Здравствуйте, P0170 O2 Sensor Rich/Lean Exhaust, первый лямбда зонд фиксирует слишком богатую топливо-воздушную смесь. Лучшим вариантом поиска неисправности вызвавшей эту ошибку будет отслеживание показаний датчиков, участвующих в приготовлении топливо-воздушной смеси, в реальном времени т.е проехать с подключенным сканером и специалистом способным отследить эти данные. Эту ошибку могут вызвать следующие неисправности:

1. Плохое качество топлива, израсходуйте топливо залитое в баке на данный момент, заправьтесь на проверенной АЗС, сбросьте ошибку и продолжите эксплуатацию автомобиля, если ошибка не возникнет вновь вероятно дело было в не качественном топливе.

2. Подсос воздуха во впускном тракте в обход ДМРВ, проверьте герметичность соединений впускного тракта, герметичность всех вакуумных линий, проведите протяжгу хомутов впускного тракта.

3. Неисправность или загрязнение ДМРВ, снимите ДМРВ и промойте его спираль жидкостью для очистки карбюратора, будьте предельно осторожны это очень точный и хрупки узел его легко повредить. если расходомер неисправен замените.

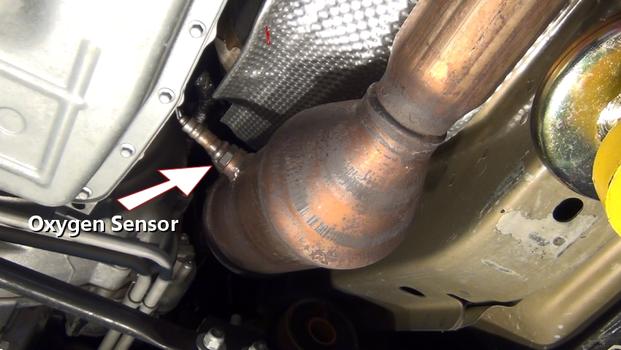

4. Неисправность самого лямбда зонда или плохой контакт в его разъеме, проведите инспекцию разъема на предмет окисления, загрязнения, обрыва контактов.

Красноярск, Nissan Gloria

Trouble Code 44 indicates that the O2 sensor is showing a persistently high exhaust oxygen content (lean), despite the efforts of the ECM to increase injector on-time (thus increasing fuel delivered).

What is obd1 Code 44?

Oxygen Sensor Error (Lean Condition Indicated) If there is excess oxygen in the exhaust, it is in lean condition and the O2 sensor voltage will be low. The ECM uses this information to adjust the amount of fuel delivered to each cylinder.

What does the code 44 on a GM ECM mean?

This is the description of a Code 44 as set on GM products It is an indication of a lean mixture as indicated by the oxygen sensor readings. Circuit description: The ECM supplies a voltage of about .45 volts between the appropriate terminals of the sensor.

Why does my car have code 44 lean exhaust?

The code 44 for lean exhaust is most likely caused by one or more of the following: 1.) O2 sensor wire – Sensor pigtail may be mispositioned and contacting the exhaust manifold. 2.) Check for an intermittent ground wire between connector and sensor. 3.) Poor ECM to engine block ground.

What does a code 44 mean on an oxygen sensor?

This is the description of a Code 44 as set on GM products It is an indication of a lean mixture as indicated by the oxygen sensor readings. Circuit description: The ECM supplies a voltage of about .45 volts between the appropriate terminals of the sensor. (If measured with a ten megohm DVM, this may read as low as .32 volt).

What does code 32 mean on a fuel injection computer?

Rough idle. Code 32: EGR System Problem. Code 33: MAP Sensor Signal High. Bad gas mileage. Won’t pass the state mandated emission test. The fuel injection computer is the one that regulates the opening and closing of the EGR valve thru’ the application and release of vacuum (through a vacuum solenoid).

What are the trouble codes on a Chevy truck?

Watch the “check engine” light. It will start flashing. Chevy trouble codes are two digits. The first digit will be represented by a long flash. Secondary digits will be relayed through quicker flashes. For example, trouble code 16 will be relayed with one long flash and six short ones. Write the codes down as the “check engine” light sends them.

This is the description of a Code 44 as set on GM products It is an indication of a lean mixture as indicated by the oxygen sensor readings. Circuit description: The ECM supplies a voltage of about .45 volts between the appropriate terminals of the sensor.

How to run a diagnostic test on a 1993 Chevy truck?

They will be on the end of the row to the far right, and the will be side by side. Place your key into the Chevy’s ignition and turn it, but don’t crank the engine. Watch the “check engine” light. It will start flashing. Chevy trouble codes are two digits. The first digit will be represented by a long flash.

What does code 43 mean on a truck?

Code 43: My Truck Shows Code 43 but Had No Plug for the Electronic… My truck shows code 43 but had no plug for the electronic spark control or the control its self on my motor I do believe its code 43 I ran it earlier to day what do I need to do to fix this it just has a little bit of a rough idle. have the same problem?

What does code 44 lean exhaust mean?

Trouble Code 44 indicates that the O2 sensor is showing a persistently high exhaust oxygen content (lean), despite the efforts of the ECM to increase injector on-time (thus increasing fuel delivered).

What is code 44 on obd1?

Oxygen Sensor Error (Lean Condition Indicated) If there is excess oxygen in the exhaust, it is in lean condition and the O2 sensor voltage will be low. The ECM uses this information to adjust the amount of fuel delivered to each cylinder. Fault Code Description. 44 – Oxygen sensor error (lean condition indicated)

What does the code 44 on a GM ECM mean?

This is the description of a Code 44 as set on GM products It is an indication of a lean mixture as indicated by the oxygen sensor readings. Circuit description: The ECM supplies a voltage of about .45 volts between the appropriate terminals of the sensor.

Why does my car have code 44 lean exhaust?

The code 44 for lean exhaust is most likely caused by one or more of the following: 1.) O2 sensor wire – Sensor pigtail may be mispositioned and contacting the exhaust manifold. 2.) Check for an intermittent ground wire between connector and sensor. 3.) Poor ECM to engine block ground.

What does a code 44 mean on an oxygen sensor?

This is the description of a Code 44 as set on GM products It is an indication of a lean mixture as indicated by the oxygen sensor readings. Circuit description: The ECM supplies a voltage of about .45 volts between the appropriate terminals of the sensor. (If measured with a ten megohm DVM, this may read as low as .32 volt).

What are the GM trouble codes for 2008?

Here is what I have done since Aug. 2008 I have replaced the MAF sensor, air filter, knock sensor, fuel pump, coil, tps, fuel filter, distributor cap and rotor. But guess what I am still having the same codes in this order P0327,P0171, and P0174.

What is code 44 on a fuel pump?

Code 44 is a lean code. Could be an O2 sensor but most likely it’s the fuel pump. Fuel pressure needs tested. Specs are 9-13 psi. Deadhead pressure should be 18-20 psi. These vehicles have had a problem splitting the fuel hose between the fuel pump and the pipe in the tank allowing the fuel to get pumped directly back into the tank.

This is the description of a Code 44 as set on GM products It is an indication of a lean mixture as indicated by the oxygen sensor readings. Circuit description: The ECM supplies a voltage of about .45 volts between the appropriate terminals of the sensor.

The code 44 for lean exhaust is most likely caused by one or more of the following: 1.) O2 sensor wire – Sensor pigtail may be mispositioned and contacting the exhaust manifold. 2.) Check for an intermittent ground wire between connector and sensor. 3.) Poor ECM to engine block ground.

What causes code 44 on an O2 sensor?

The code 44 for lean exhaust is most likely caused by one or more of the following: 1.) O2 sensor wire – Sensor pigtail may be mispositioned and contacting the exhaust manifold. 2.) Check for an intermittent ground wire between connector and sensor.

Как просмотреть коды

— Выключаем зажигание

— Находим разъем ALDL (Assembly Line Data Link) как на картинке

— Замыкаем контакты A и B

— Включаем зажигание НО НЕ ЗАВОДИМ!

— считаем количество вспышек лампочки MIL («CHECK ENGINE», «SERVICE ENGINE»)

ВСПЫШКА пауза ВСПЫШКА ВСПЫШКА = код 12

ВНИМАНИЕ: Некоторые модели 94 и 95 не имеют контакта B — нужен сканер

ВНИМАНИЕ: Некоторые модели 94 и 95 не имеют контакта А и B — нужен сканер

Все машины после 1996 года оснащены OBD II и требуется сканер.

Описание контактов разъема

A — Ground

B — Test Terminal

C — Air Injection

E — Serial Data

F — TCC

G — Fuel Pump

H — Brake Sense Speed Input

M — Serial Data

Как сбросить коды

Достаточно отключить землю АКБ не менее чем на 20 секунд или вынуть предохранитель с пометкой «ECM»

OBDI Codes

4.3L VIN Z and W

12 – Diagnostic mode

13 — Oxygen sensor circuit — Oxygen sensor voltage stays between 0.35 and 0.55 volts for 30 seconds when the TPS signal was above 0.55 volts. The engine had been running for at least 40 seconds with an engine temperature above 110? F.

14 — Coolant temperature sensor or circuit/ high temperature indicated — Coolant temperature sensor signal indicates a temperature of over 284? F for 4 seconds after the engine had been running for at least 10 seconds.

15 — Coolant temperature sensor or circuit/ low temperature indicated — Coolant temperature sensor signal indicates a temperature colder than -36? F for at least 4 seconds after the engine had been running for 2 seconds.

16 – System voltage high — Charging system voltage was either below 9 volts or above 17 volts for 10 seconds.

17 – Crank Signal Circuit — PCM did not detect any spark reference pulses within 240 fuel control reference pulses (80 crank revolutions) while engine was running below 1200 RPM.

19 – Crankshaft Position Sensor or circuit

21 – Throttle Position Sensor TPS or circuit voltage high — TPS voltage was above 0.8 volts for 5 seconds when engine was running and air flow was less than 15 gm /sec, or the TPS voltage was over 4.8 volts at any time.

22 – Throttle Position Sensor TPS or circuit voltage low — TPS voltage was under 0.2 volts for 4 seconds when the ignition was on.

23 – Intake Air Temperature (IAT) sensor circuit – low temperature indicated — Inlet air temperature sensor signal showed an air temperature of -29? F for 4 seconds.

24 — Vehicle Speed sensor circuit — Vehicle speed sensor signal showed less than 3 MPH for 2 seconds when engine speed was greater than 3000 RPM and transmission has not been in park or neutral for more than 4 seconds. Or vehicle speed goes from above 18 MPH to 0 in less than 2 seconds without applying brake.

25 – Intake Air Temperature (IAT) sensor or circuit – high temperature indicated — Inlet air temperature sensor signal showed an air temperature of over 218? F for 5 seconds when vehicle speed was greater than 35 MPH.

26 — Quad-Driver sense voltage shows a low voltage when battery voltage should be present, or if the sense voltage shows battery voltage when a low voltage should be present for at least 5 seconds when the engine was running.

27 — 2nd gear switch was closed or grounded for 10 seconds when vehicle was in 4th gear, or 2nd or 4th gear switch was open when engine was first started.

28 — 3rd gear switch was closed or grounded for 10 seconds when vehicle was in 4th gear, or 3rd or 4th gear switch was open when engine was first started.

29 — 4th gear switch was closed or grounded for 10 seconds when vehicle was in 4th gear, or 4th gear switch was open when engine was first started.

31 — Park/Neutral Position (PNP) switch circuit — PRNDL indicates a gear other than park or neutral for 13 seconds for 3 consecutive startups when ignition was on, engine was off and vehicle speed was 0. Or the PRNDL status indicators (A, B, C, P) showed an incorrect combination of Lo and Hi for more than 10 seconds.

32 — Exhaust Gas Recirculation (EGR) Circuit — EGR open command did not change the fuel mixture when the command was given during off idle operation. EGR opening should cause the mixture to be slightly richer because of the low oxygen content of exhaust gas.

33 — MAP sensor signal voltage was too high (low vacuum) for 5 seconds when throttle opening was under 2%.

34 — MAP sensor signal voltage low — MAP sensor signal voltage was too low (high vacuum) when engine speed was over 1200 RPM, or the throttle angle was above 21% when engine speed was over 1200 RPM.

35 — Idle Air Control (IAC) System

38 – Brake Switch

41 – Camshaft Sensor Circuit

42 – Bypass or Electronic Spark Timing circuit — The EST signal did not change when the ECM applied bypass voltage to the ignition module.

43 – Knock Sensor Ciruit — Knock sensor signal was either above 3.5 volts or below 1.5 volts for at least 20 seconds.

44 — Oxygen sensor or circuit – lean exhaust detected. — Oxygen sensor voltage was under 0.25 volts for up to 4 1/2 minutes of closed loop operation.

45 — Oxygen sensor or circuit — rich exhaust detected. — Oxygen sensor voltage was over 0.750 volts for 2 minutes in closed loop operation with a throttle angle between 0.6 and 1.9 volts.

46 – Power Steering Pressure Switch circuit

47 — Momentary loss of power to Body Computer Module (BCM).

48 – Misfire Diagnosis

51 — MEM-CAL, PROM, or ECM Error (Faulty or Incorrect Calibration)

52 – CALPAK or ECM problem

53 – System over-voltage – ECM over 17.7 volts

54 – Fuel Pump Circuit

55 — ECM problem

2.8 VIN R

13 — Oxygen Sensor Open Circuit Open circuit

14 — Coolant Temperature Sensor Circuit High temp indicated

15 — Coolant Temperature Sensor Circuit Low Temp indicated

21 — Throttle Position Sensor (TPS) Circuit (Signal Voltage High)

22 — Throttle Position Sensor (TPS) Circuit (Signal Voltage Low)

24 — VSS Circuit Fault

32 — EGR System Failure

33 — MAP Sensor Circuit Signal Voltage High (Low Vacuum)

34 — MAP Sensor Circuit Signal Voltage Low (High Vacuum)

42 — Electronic Spark Timing (EST)

43 — Electronic Spark Control (ESC) Circuit

44 — Lean Exhaust Indicated

45 — Rich Exhaust Indicated

51 — FAULTY MEM-CAL OR PROM PROBLEM

52 — FUEL CALPAK MISSING

53 — VOLTAGE AT ECM TERMINAL B1 IS GREATER THAN 17.1 VOLTS FOR 2 SECONDS.

54 — Fuel Pump Circuit (Low Voltage)

55 — FAULTY ECM

2.2L VIN 4

13 — Oxygen Sensor Open Circuit Open circuit — Oxygen sensor voltage stays between 0.35 and 0.55 volts for 20 seconds. Engine was at normal operating temperature and had been running for at least 2 minutes after start with a throttle angle above 6%.

14 — Coolant Temperature Sensor Circuit High temp indicated — Coolant temperature sensor signal indicates a temperature above 285? F after the engine has been running for at least 2 minutes.

15 — Coolant Temperature Sensor Circuit Low Temp indicated — Coolant temperature sensor signal indicates a temperature colder than -38? F after the engine has been running for at least 1 minute.

21 — Throttle Position Sensor (TPS) Circuit (Signal Voltage High) — TPS voltage was above 3.9 volts for 5 seconds when the MAP sensor signal showed manifold vacuum to be 15 pounds or more and engine speed was less than 1750 RPM or TPS voltage was below 1.9 volts for 64 seconds.

22 — Throttle Position Sensor (TPS) Circuit (Signal Voltage Low) — TPS voltage was under 0.21 volts for 5 seconds when the engine was running.

23 – Intake Air Temperature (IAT) sensor circuit – low temperature indicated — Inlet Air Temperature Sensor signal showed an air temperature below -30? F or above 302? F for more than 2 seconds after the engine has been running for 2 minutes.

24 — VSS Circuit Fault — Vehicle speed sensor signal showed less than 3 MPH for 2 seconds when engine speed was greater than 3000 RPM and transmission has not been in park or neutral for more than 4 seconds. Or vehicle speed goes from above 18 MPH to 0 in less than 2 seconds without applying brake.

25 – Intake Air Temperature (IAT) sensor circuit – high temperature indicated — Inlet Air Temperature Sensor signal showed an air temperature over 304? F after the engine has been running for 5 minutes and 20 seconds and the vehicle speed was greater than 15 MPH.

26 – Quad Module Driver Circuit — Quad-Driver sense voltage shows a low voltage when battery should be present or the sense voltage shows battery voltage when a low voltage should be present for at least 20 seconds.

27 – Quad Module Driver Circuit — Quad-Driver sense voltage shows a low voltage when battery should be present or the sense voltage shows battery voltage when a low voltage should be present for at least 20 seconds.

28 – Quad Module Driver Circuit — Quad-Driver sense voltage shows a low voltage when battery should be present or the sense voltage shows battery voltage when a low voltage should be present for at least 20 seconds.

29 – Quad Module Driver Circuit — Quad-Driver sense voltage shows a low voltage when battery should be present or the sense voltage shows battery voltage when a low voltage should be present for at least 20 seconds.

32 — EGR System Failure — EGR open command did not change the fuel mixture when the command was given during off idle operation. EGR opening should cause the mixture to be slightly richer because of the low oxygen content of exhaust gas.

33 — MAP Sensor Circuit Signal Voltage High (Low Vacuum) — MAP sensor signal voltage was too high for 10 seconds when throttle opening was under 12%.

34 — MAP Sensor Circuit Signal Voltage Low (High Vacuum) — When engine speed was between 1700 and 3600 RPM and throttle position angle was less than 1%, the MAP signal showed low voltage (high manifold vacuum) for at least 5 seconds.

43 — Electronic Spark Control (ESC) Circuit — The ECM did not detect a knock signal during near wide open throttle operation, or the knock signal was present for 3.5 seconds or more during normal engine operation.

44 — Lean Exhaust Indicated — Oxygen sensor voltage was under 0.3 volts for 50 seconds of closed loop operation. Throttle angle was above 5%.

45 — Rich Exhaust Indicated — Oxygen sensor voltage was over 0.700 volts for at least 51 seconds of closed loop operation. Throttle angle was above 5% and engine had been running for at least 2 minutes.

51 — FAULTY MEM-CAL OR PROM PROBLEM

53 – System Over-Voltage — Battery voltage was higher than 17.1 volts for 0.2 seconds, or below 10 volts for 4 minutes.

54 — Fuel Pump Circuit (Low Voltage)

55 – Fuel Lean Monitor — Oxygen sensor voltage was less than 0.3 volts for 5 seconds of closed loop operation.

66 – A/C Pressure Switch or Circuit — A/C refrigerant pressure voltage was either less than 0.19 volts or greater than 4.9 volts for 15 seconds, or the pressure voltage was above 4.0 volts when A/C clutch was not requested.

Common Misconception: When an engine misfires, the cylinder runs lean, not rich,

this is because the air to fuel ratio favors air by 14x. Therefore, an engine must

be running properly without cylinder

misfires to avoid lean mixture codes. Optimum air to fuel mixture (14 to 1)

is called stoichiometric,

which means: chemically balanced. The engine fuel management system is controlled

by the computer and various sensors which feedback data. After repairs are completed,

clear the trouble codes and allow the computer monitors to reset by driving between

20 and 40 miles to confirm correct system functionality.

Best Practices

- Check all vacuum hoses when replacing a single failed hose.

- Check connecting hoses to such items as a breather tube or EVAP system

Let’s Jump In!

Once a

check engine or service engine soon light has determined a lean engine code

has materialized, a repair procedure inspection is needed. Explanation: A lean code

is enabled when the computer has detected enrichment adjustments have maxed out,

with no results, this inability triggers the lean code.

Un-metered air which enters the intake system of the engine can cause a lean

mixture code to be triggered, inspect all vacuum lines for cracks or dilapidation.

Check the integrity of vacuum hoses at each end of the hose.

SPONSORED LINKS

The intake system utilizes gaskets which seal various components, if these gaskets

fail a vacuum leak will

result, causing the code failure. Use carburetor cleaner to help locate any potential

leaks by spraying around gasket surfaces and observe a rise in engine idle speed

if a leak exists.

An exhaust leak will allow fresh air to enter the system on the negative pressure

side of an exhaust event, this will cause an

oxygen sensor to

produce a lean reading. An exhaust system manages both pressure and vacuum cycles

while an engine runs. To inspect for an exhaust leak, have a helper start the engine

and hold the idle at about 1500 rpm, listen for additional exhaust noises coming

from the system including manifolds

and head pipes. Also, look for black soot at any point in the system as this

can indicate an exhaust leak.

After miles of driving, the mass air flow sensor’s filament or hot wire, can

become contaminated due air impurities which create false readings. Using sensor

safe carburetor cleaner to clean this filament can sometimes remove these deposits

allowing the sensor to obtain a correct reading.

Testing the exhaust system

oxygen sensors can

help determine the functionality of the sensor. If the sensing element fails, feedback

information will be incorrect causing a lean mixture code.

When an engine misfires an almost clean charge of oxygen is released into the

exhaust system. This will cause the exhaust system to test lean as tested by the

O2 sensors, this can sometimes be fixed by a

tune up.

SPONSORED LINKS

An air intake boot transfers engine air from the mass air flow sensor to the

throttle actuator. If the boot

fails, it can cause a false reading from the mass air flow sensor producing the

code.

Questions?

Our certified technicians are ready to answer lean exhaust

questions for free. We hope you saved money and learned from this guide. We

are creating a full set of car repair guides. Please subscribe

to our 2CarPros YouTube channel

and check back often for new videos which are uploaded regularly.

Article published 2022-03-11

1. O2S Wire. Sensor pigtail may be mispositioned and contacting the exhaust manifold.

check for intermittent ground in wire between connector and sensor.

2. Poor ECM Ground. Check ground connections at transaxle stud and ECM connectors, making sure all connections are clean and tight.

3. MAF Sensor. A MAF sensor output that causes the ECM to sense a lower than normal air flow will cause the sistem to go lean. Disconnect the MAF sensor and if the lean condition is gone, replace MAF sensor.

4. Lean Injector(s). Perform «Injector Balance Test»

5. Fuel Contamination. Water, even in small amounts, near the in-tank fuel pump inlet can be delivered to the injectors. The water causes a lean exhaust and can set DTC 44.

6. Vacuum or Crankcase Leaks can cause a lean condition.

7. Fuel Pressure. System will be lean if pressure is too low. It may be necessary to monitor fuel pressure while driving the vehicle at various road speeds and\or loads to confirm.

8. Exhaust Leaks. If there is an Exhaust Leaks, the engine can cause outside air to be pulled into the exhaust and past the sensor.

If the above are OK, it is a faulty oxygen sensor.