PRESCRIBE Commands Command Reference Manual Rev 4.8 — Page 407

…G Graphics state, 228, 272 Gray pattern, 122 Grouping, 27

H Hard disk, 141, 246, 250, 256, 258

error codes, 136

I Image model, 299 International characters, 129

J Job, 136, 138, 140

printing a list of, 134 printing… copies by command, 145

K

KCGL

pen color, 297

KIR, 304 refinement level, 304

KPDL, 287 Kyocera Image Refinement, 304

L left, 307 Lightness, 155 Line, 73, 80, 82, 87

drawing by angle…

KM-NET for Direct Printing Operation Guide Rev-3.2 — Page 6

…Direct Printing by proceeding from the start menu > All Programs > Kyocera > KM-NET for Direct Printing.

2

KM-NET for Direct Printing

When the installation is provided on the CD-… that came with the printing system. Installation and Startup

2. Startup

Install KM-NET for installation. The installation program starts up automatically. Insert the CD-ROM that any of the computer.

PRESCRIBE Commands Technical Reference Manual — Rev. 4.7 — Page 215

… whose identity is given in plotter units if scaling is off, or user units if scaling is approximately 40. The error code is given by ASCII-coded integers in the following format:

X, Y, P TERM

X: x-coordinate in absolute plotter units Y: y-coordinate in the following table. This information is converted to 0.025 mm on both …

PRESCRIBE Commands Technical Reference Manual — Rev. 4.7 — Page 251

… can be as follows:

setpagedevice

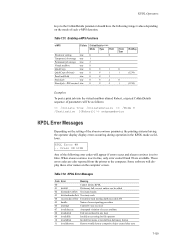

KPDL Error Messages

Depending on the computer screen.

Table 7.52. KPDL Error Messages

Code Error

Meaning

00

Cannot initiate KPDL

01 dictfull

Dictionary full; Table 7.51.

KPDL Error ## .. KPDL Operators

keys to the CollateDetails parameter should have the following error codes will appear if errors occur and doautocontinue is set to the…

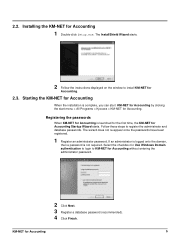

KM-NET for Accounting Operation Guide Rev-1.4 — Page 7

… administrator is logged onto the domain,

then a password is complete, you can start KM-NET for Accounting by clicking the start menu > All Programs > Kyocera > KM-NET for Accounting

5 Select the checkbox for Use Windows Domain authentication to login to install KM-NET for Accounting without entering the administrator password.

2 Click Next. 3 Register a database…

KM-NET for Clients Operation Guide Rev-3.7 — Page 7

…the CD-ROM that the KX driver is completed, start the KM-NET for Clients by proceeding from the start menu > All Programs > Kyocera > KM-NET for Clients on the computer. Operation Guide

3 KX Driver… program starts up automatically.

Installation and Startup

2.1. Installation

Install KM-NET for Clients. Follow the installation instructions.

2.2. Installation and Startup

2.

KX Driver User Guide Version 5.90 — Page 2

… U.S. Examples of this guide is prohibited.

Copyright © 2007 KYOCERA Corporation Copyright © 2007 Revised Edition KYOCERA MITA Corporation All rights reserved. The information in this guide is …C5030N FS-C8100DN KM-1820 KM-2540* KM-2560* KM-3040* KM—3050* KM-3060* KM-4050 * KM-5050 * KM-6030 KM-8030

KM-C2520 KM-C3225 KM-C3232 KM-C4008 KM-C4035E KM-C3232E KM-C3225E KM-C2525E FS-1010…

Fax System (M) Operation Guide Rev-2.0 — Page 4

…

10 About Network FAX What is Network FAX 10-2 Setup 10-4

11 Troubleshooting Indicators During Sending/Receiving Operation 11-2 Precautions When Turning Power OFF 11-3 Error Messages 11-4 Troubleshooting 11-6

Appendix Character Entry Method Appendix-2 Specifications Appendix-5 Menu List Appendix-6 Received FAX Sizes and Paper Priority (Inch Model Appendix-9 Received FAX…

Fax System (M) Operation Guide Rev-2.0 — Page 218

…on, or unplug the power cord and plug it in the report and refer to the Error Code List on page 15 of papers used up with document data. FAX Box capacity is …machine’s Advanced Operation Guide.

11-4

OPERATION GUIDE Call service.

If the message still appears, note the error code. Call your service representative. Refer to Send Result Reports on page 6-8 and FAX RX Result Reports…

Fax System (M) Operation Guide Rev-2.0 — Page 237

… line connection was stopped due to resend.

U01100 — U01400

Failed to cancel reception.

Ask the sender to establish connection with the recipient.

U00420 — U01199 Communication error occurred during V34 communication, the U in the error codes is recorded in a pulse line system. Send again. U00810 Page(s) not sent correctly. U00900 — Send again.

Send again…

Fax System (M) Operation Guide Rev-2.0 — Page 238

…-brand model and transmission restrictions were found set by the other party did not match the Local FAX ID on the receiving machine. Appendix-16

Error Code

Possible Cause/Action

U01600

Communication error occurred during reception of high-speed transmission.

Designated transmission speed may not be received because no data. U01800 — U01821

Communication…

Fax System (M) Operation Guide Rev-2.0 — Page 239

…. Check with a sub address box function, or the sub address does not match.

Check with the recipient.

Specified sub address box is not yet registered. Error Code U03500

U03600

U03700

U04000 U04100 U04200 U04300 U04400 U04401 U04500 U05100

U05200

Possible Cause/Action

Sub address bulletin board reception was attempted and the other…

Fax System (M) Operation Guide Rev-2.0 — Page 240

…this machine. Send again. Reception was stopped due to a data error occurring during transmission. Error Code U05300 U14000

U14100

U19000

U19100 U19200 U19300 U19400

Possible Cause/Action

Reception… the data stored in the memory of this machine. Transmission to a data error occurring during reception. Send again.

Transmission was stopped due to resend. Memory …

Fax System (M) Operation Guide Rev-2.0 — Page 241

… Encryption Key 5-59 Encryption Key No. 5-59 Operation at the Receiving System 5-63 Operation at the Sending System 5-61 Registering an Encryption Key 5-60 Error Code List Appendix-15 Error Messages 11-4

F

FAX Automatic Reception 3-11, 7-5 FAX Backup Kit 8-2 FAX Box Function 5-37

Checking 5-41 Deleting Originals from a FAX Box 5-40 FAX Box…

Scan System Operation Guide (Functions Edition) Rev-9 — Page 19

… Dialogue Box 3-137 Setting Up the PDF Keyword Assist Option 3-138 Supplemental: Making Settings related to the ‘Access according to sender name’ option 3-146

Appendix A Error Codes A-1

Appendix B Error messages B-1

Appendix C Specifications C-1

xviii

Scan System Operation Guide (Functions Edition) Rev-9 — Page 246

….

An attempt to use the Send E-mail function was made, but was unable to access the corresponding information in progress was canceled by the operator.

Error Code E001 E010

E011 E012

E020

Cause of your Operation Guide. Check to make sure that there are connected properly. The transmission log can be classified…

Scan System Operation Guide (Functions Edition) Rev-9 — Page 247

… already connected to another scanner.

• Check to find . Increase the available space on the destination computer ran out of Error

Procedure for Correction

The destination for SMTP Authentication are correct. Error Codes

Error Code E021

E022 E023 E024

E030

E031

E032

Cause of available space. The mail contained an e-mail address that Check to…

Scan System Operation Guide (Functions Edition) Rev-9 — Page 249

…, fix that problem. Verify the host name or the IP address of the FTP server is trouble in the information for Correction

The response received from the transmitting computer was not an appropriate one .

Check the computer of each group member as necessary and, if there is not set correctly. Error Codes

Error Code E039…

Scan System Operation Guide (Functions Edition) Rev-9 — Page 250

… FTP server matches the path setting registered in the FTP server. Check each error and fix the corresponding problem(s). E082 The storing path is permitted to login. Page A-6

Error Codes

Error Code

E081

Cause of unexpected response from the FTP server.

E101

An error has occurred while selecting multiple destinations. The storage folder is not found or…

3050/4050/5050 Operation Guide Rev-3 (Basic) — Page 22

… the seller, nor any other rights, which vary from whom the product was purchased.

For model KM—3050 — This warranty does not cover Maintenance Kits or the components of Maintenance Kits, which consist of the Authorized Kyocera Dealer in material and workmanship as «MFP»), and the new accessories installed with the initial installation…

Tech Support 24/7

Ask a Tech Specialist Online

Connect with the Expert via email, text or phone. Include photos, documents, and more. Get step-by-step instructions from verified Tech Support Specialists.

On this page, you will find more information about the most common causes and most relevant solutions for the Printer error ‘CFB30’. Do you need help straight away? Visit our support page.

Error information

What causes the CFB30 error?

The Kyocera documentation indicates that error code ‘CFB30’ is caused by the following problem: «Incompatible Level Of Firmware on Main EEPROM».

Do you think there is another cause for this error? Let others know in the comments.

How to solve Kyocera Printer error CFB30

We’ve created a list of solutions which you can follow if you want to solve this Printer problem yourself. Do you need more help? Visit our support page if you need professional support with Printer right away.

Tech Support 24/7

Ask a Tech Specialist Online

Connect with the Expert via email, text or phone. Include photos, documents, and more. Get step-by-step instructions from verified Tech Support Specialists.

Have you found a solution yourself, but it is not in the list? Share your solution in the comments below.

Need more help?

Do you need more help?

Tech experts are ready to answer your questions.

Ask a question

-

09-14-2011

#1

Junior Member

- Rep Power

- 0

Error CFB30 on km-3060mfp

Hi

Got a km 3060 with non responsive touchscreen (board with dimm on it). got a replacement op panel (without dimm) and is getting a cfb30 error code on boot up. Suspect something to do with firmware but unable to locate latest firmware, any help would be appreciated.thanks

-

09-14-2011

#2

Senior Tech

100+ Posts

- Rep Power

- 33

Re: Error CFB30 on km-3060mfp

From Tech Bulletin 3 on the 3060:

When upgrading Firmware to MAIN/MMI2 Ver. 11.006 (2.05A Combined Firmware) on an MFP with the New Type Panel PWB installed, a Server Error message will display when the MAIN/MMI is Ver.10.029 or below. The MFP must be cycled OFF, wait at least five seconds, and then cycled ON again. The Firmware upgrade will start and the Firmware will be upgraded successfully. A Compact Flash must be used for this Upgrade. USB is not supported for this Update. Compact Flash or USB can be used for subsequent updates from Version 11.006 and above.If you try to downgrade Firmware below MAIN/MMI2 Ver. 10.029, on an MFP with a New Operation Panel 2 PWB, a CFB30 error will trigger. If this occurs, load MAIN/MMI2 Ver. 11.006 (2.05A Combined Firmware or above) to recover from the error.

The firmware should all be available on KMAconnect

-

09-15-2011

#3

Re: Error CFB30 on km-3060mfp

It might just be that the panel is not at a compatible level of firmware to talk to the main firmware. Whenever a board is changed a firmware upgrade is necessary. =^..^=

If you’d like a serious answer to your request:

1) demonstrate that you’ve read the manual

2) demonstrate that you made some attempt to fix it.

3) if you’re going to ask about jams include the jam code.

4) if you’re going to ask about an error code include the error code.

5) You are the person onsite. Only you can make observations.

blackcat: Master Of The Obvious =^..^=

Tags for this Thread

Bookmarks

Bookmarks

Posting Permissions

- You may not post new threads

- You may not post replies

- You may not post attachments

- You may not edit your posts

- BB code is On

- Smilies are On

- [IMG] code is On

- [VIDEO] code is On

- HTML code is Off

Forum Rules

- Code: 0030

- Description: FAX control PWB system error

Processing with the fax software was disabled due to a hardware problem. - Causes: Defective FAX control PWB.

- Remedy: Replace the fax control PWB and check for correct operation.

- Code: 0070

- Description: FAX control PWB incompatible detection error

Abnormal detection of FAX control PWB incompatibility In the initial communication with the FAX control PWB, any normal communication command is not transmitted. - Causes: Defective FAX software.

Defective FAX control PWB. - Remedy: Defective FAX software. Install the fax software.

Defective FAX control PWB. Replace the fax control PWB and check for correct operation.

- Code: 0100

- Description: Backup memory device error

- Causes: Defective flash memory.

Defective main PWB. - Remedy: Defective flash memory. Replace the main PWB and check for correct operation.

Defective main PWB. Replace the main PWB and check for correct operation.

- Code: 0120

- Description: MAC address data error

For data in which the MAC address is invalid. - Causes: Defective flash memory.

Defective engine PWB. - Remedy: Defective flash memory. Replace the main PWB and check for correct operation.

Defective engine PWB. Replace the engine PWB and check for correct operation.

- Code: 0150

- Description: Backup memory read/write error (engine PWB)

No response is issued from the device in reading/writing for 5 ms or more and this problem is repeated 5 times successively. Mismatch of reading data from 2 locations occurs 8 times successively. Mismatch between writing data and reading data occurs 8 times successively. - Causes: Improper installation EEPROM.

Device damage of EEPROM. - Remedy: Improper installation EEPROM. Check the installation of the EEPROM and remedy if necessary.

Defective engine PWB. Replace the engine PWB and check for correct operation.

Device damage of EEPROM. Contact the Service Administrative Division.

- Code: 0160

- Description: Backup memory data error

(engine PWB) Reading data from EEPROM is abnormal. - Causes: Data damage of EEPROM.

- Remedy: Contact the Service Administrative Division.

- Code: 0170

- Description: Billing counting error

A checksum error is detected in the main and engine backup memories for the billing counters. - Causes: Data damage of EEPROM.

Defective PWB. - Remedy: Data damage of EEPROM. Contact the Service Administrative Division.

Defective PWB. Replace the main PWB or the engine PWB and check for correct operation.

- Code: 0180

- Description: Machine number mismatch

Machine number of main and engine does not match. - Causes: Data damage of EEPROM.

- Remedy: Data damage of EEPROM. Contact the Service Administrative Division.

- Code: 0620

- Description: FAX image DIMM error

DIMM is not installed correctly. DIMM cannot be accessed. - Causes: DIMM installed incorrectly.

Defective main PWB. - Remedy: DIMM installed incorrectly. Check if the DIMM is inserted into the socket on the main PWB correctly.

Defective main PWB. Replace the main PWB and check for correct operation.

- Code: 0630

- Description: DMA error

DMA transmission of image data does not complete within the specified period of time. - Causes: Poor contact in the connector terminals.

Defective main PWB. - Remedy: Poor contact in the connector terminals. Check the connection the signal cable for CIS and the main PWB, and the continuity across the connector terminals. Repair or replace if necessary.

Defective main PWB. Replace the main PWB and check for correct operation.

- Code: 0640

- Description: Hard disk error

The hard disk cannot be accessed. - Causes: Defective hard disk.

Defective main PWB. - Remedy: Defective hard disk. Replace the hard disk and check for correct operation.

Defective main PWB. Replace the main PWB and check for correct operation.

- Code: 0650

- Description: FAX image DIMM check error

Improper DIMM is installed. - Causes: DIMM installed incorrectly.

Defective main PWB. - Remedy: DIMM installed incorrectly. Check if the DIMM is inserted into the socket on the main PWB correctly.

Defective main PWB. Replace the main PWB and check for correct operation.

- Code: 0800

- Description: Image processing error

JAM010X is detected twice. - Causes: Defective main PWB.

- Remedy: Replace the main PWB and check for correct operation.

- Code: 0830

- Description: FAX control PWB flash program area checksum error

A checksum error occurred with the program of the FAX control PWB. - Causes: Defective FAX software.

Defective FAX control PWB. - Remedy: Defective FAX software. Install the fax software.

Defective FAX control PWB. Replace the fax control PWB and check for correct operation.

- Code: 0840

- Description: Faults of RTC

The time is judged to go back based on the comparison of the RTC time and the current time or five years or more have passed. - Causes: The battery is disconnected from the main PWB.

Defective main PWB. - Remedy: The battery is disconnected from the main PWB. Check visually and remedy if necessary

Defective main PWB. Replace the main PWB and check for correct operation.

- Code: 0870

- Description: FAX control PWB to main PWB high capacity data transfer error

High-capacity data transfer between the FAX control PWB and the main PWB of the machine was not normally performed even if the data transfer was retried the specified times. - Causes: Improper installation FAX control PWB.

Defective FAX control PWB or main PWB. - Remedy: Improper installation FAX control PWB. Reinstall the FAX control PWB.

Defective FAX control PWB or main PWB. Replace the FAX control PWB or main PWB and check for correct operation.

- Code: 0900

- Description: FAX software incompatible detection error

Incompatible FAX control PWB is installed. - Causes: Defective FAX software.

Defective FAX control PWB. - Remedy: Defective FAX software. Install the fax software.

Defective FAX control PWB. Replace the fax control PWB and check for correct operation.

- Code: 0920

- Description: Fax file system error

The backup data is not retained for file system abnormality of flash memory of the FAX control PWB. - Causes: Defective FAX control PWB.

- Remedy: Replace the fax control PWB and check for correct operation.

- Code: 0970

- Description: 12 V power down detect

Power is disconnected during sleeping. - Causes: Defective power source PWB.

- Remedy: Replace the power source PWB and check for correct operation.

- Code: 0980

- Description: 24 V power down detect

24V disconnection signal is detected for 1 s and 12V disconnection signal is not detected. - Causes: Defective power source PWB.

- Remedy: Replace the power source PWB and check for correct operation.

- Code: 1000

- Description: MP lift motor error

After the MP lift motor is driven, the ON status of MP lift sensors 1 and 2 cannot be detected for 1.5 s. - Causes: Defective MP plate elevation mechanism.

Defective connector cable or poor contact in the connector.

Defective drive transmission system of motor.

Defective MP lift motor.

Defective engine PWB. - Remedy: Defective MP plate elevation mechanism. Check to see if the MP plate can move smoothly and repair it if any problem is found.

Defective connector cable or poor contact in the connector. Reinsert the connector. Also check for continuity within the connector cable. If none, replace the cable. MP lift motor and relay PWB (YC3) Relay PWB (YC12) and feed PWB 1 (YC17) Feed PWB 1 (YC1) and engine PWB (YC6)

Defective drive transmission system of motor. Check if the gears rotate smoothly. If not, grease the bushes and gears. Check for broken gears and replace if any.

Defective MP lift motor. Replace the MP lift motor.

Defective engine PWB. Replace the engine PWB and check for correct operation.

- Code: 1010

- Description: Lift motor 1 error

After cassette 1 is inserted, lift sensor 1 does not turn on within 12 s. This error is detected 4 times successively. The lock signal of the motor is detected continuously for 1 s. - Causes: Defective bottom plate elevation mechanism in the cassette.

Defective connector cable or poor contact in the connector.

Defective drive transmission system of motor

Defective lift motor 1.

Defective engine PWB. - Remedy: Defective bottom plate elevation mechanism in the cassette. Check to see if the bottom plate can move smoothly and repair it if any problem is found.

Defective connector cable or poor contact in the connector. Reinsert the connector. Also check for continuity within the connector cable. If none, replace the cable. Lift motor 1 and feed PWB 2 (YC3) Feed PWB 2 (YC1) and engine PWB (YC4)

Defective drive transmission system of motor. Check if the gears rotate smoothly. If not, grease the bushes and gears. Check for broken gears and replace if any.

Defective lift motor 1. Replace the lift motor 1.

Defective engine PWB. Replace the engine PWB and check for correct operation.

- Code: 1020

- Description: Lift motor 2 error

After cassette 2 is inserted, lift sensor 2 does not turn on within 12 s. This error is detected 4 times successively. The lock signal of the motor is detected continuously for 1 s. - Causes: Defective bottom plate elevation mechanism in the cassette.

Defective connector cable or poor contact in the connector.

Defective drive transmission system of motor.

Defective lift motor 2.

Defective engine PWB. - Remedy: Defective bottom plate elevation mechanism in the cassette. Check to see if the bottom plate can move smoothly and repair it if any problem is found.

Defective connector cable or poor contact in the connector. Reinsert the connector. Also check for continuity within the connector cable. If none, replace the cable. Lift motor 2 and feed PWB 2 (YC3) Feed PWB 2 (YC1) and engine PWB (YC4)

Defective drive transmission system of motor. Check if the gears rotate smoothly. If not, grease the bushes and gears. Check for broken gears and replace if any.

Defective lift motor 2. Replace the lift motor 2.

Defective engine PWB. Replace the engine PWB and check for correct operation.

- Code: 1030

- Description: PF lift motor 1 error (paper feeder)

After cassette 3 is inserted, PF lift sensor 1 does not turn on within 12 s. This error is detected 5 times successively. During driving the motor, the lift overcurrent protective monitor signal is detected for 1 s or more 5 times successively. However, the first 1 s after motor is turned on is excluded from detection. - Causes: Defective bottom plate elevation mechanism in the cassette.

Defective connector cable or poor contact in the connector.

Defective drive transmission system of motor.

Defective PF lift motor 1.

Defective PF main PWB. - Remedy: Defective bottom plate elevation mechanism in the cassette. Check to see if the bottom plate can move smoothly and repair it if any problem is found.

Defective connector cable or poor contact in the connector. Reinsert the connector. Also check for continuity within the connector cable. If none, replace the cable. PF lift motor 1 and PF main PWB (YC7)

Defective drive transmission system of motor. Check if the gears rotate smoothly. If not, grease the bushes and gears. Check for broken gears and replace if any.

Defective PF lift motor 1. Replace the PF lift motor 1.

Defective PF main PWB. Replace the PF main PWB (Refer to the service manual for the paper feeder).

- Code: 1040

- Description: PF lift motor 2 error (paper feeder)

After cassette 4 is inserted, PF lift sensor 2 does not turn on within 12 s. This error is detected 5 times successively. During driving the motor, the lift overcurrent protective monitor signal is detected for 1 s or more 5 times successively. However, the first 1 s after motor is turned on is excluded from detection. - Causes: Defective bottom plate elevation mechanism in the cassette.

Defective connector cable or poor contact in the connector.

Defective drive transmission system of motor.

Defective PF lift motor 2.

Defective PF main PWB. - Remedy: Defective bottom plate elevation mechanism in the cassette. Check to see if the bottom plate can move smoothly and repair it if any problem is found.

Defective connector cable or poor contact in the connector. Reinsert the connector. Also check for continuity within the connector cable. If none, replace the cable. PF lift motor 2 and PF main PWB (YC7)

Defective drive transmission system of motor. Check if the gears rotate smoothly. If not, grease the bushes and gears. Check for broken gears and replace if any.

Defective PF lift motor 2. Replace the PF lift motor 2.

Defective PF main PWB. Replace the PF main PWB (Refer to the service manual for the paper feeder).

- Code: 1050

- Description: SM lift motor error (side multi tray)

After cassette 5 is inserted, SM lift sensor does not turn on within 12 s. This error is detected 5 times successively. During driving the motor, the lift overcurrent protective monitor signal is detected for 1 s or more 5 times successively. However, the first 1 s after motor is turned on is excluded from detection. - Causes: Defective bottom plate elevation mechanism in the cassette.

Defective connector cable or poor contact in the connector.

Defective drive transmission system of motor.

Defective SM lift motor.

Defective SM main PWB. - Remedy: Defective bottom plate elevation mechanism in the cassette. Check to see if the bottom plate can move smoothly and repair it if any problem is found.

Defective connector cable or poor contact in the connector. Reinsert the connector. Also check for continuity within the connector cable. If none, replace the cable. SM lift motor and SM main PWB (YC5)

Defective drive transmission system of motor. Check if the gears rotate smoothly. If not, grease the bushes and gears. Check for broken gears and replace if any.

Defective SM lift motor. Replace the SM lift motor.

Defective SM main PWB. Replace the SM main PWB (Refer to the service manual for the paper feeder).

- Code: 1060

- Description: PF lift motor 1 error (side paper feeder)

After cassette 6 is inserted, PF lift sensor 1 does not turn on within 12 s. This error is detected 5 times successively. During driving the motor, the lift overcurrent protective monitor signal is detected for 1 s or more 5 times successively. However, the first 1 s after motor is turned on is excluded from detection. - Causes: Defective bottom plate elevation mechanism in the cassette.

Defective connector cable or poor contact in the connector.

Defective drive transmission system of motor.

Defective PF lift motor 1.

Defective PF main PWB. - Remedy: Defective bottom plate elevation mechanism in the cassette. Check to see if the bottom plate can move smoothly and repair it if any problem is found.

Defective connector cable or poor contact in the connector. Reinsert the connector. Also check for continuity within the connector cable. If none, replace the cable. PF lift motor 1 and PF main PWB (YC7)

Defective drive transmission system of motor. Check if the gears rotate smoothly. If not, grease the bushes and gears. Check for broken gears and replace if any.

Defective PF lift motor 1. Replace the PF lift motor 1.

Defective PF main PWB. Replace the PF main PWB (Refer to the service manual for the paper feeder).

- Code: 1070

- Description: PF lift motor 2 error (side paper feeder)

After cassette 7 is inserted, PF lift sensor 2 does not turn on within 12 s. This error is detected 5 times successively. During driving the motor, the lift overcurrent protective monitor signal is detected for 1 s or more 5 times successively. However, the first 1 s after motor is turned on is excluded from detection. - Causes: Defective bottom plate elevation mechanism in the cassette.

Defective connector cable or poor contact in the connector.

Defective drive transmission system of motor.

Defective PF lift motor 2.

Defective PF main PWB. - Remedy: Defective bottom plate elevation mechanism in the cassette. Check to see if the bottom plate can move smoothly and repair it if any problem is found.

Defective connector cable or poor contact in the connector. Reinsert the connector. Also check for continuity within the connector cable. If none, replace the cable. PF lift motor 2 and PF main PWB (YC7)

Defective drive transmission system of motor. Check if the gears rotate smoothly. If not, grease the bushes and gears. Check for broken gears and replace if any.

Defective PF lift motor 2. Replace the PF lift motor 2.

Defective PF main PWB. Replace the PF main PWB (Refer to the service manual for the paper feeder).

- Code: 1100

- Description: PF lift motor 1 error (large capacity feeder)

After cassette 3 is inserted, PF lift sensor 1 does not turn on within 12 s. This error is detected 2 times successively. During driving the motor, the lift overcurrent protective monitor signal is detected for 500 ms or more 2 times successively. However, the first 1 s after PF lift motor 1 is turned on is excluded from detection. - Causes: Defective connector cable or poor contact in the connector.

Defective drive transmission system of motor.

Defective PF lift motor 1.

Defective PF main PWB. - Remedy: Defective connector cable or poor contact in the connector. Reinsert the connector. Also check for continuity within the connector cable. If none, replace the cable. PF lift motor 1 and PF main PWB (YC7)

Defective drive transmission system of motor. Check if the gears rotate smoothly. If not, grease the bushes and gears. Check for broken gears and replace if any.

Defective PF lift motor 1. Replace the PF lift motor 1.

Defective PF main PWB. Replace the PF main PWB (Refer to the service manual for the paper feeder).

- Code: 1110

- Description: PF lift motor 2 error (large capacity feeder)

After cassette 4 is inserted, PF lift sensor 2 does not turn on within 12 s. This error is detected 2 times successively. During driving the motor, the lift overcurrent protective monitor signal is detected for 500 ms or more 2 times successively. However, the first 1 s after PF lift motor 2 is turned on is excluded from detection. - Causes: Defective connector cable or poor contact in the connector.

Defective drive transmission system of motor.

Defective PF lift motor 2.

Defective PF main PWB. - Remedy: Defective connector cable or poor contact in the connector. Reinsert the connector. Also check for continuity within the connector cable. If none, replace the cable. PF lift motor 2 and PF main PWB (YC7)

Defective drive transmission system of motor. Check if the gears rotate smoothly. If not, grease the bushes and gears. Check for broken gears and replace if any.

Defective PF lift motor 2. Replace the PF lift motor 2.

Defective PF main PWB. Replace the PF main PWB (Refer to the service manual for the paper feeder).

- Code: 1140

- Description: SD lift motor error (side deck)

After cassette 5 is inserted, SD lift sensor does not turn on within 30 s. The lock signal of the motor is detected continuously for 200 ms. - Causes: Defective connector cable or poor contact in the connector.

Defective drive transmission system of motor.

Defective SD lift motor.

Defective SD main PWB. - Remedy: Defective connector cable or poor contact in the connector. Reinsert the connector. Also check for continuity within the connector cable. If none, replace the cable. SD lift motor and SD main PWB (YC8)

Defective drive transmission system of motor. Check if the gears rotate smoothly. If not, grease the bushes and gears. Check for broken gears and replace if any.

Defective SD lift motor. Replace the SD lift motor.

Defective SD main PWB. Replace the SD main PWB (Refer to the service manual for the paper feeder).

- Code: 1250

- Description: SM multi feed sensor communication error (side multi tray)

A communication error is detected 3 times in succession. - Causes: Improper installation side multi tray.

Defective connector cable or poor contact in the connector.

Defective engine PWB.

Defective SM main PWB. - Remedy: Improper installation side multi tray. Follow installation instruction carefully again.

Defective connector cable or poor contact in the connector. Reinsert the connector. Also check for continuity within the connector cable. If none, replace the cable. SM main PWB (YC1) and engine PWB (YC19)

Defective engine PWB. Replace the engine PWB and check for correct operation.

Defective SM main PWB. Replace the SM main PWB (Refer to the service manual for the paper feeder).

- Code: 1350

- Description: SM multi feed sensor error (side multi tray)

The SM multi feed sensor has signaled the presence of paper for 10 ms continuously. - Causes: Defective connector cable or poor contact in the connector.

Defective SM multi feed sensor.

Defective SM main PWB. - Remedy: Defective connector cable or poor contact in the connector. Reinsert the connector. Also check for continuity within the connector cable. If none, replace the cable. SM multi feed sensor and SM main PWB (YC11)

Defective SM multi feed sensor. Replace the SM multi feed sensor.

Defective SM main PWB. Replace the SM main PWB (Refer to the service manual for the paper feeder).

- Code: 1450

- Description: SM multi feed sensor backup error (side multi tray)

When writing the data, read and write data does not match 3 times in succession. - Causes: Defective connector cable or poor contact in the connector.

Defective SM multi feed sensor.

Defective SM main PWB. - Remedy: Defective connector cable or poor contact in the connector. Reinsert the connector. Also check for continuity within the connector cable. If none, replace the cable. SM multi feed sensor and SM main PWB (YC11)

Defective SM multi feed sensor. Replace the SM multi feed sensor.

Defective SM main PWB. Replace the SM main PWB (Refer to the service manual for the paper feeder).

- Code: 1710

- Description: Side multi tray incompatible detection error

The side multi tray has been installed with a device to which it is incompatible. - Causes: The side multi tray is installed with a device to which it is incompatible.

- Remedy: The side multi tray must be installed with the devices to which it is compatible.

- Code: 1720

- Description: Paper feeder incompatible detection error

The paper feeder has been installed with a device to which it is incompatible. - Causes: The paper feeder is installed with a device to which it is incompatible.

- Remedy: The paper feeder must be installed with the devices to which it is compatible.

- Code: 1800

- Description: Paper feeder communication error

A communication error from paper feeder is detected 10 times in succession. - Causes: Improper installation paper feeder.

Defective connector cable or poor contact in the connector.

Defective engine PWB.

Defective PF main PWB. - Remedy: Improper installation paper feeder. Follow installation instruction carefully again.

Defective connector cable or poor contact in the connector. Reinsert the connector. Also check for continuity within the connector cable. If none, replace the cable. PF main PWB (YC13) and engine PWB (YC19)

Defective engine PWB. Replace the engine PWB and check for correct operation.

Defective PF main PWB. Replace the PF main PWB (Refer to the service manual for the paper feeder).

- Code: 1810

- Description: Side multi tray communication error

A communication error from paper feeder is detected 10 times in succession. - Causes: Improper installation side multi tray.

Defective connector cable or poor contact in the connector.

Defective engine PWB.

Defective SM main PWB. - Remedy: Improper installation side multi tray. Follow installation instruction carefully again.

Defective connector cable or poor contact in the connector. Reinsert the connector. Also check for continuity within the connector cable. If none, replace the cable. SM main PWB (YC1) and engine PWB (YC19)

Defective engine PWB. Replace the engine PWB and check for correct operation.

Defective SM main PWB. Replace the SM main PWB (Refer to the service manual for the paper feeder).

- Code: 1820

- Description: Side paper feeder communication error

A communication error from paper feeder is detected 10 times in succession. - Causes: Improper installation side paper feeder.

Defective connector cable or poor contact in the connector.

Defective engine PWB.

Defective SM main PWB.

Defective PF main PWB. - Remedy: Improper installation side paper feeder. Follow installation instruction carefully again.

Defective connector cable or poor contact in the connector. Reinsert the connector. Also check for continuity within the connector cable. If none, replace the cable. PF main PWB (YC13) and SM main PWB (YC4) SM main PWB (YC1) and engine PWB (YC19)

Defective engine PWB. Replace the engine PWB and check for correct operation.

Defective SM main PWB. Replace the SM main PWB (Refer to the service manual for the paper feeder).

Defective PF main PWB. Replace the PF main PWB (Refer to the service manual for the paper feeder).

- Code: 1900

- Description: Paper feeder EEPROM error

When writing the data, read and write data does not match 3 times in succession. - Causes: Defective PF main PWB.

Device damage of EEPROM. - Remedy: Defective PF main PWB. Replace the PF main PWB (Refer to the service manual for the paper feeder).

Device damage of EEPROM. Contact the Service Administrative Division.

- Code: 1910

- Description: Side multi tray EEPROM error

When writing the data, read and write data does not match 3 times in succession. - Causes: Defective SM main PWB.

Device damage of EEPROM. - Remedy: Defective SM main PWB. Replace the SM main PWB (Refer to the service manual for the paper feeder).

Device damage of EEPROM. Contact the Service Administrative Division.

- Code: 1920

- Description: Side paper feeder EEPROM error

When writing the data, read and write data does not match 3 times in succession. - Causes: Defective PF main PWB.

Device damage of EEPROM. - Remedy: Defective PF main PWB. Replace the PF main PWB (Refer to the service manual for the paper feeder).

Device damage of EEPROM. Contact the Service Administrative Division.

- Code: 1950

- Description: Transfer belt unit EEPROM error

No response is issued from the device in reading/writing for 5 ms or more and this problem is repeated 5 times successively. Mismatch of reading data from 2 locations occurs 8 times successively. Mismatch between writing data and reading data occurs 8 times successively. - Causes: Defective connector cable or poor contact in the connector.

Defective transfer belt unit. - Remedy: Defective connector cable or poor contact in the connector. Reinsert the connector. Also check for continuity within the connector cable. If none, replace the cable. Transfer belt unit and engine PWB (YC3)

Defective transfer belt unit. Replace the transfer belt unit and check for correct operation.

- Code: 2101

- Description: Developer motor K error

After developer motor K is driven, the ready signal does not turn to L within 5 s. After developer motor K is stabilized, the ready signal is at the H level for 5 s continuously. - Causes: Defective connector cable or poor contact in the connector.

Defective drive transmission system of motor.

Defective developer motor K.

Defective engine PWB. - Remedy: Defective connector cable or poor contact in the connector. Reinsert the connector. Also check for continuity within the connector cable. If none, replace the cable. Developer motor K and motor control PWB (YC7) Motor control PWB (YC3) and engine PWB (YC9)

Defective drive transmission system of motor. Check if the gears rotate smoothly. If not, grease the bushes and gears. Check for broken gears and replace if any.

Defective developer motor K. Replace the developer motor K.

Defective engine PWB. Replace the engine PWB and check for correct operation.

- Code: 2102

- Description: Developer motor MCY error

After developer motor MCY is driven, the ready signal does not turn to L within 5 s. After developer motor MCY is stabilized, the ready signal is at the H level for 5 s continuously. - Causes: Defective connector cable or poor contact in the connector.

Defective drive transmission system of motor.

Defective developer motor MCY.

Defective engine PWB. - Remedy: Defective connector cable or poor contact in the connector. Reinsert the connector. Also check for continuity within the connector cable. If none, replace the cable. Developer motor MCY and motor control PWB (YC7) Motor control PWB (YC3) and engine PWB (YC9)

Defective drive transmission system of motor. Check if the gears rotate smoothly. If not, grease the bushes and gears. Check for broken gears and replace if any.

Defective developer motor MCY. Replace the developer motor MCY.

Defective engine PWB. Replace the engine PWB and check for correct operation.

- Code: 2201

- Description: Drum motor K steady-state error

After drum motor K is stabilized, the ready signal is at the H level for 5 s continuously. - Causes: Defective connector cable or poor contact in the connector.

Defective drive transmission system of motor.

Defective drum motor K.

Defective engine PWB. - Remedy: Defective connector cable or poor contact in the connector. Reinsert the connector. Also check for continuity within the connector cable. If none, replace the cable. Drum motor K and motor control PWB (YC5) Motor control PWB (YC3) and engine PWB (YC9)

Defective drive transmission system of motor. Check if the gears rotate smoothly. If not, grease the bushes and gears. Check for broken gears and replace if any.

Defective drum motor K. Replace the drum motor K.

Defective engine PWB. Replace the engine PWB and check for correct operation.

- Code: 2202

- Description: Drum motor C steady-state error [45 ppm/55 ppm model]

After drum motor C is stabilized, the ready signal is at the H level for 5 s continuously. - Causes: Defective connector cable or poor contact in the connector.

Defective drive transmission system of motor.

Defective drum motor C.

Defective engine PWB. - Remedy: Defective connector cable or poor contact in the connector. Reinsert the connector. Also check for continuity within the connector cable. If none, replace the cable. Drum motor C and motor control PWB (YC4) Motor control PWB (YC3) and engine PWB (YC9)

Defective drive transmission system of motor. Check if the gears rotate smoothly. If not, grease the bushes and gears. Check for broken gears and replace if any.

Defective drum motor C. Replace the drum motor C.

Defective engine PWB. Replace the engine PWB and check for correct operation.

- Code: 2202

- Description: Drum motor MCY steady-state error [30 ppm/35 ppm model]

After drum motor MCY is stabilized, the ready signal is at the H level for 5 s continuously. - Causes: Defective connector cable or poor contact in the connector.

Defective drive transmission system of motor.

Defective drum motor MCY.

Defective engine PWB. - Remedy: Defective connector cable or poor contact in the connector. Reinsert the connector. Also check for continuity within the connector cable. If none, replace the cable. Drum motor MCY and motor control PWB (YC5) Motor control PWB (YC3) and engine PWB (YC9)

Defective drive transmission system of motor. Check if the gears rotate smoothly. If not, grease the bushes and gears. Check for broken gears and replace if any.

Defective drum motor MCY. Replace the drum motor MCY.

Defective engine PWB. Replace the engine PWB and check for correct operation.

- Code: 2203

- Description: Drum motor M steady-state error

After drum motor M is stabilized, the ready signal is at the H level for 5 s continuously. - Causes: Defective connector cable or poor contact in the connector.

Defective drive transmission system of motor.

Defective drum motor M.

Defective engine PWB. - Remedy: Defective connector cable or poor contact in the connector. Reinsert the connector. Also check for continuity within the connector cable. If none, replace the cable. Drum motor M and motor control PWB (YC5) Motor control PWB (YC3) and engine PWB (YC9)

Defective drive transmission system of motor. Check if the gears rotate smoothly. If not, grease the bushes and gears. Check for broken gears and replace if any.

Defective drum motor M. Replace the drum motor M.

Defective engine PWB. Replace the engine PWB and check for correct operation.

- Code: 2204

- Description: Drum motor Y steady-state error

After drum motor Y is stabilized, the ready signal is at the H level for 5 s continuously. - Causes: Defective connector cable or poor contact in the connector.

Defective drive transmission system of motor.

Defective drum motor Y.

Defective engine PWB. - Remedy: Defective connector cable or poor contact in the connector. Reinsert the connector. Also check for continuity within the connector cable. If none, replace the cable. Drum motor Y and motor control PWB (YC4) Motor control PWB (YC3) and engine PWB (YC9)

Defective drive transmission system of motor. Check if the gears rotate smoothly. If not, grease the bushes and gears. Check for broken gears and replace if any.

Defective drum motor Y. Replace the drum motor Y.

Defective engine PWB. Replace the engine PWB and check for correct operation.

- Code: 2211

- Description: Drum motor K startup error

Drum motor K is not stabilized within 5 s since the motor is activated. - Causes: Defective connector cable or poor contact in the connector.

Defective drive transmission system of motor.

Defective drum motor K.

Defective engine PWB. - Remedy: Defective connector cable or poor contact in the connector. Reinsert the connector. Also check for continuity within the connector cable. If none, replace the cable. Drum motor K and motor control PWB (YC5) Motor control PWB (YC3) and engine PWB (YC9)

Defective drive transmission system of motor. Check if the gears rotate smoothly. If not, grease the bushes and gears. Check for broken gears and replace if any.

Defective drum motor K. Replace the drum motor K.

Defective engine PWB. Replace the engine PWB and check for correct operation.

- Code: 2212

- Description: Drum motor C startup error

Drum motor C is not stabilized within 5 s since the motor is activated. - Causes: Defective connector cable or poor contact in the connector.

Defective drive transmission system of motor.

Defective drum motor C.

Defective engine PWB. - Remedy: Defective connector cable or poor contact in the connector. Reinsert the connector. Also check for continuity within the connector cable. If none, replace the cable. Drum motor C and motor control PWB (YC4) Motor control PWB (YC3) and engine PWB (YC9)

Defective drive transmission system of motor. Check if the gears rotate smoothly. If not, grease the bushes and gears. Check for broken gears and replace if any.

Defective drum motor C. Replace the drum motor C.

Defective engine PWB. Replace the engine PWB and check for correct operation.

- Code: 2213

- Description: Drum motor M startup error

Drum motor M is not stabilized within 5 s since the motor is activated. - Causes: Defective connector cable or poor contact in the connector.

Defective drive transmission system of motor.

Defective drum motor M.

Defective engine PWB. - Remedy: Defective connector cable or poor contact in the connector. Reinsert the connector. Also check for continuity within the connector cable. If none, replace the cable. Drum motor M and motor control PWB (YC5) Motor control PWB (YC3) and engine PWB (YC9)

Defective drive transmission system of motor. Check if the gears rotate smoothly. If not, grease the bushes and gears. Check for broken gears and replace if any.

Defective drum motor M. Replace the drum motor M.

Defective engine PWB. Replace the engine PWB and check for correct operation.

- Code: 2214

- Description: Drum motor Y startup error

Drum motor Y is not stabilized within 5 s since the motor is activated. - Causes: Defective connector cable or poor contact in the connector.

Defective drive transmission system of motor.

Defective drum motor Y.

Defective engine PWB. - Remedy: Defective connector cable or poor contact in the connector. Reinsert the connector. Also check for continuity within the connector cable. If none, replace the cable. Drum motor Y and motor control PWB (YC4) Motor control PWB (YC3) and engine PWB (YC9)

Defective drive transmission system of motor. Check if the gears rotate smoothly. If not, grease the bushes and gears. Check for broken gears and replace if any.

Defective drum motor Y. Replace the drum motor Y.

Defective engine PWB. Replace the engine PWB and check for correct operation.

- Code: 2300

- Description: Fuser motor error

After fuser motor is driven, the ready signal does not turn to L within 2 s. After fuser motor is stabilized, the ready signal is at the H level for 1 s continuously. - Causes: Defective connector cable or poor contact in the connector.

Defective drive transmission system of motor.

Defective fuser motor.

Defective engine PWB. - Remedy: Defective connector cable or poor contact in the connector. Reinsert the connector. Also check for continuity within the connector cable. If none, replace the cable. Fuser motor and feed PWB 1 (YC18) Feed PWB 1 (YC1) and engine PWB (YC6)

Defective drive transmission system of motor. Check if the gears rotate smoothly. If not, grease the bushes and gears. Check for broken gears and replace if any.

Defective fuser motor. Replace the fuser motor.

Defective engine PWB. Replace the engine PWB and check for correct operation.

- Code: 2550

- Description: Paper feed motor error

After paper feed motor is driven, the ready signal does not turn to L within 2 s. After paper feed motor is stabilized, the ready signal is at the H level for 1 s continuously. - Causes: Defective connector cable or poor contact in the connector.

Defective drive transmission system of motor.

Defective paper feed motor.

Defective engine PWB. - Remedy: Defective connector cable or poor contact in the connector. Reinsert the connector. Also check for continuity within the connector cable. If none, replace the cable. Paper feed motor and feed PWB 2 (YC2) Feed PWB 2 (YC1) and engine PWB (YC4)

Defective drive transmission system of motor. Check if the gears rotate smoothly. If not, grease the bushes and gears. Check for broken gears and replace if any.

Defective paper feed motor. Replace the paper feed motor.

Defective engine PWB. Replace the engine PWB and check for correct operation.

- Code: 2600

- Description: PF paper feed motor error (large capacity feeder)

After PF paper feed motor is driven, the ready signal does not turn to L within 2 s. - Causes: Defective connector cable or poor contact in the connector.

Defective drive transmission system of motor.

Defective PF paper feed motor

Defective PF main PWB. - Remedy: Defective connector cable or poor contact in the connector. Reinsert the connector. Also check for continuity within the connector cable. If none, replace the cable. PF paper feed motor and PF main PWB (YC16)

Defective drive transmission system of motor. Check if the gears rotate smoothly. If not, grease the bushes and gears. Check for broken gears and replace if any.

Defective PF paper feed motor. Replace the PF paper feed motor.

Defective PF main PWB. Replace the PF main PWB (Refer to the service manual for the paper feeder)

- Code: 2610

- Description: PF paper feed motor error (paper feeder)

After PF paper feed motor is driven, the ready signal does not turn to L within 2 s. - Causes: Defective connector cable or poor contact in the connector.

Defective drive transmission system of motor.

Defective PF paper feed motor

Defective PF main PWB. - Remedy: Defective connector cable or poor contact in the connector. Reinsert the connector. Also check for continuity within the connector cable. If none, replace the cable. PF paper feed motor and PF main PWB (YC16)

Defective drive transmission system of motor. Check if the gears rotate smoothly. If not, grease the bushes and gears. Check for broken gears and replace if any.

Defective PF paper feed motor. Replace the PF paper feed motor.

Defective PF main PWB. Replace the PF main PWB (Refer to the service manual for the paper feeder).

- Code: 2640

- Description: SD paper feed motor error (side deck)

After SD paper feed motor is driven, the ready signal does not turn to L within 2 s. - Causes: Defective connector cable or poor contact in the connector.

Defective drive transmission system of motor.

Defective SD paper feed motor

Defective SD main PWB. - Remedy: Defective connector cable or poor contact in the connector. Reinsert the connector. Also check for continuity within the connector cable. If none, replace the cable. SD paper feed motor and SD main PWB (YC16)

Defective drive transmission system of motor. Check if the gears rotate smoothly. If not, grease the bushes and gears. Check for broken gears and replace if any.

Defective SD paper feed motor. Replace the SD paper feed motor.

Defective SD main PWB. Replace the SD main PWB (Refer to the service manual for the paper feeder).

- Code: 2650

- Description: SM paper feed motor error (side multi tray)

After SM paper feed motor is driven, the ready signal does not turn to L within 2 s. - Causes: Defective connector cable or poor contact in the connector.

Defective drive transmission system of motor.

Defective SM paper feed motor.

Defective SM main PWB. - Remedy: Defective connector cable or poor contact in the connector. Reinsert the connector. Also check for continuity within the connector cable. If none, replace the cable. SM paper feed motor and SM main PWB (YC5)

Defective drive transmission system of motor. Check if the gears rotate smoothly. If not, grease the bushes and gears. Check for broken gears and replace if any.

Defective SM paper feed motor. Replace the SM paper feed motor.

Defective SM main PWB. Replace the SM main PWB (Refer to the service manual for the paper feeder).

- Code: 2660

- Description: PF paper feed motor error (side large capacity feeder)

After PF paper feed motor is driven, the ready signal does not turn to L within 2 s. - Causes: Defective connector cable or poor contact in the connector.

Defective drive transmission system of motor.

Defective PF paper feed motor.

Defective PF main PWB. - Remedy: Defective connector cable or poor contact in the connector. Reinsert the connector. Also check for continuity within the connector cable. If none, replace the cable. PF paper feed motor and PF main PWB (YC16)

Defective drive transmission system of motor. Check if the gears rotate smoothly. If not, grease the bushes and gears. Check for broken gears and replace if any.

Defective PF paper feed motor. Replace the PF paper feed motor.

Defective PF main PWB. Replace the PF main PWB (Refer to the service manual for the paper feeder).

- Code: 2670

- Description: PF paper feed motor error (side paper feeder)

After PF paper feed motor is driven, the ready signal does not turn to L within 2 s. - Causes: Defective connector cable or poor contact in the connector.

Defective drive transmission system of motor.

Defective PF paper feed motor.

Defective PF main PWB. - Remedy: Defective connector cable or poor contact in the connector. Reinsert the connector. Also check for continuity within the connector cable. If none, replace the cable. PF paper feed motor and PF main PWB (YC16)

Defective drive transmission system of motor. Check if the gears rotate smoothly. If not, grease the bushes and gears. Check for broken gears and replace if any.

Defective PF paper feed motor. Replace the PF paper feed motor.

Defective PF main PWB. Replace the PF main PWB (Refer to the service manual for the paper feeder).

- Code: 2700

- Description: Color release motor error

When the color release motor is driven, the color release sensor does not turn on/off for 1 s. - Causes: Defective connector cable or poor contact in the connector.

Defective drive transmission system of motor.

Defective color release motor.

Defective engine PWB. - Remedy: Defective connector cable or poor contact in the connector. Reinsert the connector. Also check for continuity within the connector cable. If none, replace the cable. Color release motor and engine PWB (YC3)

Defective drive transmission system of motor. Check if the gears rotate smoothly. If not, grease the bushes and gears. Check for broken gears and replace if any.

Defective color release motor. Replace the color release motor.

Defective engine PWB. Replace the engine PWB and check for correct operation.

- Code: 2730

- Description: Transfer release motor error

When the transfer release motor is driven, the transfer release sensor does not turn on/off for 1 s. - Causes: Defective connector cable or poor contact in the connector.

Defective drive transmission system of motor.

Defective transfer release motor.

Defective engine PWB. - Remedy: Defective connector cable or poor contact in the connector. Reinsert the connector. Also check for continuity within the connector cable. If none, replace the cable. Transfer release motor and relay PWB (YC14) Relay PWB (YC14) and feed PWB 1 (YC14) Feed PWB 1 (YC1) and engine PWB (YC6)

Defective drive transmission system of motor. Check if the gears rotate smoothly. If not, grease the bushes and gears. Check for broken gears and replace if any.

Defective transfer release motor. Replace the transfer release motor.

Defective engine PWB. Replace the engine PWB and check for correct operation.

- Code: 2760

- Description: Transfer motor startup error

Transfer motor is not stabilized within 5 s since the motor is activated. - Causes: Defective connector cable or poor contact in the connector.

Defective drive transmission system of motor

Defective transfer motor.

Defective engine PWB. - Remedy: Defective connector cable or poor contact in the connector. Reinsert the connector. Also check for continuity within the connector cable. If none, replace the cable. Transfer motor and feed PWB 1 (YC13) Feed PWB 1 (YC2) and engine PWB (YC5)

Defective drive transmission system of motor. Check if the gears rotate smoothly. If not, grease the bushes and gears. Check for broken gears and replace if any.

Defective transfer motor. Replace the transfer motor.

Defective engine PWB. Replace the engine PWB and check for correct operation.

- Code: 2770

- Description: Transfer skew error

An abnormal value is detected to transfer skew sensor. - Causes: Defective connector cable or poor contact in the connector.

Defective transfer skew sensor.

Defective engine PWB. - Remedy: Defective connector cable or poor contact in the connector. Reinsert the connector. Also check for continuity within the connector cable. If none, replace the cable. Transfer belt unit and engine PWB (YC3)

Defective transfer skew sensor. Replace the transfer skew sensor.

Defective engine PWB. Replace the engine PWB and check for correct operation.

- Code: 2780

- Description: Transfer skew sensor error

An abnormal value is detected to transfer skew sensor. - Causes: Defective connector cable or poor contact in the connector.

Defective transfer skew sensor.

Defective engine PWB. - Remedy: Defective connector cable or poor contact in the connector. Reinsert the connector. Also check for continuity within the connector cable. If none, replace the cable. Transfer belt unit and engine PWB (YC3)

Defective transfer skew sensor. Replace the transfer skew sensor.

Defective engine PWB. Replace the engine PWB and check for correct operation.

- Code: 2790

- Description: Transfer skew motor error

When the transfer skew motor is driven, timeouts were detected twice in a row. - Causes: Defective connector cable or poor contact in the connector.

Defective drive transmission system of motor.

Defective transfer skew motor.

Defective engine PWB. - Remedy: Defective connector cable or poor contact in the connector. Reinsert the connector. Also check for continuity within the connector cable. If none, replace the cable. Transfer skew motor and engine PWB (YC3)

Defective drive transmission system of motor. Check if the gears rotate smoothly. If not, grease the bushes and gears. Check for broken gears and replace if any.

Defective transfer skew motor. Replace the transfer skew motor.

Defective engine PWB. Replace the engine PWB and check for correct operation.

- Code: 2820

- Description: Transfer motor steady-state error

After transfer motor is stabilized, the ready signal is at the H level for 5 s continuously. - Causes: Defective connector cable or poor contact in the connector.

Defective drive transmission system of motor.

Defective transfer motor.

Defective engine PWB. - Remedy: Defective connector cable or poor contact in the connector. Reinsert the connector. Also check for continuity within the connector cable. If none, replace the cable. Transfer motor and feed PWB 1 (YC13) Feed PWB 1 (YC2) and engine PWB (YC5)

Defective drive transmission system of motor. Check if the gears rotate smoothly. If not, grease the bushes and gears. Check for broken gears and replace if any.

Defective transfer motor. Replace the transfer motor.

Defective engine PWB. Replace the engine PWB and check for correct operation.

- Code: 2840

- Description: Transfer cleaning motor error

After transfer cleaning motor is driven, the ready signal does not turn to L within 2 s.

After transfer cleaning motor is stabilized, the ready signal is at the H level for 1 s continuously. - Causes: Defective connector cable or poor contact in the connector.

Defective drive transmission system of motor.

Defective transfer cleaning motor.

Defective engine PWB. - Remedy: Defective connector cable or poor contact in the connector. Reinsert the connector. Also check for continuity within the connector cable. If none, replace the cable. Transfer cleaning motor and engine PWB (YC3)

Defective drive transmission system of motor. Check if the gears rotate smoothly. If not, grease the bushes and gears. Check for broken gears and replace if any.

Defective transfer cleaning motor. Replace the transfer cleaning motor.

Defective engine PWB. Replace the engine PWB and check for correct operation.

- Code: 2850

- Description: Transfer belt sensor error

The signal is not received for 100 ms in succession. - Causes: Defective connector cable or poor contact in the connector

Defective transfer belt sensor.

Defective engine PWB. - Remedy: Defective connector cable or poor contact in the connector. Reinsert the connector. Also check for continuity within the connector cable. If none, replace the cable. Transfer belt sensor and engine PWB (YC3)

Defective transfer belt sensor. Replace the transfer belt sensor.

Defective engine PWB. Replace the engine PWB and check for correct operation.

- Code: 2860

- Description: Transfer belt sensor error

The signal is not received for 100 ms in succession. - Causes: Defective connector cable or poor contact in the connector.

Defective transfer belt sensor.

Defective engine PWB. - Remedy: Defective connector cable or poor contact in the connector. Reinsert the connector. Also check for continuity within the connector cable. If none, replace the cable. Transfer belt sensor and engine PWB (YC3)

Defective transfer belt sensor. Replace the transfer belt sensor.

Defective engine PWB. Replace the engine PWB and check for correct operation.

- Code: 2950

- Description: Motor control PWB communication error

A communication error from the motor control PWB is detected 10 times in succession. - Causes: Defective connector cable or poor contact in the connector.

Defective motor control PWB.

Defective engine PWB. - Remedy: Defective connector cable or poor contact in the connector. Reinsert the connector. Also check for continuity within the connector cable. If none, replace the cable. Motor control PWB (YC3) and engine PWB (YC9)

Defective motor control PWB. Replace the motor control PWB and check for correct operation.

Defective engine PWB. Replace the engine PWB and check for correct operation.

- Code: 3100

- Description: Scanner carriage error

The home position is not correct when the power is turned on or at the start of copying using the table. - Causes: Defective connector cable or poor contact in the connector.

Defective home position sensor.

Defective scanner motor.

Defective ISC PWB.

Defective main PWB. - Remedy: Defective connector cable or poor contact in the connector. Reinsert the connector. Also check for continuity within the connector cable. If none, replace the cable. Home position sensor and ISC PWB (YC8) Scanner motor and ISC PWB (YC5) ISC PWB (YC3) and main PWB (YC11)

Defective home position sensor. Replace the home position sensor.

Defective scanner motor. Replace the scanner motor.

Defective ISC PWB. Replace the ISC PWB and check for correct operation.

Defective main PWB. Replace the main PWB and check for correct operation.

- Code: 3200

- Description: Exposure lamp error

When input value at the time of LED lamp PWB illumination does not exceed the threshold value between 5 s. - Causes: Defective connector cable or poor contact in the connector.

Defective LED lamp PWB.

Defective ISC PWB.

Defective main PWB. - Remedy: Defective connector cable or poor contact in the connector. Reinsert the connector. Also check for continuity within the connector cable. If none, replace the cable. LED lamp PWB and ISC PWB (YC6) ISC PWB (YC3) and main PWB (YC11)

Defective LED lamp PWB. Replace the LED lamp PWB and check for correct operation.

Defective ISC PWB. Replace the ISC PWB and check for correct operation.

Defective main PWB. Replace the main PWB and check for correct operation.

- Code: 3210

- Description: CIS lamp error

When input value at the time of CIS illumination does not exceed the threshold value between 5 s. - Causes: Defective connector cable or poor contact in the connector

Defective CIS.

Defective DPSHD PWB.

Defective DP relay PWB. - Remedy: Defective connector cable or poor contact in the connector. Reinsert the connector. Also check for continuity within the connector cable. If none, replace the cable. CIS and DPSHD PWB (YC2) DPSHD PWB (YC3) and DP relay PWB (YC2)

Defective CIS. Replace the CIS and check for correct operation.

Defective DPSHD PWB. Replace the DPSHD PWB and check for correct operation.

Defective DP relay PWB. Replace the DP relay PWB and check for correct operation.

- Code: 3300

- Description: Optical system (AGC) error

After AGC, correct input is not obtained at CCD. - Causes: Defective connector cable or poor contact in the connector.

Defective exposure lamp.

Defective CCD PWB.

Defective ISC PWB.

Defective main PWB. - Remedy: Defective connector cable or poor contact in the connector. Reinsert the connector. Also check for continuity within the connector cable. If none, replace the cable. CCD PWB (YC2) and ISC PWB (YC9) ISC PWB (YC3) and main PWB (YC11)

Defective exposure lamp. Replace the LED lamp PWB and check for correct operation.

Defective CCD PWB. Replace the CCD PWB and check for correct operation.

Defective ISC PWB. Replace the ISC PWB and check for correct operation.

Defective main PWB. Replace the main PWB and check for correct operation.

- Code: 3310

- Description: CIS AGC error

After AGC, correct input is not obtained at CIS. - Causes: Defective CIS.

Defective DPSHD PWB.

Defective DP relay PWB. - Remedy: Defective CIS. Replace the CIS and check for correct operation.

Defective DPSHD PWB. Replace the DPSHD PWB and check for correct operation.

Defective DP relay PWB. Replace the DP relay PWB and check for correct operation.

- Code: 3500

- Description: Communication error between scanner and ASIC An error code is detected.

- Causes: Defective connector cable or poor contact in the connector

Defective ISC PWB.

Defective main PWB. - Remedy: Defective connector cable or poor contact in the connector. Reinsert the connector. Also check for continuity within the connector cable. If none, replace the cable. ISC PWB (YC3) and main PWB (YC11)

Defective ISC PWB. Replace the ISC PWB and check for correct operation.

Defective main PWB. Replace the main PWB and check for correct operation.

- Code: 3600

- Description: Scanner sequence error

- Causes: Defective ISC PWB.

- Remedy: Replace the ISC PWB and check for correct operation.

- Code: 3700

- Description: Scanner device error

- Causes: CCD connector inserted incorrectly.

- Remedy: Reinsert the image scanner unit connector if necessary.

- Code: 3800

- Description: AFE error

When writing the data, read and write data does not match 3 times in succession. - Causes: Defective ISC PWB.

- Remedy: Replace the ISC PWB and check for correct operation.

- Code: 3900

- Description: Backup memory read/write error (ISC PWB)

Read and write data does not match. - Causes: Defective backup memory or PWB.

- Remedy: Replace the ISC PWB and check for correct operation.

- Code: 4001

- Description: Polygon motor K synchronization error

After polygon motor K is driven, the ready signal does not turn to L within 30 s. - Causes: Defective connector cable or poor contact in the connector.

Defective polygon motor K.

Defective engine PWB. - Remedy: Defective connector cable or poor contact in the connector. Reinsert the connector. Also check for continuity within the connector cable. If none, replace the cable. Polygon motor K and LSU relay PWB (YC4) LSU relay PWB (YC4) and engine PWB (YC12)

Defective polygon motor K. Replace the laser scanner unit.

Defective engine PWB. Replace the engine PWB and check for correct operation.

- Code: 4002

- Description: Polygon motor C synchronization error

After polygon motor C is driven, the ready signal does not turn to L within 30 s. - Causes: Defective connector cable or poor contact in the connector.

Defective polygon motor C.

Defective engine PWB. - Remedy: Defective connector cable or poor contact in the connector. Reinsert the connector. Also check for continuity within the connector cable. If none, replace the cable. Polygon motor C and LSU relay PWB (YC9) LSU relay PWB (YC3) and engine PWB (YC12)

Defective polygon motor C. Replace the laser scanner unit.

Defective engine PWB. Replace the engine PWB and check for correct operation.

- Code: 4003

- Description: Polygon motor M synchronization error

After polygon motor M is driven, the ready signal does not turn to L within 30 s. - Causes: Defective connector cable or poor contact in the connector.

Defective polygon motor M.

Defective engine PWB. - Remedy: Defective connector cable or poor contact in the connector. Reinsert the connector. Also check for continuity within the connector cable. If none, replace the cable. Polygon motor M and LSU relay PWB (YC7) LSU relay PWB (YC3) and engine PWB (YC12)

Defective polygon motor M. Replace the laser scanner unit.

Defective engine PWB. Replace the engine PWB and check for correct operation.

- Code: 4004

- Description: Polygon motor Y synchronization error

After polygon motor Y is driven, the ready signal does not turn to L within 30 s. - Causes: Defective connector cable or poor contact in the connector.

Defective polygon motor Y.

Defective engine PWB. - Remedy: Defective connector cable or poor contact in the connector. Reinsert the connector. Also check for continuity within the connector cable. If none, replace the cable. Polygon motor Y and LSU relay PWB (YC11) LSU relay PWB (YC3) and engine PWB (YC12)

Defective polygon motor Y. Replace the laser scanner unit.

Defective engine PWB. Replace the engine PWB and check for correct operation.

- Code: 4011

- Description: Polygon motor K steady-state error

After polygon motor K is stabilized, the ready signal is at the H level for 15 s continuously. - Causes: Defective connector cable or poor contact in the connector.

Defective polygon motor K.

Defective engine PWB. - Remedy: Defective connector cable or poor contact in the connector. Reinsert the connector. Also check for continuity within the connector cable. If none, replace the cable. Polygon motor K and LSU relay PWB (YC4) LSU relay PWB (YC4) and engine PWB (YC12)

Defective polygon motor K. Replace the laser scanner unit.

Defective engine PWB. Replace the engine PWB and check for correct operation.

- Code: 4012

- Description: Polygon motor C steady-state error

After polygon motor C is stabilized, the ready signal is at the H level for 15 s continuously. - Causes: Defective connector cable or poor contact in the connector.

Defective polygon motor C.

Defective engine PWB. - Remedy: Defective connector cable or poor contact in the connector. Reinsert the connector. Also check for continuity within the connector cable. If none, replace the cable. Polygon motor C and LSU relay PWB (YC9) LSU relay PWB (YC3) and engine PWB (YC12)

Defective polygon motor C. Replace the laser scanner unit.

Defective engine PWB. Replace the engine PWB and check for correct operation.

- Code: 4013

- Description: Polygon motor M steady-state error

After polygon motor M is stabilized, the ready signal is at the H level for 15 s continuously. - Causes: Defective connector cable or poor contact in the connector

Defective polygon motor M.

Defective engine PWB. - Remedy: Defective connector cable or poor contact in the connector. Reinsert the connector. Also check for continuity within the connector cable. If none, replace the cable. Polygon motor M and LSU relay PWB (YC7) LSU relay PWB (YC3) and engine PWB (YC12)

Defective polygon motor M. Replace the laser scanner unit.

Defective engine PWB. Replace the engine PWB and check for correct operation.

- Code: 4014

- Description: Polygon motor Y steady-state error

After polygon motor Y is stabilized, the ready signal is at the H level for 15 s continuously. - Causes: Defective connector cable or poor contact in the connector.

Defective polygon motor Y.

Defective engine PWB. - Remedy: Defective connector cable or poor contact in the connector. Reinsert the connector. Also check for continuity within the connector cable. If none, replace the cable. Polygon motor Y and LSU relay PWB (YC11) LSU relay PWB (YC3) and engine PWB (YC12)

Defective polygon motor Y. Replace the laser scanner unit.

Defective engine PWB. Replace the engine PWB and check for correct operation.

- Code: 4101

- Description: BD initialization error K

After polygon motor K is driven, ASIC detects a BD error for 1 s. - Causes: Defective connector cable or poor contact in the connector.

Defective PD PWB K.

Defective engine PWB. - Remedy: Defective connector cable or poor contact in the connector. Reinsert the connector. Also check for continuity within the connector cable. If none, replace the cable. Laser scanner unit and LSU relay PWB (YC5) LSU relay PWB (YC3) and engine PWB (YC12)

Defective PD PWB K. Replace the laser scanner unit.

Defective engine PWB. Replace the engine PWB and check for correct operation.

- Code: 4102

- Description: BD initialization error C

After polygon motor C is driven, ASIC detects a BD error for 1 s. - Causes: Defective connector cable or poor contact in the connector.

Defective PD PWB C.

Defective engine PWB. - Remedy: Defective connector cable or poor contact in the connector. Reinsert the connector. Also check for continuity within the connector cable. If none, replace the cable. Laser scanner unit and LSU relay PWB (YC10) LSU relay PWB (YC3) and engine PWB (YC12)