. If none, replace the cable. PF lift motor 3 and PF main PWB (YC7)

Defective drive transmission system of the PF lift motor. Check if the gears rotate smoothly. If not, grease the bushes and gears. Check for broken gears and replace if any.

Defective PF lift motor. Replace the PF lift motor 3.

Defective PF main PWB. Replace the PF main PWB.

- Code: 1050

- Description: PF lift motor 4 error (paper feeder)

After cassette 5 is inserted, PF lift sensor 4 does not turn on. This error is detected four times successively. - Causes:

- Remedy: Defective bottom plate elevation mechanism in the cassette. Check to see if the bottom plate can move smoothly and repair it if any problem is found.

Defective connector cable or poor contact in the connector. Reinsert the connector. Also check for continuity within the connector cable. If none, replace the cable. PF lift motor 4 and PF main PWB (YC7)

Defective drive transmission system of the PF lift motor. Check if the gears rotate smoothly. If not, grease the bushes and gears. Check for broken gears and replace if any.

Defective PF lift motor. Replace the PF lift motor 4.

Defective PF main PWB. Replace the PF main PWB.

- Code: 1140

- Description: BPF lift motor upward error (Bulk paper feeder)

BPF lift maximum sensor does not turn on. The lock signal of the motor is detected continuously three times. - Causes:

- Remedy: Defective connector cable or poor contact in the connector. Reinsert the connector. Also check for continuity within the connector cable. If none, replace the cable. BPF lift motor and BPF main PWB (YC4)

Defective drive transmission system of the motor. Check if the gears rotate smoothly. If not, grease the bushes and gears. Check for broken gears and replace if any.

Defective BPF lift motor. Replace the BPF lift motor.

Defective BPF main PWB. Replace the BPF main PWB.

- Code: 1150

- Description: BPF lift motor downward error (Bulk paper feeder)

BPF lift minimum sensor does not turn on. The lock signal of the motor is detected continuously three times. When detecting an overcurrent detection signal. - Causes:

- Remedy: Defective connector cable or poor contact in the connector. Reinsert the connector. Also check for continuity within the connector cable. If none, replace the cable. BPF lift motor and BPF main PWB (YC4)

Defective drive transmission system of the motor. Check if the gears rotate smoothly. If not, grease the bushes and gears. Check for broken gears and replace if any.

Defective BPF lift motor. Replace the BPF lift motor.

Defective BPF main PWB. Replace the BPF main PWB.

- Code: 1800

- Description: Paper feeder 1 communication error

A communication error is detected 10 times in succession. - Causes:

- Remedy: Improper installation paper feeder. Follow installation instruction carefully again.

Defective connector cable or poor contact in the connector. Reinsert the connector. Also check for continuity within the connector cable. If none, replace the cable. PF main PWB (YC3) and engine PWB (YC22)

Defective engine PWB. Replace the engine PWB and check for correct operation.

Defective PF main PWB. Replace the PF main PWB.

- Code: 1810

- Description: Paper feeder 2 communication error

A communication error is detected 10 times in succession. - Causes:

- Remedy: Improper installation paper feeder. Follow installation instruction carefully again.

Defective connector cable or poor contact in the connector. Reinsert the connector. Also check for continuity within the connector cable. If none, replace the cable. PF main PWB (YC3) and engine PWB (YC22)

Defective PF main PWB. Replace the PF main PWB.

- Code: 1820

- Description: Paper feeder 3 communication error

A communication error is detected 10 times in succession. - Causes:

- Remedy: Improper installation paper feeder. Follow installation instruction carefully again.

Defective connector cable or poor contact in the connector. Reinsert the connector. Also check for continuity within the connector cable. If none, replace the cable. PF main PWB (YC3) and engine PWB (YC22)

Defective PF main PWB. Replace the PF main PWB.

- Code: 1830

- Description: Paper feeder 4 communication error

A communication error is detected 10 times in succession. - Causes:

- Remedy: Improper installation paper feeder. Follow installation instruction carefully again.

Defective connector cable or poor contact in the connector. Reinsert the connector. Also check for continuity within the connector cable. If none, replace the cable. PF main PWB (YC3) and engine PWB (YC22)

Defective PF main PWB. Replace the PF main PWB.

- Code: 1900

- Description: Paper feeder 1/BPF paper feeder EEPROM error

When writing the data, the write data and the read data is not in agreement. - Causes: Defective PF main PWB.

Device damage of EEPROM. - Remedy: Replace the PF main PWB or the BPF main PWB.

- Code: 1910

- Description: Paper feeder 2 EEPROM error

When writing the data, the write data and the read data is not in agreement. - Causes: Defective PF main PWB.

Device damage of EEPROM. - Remedy: Replace the PF main PWB.

- Code: 1920

- Description: Paper feeder 3 EEPROM error

When writing the data, the write data and the read data is not in agreement. - Causes: Defective PF main PWB.

Device damage of EEPROM. - Remedy: Replace the PF main PWB.

- Code: 1930

- Description: Paper feeder 4 EEPROM error

When writing the data, the write data and the read data is not in agreement. - Causes: Defective PF main PWB.

Device damage of EEPROM. - Remedy: Replace the PF main PWB.

- Code: 2000

- Description: Main motor drive error

The main motor is not stabilized within 2 s after driving starts. - Causes:

- Remedy: Defective connector cable or poor contact in the connector. Reinsert the connector. Also check for continuity within the connector cable. If none, replace the cable. Main motor and engine PWB (YC4)

Defective drive transmission system of the main motor. Check if the rollers and gears rotate smoothly. If not, grease the bushes and gears. Check for broken gears and replace if any.

Defective main motor. Replace the main motor.

Defective engine PWB. Replace the engine PWB and check for correct operation.

- Code: 2010

- Description: Main motor steady-state error

Stable OFF is detected for 2 s continuously after main motor stabilized. - Causes:

- Remedy: Defective connector cable or poor contact in the connector. Reinsert the connector. Also check for continuity within the connector cable. If none, replace the cable. Main motor and engine PWB (YC4)

Defective drive transmission system of the main motor. Check if the rollers and gears rotate smoothly. If not, grease the bushes and gears. Check for broken gears and replace if any.

Defective main motor. Replace the main motor.

Defective engine PWB. Replace the engine PWB and check for correct operation.

- Code: 2200

- Description: Drum motor drive error

The drum motor is not stabilized within 2 s after driving starts. - Causes:

- Remedy: Defective connector cable or poor contact in the connector. Reinsert the connector. Also check for continuity within the connector cable. If none, replace the cable. Drum motor and engine PWB (YC4)

Defective drive transmission system of the drum motor. Check if the rollers and gears rotate smoothly. If not, grease the bushes and gears. Check for broken gears and replace if any.

Defective drum motor. Replace the drum motor.

Defective engine PWB. Replace the engine PWB and check for correct operation.

- Code: 2210

- Description: Drum motor steady-state error

Stable OFF is detected for 2 s continuously after drum motor stabilized. - Causes:

- Remedy: Defective connector cable or poor contact in the connector. Reinsert the connector. Also check for continuity within the connector cable. If none, replace the cable. Drum motor and engine PWB (YC4)

Defective drive transmission system of the drum motor. Check if the rollers and gears rotate smoothly. If not, grease the bushes and gears. Check for broken gears and replace if any.

Defective drum motor. Replace the drum motor.

Defective engine PWB. Replace the engine PWB and check for correct operation.

- Code: 2330

- Description: Fuser pressure release motor error (Over-current)

The over-current detection signal of the motor is detected continuously twenty times. - Causes:

- Remedy: Defective connector cable or poor contact in the connector. Reinsert the connector. Also check for continuity within the connector cable. If none, replace the cable. Fuser pressure release motor and relay-L PWB(YC11) Relay-L PWB(YC3) and engine PWB(YC2)

Defective drive transmission system of the fuser pressure release motor. Check if the gears rotate smoothly. If not, grease the bushes and gears. Check for broken gears and replace if any.

Defective fuser pressure release motor. Replace the fuser pressure release motor.

Defective PWB. Replace the relay-L PWB or engine PWB.

- Code: 2340

- Description: Fuser pressure release motor error (Timeout)

The position detection sensor is not detected continuously for 30 s. - Causes:

- Remedy: Defective connector cable or poor contact in the connector. Reinsert the connector. Also check for continuity within the connector cable. If none, replace the cable. Fuser pressure release motor and relay-L PWB(YC11) Relay-L PWB(YC1) and engine PWB(YC2)

Defective drive transmission system of the fuser pressure release motor. Check if the gears rotate smoothly. If not, grease the bushes and gears. Check for broken gears and replace if any.

Defective fuser pressure release motor. Replace the fuser pressure release motor.

Defective PWB. Replace the relay-L PWB or engine PWB.

- Code: 2600

- Description: PF drive motor 1 error (paper feeder 1)

When the PF drive motor is driven, error signal is detected continuously for 2 s. - Causes:

- Remedy: Defective connector cable or poor contact in the connector. Reinsert the connector. Also check for continuity within the connector cable. If none, replace the cable. PF drive motor 1 and PF main PWB (YC6)

Defective drive transmission system of the PF drive motor. Check if the rollers and gears rotate smoothly. If not, grease the bushes and gears. Check for broken gears and replace if any.

Defective PF drive motor. Replace the PF drive motor 1.

Defective PF main PWB. Replace the PF main PWB.

- Code: 2610

- Description: PF drive motor 2 error (paper feeder 2)

When the PF drive motor is driven, error signal is detected continuously for 2 s. - Causes:

- Remedy: Defective connector cable or poor contact in the connector. Reinsert the connector. Also check for continuity within the connector cable. If none, replace the cable. PF drive motor 2 and PF main PWB (YC6)

Defective drive transmission system of the PF drive motor. Check if the rollers and gears rotate smoothly. If not, grease the bushes and gears. Check for broken gears and replace if any.

Defective PF drive motor. Replace the PF drive motor 2.

Defective PF main PWB. Replace the PF main PWB.

- Code: 2620

- Description: PF drive motor 3 error (paper feeder 3)

When the PF drive motor is driven, error signal is detected continuously for 2 s. - Causes:

- Remedy: Defective connector cable or poor contact in the connector. Reinsert the connector. Also check for continuity within the connector cable. If none, replace the cable. PF drive motor 3 and PF main PWB (YC6)

Defective drive transmission system of the PF drive motor. Check if the rollers and gears rotate smoothly. If not, grease the bushes and gears. Check for broken gears and replace if any.

Defective PF drive motor. Replace the PF drive motor 3.

Defective PF main PWB. Replace the PF main PWB.

- Code: 2630

- Description: PF drive motor 4 error (paper feeder 4)

When the PF drive motor is driven, error signal is detected continuously for 2 s. - Causes:

- Remedy: Defective connector cable or poor contact in the connector. Reinsert the connector. Also check for continuity within the connector cable. If none, replace the cable. PF drive motor 4 and PF main PWB (YC6)

Defective drive transmission system of the PF drive motor. Check if the rollers and gears rotate smoothly. If not, grease the bushes and gears. Check for broken gears and replace if any.

Defective PF drive motor. Replace the PF drive motor 4.

Defective PF main PWB. Replace the PF main PWB.

- Code: 4000

- Description: Polygon motor synchronization error

The polygon motor is not stabilized within 20 s after driving starts. - Causes:

- Remedy: Defective connector cable or poor contact in the connector. Reinsert the connector. Also check for continuity within the connector cable. If none, replace the cable. Polygon motor and engine PWB (YC15)

Defective polygon motor. Replace the laser scanner unit.

Defective engine PWB. Replace the engine PWB and check for correct operation.

- Code: 4101

- Description: BD steady-state error

When the value of Register BDSET is 1 after setting Register BDSET as one and passing by BD1 cycle. - Causes:

- Remedy: Defective connector cable or poor contact in the connector. Reinsert the connector. Also check for continuity within the connector cable. If none, replace the cable. APC PWB(YC1) and engine PWB (YC16) APC PWB(YC2) and PD PWB(YC1)

Defective PD PWB. Replace the laser scanner unit.

Defective engine PWB. Replace the engine PWB and check for correct operation.

- Code: 5100

- Description: Chager current error When the current value measured at the time of potential adjustment is less than 20 uA.

- Causes:

- Remedy: Defective connector cable or poor contact in the connector. Reinsert the connector. Also check for continuity within the connector cable. If none, replace the cable. Chager unit and high voltage PWB High voltage PWB (YC101) and engine PWB (YC19)

Defective high voltage PWB. Replace the high voltage PWB and check for correct operation.

Defective engine PWB. Replace the engine PWB and check for correct operation.

- Code: 6000

- Description: Broken fuser heater wire

The detection temperature of fuser thermistor 2 is 100 °C/212°F or less after the fuser heater lamp has been turned on continuously for 30 s. - Causes:

- Remedy: Defective connector cable or poor contact in the connector. Reinsert the connector. Also check for continuity within the connector cable. If none, replace the cable. Fuser heater and power source PWB (YC2) Fuser thermistor and Fuser thermistor connect PWB(YC1 and YC2) Fuser thermistor connect PWB(YC3) and engine PWB (YC21)

Deformed connector pin.

Defective triac.

Fuser thermostat triggered. Reinsert the fuser unit.

Broken fuser heater wire.

Defective engine PWB. Replace the engine PWB and check for correct operation.

- Code: 6020

- Description: Abnormally high fuser thermistor 2 temperature

The detection temperature of fuser thermistor 2 is higher than 235°C/ 455°F.

In a heater-off state, the detection temperature of fuser thermistor 2 is higher than 195°C/383°F after the detection temperature of fuser thermistor 2 was 155°C/311°F or less. - Causes:

- Remedy: Deformed connector pin.

Defective triac.

Shorted fuser thermistor. Replace the fuser unit.

Defective engine PWB. Replace the engine PWB and check for correct operation.

- Code: 6030

- Description: Broken fuser thermistor 2 wire

A/D value of the fuser thermistor 2 exceeds 1019 bit continuously for 4 s during warming up. - Causes:

- Remedy: Defective connector cable or poor contact in the connector. Reinsert the connector. Also check for continuity within the connector cable. If none, replace the cable. Fuser thermistor and fuser thermistor connect PWB(YC2) Fuser thermistor connect PWB(YC3) and engine PWB (YC21)

Deformed connector pin.

Defective triac.

Defective fuser thermistor. Replace the fuser unit.

Defective engine PWB. Replace the engine PWB and check for correct operation.

- Code: 6120

- Description: Abnormally high fuser thermistor 1 temperature

The detection temperature of fuser thermistor 1 is higher than 245°C/ 473°F.

In a heater-off state, the detection temperature of fuser thermistor 1 is higher than 195°C/383°F after the detection temperature of fuser thermistor 1 was 155°C/311°F or less. - Causes:

- Remedy: Deformed connector pin.

Defective triac.

Shorted fuser thermistor. Replace the fuser unit.

Defective engine PWB. Replace the engine PWB and check for correct operation.

- Code: 6130

- Description: Broken fuser thermistor 1 wire

A/D value of the fuser thermistor 1 exceeds 1019 bit continuously for 4 s during warming up. - Causes:

- Remedy: Defective connector cable or poor contact in the connector. Reinsert the connector. Also check for continuity within the connector cable. If none, replace the cable. Fuser thermistor and fuser thermistor connect PWB(YC1) Fuser thermistor connect PWB(YC3) and engine PWB (YC21)

Deformed connector pin.

Defective triac.

Defective fuser thermistor. Replace the fuser unit.

Defective engine PWB. Replace the engine PWB and check for correct operation.

- Code: 6400

- Description: Zero-cross signal error

While fuser heater control is performed, the zero-cross signal is not input within 2 s. - Causes:

- Remedy: Defective connector cable or poor contact in the connector. Reinsert the connector. Also check for continuity within the connector cable. If none, replace the cable. Power source PWB (YC3) and engine PWB (YC1)

Defective power source PWB or engine PWB. Replace the power source PWB or the engine PWB and check for correct operation.

- Code: 7100

- Description: Toner sensor error

Sensor output value of 930 or more continuously for 5 s. - Causes:

- Remedy: Defective connector cable or poor contact in the connector. Reinsert the connector. Also check for continuity within the connector cable. If none, replace the cable. Toner sensor and drum PWB (YC3) Drum connect PWB(YC2) and relay-L PWB (YC3) Relay-L PWB(YC1) and engine PWB (YC2)

Defective toner sensor. Replace the developer unit.

Defective engine PWB. Replace the engine PWB and check for correct operation.

- Code: 7400

- Description: Developer unit non-installing error

Sensor output value of 31 or less continuously for 5 s. - Causes:

- Remedy: Defective connector cable or poor contact in the connector. Reinsert the connector. Also check for continuity within the connector cable. If none, replace the cable. Toner sensor and drum PWB (YC3) Drum connect PWB(YC2) and relay-L PWB (YC3) Relay-L PWB(YC1) and engine PWB (YC2)

Defective toner sensor. Replace the developer unit.

Defective engine PWB. Replace the engine PWB and check for correct operation.

- Code: 7410

- Description: Drum unit type mismatch error

The drum PWB EEPROM does not communicate normally. Absence of the drum unit is detected. - Causes:

- Remedy: Defective connector cable or poor contact in the connector. Reinsert the connector. Also check for continuity within the connector cable. If none, replace the cable. Drum unit and drum connect PWB (YC1) Drum connect PWB(YC2) and relay-L PWB (YC3) Relay-L PWB(YC1) and engine PWB (YC2)

Defective toner sensor. Replace the drum unit.

Defective engine PWB. Replace the engine PWB and check for correct operation.

- Code: 7800

- Description: Broken external thermistor wire

The average of thermistor output value of 93 or less. - Causes:

- Remedy: Defective connector cable or poor contact in the connector. Reinsert the connector. Also check for continuity within the connector cable. If none, replace the cable. Operation PWB (YC1) and engine PWB (YC17)

Defective temperature sensor. Replace the operation PWB.

- Code: 7810

- Description: Short-circuited external thermistor wire

The average of thermistor output value of 930 or more. - Causes:

- Remedy: Defective connector cable or poor contact in the connector. Reinsert the connector. Also check for continuity within the connector cable. If none, replace the cable. Operation PWB (YC1) and engine PWB (YC17)

Defective temperature sensor. Replace the operation PWB.

- Code: 7900

- Description: Drum unit EEPROM error

No response is issued from the device in reading/writing for 5 ms or more and this problem is repeated five times successively. Mismatch of reading data from two locations occurs eight times successively. Mismatch between writing data and reading data occurs eight times successively. - Causes:

- Remedy: Defective connector cable or poor contact in the connector. Reinsert the connector. Also check for continuity within the connector cable. If none, replace the cable. Drum unit and drum connect PWB (YC1) Drum connect PWB(YC2) and relay-L PWB (YC3) Relay-L PWB(YC1) and engine PWB (YC2)

Defective drum unit. Replace the drum unit.

- Code: F000

- Description: Main PWB — operation PWB communication error

- Causes:

- Remedy: Defective connector cable or poor contact in the connector. Reinsert the connector. Also check for continuity within the connector cable. If none, replace the cable. Operation PWB(YC1) and engine PWB (YC17)

Defective main PWB. Turn the main power switch off/on to restart the machine. If the error is not resolved, replace main PWB.

Defective operation PWB. Replace the operation PWB and check for correct operation.

- Code: F010

- Description: Main PWB checksum error

- Causes: Defective main PWB.

- Remedy: Turn the main power switch off/on to restart the machine. If the error is not resolved, replace main PWB.

- Code: F020

- Description: Main PWB RAM checksum error

- Causes:

- Remedy: Defective main memory (RAM) in main PWB Turn the main power switch off/on to restart the machine. If the error is not resolved, replace main PWB.

Defective expended memory (DIMM) Replace the expansion memory (DIMM). Also in the case of the capacity besides specification, it displays.

- Code: F040

- Description: Main PWB — print engine communication error

- Causes:

- Remedy: Defective main PWB. Turn the main power switch off/on to restart the machine. If the error is not resolved, replace main PWB.

Defective engine PWB. Replace the engine PWB and check for correct operation.

- Code: F050

- Description: Print engine ROM checksum error

- Causes: Defective engine PWB.

- Remedy: Turn the main power switch off/on to restart the machine. If the error is not resolved, replace engine PWB.

- Code: F050

- Description: Print engine ROM checksum error

- Causes: Defective engine PWB.

- Remedy: Turn the main power switch off/on to restart the machine. If the error is not resolved, replace engine PWB.