-

Alex12

- Увидел чернила

-

- Сайт

Alex12 » Вт июл 28, 2020 12:34 pm

Goldwater писал(а):Есть два варианта решения проблемы: японский подороже но побыстрее и русский подешевле но подольше.

Оба начинаются с обязательного обновления прошивки.

Вам который?

Прошивка не помогла, рассмотрю оба варианта.

-

Alex12

- Увидел чернила

-

- Сайт

-

-

Kyocera FS-1120d индикатор «Нет бумаги»

vs-dos в форуме Принтеры, МФУ, факсы, копиры формата A4

- 11

- 15427

СТРОНЦИЙ

Вт ноя 02, 2021 2:24 pm

-

Kyocera FS-1120d индикатор «Нет бумаги»

-

-

[SCANNER ERROR] Lamp Error Kyocera FS-1016

мастерчип в форуме Принтеры, МФУ, факсы, копиры формата A4

- 3

- 6736

Усатый Полосатый

Вс окт 28, 2018 11:08 pm

-

[SCANNER ERROR] Lamp Error Kyocera FS-1016

-

-

Kyocera 1035 «бледная» печать

srMax в форуме Принтеры, МФУ, факсы, копиры формата A4

- 2

- 14198

srMax

Пт янв 23, 2015 2:49 pm

-

Kyocera 1035 «бледная» печать

-

-

Kyocera Ecosys M2635dn «поворот» изображения

Искатель в форуме Принтеры, МФУ, факсы, копиры формата A4

- 10

- 6312

MatrixAgent

Ср апр 08, 2020 5:18 am

-

Kyocera Ecosys M2635dn «поворот» изображения

-

-

Стирание вала ведущей шестерни в «печке» Kyocera M2035dn

Грецкий орех в форуме Принтеры, МФУ, факсы, копиры формата A4

- 12

- 3777

СТРОНЦИЙ

Пн дек 13, 2021 3:35 pm

-

Стирание вала ведущей шестерни в «печке» Kyocera M2035dn

Вернуться в Принтеры, МФУ, копиры формата A3

Кто сейчас на форуме

Сейчас этот форум просматривают: нет зарегистрированных пользователей и гости: 10

Code

0000

Initial jam

0100

Secondary feeding timeout

0101

Wait for ready of print-process

package

0104

Wait for ready of conveying

package

0105

Driving prevention

0106

Paper feeding request for

duplex printing time out

0107

Wait for ready of fuser pack-

age

0110

Rear cover open

0111

Top cover open

0120

Receiving a duplex paper

feeding request while paper is

empty

0121

Exceeding number of duplex

pages circulated

0501

No paper feed of jam

0502

0503

0504

0505

0508

0509

Contents

The power is turned on when a sensor in the con-

veying system is on.

Secondary paper feed request given by the con-

troller is unreachable.

Process package won’t become ready.

Conveying package won’t become ready.

A drive does not stop.

Paper feeding request for duplex printing given by

the controller is unreachable.

Fuser package won’t become ready.

The rear cover is opened during printing.

The top cover is opened during printing.

Paper feed request was received from the duplex

section despite the absence of paper in the

duplex section.

The controller issued the duplex section a request

for more pages than the duplex print cycle con-

tains.

The registration sensor 1 (RS1)*1 or sensor 3

(RS3)*2 does not turn on during paper feed from

cassette 1.

PF feed sensor 1 (PFFS1) does not turn on dur-

ing paper feed from cassette 2.

PF feed sensor 2 (PFFS2) does not turn on dur-

ing paper feed from cassette 3.

PF feed sensor 3 (PFFS3) does not turn on dur-

ing paper feed from cassette 4.

PF feed sensor 4 (PFFS4) does not turn on dur-

ing paper feed from cassette 5.

The registration sensor 1 (RS1)*1 or sensor 3

(RS3)*2 does not turn on during paper feed from

duplex section.

The registration sensor 1 (RS1)*1 or sensor 3

(RS3)*2 does not turn on during paper feed from

MP tray.

Conditions

1-4-3

2NM/2NX/2NY/2NZ/2P0/2P6

Jam

location*

H

H

H

H

H

B

—

I

—

—

I

I

1

2

3

4

5

I

-

Alex12

- Увидел чернила

-

- Сайт

Alex12 » Вт июл 28, 2020 12:34 pm

Goldwater писал(а):Есть два варианта решения проблемы: японский подороже но побыстрее и русский подешевле но подольше.

Оба начинаются с обязательного обновления прошивки.

Вам который?

Прошивка не помогла, рассмотрю оба варианта.

-

Alex12

- Увидел чернила

-

- Сайт

-

- [SCANNER ERROR] Lamp Error Kyocera FS-1016

мастерчип в форуме Принтеры, МФУ, факсы, копиры формата A4

- 3

- 6431

Усатый Полосатый

Вс окт 28, 2018 11:08 pm

- [SCANNER ERROR] Lamp Error Kyocera FS-1016

-

- Kyocera 1035 «бледная» печать

srMax в форуме Принтеры, МФУ, факсы, копиры формата A4

- 2

- 13540

srMax

Пт янв 23, 2015 2:49 pm

- Kyocera 1035 «бледная» печать

-

- Kyocera FS-1120d индикатор «Нет бумаги»

vs-dos в форуме Принтеры, МФУ, факсы, копиры формата A4

- 11

- 14579

СТРОНЦИЙ

Вт ноя 02, 2021 2:24 pm

- Kyocera FS-1120d индикатор «Нет бумаги»

-

- Kyocera Ecosys M2635dn «поворот» изображения

Искатель в форуме Принтеры, МФУ, факсы, копиры формата A4

- 10

- 5742

MatrixAgent

Ср апр 08, 2020 5:18 am

- Kyocera Ecosys M2635dn «поворот» изображения

-

- Стирание вала ведущей шестерни в «печке» Kyocera M2035dn

Грецкий орех в форуме Принтеры, МФУ, факсы, копиры формата A4

- 12

- 2898

СТРОНЦИЙ

Пн дек 13, 2021 3:35 pm

- Стирание вала ведущей шестерни в «печке» Kyocera M2035dn

Вернуться в Принтеры, МФУ, копиры формата A3

Кто сейчас на форуме

Сейчас этот форум просматривают: нет зарегистрированных пользователей и гости: 16

Все современные копировальные аппараты, мфу и принтеры Kyocera имеют возможность диагностировать все узлы устройства в режиме запуска и во время работы аппарата. По этому, если во время включения или во время работы произошел сбой, то техника Kyocera сможет сообщить о наличии ошибки.

В большинстве случаев у аппаратов Kyocera код ошибки отображается на дисплее, в остальных случаях тип ошибки зависит от последовательности и количества миганий индикаторов.

Если Ваш копировальный аппарат, МФУ или принтер Kyocera выдал на дисплее некий код, то узнать причину, описание возникновения ошибки, а так же в каком узле аппарата стоит искать проблему, Вы можете в этом разделе выбрав интересующую модель из списка.

Но диагностика не решит проблему сбоя аппарата, для этого лучше обратиться к профессиональным и опытным сервисным специалистам компании Kyomart! Позвоните нам по телефону

8 (343) 288-23-45 или отправьте запрос на электронную почту: sales@kyomart.ru , и мы обязательно свяжемся с Вами в кратчайшие сроки.

| Код ошибки | Описание ошибки | Причина ошибки |

|---|---|---|

| 0030 | FAX control PWB system error Processing with the fax software was disabled due to a hardware problem. |

Defective FAX control PWB. |

| 0060 | Engine PWB type error | Defective engine sub PCB. |

| 0070 | FAX control PWB incompatible detection error Abnormal detection of FAX control PWB incompatibility In the initial communication with the FAX control PWB, any normal communication command is not transmitted. |

Defective FAX software Defective FAX control PWB. |

| 0100 | Backup memory device error | Defective flash memory. |

| 0120 | MAC address data error For data in which the MAC address is invalid. |

Defective main PWB. Defective flash memory. Defective engine PWB. |

| 0130 | Backup memory read/write error (main PWB) | Defective flash memory. Defective main PWB. |

| 0140 | Backup memory data error (main PWB) | Defective flash memory. Defective main PWB. |

| 0150 | Backup memory read/write error (engine PWB) Detecting engine PWB EEPROM communication error. |

Improper installation engine PWB EEPROM. Defective engine PWB. Device damage of EEPROM. |

| 0160 | Backup memory data error (engine PWB) | Defective flash memory. Defective engine PWB. |

| 0170 | Billing counting error A checksum error is detected in the main and engine backup memories for the billing counters. |

Data damage of EEPROM. Defective PWB. |

| 0180 | Machine number mismatch Machine number of main and engine does not match. |

Data damage of EEPROM. |

| 0320 | I/O CPU communication error A communication error is detected 10 times in succession. |

Defective PWB. |

| 0630 | DMA error DMA transmission of image data does not complete within the specified period of time. | Poor contact in the connector terminals. Defective main PWB. |

| 0800 | Image processing error JAM05 is detected twice. |

Defective main PWB. |

| 0830 | FAX control PWB flash program area checksum error A checksum error occurred with the program of the FAX control PWB. |

Defective FAX software. Defective FAX control PWB. |

| 0840 | Faults of RTC The time is judged to go back based on the comparison of the RTC time and the current time or five years or more have passed. |

The battery is disconnected from the main PWB. Defective main PWB. |

| 0870 | FAX control PWB to main PWB high capacity data transfer error High-capacity data transfer between the FAX control PWB and the main PWB of the machine was not normally performed even if the data transfer was retried the specified times. |

Improper installation FAX control PWB. Defective FAX control PWB or main PWB. |

| 0920 | Fax file system error The backup data is not retained for file system abnormality of flash memory of the FAX control PWB. |

Defective FAX control PWB. |

| 1010 | Lift motor error After cassette 1 is inserted, lift sensor does not turn on within 12 s. This error is detected four times successively. |

Defective bottom plate elevation mechanism in the cassette. Defective connector cable or poor contact in the connector. Defective drive transmission system of the lift motor. Defective lift motor. Defective engine PWB. |

| 1020 | PF lift motor error (paper feeder) After cassette 2 is inserted, PF lift sensor 1 does not turn on within 12 s. This error is detected four times successively. |

Defective bottom plate elevation mechanism in the cassette. Defective connector cable or poor contact in the connector. Defective drive transmission system of the PF lift motor 1. Defective PF lift motor 1. Defective PF main PWB. |

| 1030 | PF lift motor error (paper feeder) After cassette 3 is inserted, PF lift sensor 2 does not turn on within 12 s. This error is detected four times successively. |

Defective bottom plate elevation mechanism in the cassette. Defective connector cable or poor contact in the connector. Defective drive transmission system of the PF lift motor 2. Defective PF lift motor 2. Defective PF main PWB. |

| 1800 | Paper feeder communication error A communication error is detected 10 times in succession. |

Improper installation paper feeder. Defective connector cable or poor contact in the connector. Defective engine PWB. Defective PF main PWB. |

| 1900 | Paper feeder EEPROM error When writing the data, the write data and the read data is not continuously in agreement 5 times. |

Defective PF main PWB. Device damage of EEPROM. |

| 2000 | Main motor steady-state error Stable OFF is detected for 1 s continuously after main motor stabilized. |

Defective connector cable or poor contact in the connector. Defective drive transmission system of the main motor. Defective main motor. Defective engine PWB. |

| 2010 | Main motor drive error The main motor is not stabilized within 2 s after driving starts. |

Defective connector cable or poor contact in the connector. Defective drive transmission system of the main motor. Defective main motor. Defective engine PWB. |

| 2600 | PF drive motor error (paper feeder) When the PF drive motor is driven, error signal is detected continuously for 1 s. |

Defective connector cable or poor contact in the connector. Defective drive transmission system of the PF drive motor. Defective PF drive motor. Defective PF main PWB. |

| 3100 | ISU home position error The home position is not correct when the power is turned on or at the start of copying using the table. |

Defective connector cable or poor contact in the connector. Defective home position sensor. Defective ISU motor. Defective CCD PWB. Defective engine PWB. |

| 3200 | Exposure lamp error When input value at the time of exposure lamp illumination does not exceed the threshold value between 5 s. |

Defective connector cable or poor contact in the connector. Defective exposure lamp. Defective CCD PWB. Defective main PWB. |

| 3500 | Communication error between scanner and ASIC An error code is detected 3 times in succession. |

Defective connector cable or poor contact in the connector. Defective CCD PWB. Defective main PWB. |

| 3600 | Scanner sequence error | Defective main PWB or engine PWB. |

| 4000 | Polygon motor synchronization error The polygon motor is not stabilized within 10 s after driving starts. |

Defective connector cable or poor contact in the connector. Defective polygon motor. Defective engine PWB. |

| 4010 | Polygon motor steady-state error Stable OFF is detected for 1 s continuously after polygon motor stabilized. |

Defective connector cable or poor contact in the connector. Defective polygon motor. Defective engine PWB. |

| 4100 | BD initialization error BD is not detected within 1 s after polygon motor stabilized. |

Defective connector cable or poor contact in the connector. Defective APC PWB. Defective BD PWB. Defective main PWB. |

| 4700 | VIDEO ASIC device error | Defective connector cable or poor contact in the connector. Defective main PWB or engine PWB. |

| 6000 | Broken fuser heater wire The detected temperature of fuser thermistor does not reach the specified temperature (ready indication temperature) after the fuser heater has been turned on continuously for 60 s in warming up. The fusing temperature at 7 seconds and 20 seconds since fuser temperature control has occurred differs by 43°C/109.4°F or less. |

Defective connector cable or poor contact in the connector. Deformed connector pin. Defective triac. Fuser thermostat triggered. Broken fuser heater wire. Defective engine PWB. |

| 6000 6020 6030 6050 |

Broken fuser heater wire Abnormally high fuser thermistor temperature Broken fuser thermistor wire Abnormally low fuser thermistor temperature |

Deformed connector pin. Defective triac. |

| 6020 | Abnormally high fuser thermistor temperature The fuser thermistor detects a temperature higher than 230°C/446°F continuously for 40 ms. High fuser temperature signal detects a temperature of 255°C/491°F continuously for 40 ms. |

Deformed connector pin. Defective triac. Shorted fuser thermistor. Defective engine PWB. |

| 6030 | Broken fuser thermistor wire A/D value of the fuser thermistor exceeds 251 bit continuously for 7 s during warming up. |

Defective connector cable or poor contact in the connector. Deformed connector pin. Defective triac. Defective fuser thermistor. Defective engine PWB |

| 6050 | Abnormally low fuser thermistor temperature As the stable temperature has reached the second time, the decrease in the fuser thermistor temperature of 60°C/140°F or greater is detected for one second. |

Deformed connector pin. Defective triac. Defective fuser thermistor Defective fuser heater. Defective engine PWB. |

| 6400 | Zero-cross signal error While fuser heater control is performed, the zero-cross signal is not input within 3 s. |

Defective connector cable or poor contact in the connector Defective power source PWB or engine PWB. |

| 7800 | Broken external thermistor wire The thermistor output value is 0.3 V or less. |

Defective connector cable or poor contact in the connector. Defective temperature sensor. |

| 7810 | Short-circuited external thermistor wire The thermistor output value is 3 V or more. |

Defective connector cable or poor contact in the connector. Defective temperature sensor. |

| 7900 | Drum unit EEPROM error No response is issued from the device in reading/writing for 5 ms or more and this problem is repeated five times successively. Mismatch of reading data from two locations occurs eight times successively. Mismatch between writing data and reading data occurs eight times successively. |

Defective connector cable or poor contact in the connector. Defective drum unit. |

| 7910 | Developer unit EEPROM error No response is issued from the device in reading/writing for 5 ms or more and this problem is repeated five times successively. Mismatch of reading data from two locations occurs eight times successively. Mismatch between writing data and reading data occurs eight times successively. |

Defective connector cable or poor contact in the connector. Defective developer unit. |

| 8030 | Tray upper limit detection problem (document finisher) When the tray elevation motor raises a tray, the ON status of the tray upper limit sensor is detected. |

Defective connector cable or poor contact in the connector. Defective tray upper limit sensor, paper surface sensor 1/2. Defective DF main PWB. |

| 8040 | Belt problem (document finisher) The belt sensor does not turn on/off within specified time of the belt solenoid turning on. |

Defective connector cable or poor contact in the connector. Defective belt sensor. Defective belt solenoid. Defective DF main PWB. |

| 8140 | Tray elevation motor problem (document finisher) The tray low limit sensor or paper surface sensor 1/2 cannot be detected to be on within 10 s since the tray elevation motor is activated. |

Defective connector cable or poor contact in the connector. Defective connector cable or poor contact in the connector. The tray elevation motor malfunctions. Defective tray lower limit sensor, paper surface sensor 1/2. Defective DF main PWB. |

| 8210 | Stapler problem (document finisher) Jam 7012 or 7023 is indicated. |

Defective connector cable of staple or poor contact in the connector. The stapler is blocked with a staple. The stapler is broken Defective DF main PWB. |

| 8320 | Adjustment motor 2 problem (document finisher) The adjustment sensor 2 does not turn on/off within specified time of the adjustment motor 2 turning on. |

Defective connector cable or poor contact in the connector. Defective adjustment sensor 2. Defective adjustment motor 2. Defective DF main PWB. |

| 8330 | Adjustment motor 1 problem (document finisher) The adjustment sensor 1 does not turn on/off within specified time of the adjustment motor 1 turning on. |

Defective connector cable or poor contact in the connector. Defective adjustment sensor 1. Defective adjustment motor 1. |

| 8350 | Roller motor problem (document finisher) The roller sensor does not turn on/off within specified time of the roller motor turning on. |

Defective DF main PWB. Defective connector cable or poor contact in the connector. Defective roller sensor. Defective roller motor. Defective DF main PWB. |

| 8360 | Slide motor problem (document finisher) The slide sensor does not turn on/off within specified time of the slide motor turning on. |

Defective connector cable or poor contact in the connector. Defective slide sensor. Defective slide motor. Defective DF main PWB. |

| 8460 | EEPROM problem (document finisher) Reading from or writing to EEPROM cannot be performed. |

Defective EEPROM or DF main PWB. |

| 8800 | Document finisher communication error A communication error is detected 10 times in succession. |

Defective connector cable or poor contact in the connector Defective DF main PWB. Defective engine PWB. |

| 8830 | Bridge communication error (document finisher) A communication error is detected 10 times in succession. |

Defective connector cable or poor contact in the connector. Defective bridge PWB. Defective engine PWB. |

| 8990 | Document finisher communication error | Defective connector cable or poor contact in the connector. Defective DF main PWB. Defective bridge PWB. |

| 9000 | Document processor communication error A communication error is detected 10 times in succession. |

Defective connector cable or poor contact in the connector. Defective DP main PWB. |

| 9060 | DP EEPROM error Read and write data does not match. Data in the specified area of the backup memory does not match the specified values. | Defective DP main PWB. Device damage of EEPROM. |

| 9500 | BRU communication error | IPU PWB error |

| 9510 | BRU PWB error | IPU PWB error |

| 9520 | BRU PWB data error | IPU PWB error |

| F000 | Main PWB — operation panel PWB communication error | Defective main PWB. Defective operation panel PWB. |

| F010 | Main PWB checksum error | Defective main PWB. |

| F040 | Main PWB — print engine communication error | Defective main PWB. Defective engine PWB. |

| F050 | Print engine ROM checksum error | Defective engine PWB. |

• Индикатор [Внимание] на панели управления горит или мигает.

• На дисплее сообщений панели управления аппарата появилось сообщение об ошибке.

Если индикатор [Внимание] горит или мигает и на дисплее сообщений панели управления аппарата появилось сообщение об ошибке, проверьте KYOCERA Client Tool или Монитор состояния.

ПРИМЕЧАНИЕ Если индикаторы постоянно горят и мигают не так, как описано выше, вероятно, произошла ошибка службы. Выключите питание, отсоедините шнур питания и вставьте его обратно, после чего включите питание. Это может помочь сбросить ошибку. Если ошибка не исчезает, свяжитесь со своим представителем сервисной службы (тел. в Минске +375 17 291-28-24)

Ниже описаны неполадки, которые не могут быть устранены пользователем

|

Дисплей сообщений |

Описание |

Меры устранения |

|

Бункер отраб тонера перепол. или не уст. |

Бункер для отработанного тонера установлен неправильно |

Установите Бункер для отработанного тонера должным образом |

|

Бункер для отработанного тонера заполнен |

Замените бункер отработанного тонера |

|

|

Встряхните картр. с тонером |

Тонер слежался |

Откройте переднюю крышку аппарата и вытяните контейнер с тонером. Сильно встряхните контейнер с тонером и установите его на место |

|

Вызовите сервисный персонал. |

В аппарате произошла ошибка |

Обратите внимание на код ошибки, отображаемый в дисплее сообщений, и свяжитесь с представителем сервисной службы (тел. в Минске +375 17 291-28-24) |

|

Выньте бумагу с внутреннего лотка |

Извлеките бумагу из внутреннего лотка. Нажмите клавишу [OK], чтобы возобновить печать |

|

|

Добавьте тонер |

Закончился тонер |

Замените контейнер с тонером TK-4105 |

|

Загрузите бумагу в кассету # |

↑↓ (отображается попеременно) |

Загрузите бумагу. Нажмите клавишу [OK] и перейдите к следующему шагу. • Для выбора другого устройства подачи выберите [Выберите бумагу]. • Для печати на бумаге, в настоящее время находящейся в устройстве подачи, выберите [Продолж. без изм.] |

|

Загрузите бумагу в универсальный лоток |

↑↓ (отображается попеременно) |

Загрузите бумагу. Нажмите клавишу [OK] и перейдите к следующему шагу. • Для выбора другого устройства подачи выберите [Выберите бумагу]. • Для печати на бумаге, в настоящее время находящейся в устройстве подачи, выберите [Продолж. без изм.] |

|

Закройте автоподатчик оригиналов |

Открыт автоподатчик оригиналов |

Откройте и закройте автоподатчик оригиналов |

|

Закройте крышку автопод. оригиналов |

Открыта верхняя крышка автоподатчика оригиналов |

Откройте и закройте крышку автоподатчика оригинало |

|

Закройте переднюю крышку |

Открыта передняя крышка |

Откройте и закройте переднюю крышку |

|

Закройте правую крышку # |

Открыта какая-либо крышка |

Откройте и закройте крышку, обозначенную на экране |

|

Замятие бумаги. (DP) |

В автоподатчике произошло замятие бумаги. |

См. Устранение замятия бумаги в Руководстве по эксплуатации и извлеките замятую бумагу |

|

Замените МК |

Необходимо производить замену деталей комплекта техобслуживания MK-4105 (ремкомплекта) каждые 150 000 страниц печати. |

Данная операция должна производиться специалистом. Обратитесь к представителю сервисной службы (тел. в Минске +375 17 291-28-24) |

|

Замятие |

Произошло замятие бумаги в кассете или универсальном лотке |

См. Устранение замятия бумаги и извлеките замятую бумагу |

|

Извлеките оригиналы из автоподатчика |

Для продолжения работы необходимо извлечь оригиналы из автоподатчика оригиналов |

Извлеките оригиналы из автоподатчика оригиналов |

|

Кабель USB был отключен |

Кабель USB не подключен |

Нажмите клавишу [OK] и подключите кабель USB |

|

ПК выключен |

Нажмите клавишу [OK] и включите ПК |

|

|

Не удается найти KYOCERA Client Tool |

Нажмите клавишу [OK] и откройте KYOCERA Client Tool на ПК |

|

|

Макс. к-во сканируемых страниц |

Превышен предел сканирования |

Дальнейшее сканирование невозможно. Задание отменено. Нажмите клавишу [OK] |

|

Мало тонера. (Зам., когда законч.) |

Скоро понадобится заменить контейнер с тонером |

Получите новый контейнер с тонером TK-4105. |

|

Не оригинальный тонер |

Установлен контейнер с тонером не марки Kyocera |

Производитель не несет ответственности за повреждения, вызванные использованием неоригинального тонера. Мы рекомендуем использовать исключительно оригинальные контейнеры с тонером TK-4105. . |

|

Неверный ид. уч. зап. Задание отменено |

Указан неверный идентификатор учетной записи при внешней обработке задания. Задание отменено |

Нажмите клавишу [OK] |

|

Невозможна двусторонняя печать на этой бумаге |

Не возможна печать на бумаге выбранного формата или типа |

Нажмите клавишу [OK] и перейдите к следующему шагу: |

|

Недостаточно памяти. Невозможно начать выполнение задания |

Невозможно начать выполнение задания |

Повторите попытку позже |

|

Ограничено алгоритмом учета заданий(Печать) |

Задание отменено, поскольку его выполнение ограничено функцией учета заданий |

Нажмите клавишу [OK] |

|

Ограничено алгоритмом учета заданий(Сканер) |

Задание отменено, поскольку его выполнение ограничено функцией учета заданий |

Нажмите клавишу [OK] |

|

Очистите сканер |

Произошло загрязнение сканера |

Очистите щелевое стекло с помощью чистящей салфетки, поставляемой вместе с автоподатчиком оригиналов. |

|

Ошибка. Выключить |

— |

Отключите и снова включите аппарат с помощью выключателя питания |

|

Память переполнена |

Невозможно продолжить выполнение задания из-за отсутствия свободной памяти |

Измените разрешение печати с Быстр1200 до 600 dpi. См. Printer Driver User Guide |

|

Память сканера переполнена |

Дальнейшее сканирование невозможно из-за нехватки памяти сканера. |

Для отмены задания нажмите [OK] |

|

Перезагрузка печати. Задание отменено |

Предупреждение. Недостаточно памяти принтера. Задание отменено |

Нажмите клавишу [OK] |

|

Превышено ограничение учета заданий |

Превышено число распечаток из-за ограничения алгоритмом учета заданий. Достигнут предел печати |

Это задание отменено. Нажмите клавишу [OK] |

|

Уст.другую кассету |

Выбрано «Сдвиг» |

Для использования сдвига необходимо загрузить в другой лоток бумагу такого же формата, что и в выбранном устройстве подачи, но в другой ориентации |

|

Установите все оригиналы обратно и нажмите клавишу [Старт]. |

Возникает при печати двусторонних документов в режиме ручной двусторонней печати |

Извлеките оригиналы из автоподатчика оригиналов, расположите их в первоначальном порядке и положите обратно. Нажмите клавишу [OK], чтобы возобновить печать. Для отмены задания нажмите [Стоп] |

|

Установлен неизвестный тонер. ПК |

Региональная спецификация контейнера с тонером не соответствует спецификации аппарата |

Установите оригинальный контейнер с тонером Замените контейнер с тонером TK-4105 |

Item No.

U000

No.

(7)

Paper Jam

cont.

Log

Items

6813: Front adjustment plate operation OFF error

6903: Rear adjustment plate operation ON error

6913: Rear adjustment plate operation OFF error

7013: Staple operation error

7023: Staple initialoperation error

7913: Sequence error 1 (operation prohibited)

7923: Sequence error 2 (initialoperation error)

7933: Sequence error 3 (Error in the reception of backup data)

7943: Sequence error 4 (standby)

7953: Sequence error 5 (Error in between copies)

9000: No original feed

9001: DP original conveying jam

9004: DP original swichback jam

9010: DP open

9011: DP top cover open

9110: DP paper feed sensor stay jam

9200: DP registration sensor non arrival jam

9400: DP timing sensor non arrival jam

9410: DP timing sensor stay jam

(b) Detail of paper source (Hexadecimal)

00: MP tray

01: Cassette 1

02: Cassette 2 (paper feeder 1)

03: Cassette 3 (paper feeder 2)

04 to 09: Reserved

(c) Detail of paper size (Hexadecimal)

00: (Not specified)

01: Monarch

02: Business

03: International DL

04: International C5

05: Executive

06: Letter-R

86: Letter-E

07: Legal

08: A4R

88: A4E

09: B5R

89: B5E

0A: A3

Description

Description

0B: B4

0C: Ledger

0D: A5R

0E: A6

0F: B6

10: Commercial #9

11: Commercial #6

12: ISO B5

13: Custom size

1E: C4

1F: Postcard

20: Reply-paid post-

card

21: Oficio II

1-3-11

2MW/2MX

22: Special 1

23: Special 2

24: A3 wide

25: Ledger wide

26: Full bleed paper

(12 x

27: 8K

28: 16K-R

A8: 16K-E

32: Statement-R

B2: Statement-E

33: Folio

34: Western type 2

35: Western type 4

Замятие, зажёвывание бумаги в принтерах Kyocera FS-1035MFP/1035MFP/DP-1135/1135MFP/M2035/FS-1030MFP/1130MFP, ошибки 501 и 518, а так же разбор проблем, которые могут возникнуть сразу после замены роликов.

Сегодня мы с вами разберём причины замятия бумаги в некоторых принтерах Kyocera, поговорим о способах устранения данной проблемы и некоторых важных нюансах, о которых стоит знать любому, кто хочет провести ремонт своего принетра результативно и качественно.

Сразу к делу: если принтер Kyocera заминает или зажёвывает бумагу (Ошибка 501), то в подавляющем большинстве случаев причина в износе роликов захвата и/или отделения (сепарации) бумаги. В таком случае ролики нужно заменить. Обычно эти ролики изнашиваются почти одновременно, поэтому менять следует сразу и ролики захвата, и ролик сеперации. В этой статье я расскажу и покажу как это сделать.

Начнём с того, что вынем из принтера лоток для бумаги. Затем принтер нужно поставить «на дыбы», чтобы с областью над лотком было удобно работать.

Теперь нам хорошо видны ролики захвата бумаги.

Чтобы заменить ролики, нам нужно снять пластиковую колодку, в которой они нахоятся. Для этого просто отщёлкиваем колодку снизу, как показано на фото.

Сверху колодка держится на двух зацепах, с ними нужно быть аккуратным, чтобы ни в коем случае не сломать их.

После извлечения колодки просто отжимаем пластик вбок и получаем возможность вынуть ролики.

Оригинальные ролики продаются сразу со втулками, на которых они находятся. Если же вы приобрели совместимые ролики, то у вас в комплекте будут только резинки, и вам придётся самостоятельно стягивать со втулок старые и надевать на их место новые. Но делать так я крайне не рекомендую, и чуть дальше я подробно расскажу — почему.

Установив новые ролики, можем смело вернуть пластиковую колодку на место, процесс её установки ничем не отличается от снятия.

Далее в нашем списке ролик отделения бумаги, он находится в самом лотке, и тоже в пластиковой колодке.

Чтобы снять его, нужно отогнуть пластик этой колодки с одной из сторон.

Обратите внимание, что под колодкой с роликом находится пружина, терять её ни в коем случае нельзя.

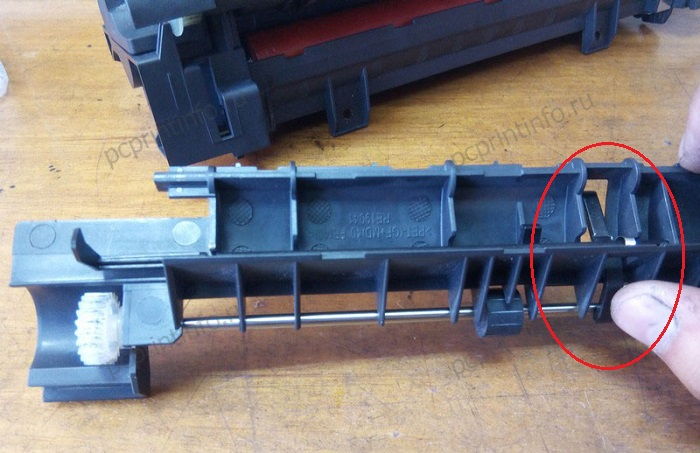

А вот выступ на самой колодке, которым в эту пружину нужно будет попасть при установке деталей на место.

Сам ролик извлекается из колодки и заменяется на новый аналогично предыдущим.

Установив все ролики и колодки на место, возвращаем принтер в нормальное положение и вставляем обратно лоток.

На этом замена роликов закончена, это решит проблему с ошибкой 501.

А теперь немного о совместимых роликах и ошибке 518, которая может возникнуть у вас сразу после установки новеньких роликов стороннего производителя.

Компания, в которой я работаю, довльно активно занимается ремонтом принетров, а износ роликов — самая распостранённая проблема печатающей техники Kyocera. И мы перепробовали довольно много различных совместимых роликов, от самых дешёвых, до близких к оригинальным по цене. И ни одни не работали как надо. Либо материал резинок оказывался слишком некачественным и они стирались за несколько тысяч страниц, либо размер самих резинок чуть-чуть не совпадал с оригинальным. К слову, средний срок службы оригинальных роликов около 60-70 тысяч листов. Хотя у некоторых они «бегают» и сотни тысяч. Были и случаи износа оригиналов за 40 тысяч листов, но это большая редкость.

Казалось бы, пол миллиметра разницы в размере — мелочь, но на деле это приводило к серьёзным проблемам со всё тем же замятием бумаги, только на этот раз с оишбкой 518. Её, и все прочие ошибки, можно посмотреть в журнале событий принтера.

Причина в том, что из-за неверного диаметра совместимых роликов листы бумаги протягивались чуть дальше чем должны, попадая в «поле зрения» датчика прохода бумаги слишком рано. Особенно быстро и часто с данной проблемой будут сталкиваться те, кто печатает дуплексом (на обеих сторонах листа). Поэтому крайне рекомендую к установке только оригинальные ролики Kyocera.

Источник

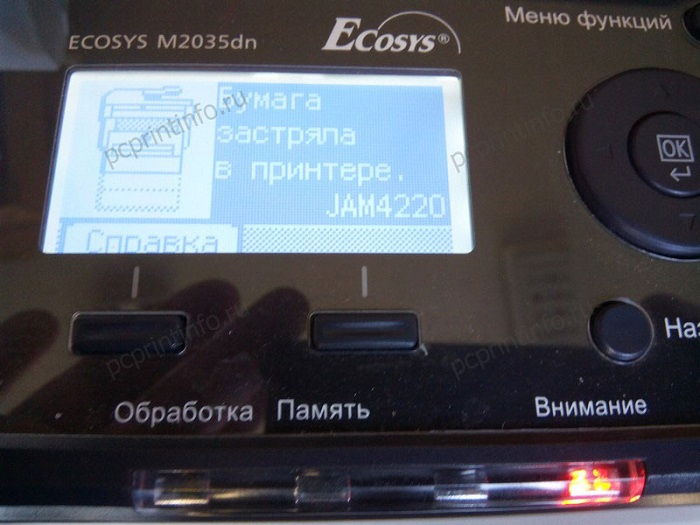

Ошибка Jam 4220 в МФУ Kyocera Ecosys M2035

Доброго времени суток! Дорогие друзья! Сегодня речь пойдет об ошибке Jam 4220. На примере МФУ Kyocera Ecosys M2035 вы увидите, где расположен датчик вызывающий данную ошибку. И в каких ситуациях, помимо реального замятия, может появиться эта ошибка.

Именно в аппарате M2035, ошибку вызывает датчик, расположенный на выходе бумаги из термоузла (в других принтерах, возможно, это может быть и другой датчик).

Первым делом проверьте МФУ на наличие замятой бумаги. Для этого откройте заднюю крышку.

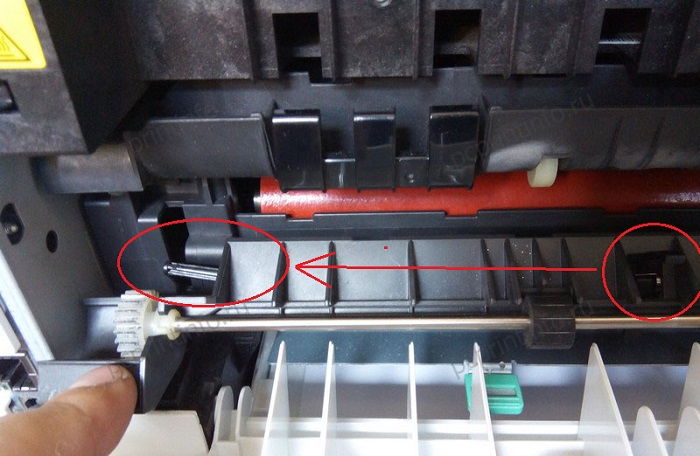

В нижней части вы увидите термоузел, у которого есть возможность отодвинуть шторку и заглянуть вовнутрь. Как раз на этой шторке находится датчик успешного прохождения бумаги из печи. Если бумага застряла и оставила лапку датчика в сдвинутом состоянии, то при включении или окончания распечатки листа, МФУ видит проблему и отображает ошибку.

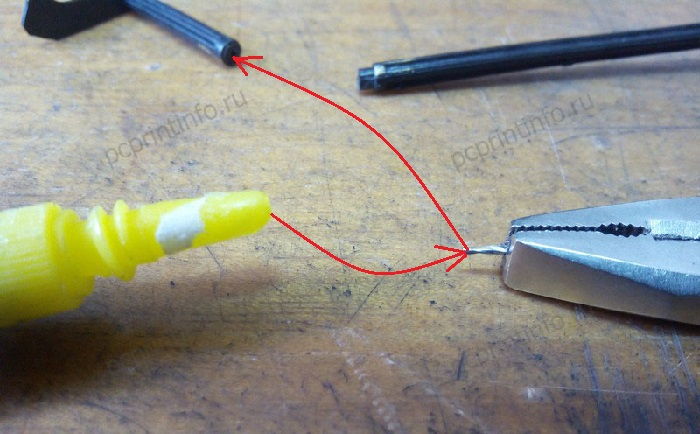

Как вы видите на фото, никакой бумаги у меня не застряло, значит, проблема может быть в лапке датчика (сломался, проблема с пружинкой), в самом датчике (засорился, сломался), или в контактах подходящих к датчику.

В моем случае лапка датчика была лопнута. Ну что ж, я буду её клеить. Чтобы снять эту лапку, мне понадобится снять термоузел. Если вам нужно подробно посмотреть, как снять печь, то перейдите на статью об ошибке C6000, здесь покажу вкратце.

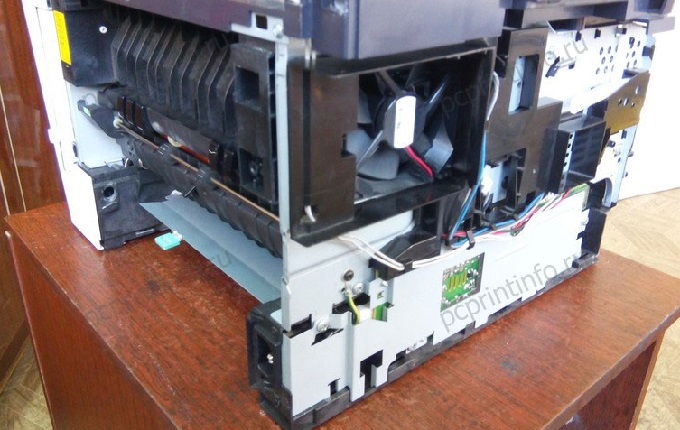

Снимаем заднюю крышку, сняв её с защелок.

Далее снимем небольшую пластиковую планку сверху, держится она на болтике и двух защелках.

Теперь мы можем снять левую боковую крышку, но для удобства разбора, я сниму ещё и переднюю дверцу.

У боковой крышки с задней стороны есть две защелки, отгибаем и сдвигаем крышку.

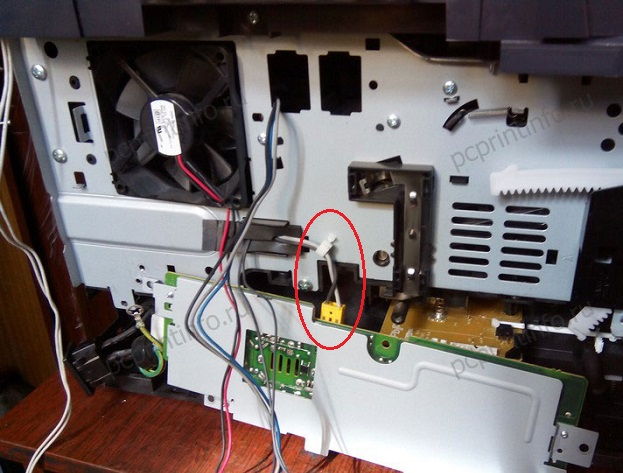

Под крышкой доберемся до контактов термоузла. Снимаем большую пластиковую направляющую, и откручиваем высоковольтную плату снизу.

С этой платы отключаем все контакты и убираем её в сторону.

На термоузел идут два контакта, освобождаем их от прокладки.

Теперь мы можем окрутить термоузел с задней стороны.

Аккуратно вытягиваем его и отключаем контакт с левой стороны. Это и есть тот контакт, который соединяет датчик со всей системой.

Итак, снимаем шторку с термоузла (чтобы снять, откройте шторку сильнее обычного).

Смотрим на лапку датчика. Сейчас вы видите уже мои наброски, то есть до того как фотографировать я уже снял печь. Тогда часть лапки вообще лежала в стороне (хорошо хоть не выпала с аппарата), а сейчас я уже подобрал внутренний стержень (маленький кусочек от сверла), но пока не склеивал его, так как решил написать статью.

Я сразу же сниму с лапки пружину, чтобы в дальнейшем не потерять её нечаянно. Кстати об этой пружине я писал в начале, если она выпадет с посадочного места, то не будет прижимать лапку в нужном направлении, и аппарат незамедлительно выдаст вам ошибку Jam 4220.

Теперь я покажу вам сам датчик.

Находится он сбоку термоузла и держится на трех защелках. В целях профилактики я сниму его и тщательно продую.

Далее нам нужно понять, в каком положении клеить две части лапки, для этого я нажеулю стержень и соберу термоузел, предварительно сняв со шторки пружины.

В собранном состоянии ставлю лапку, в нужное положение, отгибаю шторку и закрашиваю две части лапки в местах будущего склеивания.

Теперь мы понимаем, в каком положении склеивать.

Для таких целей у меня припасено несколько тюбиков суперклея. Наносим его стержень и вставляем стержень в лапку, затем наносим на другую сторону и скрепляем.

В месте склеивания остался клей, который может мешать свободному ходу лапки. Я прошелся надфилем и убрал лишнее. Ждем пару минут, пока засохнет клей и собираем все детали.

На лапку надеваем пружину и ставим лапку на место, на фото видно, как лучше завести лапку в пазы.

Теперь понажимаем на лапку, она должна ходить свободно.

Вставляем пружины в шторку, а шторку в термоузел.

Для полной уверенности проверьте, чтобы лапка перекрывала датчик.

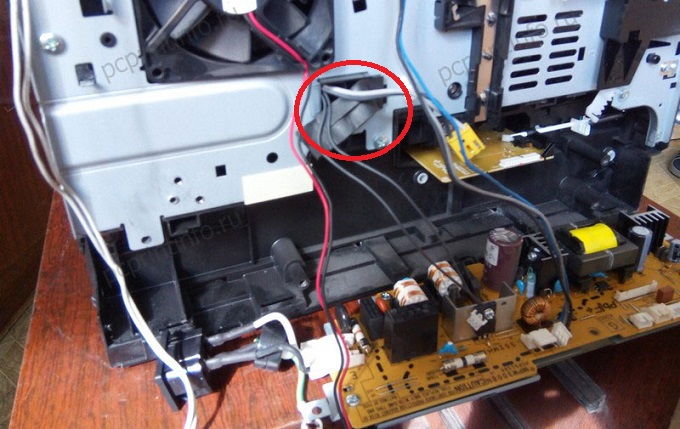

Подключаем контакт к датчику, и устанавливаем печь, предварительно подсунув два контакта в отверстие.

Подключаем высоковольтную плату, закручиваем её и ставим на место направляющую. Обратите внимание, высоковольтная плата должна быть подключена к плате внутри МФУ. С внутренней стороны высоковольтной платы находится штекер. Если плата не подключится должным образом, ваш аппарат не включится. Наглядно вы можете увидеть в статье про ошибку C6000.

Вставляем боковую стенку и переднюю крышку, а затем лоток с бумагой и пластиковую планку с задней стороны.

Завершаем сборку, надев заднюю крышку.

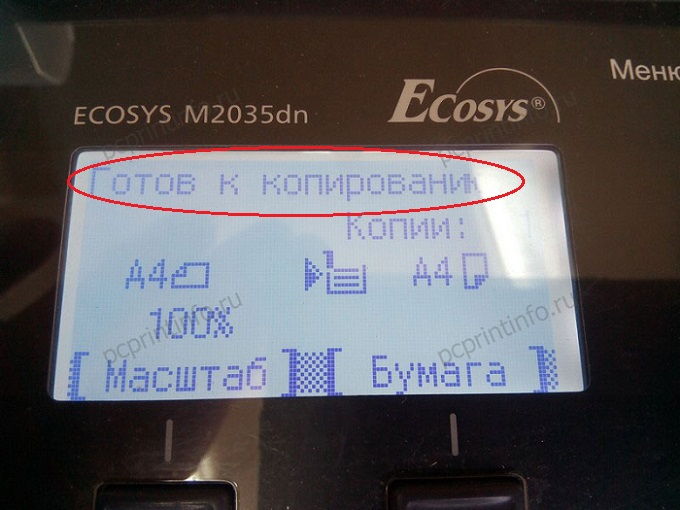

Вставляем шнур питания, включаем МФУ. Аппарат готов к копированию и печати. Ошибка Jam 4220 исправлена.

Комментарии

Такая ошибка уже на 2 машинах. Постоянно, с периодичностью 10-50 листов. Менял весь термоузел в сборе, блоки барабана и проявки — результата нет. У обоих на счётчике около 100 000 отпечатков.

а если ошибка JAM4020 замятие бумаги, датчик цел по крайней мере визуально, лапка цела как быть? внутри бумаги нет, под картриджем под прозрачной пластинкой тоже нет… как быть ребят?

я бы с удовольствием узнал как можно пофиксить пружинку на лапке. все с этим датчиком хорошо и с лапкой тоже — кроме пружинки. имею несколько аппаратов 2035 2535 и 2040, но только на 2040 эта пружинка очень уж слабенькая. Есть ли у вас опыт ее приведения в порядок?

Скажите пожалуйста, какой партномер детали, на которой стоит эта самая лапка? Деталь та самая, которую из аппарата извлекли. У меня эта деталь лопнула по центру у флажка прохождения бумаги, теперь постоянно пишет что бумага застряла.

Я могу ошибаться, но у этой детали скорее всего нет партномера, так как отдельно она не продается. Попробуйте пропаять трещину, кстати в некоторых случаях 3d ручка неплохо помогает, или хотя бы пластик для 3d ручек и паяльник.

Добавить комментарий Отменить ответ

Этот сайт использует Akismet для борьбы со спамом. Узнайте как обрабатываются ваши данные комментариев.

Источник

-

02-07-2020

#1

JAM9110 TASKalfa2551ci

Hello,

I have Jam9110 or J9001 on Document Feeder. Its on Taskalfa 2551ci, and DF is DF-773.

i changed two clutch and actuator because they were defective. I still didn’t get the solution. The Jam still appears just after the white plastic sensor, when the DF is raised. So, it passes the white plastic and stops at the entrance to the output section of the Document Feeder. I did the service three times on this machine, and I saw that the paper-pulling erasers, as they pull the paper where Jam appears, the pulleys should rotate in the other direction. Will I solve the problem if I replace the Servo motor? Thank you in advance.

Tags for this Thread

Bookmarks

Bookmarks

Posting Permissions

- You may not post new threads

- You may not post replies

- You may not post attachments

- You may not edit your posts

- BB code is On

- Smilies are On

- [IMG] code is On

- [VIDEO] code is On

- HTML code is Off

Forum Rules

Code

0000

Initial jam

0100

Secondary feeding timeout

0101

Wait for ready of print-process

package

0104

Wait for ready of conveying

package

0105

Driving prevention

0106

Paper feeding request for

duplex printing time out

0107

Wait for ready of fuser pack-

age

0110

Rear cover open

0111

Top cover open

0120

Receiving a duplex paper

feeding request while paper is

empty

0121

Exceeding number of duplex

pages circulated

0501

No paper feed of jam

0502

0503

0504

0505

0508

0509

Contents

The power is turned on when a sensor in the con-

veying system is on.

Secondary paper feed request given by the con-

troller is unreachable.

Process package won’t become ready.

Conveying package won’t become ready.

A drive does not stop.

Paper feeding request for duplex printing given by

the controller is unreachable.

Fuser package won’t become ready.

The rear cover is opened during printing.

The top cover is opened during printing.

Paper feed request was received from the duplex

section despite the absence of paper in the

duplex section.

The controller issued the duplex section a request

for more pages than the duplex print cycle con-

tains.

The registration sensor 1 (RS1)*1 or sensor 3

(RS3)*2 does not turn on during paper feed from

cassette 1.

PF feed sensor 1 (PFFS1) does not turn on dur-

ing paper feed from cassette 2.

PF feed sensor 2 (PFFS2) does not turn on dur-

ing paper feed from cassette 3.

PF feed sensor 3 (PFFS3) does not turn on dur-

ing paper feed from cassette 4.

PF feed sensor 4 (PFFS4) does not turn on dur-

ing paper feed from cassette 5.

The registration sensor 1 (RS1)*1 or sensor 3

(RS3)*2 does not turn on during paper feed from

duplex section.

The registration sensor 1 (RS1)*1 or sensor 3

(RS3)*2 does not turn on during paper feed from

MP tray.

Conditions

1-4-3

2NM/2NX/2NY/2NZ/2P0/2P6

Jam

location*

H

H

H

H

H

B

—

I

—

—

I

I

1

2

3

4

5

I

-

Alex12

- Увидел чернила

-

- Сайт

Alex12 » Вт июл 28, 2020 12:34 pm

Goldwater писал(а):Есть два варианта решения проблемы: японский подороже но побыстрее и русский подешевле но подольше.

Оба начинаются с обязательного обновления прошивки.

Вам который?

Прошивка не помогла, рассмотрю оба варианта.

-

Alex12

- Увидел чернила

-

- Сайт

-

- [SCANNER ERROR] Lamp Error Kyocera FS-1016

мастерчип в форуме Принтеры, МФУ, факсы, копиры формата A4

- 3

- 6431

Усатый Полосатый

Вс окт 28, 2018 11:08 pm

- [SCANNER ERROR] Lamp Error Kyocera FS-1016

-

- Kyocera 1035 «бледная» печать

srMax в форуме Принтеры, МФУ, факсы, копиры формата A4

- 2

- 13540

srMax

Пт янв 23, 2015 2:49 pm

- Kyocera 1035 «бледная» печать

-

- Kyocera FS-1120d индикатор «Нет бумаги»

vs-dos в форуме Принтеры, МФУ, факсы, копиры формата A4

- 11

- 14579

СТРОНЦИЙ

Вт ноя 02, 2021 2:24 pm

- Kyocera FS-1120d индикатор «Нет бумаги»

-

- Kyocera Ecosys M2635dn «поворот» изображения

Искатель в форуме Принтеры, МФУ, факсы, копиры формата A4

- 10

- 5742

MatrixAgent

Ср апр 08, 2020 5:18 am

- Kyocera Ecosys M2635dn «поворот» изображения

-

- Стирание вала ведущей шестерни в «печке» Kyocera M2035dn

Грецкий орех в форуме Принтеры, МФУ, факсы, копиры формата A4

- 12

- 2898

СТРОНЦИЙ

Пн дек 13, 2021 3:35 pm

- Стирание вала ведущей шестерни в «печке» Kyocera M2035dn

Вернуться в Принтеры, МФУ, копиры формата A3

Кто сейчас на форуме

Сейчас этот форум просматривают: нет зарегистрированных пользователей и гости: 16

Все современные копировальные аппараты, мфу и принтеры Kyocera имеют возможность диагностировать все узлы устройства в режиме запуска и во время работы аппарата. По этому, если во время включения или во время работы произошел сбой, то техника Kyocera сможет сообщить о наличии ошибки.

В большинстве случаев у аппаратов Kyocera код ошибки отображается на дисплее, в остальных случаях тип ошибки зависит от последовательности и количества миганий индикаторов.

Если Ваш копировальный аппарат, МФУ или принтер Kyocera выдал на дисплее некий код, то узнать причину, описание возникновения ошибки, а так же в каком узле аппарата стоит искать проблему, Вы можете в этом разделе выбрав интересующую модель из списка.

Но диагностика не решит проблему сбоя аппарата, для этого лучше обратиться к профессиональным и опытным сервисным специалистам компании Kyomart! Позвоните нам по телефону

8 (343) 288-23-45 или отправьте запрос на электронную почту: sales@kyomart.ru , и мы обязательно свяжемся с Вами в кратчайшие сроки.

| Код ошибки | Описание ошибки | Причина ошибки |

|---|---|---|

| 0030 | FAX control PWB system error Processing with the fax software was disabled due to a hardware problem. |

Defective FAX control PWB. |

| 0060 | Engine PWB type error | Defective engine sub PCB. |

| 0070 | FAX control PWB incompatible detection error Abnormal detection of FAX control PWB incompatibility In the initial communication with the FAX control PWB, any normal communication command is not transmitted. |

Defective FAX software Defective FAX control PWB. |

| 0100 | Backup memory device error | Defective flash memory. |

| 0120 | MAC address data error For data in which the MAC address is invalid. |

Defective main PWB. Defective flash memory. Defective engine PWB. |

| 0130 | Backup memory read/write error (main PWB) | Defective flash memory. Defective main PWB. |

| 0140 | Backup memory data error (main PWB) | Defective flash memory. Defective main PWB. |

| 0150 | Backup memory read/write error (engine PWB) Detecting engine PWB EEPROM communication error. |

Improper installation engine PWB EEPROM. Defective engine PWB. Device damage of EEPROM. |

| 0160 | Backup memory data error (engine PWB) | Defective flash memory. Defective engine PWB. |

| 0170 | Billing counting error A checksum error is detected in the main and engine backup memories for the billing counters. |

Data damage of EEPROM. Defective PWB. |

| 0180 | Machine number mismatch Machine number of main and engine does not match. |

Data damage of EEPROM. |

| 0320 | I/O CPU communication error A communication error is detected 10 times in succession. |

Defective PWB. |

| 0630 | DMA error DMA transmission of image data does not complete within the specified period of time. | Poor contact in the connector terminals. Defective main PWB. |

| 0800 | Image processing error JAM05 is detected twice. |

Defective main PWB. |

| 0830 | FAX control PWB flash program area checksum error A checksum error occurred with the program of the FAX control PWB. |

Defective FAX software. Defective FAX control PWB. |

| 0840 | Faults of RTC The time is judged to go back based on the comparison of the RTC time and the current time or five years or more have passed. |

The battery is disconnected from the main PWB. Defective main PWB. |

| 0870 | FAX control PWB to main PWB high capacity data transfer error High-capacity data transfer between the FAX control PWB and the main PWB of the machine was not normally performed even if the data transfer was retried the specified times. |

Improper installation FAX control PWB. Defective FAX control PWB or main PWB. |

| 0920 | Fax file system error The backup data is not retained for file system abnormality of flash memory of the FAX control PWB. |

Defective FAX control PWB. |

| 1010 | Lift motor error After cassette 1 is inserted, lift sensor does not turn on within 12 s. This error is detected four times successively. |

Defective bottom plate elevation mechanism in the cassette. Defective connector cable or poor contact in the connector. Defective drive transmission system of the lift motor. Defective lift motor. Defective engine PWB. |

| 1020 | PF lift motor error (paper feeder) After cassette 2 is inserted, PF lift sensor 1 does not turn on within 12 s. This error is detected four times successively. |

Defective bottom plate elevation mechanism in the cassette. Defective connector cable or poor contact in the connector. Defective drive transmission system of the PF lift motor 1. Defective PF lift motor 1. Defective PF main PWB. |

| 1030 | PF lift motor error (paper feeder) After cassette 3 is inserted, PF lift sensor 2 does not turn on within 12 s. This error is detected four times successively. |

Defective bottom plate elevation mechanism in the cassette. Defective connector cable or poor contact in the connector. Defective drive transmission system of the PF lift motor 2. Defective PF lift motor 2. Defective PF main PWB. |

| 1800 | Paper feeder communication error A communication error is detected 10 times in succession. |

Improper installation paper feeder. Defective connector cable or poor contact in the connector. Defective engine PWB. Defective PF main PWB. |

| 1900 | Paper feeder EEPROM error When writing the data, the write data and the read data is not continuously in agreement 5 times. |

Defective PF main PWB. Device damage of EEPROM. |

| 2000 | Main motor steady-state error Stable OFF is detected for 1 s continuously after main motor stabilized. |

Defective connector cable or poor contact in the connector. Defective drive transmission system of the main motor. Defective main motor. Defective engine PWB. |

| 2010 | Main motor drive error The main motor is not stabilized within 2 s after driving starts. |

Defective connector cable or poor contact in the connector. Defective drive transmission system of the main motor. Defective main motor. Defective engine PWB. |

| 2600 | PF drive motor error (paper feeder) When the PF drive motor is driven, error signal is detected continuously for 1 s. |

Defective connector cable or poor contact in the connector. Defective drive transmission system of the PF drive motor. Defective PF drive motor. Defective PF main PWB. |

| 3100 | ISU home position error The home position is not correct when the power is turned on or at the start of copying using the table. |

Defective connector cable or poor contact in the connector. Defective home position sensor. Defective ISU motor. Defective CCD PWB. Defective engine PWB. |

| 3200 | Exposure lamp error When input value at the time of exposure lamp illumination does not exceed the threshold value between 5 s. |

Defective connector cable or poor contact in the connector. Defective exposure lamp. Defective CCD PWB. Defective main PWB. |

| 3500 | Communication error between scanner and ASIC An error code is detected 3 times in succession. |

Defective connector cable or poor contact in the connector. Defective CCD PWB. Defective main PWB. |

| 3600 | Scanner sequence error | Defective main PWB or engine PWB. |

| 4000 | Polygon motor synchronization error The polygon motor is not stabilized within 10 s after driving starts. |

Defective connector cable or poor contact in the connector. Defective polygon motor. Defective engine PWB. |

| 4010 | Polygon motor steady-state error Stable OFF is detected for 1 s continuously after polygon motor stabilized. |

Defective connector cable or poor contact in the connector. Defective polygon motor. Defective engine PWB. |

| 4100 | BD initialization error BD is not detected within 1 s after polygon motor stabilized. |

Defective connector cable or poor contact in the connector. Defective APC PWB. Defective BD PWB. Defective main PWB. |

| 4700 | VIDEO ASIC device error | Defective connector cable or poor contact in the connector. Defective main PWB or engine PWB. |

| 6000 | Broken fuser heater wire The detected temperature of fuser thermistor does not reach the specified temperature (ready indication temperature) after the fuser heater has been turned on continuously for 60 s in warming up. The fusing temperature at 7 seconds and 20 seconds since fuser temperature control has occurred differs by 43°C/109.4°F or less. |

Defective connector cable or poor contact in the connector. Deformed connector pin. Defective triac. Fuser thermostat triggered. Broken fuser heater wire. Defective engine PWB. |

| 6000 6020 6030 6050 |

Broken fuser heater wire Abnormally high fuser thermistor temperature Broken fuser thermistor wire Abnormally low fuser thermistor temperature |

Deformed connector pin. Defective triac. |

| 6020 | Abnormally high fuser thermistor temperature The fuser thermistor detects a temperature higher than 230°C/446°F continuously for 40 ms. High fuser temperature signal detects a temperature of 255°C/491°F continuously for 40 ms. |

Deformed connector pin. Defective triac. Shorted fuser thermistor. Defective engine PWB. |

| 6030 | Broken fuser thermistor wire A/D value of the fuser thermistor exceeds 251 bit continuously for 7 s during warming up. |

Defective connector cable or poor contact in the connector. Deformed connector pin. Defective triac. Defective fuser thermistor. Defective engine PWB |

| 6050 | Abnormally low fuser thermistor temperature As the stable temperature has reached the second time, the decrease in the fuser thermistor temperature of 60°C/140°F or greater is detected for one second. |

Deformed connector pin. Defective triac. Defective fuser thermistor Defective fuser heater. Defective engine PWB. |

| 6400 | Zero-cross signal error While fuser heater control is performed, the zero-cross signal is not input within 3 s. |

Defective connector cable or poor contact in the connector Defective power source PWB or engine PWB. |

| 7800 | Broken external thermistor wire The thermistor output value is 0.3 V or less. |

Defective connector cable or poor contact in the connector. Defective temperature sensor. |

| 7810 | Short-circuited external thermistor wire The thermistor output value is 3 V or more. |

Defective connector cable or poor contact in the connector. Defective temperature sensor. |

| 7900 | Drum unit EEPROM error No response is issued from the device in reading/writing for 5 ms or more and this problem is repeated five times successively. Mismatch of reading data from two locations occurs eight times successively. Mismatch between writing data and reading data occurs eight times successively. |

Defective connector cable or poor contact in the connector. Defective drum unit. |

| 7910 | Developer unit EEPROM error No response is issued from the device in reading/writing for 5 ms or more and this problem is repeated five times successively. Mismatch of reading data from two locations occurs eight times successively. Mismatch between writing data and reading data occurs eight times successively. |

Defective connector cable or poor contact in the connector. Defective developer unit. |

| 8030 | Tray upper limit detection problem (document finisher) When the tray elevation motor raises a tray, the ON status of the tray upper limit sensor is detected. |

Defective connector cable or poor contact in the connector. Defective tray upper limit sensor, paper surface sensor 1/2. Defective DF main PWB. |

| 8040 | Belt problem (document finisher) The belt sensor does not turn on/off within specified time of the belt solenoid turning on. |

Defective connector cable or poor contact in the connector. Defective belt sensor. Defective belt solenoid. Defective DF main PWB. |

| 8140 | Tray elevation motor problem (document finisher) The tray low limit sensor or paper surface sensor 1/2 cannot be detected to be on within 10 s since the tray elevation motor is activated. |

Defective connector cable or poor contact in the connector. Defective connector cable or poor contact in the connector. The tray elevation motor malfunctions. Defective tray lower limit sensor, paper surface sensor 1/2. Defective DF main PWB. |

| 8210 | Stapler problem (document finisher) Jam 7012 or 7023 is indicated. |

Defective connector cable of staple or poor contact in the connector. The stapler is blocked with a staple. The stapler is broken Defective DF main PWB. |

| 8320 | Adjustment motor 2 problem (document finisher) The adjustment sensor 2 does not turn on/off within specified time of the adjustment motor 2 turning on. |

Defective connector cable or poor contact in the connector. Defective adjustment sensor 2. Defective adjustment motor 2. Defective DF main PWB. |

| 8330 | Adjustment motor 1 problem (document finisher) The adjustment sensor 1 does not turn on/off within specified time of the adjustment motor 1 turning on. |

Defective connector cable or poor contact in the connector. Defective adjustment sensor 1. Defective adjustment motor 1. |

| 8350 | Roller motor problem (document finisher) The roller sensor does not turn on/off within specified time of the roller motor turning on. |

Defective DF main PWB. Defective connector cable or poor contact in the connector. Defective roller sensor. Defective roller motor. Defective DF main PWB. |

| 8360 | Slide motor problem (document finisher) The slide sensor does not turn on/off within specified time of the slide motor turning on. |

Defective connector cable or poor contact in the connector. Defective slide sensor. Defective slide motor. Defective DF main PWB. |

| 8460 | EEPROM problem (document finisher) Reading from or writing to EEPROM cannot be performed. |

Defective EEPROM or DF main PWB. |

| 8800 | Document finisher communication error A communication error is detected 10 times in succession. |

Defective connector cable or poor contact in the connector Defective DF main PWB. Defective engine PWB. |

| 8830 | Bridge communication error (document finisher) A communication error is detected 10 times in succession. |

Defective connector cable or poor contact in the connector. Defective bridge PWB. Defective engine PWB. |

| 8990 | Document finisher communication error | Defective connector cable or poor contact in the connector. Defective DF main PWB. Defective bridge PWB. |

| 9000 | Document processor communication error A communication error is detected 10 times in succession. |

Defective connector cable or poor contact in the connector. Defective DP main PWB. |

| 9060 | DP EEPROM error Read and write data does not match. Data in the specified area of the backup memory does not match the specified values. | Defective DP main PWB. Device damage of EEPROM. |

| 9500 | BRU communication error | IPU PWB error |

| 9510 | BRU PWB error | IPU PWB error |

| 9520 | BRU PWB data error | IPU PWB error |

| F000 | Main PWB — operation panel PWB communication error | Defective main PWB. Defective operation panel PWB. |

| F010 | Main PWB checksum error | Defective main PWB. |

| F040 | Main PWB — print engine communication error | Defective main PWB. Defective engine PWB. |

| F050 | Print engine ROM checksum error | Defective engine PWB. |

• Индикатор [Внимание] на панели управления горит или мигает.

• На дисплее сообщений панели управления аппарата появилось сообщение об ошибке.

Если индикатор [Внимание] горит или мигает и на дисплее сообщений панели управления аппарата появилось сообщение об ошибке, проверьте KYOCERA Client Tool или Монитор состояния.

ПРИМЕЧАНИЕ Если индикаторы постоянно горят и мигают не так, как описано выше, вероятно, произошла ошибка службы. Выключите питание, отсоедините шнур питания и вставьте его обратно, после чего включите питание. Это может помочь сбросить ошибку. Если ошибка не исчезает, свяжитесь со своим представителем сервисной службы (тел. в Минске +375 17 291-28-24)

Ниже описаны неполадки, которые не могут быть устранены пользователем

|

Дисплей сообщений |

Описание |

Меры устранения |

|

Бункер отраб тонера перепол. или не уст. |

Бункер для отработанного тонера установлен неправильно |

Установите Бункер для отработанного тонера должным образом |

|

Бункер для отработанного тонера заполнен |

Замените бункер отработанного тонера |

|

|

Встряхните картр. с тонером |

Тонер слежался |

Откройте переднюю крышку аппарата и вытяните контейнер с тонером. Сильно встряхните контейнер с тонером и установите его на место |

|

Вызовите сервисный персонал. |

В аппарате произошла ошибка |

Обратите внимание на код ошибки, отображаемый в дисплее сообщений, и свяжитесь с представителем сервисной службы (тел. в Минске +375 17 291-28-24) |

|

Выньте бумагу с внутреннего лотка |

Извлеките бумагу из внутреннего лотка. Нажмите клавишу [OK], чтобы возобновить печать |

|

|

Добавьте тонер |

Закончился тонер |

Замените контейнер с тонером TK-4105 |

|

Загрузите бумагу в кассету # |

↑↓ (отображается попеременно) |

Загрузите бумагу. Нажмите клавишу [OK] и перейдите к следующему шагу. • Для выбора другого устройства подачи выберите [Выберите бумагу]. • Для печати на бумаге, в настоящее время находящейся в устройстве подачи, выберите [Продолж. без изм.] |

|

Загрузите бумагу в универсальный лоток |

↑↓ (отображается попеременно) |

Загрузите бумагу. Нажмите клавишу [OK] и перейдите к следующему шагу. • Для выбора другого устройства подачи выберите [Выберите бумагу]. • Для печати на бумаге, в настоящее время находящейся в устройстве подачи, выберите [Продолж. без изм.] |

|

Закройте автоподатчик оригиналов |

Открыт автоподатчик оригиналов |

Откройте и закройте автоподатчик оригиналов |

|

Закройте крышку автопод. оригиналов |

Открыта верхняя крышка автоподатчика оригиналов |

Откройте и закройте крышку автоподатчика оригинало |

|

Закройте переднюю крышку |

Открыта передняя крышка |

Откройте и закройте переднюю крышку |

|

Закройте правую крышку # |

Открыта какая-либо крышка |

Откройте и закройте крышку, обозначенную на экране |

|

Замятие бумаги. (DP) |

В автоподатчике произошло замятие бумаги. |

См. Устранение замятия бумаги в Руководстве по эксплуатации и извлеките замятую бумагу |

|

Замените МК |

Необходимо производить замену деталей комплекта техобслуживания MK-4105 (ремкомплекта) каждые 150 000 страниц печати. |

Данная операция должна производиться специалистом. Обратитесь к представителю сервисной службы (тел. в Минске +375 17 291-28-24) |

|

Замятие |

Произошло замятие бумаги в кассете или универсальном лотке |

См. Устранение замятия бумаги и извлеките замятую бумагу |

|

Извлеките оригиналы из автоподатчика |

Для продолжения работы необходимо извлечь оригиналы из автоподатчика оригиналов |

Извлеките оригиналы из автоподатчика оригиналов |

|

Кабель USB был отключен |

Кабель USB не подключен |

Нажмите клавишу [OK] и подключите кабель USB |

|

ПК выключен |

Нажмите клавишу [OK] и включите ПК |

|

|

Не удается найти KYOCERA Client Tool |

Нажмите клавишу [OK] и откройте KYOCERA Client Tool на ПК |

|

|

Макс. к-во сканируемых страниц |

Превышен предел сканирования |

Дальнейшее сканирование невозможно. Задание отменено. Нажмите клавишу [OK] |

|

Мало тонера. (Зам., когда законч.) |

Скоро понадобится заменить контейнер с тонером |

Получите новый контейнер с тонером TK-4105. |

|

Не оригинальный тонер |

Установлен контейнер с тонером не марки Kyocera |

Производитель не несет ответственности за повреждения, вызванные использованием неоригинального тонера. Мы рекомендуем использовать исключительно оригинальные контейнеры с тонером TK-4105. . |

|

Неверный ид. уч. зап. Задание отменено |

Указан неверный идентификатор учетной записи при внешней обработке задания. Задание отменено |

Нажмите клавишу [OK] |

|

Невозможна двусторонняя печать на этой бумаге |

Не возможна печать на бумаге выбранного формата или типа |

Нажмите клавишу [OK] и перейдите к следующему шагу: |

|

Недостаточно памяти. Невозможно начать выполнение задания |

Невозможно начать выполнение задания |

Повторите попытку позже |

|

Ограничено алгоритмом учета заданий(Печать) |

Задание отменено, поскольку его выполнение ограничено функцией учета заданий |

Нажмите клавишу [OK] |

|

Ограничено алгоритмом учета заданий(Сканер) |

Задание отменено, поскольку его выполнение ограничено функцией учета заданий |

Нажмите клавишу [OK] |

|

Очистите сканер |

Произошло загрязнение сканера |

Очистите щелевое стекло с помощью чистящей салфетки, поставляемой вместе с автоподатчиком оригиналов. |

|

Ошибка. Выключить |

— |

Отключите и снова включите аппарат с помощью выключателя питания |

|

Память переполнена |

Невозможно продолжить выполнение задания из-за отсутствия свободной памяти |

Измените разрешение печати с Быстр1200 до 600 dpi. См. Printer Driver User Guide |

|

Память сканера переполнена |

Дальнейшее сканирование невозможно из-за нехватки памяти сканера. |

Для отмены задания нажмите [OK] |

|

Перезагрузка печати. Задание отменено |

Предупреждение. Недостаточно памяти принтера. Задание отменено |

Нажмите клавишу [OK] |

|

Превышено ограничение учета заданий |

Превышено число распечаток из-за ограничения алгоритмом учета заданий. Достигнут предел печати |

Это задание отменено. Нажмите клавишу [OK] |

|

Уст.другую кассету |

Выбрано «Сдвиг» |

Для использования сдвига необходимо загрузить в другой лоток бумагу такого же формата, что и в выбранном устройстве подачи, но в другой ориентации |

|

Установите все оригиналы обратно и нажмите клавишу [Старт]. |

Возникает при печати двусторонних документов в режиме ручной двусторонней печати |

Извлеките оригиналы из автоподатчика оригиналов, расположите их в первоначальном порядке и положите обратно. Нажмите клавишу [OK], чтобы возобновить печать. Для отмены задания нажмите [Стоп] |

|

Установлен неизвестный тонер. ПК |

Региональная спецификация контейнера с тонером не соответствует спецификации аппарата |

Установите оригинальный контейнер с тонером Замените контейнер с тонером TK-4105 |

Item No.

U000

No.

(7)

Paper Jam

cont.

Log

Items

6813: Front adjustment plate operation OFF error

6903: Rear adjustment plate operation ON error

6913: Rear adjustment plate operation OFF error

7013: Staple operation error

7023: Staple initialoperation error

7913: Sequence error 1 (operation prohibited)

7923: Sequence error 2 (initialoperation error)

7933: Sequence error 3 (Error in the reception of backup data)

7943: Sequence error 4 (standby)

7953: Sequence error 5 (Error in between copies)

9000: No original feed

9001: DP original conveying jam

9004: DP original swichback jam

9010: DP open

9011: DP top cover open

9110: DP paper feed sensor stay jam

9200: DP registration sensor non arrival jam

9400: DP timing sensor non arrival jam

9410: DP timing sensor stay jam

(b) Detail of paper source (Hexadecimal)

00: MP tray

01: Cassette 1

02: Cassette 2 (paper feeder 1)

03: Cassette 3 (paper feeder 2)

04 to 09: Reserved

(c) Detail of paper size (Hexadecimal)

00: (Not specified)

01: Monarch

02: Business

03: International DL

04: International C5

05: Executive

06: Letter-R

86: Letter-E

07: Legal

08: A4R

88: A4E

09: B5R

89: B5E

0A: A3

Description

Description

0B: B4

0C: Ledger

0D: A5R

0E: A6

0F: B6

10: Commercial #9

11: Commercial #6

12: ISO B5

13: Custom size

1E: C4

1F: Postcard

20: Reply-paid post-

card

21: Oficio II

1-3-11

2MW/2MX

22: Special 1

23: Special 2

24: A3 wide

25: Ledger wide

26: Full bleed paper

(12 x

27: 8K

28: 16K-R

A8: 16K-E

32: Statement-R

B2: Statement-E

33: Folio

34: Western type 2

35: Western type 4

Замятие, зажёвывание бумаги в принтерах Kyocera FS-1035MFP/1035MFP/DP-1135/1135MFP/M2035/FS-1030MFP/1130MFP, ошибки 501 и 518, а так же разбор проблем, которые могут возникнуть сразу после замены роликов.

Сегодня мы с вами разберём причины замятия бумаги в некоторых принтерах Kyocera, поговорим о способах устранения данной проблемы и некоторых важных нюансах, о которых стоит знать любому, кто хочет провести ремонт своего принетра результативно и качественно.

Сразу к делу: если принтер Kyocera заминает или зажёвывает бумагу (Ошибка 501), то в подавляющем большинстве случаев причина в износе роликов захвата и/или отделения (сепарации) бумаги. В таком случае ролики нужно заменить. Обычно эти ролики изнашиваются почти одновременно, поэтому менять следует сразу и ролики захвата, и ролик сеперации. В этой статье я расскажу и покажу как это сделать.

Начнём с того, что вынем из принтера лоток для бумаги. Затем принтер нужно поставить «на дыбы», чтобы с областью над лотком было удобно работать.

Теперь нам хорошо видны ролики захвата бумаги.

Чтобы заменить ролики, нам нужно снять пластиковую колодку, в которой они нахоятся. Для этого просто отщёлкиваем колодку снизу, как показано на фото.

Сверху колодка держится на двух зацепах, с ними нужно быть аккуратным, чтобы ни в коем случае не сломать их.

После извлечения колодки просто отжимаем пластик вбок и получаем возможность вынуть ролики.

Оригинальные ролики продаются сразу со втулками, на которых они находятся. Если же вы приобрели совместимые ролики, то у вас в комплекте будут только резинки, и вам придётся самостоятельно стягивать со втулок старые и надевать на их место новые. Но делать так я крайне не рекомендую, и чуть дальше я подробно расскажу — почему.

Установив новые ролики, можем смело вернуть пластиковую колодку на место, процесс её установки ничем не отличается от снятия.

Далее в нашем списке ролик отделения бумаги, он находится в самом лотке, и тоже в пластиковой колодке.

Чтобы снять его, нужно отогнуть пластик этой колодки с одной из сторон.

Обратите внимание, что под колодкой с роликом находится пружина, терять её ни в коем случае нельзя.

А вот выступ на самой колодке, которым в эту пружину нужно будет попасть при установке деталей на место.

Сам ролик извлекается из колодки и заменяется на новый аналогично предыдущим.

Установив все ролики и колодки на место, возвращаем принтер в нормальное положение и вставляем обратно лоток.

На этом замена роликов закончена, это решит проблему с ошибкой 501.

А теперь немного о совместимых роликах и ошибке 518, которая может возникнуть у вас сразу после установки новеньких роликов стороннего производителя.

Компания, в которой я работаю, довльно активно занимается ремонтом принетров, а износ роликов — самая распостранённая проблема печатающей техники Kyocera. И мы перепробовали довольно много различных совместимых роликов, от самых дешёвых, до близких к оригинальным по цене. И ни одни не работали как надо. Либо материал резинок оказывался слишком некачественным и они стирались за несколько тысяч страниц, либо размер самих резинок чуть-чуть не совпадал с оригинальным. К слову, средний срок службы оригинальных роликов около 60-70 тысяч листов. Хотя у некоторых они «бегают» и сотни тысяч. Были и случаи износа оригиналов за 40 тысяч листов, но это большая редкость.

Казалось бы, пол миллиметра разницы в размере — мелочь, но на деле это приводило к серьёзным проблемам со всё тем же замятием бумаги, только на этот раз с оишбкой 518. Её, и все прочие ошибки, можно посмотреть в журнале событий принтера.

Причина в том, что из-за неверного диаметра совместимых роликов листы бумаги протягивались чуть дальше чем должны, попадая в «поле зрения» датчика прохода бумаги слишком рано. Особенно быстро и часто с данной проблемой будут сталкиваться те, кто печатает дуплексом (на обеих сторонах листа). Поэтому крайне рекомендую к установке только оригинальные ролики Kyocera.

Источник

Ошибка Jam 4220 в МФУ Kyocera Ecosys M2035

Доброго времени суток! Дорогие друзья! Сегодня речь пойдет об ошибке Jam 4220. На примере МФУ Kyocera Ecosys M2035 вы увидите, где расположен датчик вызывающий данную ошибку. И в каких ситуациях, помимо реального замятия, может появиться эта ошибка.

Именно в аппарате M2035, ошибку вызывает датчик, расположенный на выходе бумаги из термоузла (в других принтерах, возможно, это может быть и другой датчик).

Первым делом проверьте МФУ на наличие замятой бумаги. Для этого откройте заднюю крышку.

В нижней части вы увидите термоузел, у которого есть возможность отодвинуть шторку и заглянуть вовнутрь. Как раз на этой шторке находится датчик успешного прохождения бумаги из печи. Если бумага застряла и оставила лапку датчика в сдвинутом состоянии, то при включении или окончания распечатки листа, МФУ видит проблему и отображает ошибку.

Как вы видите на фото, никакой бумаги у меня не застряло, значит, проблема может быть в лапке датчика (сломался, проблема с пружинкой), в самом датчике (засорился, сломался), или в контактах подходящих к датчику.

В моем случае лапка датчика была лопнута. Ну что ж, я буду её клеить. Чтобы снять эту лапку, мне понадобится снять термоузел. Если вам нужно подробно посмотреть, как снять печь, то перейдите на статью об ошибке C6000, здесь покажу вкратце.

Снимаем заднюю крышку, сняв её с защелок.

Далее снимем небольшую пластиковую планку сверху, держится она на болтике и двух защелках.

Теперь мы можем снять левую боковую крышку, но для удобства разбора, я сниму ещё и переднюю дверцу.

У боковой крышки с задней стороны есть две защелки, отгибаем и сдвигаем крышку.

Под крышкой доберемся до контактов термоузла. Снимаем большую пластиковую направляющую, и откручиваем высоковольтную плату снизу.

С этой платы отключаем все контакты и убираем её в сторону.

На термоузел идут два контакта, освобождаем их от прокладки.

Теперь мы можем окрутить термоузел с задней стороны.

Аккуратно вытягиваем его и отключаем контакт с левой стороны. Это и есть тот контакт, который соединяет датчик со всей системой.

Итак, снимаем шторку с термоузла (чтобы снять, откройте шторку сильнее обычного).

Смотрим на лапку датчика. Сейчас вы видите уже мои наброски, то есть до того как фотографировать я уже снял печь. Тогда часть лапки вообще лежала в стороне (хорошо хоть не выпала с аппарата), а сейчас я уже подобрал внутренний стержень (маленький кусочек от сверла), но пока не склеивал его, так как решил написать статью.

Я сразу же сниму с лапки пружину, чтобы в дальнейшем не потерять её нечаянно. Кстати об этой пружине я писал в начале, если она выпадет с посадочного места, то не будет прижимать лапку в нужном направлении, и аппарат незамедлительно выдаст вам ошибку Jam 4220.

Теперь я покажу вам сам датчик.

Находится он сбоку термоузла и держится на трех защелках. В целях профилактики я сниму его и тщательно продую.

Далее нам нужно понять, в каком положении клеить две части лапки, для этого я нажеулю стержень и соберу термоузел, предварительно сняв со шторки пружины.

В собранном состоянии ставлю лапку, в нужное положение, отгибаю шторку и закрашиваю две части лапки в местах будущего склеивания.

Теперь мы понимаем, в каком положении склеивать.

Для таких целей у меня припасено несколько тюбиков суперклея. Наносим его стержень и вставляем стержень в лапку, затем наносим на другую сторону и скрепляем.

В месте склеивания остался клей, который может мешать свободному ходу лапки. Я прошелся надфилем и убрал лишнее. Ждем пару минут, пока засохнет клей и собираем все детали.