-

- Новое

Модератор: central

Сброс ошибок на NCR безе перезагрузки банкомата

Sterialmurder » 02 апр 2016, 16:11

Помогите разобраться. Выхожу из ПО банкомата. Попадаю на рабочий стол. Далее запускаю NCR Aptra, ошибки сбрасываются, а вот где найти bat файл для запуска рабочего состояния банкомата?

p/s на некоторых УС лежит на рабочем столе, а на других нет.

- Sterialmurder

- Сбербанк

- Сообщения: 2

- Зарегистрирован: 02 апр 2016, 15:08

-

Sinbadsup - Сбербанк

- Сообщения: 59

- Зарегистрирован: 15 апр 2015, 13:48

-

TichoblinII - Сбербанк

- Сообщения: 397

- Зарегистрирован: 29 янв 2011, 02:45

Сообщений: 3

• Страница 1 из 1

Вернуться в APTRA

Кто сейчас на конференции

Сейчас этот форум просматривают: нет зарегистрированных пользователей и гости: 1

Слайд 1Банкоматы

NCR

Курс базового уровня

Б-003

v.1.0

Слайд 2Банкоматы NCR

Банкоматы серии SelfServ являются

наиболее распространенными в

парке

банкоматов ПАО Сбербанк.

Модельный ряд банкоматов состоит из:

SelfServ 22 (офисного исполнения)

SelfServ 25 (за стенного исполнения)

SelfServ 32 (офисный с модулем приема

наличных)

SelfServ 34 (с модулем приема наличных

за стенного исполнения)

Personas M Series 76 (офисный с модулем

приема наличных)

Personas M Series 77 (офисный без приема

наличных)

Personas M Series 86 (с модулем приема

наличных за стенного исполнения)

Personas M Series 87 (за стенного

исполнения без приема наличных)

Слайд 3Основные элементы устройства

банкоматов NCR

Назначение и расположение

Слайд 4Элементы и их расположение

Банкоматы серии SelfServ являются

наиболее распространенными в парке банкоматов ПАО Сбербанк.

А представленная модель SelfSerf 6632 является наиболее популярным офисным банкоматом.

Слайд 5ПИН-клавиатура

ПИН-клавиатура

• Металлическая, USB-клавиатура, SDC-клавиатура

• Стандартная, антивандальная

•

Используется для ввода ПИН-кода, требуемых данных (сумма,

номер телефона, договора и т. д.), подтверждения или отмены операции

Слайд 6Чековый принтер

Принтер квитанций: печатает и выдает отчет

о каждой транзакции по запросу держателя карты.

Печатающая головка печатает непосредственно на термографической бумаге, поэтому лента для принтера не используется. Технология, используемая в термографическом принтере, позволяет печатать графику и расширенные наборы символов.

В моделях серии SelfServ используются принтеры с шиной – USB

В моделях серии PersonaS – COM (офисные), SDC (застенные)

Термобумага для чековых принтеров банкоматов NCR.

Размер: 80×200×18 (мм), 0,55 г/ м²

Расположение термослоя: Внутренний

Основные узлы:

Печатающая головка.

Транспорт выдачи чеков.

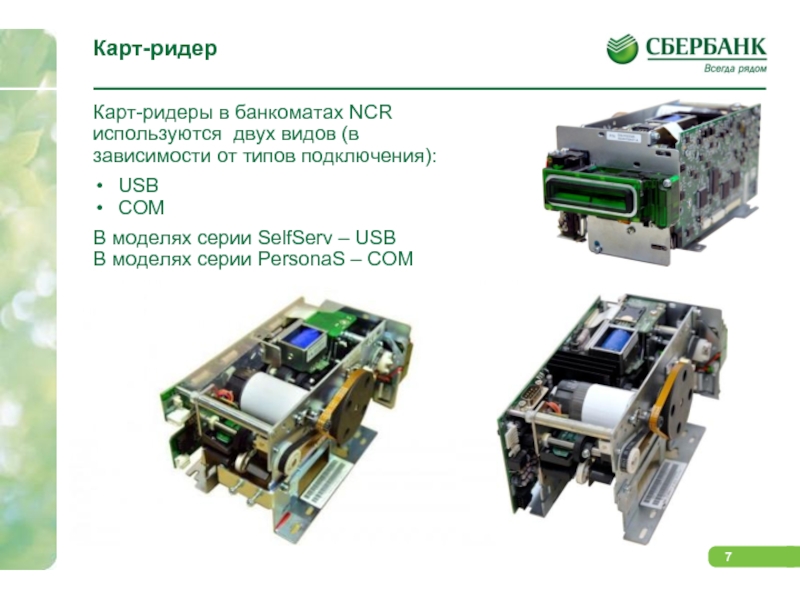

Слайд 7Карт-ридер

Карт-ридеры в банкоматах NCR используются двух видов

(в зависимости от типов подключения):

USB

COM

В моделях серии

SelfServ – USB

В моделях серии PersonaS – COM

Слайд 8Панель оператора

Банкоматы за стенного исполнения имеют «Панель

оператора».

Она предназначена для проведения сервисного обслуживания и

выполнения административного функционала находясь в сервисной зоне ( не зоне обслуживания клиентов).

Так же, есть возможность переключить отображения экрана с панели оператора на главный монитор.

Существует два типа консолей оператора, в зависимости от моделей устройств :

На PersonaS – «аналогавая» (консоль со встроенным ЖК-экраном с аналоговыми кнопками.

На SelfSerf — «цифровая» (10,4 – дюймовый сенсорный ЖК-экран).

Слайд 9Диспенсер

Банкоматы NCR в своих диспенсерах используют вакуумный

набор купюр.

Диспенсер состоит из презенторной части и

двух сдвоенных пик-модулей. Оснащается четырьмя кассетами для банкнот и одной кассетой для отбракованных или забытых купюр (реджект кассета).

Основное назначение модуля выдачи наличных (диспенсера) — набрать из кассет необходимое количество купюр, собрать их в пачку и выдать клиенту.

Кассета для купюр, представляет из себя пластиковый бокс с установленными планками-направляющими для купюр и планка с магнитами-герконами, для настройки типа кассеты.

Реджект кассета – пластиковый бокс.

Герконы для определения типа кассеты

Слайд 10Депозитный модуль – модуль приема наличных

BNA (Bunch

Note Acceptor) – модуль приема банкнот (наличных).

Прием

до 30 банкнот пачкой и распознавание до 50 номиналов.

Две приемные кассеты общей вместимостью 3500 купюр.

Закрытый бункер с индикацией вскрытия.

Условное депонирование с функцией возврата пачки пользователю.

Слайд 11Депозитная кассета

Различают:

Передняя «F» и задняя «R» кассета

депозита.

В первую очередь заполняется задняя кассета, потом

передняя.

Емкость кассеты ориентировочно 1750 купюр.

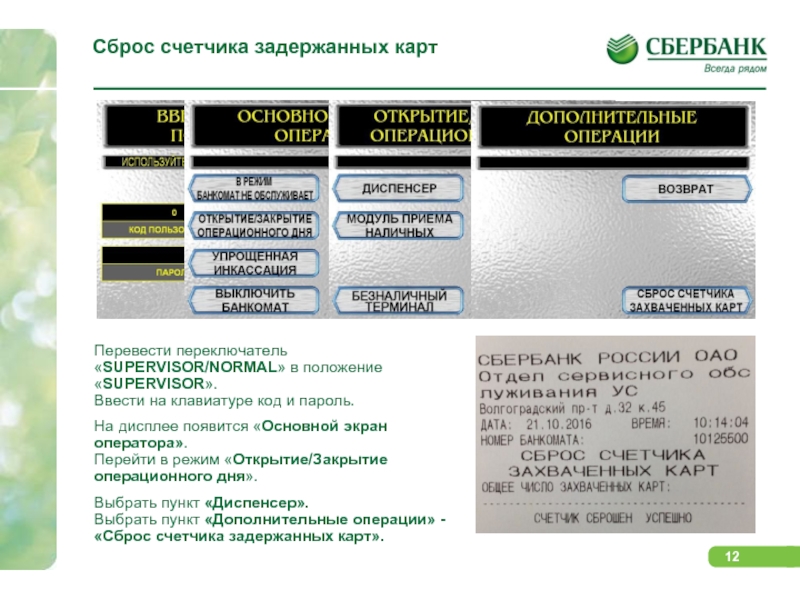

Слайд 12Сброс счетчика задержанных карт

Перевести переключатель «SUPERVISOR/NORMAL» в

положение «SUPERVISOR».

Ввести на клавиатуре код и

пароль.

На дисплее появится «Основной экран оператора».

Перейти в режим «Открытие/Закрытие операционного дня».

Выбрать пункт «Диспенсер».

Выбрать пункт «Дополнительные операции» -«Сброс счетчика задержанных карт».

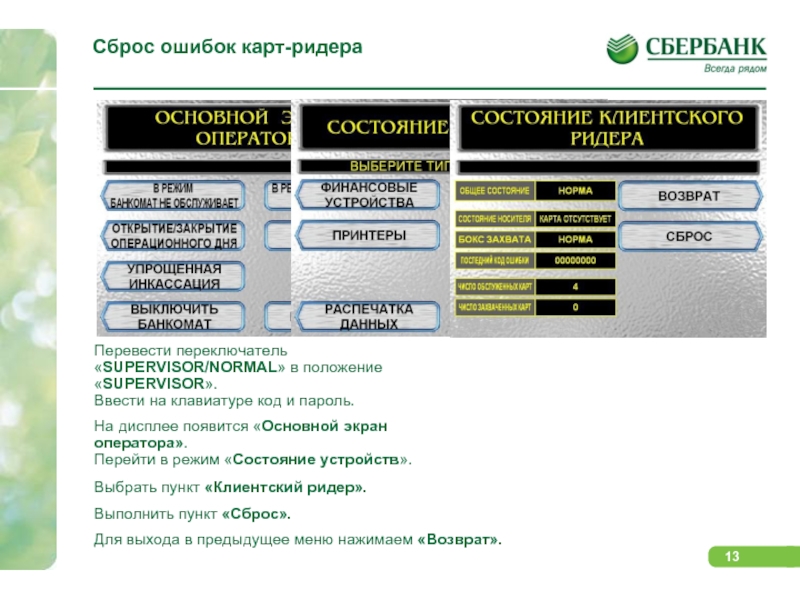

Слайд 13Сброс ошибок карт-ридера

Перевести переключатель «SUPERVISOR/NORMAL» в положение

«SUPERVISOR».

Ввести на клавиатуре код и пароль.

На

дисплее появится «Основной экран оператора».

Перейти в режим «Состояние устройств».

Выбрать пункт «Клиентский ридер».

Выполнить пункт «Сброс».

Для выхода в предыдущее меню нажимаем «Возврат».

Слайд 14Сброс ошибок чекового принтера

Перевести переключатель «SUPERVISOR/NORMAL» в

положение «SUPERVISOR».

Ввести на клавиатуре код и

пароль.

На дисплее появится «Основной экран оператора».

Перейти в режим «Состояние устройств».

Выбрать пункт «Принтеры».

Выбрать пункт «Чековый принтер».

Выполнить пункт «Сброс».

Для выхода в предыдущее меню нажимаем «Возврат».

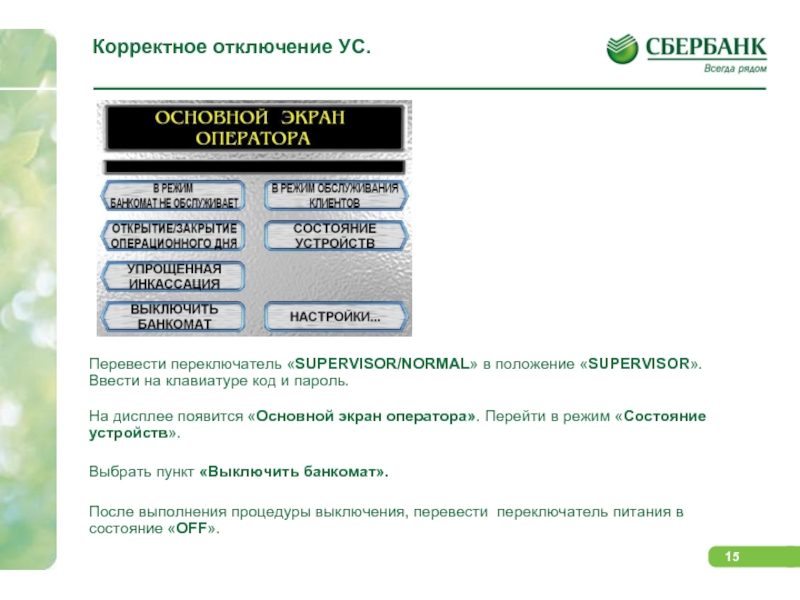

Слайд 15Корректное отключение УС.

Перевести переключатель «SUPERVISOR/NORMAL» в положение

«SUPERVISOR».

Ввести на клавиатуре код и пароль.

На

дисплее появится «Основной экран оператора». Перейти в режим «Состояние устройств».

Выбрать пункт «Выключить банкомат».

После выполнения процедуры выключения, перевести переключатель питания в состояние «OFF».

Слайд 16СПАСИБО ЗА ВНИМАНИЕ!

ДЛЯ ПРОДОЛЖЕНИЯ ОБУЧЕНИЯ ВАМ НЕОБХОДИМО

ПРОЙТИ ТЕСТ ПО КУРСУ «Б-003» НА ПОРТАЛЕ

-

Contents

-

Table of Contents

-

Troubleshooting

-

Bookmarks

Quick Links

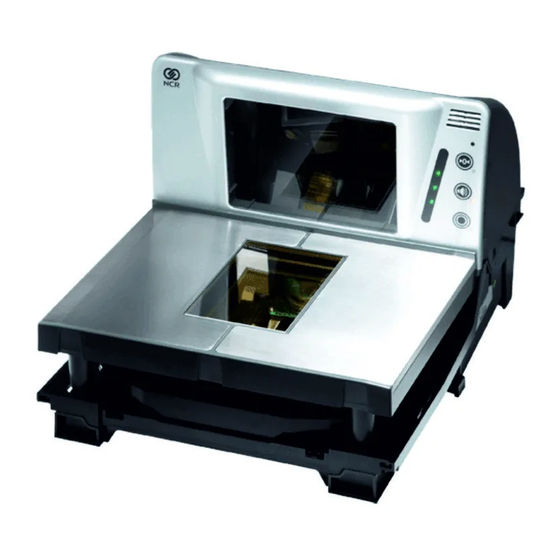

NCR RealScan 74

(7874)

OFX

Release 1.1

User Guide

25315

B005-0000-1822

Issue C

Related Manuals for NCR 74 OFX (7874)

Summary of Contents for NCR 74 OFX (7874)

-

Page 1: User Guide

NCR RealScan 74 (7874) Release 1.1 User Guide 25315 B005-0000-1822 Issue C…

-

Page 2

The product described in this book is a licensed product of NCR Corporation. NCR is a registered trademark of NCR Corporation. NCR RealPOS, NCR RealPrice, NCR RealScan, NCR EasyPoint and NCR FastLane are either registered trademarks or trademarks of NCR Corporation in the United States and/or other countries. IBM is a registered trademark of IBM Corporation. Symbol is a registered trademark of Symbol Technologies Incorporated. Metrologic is a registered trademark of Metrologic Instruments Incorporated. Sensormatic is a registered trademark of Sensormatic Electronics Corporation. Checkpoint is a registered trademark of Checkpoint Systems Incorporated. Mettler Toledo is a registered trademark of Mettler Toledo Corporation. It is the policy of NCR Corporation (NCR) to improve products as new technology, components, software, and firmware become available. NCR, therefore, reserves the right to change specifications without prior notice. All features, functions, and operations described herein may not be marketed by NCR in all parts of the world. In some instances, photographs are of equipment prototypes. Therefore, before using this document, consult with your NCR representative or NCR office for information that is applicable and current. To maintain the quality of our publications, we need your comments on the accuracy, clarity, organization, and value of this book. Address correspondence to: Manager, Information Products NCR Corporation 2651 Satellite Blvd. Duluth, GA 30096 Copyright © 2008 By NCR Corporation Dayton, Ohio U.S.A. All Rights Reserved … -

Page 3

Preface Audience This book is written for hardware installer/service personnel, system integrators, and field engineers. Notice: This document is NCR proprietary information and is not to be disclosed or reproduced without consent. References • NCR Scanner Programming Tags (BST0‐2121‐74) • NCR Scanner/Scale Interface Programmer’s Guide (BD20‐1074‐A) • NCR RealScan Safety and Regulatory Information (B005‐0000‐1699) … -

Page 4: Table Of Contents

Table of Contents Chapter 1: Product Information Available Models………………….1-2 Features and Options ………………….1-2 Bi-Optic Scanning …………………1-2 Communications Protocol ………………1-4 Autodiscrimination………………..1-4 Remote Compact Display ………………1-5 Dual Peripheral RS232 Ports ……………….1-5 USB……………………..1-7 Firmware Flashing ………………..1-7 Operator Interface…………………1-8 Voice Messages …………………1-8 Power Supply ………………….1-9 PACESETTER ………………….1-9 PACESETTER Plus …………………1-10 PACESETTER III………………..1-10…

-

Page 5

Specific Function Programming ……………3-28 Power-up the System ………………3-32 Check Sensormatic® Deactivation System ………….3-33 Step 9: Operational Unit Verification …………..3-34 NCR RealScan 74 Scanner-Only Models …………3-34 NCR RealScan 74 Scanner/Scale Models…………3-34 RealScan 74 Power-On Wellness Check …………..3-35 Checkout Reading Operation …………….3-35… -

Page 6

Programming the RealScan 74…………….3-43 Programming RealScan 2357 Hand-Held Scanner if Connected through the USB Peripheral Port ………………3-44 NCR RealScan 2356 and Symbol (Motorola) Type Hand-Held Scanner ..3-45 Programming the RealScan 2356 Hand-Held if Connected through the Auxiliary RS232 Port ………………3-45 Programming the RealScan 74…………….3-46… -

Page 7

Multiple Reads ………………….4-10 Operating Instructions………………..4-11 Turning the RealScan 74 On and Off …………..4-11 Scanner Only Model……………….4-11 Scanner/Scale Model ………………4-11 Scanning Procedure ………………..4-12 Weighing Procedure………………..4-12 Sensormatic® Security Tag Deactivation Procedure ………4-13 Normal Operation ………………..4-13 Manual Deactivation ………………4-14 Adjusting the Good Read Tone…………….4-14 Not-On-File Error………………..4-15 Cleaning Instructions………………..4-16 Scanner Body ………………….4-16… -

Page 8

Program Parameter Descriptions …………….5-18 Communications Protocol ………………5-18 IBM Slot Scanner………………..5-18 IBM USB…………………..5-18 NCR (RS232 USB) ………………..5-18 RS232 ……………………5-19 Good Read Tone………………….5-19 Tone On/Off …………………..5-20 Tone Frequency (Hertz)………………5-20 Tone Length (Milliseconds)…………….5-20 Tone Volume …………………..5-20 Not-On-File Volume……………….5-21 Timers ……………………5-22 Lockout Time ………………….5-22 Restart Lockout Timer ………………5-23… -

Page 9

Scans Required………………..5-29 Overlap Characters…………………5-29 Minimum Segment Size………………5-29 Bar Codes–3 ………………….5-30 Interleaved 2 of 5 ………………..5-30 Bar Code Length ………………..5-31 Value 1 and 2…………………..5-31 Check Digit Present………………..5-31 Transmit Check Digit ………………5-31 Interleaved 2 of 5 Tone………………5-32 Tone Length………………….5-32 Tone Frequency………………..5-32 Interleaved 2 of 5 Check Digit Length1 …………5-32 Interleaved 2 of 5 Check Digit Length2 …………5-33 Enable Interleaved 2 of 5 Stitching…………..5-33 Scans Required………………..5-33… -

Page 10

viii Codabar Stitch…………………5-39 Number of Codabar Scans Required ……………5-39 Bar Codes–7 ………………….5-39 Pharmacode Check Digit Transmission …………5-39 Label Identifiers ………………….5-40 Identifier Type…………………5-40 Common Byte 1 and Common Byte 2 ………….5-41 Bar Code Type…………………5-42 Common Byte………………….5-42 Unique Identifier ………………..5-42 RS232 Parameters 1………………..5-43 Baud Rate………………….5-43 Parity ……………………5-43 Stop Bits and Character Length …………….5-44… -

Page 11

Dual Cable Interface ………………..5-54 Avery Scale Emulation………………5-54 Programming Worksheets ……………….5-55 Communications Protocol ………………5-55 Good Read Tone………………….5-56 Timers ……………………5-57 Bar Codes–1 ………………….5-58 Bar Codes–2 ………………….5-59 Bar Codes–3 ………………….5-60 Bar Codes–4 ………………….5-61 Bar Codes–5 ………………….5-62 Bar Codes–6 ………………….5-63 Bar Codes–7 ………………….5-63 Label Identifiers ………………….5-64 Number System Character ………………5-65 Sensormatic Deactivation Tone Frequency …………5-65 Sensormatic Deactivation Tone Pulse …………..5-65… -

Page 12

Code 39 Minimum and Maximum Length ………….5-74 Interleaved 2 of 5 Tone Length ……………..5-74 Interleaved 2 of 5 Tone Frequency …………..5-75 Interleaved 2 of 5 Tone………………5-75 Interleaved 2 of 5 CD Length1 …………….5-75 Interleaved 2 of 5 CD Length2 …………….5-76 Interleaved 2 of 5 Scans Required …………..5-76 Interleaved 2 of 5 Overlap ……………..5-76 Interleaved 2 of 5 Minimum Segment Size ………….5-77… -

Page 13

Ignore RS232 Commands from POS …………..5-84 Enable UPC NS5 Coupon ………………5-85 GS1 DataBar AI 8110 coupons …………….5-85 EAN–13 98 coupons ……………….5-85 EAN–13 99 coupons ……………….5-85 Expand E to EAN–13 Directly …………….5-85 Checkpoint Interlock………………5-86 Scanner Power-On State ………………5-86 ASCII Code Chart ………………..5-86 Special Programming………………..5-87 Set Current Parameters to Default Values…………5-87 Enable Soft Defaults ……………….5-87… -

Page 14

Firmware Flashing Procedure…………….5-98 RealScan Flash Drive Support ……………….5-101 NCR RealScan Flash Drive Prep Application ………..5-101 Flash Drive Prep Application Installation …………5-101 RealScan Flash Drive Prep Application Functions ……….5-105 Diagnostic Download or Memory Dump ………….5-105 Parameters Upload……………….5-108 Parameters Download ………………5-111 Firmware Upload …………………5-114 Firmware Download ………………5-117… -

Page 15

Revision Record Issue Date Remarks A May 23, 2008 Release 1.1 B Sept. 19, 2008 Various artwork updates Updated Shift Test and Decreasing Load Test information C December 19, 2008 Updated scanner dimensions, checkstand cutout dimensions, and scale calibration test procedures Safety and Regulatory Information The NCR RealScan 74 conforms to all applicable legal requirements. To view the compliance statements refer to the NCR RealScan Safety and Regulatory Information (B005‐0000‐1699). -

Page 17: Chapter 1: Product Information

1 Product Information Chapter 1: The NCR RealScan 74 is a state‐of‐the‐art bi‐optic scanner. Its primary use is in high‐performance checkout areas of food distribution and general merchandise sales. The RealScan 74 can read bar codes on all six sides of the product as it passes through the scan zone. This and other features reduce the amount of operator training and increase operator efficiency. …

-

Page 18: Available Models

Chapter 1: Product Information Available Models NCR RealScan 74 Scanner/Scale NCR RealScan 74 Scanner Only 25319 The NCR RealScan 74 is available in six RoHS‐compliant models. The following table identifies the major models along with a brief description of each. Model Description RealScan 7874–3000 Third‐party scale ready Scanner (sold with a 15.7ʺ top plate) RealScan 7874–3020 13.9“ Compact Scanner Only RealScan 7874–4xxx 15.7” or 16” Scanner Only RealScan 7874–5xxx 15.7” or 16” Scanner/Scale RealScan 7874‐4xxx (Plus 7874‐K200) 20” Scanner Only RealScan 7874‐5xxx (Plus 7874‐K200) 20” Scanner/Scale Features and Options The RealScan 74 is rich in features and options which puts it in a class by itself. This section identifies the many features and options that are available. …

-

Page 19

Chapter 1: Product Information The RealScan 74 vertical scan window is mounted to a tower that rises above the checkstand surface. The upper console is designed to withstand constant impact from items being scanned. The horizontal scan window is flush–mounted to a part plastic, part steel top plate, permitting users to slide a product across the top plate without lifting the product. Furthermore, loosely wrapped products cannot snag on the top plate. Because of its expanded scan zone, the RealScan 74 is very easy to use. It can read labels on all six sides of the product as they pass through the scan zone. Products can be read from right to left or from left to right. The following is the scan pattern produced on both the vertical and horizontal scan windows. Horizontal Scan Pattern 24 scan lines Vertical Scan Pattern 30 scan lines 25318 … -

Page 20: Communications Protocol

Chapter 1: Product Information Communications Protocol The RealScan 74 communicates with the host terminal through: • RS232 • USB • IBM 46xx • Dual‐cable RS232 Autodiscrimination The RealScan 74 can decode a variety of bar codes. The ability to discriminate among the different bar code types is a standard feature of the RealScan 74. The following lists the different bar code types. • UPC–A and UPC–E • UPC–A and UPC–E with two‐digit Add‐on Symbols • UPC–A and UPC–E with five‐digit Add‐on Symbols • GS1–128 Coupon Extended Code • Code 128 Markdown Code • EAN–8 and EAN–13 • EAN–13 with two‐digit Add‐on Symbols • EAN–13 with five‐digit Add‐on Symbols • GS1 DataBar, formerly Reduced Space Symbology (RSS) GS1 DataBar–14 GS1 DataBar–14 Stacked Omni–directional GS1 DataBar Expanded GS1 DataBar Expanded Stacked …

-

Page 21: Remote Compact Display

Chapter 1: Product Information Remote Compact Display 16217 The RealScan 74 Scanner/Scale units are available with no weight display or with a remote post mounted display. When no display is used, scale information is sent to the host terminal and displayed on the terminalʹs customer display. However, this is not available for all host terminals, and in some countries Weight and Measures authorities do not permit this configuration. Note: It is acceptable to use the host terminal display if the host terminal is approved to perform the live/gross scale weight. Also, most countries require that both the operator and the consumer must be able to observe the scale live/gross weight display and the sale weight platform during a weighing operation. When a display is needed, use the RealScan 25 Remote Compact Display. It is available with one or two display modules. Dual Peripheral RS232 Ports The RealScan 74 includes the Dual Peripheral Ports feature. The purpose of this feature is to permit other peripheral devices to connect to the host terminal through the RealScan 74. This eliminates the need of the host terminal having additional RS232 ports. A typical use of this feature is to connect a hand–held scanner for items too large to place on the checkstand. It also provides a connection for some security tag deactivation systems. …

-

Page 22

Chapter 1: Product Information Special programming is required for each peripheral device using a peripheral port. The connector is wired as follows. Auxiliary RS232 Peripheral Port Pin Number Signal Name 1 +5 Vdc 2 NC 3 GND 4 TXD 5 RXD 6 +12 Vdc 7 CTS 8 RTS The RealScan 74 Auxiliary RS232 Peripheral Port hardware is limited to the following fixed parameters. Baud Rate 9600 Parity Even Stop Bits 1 Number of Data Bits 7 … -

Page 23: Usb

Chapter 1: Product Information The two auxiliary RS232 ports are both located at the back of the unit. Port 1 (located on the right side when facing the rear of the unit) is the most convenient port for connecting a hand–held scanner. Each peripheral device using a peripheral port requires special programming. The total combined +5V current for the one USB peripheral port and two RS232 auxiliary ports should be less than 750mA. The total combined +12V current for two RS232 auxiliary ports should be less than 350mA. The RealScan 74 includes a single USB Peripheral port, a Main (POS) USB Communication Port, and a Main (POS) RS232/RS485 Communication Port. These ports are included to permit easy connections for peripherals and to improve the scanner’s capabilities by permitting the devices to be hot‐swappable (connecting or disconnecting devices without restarting the unit). The USB peripheral port is located on the left‐most side on the rear of the unit. The purpose of the USB peripheral port is to permit other peripheral devices with IBM SurePOS USB handheld interfaces to connect to the host terminal through the RealScan 74. The Main (POS) USB and Main (POS) RS232/RS485 Communication Ports are located on the right side at the back of the unit. These ports are used to connect the scanner to the host terminal. The total combined +5V current for the one USB peripheral port plus two Auxiliary RS232 ports should be less than 750mA. The maximum +5V current for the USB peripheral port should be less than 500mA. The total combined +12V current for two RS232 auxiliary ports should be less than 350mA. The RealScan 74 is compatible with both the NCR 2356 and NCR 2357 Handheld scanners. Note: Normally, other SurePOS–compliant handheld scanners are compatible with the RealScan 74. However, NCR recommends a thorough integration testing before using any 3rd–party handheld scanner. Firmware Flashing The RealScan 74 includes Firmware Flashing. This permits upgrades to the scanner’s firmware. The latest firmware may be downloaded from NCR web site then flashed to the scanner through a PC, POS terminal, or a flash drive. The software comes in two forms. The first one is free from The http://www5.ncr.com/support/support_drivers_patches.asp?Class=retail_RealScan. others provide various Enterprise functions and are sold separately. …

-

Page 24: Operator Interface

Chapter 1: Product Information Refer to the “Firmware Flashing” section in Chapter 5 for more information on firmware flashing. Operator Interface There is very little interface required between the operator and the RealScan 74. Messages are sent from the RealScan 74 to the operator through status indicators on the Operator Display Panel, audio tones, and voice messages. Light Bar Status Indicator Motion Detector Scale Zero Button Volume Adjust Button Manual Deactivation Button 25317 Note: Refer to Chapter 4 for more details on the functions of the status indicators and buttons of the Operator Display Panel. Voice Messages If the RealScan 74 has voice enabled, certain mode changes and error conditions are alerted by synthesized voice messages. These messages give either the changed mode or the error message with the suggested corrective action. Voice is enabled and disabled in the Miscellaneous Parameter program. The scanner provides audible voice messages during the following events. • When checking the communications protocol (Diagnostic Mode) •…

-

Page 25: Power Supply

Chapter 1: Product Information Power Supply 23756 A green light at the corner of the power supply indicates that the power supply is On. The optional Power Supply provides the necessary 12V DC voltage required by the RealScan 74 if power is not supplied from the POS terminal. The Power Cord plugs into an electrical outlet and connects to the Power Supply. A low voltage Power Cable is integrated with the Power Supply. Several Power Cords are available depending on the country installation. The Power Supply input can be 90 Vac to 264 Vac at a frequency of 47 Hz to 63 Hz. In addition, some POS interface types can power the RealScan 74 without the use of this power supply. Please contact your NCR sales representative for details. The following table shows the Power Requirement Matrix for the RealScan 74: Power source RealScan 74 Power Requirements Matrix 115Vac 230Vac 12Vdc Typical Operating Power (Motor and Laser On) 7 W 8 W 6 W Typical Standby Power (Motor and Laser off) 3 W 4 W 2 W PACESETTER NCR has continually improved its PACESETTER technology used on NCR RealScan products. Starting out as PACESETTER, it progressed to PACESETTER Plus, and then to PACESETTER III. Vendors and printers regularly supply products with …

-

Page 26: Pacesetter Plus

1-10 Chapter 1: Product Information PACESETTER Plus PACESETTER Plus determines what is wrong with a bar code label, fixes the data, and then transfers the information to the host terminal. It provides information on possible bar code printer problems but is not a bar code specification conformity verifier. The three modes of PACESETTER Plus operation are summarized in the following paragraphs. Mode 1–Inquiry PACESETTER Plus can be used as a management tool by store personnel and chain management to monitor and report the status of label readability. Tally counters are kept for the following. • Good reads • No read due to lack of full label (missing bars or folded label) • Good reads with overprinted bars • Good reads with underprinted bars • Missing margins • Missing print lines In Mode 1, the tally count displays on the RealScan 25 Remote Compact Display. The percentage of each error type to the good reads tally also displays. All tally counts can be reset to zero. Mode 2–Demonstration Mode In Mode 2, the scanner is offline. Each subsequent scan of a bar code causes the scanner to indicate the status of label readability. The scanner recognizes missing bars in labels, highly overprinted or underprinted labels, missing margins, or a “no read” condition. Mode 3–Operations Mode 3 is the normal operating mode. The scanner can be programmed to add …

-

Page 27: Pacesetter Iii

Chapter 1: Product Information 1-11 PACESETTER III also detects, corrects, and reports errors discovered in UPC Number System Two and Number System Four labels. These two label types are printed in the store and account for a significant number of unreadable labels due to failures of the in–store printing mechanism. PACESETTER III looks for errors in these labels and learns from each attempted scan. After seeing a particular printing error a number of times, PACESETTER III may determine that an error is present in the label and that the error may be correctable. If the correction capability of PACESETTER III is enabled, the scanner attempts an error–free correction of the label and passes the results to the host terminal. Whenever an error–free correction is not possible, PACESETTER III does not pass label data to the terminal. Parameter Programming The NCR RealScan 74 may need to be configured to meet specific installation needs. The RealScan 74 uses special programming tags to modify the various programming parameters (refer to Chapter 5). This programming data may be scanned with special tags, sent from a PC with the free tools or http://www5.ncr.com/support/support_drivers_patches.asp?Class=retail_RealScan remotely through the POS using special software (sold separately). Scan Doctor Diagnostics Scan Doctor is the state‐of‐the‐art diagnostic software included in every RealScan 74. It continually monitors the unit to identify components that are not functioning correctly. It also provides inquiry capability for the host terminal to access specific diagnostic data. Scan Doctor diagnoses the RealScan 74 each time power is applied and continually during operation. When a problem is found, it notifies the operator through patterns of color LEDs on the Scan Adviser (beside the Vertical Window), an error code on the remote display (if attached), and voice messages. It lists the most probable causes first. Many Scan Doctor statuses are available from the scanner using NCR software tools sold separately. Refer to the RealScan 74 Diagnostics and Troubleshooting section on chapter 5 for more information. …

-

Page 28: Ongoing Wellness Check

1-12 Chapter 1: Product Information • Spinner Motor • Scale Board • Laser Diodes • FPGA • Scale Hardware If Scan Doctor finds a problem hindering proper operation of the RealScan 74, it disables the unit; otherwise the problem is identified and operation continues. Ongoing Wellness Check Scan Doctor runs all the time, from the moment the RealScan 74 is turned on. It constantly monitors RAM, the Spinner Motor, Laser Diodes and Scale Hardware. Service Diagnostics Scan Doctor includes service diagnostics for the trained service technician. These go beyond the wellness checks and are accessed through the use of special programming tags. Refer to Appendix B for more information on the Scanner Service Diagnostics Tests. Soft Power Down/Power Up The RealScan 74 senses periods of scanner inactivity. The scannerʹs soft power down feature extends the life of the RealScan 74 by disabling major portions of the unit, including the laser diodes, spinner motor, and associated electronics. The length of the inactive period prior to the soft power down is user‐selected and programmed remotely or through tags. Scanner power up occurs when the RealScan 74 motion detector detects movement. This detector is located on the operator display panel, to the right of the vertical scan window. The RealScan 74 can also be powered up with the checker signs on the host terminal. This capability assumes appropriate host terminal software. …

-

Page 29: Chapter 2: Site Preparation

2 Site Preparation Chapter 2: Customer Responsibilities The NCR customer is responsible in preparing the site for installation of the NCR RealScan 74. The following information is provided to help with this task. The customer must do or provide the following. • When required by NCR, provide the NCR Customer Services Representative with appropriate drawings that indicate the following. Location of equipment Site wiring (power and signal, paths, and lengths) Location of other equipment capable of generating large amounts of electrical noise, electromagnetic interference, heat, and so forth • Provide floor coverings and environmental systems that prevent static electricity build‐up and discharge. • Provide and install necessary power distribution boxes, conduits, grounds, lightning arrestors, and associated hardware. • Ensure clear space and environmental requirements of the unit are met. • Make all building alterations necessary to meet wiring and other site requirements. • Ensure all applicable codes, regulations, and laws (including, but not limited to, electrical, building, safety, and health) are met. • Provide and install all communication cables, wall jacks, special connectors, and associated hardware. • Provide and install auxiliary power or other equipment as required. …

-

Page 30: Preparing The Site

Chapter 2: Site Preparation Preparing the Site This document contains information necessary for the preparation of a site conforming to NCR specifications. It is important that the site complies with the requirements specified in this document because, once the equipment has been installed, deficiencies in the site or the problems caused by these deficiencies are much more difficult to detect and correct. Further, failure to comply with these requirements or to take proper steps to protect equipment against risks identified in this document may cause serious damage to the equipment and to the customerʹs business. In addition to the need to comply with the requirements specified, electrical wiring and mechanical systems must also comply with all relevant codes, laws, and regulations. It is important that a customer or a customer agent who is very familiar with the special requirements of electronic equipment prepare the site. The responsibility of ensuring that the site is prepared in compliance with this document remains with the customer. For information and guidance purposes only, a list of Customer Responsibilities is provided, in general terms, of those matters for which the customer is responsible. This list is not intended to be comprehensive, and in no way modifies, alters, or limits the responsibility of the customer for all aspects of adequate site preparation. No comment, suggestion, or advice offered or not offered about preparation of the site nor any inspection of the site whether before or after preparation is to be taken as approval of the location of the site and equipment or of its preparation, and NCR is not liable in respect of any comment, suggestion, or advice given by its staff or in respect of any failure to give advice. Finally, only the customer can know the full extent of damage that may be caused to his business by reason of failure of the equipment that is to be installed. For this reason, it is the customerʹs responsibility to ascertain the extent of any such possible damage to his existing or planned business, and to effect full insurance in respect of it. …

-

Page 31: Weight

Chapter 2: Site Preparation Weight The weight of the RealScan 74 depends on the model. The following are the installed weights of basic models. Note: Weight of the power supply and power cord are not included. With Top Plate Without Top Plate Model Kilograms Pounds Kilograms Pounds RealScan 7874‐3000 4.25 9.37 2.90 6.20 RealScan 7874‐3020 4.50 9.90 2.90 6.20 RealScan 7874‐4xxx 4.25 9.37 3.43 7.56 RealScan 7874‐5xxx 5.06 11.15 4.24 9.34 RealScan 7874‐4xxx (Plus 7874‐K200) …

-

Page 32: Checkstand Cutout

(a flat-sided box) when measuring the checkstand for a fit. Do not take advantage of voids or angles in the design of the scanner base as NCR reserves the right to change the profile without notice as long as the change does not impact overall outside dimensions.

-

Page 33: Realscan 7874-3000/4Xxx/5Xxx (15.7 Inch)

(a flat-sided box) when measuring the checkstand for a fit. Do not take advantage of voids or angles in the design of the scanner base as NCR reserves the right to change the profile without notice as long as the change does not impact overall outside dimensions.

-

Page 34: Realscan 7874-4Xxx/5Xxx With F030 / K002 (40.6 Cm / 16 Inch)

(a flat-sided box) when measuring the checkstand for a fit. Do not take advantage of voids or angles in the design of the scanner base as NCR reserves the right to change the profile without notice as long as the change does not impact overall outside dimensions.

-

Page 35: Realscan 7874-4Xxx/5Xxx With 7874-K200 (50.8 Cm / 20 Inch)

(a flat-sided box) when measuring the checkstand for a fit. Do not take advantage of voids or angles in the design of the scanner base as NCR reserves the right to change the profile without notice as long as the change does not impact overall outside dimensions.

-

Page 36: No Side Rails

(a flat-sided box) when measuring the checkstand for a fit. Do not take advantage of voids or angles in the design of the scanner base as NCR reserves the right to change the profile without notice as long as the change does not impact overall outside dimensions.

-

Page 37: Realscan Checkstand Wiring

Circuit Breakers Isolated/Insulated Ground Bus NCR circuits should be run in separate metal Conduits. Note: NCR circuits must be dedicated to NCR equipment or other logically connected electronic equipment (modems, DAA, bridges, etc.)

-

Page 38: Power Considerations

2-10 Chapter 2: Site Preparation Power Considerations The RealScan 74 receives power from an external DC power supply or from +12V DC supplied by the POS terminal. The power supply mounts in a remote location close to the RealScan 74. The NCR supplied power supply is a 40‐watt switching power supply with the following inputs. • Voltage: 90 to 264 Vac • Frequency: 47 to 63 Hz • Current: 0.9 A The RealScan 74 has no power switch in the unit, therefore the operator of RealScan74 must have a way to remove AC power in the event of an emergency. The power supply has a green LED which is lit when there is an AC voltage present and the power supply is functioning correctly. Power Transient Protection Voltage transients, surges, sags, impulses, and spikes may be experienced routinely or sporadically. When such phenomena occur, the equipment requires the use of protective devices to ensure proper operation. Cable Connections The following diagram shows the wiring connections located at the rear of the RealScan 74. Scale Display Port Main (POS) Auxiliary RS232 Port 1…

-

Page 39: Service Clearance

Chapter 2: Site Preparation 2-11 Service Clearance Although many of the RealScan 74 components are accessed without removing the unit from the checkstand, service clearance must be provided. Clearance is also required for cleaning the unit. Refer to the following illustration for the required clearances. Mounting surface for keyboard must be removable for the following. • Servicing the unit • Replacing the vertical window Item Flow Area A = 20.32 cm (8.00 in) minimum if checkstand structure is not removable for servicing. 2.54 cm (1.00 in) minimum if checkstand structure is removable for servicing.

-

Page 40: Environmental Considerations

2-12 Chapter 2: Site Preparation Environmental Considerations The RealScan 74 operates in most standard working environments. Temperature ranges permitted are greater when the RealScan 74 is in storage or transit. The RealScan 74 can operate up to one hour at extreme temperatures without suffering damage. The following table gives the various environmental requirements: Physical Extreme Operating Normal Operating Storage Transit Variable (One Hour Maximum) 5ºC-40ºC -0ºC-45ºC -10ºC-55ºC -40ºC-60ºC Temperature 41ºF-104ºF 32ºF-113ºF 14ºF-131ºF -40ºF-140ºF 10ºC/hour Temperature 20ºC/hour 20ºC/hour 20ºC/hour Change 18ºF/hour 36ºF/hour 36ºF/hour 36ºF/hour Relative 20% to 80%…

-

Page 41: Realscan 25 Compact Display Dimensions

Chapter 2: Site Preparation 2-13 RealScan 25 Compact Display Dimensions The following are dimensions of the RealScan 25 Compact Display. The holes are spaced to align with those of the older RealScan 25 Remote Post Display and with some competitor models. BASE 115.31 mm 93.98 mm 3.96 mm 7.62 mm 84.83 mm 4.54 in 3.70 in 0.156 in 0.30 in 3.34 in 11.17 mm 16.25 mm 41.65 mm 266.19 mm 104.39 mm 314.96 mm 0.44 in 0.64 in 1.64 in…

-

Page 43: Chapter 3: Installation

3 Installation Chapter 3: Installing the RealScan 74 consists of eight main steps. Sometimes additional information is required depending on the installation. Information about enabling special functions is provided in Programming chapter. …

-

Page 44: Installation Steps

1. Verify installation preparation (scanner and checkstand) 2. Cable installation preparation 3. Install Sensormatic® or Checkpoint antenna (optional) 4. Connect Cables 5. Put RealScan 74 in checkstand cutout 6. Verify Top Plate alignment 7. Calibrate the scale 8. Setup Sensormatic® or Checkpoint deactivation (applicable only if Sensormatic® or Checkpoint antenna is installed) 9. Verify unit is operational Step 1: Verify Installation Preparation Reporting a Damaged Unit After receiving the NCR RealScan 74, inspect the shipping carton for damage. If the RealScan 74 is damaged due to shipping, notify the carrier, the NCR representative, or the supplier if the unit is not purchased directly from NCR. Package Contents After unpacking the RealScan 74, take inventory to ensure that all components are received. The following list identifies the package contents. • NCR RealScan 74 • Power Supply (separate package if ordered) •…

-

Page 45: Step 2: Cable Installation Preparation

Chapter 3: Installation Step 2: Cable Installation Preparation Note: Before attempting to install the RealScan 74, the site must be prepared in accordance with the requirements described in Site Preparation chapter. Note: The RealScan 74 ships complete from the factory and requires no operator assembly. The laser module is an integral part of the factory assembled device and does not have any controls that can increase the level of laser light or collateral radiation from the RealScan 74. Follow these steps in preparation to install the NCR RealScan 74 cables to the scanner. 1. Verify that the RealScan 74 power receptacle switch is off. Plug the power cord into the RealScan 74 power supply unit. Pass the power cable from the power supply through the checkstand opening. 2. Connect the communications interface cable to the host terminal. Refer to the terminal documentation for instructions on how to connect the interface cables. Note: Some terminals may require a trained service technician to open the terminal and connect the interface cables. 3. Pass the interface cables through the checkstand opening. 4. If connecting a remote display, pass the remote display cable through the checkstand opening. 5. If connecting an RS232 peripheral device below the checkstand, pass its interface cable through the checkstand opening. 6. Place the unit so that a portion of the tower end is directly over the hole in the checkstand. Skip to “Step 4: Cable Connection” when not installing a RealScan 74 with a Sensormatic® deactivation system. …

-

Page 46: Step 3: Sensormatic® Coil Installation

Chapter 3: Installation Step 3: Sensormatic® Coil Installation To install the Sensormatic® Coil, perform the following procedure. 1. Position the RealScan 74 facing the operator. 2. Remove the Top Plate. Hold the front edge of the Top Plate between your fingers. Lift the Top Plate to remove it from the RealScan 74. 25518 3. Remove the Front Bezel. Place one hand and slightly apply downward pressure on the top corner of the Bezel. Use a flat tip screw driver to push the snap features found at the bottom‐corner of the Bezel. Note: Do this procedure on both sides of the Bezel to detach it from the scanner. 25464…

-

Page 47

Chapter 3: Installation Lift the Bezel up and set aside. 25572 5. Install the Sensormatic® Coil. Connect the horizontal coil cable and the vertical coil cable as shown. 25692 Route the coil cable at the bottom of the tower as shown and press the strain relief into the notch. 25691 … -

Page 48

Chapter 3: Installation Lay the horizontal coil down and around the horizontal window. 25690 Install the three screws to hold the horizontal coil in place. 25659 Route the horizontal coil cable on the tower as shown. 25693 … -

Page 49

Chapter 3: Installation Attach the vertical coil around the vertical window and route the vertical coil cable on the tower as shown. 25657 6. Replace the Bezel. Align the top edge of the Tower Cabinet with the top edge of the Front Bezel. 25571 Ensure to route the horizontal coil wires under the notch found on the bottom of the Front Bezel. The scanner will have scale issues if the wires are not routed properly under the Front Bezel. horizontal wires properly horizontal wires not properly routed under the bezel routed under the bezel Correct Wrong 25911 … -

Page 50

Chapter 3: Installation Press the bottom–left and bottom–right corners of the Front Bezel towards the tower cabinet to latch it in place. 25512 7. Replace the Top Plate. Holding the front edge of the Top Plate, lay the back edge on the two rear support posts on the RealScan 74. Lay the front of the Top Plate down onto the two front support posts. 25517 … -

Page 51: Step 4: Cable Connection

Chapter 3: Installation Step 4: Cable Connection RealScan 74 Power Cable Power Supply RS-232 Power Cord Peripheral Host Terminal Interface Cable 25505 Note: Ensure that the power is off before connecting or disconnecting cables. If the scanner is powered by a POS terminal, turn off the POS terminal. Otherwise, disconnect the AC power from the power brick. To install the cables in the RealScan 74, perform the following procedure. 1. If used, install the optional Checkpoint® Antenna. Remove the Top Plate. Remove the Front Bezel. …

-

Page 52

3-10 Chapter 3: Installation Route the Checkpoint cable as shown below. Tape may be used to hold the loop in place 25695 Route the cable out the left side of the unit. 25696 2. If used, connect the optional DC Power Cable from the Power Supply to the DC Power connector. 3. Connect the interface cable to the Scanner connector or the USB + Power Connector. Note: The scanner can connect to a separate “POS scale interface cable” through “Port 1”. Full details are added on the firmwareʹs release. 4. If used, connect the remote display cable to the Remote Display connector. 5. If the configuration includes a USB device, connect it to the USB peripheral port. 6. If used, connect one end of the Sensormatic® Communications Cable to the RS232 Port 2 connector at the back of the RealScan 74. The other end connects to the POS connector on the Sensormatic® AMB9010 Controller. 7. If used, connect the Sensormatic Coil Cable to the Coil connector on the Sensormatic® AMB9010 Controller. … -

Page 53: Step 5: Realscan 74 Installation In Checkstand Cutout

Chapter 3: Installation 3-11 8. If used, Connect the Sensormatic® AC Power Cord. 9. If used, connect the Checkpoint® interlock cable. 10. Turn on the scanner by turning on the POS terminal or by turning on the AC power of the scanner. Note: Some peripherals are limited to which port they can use. Step 5: RealScan 74 Installation in Checkstand Cutout 25510 To install the RealScan 74 in the checkstand cutout, perform the following procedure. 1. Verify that the top of the RealScan 74 supports are set to the initial distance from the top of the checkstand. Check dimensions on the “Checkstand Cutout” section in the Site Preparation chapter. 2. Holding the handles on the back of the tower cabinet and the front of the unit, slowly lower the RealScan 74 into the checkstand cutout. It should sit on supports at the bottom of the checkstand cutout. 3. Install the Top Plate on the four supports on the scanner. Note: It is important that the RealScan 74 does not rock on its supports. Make sure that all adjustable supports are securely fastened and that the RealScan 74 is sitting on all supports. Note: Place the power supply in a position where spilled liquids cannot fall onto it. …

-

Page 54: Step 6: Top Plate Alignment Verification

Verification”. Step 7: Scale Calibration Note: Only certified personnel can perform the scale calibration procedure and place the scale into service for trade to comply with governmental weights and measures regulations. The RealScan 74 must meet the following accuracy requirements. • The RealScan 74 is considered a new unit each time the scale is calibrated. This status lasts for thirty (30) days. • The RealScan 74 is considered an in‐service unit thirty (30) days after the scale is calibrated. During factory testing, the scale is calibrated one or more times to test the scale calibrating function. This calibration test is not sufficient to make the scale ready for weighing in trade.The scale MUST be calibrated when any of the following occur (this is a government requirement). • Initial installation of a RealScan 74 • When the scale cannot be zeroed • When the diagnostics indicate a calibration error • When the Scale Assembly is changed The calibration procedure sets the scale and the electronics to interpret the weight of an item accurately. The scale can be calibrated after power has been supplied for 30 minutes and if the ambient air condition has been 20° C (68° F) or above for at least 24 hours. If the ambient air condition has not been met (below 20° C (68° F)), then the scale must be on for at least 6 hours before it can be calibrated. One or more certified weight sets are required to calibrate and certify the scale. The following are examples: • Whole Pound Weight Set: NCR Part Number 998‐0633009 • Fractional Pound Weight Set: NCR Part Number 998‐0633012 • Kilogram Weight Set: Obtain locally …

-

Page 55: Perform The Calibration Procedure

Chapter 3: Installation 3-13 The RealScan 74 maintains an audit trail of scale calibration and weighs parameter setting. The audit trail consists of two even counters. Display the audit trail count by pressing and holding the Scale Zero button on the Operator Display Panel. The display alternates between and . The Cal value is the number of Cal xxx Par xxx times the scale has been calibrated. The Par value is associated with the weigh parameter setting and should never change. Note: The audit trail displays only on units with the RealScan 25 Remote Display. Note: Some host terminals can corrupt the calibration settings if they are connected during scale calibration. Therefore, NCR recommends disconnecting the interface cable before starting calibration of the scale and then reconnect it after completing the calibration procedure. Perform the Calibration Procedure Note: If a protective plastic covering is present on the Top Plate or the clear plastic door below the Top Plate, ensure that it is removed before calibrating the Scale. The scale firmware controls the calibration procedure. It waits for a response to each prompt before going to the next step. The firmware uses the voice feature and the display to identify how much weight to place on the Top Plate. After the required weight has been placed on the Top Plate and the Scale Zero button is pressed, the firmware sounds a single tone and goes to the next prompt. The calibration procedure can be ended before completion by turning the unit off. However, if this is done, the scale must still be calibrated before placing it into service. Note: The pound and kilogram weights used for calibration are not equivalent values. They are the actual weights the firmware needs to perform the calibration. …

-

Page 56

3-14 Chapter 3: Installation Calibrating and Exercising the RealScan 74 1. Determine the type of weight set to use for calibration. There a two weight sets, Kilograms and Pounds. • For the Kilogram weight set, you must have a calibrated KG weight set, 12.5 KG total. Weight combinations 2.5kg, 7.5kg, and 12.5kg are required, with suggested individual weights made up of a set of two 5 kg weights, one 2kg weight, and one 500g weight. • For the Pound weight set, you must have a calibrated LB weight set, 30 pounds total. Weight combinations 5 lb, 15 lb, and 30 lb are required, with suggested individual weights made up of a set of two10 lb weights, one 5 lb weight, two 2 lb weights, and one 1 lb weight. 2. Apply power to the RealScan 74 if it is off. The unit needs to be ON for 30 minutes prior to calibration, unless it is cool in the environment (below 20° C (68° F)), in which case the scale must be on for at least 6 hours before it can be calibrated. 3. EXERCISE THE SCALE Note: You MUST exercise the scale BEFORE the scale can be calibrated a. Remove the Top Plate. b. Press the Calibration Switch. i. Remove the clear plastic Switch Cover located on the right–front corner of the unit. Lift the left side of the cover to unlatch and remove it. 25918 If the Calibration Switch Security Cover is secured with a lead/wire or … -

Page 57

Chapter 3: Installation 3-15 ii. Unscrew the green sealing screw and pull up on the cover to access the blue Calibration Switch button. 25917 25915 iii. Press the small blue Calibration Switch button ( this button is very small s “Press and very recessed). When you press the button, the scanner speak Deck”. Scale Calibration Switch 25914 The unit will IMMEDIATELY begin a continuous clicking sound along with a steady tone. … -

Page 58

3-16 Chapter 3: Installation Note: You MUST replace the Calibration Switch Cover and Top Plate, and complete the scale exercise procedure within 90 seconds. If not, the scanner will report a ‘Calibration Error Code 8’ and you will see 1 blue and 1 green LED on the Light Bar. green blue 25688 Note: The unit prompts to perform the press‐down procedure twice, otherwise the unit will report ‘Calibration Error Code 8’. c. PRESS DOWN PROCEDURE. i. Once the Top Plate is back on and all the LEDs in the tower Light Bar are off, use both hands and press down HARD on the Top Plate with a constant and increasing pressure. Note: It will take a LOT of pressure. You might have to fully LEAN on the scale ‐ you will not break it. The goal is to light ALL 5 LEDs and keep them on for 4 seconds. … -

Page 59

Chapter 3: Installation 3-17 ii. As you press on the scale deck, an increasing number of LEDs will turn on indicating the amount of pressure you are applying. Increasing pressure orange orange orange orange orange orange orange orange orange orange orange 25689 iii. As you press, the tone also increases in pitch, producing a different, higher tone for each additional LED that lights up. If you let go, the tone will decrease in pitch as the LEDs progressively turn off. … -

Page 60

3-18 Chapter 3: Installation iv. At the highest pitch, with ALL 5 LEDs on, you MUST CONTINUE pressing down with continuous consistent pressure until the 5 LEDs turn solid red and the scanner beeps four times. 25795 v. Finally, the scanner will say “Complete” and all the 5 LEDs will turn solid blue. You can then release your hands from the deck. blue blue blue blue blue 25796 vi. Scanner will again say “Press deck”. vii. Repeat the Press Down steps again until the scanner says “Complete”. … -

Page 61

Chapter 3: Installation 3-19 4. Once the exercising is complete (press‐down done twice), the scanner will require a delay before continuing with calibration. It will say “Please wait 20 seconds…15 seconds…10 seconds…five seconds…complete”. There is a countdown shown on the 7825 remote display if one is attached. 5. The regular calibration procedure will begin after exercising is complete. Use the following procedures: Note: Use the type of calibration procedure according to the type of weight sets being used. Note: Place weights in circles shown when calibrating to ensure even distribution of weight during calibration. Start at the center and work outward horizontally with increasing weight. Do not scatter weights around the Top Plate Calibration Using Kilogram Weights a. Scanner speaks “Place zero kilograms on deck then press Scale Zero”. Make sure the scale has no weights on it (is empty) then press Scale Zero. Wait. b. Scanner speaks “Place 2.5 kilograms on deck then press Scale Zero”. Put 2.5 kg on the scale then press Scale Zero. Wait. c. Scanner speaks “Place 7.5 kilograms on deck then press Scale Zero”. Add 5.0 kg on the scale then press Scale Zero. Wait. d. Scanner speaks “Place 12.5 kilograms on deck then press Scale Zero”. Add 5.0 kg on the scale then press Scale Zero. Wait. e. Scanner speaks “Place zero kilograms on deck then press Scale Zero”. Take all the weights off the scale then press Scale Zero. Wait. Scanner speaks “Calibration complete” upon successful calibration. … -

Page 62

3-20 Chapter 3: Installation d. Scanner speaks “Place 30 pounds on deck then press Scale Zero”. Add 15 more pounds to make 30 lb on the scale then press Scale Zero. Wait. e. Scanner speaks “Place zero pounds on deck then press Scale Zero”. Take all the weights off the scale then press Scale Zero. Wait. Scanner speaks “Calibration complete” upon successful calibration. 6. When successful calibration is concluded, take the Top Plate off, ensure the Scale Calibration Switch cover is closed, and tighten the green sealing screw. 7. Seal the Calibration Switch Security Cover with one of the following seals: • Lead/Wire Seal (NCR Part Number: 603–8001097) using a Lead/Wire Seal Press (NCR Part Number: 603–9000157) • Film/Paper Seal (Obtain locally—Must meet the requirements of the local government) Note: Depending on local laws, Weights and Measures officials may be required to attach the seal. 8. Reinstall the Top plate. If Scan Doctor detects an error during the calibration procedure, one of the following error codes may be given. Error Code Problem Suspect Components Possible out of range calibration Digital Board… -

Page 63: 1. Increasing Load Test

Chapter 3: Installation 3-21 After calibrating the scale, the accuracy must be verified to assure it meets the government requirements. This consists of a series of four tests that must be run in the continuous sequence given. 1. Increasing Load Test 2. Over‐Capacity Test 3. Decreasing Load Test 4. Shift Test Increasing Load Test This test checks the scale’s accuracy when incrementally adding weight to the center of the Top Plate. Use weights that correspond to the RealScan 74 weight features. Step Weight Feature Add Weight Remove Weight Display Result Kilogram 0.100 kg 0.100 0.000 kg Pound 0.20 lb 0.20 0.00 lb Kilogram 2.500 kg 0.10 kg…

-

Page 64: Decreasing Load Test

3-22 Chapter 3: Installation Place additional weight on the center of the Top Plate as shown in the following table. Use the weight that corresponds to the RealScan 74 weight feature. The display shows a series of dashes to indicate an over‐capacity condition. Step Weight Feature Add Weight Remove Weight Display Result Kilogram 0.050 kg —.— Pound 0.10 lb —.— Kilogram 0.050 kg 15.000 kg Pound 0.10 lb 30.00 lb 24180 Note: Do NOT remove any weight from the Top Plate after completing this test. Decreasing Load Test This test checks the scaleʹs accuracy when incrementally removing weight from the …

-

Page 65: Shift Test

Chapter 3: Installation 3-23 Shift Test This test involves moving a weight off the center point of the Top Plate to check for continued accuracy. Test Pattern 25344 1. Place an appropriate Test Load weight for each weight feature on each of the four circles individually. The display must show the same weight between any of the 4 readings. Note: Each circle is half‐way between the center of the Top Plate and the corner. 2. Remove all weights. The display must read 0.000 ± 0.005 kg (0.00 ± 0.01 lb). Test max thirty pounds (30.00 lb) in center only. 3. Press and hold the Scale Zero button. Record the Cal and Par values shown on the display. Position Weight Feature Test Load Display Result Kilogram 5.000 kg 5.000 kg Pound 10.00 lb 10.00 lb Kilogram 5.000 kg 5.000 kg…

-

Page 66: Securing The Calibration Switch

3-24 Chapter 3: Installation Securing the Calibration Switch After performing a scale calibration, attach a seal to the scale calibration security cover. Depending on the local laws, Weights and Measures officials may be required to attach the seal. Note: In the United States and Canada, the audit trail serves as an acceptable security seal when the RealScan 25 Compact Display is present. Perform the following procedure to secure the calibration switch. 1. Remove the Top Plate. 2. Remove the clear plastic Calibration Switch Cover located on the right–front corner of the unit. Lift the left side of the cover to unlatch and remove it. 25918 3. Move the Calibration Switch Security Cover until the screw holes and the seal holes are properly aligned and fasten the green thumbscrew in the Calibration Switch Security Cover to secure the Calibration Switch. 25916 …

-

Page 67

Chapter 3: Installation 3-25 4. Seal the Calibration Switch Security Cover with one of the following seals: • Lead/Wire Seal (NCR Part Number: 603‐8001097) using a Lead/Wire Seal Press (NCR Part Number: 603‐9000157) • Film/Paper Seal (Obtain locally—Must meet the requirements of the local government) 5. Install the Calibration Switch Cover. 25979 6. Turn the scanner over and install the four leveling screws. 25987 7. Turn the scanner back to its upright position and install the Top Plate. … -

Page 68: Step 8: Sensormatic® Deactivation Setup

3-26 Chapter 3: Installation Step 8: Sensormatic® Deactivation Setup Sensormatic Tag Deactivation Connect the Sensormatic® Tag Deactivation System to the RS232 auxiliary port, which is Port 2. If a hand‐held scanner is used, connect the hand‐held to Port 1. When the RealScan 74 scanner reads a tag, the Sensormatic® hardware needs to receive an interlock signal for it to function. When the system is installed, the Sensormatic® Interlock Signal must be enabled. There are two modes of Sensormatic operation, Interlocked and Non‐interlocked. The mode is controlled by the Scan Enable Time which is a setting in the Sensormatic controller. When the Scan Enable Time is set to a value between 1 and 29, the system will run in the Interlock Mode. If the value is 0 or 30 the system will run in the Non‐ interlock Mode. Interlock Mode The scanner reads the Scan Enable Time from the controller. If it is between 1 to 29, it will enable the controller for deactivation for this many seconds after a bar code is read and then will disable the controller until the next bar code. Interlock mode is used in self service lanes and cashier assisted lanes. Non-Interlock Mode If the Scan Enable value is 0 or 30, the scanner will enable the Sensormatic controller for deactivation any time the scanner is enabled to read tags. In most systems, this corresponds to the time the cashier is signed into the POS Terminal. The terminal sends an “enable” to the scanner at cashier sign in and this is passed on to the Sensormatic controller. At cashier sign out, the POS sends a “disable” to the scanner and the Sensormatic controller is disabled. This is called Non‐interlock Mode. This mode is designed for the cashier lanes. Sensormatic® Online Offline Indication If the scanner is programmed for Sensormatic operation when the scanner powers up …

-

Page 69

Chapter 3: Installation 3-27 Cashier Sign In Offline Alert There is a feature to alert the cashier of the EAS system state at sign in. When the sign in occurs and the scanner is enabled if the EAS system is offline the “EAS Offline message will be spoken”. There is a programmable time limit on how long the sign out period must be before the offline message is spoken in order to prevent extraneous messages when cashier must sign in and out frequently. This message is from 1 to 15 minutes and is selected with the following programming tag sequence. 1. Program Mode—puts the scanner in programming mode. 2. Hex 7, Hex C, Hex x—where x is the time in minutes (1 to 15). 3. Save and Reset—saves the enabled setting and resets the RealScan 74. EAS Status LED There is an LED indicator beside the Manual Deactivation Button used to indicate the EAS system status. The LED will be on solid when the system is connected and operating properly. If the system is connected but not communicating the LED will be flashing. The LED is off when the EAS feature is disabled. Enable Sensormatic® Communications Scan the following sequence of programming tags to enable the Sensormatic® communications. These must be the first tags scanned after applying power to the RealScan 74. 1. Program Mode—puts the scanner in programming mode. 2. Hex 4, Hex 2, Hex B—enables Sensormatic® Interlock Signal. 3. Save and Reset—saves the enabled setting and resets the RealScan 74. … -

Page 70: Specific Function Programming

3-28 Chapter 3: Installation Scan the following sequence of programming tags to change the tone frequency of the RealScan 74. 1. Program Mode—puts scanner in programming mode. 2. Hex 5, Hex 8, Hex B—increments to the next frequencies. Continue scanning Hex B to get the desired frequency. There are eight frequencies to choose from: • 570 Hz (default) • 637 Hz • 721 Hz • 829 Hz • 976 Hz • 1186 Hz • 1512 Hz • 2083 Hz 3. End—completes the programming sequence. 4. Save and Reset—stores the setting and resets the RealScan 74. Sensormatic® Deactivation Tone Pulse Length Scan the following sequence of programming tags to change the number of pulses in the deactivation tone of the RealScan 74. 1. Program Mode—puts scanner in programming mode. 2.

-

Page 71

Chapter 3: Installation 3-29 Scanning this tag is a toggle function. The number of beeps indicates how the function is set. • 1 Beep—Manual Deactivation function is disabled • 2 Beeps—Manual Deactivation function is enabled—Factory Default • 3 Beeps—Function is enabled plus 048589999977 bar code sent After enabling or disabling the Manual Deactivation function, scan the following Reset tag to make the setting permanent in the RealScan 74. Bar Code Label Hold-Off The purpose of the Bar Code Label Hold‐Off function is to force the user to bring the bar code closer to the scanner when a live EAS tag is present on the item being scanned. When the RealScan 74 detects a live EAS tag it emits a clicking sound and sets a ½‐second timer (optional). The timer will be restarted and will not expire as long as the EAS tag is detected. During this time the RealScan 74 does not beep or send bar code data to the host terminal even though it may read the bar code. The timer will not be restarted once the EAS tag is deactivated. After the timer expires, the RealScan 74 beeps and sends bar code data to the host terminal. If the bar code has been removed from the scan field, it may have to be returned to the field to be read and sent to the host. The Bar Code Label Hold‐Off function is enabled and disabled by scanning the Bar Code Label Hold‐Off tag. Scanning this tag is a toggle function. The number of beeps indicates how the function is set. • 1 Beep—Bar Code Label Hold‐Off function is disabled … -

Page 72

3-30 Chapter 3: Installation • 2 Beeps—Bar Code Label Hold‐Off function is enabled—Factory Default After enabling or disabling the Bar Code Label Hold‐Off function, scan the following Reset tag to make the setting permanent in the RealScan 74. Audible Detection The Audible Detection function provides direct feedback to the user when a live EAS tag is in the field of view of the scanner. Clicks are enabled on the scanner. The Audible Detection (click) function toggles between 1, 2, and 3 beeps with each scan. • 1 Beep—Audible Detection function is disabled • 2 Beeps—Audible Detection function is enabled • 3 Beeps—Audible Detection function is enabled plus deactivation tone EAS Optional Communications The EAS Optional Communications function alerts the host application with a bar code communication message in three ways. This permits the host to control the sequence of events at the scanner. • The RealScan 74 sends the Error bar code (048589999999) if an EAS detection signal occurs after a bar code is read by the scanner (for example, the Sensormatic® tag is still live). The Error Bar Code Timer defines the window for permitting a deactivation to occur after a bar code is read. The timer can be set from ½ second to 4 seconds in ½‐second increments. If the timer expires and no EAS deactivation has occurred, the Error bar code is sent to the host application. • The RealScan 74 can send a Detect bar code (048589999988) every 4 seconds when EAS detections are occurring (a live EAS tag is in the detection field). • The RealScan 74 can send both bar codes if both conditions are met. … -

Page 73

Chapter 3: Installation 3-31 Scan the following EAS Communications Function tag to set the EAS Communication function. The function changes each time this tag is scanned. The number of beeps indicates how the function is set. • 1 Beep—EAS Communications function is disabled—Factory default • 2 Beeps—RealScan 74 sends Error bar code (048589999999) • 3 Beeps—RealScan 74 sends Error bar code (048589999999) and Detect bar code (048589999988) • 4 Beeps—RealScan 74 sends Detect bar code (048589999988) The following tag increments the Error bar code timer. Each time the tag is read, the time is incremented ½ second until the maximum time is reached. It then starts over with the least time. The number of beeps indicates how the timer is set. • 1 Beep—½ second • 2 Beeps—1 second • 3 Beeps—1½ seconds • 4 Beeps—2 seconds • 5 Beeps—2½ seconds • 6 Beeps—3 seconds • 7 Beeps—3½ seconds • 8 Beeps—4 seconds … -

Page 74: Power-Up The System

3-32 Chapter 3: Installation After setting the EAS Optional Communication function and the Error Bar code timer, scan the following Reset tag to make the setting permanent in the RealScan 74. Reset Bar Code Error, Detect, and Manual Deactivation Bar Codes The following are the Error, Detect, and Manual Deactivation bar codes, respectively. These bar codes are used for testing the POS system. Scan the bar code to simulate the effect on the POS system. • Error Bar Code • Detect Bar Code • Manual Deactivation Bar Code Power-up the System Note: Refer to the Sensormatic® AMB9010 Controller documentation for additional information about setting up the controller. Perform the following procedure to power‐up the system. 1. Turn on the RealScan 74. When the RealScan 74 is first turned on, all Sensormatic® parameters should be at their default settings: …

-

Page 75: Check Sensormatic® Deactivation System

Note: Voice message EAS Online must be given before continuing. If voice message EAS Online is not given, turn off the power to all components. Check all cable connections and then repeat this procedure starting at Step 1. If voice message EAS Online is still not given and the Manual Deactivation Button flashes, scan the Reset programming tag. If EAS Online status is still not given, follow instructions on the Sensormatic Card—Before You Call About…. The problem may be a bad Antenna cable. 4. Position a Hard Tag over the top of the RealScan 74. As the Hard Tag is moved, the RealScan 74 starts clicking when the tag moves within four inches of the center of the Top Plate. If the clicking sound is not generated, scan the Reset programming tag, then go to Step 3. If the second attempt fails, call for technical assistance. Refer to Appendix D for NCR Technical Support contact information. Check Sensormatic® Deactivation System Check the System Position a Hard tag above the RealScan 74 Top Plate. As the tag moves within four inches of the Top Plate, a clicking sound is heard (if programmed). Refer to the previous topic, “Audible Detection,” for instructions on enabling the clicking sound. If the Hard tag has to be closer than four inches to from the Top Plate to get the clicks, consult the Sensormatic® Card–Before You Call About…. X Axis Orientation Y Axis Orientation 4″ Above Top Plate 5″ Above Top Plate 25354 …

-

Page 76: Step 9: Operational Unit Verification

3-34 Chapter 3: Installation Next, obtain a security tag that has not been deactivated. Scan a bar code and immediately pass the security tag through the deactivation zone. The Good Read Tone should sound indicating a good read of the bar code and deactivation of the security tag. Refer to the “Sensormatic Tag Deactivation Procedure” section in chapter 4 for detailed operating instructions. Call Sensormatic® After the NCR RealScan 74 Sensormatic® configuration is installed, call Sensormatic® to have them test, tune, and phase their system. Step 9: Operational Unit Verification When power is applied to the RealScan 74, the Scan Doctor software checks many of the scanner components. NCR RealScan 74 Scanner-Only Models After passing the Scan Doctor Power‐On Wellness Check, the Scan Adviser will start out with five blue LEDs and transitions through a range of colors, and leaves only the three center LEDs lit in green. The RealScan 74 is now operational. NCR RealScan 74 Scanner/Scale Models After passing the Scan Doctor Power‐On Wellness Check, the RealScan 74 runs scale diagnostics. During this time, all segments on the RealScan 25 Remote Display are turned ON so the operator can verify the display works correctly. Then the display reads 0.000 kg (0.00 lb). The Light Bar starts out momentarily with five blue LEDs, changes to five red LEDs and blinks them five times. The unit beeps once after that and the RealScan 74 is now operational. …

-

Page 77: Realscan 74 Power-On Wellness Check

Chapter 3: Installation 3-35 RealScan 74 Power-On Wellness Check If an error occurs during the Power‐On Wellness Check, the RealScan 25 Remote Display (if the unit has one) displays an error code, and if enabled, the RealScan 74 emits an audible description of the error and what action to take. There may be some simple steps that can be performed to correct the problem (refer to chapter 6 for more information). If the problem cannot be corrected, contact the maintenance provider for warranty and service information. Checkout Reading Operation The RealScan 74 comes from the factory with the programming parameters set to default values. The Communications Protocol is set to the specifications on the order. However, some parameter changes for a particular installation can be made. Refer to chapter 5 for more information. Flash Latest Firmware The RealScan 74 includes firmware flashing. This permits upgrades to the firmware without replacing the actual firmware chip. It is possible to flash the scanner completely unattended from the POS terminal using NCR software (sold separately). Note: There is a set of instructions for loading the appropriate flash tools based on the firmware currently in the scanner. Refer to the “Firmware Flashing” section in Chapter 5 for more detailed information. …

-

Page 78: Special Host Terminal Connections

3-36 Chapter 3: Installation Special Host Terminal Connections Scanner Connected to IBM Terminals The scanner and scanner interface to any IBM system is basically Plug‐and‐Play, assuming the RealScan unit is programmed for IBM Communications (Refer to the “Programming Worksheets” section on Chapter 5 for more information). These systems are always single‐cable, that is, one cable carries traffic for the scanner. There are no configurable parameters in the IBM interface—the protocol is standardized and without any flexibility as far as bar code data formatting or interface characteristics such as baud rate. The terminal port into which the RealScan unit is plugged varies with the type of terminal. The older 468x series of terminals require the RealScan unit to be plugged into port 17. Newer IBM terminals no longer have this port; instead they use cable 1416‐C070‐0040 to plug into port 9x (the “x” varies depending on the terminal model). SNI Beetle Host Terminal For the RealScan 74 to communicate with an SNI Beetle Host Terminal, the communication parameters must be properly set. Scanning the following sequence of programming tags enables a typical installation; however, some variations may be necessary for any specific installation. The following programming tags must be the first ones scanned after applying power to the RealScan 74. 1. Program Mode—enables programming mode 2. Hex 3, Hex 4, Hex F, Hex 0, Hex 0—chooses Wincor‐Nixdorf Beetle parameters 3. Save and Reset—save Beetle parameters 4.

-

Page 79: Peripheral Connections

= «N» (4Eh) Pharmacode = «A» (41h) 25592 Peripheral Connections Please be aware that these Hand‐Held setup instructions assume Code 128, Code 39 and Interleaved 2 of 5 are enabled on the RealScan 74. Otherwise, if any of those bar code types are scanned with any of the Hand‐Helds, and they are not also enabled on the RealScan 74, then the RealScan 74 produces a “bad” tone and will NOT transmit the barcode data. Metrologic Hand-Held Scanner A Metrologic Hand‐Held Scanner can be connected to one of the RS232 auxiliary ports on the NCR RealScan 74. If the Metrologic Hand‐Held is the only peripheral device, it can be connected to either port. However, if connecting another peripheral device, there may be restrictions for the Metrologic port connection. Note: These were recently tested on a Metrologic Voyager (Metrologic MS9540) and worked. However, each additional model needs to be verified. Metrologic RealScan 74 Cable: 53-53220A No external power needed 25789 …

-

Page 80: Programming The Metrologic Hand-Held Scanner If Connected Through The Auxiliary Rs232 Port

3-38 Chapter 3: Installation Programming the Metrologic Hand-Held Scanner if Connected through the Auxiliary RS232 Port Scan the following sequence of tags with the Metrologic Hand‐Held Scanner. If the scanner encounters problems reading these tags, use the tags printed in the Metrologic Installation and User’s Guide: http://www.metrologic.com/corporate/products/pos/ms9520/ Enter Config Mode ³ 9 9 9 9 9 9 Recall Defaults ³ 9 9 9 9 9 8 …

-

Page 81

Chapter 3: Installation 3-39 UPC Prefix Id ³ 1 1 6 6 1 7 CR-LF on ³ 2 1 6 6 3 2 UPC Format ³ 8 0 7 5 1 3 0 0 … -

Page 82

3-40 Chapter 3: Installation ITF «b» ³ 8 0 6 7 0 9 8 0 Code 39 «a» ³ 8 0 6 0 0 9 7 0 Code 128 «f» ³ 8 0 6 1 1 0 2 0 … -

Page 83: Programming The Realscan 74

Chapter 3: Installation 3-41 Programming the RealScan 74 When installing a Metrologic Hand‐Held Scanner, certain programming options must be set in the RealScan 74. Program these options as follows. There are four options that must be programmed on the RealScan 74. Scan the following tags to set these options. These must be the first tags scanned after applying power to the RealScan 74. Hand-Held Processing Selection Programming Tag Sequence Setting Enable Programming Mode, Hex 4, Hex 0, Hex 1, Save and Reset Required Disable Programming Mode, Hex 4, Hex 0, Hex 0, Save and Reset …

-

Page 84: Ncr Realscan 2357 And Hand-Held Products (Honeywell) Type Hand-Held Scanner

3-42 Chapter 3: Installation NCR RealScan 2357 and Hand-Held Products (Honeywell) Type Hand-Held Scanner These instructions apply to all Hand‐Held Products scanners and 7837 models (except the 7837‐1000 specifically), including the 3800g and 4600 series imagers. When connecting a RealScan 2357 Hand‐Held Scanner , certain programming options must be set on both the RealScan 74 and the Handheld Scanner. These options are given as follows. Programming Hand-Held Products Scanner if Connected through the Auxiliary RS232 Port If the RealScan 2357 Hand‐Held Scanner (any model) is connected to the RealScan 74 through the auxiliary RS232 port, program the Hand‐Held Products Scanner by scanning the following bar codes in order. If a triple beep is emitted from the Hand‐ Held scanner, start over with the first bar code. FACTORY DEFAULT Prefixes / Code 39 — a, Code 128 — f, Code I 2of 5 — b …

-

Page 85: Programming The Realscan 74

Chapter 3: Installation 3-43 Programming the RealScan 74 There are four options that must be programmed on the RealScan 74. Scan the following programming tags to set these options. These must be the first tags scanned after applying power to the RealScan 74. Hand-Held Processing Selection Programming Tag Sequence Setting Enable Programming Mode, Hex 4, Hex 0, Hex 1, Save and Reset Required Disable Programming Mode, Hex 4, Hex 0, Hex 0, Save and Reset …

-

Page 86: Programming Realscan 2357 Hand-Held Scanner If Connected Through The Usb Peripheral Port

3-44 Chapter 3: Installation Programming RealScan 2357 Hand-Held Scanner if Connected through the USB Peripheral Port Prerequisites: Firmware Levels: • 7874, 497‐0461146 ‐ USB HH (pdf417 support not available) Programming: Use the following programming sequence if you want to make the scanner beep whenever it receives a valid barcode data through the USB host port (the scanner does not beep by default): Selection Programming Tag Sequence Setting Enable Programming Mode, Hex 4, Hex 0, Hex 5, Save and Reset Required Disable Programming Mode, Hex 4, Hex 0, Hex 4, Save and Reset…

-

Page 87: Ncr Realscan 2356 And Symbol (Motorola) Type Hand-Held Scanner