Cat. No. I533-E1-04

SMARTSTEP A SERIES

R7M-A@ (Servomotors)

R7D-AP@ (Servo Drivers)

Servomotors/Servo Drivers

USER’S MANUAL

Thank you for choosing this SMARTSTEP A-series product. Proper use and handling of the product will ensure proper product performance, will lengthen product life, and may prevent possible accidents.

Please read this manual thoroughly and handle and operate the product with care. Please keep this manual handy for reference after reading it.

1.To ensure safe and proper use of the OMRON Inverters, please read this USER’S MANUAL (Cat. No. I533-E1) to gain sufficient knowledge of the devices, safety information, and precautions before actual use.

2.The products are illustrated without covers and shieldings for closer look in this USER’S MANUAL. For actual use of the products, make sure to use the covers and shieldings as specified.

3.This USER’S MANUAL and other related user’s manuals are to be delivered to the actual end users of the products.

4.Please keep this manual close at hand for future reference.

5.If the product has been left unused for a long time, please inquire at our sales representative.

NOTICE

1.This manual describes information about installation, wiring, switch setting, and troubleshooting of the SMARTSTEP A-series Servomotors and Servo Drivers. For information about actual operating procedures using a Parameter Unit, refer to the SMARTSTEP A Series Operation Manual (I534).

2.Be sure that this manual accompanies the product to its final user.

3.Although care has been given in documenting the product, please contact your OMRON representative if you have any suggestions on improving this manual.

4.Assume that anything not specifically described in this manual is not possible.

5.Do not allow the Servomotor or Servo Driver to be wired, set, or operated (from a Parameter Unit) by anyone that is not a profession electrical engineer or the equivalent.

6.We recommend that you add the following precautions to any instruction manuals you prepare for the system into which the product is being installed.

•Precautions on the dangers of high-voltage equipment.

•Precautions on touching the terminals of the product even after power has been turned OFF. (These terminals are live even with the power turned OFF.)

7.Specifications and functions may be changed without notice in order to improve product performance.

8.Positive and negative rotation of AC Servomotors described in this manual are defined as looking at the end of the output shaft of the motor as follows: Counterclockwise rotation is positive and clockwise rotation is negative.

9.Do not perform withstand-voltage or other megameter tests on the product. Doing so may damage internal components.

10.Servomotors and Servo Drivers have a finite service life. Be sure to keep replacement products on hand and to consider the operating environment and other conditions affecting the service life.

11.Do not set values for any parameters not described in this manual. Operating errors may result. Consult your OMRON representative if you have questions.

12.Before using the product under conditions which are not described in the manual or applying the product to nuclear control systems, railroad systems, aviation systems, vehicles, combustion systems, medical equipment, amusement machines, safety equipment, and other systems, machines, and equipment that may have a serious influence on lives and property if used improperly, consult your OMRON representative.

Items to Check Before Unpacking

1.Check the following items before removing the product from the package:

•Has the correct product been delivered (i.e., the correct model number and specifications)?

•Has the product been damaged in shipping?

2.Check that the following accessories have been delivered.

•Safety Precautions

No connectors or mounting screws are provided. Obtain these separately.

USER’S MANUAL

SMARTSTEP ASERIES

MODELS R7M-A@ (Servomotors)

R7D-AP@ (Servo Drivers)

Servomotors/Servo Drivers

Notice:

OMRON products are manufactured for use according to proper procedures by a qualified operator and only for the purposes described in this manual.

The following conventions are used to indicate and classify precautions in this manual. Always heed the information provided with them. Failure to heed precautions can result in injury to people or damage to property.

!DANGER Indicates an imminently hazardous situation which, if not avoided, will result in death or serious injury. Additionally, there may be severe property damage.

!WARNING Indicates a potentially hazardous situation which, if not avoided, could result in death or serious injury. Additionally, there may be severe property damage.

!Caution Indicates a potentially hazardous situation which, if not avoided, may result in minor or moderate injury, or property damage.

OMRON Product References

All OMRON products are capitalized in this manual. The word “Unit” is also capitalized when it refers to an OMRON product, regardless of whether or not it appears in the proper name of the product.

The abbreviation “Ch,” which appears in some displays and on some OMRON products, often means “word” and is abbreviated “Wd” in documentation in this sense.

The abbreviation “PC” means Programmable Controller and is not used as an abbreviation for anything else.

Visual Aids

The following headings appear in the left column of the manual to help you locate different types of information.

Note Indicates information of particular interest for efficient and convenient operation of the product.

OMRON, 2001

All rights reserved. No part of this publication may be reproduced, stored in a retrieval system, or transmitted, in any form, or by any means, mechanical, electronic, photocopying, recording, or otherwise, without the prior written permission of OMRON.

No patent liability is assumed with respect to the use of the information contained herein. Moreover, because OMRON is constantly striving to improve its high-quality products, the information contained in this manual is subject to change without notice. Every precaution has been taken in the preparation of this manual. Nevertheless, OMRON assumes no responsibility for errors or omissions. Neither is any liability assumed for damages resulting from the use of the information contained in this publication.

General Warnings

Observe the following warnings when using the SMARTSTEP Servomotor and Servo Driver and all connected or peripheral devices.

This manual may include illustrations of the product with protective covers removed in order to describe the components of the product in detail. Make sure that these protective covers are on the product before use.

Consult your OMRON representative when using the product after a long period of storage.

!WARNING Always connect the frame ground terminals of the Servo Driver and the Servomotor to a class-3 ground (to 100 Ω or less). Not connecting to a class-3 ground may result in electric shock.

!WARNING Do not touch the inside of the Servo Driver. Doing so may result in electric shock.

!WARNING Do not remove the front cover, terminal covers, cables, or optional items while the power is being supplied. Doing so may result in electric shock.

!WARNING Installation, operation, maintenance, or inspection must be performed by authorized personnel. Not doing so may result in electric shock or injury.

!WARNING Wiring or inspection must not be performed for at least five minutes after turning OFF the power supply. Doing so may result in electric shock.

!WARNING Do not damage, press, or put excessive stress or heavy objects on the cables. Doing so may result in electric shock.

!WARNING Do not touch the rotating parts of the Servomotor in operation. Doing so may result in injury.

!WARNING Do not modify the product. Doing so may result in injury or damage to the product.

!WARNING Provide a stopping mechanism on the machine to ensure safety. The holding brake is not designed as a stopping mechanism for safety purposes.

!WARNING Provide an external emergency stopping mechanism that can stop operation and shutting off the power supply immediately. Not doing so may result in injury.

!WARNING Do not come close to the machine immediately after resetting momentary power interruption to avoid an unexpected restart. (Take appropriate measures to secure safety against an unexpected restart.) Doing so may result in injury.

!Caution Use the Servomotors and Servo Drivers in a specified combination. Using them incorrectly may result in fire or damage to the products.

!Caution Do not store or install the product in the following places. Doing so may result in fire, electric shock, or damage to the product.

•Locations subject to direct sunlight.

•Locations subject to temperatures or humidity outside the range specified in the specifications.

•Locations subject to condensation as the result of severe changes in temperature.

•Locations subject to corrosive or flammable gases.

•Locations subject to dust (especially iron dust) or salts.

•Locations subject to shock or vibration.

•Locations subject to exposure to water, oil, or chemicals.

!Caution Do not touch the Servo Driver radiator, Servo Driver regeneration resistor, or Servomotor while the power is being supplied or soon after the power is turned OFF. Doing so may result in a skin burn due to the hot surface.

Storage and Transportation Precautions

!Caution Do not hold the product by the cables or motor shaft while transporting it. Doing so may result in injury or malfunction.

!Caution Do not place any load exceeding the figure indicated on the product. Doing so may result in injury or malfunction.

Installation and Wiring Precautions

!Caution Do not step on or place a heavy object on the product. Doing so may result in injury.

!Caution Do not cover the inlet or outlet ports and prevent any foreign objects from entering the product. Doing so may result in fire.

!Caution Be sure to install the product in the correct direction. Not doing so may result in malfunction.

!Caution Provide the specified clearances between the Servo Driver and the control panel or with other devices. Not doing so may result in fire or malfunction.

!Caution Do not apply any strong impact. Doing so may result in malfunction.

!Caution Be sure to wire correctly and securely. Not doing so may result in motor runaway, injury, or malfunction.

!Caution Be sure that all the mounting screws, terminal screws, and cable connector screws are tightened to the torque specified in the relevant manuals. Incorrect tightening torque may result in malfunction.

!Caution Use crimp terminals for wiring. Do not connect bare stranded wires directly to terminals. Connection of bare stranded wires may result in burning.

!Caution Always use the power supply voltage specified in the User’s Manual. An incorrect voltage may result in malfunction or burning.

!Caution Take appropriate measures to ensure that the specified power with the rated voltage and frequency is supplied. Be particularly careful in places where the power supply is unstable. An incorrect power supply may result in malfunction.

!Caution Install external breakers and take other safety measures against short-circuiting in external wiring. Insufficient safety measures against short-circuiting may result in burning.

!Caution Take appropriate and sufficient countermeasures when installing systems in the following locations. Failure to do so may result in damage to the product.

•Locations subject to static electricity or other forms of noise.

•Locations subject to strong electromagnetic fields and magnetic fields.

•Locations subject to possible exposure to radioactivity.

•Locations close to power supplies.

Operation and Adjustment Precautions

!Caution Confirm that no adverse effects will occur in the system before performing the test operation. Not doing so may result in equipment damage.

!Caution Check the newly set parameters and switches for proper execution before actually running them. Not doing so may result in equipment damage.

!Caution Do not make any extreme adjustments or setting changes. Doing so may result in unstable operation and injury.

!Caution Separate the Servomotor from the machine, check for proper operation, and then connect to the machine. Not doing so may cause injury.

!Caution When an alarm occurs, remove the cause, reset the alarm after confirming safety, and then resume operation. Not doing so may result in injury.

!Caution Do not use the built-in brake of the Servomotor for ordinary braking. Doing so may result in malfunction.

Maintenance and Inspection Precautions

!WARNING Do not attempt to disassemble, repair, or modify any Units. Any attempt to do so may result in malfunction, fire, or electric shock.

!Caution Resume operation only after transferring to the new Unit the contents of the data required for operation. Not doing so may result in an unexpected operation.

Warning Labels

Warning labels are pasted on the product as shown in the following illustration. Be sure to follow the instructions given there.

Warning label

Example from R7D-AP01L

Example from R7D-AP01L

Read and Understand this Manual

Please read and understand this manual before using the product. Please consult your OMRON representative if you have any questions or comments.

Warranty and Limitations of Liability

WARRANTY

OMRON’s exclusive warranty is that the products are free from defects in materials and workmanship for a period of one year (or other period if specified) from date of sale by OMRON.

OMRON MAKES NO WARRANTY OR REPRESENTATION, EXPRESS OR IMPLIED, REGARDING NONINFRINGEMENT, MERCHANTABILITY, OR FITNESS FOR PARTICULAR PURPOSE OF THE PRODUCTS. ANY BUYER OR USER ACKNOWLEDGES THAT THE BUYER OR USER ALONE HAS DETERMINED THAT THE PRODUCTS WILL SUITABLY MEET THE REQUIREMENTS OF THEIR INTENDED USE. OMRON DISCLAIMS ALL OTHER WARRANTIES, EXPRESS OR IMPLIED.

LIMITATIONS OF LIABILITY

OMRON SHALL NOT BE RESPONSIBLE FOR SPECIAL, INDIRECT, OR CONSEQUENTIAL DAMAGES, LOSS OF PROFITS OR COMMERCIAL LOSS IN ANY WAY CONNECTED WITH THE PRODUCTS, WHETHER SUCH CLAIM IS BASED ON CONTRACT, WARRANTY, NEGLIGENCE, OR STRICT LIABILITY.

In no event shall the responsibility of OMRON for any act exceed the individual price of the product on which liability is asserted.

IN NO EVENT SHALL OMRON BE RESPONSIBLE FOR WARRANTY, REPAIR, OR OTHER CLAIMS REGARDING THE PRODUCTS UNLESS OMRON’S ANALYSIS CONFIRMS THAT THE PRODUCTS WERE PROPERLY HANDLED, STORED, INSTALLED, AND MAINTAINED AND NOT SUBJECT TO CONTAMINATION, ABUSE, MISUSE, OR INAPPROPRIATE MODIFICATION OR REPAIR.

Application Considerations

SUITABILITY FOR USE

OMRON shall not be responsible for conformity with any standards, codes, or regulations that apply to the combination of products in the customer’s application or use of the products.

At the customer’s request, OMRON will provide applicable third party certification documents identifying ratings and limitations of use that apply to the products. This information by itself is not sufficient for a complete determination of the suitability of the products in combination with the end product, machine, system, or other application or use.

The following are some examples of applications for which particular attention must be given. This is not intended to be an exhaustive list of all possible uses of the products, nor is it intended to imply that the uses listed may be suitable for the products:

•Outdoor use, uses involving potential chemical contamination or electrical interference, or conditions or uses not described in this manual.

•Nuclear energy control systems, combustion systems, railroad systems, aviation systems, medical equipment, amusement machines, vehicles, safety equipment, and installations subject to separate industry or government regulations.

•Systems, machines, and equipment that could present a risk to life or property.

Please know and observe all prohibitions of use applicable to the products.

NEVER USE THE PRODUCTS FOR AN APPLICATION INVOLVING SERIOUS RISK TO LIFE OR PROPERTY WITHOUT ENSURING THAT THE SYSTEM AS A WHOLE HAS BEEN DESIGNED TO ADDRESS THE RISKS, AND THAT THE OMRON PRODUCTS ARE PROPERLY RATED AND INSTALLED FOR THE INTENDED USE WITHIN THE OVERALL EQUIPMENT OR SYSTEM.

PROGRAMMABLE PRODUCTS

OMRON shall not be responsible for the user’s programming of a programmable product, or any consequence thereof.

Disclaimers

CHANGE IN SPECIFICATIONS

Product specifications and accessories may be changed at any time based on improvements and other reasons.

It is our practice to change model numbers when published ratings or features are changed, or when significant construction changes are made. However, some specifications of the products may be changed without any notice. When in doubt, special model numbers may be assigned to fix or establish key specifications for your application on your request. Please consult with your OMRON representative at any time to confirm actual specifications of purchased products.

DIMENSIONS AND WEIGHTS

Dimensions and weights are nominal and are not to be used for manufacturing purposes, even when tolerances are shown.

PERFORMANCE DATA

Performance data given in this manual is provided as a guide for the user in determining suitability and does not constitute a warranty. It may represent the result of OMRON’s test conditions, and the users must correlate it to actual application requirements. Actual performance is subject to the OMRON Warranty and Limitations of Liability.

ERRORS AND OMISSIONS

The information in this manual has been carefully checked and is believed to be accurate; however, no responsibility is assumed for clerical, typographical, or proofreading errors, or omissions.

|

Table of Contents |

|||||

|

Chapter 1. Introduction. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

1-1 |

||||

|

1-1 |

Features. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

1-2 |

|||

|

1-2 |

System Configuration . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

1-4 |

|||

|

1-3 |

Servo Driver Nomenclature . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

1-5 |

|||

|

1-4 |

Applicable Standards . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

1-6 |

|||

|

1-5 |

System Block Diagrams . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

1-7 |

|||

|

Chapter 2. Standard Models and Specifications. . . . . . . . . . . . . . . . |

2-1 |

||||

|

2-1 |

Standard Models. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

2-2 |

|||

|

2-2 |

External and Mounted Dimensions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

2-6 |

|||

|

2-3 |

Servo Driver Specifications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

2-17 |

|||

|

2-4 |

Servomotor Specifications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

2-31 |

|||

|

2-5 |

Reduction Gear Specifications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

2-39 |

|||

|

2-6 |

Cable and Connector Specifications. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

2-43 |

|||

|

2-7 |

Servo Relay Units and Cable Specifications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

2-58 |

|||

|

2-8 |

Parameter Unit Specifications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

2-111 |

|||

|

2-9 |

External Regeneration Resistor Specifications. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

2-113 |

|||

|

2-10 |

DC Reactors . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

2-114 |

|||

|

Chapter 3. System Design and Installation . . . . . . . . . . . . . . . . . . . . |

3-1 |

||||

|

3-1 |

Installation Conditions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

3-3 |

|||

|

3-2 |

Wiring. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

3-8 |

|||

|

3-3 |

Regenerative Energy Absorption . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

3-37 |

|||

|

Chapter 4. Operation. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

4-1 |

||||

|

4-1 |

Operational Procedure . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

4-3 |

|||

|

4-2 |

Switch Settings . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

4-4 |

|||

|

4-3 |

Preparing for Operation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

4-7 |

|||

|

4-4 |

Trial Operation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

4-9 |

|||

|

4-5 |

Gain Adjustments . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

4-11 |

|||

|

4-6 |

User Parameters . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

4-15 |

|||

|

4-7 |

Operating Functions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

4-26 |

|||

|

Chapter 5. Troubleshooting . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

5-1 |

||||

|

5-1 |

Measures when Trouble Occurs . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

5-2 |

|||

|

5-2 |

Alarms . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

5-5 |

|||

|

5-3 |

Troubleshooting . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

5-7 |

|||

|

5-4 |

Overload Characteristics (Electron Thermal Characteristics) . . . . . . . . . . . . . . . . . . . . . . . . |

5-15 |

|||

|

5-5 |

Periodic Maintenance . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

5-16 |

|||

|

Chapter 6. Appendix . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

6-1 |

||||

|

6-1 |

Connection Examples. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

6-2 |

|||

|

Revision History. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

R-1 |

||||

Chapter 1

Introduction

1-1 Features

1-2 System Configuration

1-3 Servo Driver Nomenclature

1-4 Applicable Standards

1-5 System Block Diagrams

1-1 Features

The SMARTSTEP A-series Servomotors and Servo Drivers have been developed as pulse string input-type Position Controllers to replace stepping motors in simple positioning systems. The SMARTSTEP A-series Servomotors and Servo Drivers combine the stepping motor’s ease of use with faster positioning resulting from high speed and high torque, higher reliability with no loss of positioning accuracy even during sudden load changes, and other advanced features.

■ Faster Response and Rotation Speed

SMARTSTEP A-series Servomotors and Servo Drivers incorporate the same high-speed and hightorque features, unachievable with stepping motors, as the OMNUC W Series. The SMARTSTEP A- series Servomotors provide faster rotation speeds of up to 4,500 r/min, with constant operation possible at this speed. Faster output torque of up to 1 s can output up to approximately 300% of the rated torque, providing even faster middleand long-stroke positioning.

■ Constant Accuracy

The A-series product line’s higher encoder resolution of 2,000 pulses/rotation provides feedback control enabling continuous operation without loss of positioning accuracy, even with sudden load changes or sudden acceleration or deceleration.

■ Minimal Setting with Servo Driver Front Panel Switches

The SMARTSTEP A Series can be operated immediately without time-consuming parameter setting. The A-series Servo Drivers’ front panel switches enable easier alteration of function or positioning resolution settings.

● Resolution Settings

SMARTSTEP A-series Servomotor resolution can be selected from the following four levels: 500 pulses/rotation (0.72°/step); 1,000 pulses/rotation (0.36°/step) (default setting); 5,000 pulses/ rotation (0.072°/step); or 10,000 pulses/rotation (0.036°/step)

● Command Pulse Input Setting

SMARTSTEP A-series command pulse input setting can be switched between CW/CCW (2-pulse) and SIGN/PULS (single-pulse) methods to easily adapt to Position Controller output specifications.

● Dynamic Brake Setting

SMARTSTEP A-series Servomotors can be forcibly decelerated to a stop at RUN OFF or when an alarm occurs.

● Gain Setting

A special rotary switch on SMARSTEP A-series Servo Drivers enables easy gain setting. Online autotuning can also be activated with the flick of a switch, and responsiveness can be easily matched to the machinery to be used.

1-2

Note Using a Parameter Unit or personal computer enables operation with parameter settings.

■ Cylinder-style and Flat-style Servomotors

The SMARTSTEP A Series offers Flanged Cylinder-style Servomotors, with a smaller mounting area, and Flat-style Servomotors, with a shorter overall length. The Flat Servomotor depth dimensions are approximately the same as those of stepping motors of the same output capacity. Servomotors can be selected by size, thereby making equipment more compact.

■ A Wider Selection of Programming Devices

Special SMARTSTEP A-series Parameter Units and personal computer monitoring software are available. The special monitoring software enables performing parameter setting, speed and current monitoring, speed and current waveform displays, I/O monitoring, autotuning, jogging, and other operations from a computer. It is also possible to perform multiple-axis communications that set the parameters and monitor operations for multiple Servo Drivers. For details, refer to the Servo Driver Personal Computer Monitor Software (CD-ROM) for Windows 95/98, Version 2.0 (WMON Win Ver.2.0) (Catalog No.: SBCE-011).

1-3

1-2 System Configuration

|

SYSMAC + Position Control Unit with pulse string output |

||||

|

B.B INP |

TGON |

REF POWER |

||

|

VCMP |

||||

|

NC413 |

||||

|

MACHINE |

||||

|

No. |

||||

|

CN1 CN2 |

||||

|

R7A–PR02A PARAMETER UNIT |

||||

|

RESET |

SCROLL |

MODE/SET |

||

|

Pulse String |

||||

|

SYSMAC CJ/CS/C/CV |

Position Control Units |

JOG |

DATA |

|

|

RUN |

||||

|

Programmable Controller |

CJ1W-NC113/213/413 |

|||

|

CJ1W-NC133/233/433 |

READ |

WRITE |

||

|

CS1W-NC113/213/413 |

DRIVER |

PR PR |

DRIVER |

|

|

CS1W-NC133/233/433 |

R7A-PR02A Parameter Unit |

|||

|

C200HW-NC113/213/413 |

(Hand-held) |

|||

|

C500-NC113/211 |

||||

|

SYSMAC Programmable Controllers with pulse outputs |

|

SYSMAC CPM2A |

SYSMAC CPM2C |

PA203

POWER

SYSMAC CQM1H

Single-shaft Positioner with pulse string output

|

MS |

OP |

EN |

|||

|

NS |

No. |

OPEN |

|||

|

13F88M- |

LINE |

||||

|

M0 |

DRT141 |

LINE |

|||

|

AXIS |

CW |

||||

|

M1 |

POSITIONER |

CCW |

|

M2 |

ALARM |

||||||||||

|

2 |

34 |

NA |

M2 |

LS |

IT |

||||||

|

9 |

M1 |

FT LIM |

|||||||||

|

78 |

×10 |

M0 |

SO SRH NG |

||||||||

|

ORG |

R ALM |

||||||||||

|

2 |

34 |

CODE |

|||||||||

|

9 |

EN |

STOP M |

|||||||||

|

87 |

×1 |

DRIVE |

R AL |

||||||||

|

R |

|||||||||||

|

1 |

DR0 |

OTHE |

|||||||||

|

2 ON |

|||||||||||

|

3 ↓ |

DR1 |

N |

|||||||||

|

L/R |

ED : |

) |

MUNICATIO |

||||||||

|

(R |

COM |

||||||||||

|

H |

SPEEDbps |

||||||||||

|

DIP SW |

ITC |

125k |

|||||||||

|

DR1 |

250kbps |

||||||||||

|

DR0 |

O |

FF |

|||||||||

|

F |

500kbps |

||||||||||

|

OFF |

OF |

− |

|||||||||

|

ON |

LOCAL/REMOTE |

||||||||||

|

ON |

ON |

||||||||||

|

OFF |

H |

MODE |

|||||||||

|

ON |

ITC |

REMOTEL |

MODE |

||||||||

|

P SW |

|||||||||||

|

DI |

L/R |

LOCA |

|||||||||

|

OFF |

|||||||||||

|

ON |

I/O

3F88M-DRT141 Single-shaft Positioner for DeviceNet

SMARTSTEP A-series

R7D-AP@ Servo Driver

SMARTSTEP A-series

R7M-A@ Servomotor

1-4

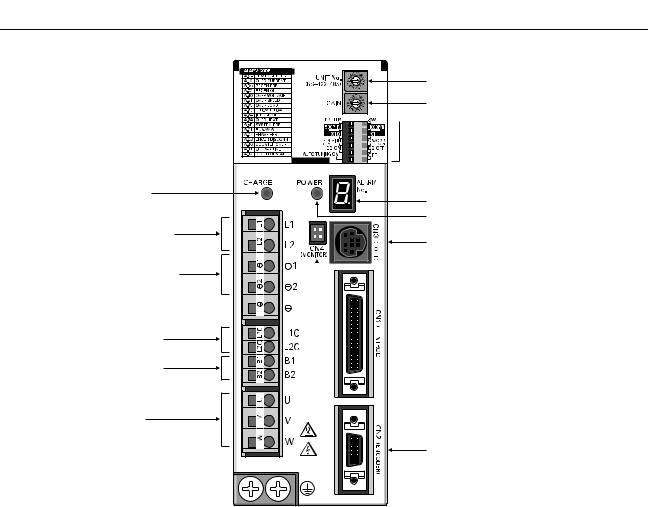

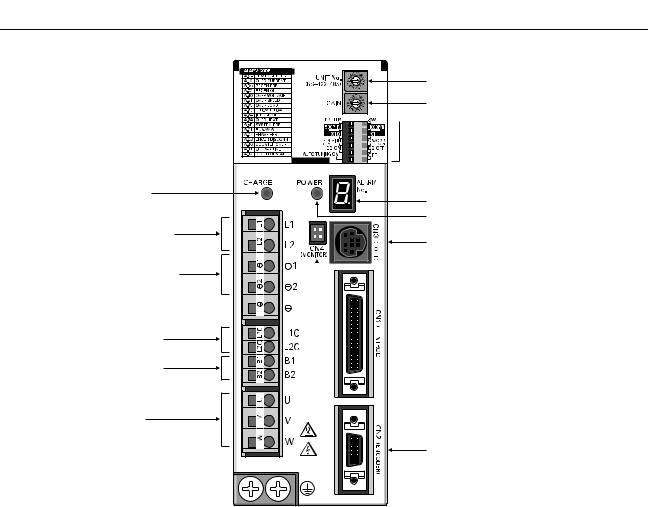

1-3 Servo Driver Nomenclature

|

Main-circuit power supply |

|

indicator |

|

Main-circuit power |

|

supply input terminals |

|

DC reactor connection terminals |

|

Control-circuit power supply |

|

input terminals |

|

External regeneration |

|

resistance terminals |

|

Servomotor power terminals |

FG terminals for power supply and

Rotary switch for unit No. selection

Rotary switch for gain adjustment

• Switch/parameter setting enable switch

• Resolution setting

• Command pulse input setting

•Dynamic braking setting

•Online autotuning switch

Alarm display

Control-circuit power supply indicator

Communications connector (CN3)

Encoder input connector (CN2)

1-5

|

Introduction |

Chapter 1 |

||

1-4 Applicable Standards |

|||

|

■ EC Directives |

|||

|

EC Directives |

Product |

Applicable standards |

Remarks |

|

Low Voltage |

AC Servo Drivers |

EN50178 |

Safety requirements for electrical |

|

Directive |

devices for measurement, control, |

||

|

and research facilities |

|||

|

AC Servomotors |

IEC60034-1, -5, -8, -9 |

Rotating electrical equipment |

|

|

EN60034-1, -9 |

|||

|

EMC Directives |

AC Servo Drivers and |

EN55011 class A group 1 |

Wireless interference and measure- |

|

AC Servomotors |

ment methods for radio-frequency |

||

|

devices for industry, science, and |

|||

|

medical application |

|||

|

EN61000-6-2 |

Electromagnetic compatibility and |

||

|

immunity standards for industrial |

|||

|

environments |

|||

Note Installation under the conditions stipulated in 3-2-5 EMC-compatible Wiring must be met to ensure conformance to EMC Directives.

■ UL and cUL Standards

|

Standards |

Product |

Applicable standards |

File No. |

Remarks |

||

|

UL |

AC Servo Drivers |

UL508C |

E179149 |

Power conversion devices |

||

|

AC Servomotors |

UL1004 |

E179189 |

Electric motors |

|||

|

cUL |

AC Servo Drivers |

cUL C22.2 |

No. 14 |

E179149 |

Industrial control devices |

|

|

AC Servomotors |

cUL C22.2 |

No. 100 |

E179189 |

Motors and generators |

||

1-6

1-5 System Block Diagrams

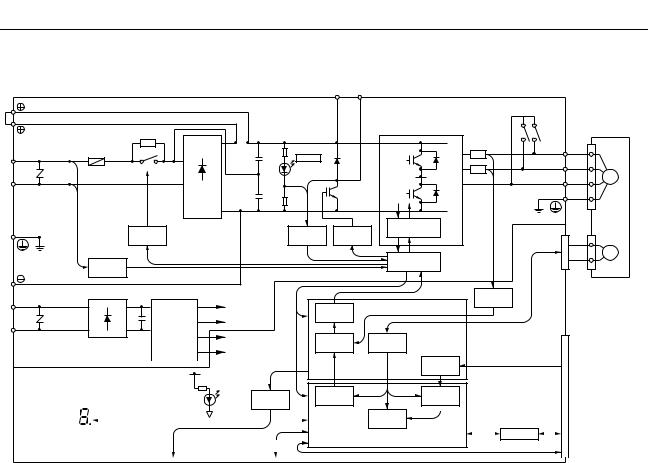

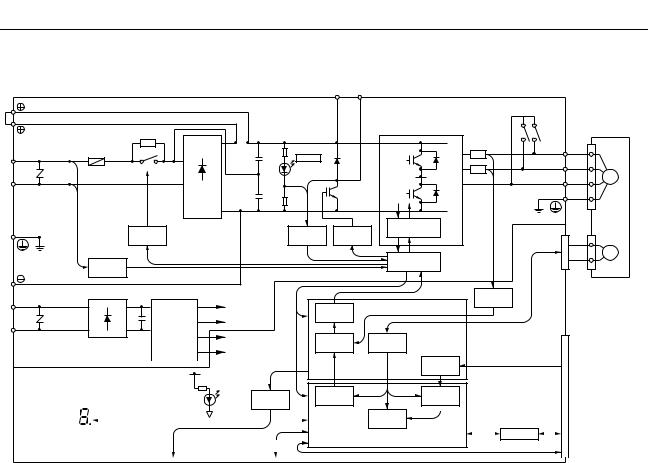

■ 100 V AC: R7D-APA3L/-APA5L/-AP01L/-AP02L/-AP04L

|

AC Servo Driver |

||||||||||||

|

1 |

B1 |

B2 |

||||||||||

|

2 |

AC Servomotor |

|||||||||||

|

Fuse |

P1 |

P2 |

U |

U |

||||||||

|

R |

CHARGE |

|||||||||||

|

V |

||||||||||||

|

L1 |

V |

|||||||||||

|

W |

M |

|||||||||||

|

T |

W |

|||||||||||

|

L2 |

+ |

(See note.) |

||||||||||

|

− |

N2 |

|||||||||||

|

N1 |

||||||||||||

|

Relay |

Voltage |

Gate drive |

||||||||||

|

overcurrent protection |

CN2 |

|||||||||||

|

drive |

detection |

Gate drive |

||||||||||

|

Interface |

E |

|||||||||||

|

Voltage |

||||||||||||

|

detection |

||||||||||||

|

L1C |

Current |

|||||||||||

|

+ |

+ |

±5 V |

PWM |

ASIC |

detection |

|||||||

|

− |

− |

DC/DC |

+16.5 V |

generation |

||||||||

|

L2C |

conversion |

+5 V |

Digital |

Encoder signal |

CN1 |

|||||||

|

±15 V |

current amp |

processing |

||||||||||

|

Command |

||||||||||||||||||||||

|

+5 V |

pulse |

Command |

||||||||||||||||||||

|

processing |

pulse input |

|||||||||||||||||||||

|

POWER |

Analog |

Current |

Position |

|||||||||||||||||||

|

command |

||||||||||||||||||||||

|

voltage |

processing |

control |

||||||||||||||||||||

|

0 V |

conversion |

Speed |

||||||||||||||||||||

|

Serial port |

control |

I/O |

Control I/O |

|||||||||||||||||||

|

Alarm code display |

CPU |

|||||||||||||||||||||

|

RS-422 |

||||||||||||||||||||||

|

CN4 |

CN3 |

Note |

Only on R7D-AP04H/AP04L. |

|||||||||||||||||||

|

Analog monitor output |

Parameter Unit/computer |

1-7

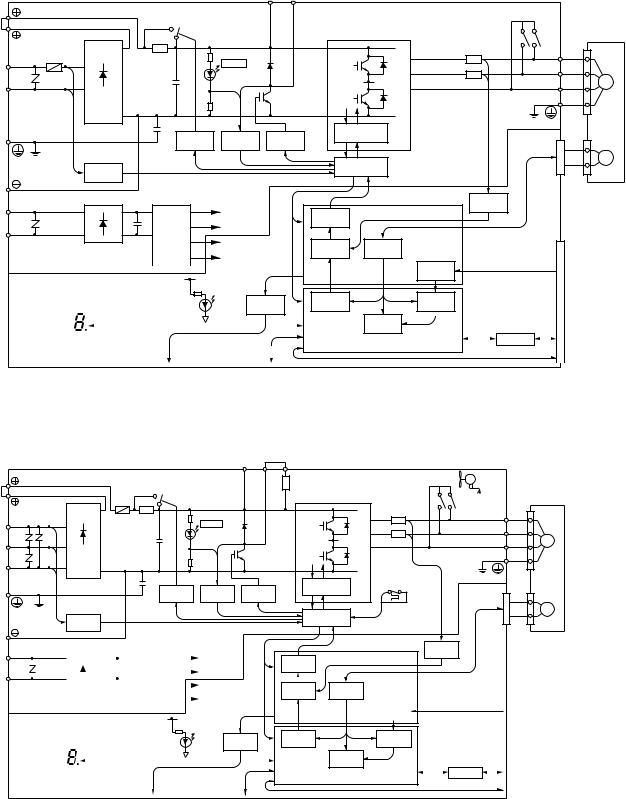

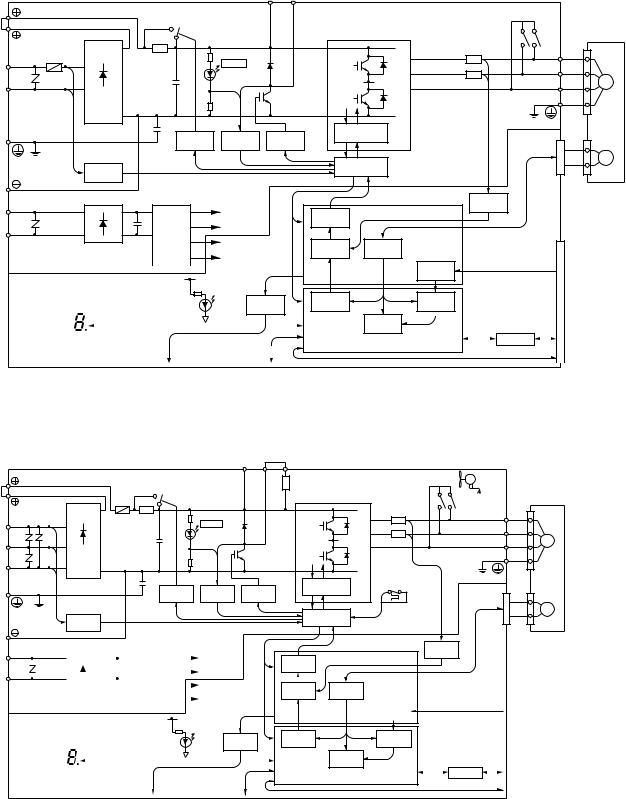

■ 200 V AC: R7D-APA3H/-APA5H/-AP01H/-AP02H/-AP04H

|

AC Servo Driver |

||||||

|

1 |

B1 |

B2 |

||||

|

2 |

P1 |

AC Servomotor |

||||

|

Fuse |

P2 |

U |

U |

|||

|

CHARGE |

||||||

|

R |

V |

|||||

|

+ |

V |

|||||

|

L1 |

W |

M |

||||

|

T |

− |

W |

||||

|

L2 |

(See note.) |

N2

N1

|

Relay |

Voltage |

Gate drive |

|

|

Gate drive |

overcurrent protection |

||

|

drive |

detection |

CN2 |

|

Interface |

E |

||||||||

|

Voltage |

|||||||||

|

detection |

|||||||||

|

L1C |

Current |

||||||||

|

+ |

±5 V |

PWM |

ASIC |

detection |

|||||

|

+ |

|||||||||

|

− |

DC/DC |

+16.5 V |

generation |

||||||

|

− |

|||||||||

|

L2C |

conversion |

+5 V |

Digital |

Encoder signal |

CN1 |

||||

|

±15 V |

current amp |

processing |

|||||||

|

Command |

||||||||||||||||||||||

|

+5 V |

pulse |

Command |

||||||||||||||||||||

|

processing |

pulse input |

|||||||||||||||||||||

|

POWER |

Analog |

Current |

Position |

|||||||||||||||||||

|

command |

||||||||||||||||||||||

|

voltage |

processing |

control |

||||||||||||||||||||

|

0 V |

conversion |

|||||||||||||||||||||

|

Speed |

||||||||||||||||||||||

|

Serial port |

control |

I/O |

Control I/O |

|||||||||||||||||||

|

Alarm code display |

CPU |

|||||||||||||||||||||

|

RS-422 |

||||||||||||||||||||||

|

CN4 |

CN3 |

Note |

Only on R7D-AP04H/AP04L. |

|||||||||||||||||||

|

Analog monitor output |

Parameter Unit/computer |

■ 200 V AC: R7D-AP08H

AC Servo Driver

|

1 |

B1 B2 B3 |

FAN |

|

±12 V |

||

|

2 |

AC Servomotor |

|

|

P |

P |

U |

U |

||||||

|

R |

Fuse |

CHARGE |

|||||||

|

V |

|||||||||

|

L1 |

+ |

V |

|||||||

|

W |

M |

||||||||

|

S |

− |

W |

|||||||

|

L2 |

|||||||||

|

L3 |

T |

N |

N |

||||||

|

Relay |

Voltage |

Gate |

Gate drive over- |

||||||

|

current protection |

CN2 |

||||||||

|

drive |

detection |

drive |

Ther- |

||||||

|

mistor |

E |

||||||||

|

Voltage |

Interface |

||||||||

|

detection |

|

L1C |

Current |

|||||||||||||||||||||||||||||||

|

ASIC |

detection |

|||||||||||||||||||||||||||||||

|

+ |

±5 V |

PWM |

||||||||||||||||||||||||||||||

|

+ |

||||||||||||||||||||||||||||||||

|

− |

− |

DC/DC |

+16.5 V |

generation |

||||||||||||||||||||||||||||

|

conversion |

CN1 |

|||||||||||||||||||||||||||||||

|

L2C |

+5 V |

Digital |

Encoder |

|||||||||||||||||||||||||||||

|

current amp |

signal |

|||||||||||||||||||||||||||||||

|

±15 V |

processing |

|||||||||||||||||||||||||||||||

|

Command |

Command |

|||||||||||||||||||||||||||||||

|

pulse |

||||||||||||||||||||||||||||||||

|

+5 V |

processing |

pulse input |

||||||||||||||||||||||||||||||

|

Position |

||||||||||||||||||||||||||||||||

|

POWER |

Analog |

Current |

||||||||||||||||||||||||||||||

|

command |

||||||||||||||||||||||||||||||||

|

voltage |

control |

|||||||||||||||||||||||||||||||

|

processing |

||||||||||||||||||||||||||||||||

|

0 V |

conversion |

|||||||||||||||||||||||||||||||

|

Speed |

||||||||||||||||||||||||||||||||

|

Serial port |

control |

I/O |

Control I/O |

|||||||||||||||||||||||||||||

|

Alarm code display |

CPU |

|||||||||||||||||||||||||||||||

|

RS-422 |

||||||||||||||||||||||||||||||||

|

CN4 |

CN3 |

|||||||||||||||||||||||||||||||

|

Analog monitor output |

Parameter Unit/computer |

1-8

Chapter 2

Standard Models and

Specifications

2-1 Standard Models

2-2 External and Mounted Dimensions

2-3 Servo Driver Specifications

2-4 Servomotor Specifications

2-5 Reduction Gear Specifications

2-6 Cable and Connector Specifications

2-7 Servo Relay Units and Cable Specifications

2-8 Parameter Unit Specifications

2-9 External Regeneration Resistor Specifications

2-10 DC Reactors

|

Standard Models and Specifications |

Chapter 2 |

|

2-1 Standard Models

■ Servomotors

● 3,000-r/min Cylinder-style Servomotors

|

Specifications |

Model |

|||

|

Without |

Straight shaft |

30 W |

R7M-A03030 |

|

|

brake |

without key |

|||

|

50 W |

R7M-A05030 |

|||

|

100 W |

R7M-A10030 |

|||

|

200 W |

R7M-A20030 |

|||

|

400 W |

R7M-A40030 |

|||

|

750 W |

R7M-A75030 |

|||

|

Straight shaft |

30 W |

R7M-A03030-S1 |

||

|

with key |

||||

|

50 W |

R7M-A05030-S1 |

|||

|

100 W |

R7M-A10030-S1 |

|||

|

200 W |

R7M-A20030-S1 |

|||

|

400 W |

R7M-A40030-S1 |

|||

|

750 W |

R7M-A75030-S1 |

|||

|

With |

Straight shaft |

30 W |

R7M-A03030-B |

|

|

brake |

without key |

|||

|

50 W |

R7M-A05030-B |

|||

|

100 W |

R7M-A10030-B |

|||

|

200 W |

R7M-A20030-B |

|||

|

400 W |

R7M-A40030-B |

|||

|

750 W |

R7M-A75030-B |

|||

|

Straight shaft |

30 W |

R7M-A03030-BS1 |

||

|

with key |

||||

|

50 W |

R7M-A05030-BS1 |

|||

|

100 W |

R7M-A10030-BS1 |

|||

|

200 W |

R7M-A20030-BS1 |

|||

|

400 W |

R7M-A40030-BS1 |

|||

|

750 W |

R7M-A75030-BS1 |

|||

● 3,000-r/min Flat-style Servomotors

|

Specifications |

Model |

|||

|

Without |

Straight shaft |

100 W |

R7M-AP10030 |

|

|

brake |

without key |

|||

|

200 W |

R7M-AP20030 |

|||

|

400 W |

R7M-AP40030 |

|||

|

750 W |

R7M-AP75030 |

|||

|

Straight shaft |

100 W |

R7M-AP10030-S1 |

||

|

with key |

||||

|

200 W |

R7M-AP20030-S1 |

|||

|

400 W |

R7M-AP40030-S1 |

|||

|

750 W |

R7M-AP75030-S1 |

|||

|

With |

Straight shaft |

100 W |

R7M-AP10030-B |

|

|

brake |

without key |

|||

|

200 W |

R7M-AP20030-B |

|||

|

400 W |

R7M-AP40030-B |

|||

|

750 W |

R7M-AP75030-B |

|||

|

Straight shaft |

100 W |

R7M-AP10030-BS1 |

||

|

with key |

||||

|

200 W |

R7M-AP20030-BS1 |

|||

|

400 W |

R7M-AP40030-BS1 |

|||

|

750 W |

R7M-AP75030-BS1 |

■ Servo Drivers

|

Specifications |

Model |

||

|

Single-phase |

30 W |

R7D-APA3L |

|

|

100 V AC |

|||

|

50 W |

R7D-APA5L |

||

|

100 W |

R7D-AP01L |

||

|

200 W |

R7D-AP02L |

||

|

400 W |

R7D-AP04L |

||

|

Single-phase |

30 W |

R7D-APA3H |

|

|

200 V AC |

|||

|

50 W |

R7D-APA5H |

||

|

100 W |

R7D-AP01H |

||

|

200 W |

R7D-AP02H |

||

|

400 W |

R7D-AP04H |

||

|

750 W |

R7D-AP08H |

||

2-2

|

Standard Models and Specifications |

Chapter 2 |

■ Reduction Gears (Straight Shaft with Key)

●For Cylinder-style Servomotors (Backlash = 3′ Max.)

|

Specifications |

Model |

|

|

Servomotor |

Reduction gears |

|

|

capacity |

(deceleration ratio) |

|

|

50 W |

1/5 |

R7G-VRSFPB05B50 |

|

1/9 |

R7G-VRSFPB09B50 |

|

|

1/15 |

R7G-VRSFPB15B50 |

|

|

1/25 |

R7G-VRSFPB25B50 |

|

|

100 W |

1/5 |

R7G-VRSFPB05B100 |

|

1/9 |

R7G-VRSFPB09B100 |

|

|

1/15 |

R7G-VRSFPB15B100 |

|

|

1/25 |

R7G-VRSFPB25B100 |

|

|

200 W |

1/5 |

R7G-VRSFPB05B200 |

|

1/9 |

R7G-VRSFPB09C400 |

|

|

1/15 |

R7G-VRSFPB15C400 |

|

|

1/25 |

R7G-VRSFPB25C200 |

|

|

400 W |

1/5 |

R7G-VRSFPB05C400 |

|

1/9 |

R7G-VRSFPB09C400 |

|

|

1/15 |

R7G-VRSFPB15C400 |

|

|

1/25 |

R7G-VRSFPB25D400 |

|

|

750 W |

1/5 |

R7G-VRSFPB05C750 |

|

1/9 |

R7G-VRSFPB09D750 |

|

|

1/15 |

R7G-VRSFPB15D750 |

|

|

1/25 |

R7G-VRSFPB25E750 |

|

Note There are no reduction gears for 30-W Servomotors.

●For Cylinder-style Servomotors (Backlash = 45′ Max.)

|

Specifications |

Model |

|

|

Servomotor |

Reduction gears |

|

|

capacity |

(deceleration ratio) |

|

|

50 W |

1/5 |

R7G-RGSF05B50 |

|

1/9 |

R7G-RGSF09B50 |

|

|

1/15 |

R7G-RGSF15B50 |

|

|

1/25 |

R7G-RGSF25B50 |

|

|

100 W |

1/5 |

R7G-RGSF05B100 |

|

1/9 |

R7G-RGSF09B100 |

|

|

1/15 |

R7G-RGSF15B100 |

|

|

1/25 |

R7G-RGSF25B100 |

|

|

200 W |

1/5 |

R7G-RGSF05B200 |

|

1/9 |

R7G-RGSF09C400 |

|

|

1/15 |

R7G-RGSF15C400 |

|

|

1/25 |

R7G-RGSF25C400 |

|

|

400 W |

1/5 |

R7G-RGSF05C400 |

|

1/9 |

R7G-RGSF09C400 |

|

|

1/15 |

R7G-RGSF15C400 |

|

|

1/25 |

R7G-RGSF25C400 |

|

|

750 W |

1/5 |

R7G-RGSF05C750 |

|

1/9 |

R7G-RGSF09C750 |

|

|

1/15 |

R7G-RGSF15C750 |

|

|

1/25 |

R7G-RGSF25C750 |

|

Note There are no reduction gears for 30-W Servomotors.

●For Flat-style Servomotors (Backlash = 3′ Max.)

|

Specifications |

Model |

|

|

Servomotor |

Reduction gears |

|

|

capacity |

(deceleration ratio) |

|

|

100 W |

1/5 |

R7G-VRSFPB05B100P |

|

1/9 |

R7G-VRSFPB09B100P |

|

|

1/15 |

R7G-VRSFPB15B100P |

|

|

1/25 |

R7G-VRSFPB25C100P |

|

|

200 W |

1/5 |

R7G-VRSFPB05B200P |

|

1/9 |

R7G-VRSFPB09C400P |

|

|

1/15 |

R7G-VRSFPB15C400P |

|

|

1/25 |

R7G-VRSFPB25C200P |

|

|

400 W |

1/5 |

R7G-VRSFPB05C400P |

|

1/9 |

R7G-VRSFPB09C400P |

|

|

1/15 |

R7G-VRSFPB15C400P |

|

|

1/25 |

R7G-VRSFPB25D400P |

|

|

750 W |

1/5 |

R7G-VRSFPB05C750P |

|

1/9 |

R7G-VRSFPB09D750P |

|

|

1/15 |

R7G-VRSFPB15D750P |

|

|

1/25 |

R7G-VRSFPB25E750P |

|

●For Flat-style Servomotors (Backlash = 45′ Max.)

|

Specifications |

Model |

|

|

Servomotor |

Reduction gears |

|

|

capacity |

(deceleration ratio) |

|

|

100 W |

1/5 |

R7G-RGSF05B100P |

|

1/9 |

R7G-RGSF09B100P |

|

|

1/15 |

R7G-RGSF15B100P |

|

|

1/25 |

R7G-RGSF25B100P |

|

|

200 W |

1/5 |

R7G-RGSF05B200P |

|

1/9 |

R7G-RGSF09C400P |

|

|

1/15 |

R7G-RGSF15C400P |

|

|

1/25 |

R7G-RGSF25C400P |

|

|

400 W |

1/5 |

R7G-RGSF05C400P |

|

1/9 |

R7G-RGSF09C400P |

|

|

1/15 |

R7G-RGSF15C400P |

|

|

1/25 |

R7G-RGSF25C400P |

|

|

750 W |

1/5 |

R7G-RGSF05C750P |

|

1/9 |

R7G-RGSF09C750P |

|

|

1/15 |

R7G-RGSF15C750P |

|

|

1/25 |

R7G-RGSF25C750P |

|

2-3

|

Standard Models and Specifications |

Chapter 2 |

■ Servo Relay Units for CN1

|

Specifications |

Model |

|||

|

Servo |

For CS1W-NC113/133 |

XW2B-20J6-1B |

||

|

Relay Unit |

CJ1W-NC113/133 |

|||

|

C200HW-NC113 |

||||

|

C200H-NC112 |

||||

|

3F88M-DRT141 |

||||

|

(No communications supported.) |

||||

|

For CS1W-NC213/233/413/433 |

XW2B-40J6-2B |

|||

|

CJ1W-NC213/233/413/433 |

||||

|

C200HW-NC213/413 |

||||

|

C500-NC113/211 |

||||

|

C200H-NC211 |

||||

|

(No communications supported.) |

||||

|

For CS1W-HCP22 |

XW2B-20J6-3B |

|||

|

CQM1H-PLB21 |

||||

|

CQM1-CPU43-V1 |

||||

|

(No communications supported.) |

||||

|

For CS1W-NC213/233/413/433 |

XW2B-40J6-4A |

|||

|

CJ1W-NC213/233/413/433 |

||||

|

(Communications supported.) |

||||

|

For CJ1M-CPU21/CPU22/ |

XW2B-20J6-8A |

|||

|

CPU23 |

||||

|

XW2B-40J6-9A |

||||

|

For CS1W-HCP22-V1 and |

XW2B-80J7-1A |

|||

|

FQM1-MMP21 |

||||

|

Servo |

No communications |

1 m |

XW2Z-100J-B5 |

|

|

Driver |

supported. |

|||

|

2 m |

XW2Z-200J-B5 |

|||

|

Cable |

||||

|

Communications sup- |

1 m |

XW2Z-100J-B7 |

||

|

ported. |

||||

|

2 m |

XW2Z-200J-B7 |

|||

|

For FQM1-MMP21 |

1 m |

XW2Z-100J-B10 |

||

|

2 m |

XW2Z-200J-B10 |

|||

|

For CS1W-HCP22-V1 |

1 m |

XW2Z-100J-B12 |

||

|

2 m |

XW2Z-200J-B12 |

|||

|

Position |

For CQM1H-PLB21, |

0.5 m |

XW2Z-050J-A3 |

|

|

Control |

CQM1-CPU43-V1 |

|||

|

1 m |

XW2Z-100J-A3 |

|||

|

Unit Cable |

||||

|

For C200H-NC112 |

0.5 m |

XW2Z-050J-A4 |

||

|

1 m |

XW2Z-100J-A4 |

|||

|

For C200H-NC211, |

0.5 m |

XW2Z-050J-A5 |

||

|

C500-NC113/211 |

||||

|

1 m |

XW2Z-100J-A5 |

|||

|

For CS1W-NC113, |

0.5 m |

XW2Z-050J-A8 |

||

|

C200HW-NC113 |

||||

|

1 m |

XW2Z-100J-A8 |

|||

|

For CS1W-NC213/413, |

0.5 m |

XW2Z-050J-A9 |

||

|

C200HW-NC213/413 |

||||

|

1 m |

XW2Z-100J-A9 |

|||

|

For CS1W-NC133 |

0.5 m |

XW2Z-050J-A12 |

||

|

1 m |

XW2Z-100J-A12 |

|||

|

For CS1W-NC233/433 |

0.5 m |

XW2Z-050J-A13 |

||

|

1 m |

XW2Z-100J-A13 |

|||

|

For CJ1W-NC113 |

0.5 m |

XW2Z-050J-A16 |

||

|

1 m |

XW2Z-100J-A16 |

|||

|

For CJ1W-NC213/413 |

0.5 m |

XW2Z-050J-A17 |

||

|

1 m |

XW2Z-100J-A17 |

|||

|

For CJ1W-NC133 |

0.5 m |

XW2Z-050J-A20 |

||

|

1 m |

XW2Z-100J-A20 |

|||

|

For CJ1W-NC233/433 |

0.5 m |

XW2Z-050J-A21 |

||

|

1 m |

XW2Z-100J-A21 |

|||

|

For CS1W-HCP22 |

0.5 m |

XW2Z-050J-A22 |

||

|

(1 axis) |

||||

|

1 m |

XW2Z-100J-A22 |

|||

|

For CS1W-HCP22 |

0.5 m |

XW2Z-050J-A23 |

||

|

(2 axes) |

||||

|

1 m |

XW2Z-100J-A23 |

|||

|

For 3F88M-DRT141 |

0.5 m |

XW2Z-050J-A25 |

||

|

1 m |

XW2Z-100J-A25 |

|||

|

Specifications |

Model |

|||

|

Position |

For CJ1M-CPU21/ |

1 m |

XW2Z-100J-A26 |

|

|

Control |

CPU22/CPU23 |

|||

|

Unit Cable |

||||

|

For FQM1-MMP21 for |

0.5 m |

XW2Z-050J-A28 |

||

|

general-purpose I/O |

||||

|

1 m |

XW2Z-100J-A28 |

|||

|

For CS1W-HCP22-V1 |

0.5 m |

XW2Z-050J-A29 |

||

|

for general-purpose I/O |

||||

|

1 m |

XW2Z-100J-A29 |

|||

|

For FQM1-MMP21 for |

0.5 m |

XW2Z-050J-A30 |

||

|

special I/O |

||||

|

1 m |

XW2Z-100J-A30 |

|||

|

For CS1W-HCP22-V1 |

0.5 m |

XW2Z-050J-A32 |

||

|

for special I/O |

||||

|

1 m |

XW2Z-100J-A32 |

|||

|

■ Control Cables for CN1 |

|

Specifications |

Model |

||

|

General-purpose Control Cable |

1 m |

R88A-CPU001S |

|

|

(with Connector on one end) |

|||

|

2 m |

R88A-CPU002S |

||

|

Connector Terminal Block Cable |

1 m |

R88A-CTU001N |

|

|

2 m |

R88A-CTU002N |

||

|

Connector Terminal Blocks |

XW2B-40F5-P |

||

■ Integrated Servomotor Cables

|

Specifications |

Model |

||

|

For Servomotors without |

3 m |

R7A-CEA003S |

|

|

brakes (both Cylinderand |

|||

|

5 m |

R7A-CEA005S |

||

|

Flat-style) |

|||

|

10 m |

R7A-CEA010S |

||

|

15 m |

R7A-CEA015S |

||

|

20 m |

R7A-CEA020S |

||

|

For Servomotors with |

3 m |

R7A-CEA003B |

|

|

brakes (both Cylinderand |

|||

|

5 m |

R7A-CEA005B |

||

|

Flat-style) |

|||

|

10 m |

R7A-CEA010B |

||

|

15 m |

R7A-CEA015B |

||

|

20 m |

R7A-CEA020B |

||

■ Separate Servomotor Cables

● Power Cables

|

Specifications |

Standard cable |

Robot cable |

||

|

model |

model |

|||

|

For Servo- |

3 m |

R88A-CAWA003S |

R88A-CAWA003SR |

|

|

motors with- |

||||

|

5 m |

R88A-CAWA005S |

R88A-CAWA005SR |

||

|

out brakes |

||||

|

(both Cylin- |

10 m |

R88A-CAWA010S |

R88A-CAWA010SR |

|

|

derand |

15 m |

R88A-CAWA015S |

R88A-CAWA015SR |

|

|

Flat-style) |

||||

|

20 m |

R88A-CAWA020S |

R88A-CAWA020SR |

||

|

For Servo- |

3 m |

R88A-CAWA003B |

R88A-CAWA003BR |

|

|

motors with |

||||

|

5 m |

R88A-CAWA005B |

R88A-CAWA005BR |

||

|

brakes (both |

||||

|

10 m |

R88A-CAWA010B |

R88A-CAWA010BR |

||

|

Cylinder- |

||||

|

and Flat- |

15 m |

R88A-CAWA015B |

R88A-CAWA015BR |

|

|

style) |

||||

|

20 m |

R88A-CAWA020B |

R88A-CAWA020BR |

||

● Encoder Cables

|

Specifications |

Standard cable |

Robot cable |

||

|

model |

model |

|||

|

For Servo- |

3 m |

R7A-CRA003C |

R7A-CRA003CR |

|

|

motors (Cyl- |

||||

|

5 m |

R7A-CRA005C |

R7A-CRA005CR |

||

|

inder-style or |

||||

|

Flat-style) |

10 m |

R7A-CRA010C |

R7A-CRA010CR |

|

|

15 m |

R7A-CRA015C |

R7A-CRA015CR |

||

|

20 m |

R7A-CRA020C |

R7A-CRA020CR |

||

Note Use a robot cable if cable flexibility is required.

2-4

|

Standard Models and Specifications |

Chapter 2 |

||||||||||

|

■ Peripheral Cable Connectors |

|||||||||||

|

Specifications |

Model |

||||||||||

|

Analog Monitor Cable (CN4) |

1 m |

R88A-CMW001S |

|||||||||

|

Computer Monitor Cable (CN3) |

DOS |

2 m |

R7A-CCA002P2 |

||||||||

|

PC98 |

2 m |

R7A-CCA002P3 |

|||||||||

|

Control I/O Connector (CN1) |

R88A-CNU01C |

||||||||||

|

Encoder Connector (CN2) |

R7A-CNA01R |

||||||||||

|

Encoder Connector (Servomotor end) |

R7A-CNA02R |

||||||||||

|

Communications Cable |

1 m |

XW2Z-100J-C1 |

|||||||||

|

2 m |

XW2Z-200J-C1 |

||||||||||

|

■ Parameter Units |

|||||||||||

|

Specifications |

Model |

||||||||||

|

Hand-held (with 1-m cable) |

R7A-PR02A |

||||||||||

|

■ External Regeneration Resistors |

|||||||||||

|

Specifications |

Model |

||||||||||

|

Resistor |

220 W 47 Ω |

R88A-RR22047S |

|||||||||

|

■ DC Reactors |

|||||||||||

|

Specifications |

Model |

||||||||||

|

For R7D-APA3L/APA5L/APA01L |

R88A-PX5063 |

||||||||||

|

For R7D-AP02L |

R88A-PX5062 |

||||||||||

|

For R7D-AP04L |

R88A-PX5061 |

||||||||||

|

For R7D-APA3H/APA5H/AP01H |

R88A-PX5071 |

||||||||||

|

For R7D-AP02H |

R88A-PX5070 |

||||||||||

|

For R7D-AP04H |

R88A-PX5069 |

||||||||||

|

For R7D-AP08H |

R88A-PX5061 |

||||||||||

|

■ Front-panel Brackets |

|||||||||||

|

Specifications |

Model |

||||||||||

|

For the SMARTSTEP A Series |

R88A-TK01W |

2-5

|

Standard Models and Specifications |

Chapter 2 |

|

2-2 External and Mounted Dimensions

2-2-1 Servo Drivers

■Single-phase 100 V AC: R7D-APA3L/-APA5L/-AP01L/-AP02L (30 W to 200 W) Single-phase 200 V AC: R7D-APA3H/-APA5H/-AP01H/-AP02H (30 W to 200 W)

● Wall Mounting

|

External dimensions |

Mounted dimensions |

17

● Front Panel Mounting (Using Mounting Brackets)

External dimensions

|

195 |

180 |

|||

Mounted dimensions

|

7.5 |

Two, M4 |

|

|

6 |

||

|

10 |

||

|

195 |

180±0.5 |

(168) |

(7.5)

2-6

|

Standard Models and Specifications |

Chapter 2 |

■Single-phase 100 V AC: R7D-AP04L (400 W) Single-phase 200 V AC: R7D-AP04H (400 W)

● Wall Mounting

|

External dimensions |

Mounted dimensions |

|

5.5 |

5 dia. |

5.5 |

|||

|

160 |

149.5 |

160 |

149.5±0.5 |

||

|

(5) |

5 |

(5) |

|||

|

12 |

(75) |

130 |

|||

|

75 |

17

● Front Panel Mounting (Using Mounting Brackets)

|

External dimensions |

|||

|

5 dia. |

24.5 |

||

|

7.5 |

52 |

1.5 |

2 |

|

195 |

180 |

|||

Mounted dimensions

|

7.5 |

Two, M4 |

|

|

6 |

||

|

10 |

||

|

195 |

180±0.5 |

(168) |

(7.5)

2-7

|

Standard Models and Specifications |

Chapter 2 |

■ Single-phase/Three-phase 200 V AC: R7D-AP08H (750 W)

● Wall Mounting

|

External dimensions |

Mounted dimensions |

|

5.5 |

5 dia. |

5.5 |

|

|

160 |

149.5 |

160 |

149.5±0.5 |

|

(5) |

90 |

(5) |

|

17

● Front Panel Mounting (Using Mounting Brackets)

External dimensions

|

5 dia. |

24.5 |

||||||

|

7.5 |

52 |

12.5 |

2 |

||||

|

195 |

180 |

|||||||||

|

(7.5) |

5 |

||||||

|

43.5 |

|||||||

|

42 |

22.5 |

||||||

Mounted dimensions

|

7.5 |

Two, M4 |

|

|

6 |

||

|

10 |

||

|

195 |

180±0.5 |

(168) |

(7.5)

2-8

|

Standard Models and Specifications |

Chapter 2 |

2-2-2 Parameter Unit

■ R7A-PR02A Hand-held Parameter Unit

17 0.8

|

B.B |

INP TGON REF POWER |

|

VCMP |

R7A–PR02A PARAMETER UNIT

SCROLL MODE/SET

RESET

JOG

DATA

RUN

READ WRITE

4.8 dia.

2-9

|

Standard Models and Specifications |

Chapter 2 |

2-2-3 Servomotors

■ Cylinder-style Servomotors without a Brake

● 30 W/50 W/100 W R7M-A03030(-S1)/-A05030(-S1)/-A10030(-S1)

300±30

|

19.5 |

20 |

300±30 |

21.5 |

5 |

||||

|

9.5 |

Two, 4.3 dia. |

Dimensions of shaft end with key (-S1) |

||||||

|

11 |

dia.S |

dia.30h7 |

46 |

40 |

h |

|||

|

dia. |

b |

|||||||

|

14 |

t1 |

|||||||

|

5 |

2.5 |

40 |

||||||

|

LL |

25 |

|||||||

|

Model |

Dimensions (mm) |

|||||||

|

LL |

S |

b |

h |

t1 |

||||

|

R7M-A03030-@ |

69.5 |

6h6 |

2 |

2 |

1.2 |

|||

|

R7M-A05030-@ |

77 |

6h6 |

2 |

2 |

1.2 |

|||

|

R7M-A10030-@ |

94.5 |

8h6 |

3 |

3 |

1.8 |

|||

|

■ Cylinder-style Servomotors with a Brake |

● 30 W/50 W/100 W R7M-A03030-B(S1)/-A05030-B(S1)/-A10030-B(S1)

300±30

|

6 dia. |

7 dia. |

300±30 |

|||||

|

19.5 |

27 |

21.5 |

5 |

||||

|

9.5 |

Two, 4.3 dia. |

Dimensions of shaft end with key (-BS1) |

|||||

|

11 |

dia.S |

dia.30h7 |

46 |

40 |

h |

||

|

dia. |

b |

||||||

|

14 |

t1 |

||||||

|

5 |

2.5 |

40 |

|||||

|

LL |

25 |

|

Model |

Dimensions (mm) |

||||

|

LL |

S |

b |

h |

t1 |

|

|

R7M-A03030-B@ |

101 |

6h6 |

2 |

2 |

1.2 |

|

R7M-A05030-B@ |

108.5 |

6h6 |

2 |

2 |

1.2 |

|

R7M-A10030-B@ |

135 |

8h6 |

3 |

3 |

1.8 |

2-10

|

Standard Models and Specifications |

Chapter 2 |

■ Cylinder-style Servomotors without a Brake

● 200 W/400 W/750 W R7M-A20030(-S1)/-A40030(-S1)/-A75030(-S1)

300±30

|

6 dia. |

Dimensions of output section of 750-W Servomotors |

|||||||

|

13 |

7 dia. |

|||||||

|

20 |

300±30 |

21.5 |

||||||

|

9 |

Four, Z dia. |

|||||||

|

2 |

||||||||

|

11 |

dia. |

D1 |

dia. |

Dimensions of shaft end with key (-S1) |

||||

|

S |

||||||||

|

D2dia. |

||||||||

|

C |

5 |

|||||||

|

5 |

||||||||

|

G |

3 |

C |

QK |

3 |

||||

|

LL |

LR |

|

Model |

Dimensions (mm) |

||||||||

|

LL |

LR |

C |

D1 |

D2 |

G |

Z |

S |

QK |

|

|

R7M-A20030-@ |

96.5 |

30 |

60 |

70 |

50h7 |

6 |

5.5 |

14h6 |

20 |

|

R7M-A40030-@ |

124.5 |

30 |

60 |

70 |

50h7 |

6 |

5.5 |

14h6 |

20 |

|

R7M-A75030-@ |

145 |

40 |

80 |

90 |

70h7 |

8 |

7 |

16h6 |

30 |

■ Cylinder-style Servomotors with a Brake

● 200 W/400 W/750 W R7M-A20030-B(S1)/-A40030-B(S1)/-A75030-B(S1)

300±30

|

6 dia. |

7 dia. |

|

|

13 |

27 |

300±30 |

|

21.5 |

||

|

9 |

Four, Z dia. |

|

|

11 |

dia. |

D |

1 |

dia. |

|

|

S |

|||||

|

D2 dia. |

C |

||||

|

G |

3 |

C |

|||

|

LL |

LR |

Dimensions of output section of 750-W Servomotors

2

Dimensions of shaft end with key (-BS1)

|

Model |

Dimensions (mm) |

||||||||

|

LL |

LR |

C |

D1 |

D2 |

G |

Z |

S |

QK |

|

|

R7M-A20030-B@ |

136 |

30 |

60 |

70 |

50h7 |

6 |

5.5 |

14h6 |

20 |

|

R7M-A40030-B@ |

164 |

30 |

60 |

70 |

50h7 |

6 |

5.5 |

14h6 |

20 |

|

R7M-A75030-B@ |

189.5 |

40 |

80 |

90 |

70h7 |

8 |

7 |

16h6 |

30 |

2-11

|

Standard Models and Specifications |

Chapter 2 |

■ Flat-style Servomotors without a Brake

● 100 W/200 W/400 W/750 W R7M-AP10030(-S1)/-AP20030(-S1)/-AP40030(-S1)/AP75030(-S1)

|

13 |

dia. |

|

|

7 |

||

|

300±30 |

||

|

A2 |

||

|

A1 |

A5 |

|

|

D1 |

Dimensions of shaft end with key (-S1) |

||

|

dia. |

h |

||

|

b |

|||

|

C |

|||

|

QK |

t1 |

|

Model |

Dimensions (mm) |

|||||||||||||||||

|

Basic servomotor dimensions |

With key (shaft |

Cable outlet dimensions |

||||||||||||||||

|

end dimensions) |

||||||||||||||||||

|

LL |

LR |

C |

D1 |

D2 |

F |

G |

Z |

S |

QK |

b |

h |

t1 |

A1 |

A2 |

A3 |

A4 |

A5 |

|

|

R7M-AP10030-@ |

62 |

25 |

60 |

70 |

50h7 |

3 |

6 |

5.5 |

8h6 |

14 |

3 |

3 |

1.8 |

9 |

18 |

25 |

21 |

14 |

|

R7M-AP20030-@ |

67 |

30 |

80 |

90 |

70h7 |

3 |

8 |

7 |

14h6 |

16 |

5 |

5 |

3 |

|||||

|

R7M-AP40030-@ |

87 |

|||||||||||||||||

|

R7M-AP75030-@ |

86.5 |

40 |

120 |

145 |

110h7 |

3.5 |

10 |

10 |

16h6 |

22 |

5 |

5 |

3 |

28 |

38 |

19 |

■ Flat-style Servomotors with a Brake

● 100 W/200 W/400 W/750 W R7M-AP10030-B(S1)/-AP20030-B(S1)/-AP40030-B(S1)/AP75030-B(S1)

300±30

|

6 dia. |

|

|

7 dia. |

|

|

13 |

300±30 |

|

A2 |

|

|

A1 |

A5 |

|

S dia. |

D1 |

Dimensions of shaft end with key (-BS1) |

||

|

dia. |

h |

|||

|

D2 dia. |

C |

b |

||

|

QK |

t1 |

|

Model |

Dimensions (mm) |

||||||||||||||||||

|

Basic servomotor dimensions |

With key (shaft |

Cable outlet dimensions |

|||||||||||||||||

|

end dimensions) |

|||||||||||||||||||

|

LL |

LR |

C |

D1 |

D2 |

F |

G |

Z |

S |

QK |

b |

h |

t1 |

A1 |

A2 |

A3 |

A4 |

A5 |

||

|

R7M-AP10030-B@ |

91 |

25 |

60 |

70 |

50h7 |

3 |

6 |

5.5 |

8h6 |

14 |

3 |

3 |

1.8 |

9 |

18 |

25 |

21 |

23 |

|

|

R7M-AP20030-B@ |

98.5 |

30 |

80 |

90 |

70h7 |

3 |

8 |

7 |

14h6 |

16 |

5 |

5 |

3 |

||||||

|

R7M-AP40030-B@ |

118.5 |

||||||||||||||||||

|

R7M-AP75030-B@ |

120 |

40 |

120 |

145 |

110h7 |

3.5 |

10 |

10 |

16h6 |

22 |

5 |

5 |

3 |

28 |

38 |

26 |

2-12

|

Standard Models and Specifications |

Chapter 2 |

||||||||||||||||||||||||

|

2-2-4 |

Reduction Gears |

||||||||||||||||||||||||

|

■ For Cylinder-style Servomotors (Backlash = 3′ |

Max.) |

||||||||||||||||||||||||

|

Model |

Dimensions (mm) |

Weight |

|||||||||||||||||||||||

|

(kg) |

|||||||||||||||||||||||||

|

LM |

LR |

C1 |

C2 |

D1 |

D2 |

D3 |

D4 |

E3 |

F |

G |

S |

T |

Z1 |

Z2 |

AT* |

l |

Key dimensions |

||||||||

|

QK |

b |

h |

t1 |

||||||||||||||||||||||

|

50 W |

1/5 |

R7G-VRSFPB05B50 |

67.5 |

32 |

52 |

40 |

46 |

60 |

50 |

45 |

10 |

3 |

6 |

12 |

20 |

M4 |

M5 |

M3 |

12 |

16 |

4 |

4 |

2.5 |

0.55 |

|

|

1/9 |

R7G-VRSFPB09B50 |

67.5 |

32 |

52 |

40 |

46 |

60 |

50 |

45 |

10 |

3 |

6 |

12 |

20 |

M4 |

M5 |

M3 |

12 |

16 |

4 |

4 |

2.5 |

0.55 |

||

|

1/15 |

R7G-VRSFPB15B50 |

78 |

32 |

52 |

40 |

46 |

60 |

50 |

45 |

10 |

3 |

6 |

12 |

20 |

M4 |

M5 |

M3 |

12 |

16 |

4 |

4 |

2.5 |

0.7 |

||

|

1/25 |

R7G-VRSFPB25B50 |

78 |

32 |

52 |

40 |

46 |

60 |

50 |

45 |

10 |

3 |

6 |

12 |

20 |

M4 |

M5 |

M3 |

12 |

16 |

4 |

4 |

2.5 |

0.7 |

||

|

100 W |

1/5 |

R7G-VRSFPB05B100 |

67.5 |

32 |

52 |

40 |

46 |

60 |

50 |

45 |

10 |

3 |

6 |

12 |

20 |

M4 |

M5 |

M3 |

12 |

16 |

4 |

4 |

2.5 |

0.55 |

|

|

1/9 |

R7G-VRSFPB09B100 |

67.5 |

32 |

52 |

40 |

46 |

60 |

50 |

45 |

10 |

3 |

6 |

12 |

20 |

M4 |

M5 |

M3 |

12 |

16 |

4 |

4 |

2.5 |

0.55 |

||

|

1/15 |

R7G-VRSFPB15B100 |

78 |

32 |

52 |

40 |

46 |

60 |

50 |

45 |

10 |

3 |

6 |

12 |

20 |

M4 |

M5 |

M3 |

12 |

16 |

4 |

4 |

2.5 |

0.7 |

||

|

1/25 |

R7G-VRSFPB25C100 |

92 |

50 |

78 |

40 |

46 |

90 |

70 |

62 |

17 |

3 |

6 |

19 |

30 |

M4 |

M6 |

M3 |

20 |

22 |

6 |

6 |

3.5 |

1.7 |

||

|

200 W |

1/5 |

R7G-VRSFPB05B200 |

72.5 |

32 |

52 |

60 |

70 |

60 |

50 |

45 |

10 |

3 |

10 |

12 |

20 |

M5 |

M5 |

M4 |

12 |

16 |

4 |

4 |

2.5 |

0.72 |

|

|

1/9 |

R7G-VRSFPB09C400 |

89.5 |

50 |

78 |

60 |

70 |

90 |

70 |

62 |

17 |

3 |

8 |

19 |

30 |

M5 |

M6 |

M4 |

20 |

22 |

6 |

6 |

3.5 |

1.7 |

||

|

1/15 |

R7G-VRSFPB15C400 |

100 |

50 |

78 |

60 |

70 |

90 |

70 |

62 |

17 |

3 |

8 |

19 |

30 |