Коды ошибок настенных сплит систем

| Проблемы | Дисплей | Дисплей | LCD |

| Внутренний блок | RUNNING LAMP | TAMER LAMP | |

| Датчик комнатной температуры | моргает 1\светится 8сек | светится | E2 |

| Сенсор температуры испарителя | моргает 2\светится 8сек | светится | E3 |

| Перегрев кондиционера | моргает 3\светится 8сек | светится | E8 |

| Помпа(Перелив) | моргает 4\светится 8сек | светится | E9 |

| Мотор вентилятора | моргает 6\светится 8сек | светится | E5 |

| Нет связи с внешним блоком | моргает 7\светится 8сек | светится | E7 |

| Не закрыта крышка | светится | моргает 3\светится 8сек | E0 |

| Датчик температуры конденсатора | светится | моргает 4\светится 8сек | E1 |

| Не работает EEPROM | светится | моргает 6\светится 8сек | E6 |

Для систем с трёхфазным питанием

| Проблемы | Дисплей | Дисплей | LCD |

| Внешний Блок | RUNNING LAMP | TAMER LAMP | |

| Сенсор температуры на улице | светится | моргает 1\светится 8сек | E2 |

| Сенсор трубной температуры | светится | моргает 2\светится 8сек | E3 |

| Перегрев компрессора | светится | моргает 3\светится 8сек | E7 |

| светится | моргает 4\светится 8сек | E1 | |

| Нет межблочной связи | светится | моргает 6\светится 8сек | E6 |

| светится | моргает 7\светится 8сек | E5 |

Индикация неисправностей кассетных кондиционеров

| Расшифровка ошибок | Индикация |

| Оттайка | мигает 1 раз \ не светиться 1 секунда. |

| Защита от обмерзания | мигает 1 раз \ не светиться 3 секунды. |

| Сенсор комнатной температуры | мигает 2 раза \ не светиться 4 секунды. |

| Сенсор трубной температуры | мигает 3 раза \ не светиться 5 секунд. |

| Ошибка с внешнего блока | мигает 4 раза \ не светиться 6 секунд. |

| Защита от обмерзания внут блока | мигает 5 раза \ не светиться 7 секунд. |

| Защита по низкому давлению | мигает 6 раз \ не светиться 8 секунд. |

| Защита по питанию внешнего блока | мигает 7 раз \ не светиться 9 секунд. |

| Защита от перегрева | мигает 8 раз \ не светиться 10 секунд. |

| Защита от перелива конденсата | мигает 9 раз \ не светиться 11 секунд. |

Индикация неисправностей канальных кондиционеров

| Неисправность | Код аварии |

| E1 | |

| аномальная температура сенсора | E2 |

| Сенсор комнатной температуры | E3 |

| Ошибка с внешнего блока | Е4 |

| Нет межблочной связи | Е7 |

| Защита от перегрева\обмерзания | Е8 |

| Е9 |

Коды ошибок колонных кондиционеров

| Ошибки | Индикация на дисплее |

| Нет межблочной связи | E1 |

| Термодатчик комнатного воздуха | E2 |

| Термодатчик испарителя | E3 |

| Защита по низкому давлению | Е4 |

| Ошибка фазировки | Е7 |

| Защита от перегрева | Е8 |

| Ошибка с внешнего блока | Е9 |

Коды неисправностей подпотолочных сплит систем

| Неисправности | Индикация |

| Режим разморозки | моргает 1 раз \ не светиться 1 секунда. |

| Защита от обмерзания | моргает 1 раз \ не светиться 3 секунды. |

| Датчик комнатной температуры | моргает 2 раза \ не светиться 4 секунды. |

| Сенсор температуры испарителя | моргает 3 раза \ не светиться 5 секунд. |

| Ошибка наружного блока | моргает 4 раза \ не светиться 6 секунд. |

| Защита от обмерзания внутреннего блока | моргает 5 раза \ не светиться 7 секунд. |

| Ошибка по низкому давлению | моргает 6 раз \ не светиться 8 секунд. |

| Авария по питанию внешнего блока | моргает 7 раз \ не светиться 9 секунд. |

| Защита от перегрева | моргает 8 раз \ не светиться 10 секунд. |

| Авария по переливу конденсата | моргает 9 раз \ не светиться 11 секунд. |

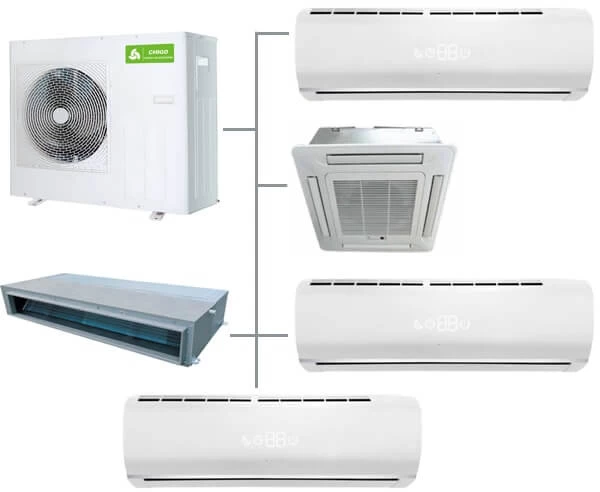

CMD intelligent vulti connected series

| Неисправности | Индикация |

| Термодатчик внутреннего воздуха | E2 |

| Термодатчик испарителя | E3 |

| Ошибка с внешнего блока | Е4 |

| Неисправность двигателя вентилятора | Е5 |

| Режим оттайки | Е6 |

Коды ошибок настенных сплит систем

| Проблемы | Дисплей | Дисплей | LCD |

| Внутренний блок | RUNNING LAMP | TAMER LAMP | |

| Датчик комнатной температуры | моргает 1\светится 8сек | светится | E2 |

| Сенсор температуры испарителя | моргает 2\светится 8сек | светится | E3 |

| Перегрев кондиционера | моргает 3\светится 8сек | светится | E8 |

| Помпа(Перелив) | моргает 4\светится 8сек | светится | E9 |

| Мотор вентилятора | моргает 6\светится 8сек | светится | E5 |

| Нет связи с внешним блоком | моргает 7\светится 8сек | светится | E7 |

| Не закрыта крышка | светится | моргает 3\светится 8сек | E0 |

| Датчик температуры конденсатора | светится | моргает 4\светится 8сек | E1 |

| Не работает EEPROM | светится | моргает 6\светится 8сек | E6 |

Для систем с трёхфазным питанием

| Проблемы | Дисплей | Дисплей | LCD |

| Внешний Блок | RUNNING LAMP | TAMER LAMP | |

| Сенсор температуры на улице | светится | моргает 1\светится 8сек | E2 |

| Сенсор трубной температуры | светится | моргает 2\светится 8сек | E3 |

| Перегрев компрессора | светится | моргает 3\светится 8сек | E7 |

| светится | моргает 4\светится 8сек | E1 | |

| Нет межблочной связи | светится | моргает 6\светится 8сек | E6 |

| светится | моргает 7\светится 8сек | E5 |

Индикация неисправностей кассетных кондиционеров

| Расшифровка ошибок | Индикация |

| Оттайка | мигает 1раз \не светиться 1 секунда. |

| Защита от обмерзания | мигает 1раз \не светиться 3 секунды. |

| Сенсор комнатной температуры | мигает 2раза \не светиться 4 секунды. |

| Сенсор трубной температуры | мигает 3раза \не светиться 5 секунд. |

| Ошибка с внешнего блока | мигает 4раза \не светиться 6 секунд. |

| Защита от обмерзания внут блока | мигает 5раза \не светиться 7 секунд. |

| Защита по низкому давлению | мигает 6раз \не светиться 8 секунд. |

| Защита по питанию внешнего блока | мигает 7 раз \не светиться 9 секунд. |

| Защита от перегрева | мигает 8 раз \не светиться 10 секунд. |

| Защита от перелива конденсата | мигает 9 раз \не светиться 11 секунд. |

Индикация неисправностей канальных кондиционеров

| Неисправность | Код аварии |

| E1 | |

| аномальная температура сенсора | E2 |

| Сенсор комнатной температуры | E3 |

| Ошибка с внешнего блока | Е4 |

| Нет межблочной связи | Е7 |

| Защита от перегрева\обмерзания | Е8 |

| Е9 |

Коды ошибок колонных кондиционеров

| Ошибки | Индикация на дисплее |

| Нет межблочной связи | E1 |

| Термодатчик комнатного воздуха | E2 |

| Термодатчик испарителя | E3 |

| Защита по низкому давлению | Е4 |

| Ошибка фазировки | Е7 |

| Защита от перегрева | Е8 |

| Ошибка с внешнего блока | Е9 |

Коды неисправностей подпотолочных сплит систем

| Неисправности | Индикация |

| Режим разморозки | моргает 1раз \не светиться 1 секунда. |

| Защита от обмерзания | моргает 1раз \не светиться 3 секунды. |

| Датчик комнатной температуры | моргает 2раза \не светиться 4 секунды. |

| Сенсор температуры испарителя | моргает 3раза \не светиться 5 секунд. |

| Ошибка наружного блока | моргает 4раза \не светиться 6 секунд. |

| Защита от обмерзания внутреннего блока | моргает 5раза \не светиться 7 секунд. |

| Ошибка по низкому давлению | моргает 6раз \не светиться 8 секунд. |

| Авария по питанию внешнего блока | моргает 7 раз \не светиться 9 секунд. |

| Защита от перегрева | моргает 8 раз \не светиться 10 секунд. |

| Авария по переливу конденсата | моргает 9 раз \не светиться 11 секунд. |

CMD intelligent vulti connected series

| Неисправности | Индикация |

| Термодатчик внутреннего воздуха | E2 |

| Термодатчик испарителя | E3 |

| Ошибка с внешнего блока | Е4 |

| Неисправность двигателя вентилятора | Е5 |

| Режим оттайки | Е6 |

Коды ошибок кондиционеров марки Chigo (Чиго)

Сегодня Chigo (Чиго) — это крупная современная компания, основным видом деятельности которой является разработка, проектирование, производство, а также продажа бытовой и коммерческой климатической техники. Компания входит в число крупнейших мировых производителей оборудования для систем кондиционирования с годовым объемом производства в 10 млн комплектов. Chigo (Чиго) — производитель климатической техники с высокой промышленной интеграцией — это позволяет создавать максимально широкие продуктовые линейки, удовлетворяющие любым требованиям.

Коды ошибок настенных сплит систем.

| Проблемы | Дисплей | Дисплей | LCD |

| Внутренний блок | RUNNING LAMP | TAMER LAMP | |

| Датчик комнатной температуры | моргает 1светится 8сек | светится | E2 |

| Сенсор температуры испарителя | моргает 2светится 8сек | светится | E3 |

| Перегрев кондиционера | моргает 3светится 8сек | светится | E8 |

| Помпа(Перелив) | моргает 4светится 8сек | светится | E9 |

| Мотор вентилятора | моргает 6светится 8сек | светится | E5 |

| Нет связи с внешним блоком | моргает 7светится 8сек | светится | E7 |

| Не закрыта крышка | светится | моргает 3светится 8сек | E0 |

| Датчик температуры конденсатора | светится | моргает 4светится 8сек | E1 |

| Не работает EEPROM | светится | моргает 6светится 8сек | E6 |

Для систем с трёхфазным питанием.

| Проблемы | Дисплей | Дисплей | LCD |

| Внешний Блок | RUNNING LAMP | TAMER LAMP | |

| Сенсор температуры на улице | светится | моргает 1светится 8сек | E2 |

| Сенсор трубной температуры | светится | моргает 2светится 8сек | E3 |

| Перегрев компрессора | светится | моргает 3светится 8сек | E7 |

| светится | моргает 4светится 8сек | E1 | |

| Нет межблочной связи | светится | моргает 6светится 8сек | E6 |

| светится | моргает 7светится 8сек | E5 |

Индикация неисправностей кассетных кондиционеров.

| Расшифровка ошибок | Индикация |

| Оттайка | мигает 1раз не светиться 1 секунда. |

| Защита от обмерзания | мигает 1раз не светиться 3 секунды. |

| Сенсор комнатной температуры | мигает 2раза не светиться 4 секунды. |

| Сенсор трубной температуры | мигает 3раза не светиться 5 секунд. |

| Ошибка с внешнего блока | мигает 4раза не светиться 6 секунд. |

| Защита от обмерзания внут блока | мигает 5раза не светиться 7 секунд. |

| Защита по низкому давлению | мигает 6раз не светиться 8 секунд. |

| Защита по питанию внешнего блока | мигает 7 раз не светиться 9 секунд. |

| Защита от перегрева | мигает 8 раз не светиться 10 секунд. |

| Защита от перелива конденсата | мигает 9 раз не светиться 11 секунд. |

Индикация неисправностей канальных кондиционеров.

| Неисправность | Код аварии |

| E1 | |

| аномальная температура сенсора | E2 |

| Сенсор комнатной температуры | E3 |

| Ошибка с внешнего блока | Е4 |

| Нет межблочной связи | Е7 |

| Защита от перегреваобмерзания | Е8 |

| Е9 |

Коды ошибок колонных кондиционеров.

| Ошибки | Индикация на дисплее |

| Нет межблочной связи | E1 |

| Термодатчик комнатного воздуха | E2 |

| Термодатчик испарителя | E3 |

| Защита по низкому давлению | Е4 |

| Ошибка фазировки | Е7 |

| Защита от перегрева | Е8 |

| Ошибка с внешнего блока | Е9 |

Коды неисправностей подпотолочных сплит систем.

| Неисправности | Индикация |

| Режим разморозки | моргает 1раз не светиться 1 секунда. |

| Защита от обмерзания | моргает 1раз не светиться 3 секунды. |

| Датчик комнатной температуры | моргает 2раза не светиться 4 секунды. |

| Сенсор температуры испарителя | моргает 3раза не светиться 5 секунд. |

| Ошибка наружного блока | моргает 4раза не светиться 6 секунд. |

| Защита от обмерзания внутреннего блока | моргает 5раза не светиться 7 секунд. |

| Ошибка по низкому давлению | моргает 6раз не светиться 8 секунд. |

| Авария по питанию внешнего блока | моргает 7 раз не светиться 9 секунд. |

| Защита от перегрева | моргает 8 раз не светиться 10 секунд. |

| Авария по переливу конденсата | моргает 9 раз не светиться 11 секунд. |

CMD intelligent vulti connected series.

| Неисправности | Индикация |

| Термодатчик внутреннего воздуха | E2 |

| Термодатчик испарителя | E3 |

| Ошибка с внешнего блока | Е4 |

| Неисправность двигателя вентилятора | Е5 |

| Режим оттайки | Е6 |

Chicago was founded in 1994 but has quickly gained a great deal of attraction and attention from the world. Known as Guangdong Chigo Air Conditioning Co., Ltd, the 26-year-old corporation has seen great highs in terms of manufacturing and sales. With headquarters in Nanhai District, Foshan City they are regarded as the key manufacturers of air conditioners, refrigerators, washing machines, and other household appliances.

In only 2 decades the business was able to double its capacity, and offer more than 10 million air conditioner sets that are available in more than 200 countries around the world. Making sure you get access to the best appliance the company has to offer no matter where you are located.

There is a time in your life when the most reliable appliance you have starts to show an error. While it might be a dark day, fortunately for you there is a simple solution for most error codes. To help you out we have accumulated a complete list of the Chigo air conditioner error codes. Offering you a chance to find out exactly what is wrong with your appliance, so you can finally make a decision. Rather than fighting with the appliance, or spending endless money on the repair, we suggest you first find the problem and then look for a solution.

Codes List

| Error Codes | Solution |

|---|---|

| E1 | Condenser temperature aensor fault |

| E2 | Room temp. sensor fault |

| E3 | Coil temp. sensor fault |

| E4 | Outdoor unit abnormal |

| E5 | No feedback signal of indoor fan |

| E6 | No over zero signal |

| E7 | Outdoor feedback fault |

| E8 | Frost protection/over heat protection |

| F1 | Communication fault |

| F2 | Ambient temp. sensor fault |

| F3 | Coil pipe temp. sensor of indoor unit fault |

| F4 | Fan motor of indoor |

| F5 | Module of outdoor unit fault |

| F6 | Ambient temp. sensor of outdoor fault |

| F7 | Coil pipe temp. sensor of outdoor unit fault |

| F8 | Suction temp. sensor of compressor fault |

| F9 | Discharge temp. sensor of compressor fault |

| FA | Inductor of current or voltage fault |

| FC | Compressor drive fault |

| FD | Phase lacking or phase sequence fault |

| FE | Gas return sensor fault |

| FF | Other fault |

| P1 | Temp. of evaporator protection |

| P2 | Overheat, over current protection of inverter module |

| P3 | Over current protection |

| P4 | Discharge temp. of compressor protection |

| P5 | Over heat of compressor top protection |

| P6 | Suction temp. of compressor protection |

| P7 | Low or high voltage protection |

| P8 | Low presser of gas return protection |

| P9 | High pressure of discharge protection |

| PA | High temp. of condenser protection |

| PC | High temp. of outdoor ambient protection |

| PF | Other protection |

| DF | Defrost indication |

Wall Split AC Series

Code: DF

Failure: Defrost indication

The reason of fault and solution: Normal, the defrost state is removed, it will return to normal condition automatically

Code: E2

Failure: Room temp. sensor fault

The reason of fault and solution:

- Check whether the resistance of the sensor is normal (the resistance is 5КΩ in the normal temperature 25 ) ℃ , when it is abnormal the sensor should be replaced.

- Check whether there is short circuit or open circuit in the wire of the sensor, and whether the plug is connected well, whether there is welding off or rosin joint on the electric control board, if there is any, it should be repaired.

- When the 1 and 2 are both normal, then the components or integrated circuit is damaged, the electric control board should be replaced.

Code: E3

Failure: Coil temp. sensor fault

The reason of fault and solution:

- Check whether the resistance of the sensor is normal (the resistance is 5КΩ in the normal temperature 25 ) ℃ , when it is abnormal the sensor should be replaced.

- Check whether there is short circuit or open circuit in the wire of the sensor, and whether the plug is connected well, whether there is welding off or rosin joint on the electric control board, if there is any, it should be repaired.

- When the 1 and 2 are both normal, then the components or integrated circuit is damaged, the electric control board should be replaced.

Code: E4

Failure: Outdoor unit abnormal

The reason of fault and solution:

- Check whether the winding resistance and operation current of the compressor are normal.

- Check whether the high and low pressure is normal when the unit is running.

- Check (whether the coil pipe sensor is normal) whether the contact of the inserter on the circuit board is well, the coil pipe temperature sensor is fixed, the evaporation of the indoor unit is well, the key is to check the evaporator temperature detected by the coil pipe temperature sensor has reached the cooling or heating temperature.

- Check whether the surface of the condenser is too dirty, it should be cleaned when it is too dirty.

- Check whether the capacitance of the outdoor motor and the fan is damaged, it should be replaced when

Code: E5

Failure: No feedback signal of indoor fan

The reason of fault and solution:

- Check whether two sets of plugs on the outlet end of the motor have loosed from the socket of the electric control board, insert it firmly when loosing.

- Check whether the indoor motor has damaged, the motor should be replaced when it is damaged

- Check whether the controllable silicon and other components on the electric control board have damaged, replace the controllable silicon or electric control board when they are damaged.

Code: E6

Failure: No over zero signal

The reason of fault and solution:

- Firstly check whether the indoor fan is normal.

- Check whether the signal outputting from the integrated chip of the electric control board is normal, the electric control board should be replaced when the signal is abnormal.

Code: E7

Failure: Outdoor feedback fault

The reason of fault and solution:

- Check whether the winding resistance and operation current of the compressor are normal

- Check whether the high and low pressure is normal when the unit is running.

- Check whether the indoor and outdoor wiring is right; when it is wrong, connect them again according to the circuit diagram

- Check whether the contact of the inserter on the circuit board and the connection are well, otherwise repair.

- Check whether the signal feedback wire is disconnected, replace or connect the feedback signal wire.

- Check whether the supply power is phase-lacking or phase opposition.

- Check whether the AC electromagnetic contactor is well.

Code: E8

Failure: Frost protection/over heat protection

The reason of fault and solution:

- Check whether the filter of the indoor unit is dirty or blocked, and clean if it is dirty.

- Check whether the indoor fan is running normally, and replace the motor if it is abnormal.

- Check whether indoor pipe temperature sensor is normal, and replace the sensor if it is abnormal.

- Check whether the system pressure is normal, if abnormal, should check whether there is leakage, and fill the refrigerant again.

Floor Standing AC Series

Code: E2

Failure: Room temp. sensor fault

The reason of fault and solution:

- Check whether the resistance of the sensor is normal (the resistance is 5КΩ in the normal temperature 25 ) ℃ , when it is abnormal the sensor should be replaced.

- Check whether there is short circuit or open circuit in the wire of the sensor, and whether the plug is connected well, whether there is welding off or rosin joint on the electric control board, if there is any, it should be repaired.

- When the 1 and 2 are both normal, then the components or integrated circuit is damaged, the electric control board should be replaced.

Code: E3

Failure: Coil temp. sensor fault

The reason of fault and solution:

- Check whether the resistance of the sensor is normal (the resistance is 5КΩ in the normal temperature 25 ) ℃ , when it is abnormal the sensor should be replaced.

- Check whether there is short circuit or open circuit in the wire of the sensor, and whether the plug is connected well, whether there is welding off or rosin joint on the electric control board, if there is any, it should be repaired.

- When the 1 and 2 are both normal, then the components or integrated circuit is damaged, the electric control board should be replaced.

Code: E4

Failure: Outdoor unit abnormal

The reason of fault and solution:

- Check whether the winding resistance and operation current of the compressor are normal.

- Check whether the high and low pressure is normal when the unit is running.

- Check (whether the coil pipe sensor is normal) whether the contact of the inserter on the circuit board is well, the coil pipe temperature sensor is fixed, the evaporation of the indoor unit is well, the key is to check the evaporator temperature detected by the coil pipe temperature sensor has reached the cooling or heating temperature.

- Check whether the surface of the condenser is too dirty, it should be cleaned when it is too dirty.

- Check whether the capacitance of the outdoor motor and the fan is damaged, it should be replaced when it is damaged.

- If the above items are normal, the electric control board should be replaced.

Code: E7

Failure: Outdoor feedback fault

The reason of fault and solution:

- Check whether the winding resistance and operation current of the compressor are normal

- Check whether the high and low pressure is normal when the unit is running

- Check whether the indoor and outdoor wiring is right; when it is wrong, connect them again according to the circuit diagram

- Check whether the contact of the inserter on the circuit board and the connection are well, otherwise repair.

- Check whether the signal feedback wire is disconnected, replace or connect the feedback signal wire.

- Check whether the supply power is phase-lacking or phase opposition.

- Check whether the AC electromagnetic contactor is well.

Code: E8

Failure: Frost protection /over heat protection

The reason of fault and solution:

- Check whether the filter of the indoor unit is dirty or blocked, and clean if it is dirty.

- Check whether the indoor fan is running normally, and replace the motor if it is abnormal.

- Check whether indoor pipe temperature sensor is normal, and replace the sensor if it is abnormal.

- Check whether the system pressure is normal, if abnormal, should check whether there is leakage, and fill the refrigerant again.

Portable AC Codes

Code: E2

Failure: Room temp. sensor fault

The reason of fault and solution:

- Check whether the resistance of the sensor is normal (the resistance is 5КΩ in the normal temperature 25 ) ℃ , when it is abnormal the sensor should be replaced.

- Check whether there is short circuit or open circuit in the wire of the sensor, and whether the plug is connected well, whether there is welding off or rosin joint on the electric control board, if there is any, it should be repaired.

- When the 1 and 2 are both normal, then the components or integrated circuit is damaged, the electric control board should be replaced.

Code: E3

Failure: Coil temp. sensor fault

The reason of fault and solution:

- Check whether the resistance of the sensor is normal (the resistance is 5КΩ in the normal temperature 25 ) ℃ , when it is abnormal the sensor should be replaced.

- Check whether there is short circuit or open circuit in the wire of the sensor, and whether the plug is connected well, whether there is welding off or rosin joint on the electric control board, if there is any, it should be repaired.

- When the 1 and 2 are both normal, then the components or integrated circuit is damaged, the electric control board should be replaced.

Code: E4

Failure: Abnormal protection

The reason of fault and solution:

- Check whether the operation current and power of the unit is abnormal.

- Check whether the speed and wind quantity of the fan is normal, otherwise replace the outdoor fan or capacitance

- Check whether the surface of the condenser is too dirty, and it should be cleaned when it is too dirty.

- Check whether the unit is short of the refrigerant, add the refrigerant after leakage detection and repair welding.

- Check whether the sensor and electric control board is normal, otherwise replace the board.

Code: E5

Failure: Water level over limit

The reason of fault and solution:

- Normal, discharge the water out, it will return to normal condition automatically

- Check the water level switch, and replace it when fault.

Code: E8

Failure: Over heat protection

The reason of fault and solution:

- Check whether the fan is normal, otherwise replace corresponding motor or capacitance.

- Check the resistance of the electric heater is normal, otherwise replace it.

Dehumidifer Codes

Code: Continuous lamp flicker 2 times

Failure:Room temp. sensor fault

The reason of fault and solution:

- Check whether the resistance of the sensor is normal, when it is abnormal the sensor should be replaced.

- Check whether there is short circuit or open circuit in the wire of the sensor, and whether the plug is connected well, whether there is welding off or rosin joint on the electric control board, if there is any, it should be repaired.

- When the 1 and 2 are both normal, then the components or integrated circuit is damaged, the electric control board should be replaced.

Code: Continuous lamp flicker 2/3 SEC

Failure: Coil temp. sensor fault

The reason of fault and solution:

- Check whether the resistance of the sensor is normal, when it is abnormal the sensor should be replaced.

- Check whether there is short circuit or open circuit in the wire of the sensor, and whether the plug is connected well, whether there is welding off or rosin joint on the electric control board, if there is any, it should be repaired.

- When the 1 and 2 are both normal, then the components or integrated circuit is damaged, the electric control board should be replaced.

Code: Continuous lamp flicker 3 times

Failure: Humidity sensor fault

The reason of fault and solution:

- Check whether the humidity sensor is normal, otherwise replace it.

- Check whether the sensor wire is short circuit or open circuit, and whether the plug is well contacted, whether there is welding off or rosin joint on the electric control board, repair it if there is any above.

- When the 1 and 2 are both normal, then the components or integrated circuit is damaged, the electric control board should be replaced.

Code: Continuous lamp flicker 4 times

Failure: Temp. sensor and humidity sensor all fault

The reason of fault and solution:

- Check whether the resistance of the temperature sensor is normal, otherwise replace it.

- Check whether the humidity sensor is normal, otherwise replace it.

Code: Water full lamp flicker (light 0.5 SEC, extinguish 0.5 SEC)

Failure: Water full of water tank

The reason of fault and solution: Normal, discharge the water out, it will return to normal condition automatically

Inverter Split Codes

Code: F1

Failure: Communication fault

The reason of fault and solution:

- Check whether the connection of the outdoor unit and indoor unit is one to one, otherwise connect the L, N and communication line of the indoor unit and outdoor unit one to one.

- Measure whether the voltage between the zero line and the communication line is 18V-30AC half-wave signal, check whether the communication circuit on the indoor and outdoor electric control board has been damaged, otherwise replace it.

- Check whether the LED on the outdoor power board has been on, otherwise replace the electric control board.

- Check whether the unit is abnormal caused by the external interference, if it is, then find the interfering source, and removes it.

Code: F2

Failure: Ambient temp. sensor fault

The reason of fault and solution:

- Check whether the resistance of sensor is normal, otherwise replace it.

- Check whether the sensor wire is short circuit or open circuit, and whether the plug is well contacted, whether there is welding off or rosin joint on the electric control board, repair it if there is any above.

- When the 1 and 2 are both normal, then the components or integrated circuit is damaged, the electric control board should be replaced.

Code: F3

Failure: Coil pipe temp. sensor of indoor unit fault

The reason of fault and solution:

- Check whether the resistance of sensor is normal, otherwise replace it.

- Check whether the sensor wire is short circuit or open circuit, and whether the plug is well contacted, whether there is welding off or rosin joint on the electric control board, repair it if there is any above.

- When the 1 and 2 are both normal, then the components or integrated circuit is damaged, the electric control board should be replaced.

Code: F4

Failure: Fan motor of indoor

The reason of fault and solution:

- Check whether the contact of the plug of the motor wire and socket is well, making sure well contact

- Check whether the indoor motor has damaged, the motor should be replaced when it is damaged.

- Check whether the controllable silicon and other components on the electric control board have damaged, replace the controllable silicon or electric control board when they are damaged.

Code: F5

Failure: Module of outdoor unit fault

The reason of fault and solution:

- Check whether the connection of the compressor is reliable, otherwise connect firmly again.

- Check whether the fixation between the IPM module and the radiator is firm.

- Check whether the compressor is well, otherwise replace it.

- Check whether the IPM module is abnormal, otherwise replace it.

Code: F6

Failure: Ambient temp. sensor of outdoor fault

The reason of fault and solution:

- Check whether the resistance of sensor is normal, otherwise replace it.

- Check whether the sensor wire is short circuit or open circuit, and whether the plug is well contacted, whether there is welding off or rosin joint on the electric control board, repair it if there is any above.

- When the 1 and 2 are both normal, then the components or integrated circuit is damaged, the electric control board should be replaced.

Code: F7

Failure: Coil pipe temp. sensor of outdoor unit fault

The reason of fault and solution:

- Check whether the resistance of sensor is normal, otherwise replace it.

- Check whether the sensor wire is short circuit or open circuit, and whether the plug is well contacted, whether there is welding off or rosin joint on the electric control board, repair it if there is any above.

- When the 1 and 2 are both normal, then the components or integrated circuit is damaged, the electric control board should be replaced.

Code: F8

Failure: Suction temp. sensor of compressor fault

The reason of fault and solution:

- Check whether the resistance of sensor is normal, otherwise replace it.

- Check whether the sensor wire is short circuit or open circuit, and whether the plug is well contacted, whether there is welding off or rosin joint on the electric control board, repair it if there is any above.

- When the 1 and 2 are both normal, then the components or integrated circuit is damaged, the electric control board should be replaced.

Code: F9

Failure: Discharge temp. sensor of compressor fault

The reason of fault and solution:

- Check whether the resistance of sensor is normal, otherwise replace it.

- Check whether the sensor wire is short circuit or open circuit, and whether the plug is well contacted, whether there is welding off or rosin joint on the electric control board, repair it if there is any above.

- When the 1 and 2 are both normal, then the components or integrated circuit is damaged, the electric control board should be replaced.

Code: FA

Failure: Inductor of current or voltage fault

The reason of fault and solution: Check whether inductor of current or voltage have been damaged, they should be replaced if they are fault.

Code: FC

Failure: Compressor drive fault

The reason of fault and solution:

- Power on again, and check the operation of the compressor is normal.

- Check whether the connection of the compressor is reliable, otherwise repair.

- Check whether the components on the electric control board have been damaged, if they are damaged, the components or the electric control board should be replaced.

Code: FD

Failure: Phase lacking or phase sequence fault

The reason of fault and solution: Check power wire voltage or change two power wires.

Code: FE

Failure: Gas return sensor fault

The reason of fault and solution:

- Check whether the resistance of sensor is normal, otherwise replace it.

- Check whether the sensor wire is short circuit or open circuit, and whether the plug is well contacted, whether there is welding off or rosin joint on the electric control board, repair it if there is any above.

- When the 1 and 2 are both normal, then the components or integrated circuit is damaged, the electric control board should be replaced.

Code: FF

Failure: Other fault

Code: P1

Failure: Temp. of evaporator protection

The reason of fault and solution:

- Check whether the filter of indoor unit is too dirty, and it should be cleaned when it is too dirty.

- Check whether it has barrier around indoor unit, it should be remove if it has.

- Check whether the indoor motor is damaged, it should be replaced motor or electrical control board when it is damaged.

Code: P2

Failure: Overheat, over current protection of inverter module

The reason of fault and solution:

- Check whether the fixation between the IPM module and the radiator is firm.

- Check whether the compressor is well, otherwise replace it.

- Check whether the IPM module is abnormal, otherwise replace it.

Code: P3

Failure: Over current protection

The reason of fault and solution:

- Check whether the ambient temperature exceeds the operation range for the air conditioner

- Check whether the current detection circuit is abnormal, the electric control should be replaced when it is abnormal.

Code: P4

Failure: Discharge temp. of compressor protection

The reason of fault and solution:

- Check whether the air condition system and pressure are normal.

- Check whether the sensor, connecting wire of the sensor and the detection circuit are abnormal.

Code: P5

Failure: Over heat of compressor top protection

The reason of fault and solution:

- Check whether the air condition system and pressure are normal.

- Check whether the sensor, connecting wire of the sensor and the detection circuit are abnormal.

Code: P6

Failure: Suction temp. of compressor protection

The reason of fault and solution:

- Check whether the air condition system and pressure are normal.

- Check whether the sensor, connecting wire of the sensor and the detection circuit are abnormal.

Code: P7

Failure: Low or high voltage protection

The reason of fault and solution:

- Check whether the supply voltage is out of rang from 150 to 270V

- Check the voltage detection circuit of the IPM base board is abnormal, if it is abnormal, the IPM base board or the electric control board should be replaced.

Code: P8

Failure: Low presser of gas return protection

The reason of fault and solution: Check whether the pressure is normal when the unit is running, if it is abnormal, should detect the leakage and welding add refrigerant.

Code: P9

Failure: High pressure of discharge protection

The reason of fault and solution: Check whether the pressure is normal when the unit is running, if it is abnormal, should detect the leakage and welding add refrigerant.

Code: PA

Failure: High temp. of condenser protection

The reason of fault and solution:

- Check whether the condenser of outdoor unit is too dirty, and it should be cleaned when it is too dirty.

- Check whether it is running at bad condition long time.

- Check whether senor and wire are normal.

Code: PC

Failure: High temp. of outdoor ambient protection

The reason of fault and solution:

- Check the outdoor ambient temperature is too high or there is heat source around the outdoor unit.

- Check whether the sensor and sensor wire are normal.

Code: PF

Failure: Other protection

Multi-Split Series Codes

Code: F1

Failure: Communicate fault

The reason of fault and solution:

- Check whether the connection of the outdoor unit and indoor unit is one to one.

- Check whether the unit is abnormal caused by the external interference, if it is, then find the interfering source, and removes it.

- Check whether the electrical control board is damage, it should be replaced when it is damaged.

Code: F2

Failure: Indoor temp. sensor fault

The reason of fault and solution:

- Check whether the resistance of sensor is normal, otherwise replace it.

- Check whether the sensor wire is short circuit or open circuit, and whether the plug is well contacted, whether there is welding off or rosin joint on the electric control board, repair it if there is any above.

- When the 1 and 2 are both normal, then the components or integrated circuit is damaged, the electric control board should be replaced.

Code: F3

Failure: Outlet e temp. sensor of indoor unit coil pipe fault

The reason of fault and solution:

- Check whether the resistance of sensor is normal, otherwise replace it.

- Check whether the sensor wire is short circuit or open circuit, and whether the plug is well contacted, whether there is welding off or rosin joint on the electric control board, repair it if there is any above.

- When the 1 and 2 are both normal, then the components or integrated circuit is damaged, the electric control board should be replaced.

Code: F3

Failure: Suction temp. sensor of indoor unit coil pipe fault

The reason of fault and solution:

- Check whether the resistance of sensor is normal, otherwise replace it.

- Check whether the sensor wire is short circuit or open circuit, and whether the plug is well contacted, whether there is welding off or rosin joint on the electric control board, repair it if there is any above.

- When the 1 and 2 are both normal, then the components or integrated circuit is damaged, the electric control board should be replaced.

Code: F3

Failure: Middle temp. sensor of indoor unit coil pipe fault

The reason of fault and solution:

- Check whether the resistance of sensor is normal, otherwise replace it.

- Check whether the sensor wire is short circuit or open circuit, and whether the plug is well contacted, whether there is welding off or rosin joint on the electric control board, repair it if there is any above.

- When the 1 and 2 are both normal, then the components or integrated circuit is damaged, the electric control board should be replaced

Code: F4

Failure: PG motor fault

The reason of fault and solution:

- Check whether the contact of the plug of the motor wire and socket is well, making sure well contact.

- Check whether the indoor motor has damaged, the motor should be replaced when it is damaged.

- Check whether the controllable silicon and other components on the electric control board have damaged, replace the controllable silicon or electric control board when they are damaged.

Code: P2

Failure: Protection of module fault

The reason of fault and solution:

- Check whether the connection of the compressor is reliable, otherwise connect firmly again.

- Check whether the fixation between the IPM module and the radiator is firm.

- Check whether the compressor is well, otherwise replace it.

- Check whether the IPM module is abnormal, otherwise replace it.

Code: P3

Failure: Over current of outdoor unit

The reason of fault and solution:

- Check whether the ambient temperature exceeds the operation range for the air conditioner

- Check whether the current detection circuit is abnormal, the electric control should be replaced when it is abnormal.

Code: P4

Failure: Discharge temp. of compressor too high, outside ambient temp. too high, temp. switch of compressor crust cut off, temp. of module too high.

The reason of fault and solution:

- Check whether the pressure is normal when the unit is running, if it is abnormal, should detect the leakage and welding add refrigerant.

- Check whether ambient temp. is too high or too low, when the temp. more than -20 degree and less 55 degree, it can disappear automatically.

- communicate interference, earth wire and communicate wire can’t put in one cable.

- Check whether temp. switch of compressor is damage, it should be replace if it damaged.

Code: P7

Failure: DC voltage abnormal of outdoor unit

The reason of fault and solution:

- Check whether the supply voltage is out of rang from 150 to 270V

- Check the voltage detection circuit of the IPM base board is abnormal, if it is abnormal, the IPM base board or the electric control board should be replaced.

Code: P8

Failure: Lack refrigerant or reverse valve fault

The reason of fault and solution:

- Check whether the high and low pressure valves have been opened, otherwise open the valves.

- Check whether the indoor coil pipe temperature sensor is normal, if it is abnormal, the sensor should be replaced.

- Check the system pressure is abnormal, if it is abnormal, should detect leakage repairing welding and adding the refrigerant.

Code: F6

Failure: Outside sensor fault

The reason of fault and solution:

- Check whether the resistance of sensor is normal, otherwise replace it.

- Check whether the sensor wire is short circuit or open circuit, and whether the plug is well contacted, whether there is welding off or rosin joint on the electric control board, repair it if there is any above.

- When the 1 and 2 are both normal, then the components or integrated circuit is damaged, the electric control board should be replaced.

Code: FC

Failure: Outdoor unit drive fault, start compressor failure

The reason of fault and solution:

- Power on again, and check the operation of the compressor is normal.

- Check whether the connection of the compressor is reliable, otherwise repair.

- Check whether the components on the electric control board have been damaged, if they are damaged, the components or the electric control board should be replaced.

VRF System Error Codes

| Eror Codes | Cause |

|---|---|

| FE | The first time to switch on and there is no address |

| E0 | Errors of phase sequence or fault of losing phase |

| E1 | Communication failure of indoor and outdoor unit |

| E2 | T1 sensor fault |

| E3 | T2 sensor fault |

| E4 | T2B sensor fault |

| E5 | Malfunction of outdoor unit |

| E6 | Testing fault of zero-crossing signal |

| E7 | EEPROM malfunction |

| E8 | Wind testing fault of PG electric motor |

| E9 | Communication fault of wire controller |

| EE | Alarming fault of water level switch |

| EF | Model conflict |

Manuals Pdf

Chigo Air Conditioner Manual PDF

Chigo Portable AC Manual PDF

- Author

- Recent Posts

Regarding error and fault codes, we believe sharing knowledge is the best way to help everyone. That is why we established ACErrorCode.com, to give you every bit of info you need as a customer. HVAC Expert Contact: dannyreese@acerrorcode.com Call: 916-954-2677

*If you can’t find the code you’re looking for on our site, please let us know, and we’ll update our database as soon as possible.

Modern CHIGO air conditioners have a developed self-diagnosis system, according to the results of which the control system, upon detection of a malfunction, blocks the operation of the entire

device and at the same time reports the cause of the malfunction.

The CHIGO air conditioning control system reports any malfunctions by flashing the LED on the panel of the indoor unit. If one or another malfunction of the air conditioner is

detected, the LEDs light or flash in a certain sequence, which corresponds to the detected error. If the control system of the air conditioner has detected more than one error, then the fault

with the highest priority is displayed first, and then all the others.

The codes of malfunctions (errors) of CHIGO air conditioners are given in the table:

|

Problems |

Display |

Display |

LCD |

|

Indoor unit |

RUNNING LAMP |

TAMER LAMP |

|

|

Room temperature sensor |

blinks 1 \ lights 8 sec |

glows |

E2 |

|

Evaporator Temperature Sensor |

blinks 2 \ lights 8 sec |

glows |

E3 |

|

Air conditioner overheating |

blinks 3 \ lights 8 sec |

glows |

E8 |

|

Pump (Overflow) |

blinks 4 \ lights 8 sec |

glows |

E9 |

|

Fan motor |

blinks 6 \ lights 8 sec |

glows |

E5 |

|

No communication with external unit |

7 blinks / 8s |

glows |

E7 |

|

Lid not closed |

glows |

blinks 3 \ lights 8 sec |

E0 |

|

Condenser temperature sensor |

glows |

blinks 4 \ lights 8 sec |

E1 |

|

EEPROM does not work |

glows |

blinks 6 \ lights 8 sec |

E6 |

|

Problems |

Display |

Display |

LCD |

|

External Block |

RUNNING LAMP |

TAMER LAMP |

|

|

Outdoor temperature sensor |

glows |

blinks 1 \ lights 8 sec |

E2 |

|

Pipe temperature sensor |

glows |

blinks 2 \ lights 8 sec |

E3 |

|

Compressor overheating |

glows |

blinks 3 \ lights 8 sec |

E7 |

|

glows |

blinks 4 \ lights 8 sec |

E1 |

|

|

No inter-unit communication |

glows |

blinks 6 \ lights 8 sec |

E6 |

|

glows |

7 blinks / 8s |

E5 |

|

Error decoding |

Indication |

|

Defrost |

blinks 1 time \ does not light up 1 second. |

|

Frost protection |

flashes 1 time \ does not light for 3 seconds. |

|

Room temperature sensor |

blinks 2 times \ does not glow for 4 seconds. |

|

Pipe temperature sensor |

flashes 3 times \ does not light up for 5 seconds. |

|

Error from external unit |

blinks 4 times \ does not light up for 6 seconds. |

|

Block frost protection |

blinks 5 times \ does not light up for 7 seconds. |

|

Low pressure protection |

blinks 6 times \ does not light up for 8 seconds. |

|

Power Protection for External Unit |

blinks 7 times \ does not light up for 9 seconds. |

|

overheat protection |

blinks 8 times \ does not light up 10 seconds. |

|

Condensation overflow protection |

flashes 9 times \ does not light for 11 seconds. |

|

Malfunction |

Alarm Code |

|

E1 |

|

|

abnormal sensor temperature |

E2 |

|

Room temperature sensor |

E3 |

|

Error from external unit |

E4 |

|

No inter-unit communication |

E7 |

|

Overheat / frost protection |

E8 |

|

E9 |

| Malfunction |

Display |

|

No inter-unit communication |

E1 |

|

Room air temperature sensor |

E2 |

|

Evaporator Temperature Sensor |

E3 |

|

Low pressure protection |

E4 |

|

Phasing error |

E7 |

|

overheat protection |

E8 |

|

Error from external unit |

E9 |

|

Malfunctions |

Indication |

|

Defrost mode |

blinks 1 time \ does not light up 1 second. |

|

Frost protection |

blinks 1 time; does not light for 3 seconds. |

|

Room temperature sensor |

2 times blinks \ do not glow for 4 seconds. |

|

Evaporator Temperature Sensor |

3 times blinks / do not glow for 5 seconds. |

|

Outdoor unit error |

4 times blinks \ do not glow for 6 seconds. |

|

Anti-freeze protection of indoor unit |

blinks 5 times \ does not glow for 7 seconds. |

|

Low Pressure Error |

blinks 6 times \ does not glow for 8 seconds. |

|

External unit power failure |

blinks 7 times \ does not glow for 9 seconds. |

|

overheat protection |

blinks 8 times \ does not glow for 10 seconds. |

|

Condensate overflow accident |

blinks 9 times / does not light for 11 seconds. |

|

Malfunctions |

Indication |

|

Internal air temperature sensor |

E2 |

|

Evaporator Temperature Sensor |

E3 |

|

Error from external unit |

E4 |

|

Fan motor failure |

E5 |

|

Defrost mode |

E6 |