Kawasaki Ninja ZX-10R motorcycles have engines, which are made up of many different parts.

These parts must work together in order for the engine to function. A problem with one of the

parts can make the engine not run. There are many different parts that make up an engine.

The following kawasaki ninja zx-10r faults are the list of some of the parts of a motorcycle engine.

What’s wrong with my Kawasaki Ninja ZX-10R motorcycle brake light and what can I do about it? There are a few possibilities. One is that your break switch is defective and will need to be replaced. Another is that your brake fluid level may be low.

Kawasaki Ninja ZX-10R Faults :

Your bike engine consists of a great deal of elements like the casting, cylinder heads and pistons. it’s necessary to form certain these area unit all clean and lubricated to avoid engine issues. Conjointly keep in mind that Kawasaki Ninja ZX-10R motorbike engine could be a terribly delicate piece of machinery therefore it is best to handle it with care.

Kawasaki Diagnosis

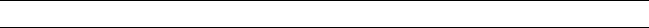

Under the seat, along the right subframe rail is a short orange/black wire with a bullet connector

sticking out of the thick loom. This is the self-diagnosis terminal. There is another bullet connector

protruding nearby — make sure it’s the orange and black which can take some tugging.

In order to read out the Service Codes below, ground that connector with a bit of wire with the motor

running.

The red FI light will begin to flash codes. There will be a 5 second delay and then the codes begin.

The first flash is always a LONG (1 sec) followed by either LONG or SHORT (0.5 sec) flashes. LONG

flashes indicate TENS and short flashes ONES.

One LONG followed by two SHORT = 12. Two LONG, one SHORT = 21. Three LONG, two short = 32, etc. There is an interval of 1.5 seconds between TENS and ONES. There is a 3 second interval between codes.

To recover codes set in memory ground the self-diagnosis terminal rapidly more than 5 times within

2 seconds. The lead must remain grounded after 5 groundings for the remainder of the diagnostic

session. You can then clear codes from the ECU by pulling the clutch lever in for more than 5

seconds.

KAWASAKI Motorcycles Fault Codes DTC List

| Trouble Code | Problem Description |

|---|---|

| 11 | Main throttle sensor malfunction, wiring open or short |

| 12 | Inlet air pressure sensor malfunction, wiring open or short |

| 13 | Inlet air temperature sensor malfunction, wiring open or short |

| 14 | Water temperature sensor malfunction, wiring open or short |

| 15 | Atmospheric pressure sensor malfunction, wiring open or short |

| 21 | Crankshaft sensor malfunction, wiring open or short |

| 23 | Camshaft position sensor malfunction, wiring open or short |

| 24 | Speed sensor malfunction, wiring open or short |

| 25 | Gear position switch malfunction, wiring open or short |

| 31 | Vehicle-down sensor malfunction, wiring open or short |

| 32 | Subthrottle sensor malfunction, wiring open or short |

| 33 | Oxygen sensor #1 inactivation, wiring open or short (Equipped Models) |

| 34 | Exhaust butterfly valve actuator sensor malfunction, wiring open or short |

| 35 | Immobilizer amplifier malfunction |

| 36 | Blank Key detection |

| 39 | ECU communication error |

| 51 | Stick coil #1 malfunction, wiring open or short |

| 52 | Stick coil #2 malfunction, wiring open or short |

| 53 | Stick coil #3 malfunction, wiring open or short |

| 54 | Stick coil #4 malfunction, wiring open or short |

| 56 | Radiator fan relay malfunction, wiring open or short |

| 62 | Subthrottle valve actuator malfunction, wiring open or short |

| 63 | Exhaust butterfly valve actuator malfunction, wiring open or short |

| 64 | Air switching valve malfunction, wiring open or short |

| 67 | Oxygen sensor heater malfunction, wiring open or short (Equipped Models) |

| 83 | Oxygen Sensor #2 inactivation, wiring open or shout (Equipped Models) |

| 94 | Oxygen sensor #1 malfunction, wiring open or short (Equipped Models) |

| 95 | Oxygen sensor #2 malfunction, wiring open or short (Equipped Models) |

Kawasaki Ninja ZX-10R Motorcycle Problems :

- Kawasaki ninja zx-10r after fire

- Kawasaki ninja zx-10r air cleaner clogged, poorly sealed, or missing

- Kawasaki ninja zx-10r air cleaner element clogged

- Kawasaki ninja zx-10r air duct loose

- Kawasaki ninja zx-10r air suction valve trouble

- Kawasaki ninja zx-10r air switching valve trouble

- Kawasaki ninja zx-10r backfiring when deceleration

- Kawasaki ninja zx-10r cracked or obstructed intake air pressure sensor

- Kawasaki ninja zx-10r crankshaft sensor trouble

- Kawasaki ninja zx-10r eCU ground and power supply trouble

- Kawasaki ninja zx-10r eCU trouble

- Kawasaki ninja zx-10r engine overheating — Water temperature sensor or crankshaft sensor trouble

- Kawasaki ninja zx-10r engine stalls easily

- Kawasaki ninja zx-10r engine vacuum not synchronizing

- Kawasaki ninja zx-10r exhaust Smokes Excessively

- Kawasaki ninja zx-10r firing incorrect

- Kawasaki ninja zx-10r fuel filter clogged

- Kawasaki ninja zx-10r fuel injector clogged

- Kawasaki ninja zx-10r fuel injector O-ring damage

- Kawasaki ninja zx-10r fuel injector trouble

- Kawasaki ninja zx-10r fuel line clogged

- Kawasaki ninja zx-10r fuel poor quality or incorrect

- Kawasaki ninja zx-10r fuel pressure regulator trouble

- Kawasaki ninja zx-10r fuel pressure too low or too high

- Kawasaki ninja zx-10r fuel pump bearings may wear. Replace the fuel pump

- Kawasaki ninja zx-10r fuel pump not operating

- Kawasaki ninja zx-10r fuel pump operates intermittently and often DFI fuse blows

- Kawasaki ninja zx-10r fuel pump relay trouble

- Kawasaki ninja zx-10r fuel pump trouble

- Kawasaki ninja zx-10r fuel/air mixture incorrect

- Kawasaki ninja zx-10r fuel/air mixture incorrect

- Kawasaki ninja zx-10r gear position sensor, starter lockout or side stand switch trouble

- Kawasaki ninja zx-10r inspect and repair or replace

- Kawasaki ninja zx-10r intake air pressure sensor trouble

- Kawasaki ninja zx-10r intake air temperature sensor trouble

- Kawasaki ninja zx-10r intake air temperature sensor trouble

- Kawasaki ninja zx-10r intermittent any DFI fault and its recovery

- Kawasaki ninja zx-10r little fuel in tank

- Kawasaki ninja zx-10r main throttle sensor trouble

- Kawasaki ninja zx-10r no or little fuel in tank

- Kawasaki ninja zx-10r poor acceleration

- Kawasaki ninja zx-10r spark plug burned or gap maladjusted

- Kawasaki ninja zx-10r spark plug dirty, broken or gap maladjusted

- Kawasaki ninja zx-10r spark plug incorrect

- Kawasaki ninja zx-10r spark weak

- Kawasaki ninja zx-10r stick coil shorted or not in good contact

- Kawasaki ninja zx-10r stick coil trouble

- Kawasaki ninja zx-10r subthrottle sensor trouble

- Kawasaki ninja zx-10r subthrottle valve actuator trouble

- Kawasaki ninja zx-10r throttle body assy dust seal damage

- Kawasaki ninja zx-10r throttle body assy holder loose

- Kawasaki ninja zx-10r throttle valves will not fully open

- Kawasaki ninja zx-10r unstable (rough) idling

- Kawasaki ninja zx-10r unstable fuel pressure

- Kawasaki ninja zx-10r vacuum hose

- Kawasaki ninja zx-10r vehicle-down sensor trouble

- Kawasaki ninja zx-10r water or foreign matter in fuel Change fuel

- Kawasaki ninja zx-10r water temperature sensor trouble

Fault problems that can occur with yourKawasaki Ninja ZX-10Rmotorcycle engine is a blown head gasket. This can cause your engine to overheat and possibly crack the cylinder heads. In this case, it is best to take your Kawasaki Ninja ZX-10R motorcycle to a professional mechanic to have it checked out. Another common problem is with the carburetor. The carburetor is the part of your motorcycle that mixes air and fuel to create the combustion needed to power the engine.

Possible Failure Types :

- Strange Kawasaki Ninja ZX-10R engine noise.

- Kawasaki Ninja ZX-10R fog from engine.

- Strange Kawasaki Ninja ZX-10R engine noise.

- Kawasaki Ninja ZX-10R Vibrations and Rattling

- Kawasaki Ninja ZX-10R Loud Acceleration

- Kawasaki Ninja ZX-10R rusty exhaust

- Kawasaki Ninja ZX-10R blockages in exhaust pipe

- Kawasaki Ninja ZX-10R wear and tear exhaust

Kawasaki Heavy Industries was started in 1878, as a producer of maritime equipment and vessels. Kawasaki began motorcycle manufacturing in the late 1960’s and today, their bikes are famous for being nearly bulletproof, and many of their models being friendly for new riders.

Check other Kawasaki fault codes.

Common abbreviations and their meanings below:

ABS: Anti-Lock Braking System ACR: Automatic Compression Release AFR: Air Fuel Ratio AIS: Active Intake Solenoid ATS: Air Temperature Sensor BAS: Bank Angle Sensor BCM: Body Control Module CAN: Controller Area Network CCM: Cruise Control Module CKP: Crank Position Sensor DLC: Datalink Connector DTC: Diagnostic Trouble Codes ECM: Electronic Control Module ECT: Engine Coolant Temperature ECU: Electronic Control Unit EFI: Electronic Fuel Injection EFP: Electronic Fuel Pump ET: Engine Temperature sensor FI: Fuel Injectors FPR: Fuel Pressure Regulator H-DSSS: Harley-Davidson® Smart Security System HCU: Hydraulic Control Unit, ABS HFSM: Hands Free Security Module HO2S: Heated Oxygen Sensor IAC: Idle Air Control actuator IAT: Intake Air Temperature sensor ICM: Ignition Control Module IMAP: MAP + IAT in one unit ISS: Ion Sensing System JSS: Jiffy Stand Sensor LHCM: Left Hand Control Module MAP: Manifold Absolute Pressure sensor MHR: Right Hand Control Module RCM: Reverse Control Module TCA: Throttle Control Actuator TGS: Twist Grip Sensor TMAP: Intake Air Temperature / Manifold Absolute Pressure equipment TPS: Throttle Position Sensor TSM / TSSM: (Turn Signal / Turn Signal Security Module) VE: Volume Efficiency VIN: Vehicle Identification Number VSS: Vehicle Speed Sensor WSS: Wheel Speed Sensor

These abbreviations, and the accompanying list of trouble codes, can be a

great start when your Kawasaki check engine light comes on. As mentioned

above, if you are not comfortable with electrical diagnostic work, a dealership or qualified

technician can offer assistance. Please keep in mind that even though you have the ability to

clear a DTC using the onboard diagnostic feature, you shouldn’t clear the code prior to your

service appointment. Let the technician view and clear the codes as they troubleshoot the issue.

Kawasaki and logo are registered trademarks of Kawasaki. We are fan of MOTORCYCLES ! We love them.

Motorcycle electrical systems are very complex to fix it, check with your motorcycle diagnosis tool for the fault code and start motorcycle troubleshooting process.Some bike problems require professional troubleshooting and repair. However, there are many issues that you can easily fix on your own.

About Us | Contact | Privacy

Copyright 2022 — © MotorcycleTroubleshooting.com

#1

vik

- Пол:Мужчина

- Страна:РФ

- Город:Мск

- Мото:zxr

Отправлено 15 Март 2014 — 10:33

Помогите кто реально знает как переключить.

В сервис мануале написано переключить в режим одометра, после чего зажать и удерживать нажатыми обе кнопки на приборке, но так включается только меню настройки блинкера, а в пользовательском мануале написано что таким образом как раз настраивается блинкер.

- Наверх

#2

vik

vik

- Пол:Мужчина

- Страна:РФ

- Город:Мск

- Мото:zxr

Отправлено 16 Март 2014 — 20:19

Помогите кто реально знает как переключить.

В сервис мануале написано переключить в режим одометра, после чего зажать и удерживать нажатыми обе кнопки на приборке, но так включается только меню настройки блинкера, а в пользовательском мануале написано что таким образом как раз настраивается блинкер.

Блин, неужели вообще никто не в курсе?

- Наверх

#3

max232

max232

- Пол:Мужчина

- Страна:Россия

- Город:Елец, Липецкая область

- Мото:zx-10r `08

Отправлено 16 Март 2014 — 20:58

Блин, неужели вообще никто не в курсе?

В общем там нет никаких проблем:

включить зажигание

переключить приборку в режим одометра

нажать две кнопки одновременно и удерживать более 2 секунд

- Наверх

#4

vik

vik

- Пол:Мужчина

- Страна:РФ

- Город:Мск

- Мото:zxr

Отправлено 17 Март 2014 — 08:45

В общем там нет никаких проблем:

включить зажигание

переключить приборку в режим одометра

нажать две кнопки одновременно и удерживать более 2 секунд

Я знаю что так написано в сервис мануале, но в том то и дело что таким образом включается настройка блинкера. И практически и в пользовательском мануале так написано

- Наверх

#5

max232

max232

- Пол:Мужчина

- Страна:Россия

- Город:Елец, Липецкая область

- Мото:zx-10r `08

Отправлено 17 Март 2014 — 14:11

Я знаю что так написано в сервис мануале, но в том то и дело что таким образом включается настройка блинкера. И практически и в пользовательском мануале так написано

Для входа в режим считываня ошибки необходимо чтобы ошибка имела место быть. Это является необходимым условием для входа в режим считывания ошибок.

В режим «гонка» переключить получилось, спасибо.

Загорелась после экспериментов ))

Если судить по твоему посту из другой ветки, то ты недоговариваешь о причине возникновения проблемы.

Есть еще вероятность, что неисправность возникла в самой системе диагностики и теперь она неисправна.

- Наверх

#6

vik

vik

- Пол:Мужчина

- Страна:РФ

- Город:Мск

- Мото:zxr

Отправлено 17 Март 2014 — 14:46

Для входа в режим считываня ошибки необходимо чтобы ошибка имела место быть. Это является необходимым условием для входа в режим считывания ошибок.

Если судить по твоему посту из другой ветки, то ты недоговариваешь о причине возникновения проблемы.

Есть еще вероятность, что неисправность возникла в самой системе диагностики и теперь она неисправна.

Горит красная лампа и FI, значит ошибка есть. Но после описанной выше манипуляции с приборкой, номер ошибки не отображается.

Более того, я не могу понять как одними и теми же действиями может настраиваться и блинкер и выводиться номер ошибки? В пользовательском мануале написано: включить зажигание, верхней кнопкой превести в режим одометра, после чего нажать и удерживать обе кнопки и включится настройка блинкера тахометра. И это работает, именно это и происходит после этих манипуляций!

А в сервис мануале написано сделать то же самое чтобы посмотреть номер ошибки! Я допускаю что при выполнении одних и тех же действий если всё ок, то настраивается блинкер, а если есть ошибка, то происходит переход в режим диагностики, но возможно, что есть какая-то фишка, например ещё что-то нажать. Я знаю что на предыдущих нинзях работает 100%, видел в ютубе, а на 11-13 год роликов нет, вот и спрашиваю кто-то сам переключал или присутствовал при этом чтобы быть точно уверенным в том что это работает. Или может у «американцев» нет сервис режима или включается по-другому.

- Наверх

#7

max232

max232

- Пол:Мужчина

- Страна:Россия

- Город:Елец, Липецкая область

- Мото:zx-10r `08

Отправлено 17 Март 2014 — 14:51

Горит красная лампа и FI, значит ошибка есть. Но после описанной выше манипуляции с приборкой, номер ошибки не отображается.

Более того, я не могу понять как одними и теми же действиями может настраиваться и блинкер и выводиться номер ошибки? В пользовательском мануале написано: включить зажигание, верхней кнопкой превести в режим одометра, после чего нажать и удерживать обе кнопки и включится настройка блинкера тахометра. И это работает, именно это и происходит после этих манипуляций!

А в сервис мануале написано сделать то же самое чтобы посмотреть номер ошибки! Я допускаю что при выполнении одних и тех же действий если всё ок, то настраивается блинкер, а если есть ошибка, то происходит переход в режим диагностики, но возможно, что есть какая-то фишка, например ещё что-то нажать. Я знаю что на предыдущих нинзях работает 100%, видел в ютубе, а на 11-13 год роликов нет, вот и спрашиваю кто-то сам переключал или присутствовал при этом чтобы быть точно уверенным в том что это работает. Или может у «американцев» нет сервис режима или включается по-другому.

алгоритм тот же то для блинкера что для режима считывания ошибок.

Предположение твое правильное, все зависит от наличия в накопителе ошибок.

Вероятно причина коснулась схемы диагностики. Из моих предположений:

-повреждена шина CAN

-приборку вскрывали и что-то накорячили.

- Наверх

#8

vik

vik

- Пол:Мужчина

- Страна:РФ

- Город:Мск

- Мото:zxr

Отправлено 17 Март 2014 — 16:20

алгоритм тот же то для блинкера что для режима считывания ошибок.

Предположение твое правильное, все зависит от наличия в накопителе ошибок.

Вероятно причина коснулась схемы диагностики. Из моих предположений:

-повреждена шина CAN

-приборку вскрывали и что-то накорячили.

Соответственно если приборкуне трогали, и провода целы, тгорот ошибка, но в режим диагностики не переходит, то ошибки нет, и проблема в блоке управления который показывает ошибку.

алгоритм тот же то для блинкера что для режима считывания ошибок.

Предположение твое правильное, все зависит от наличия в накопителе ошибок.

Вероятно причина коснулась схемы диагностики. Из моих предположений:

-повреждена шина CAN

-приборку вскрывали и что-то накорячили.

Соответственно если приборкуне трогали, и провода целы, тгорот ошибка, но в режим диагностики не переходит, то ошибки нет, и проблема в блоке управления который показывает ошибку.

- Наверх

#9

max232

max232

- Пол:Мужчина

- Страна:Россия

- Город:Елец, Липецкая область

- Мото:zx-10r `08

Отправлено 18 Март 2014 — 13:24

Соответственно если приборкуне трогали, и провода целы, тгорот ошибка, но в режим диагностики не переходит, то ошибки нет, и проблема в блоке управления который показывает ошибку.

Попробуй сделать тестовую поездку на мотоцикле. Дело в том что ошибки после устранения неисправности проподают не сразу а только после короткой поездки.

- Наверх

#10

Pasis

Pasis

- Пол:Мужчина

- Страна:Россия

- Город:Ковров

- Мото:Suzuki GSXR 1100 Turbo GSXR 750 Turbo

Отправлено 18 Март 2014 — 15:24

Лампа загорелась после того как я прошил мозги, отключил ограничитель скорости и залил евро карту зажигания в сша мозги.

Недавно скачал прошивку из мозгов, еще раз все проверил, все в норме, на всякий случай перезалил прошивку заново. Вот отправил ему мозги обратно, проверить.

Имхо тоже нужно тест драйв сделать. При прошивке что то повредиться не могло, ибо эту операцию много раз делали уже и у всех все хорошо.

- Наверх

#11

max232

max232

- Пол:Мужчина

- Страна:Россия

- Город:Елец, Липецкая область

- Мото:zx-10r `08

Отправлено 18 Март 2014 — 15:34

Вот еще что попробуй: намеренно запиши в накопитель ошибку. Например сними фишку с привода иксапа и заведи мотор.

Затем попробуй войти в режим диагностики.

Отпиши что получилось

- Наверх

#12

vik

vik

- Пол:Мужчина

- Страна:РФ

- Город:Мск

- Мото:zxr

Отправлено 18 Март 2014 — 20:00

Вот еще что попробуй: намеренно запиши в накопитель ошибку. Например сними фишку с привода иксапа и заведи мотор.

Затем попробуй войти в режим диагностики.

Отпиши что получилось

Я пробовал проехаться по паркингу, метров сто проехал, правда скоростьбыла максимум км двадцать, может нужно быстрее разогнаться.

Я пробовал отсоединить датчик температуры на впуске на заведёном на холостых, после этого в диагностику всё-равно не переключался. Кроме блока управления, бензонасоса и датчика температуры я ничего не отключал, всё это подключил обратно, провода целы, приборку не трогал. Уот так уот ))

- Наверх

#13

vik

vik

- Пол:Мужчина

- Страна:РФ

- Город:Мск

- Мото:zxr

Отправлено 22 Март 2014 — 21:49

Может пригодится кому: переключение в режим диагностики осуществляется нажатием и удержанием в течение двух секунд в режиме одометра ОДНОЙ верхней кнопки.

Кроме этого некоторые ошибки отображаются только при работающем двигателе!

- Наверх

#14

Сергей BSV

Сергей BSV

-

- Читатели

- 3 сообщений

-

Вконтакте:

- Пол:Мужчина

- Страна:Россия

- Город:ЯНАО Пурпе

- Мото:ZX10-R 2011

Отправлено 02 Апрель 2014 — 20:30

Лампа загорелась после того как я прошил мозги, отключил ограничитель скорости и залил евро карту зажигания в сша мозги.

Недавно скачал прошивку из мозгов, еще раз все проверил, все в норме, на всякий случай перезалил прошивку заново. Вот отправил ему мозги обратно, проверить.Имхо тоже нужно тест драйв сделать. При прошивке что то повредиться не могло, ибо эту операцию много раз делали уже и у всех все хорошо.

Приветствую! Подскажите, я здесь новичок. Зимой приобрел zx10r 11года с америки. Почитал, что это самый мощный стоковый мот. Но теперь узнал, что для рынка сша он задушен. То есть 200л.с. он не имеет? Живу в ЯНАО , у нас здесь туго с обслуживанием и настройками.

- Наверх

#15

86 rus

86 rus

- Пол:Мужчина

- Страна:Россия

- Город:Сургут

- Мото:Kawasaki ZX-10 08г

Отправлено 03 Апрель 2014 — 06:25

Да погода не позволяет прохватить по дороге и у нас в г.Сургут снег, попробуй на подкат поставить и на подкате разогнись до 299 поклацай передачи какое то время может уйдет ошибка раз твой тестовый заезд короткий не скинул ошибку.Пробуй с АКБ скинуть клеммы ненадолго может как то это поможет.

- Наверх

#16

max232

max232

- Пол:Мужчина

- Страна:Россия

- Город:Елец, Липецкая область

- Мото:zx-10r `08

Отправлено 03 Апрель 2014 — 08:02

Приветствую! Подскажите, я здесь новичок. Зимой приобрел zx10r 11года с америки. Почитал, что это самый мощный стоковый мот. Но теперь узнал, что для рынка сша он задушен. То есть 200л.с. он не имеет? Живу в ЯНАО , у нас здесь туго с обслуживанием и настройками.

на эу тему на нашем сайте было сломано много копий, а точнее на 2 темы

— что в мото 200 сил

— какие мотоциклы душены а какие нет

Я лично езжу с душенным американским блоком, как мне утверждают все московские специалисты.

Я вот думаю, мож раздушить ?:)

- Наверх

#17

vik

vik

- Пол:Мужчина

- Страна:РФ

- Город:Мск

- Мото:zxr

Отправлено 03 Апрель 2014 — 08:30

Да погода не позволяет прохватить по дороге и у нас в г.Сургут снег, попробуй на подкат поставить и на подкате разогнись до 299 поклацай передачи какое то время может уйдет ошибка раз твой тестовый заезд короткий не скинул ошибку.Пробуй с АКБ скинуть клеммы ненадолго может как то это поможет.

Вопрос решон, проблема была в подсевшем акб.

- Наверх

#18

vik

vik

- Пол:Мужчина

- Страна:РФ

- Город:Мск

- Мото:zxr

Отправлено 03 Апрель 2014 — 08:34

на эу тему на нашем сайте было сломано много копий, а точнее на 2 темы

— что в мото 200 сил

— какие мотоциклы душены а какие нетЯ лично езжу с душенным американским блоком, как мне утверждают все московские специалисты.

Я вот думаю, мож раздушить ?:)

Я думаю в скором времени будет точно понятно есть разница или нет, в октябре была сравнительная поездка с другим мото, как потеплеет повторим её с уже прошитым блоком управления, второй мот за зиму не притерпел никаких изменений, так что я думаю если разница есть, то она будет видна.

- Наверх

#19

AleksM

AleksM

- Пол:Мужчина

- Страна:россия

- Город:ARMAVIR

- Мото:ктм rc8 r gsf 600 zx9r 99г fgr 1200 gsx r 1000 04г cbr 929 gsx 1000r 07г cbr 600rr gsx 1000 10г ktm rc8 08г ZX-10R 08г zx10r 12г

Отправлено 03 Апрель 2014 — 13:07

Вопрос решон, проблема была в подсевшем акб.

и на тему подсевшего акб была тема на форуме

- Наверх

#20

Gibsman

Gibsman

-

- Members

- 8 сообщений

- Пол:Мужчина

- Страна:Беларусь

- Город:Витебск

- Мото:ZX10R

Отправлено 29 Июль 2014 — 11:38

Я думаю в скором времени будет точно понятно есть разница или нет, в октябре была сравнительная поездка с другим мото, как потеплеет повторим её с уже прошитым блоком управления, второй мот за зиму не притерпел никаких изменений, так что я думаю если разница есть, то она будет видна.

Была пробная поездка?

- Наверх

Думаю многие из вас, сталкивались с ситуацией, когда на приборной панели загоралась желтая лампочка двигателя и буквенная надпись OFF, правая часть экрана моргала. Это могло произойти по причинам не связанным с поломкой. Допустим, вы отсоединили разъёмы для замены воздушного фильтра, или чистки инжектора. После этого мотоцикл перестал нормально функционировать. Ниже я приведу несколько способов, как сбросить ошибки без специальных средств. Лично я испробовал всего один способ, и он сработал, в интернете есть видео о втором способе.

Первый способ (лично проверил, работает)

Необходимо обеспечить принудительное охлаждение любым подручным средством.

Мотоцикл поднять на задний подкат.

Шаг 1: Запустите двигатель более чем на 10 минут. (можно оставить работать на холостых)

Шаг 2: Поддерживайте обороты холостого хода более 30 секунд. (если во время выполнения первого пункта, мотоцикл всё время работал на холостых, этот пункт можно пропустить)

Шаг 3: Включите передачу, в течении 5 минут или более, необходимо поддерживать скорость 40 км/ч (25 миль/ч) или более.

Шаг 4: Выключите зажигание.

Повторить три раза.

Чтобы ДВС не сильно нагревался во время «Шаг 3» можно, переключится на шестую передачу, немного увеличить обороты, чтобы скорость была 45-47км/ч (это идеальное значение летом в жару), после этого начинайте отсчет времени. Запомните, скорость на приборной панели должна быть больше 40 км/ч на протяжении всего времени, иначе всё придётся повторять заново.

Совет: время и скорость всегда выберайте с запасом.

Второй способ (НЕ проверял):

Мотоцикл поставить на задний подкат.

Шаг 1: убедитесь, что включена 5-ая передача.

Шаг 2: убедитесь, что выключатель находится в рабочем положении.

Шаг 3: держите дроссельную заслонку широко открытой.

Шаг 4: включите зажигание, (но не двигатель).

Примерно через 5-8 секунд после включения зажигания при широко открытой дроссельной

заслонке код очистится. Выключите зажигание, затем снова включите его.

Этот способ есть в интернете можно найти на него видео, так как он проще можно попробовать начать с него.

Дополнение: В интернете на одном из форумов находил информацию, что данный способ работает для мотоциклов год выпуска которых начинается с 2016 года и у которых ЭБУ Митсубиси или Денсо.

Ninja ZX-10R

Ninja ZX-10R ABS

Motorcycle

Service Manual

Quick Reference Guide

This quick reference guide will assist you in locating a desired topic or procedure.

•Bend the pages back to match the black tab of the desired chapter number with the black tab on the edge at each table of contents page.

•Refer to the sectional table of contents for the exact pages to locate the specific topic required.

|

General Information |

1 |

j |

|

Periodic Maintenance |

2 |

j |

|

Fuel System (DFI) |

3 |

j |

|

Cooling System |

4 |

j |

|

Engine Top End |

5 |

j |

|

Clutch |

6 |

j |

|

Engine Lubrication System |

7 |

j |

|

Engine Removal/Installation |

8 |

j |

|

Crankshaft/Transmission |

9 |

j |

|

Wheels/Tires |

10 |

j |

|

Final Drive |

11 |

j |

|

Brakes |

12 |

j |

|

Suspension |

13 |

j |

|

Steering |

14 |

j |

|

Frame |

15 |

j |

|

Electrical System |

16 |

j |

|

Self-Diagnosis System |

17 |

j |

|

Appendix |

18 |

j |

Ninja ZX-10R

Ninja ZX-10R ABS

Motorcycle

Service Manual

All rights reserved. No parts of this publication may be reproduced, stored in a retrieval system, or transmitted in any form or by any means, electronic mechanical photocopying, recording or otherwise, without the prior written permission of Quality Assurance Division/Motorcycle & Engine Company/Kawasaki Heavy Industries, Ltd., Japan.

No liability can be accepted for any inaccuracies or omissions in this publication, although every possible care has been taken to make it as complete and accurate as possible.

The right is reserved to make changes at any time without prior notice and without incurring an obligation to make such changes to products manufactured previously. See your Motorcycle dealer for the latest information on product improvements incorporated after this publication.

All information contained in this publication is based on the latest product information available at the time of publication. Illustrations and photographs in this publication are intended for reference use only and may not depict actual model component parts.

|

© 2010 Kawasaki Heavy Industries, Ltd. |

4th Edition (0) : Aug. 7, 2012 |

LIST OF ABBREVIATIONS

|

A |

ampere(s) |

lb |

pound(s) |

|

ABDC |

after bottom dead center |

m |

meter(s) |

|

AC |

alternating current |

min |

minute(s) |

|

ATDC |

after top dead center |

N |

newton(s) |

|

BBDC |

before bottom dead center |

Pa |

pascal(s) |

|

BDC |

bottom dead center |

PS |

horsepower |

|

BTDC |

before top dead center |

psi |

pound(s) per square inch |

|

°C |

degree(s) Celsius |

r |

revolution |

|

DC |

direct current |

rpm |

revolution(s) per minute |

|

F |

farad(s) |

TDC |

top dead center |

|

°F |

degree(s) Fahrenheit |

TIR |

total indicator reading |

|

ft |

foot, feet |

V |

volt(s) |

|

g |

gram(s) |

W |

watt(s) |

|

h |

hour(s) |

Ω |

ohm(s) |

|

L |

liter(s) |

COUNTRY AND AREA CODES

|

AT |

Austria |

|

|

AU |

Australia |

|

|

BR |

Brazil |

|

|

CA |

Canada |

|

|

CAL |

California |

|

|

CH |

Switzerland |

|

|

DE |

Germany |

|

|

EUR |

Europe |

|

GB

PH SEA-B1

SEA-B2 US

WVTA (FULL H)

GB WVTA (FULL H)

WVTA (78.2 H)

United Kingdom Philippines

Southeast Asia B1 (with Evaporative Emission Control System)

Southeast Asia B2 United States

WVTA Model with Honeycomb Catalytic Converter (Full Power)

WVTA Model with Honeycomb Catalytic Converter (Left Side Traffic Full Power)

WVTA Model with Honeycomb Catalytic Converter (Restricted Power)

EMISSION CONTROL INFORMATION

To protect the environment in which we all live, Kawasaki has incorporated crankcase emission (1) and exhaust emission (2) control systems in compliance with applicable regulations of the United States Environmental Protection Agency and California Air Resources Board. Additionally, Kawasaki has incorporated an evaporative emission control system (3) in compliance with applicable regulations of the California Air Resources Board on vehicles sold in California only.

1. Crankcase Emission Control System

This system eliminates the release of crankcase vapors into the atmosphere. Instead, the vapors are routed through an oil separator to the intake side of the engine. While the engine is operating, the vapors are drawn into combustion chamber, where they are burned along with the fuel and air supplied by the fuel injection system.

2. Exhaust Emission Control System

This system reduces the amount of pollutants discharged into the atmosphere by the exhaust of this motorcycle. The fuel, ignition, and exhaust systems of this motorcycle have been carefully designed and constructed to ensure an efficient engine with low exhaust pollutant levels.

The exhaust system of this model motorcycle manufactured primarily for sale in California includes a catalytic converter system.

3. Evaporative Emission Control System

Vapors caused by fuel evaporation in the fuel system are not vented into the atmosphere. Instead, fuel vapors are routed into the running engine to be burned, or stored in a canister when the engine is stopped. Liquid fuel is caught by a vapor separator and returned to the fuel tank.

The Clean Air Act, which is the Federal law covering motor vehicle pollution, contains what is commonly referred to as the Act’s “tampering provisions”.

“Sec. 203(a) The following acts and the causing thereof are prohibited…

(3)(A) for any person to remove or render inoperative any device or element of design installed on or in a motor vehicle or motor vehicle engine in compliance with regulations under this title prior to its sale and delivery to the ultimate purchaser, or for any manufacturer or dealer knowingly to remove or render inoperative any such device or element of design after such sale and delivery to the ultimate purchaser.

(3)(B) for any person engaged in the business of repairing, servicing, selling, leasing, or trading motor vehicles or motor vehicle engines, or who operates a fleet of motor vehicles knowingly to remove or render inoperative any device or element of design installed on or in a motor vehicle or motor vehicle engine in compliance with regulations under this title following its sale and delivery to the ultimate purchaser…”

NOTE

○The phrase “remove or render inoperative any device or element of design” has been generally interpreted as follows.

1.Tampering does not include the temporary removal or rendering inoperative of devices or elements of design in order to perform maintenance.

2.Tampering could include.

a.Maladjustment of vehicle components such that the emission standards are exceeded.

b.Use of replacement parts or accessories which adversely affect the performance or durability of the motorcycle.

c.Addition of components or accessories that result in the vehicle exceeding the standards.

d.Permanently removing, disconnecting, or rendering inoperative any component or element of design of the emission control systems.

WE RECOMMEND THAT ALL DEALERS OBSERVE THESE PROVISIONS OF FEDERAL LAW, THE VIOLATION OF WHICH IS PUNISHABLE BY CIVIL PENALTIES NOT EXCEEDING $10 000 PER VIOLATION.

TAMPERING WITH NOISE CONTROL SYSTEM PROHIBITED

Federal law prohibits the following acts or the causing thereof. (1) The removal or rendering inoperative by any person other than for purposes of maintenance, repair, or replacement, of any device or element of design incorporated into any new vehicle for the purpose of noise control prior to its sale or delivery to the ultimate purchaser or while it is in use, or (2) the use of the vehicle after such device or element of design has been removed or rendered inoperative by any person.

Among those acts presumed to constitute tampering are the acts listed below.

•Replacement of the original exhaust system or muffler with a component not in compliance with Federal regulations.

•Removal of the muffler(s) or any internal portion of the muffler(s).

•Removal of the air box or air box cover.

•Modifications to the muffler(s) or air intake system by cutting, drilling, or other means if such modifications result in increased noise levels.

Foreword

This manual is designed primarily for use by trained mechanics in a properly equipped shop. However, it contains enough detail and basic information to make it useful to the owner who desires to perform his own basic maintenance and repair work. A basic knowledge of mechanics, the proper use of tools, and workshop procedures must be understood in order to carry out maintenance and repair satisfactorily. Whenever the owner has insufficient experience or doubts his ability to do the work, all adjustments, maintenance, and repair should be carried out only by qualified mechanics.

In order to perform the work efficiently and to avoid costly mistakes, read the text, thoroughly familiarize yourself with the procedures before starting work, and then do the work carefully in a clean area. Whenever special tools or equipment are specified, do not use makeshift tools or equipment. Precision measurements can only be made if the proper instruments are used, and the use of substitute tools may adversely affect safe operation.

For the duration of the warranty period, we recommend that all repairs and scheduled maintenance be performed in accordance with this service manual. Any owner maintenance or repair procedure not performed in accordance with this manual may void the warranty.

To get the longest life out of your vehicle.

•Follow the Periodic Maintenance Chart in the Service Manual.

•Be alert for problems and non-scheduled maintenance.

•Use proper tools and genuine Kawasaki Motorcycle parts. Special tools, gauges, and testers that are necessary when servicing Kawasaki motorcycles are introduced by the Service Manual. Genuine parts provided as spare parts are listed in the Parts Catalog.

•Follow the procedures in this manual carefully. Don’t take shortcuts.

•Remember to keep complete records of maintenance and repair with dates and any new parts installed.

How to Use This Manual

In this manual, the product is divided into its major systems and these systems make up the manual’s chapters. The Quick Reference

Guide shows you all of the product’s system and assists in locating their chapters. Each chapter in turn has its own comprehensive Table of Contents.

For example, if you want ignition coil information, use the Quick Reference Guide to locate the Electrical System chapter. Then, use the Table of Contents on the first page of the chapter to find the Ignition Coil section.

Whenever you see symbols, heed their instructions! Always follow safe operating and maintenance practices.

DANGER indicates a hazardous situation which, if not avoided, will result in death or serious injury.

WARNING indicates a hazardous situation which, if not avoided, could result in death or serious injury.

NOTICE

NOTICE is used to address practices not related to personal injury.

This manual contains four more symbols which will help you distinguish different types of information.

NOTE

○This note symbol indicates points of particular interest for more efficient and convenient operation.

•Indicatesdone. a procedural step or work to be ○Indicates a procedural sub-step or how to do the work of the procedural step it follows. It

also precedes the text of a NOTE.

In most chapters an exploded view illustration of the system components follows the Table of Contents. In these illustrations you will find the instructions indicating which parts require specified tightening torque, oil, grease or a locking agent during assembly.

GENERAL INFORMATION 1-1

General Information |

|||

|

Table of Contents |

|||

|

1 |

|||

|

Before Servicing |

1-2 |

||

|

Model Identification………………………………………………………………………………………………….. |

1-7 |

||

|

General Specifications……………………………………………………………………………………………… |

1-11 |

||

|

Technical Information-Sport-Kawasaki TRaction Control System (S-KTRC) ……………………. |

1-14 |

||

|

Technical Information-Power Mode ……………………………………………………………………………. |

1-17 |

||

|

Technical Information-Kawasaki Intelligent anti-lock Brake System (KIBS/ZX1000K model |

|||

|

only)……………………………………………………………………………………………………………………. |

1-19 |

||

|

Technical Information — Electronic Steering Damper (ESD/ZX1000JD/KD models) ………….. |

1-23 |

||

|

Unit Conversion Table ……………………………………………………………………………………………… |

1-26 |

1-2 GENERAL INFORMATION

Before Servicing

Before starting to perform an inspection service or carry out a disassembly and reassembly operation on a motorcycle, read the precautions given below. To facilitate actual operations, notes, illustrations, photographs, cautions, and detailed descriptions have been included in each chapter wherever necessary. This section explains the items that require particular attention during the removal and reinstallation or disassembly and reassembly of general parts.

Especially note the following.

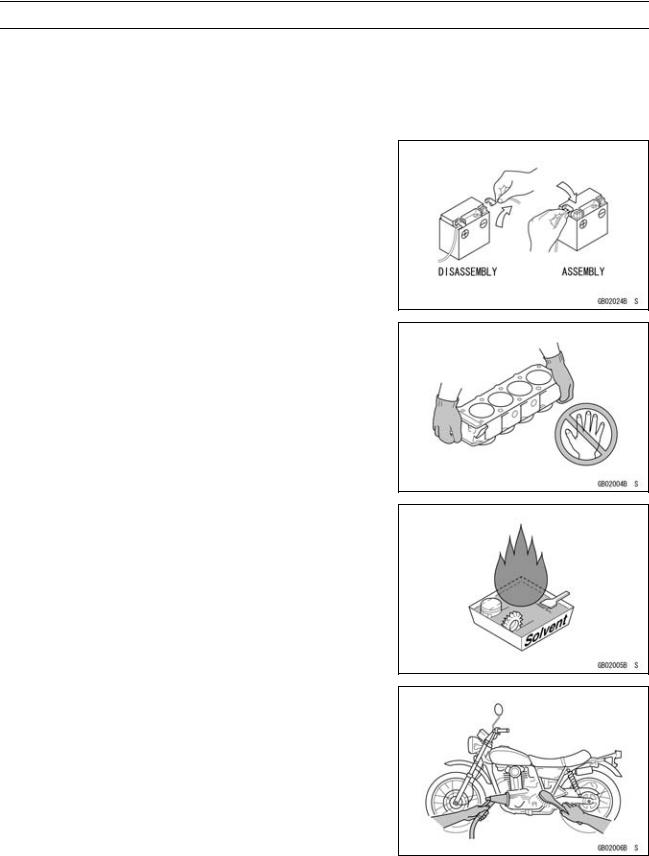

Battery Ground

Before completing any service on the motorcycle, disconnect the battery cables from the battery to prevent the engine from accidentally turning over. Disconnect the ground cable (–) first and then the positive (+). When completed with the service, first connect the positive (+) cable to the positive (+) terminal of the battery then the negative (–) cable to the negative terminal.

Edges of Parts

Lift large or heavy parts wearing gloves to prevent injury from possible sharp edges on the parts.

Solvent

Use a high flash-point solvent when cleaning parts. High flash-point solvent should be used according to directions of the solvent manufacturer.

Cleaning Vehicle before Disassembly

Clean the vehicle thoroughly before disassembly. Dirt or other foreign materials entering into sealed areas during vehicle disassembly can cause excessive wear and decrease performance of the vehicle.

GENERAL INFORMATION 1-3

Before Servicing

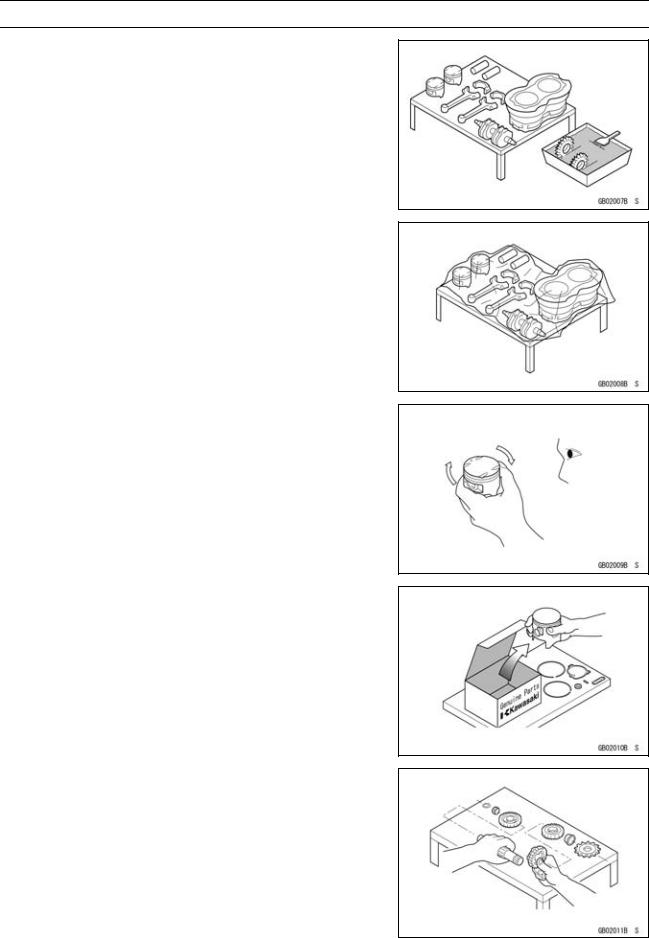

Arrangement and Cleaning of Removed Parts

Disassembled parts are easy to confuse. Arrange the parts according to the order the parts were disassembled and clean the parts in order prior to assembly.

Storage of Removed Parts

After all the parts including subassembly parts have been cleaned, store the parts in a clean area. Put a clean cloth or plastic sheet over the parts to protect from any foreign materials that may collect before re-assembly.

Inspection

Reuse of worn or damaged parts may lead to serious accident. Visually inspect removed parts for corrosion, discoloration, or other damage. Refer to the appropriate sections of this manual for service limits on individual parts. Replace the parts if any damage has been found or if the part is beyond its service limit.

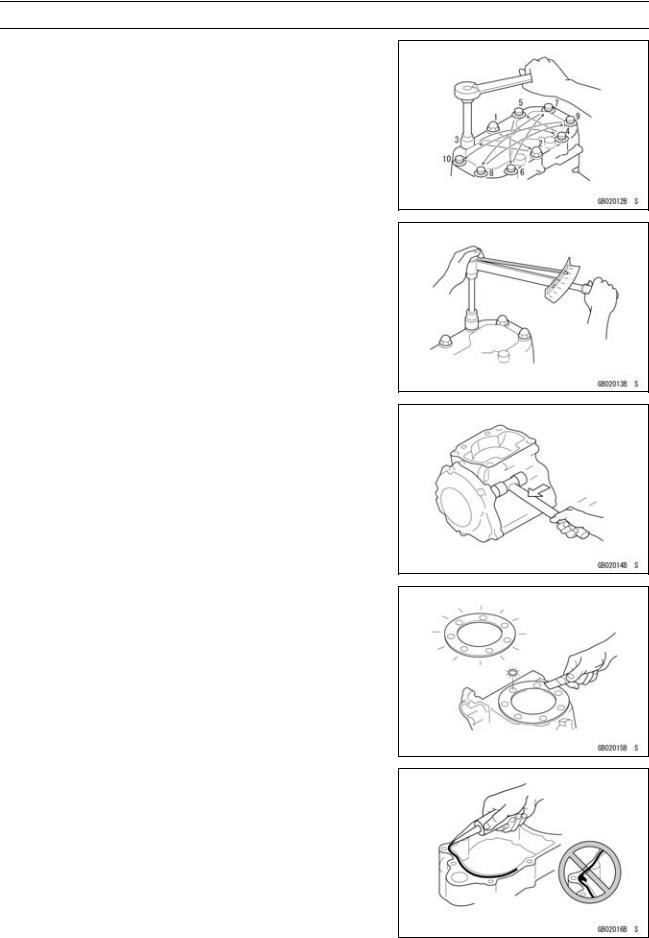

Replacement Parts

Replacement parts must be KAWASAKI genuine or recommended by KAWASAKI. Gaskets, O-rings, oil seals, grease seals, circlips, cotter pins or self-locking nuts must be replaced with new ones whenever disassembled.

Assembly Order

In most cases assembly order is the reverse of disassembly, however, if assembly order is provided in this Service Manual, follow the procedures given.

1-4 GENERAL INFORMATION

Before Servicing

Tightening Sequence

Generally, when installing a part with several bolts, nuts, or screws, start them all in their holes and tighten them to a snug fit. Then tighten them according to the specified sequence to prevent case warpage or deformation which can lead to malfunction. Conversely when loosening the bolts, nuts, or screws, first loosen all of them by about a quarter turn and then remove them. If the specified tightening sequence is not indicated, tighten the fasteners alternating diagonally.

Tightening Torque

Incorrect torque applied to a bolt, nut, or screw may lead to serious damage. Tighten fasteners to the specified torque using a good quality torque wrench.

Force

Use common sense during disassembly and assembly, excessive force can cause expensive or hard to repair damage. When necessary, remove screws that have a non -permanent locking agent applied using an impact driver. Use a plastic-faced mallet whenever tapping is necessary.

Gasket, O-ring

Hardening, shrinkage, or damage of both gaskets and O-rings after disassembly can reduce sealing performance. Remove old gaskets and clean the sealing surfaces thoroughly so that no gasket material or other material remains. Install the new gaskets and replace the used O-rings when re-assembling.

Liquid Gasket, Non-permanent Locking Agent

For applications that require Liquid Gasket or a Non-permanent Locking Agent, clean the surfaces so that no oil residue remains before applying liquid gasket or non-permanent locking agent. Do not apply them excessively. Excessive application can clog oil passages and cause serious damage.

GENERAL INFORMATION 1-5

Before Servicing

Press

For items such as bearings or oil seals that must be pressed into place, apply small amount of oil to the contact area. Be sure to maintain proper alignment and use smooth movements when installing.

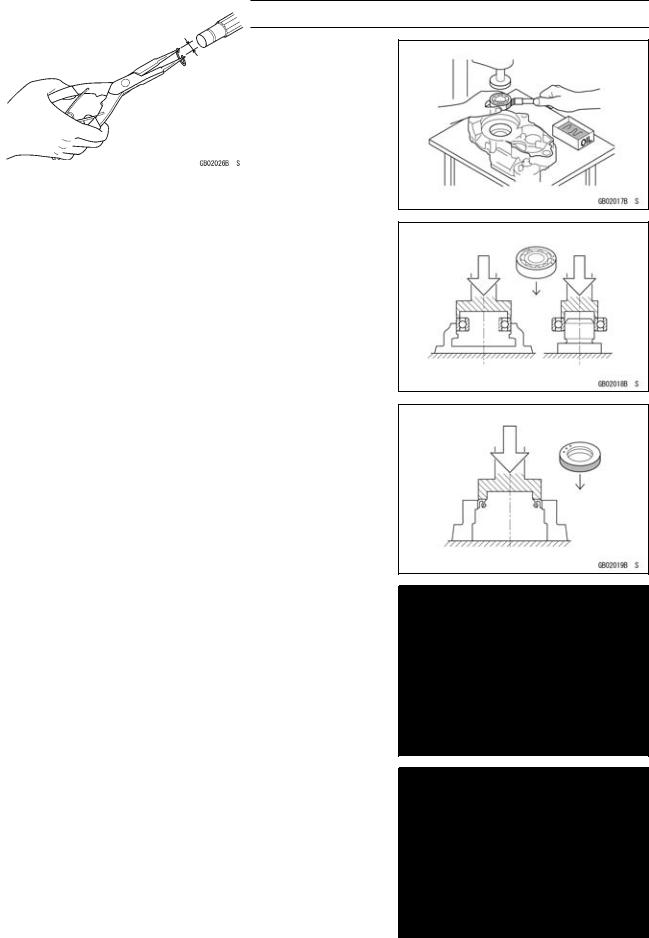

Ball Bearing and Needle Bearing

Do not remove pressed ball or needle unless removal is absolutely necessary. Replace with new ones whenever removed. Press bearings with the manufacturer and size marks facing out. Press the bearing into place by putting pressure on the correct bearing race as shown.

Pressing the incorrect race can cause pressure between the inner and outer race and result in bearing damage.

Oil Seal, Grease Seal

Do not remove pressed oil or grease seals unless removal is necessary. Replace with new ones whenever removed. Press new oil seals with manufacture and size marks facing out. Make sure the seal is aligned properly when installing.

Apply specified grease to the lip of seal before installing the seal.

Circlips, Cotter Pins

Replace the circlips or cotter pins that were removed with new ones. Take care not to open the clip excessively when installing to prevent deformation.

1-6 GENERAL INFORMATION

Before Servicing

Lubrication

It is important to lubricate rotating or sliding parts during assembly to minimize wear during initial operation. Lubrication points are called out throughout this manual, apply the specific oil or grease as specified.

Direction of Engine Rotation

When rotating the crankshaft by hand, the free play amount of rotating direction will affect the adjustment. Rotate the crankshaft to positive direction (clockwise viewed from output side).

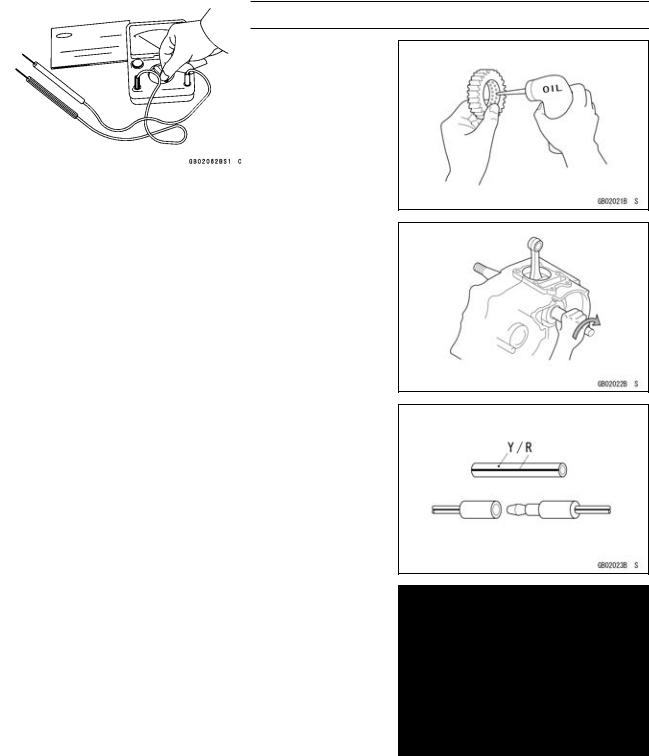

Electrical Leads

A two-color lead is identified first by the primary color and then the stripe color. Unless instructed otherwise, electrical leads must be connected to those of the same color.

Instrument

Use a meter that has enough accuracy for an accurate measurement. Read the manufacture’s instructions thoroughly before using the meter. Incorrect values may lead to improper adjustments.

GENERAL INFORMATION 1-7

Model Identification

ZX1000JB (US and CA Models) Left Side View

ZX1000JB (US and CA Models) Right Side View

1-8 GENERAL INFORMATION

Model Identification

ZX1000JB (EUR Models) Left Side View

ZX1000JB (EUR Models) Right Side View

GENERAL INFORMATION 1-9

Model Identification

ZX1000KB (US and CA Models) Left Side View

ZX1000KB (US and CA Models) Right Side View

1-10 GENERAL INFORMATION

Model Identification

ZX1000KB (EUR Models) Left Side View

ZX1000KB (EUR Models) Right Side View

|

Frame Number |

Engine Number |

|

|

GENERAL INFORMATION 1-11 |

|

General Specifications |

|

|

Items |

ZX1000JB JD/KB KD |

|

Dimensions |

|

|

Overall Length |

2 075 mm (81.69 in.) |

|

Overall Width |

715 mm (28.1 in.) |

|

Overall Height |

1 115 mm (43.90 in.) |

|

Wheelbase |

1 425 mm (56.10 in.) |

|

Road Clearance |

135 mm (5.31 in.) |

|

Seat Height |

813 mm (32.0 in.) |

|

Curb Mass: |

|

|

(ZX1000J Model) |

198 kg (437 lb) |

|

Front |

103 kg (227 lb) |

|

Rear |

95 kg (209 lb) |

|

(ZX1000K Model) |

201 kg (443 lb) |

|

Front |

104 kg (229 lb) |

|

Rear |

97 kg (214 lb) |

|

Fuel Tank Capacity |

17 L (4.5 US gal) |

|

Performance |

|

|

Minimum Turning Radius |

3.4 m (11.2 ft) |

|

Engine |

|

|

Type |

4-stroke, DOHC, 4-cylinder |

|

Cooling System |

Liquid-cooled |

|

Bore and Stroke |

76.0 × 55.0 mm (3.0 × 2.2 in.) |

|

Displacement |

998 cm³ (60.9 cu in.) |

|

Compression Ratio |

13.0:1 |

|

Maximum Horsepower |

|

|

147.1 kW (200 PS) @13 000 r/min (rpm) |

|

|

(WVTA (78.2 H)) 78.2 kW (106 PS) @12 500 r/min (rpm) |

|

|

(SEA-B1/B2) 111 kW (151 PS) @10 000 r/min (rpm) |

|

|

(US, CA, CAL) – – – |

|

|

Maximum Torque |

112 N·m (11.4 kgf·m, 82.6 ft·lb) @11 500 r/min (rpm) |

|

(WVTA (78.2 H)) 78 N·m (8.0 kgf·m, 57.5 ft·lb) @5 200 r/min |

|

|

(rpm) |

|

|

(SEA-B1/B2) 106 N·m (10.8 kgf·m, 78.2 ft·lb) @10 000 r/min |

|

|

(rpm) |

|

|

(US, CA, CAL) – – – |

|

|

Fuel System |

FI (Fuel Injection), KEIHIN TTK47 × 4 |

|

Starting System |

Electric starter |

|

Ignition System |

Battery and coil (transistorized) |

|

Timing Advance |

Electronically advanced (IC igniter in ECU) |

|

Ignition Timing: |

|

|

( ZX1000JC/KC) |

10° BTDC @1 100 r/min (rpm) |

|

(ZX1000JD/KD) |

10° BTDC @1 100 r/min (rpm) 42.5° BTDC @10 500 r/min |

|

(rpm) |

|

|

Spark Plug |

NGK CR9EIA-9 |

|

Cylinder Numbering Method |

Left to right, 1-2-3-4 |

|

Firing Order |

1-2-4-3 |

1-12 GENERAL INFORMATION

General Specifications

|

Items |

ZX1000JB JD/KB KD |

|

Valve Timing: |

|

|

Intake: |

|

|

Open |

36° (BTDC) |

|

Close |

80° (ABDC) |

|

Duration |

296° |

|

Exhaust: |

|

|

Open |

74° (BBDC) |

|

Close |

39° (ATDC) |

|

Duration |

293° |

|

Lubrication System |

Forced lubrication (wet sump with oil cooler) |

|

Engine Oil: |

|

|

Type |

API SG, SH, SJ, SL or SM with JASO MA, MA1 or MA2 |

|

Viscosity |

SAE 10W-40 |

|

Capacity |

3.7 L (3.9 US qt) |

|

Drive Train |

|

|

Primary Reduction System: |

|

|

Type |

Gear |

|

Reduction Ratio |

1.681 (79/47) |

|

Clutch Type |

Wet multi disc |

|

Transmission: |

|

|

Type |

6-speed, constant mesh, return shift |

|

Gear Ratios: |

|

|

1st |

2.600 (39/15) |

|

2nd |

|

|

2.053 (39/19) |

|

|

3rd |

1.737 (33/19) |

|

4th |

1.571 (33/21) |

|

5th |

1.444 (26/18) |

|

6th |

1.348 (31/23) |

|

Final Drive System: |

|

|

Type |

Chain drive |

|

Reduction Ratio |

2.294 (39/17) |

|

Overall Drive Ratio |

5.197 @Top gear |

|

Frame |

|

|

Type |

Tubular, diamond |

|

Caster (Rake Angle) |

25° |

|

Trail |

107 mm (4.21 in.) |

|

Front Tire: |

|

|

Type |

Tubeless |

|

Size |

120/70 ZR17 M/C (58W) |

|

Rim Size |

J17M/C × MT3.50 |

|

Rear Tire: |

|

|

Type |

Tubeless |

|

Size |

190/55 ZR17 M/C (75W) |

|

Rim Size |

J17M/C × MT6.00 |

|

GENERAL INFORMATION 1-13 |

|

|

General Specifications |

|

|

Items |

ZX1000JB JD/KB KD |

|

Front Suspension: |

|

|

Type |

Telescopic fork (upside-down) |

|

Wheel Travel |

120 mm (4.72 in.) |

|

Rear Suspension: |

|

|

Type |

Swingarm (horizontal back-link) |

|

Wheel Travel |

140 mm (5.51 in.) |

|

Brake Type: |

|

|

Front |

Dual discs |

|

Rear |

Single disc |

|

Electrical Equipment |

|

|

Battery: |

|

|

(ZX1000J Model) |

12 V 6 Ah |

|

(ZX1000K Model) |

12 V 8.6 Ah |

|

Headlight: |

|

|

Type |

Semi-sealed beam |

|

Bulb: |

|

|

High |

12 V 55 W (quartz-halogen) × 2 |

|

Low |

12 V 55 W (quartz-halogen) |

|

Tail/Brake Light |

LED |

|

Alternator: |

|

|

Type |

Three-phase AC |

|

Rated Output |

30 A/14 V @5 000 r/min (rpm) |

Specifications are subject to change without notice, and may not apply to every country.

1-14 GENERAL INFORMATION

Technical Information-Sport-Kawasaki TRaction Control System (S-KTRC)

Overview

S-KTRC is a highly sophisticated system based on MotoGP racing technology. Unlike the KTRC system used on the GTR1400 ABS (Concours 14 ABS in N. America), which is designed to offer rider reassurance when traversing slippery surfaces, S-KTRC, is designed to maximize forward motion, allowing riding at the edge of traction.

The quickest acceleration requires a certain amount of slip, so in order to optimize traction, S-KTRC actually allows slip. The ideal slip ratio varies according to conditions. The system looks at a number of parameters to get an accurate real-time picture of what is going on: front and rear wheel speed (slippage), engine rpm, throttle position, slippage, acceleration, etc.

Using complex analysis, the system is able to predict when traction conditions are about to become unfavorable. By acting before slippage exceeds the range for optimal traction, drops in power can be minimized resulting in ultra-smooth operation.

There are three available modes that riders can set according to preference (and skill level). Each mode is able to accommodate a range of riding conditions. Of course, engine manageability is such that riders can opt to turn the system OFF without fear of making the bike uncontrollable.

By combining the setting with the power mode, the rider can choose various riding modes to suit the road conditions and riding skill.

The system becomes functional at 5 km/h (3.1 mph) or more. If a failure occurs in the system, the warning indicator light (yellow LED) and mode indicator symbol blink to let the rider know that the system stops functioning.

GENERAL INFORMATION 1-15

Technical Information-Sport-Kawasaki TRaction Control System (S-KTRC)

System Components

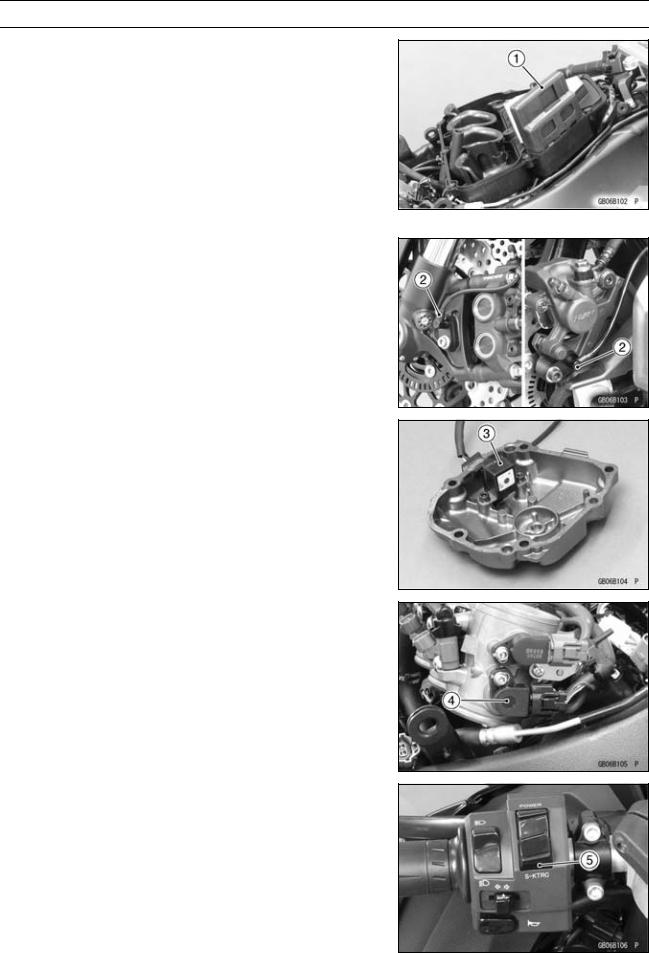

1. FI ECU

The FI ECU analyzes the motorcycle conditions based on the signals from the front/rear wheel rotation sensors and FI sensors (such as the crankshaft sensor and main throttle sensor), and controls engine power by reducing the number of ignition and retarding the ignition timing. The mode-switching signal is transmitted to the FI ECU by the CAN system via the meter ECU. If a failure occurs in the system, the FI ECU deactivates S-KTRC and displays the warning indication in the meter.

2. Wheel Rotation Sensor

The wheel rotation sensor converts front and rear wheel rotation speed to a pulse signal and transmits it to the FI ECU.

As for the KIBS (Kawasaki Intelligent anti-lock Brake System) equipped model, a pulse signal is transmitted via the KIBS ECU.

3. Crankshaft Sensor

The crankshaft sensor converts the engine speed to a pulse signal and transmits it to the FI ECU.

4. Main Throttle Sensor

The main throttle sensor converts the throttle position to a voltage signal and transmits it to the FI ECU.

5. S-KTRC Button

The mode-switching signal is transmitted to the meter ECU by depressing the S-KTRC button (0.3 0.4 sec.).

1-16 GENERAL INFORMATION

Technical Information-Sport-Kawasaki TRaction Control System (S-KTRC)

6. Multifunction Meter

The multifunction meter receives a mode-switching signal and displays the mode [A], and transmits it to the FI ECU by the CAN system.

When a failure occurs in the system, the multifunction meter displays the warning indication by blinking the warning indicator light (yellow LED) [B] and mode indicator symbol.

It also displays the S-KTRC operating conditions in the level indicator [C].

7. KIBS ECU

As for the KIBS equipped model, the front and rear wheel sensor signals are transmitted to the FI ECU via the KIBS ECU.

Mode-switching

Depress the S-KTRC button on the left handlebar switch to change the mode. The mode can be changed only when the throttle grip is closed completely.

The S-KTRC OFF can be selected only when the motorcycle is at a stop. Changing to mode 1 from S-KTRC OFF is possible while riding.

NOTE

○When changing the mode, stop the motorcycle.

○The mode is retained if the ignition switch is turned to OFF or if the battery is disconnected.

○When the ignition switch is turned to OFF, and then back to ON while S-KTRC is OFF, the system will automatically be set to mode 1.

○If the battery is disconnected and then reconnected while S-KTRC is OFF, the S-KTRC is set in mode 1.

Mode 1: S-KTRC least restrictive among the three modes. This makes lengthy drifts and wheelies possible when exiting tight corners.

Mode 2: There is more S-KTRC interaction compared to mode 1. This makes slight drifts possible when exiting tight corners.

Mode 3: S-KTRC intervenes to prevent the rear wheel from spinning whenever possible.

GENERAL INFORMATION 1-17

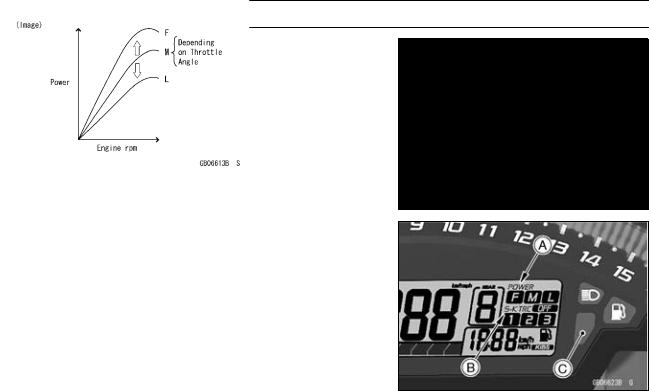

Technical Information-Power Mode

The rider can choose from three engine power modes to suit their preferences and road conditions. The FI ECU controls the engine power by adjusting fuel injection, air intake, and ignition timing. It enables three-mode selection: Full Power (Mode F), Middle Power (Mode M), and Low Power (Mode

L).

In addition, combining each mode with each S-KTRC setting allows the rider to have more choices to be able to interact with various conditions.

Power Mode Operation

To change the mode, close the throttle grip completely, and depress the power mode button [A] (0.3 0.4 sec.).

Power Mode Positions

NOTE

○The power mode setting is maintained when the ignition switch is turned OFF, or when the battery is disconnected.

1-18 GENERAL INFORMATION

Technical Information-Power Mode

Mode F: The highest engine power output is achieved. The rider can use the full power of the engine.

Mode M: The throttle response is less sharp compared to mode F. Depending on the throttle application, full power can be accessed temporarily.

Mode L: About 60% of the highest engine power output is achieved. The throttle response is mildest among the three modes.

The current mode selection is displayed on the power mode indicator [A] in the multifunction meter.

If a failure occurs with a FI related components such as a subthrottle or main throttle sensor, the warning indicator light (red LED) and FI warning symbol will go ON, and/or the S-KTRC indicator [B] and warning indicator light (yellow LED) [C] blink. The current mode cannot be changed at this time.

GENERAL INFORMATION 1-19

Technical Information-Kawasaki Intelligent anti-lock Brake System (KIBS/ZX1000K model only)

Overview

Kawasaki Intelligent anti-lock Brake System (KIBS) offers enhanced braking stability (ABS performance equivalent to the current model) to supersport models, which pitch more than most motorcycles and also offers high-precision front and rear brake pressure control (high-precision ABS) for sport riding.

Precise control of the ABS operation decreases kickback to the brake lever and brake pedal during braking compared to the conventional system.

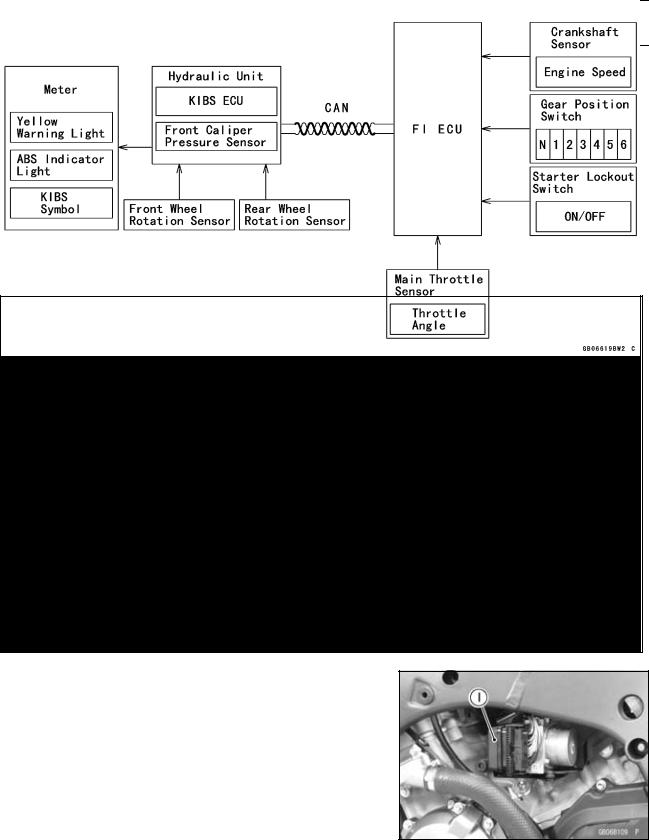

In addition to the front and rear wheel sensors in a conventional ABS, KIBS monitors a number of parameters: front caliper hydraulic pressure and information from the FI ECU (engine speed, throttle position, gear position, and clutch actuation).

KIBS uses an all-new BOSCH hydraulic unit which was designed specifically for motorcycle use. The new design is small and light weight (45% less volume and 800g lighter than current units). The unit is located close to the motorcycle’s center of gravity, behind the engine cylinder and above the sprocket cover.

System Components

1. KIBS ECU

With input from the front and rear wheel sensors and front caliper hydraulic pressure, the KIBS ECU analyzes various conditions on the motorcycle, and with additional information from the FI ECU (engine speed, throttle position, gear position, and clutch actuation) precisely controls the brake caliper hydraulic pressure. As a result, brake force is generated to suit conditions. If there is no engine information from the FI ECU, the KIBS is deactivated and the warning is displayed in the meter; however, the conventional ABS function is maintained.

2. Wheel Rotation Sensor

The wheel rotation sensor converts the front and rear wheel rotation speed to a pulse signal and transmits it to the KIBS ECU and FI ECU.

1-20 GENERAL INFORMATION

Technical Information-Kawasaki Intelligent anti-lock Brake System (KIBS/ZX1000K model only)

3. KIBS Hydraulic Unit

The KIBS hydraulic unit consists of the hydraulic unit and KIBS ECU and has the front caliper hydraulic pressure sensor built-in.

When receiving a signal from the KIBS ECU, the hydraulic unit increases or decreases the front and rear brake hydraulic pressure.

The front caliper hydraulic pressure sensor always monitors the front caliper hydraulic pressure and transmits the hydraulic pressure change to the KIBS ECU.

4. FI ECU

The FI ECU transmits information from the crankshaft sensor (engine speed), the main throttle sensor (throttle position), the gear position switch (gear position), and the starter lockout switch (ON/OFF) to the KIBS ECU by the CAN system.

5. Multifunction Meter

When a failure occurs in the system, the multifunction meter displays the warning indication by turning ON the warning indicator light (yellow LED) [A] and KIBS symbol [B].

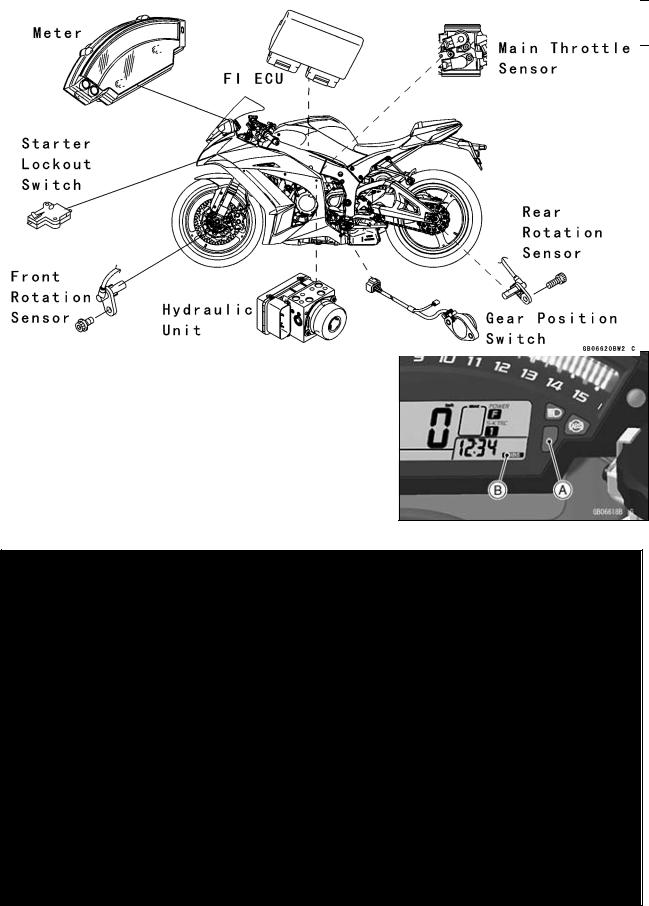

Related Parts Locations

GENERAL INFORMATION 1-21

Technical Information-Kawasaki Intelligent anti-lock Brake System (KIBS/ZX1000K model only)

KIBS Control

1. ABS performance equivalent to the current model (enhanced braking stability)

By monitoring front caliper hydraulic pressure, KIBS regulates pressure increases reducing the tendency of the rear to lift. Before the ABS system fully reacts, KIBS system prevents the pressure from increasing too quickly thus suppressing rear lift. And after the ABS has decreased pressure to prevent wheel lock, it prevents a sudden pressure increase that could induce rear lift.

2. High-precision ABS to enhance front and rear braking performance

By monitoring front caliper hydraulic pressure, the KIBS system is able to regulate pressure changes precisely, so that slips are minimized resulting in smooth operation compared to the conventional ABS system.

1-22 GENERAL INFORMATION

Technical Information-Kawasaki Intelligent anti-lock Brake System (KIBS/ZX1000K model only)

3. Rear brake control enhancement during engine braking

By recognizing rear wheel slip due to engine brake force during aggressive throttle operation, and at high rpm or downshifting, the KIBS system prevents unnecessary ABS intervention to the rear wheel compared to the conventional ABS system.

GENERAL INFORMATION 1-23

Technical Information — Electronic Steering Damper (ESD/ZX1000JD/KD models)

1) Overview

This model has an Electronic Steering Damper (ESD) [A]. Unlike conventional manual adjustment method of Kawasaki, damping characteristics are adjusted by the electronic control unit.

2) Purpose

Designed to offer increased stability at high speed without interfering with light and nimble steering at low speed.

3) Advantages

Damping characteristics are properly adjusted by the electronic control unit based on primarily vehicle speed, and additionally acceleration/deceleration.

During public road riding, lighter damping characteristics are selected to preserve the natural nimble handling of this model.

During circuit riding, stiffer damping settings are chosen to enhance stability for better cornering. Like the public road riding settings, ESD provides the rider with moderate feedback while maintaining natural handling feel. (moderate and natural work fine here)

Electronic control is based on speed and acceleration, so at high speeds stability is enhanced.

4) Difference

Change the steering damper damping adjustment method from manual ( ZX1000JC/KC) to automatic (Stepper Motor).

|

Previous Models ( ZX1000JC/KC) |

New Models (ZX1000JD/KD) |

|

1-24 GENERAL INFORMATION

Technical Information — Electronic Steering Damper (ESD/ZX1000JD/KD models)

5) Related Parts

Meter [A]

Electronic Steering Damper (ESD) [B]

GENERAL INFORMATION 1-25

Technical Information — Electronic Steering Damper (ESD/ZX1000JD/KD models)

ESD ECU [A]

FI ECU [B]

Rear Wheel Rotation Sensor [A]

6) Meter

Added an indicator “ESD” warning symbol [A] in the instruments.

The yellow warning indicator light [B] and ESD warning symbol go on whenever there is a malfunction in the ESD system.

At this time, the ESD system maintains the last damping force setting.

7) Error Display

Only Meter Diagnosis

When both “ESD” warning symbol [A] and yellow warning indicator light [B] go on , the LCD displays service code [C] by push the upper button [D] at odometer indication (see Self-Diagnosis Procedures in the Self-Diagnosis System chapter).

|

Problems |

Service Code |

|

|

ESD actuator malfunction, wiring open or |

E2E |

|

|

short |

||

|

ESD ECU trouble (ESD ECU operation |

||

|

abnormal) |

E3b |

|

|

ESD ECU — FI ECU communication error |

||

|

Input signals for ESD trouble |

||

|

Low voltage |

||

|

ESD ECU communication error |

3C |

1-26 GENERAL INFORMATION

Unit Conversion Table

|

Prefixes for Units: |

Units of Length: |

|

Prefix |

Symbol |

Power |

||

|

mega |

M |

× 1 000 |

000 |

|

|

kilo |

k |

× |

1 000 |

|

|

centi |

c |

× |

0.01 |

|

|

milli |

m |

× |

0.001 |

|

|

micro |

µ |

× 0.000001 |

Units of Mass:

|

kg |

× |

2.205 |

= |

lb |

|

g |

× |

0.03527 |

= |

oz |

Units of Volume:

|

L |

× |

0.2642 |

= |

gal (US) |

|

L |

× |

0.2200 |

= |

gal (IMP) |

|

L |

× |

1.057 |

= |

qt (US) |

|

L |

× |

0.8799 |

= |

qt (IMP) |

|

L |

× |

2.113 |

= |

pint (US) |

|

L |

× |

1.816 |

= |

pint (IMP) |

|

mL |

× |

0.03381 |

= |

oz (US) |

|

mL |

× |

0.02816 |

= |

oz (IMP) |

|

mL |

× |

0.06102 |

= |

cu in. |

Units of Force:

|

N |

× |

0.1020 |

= |

kg |

|

N |

× |

0.2248 |

= |

lb |

|

kg |

× |

9.807 |

= |

N |

|

kg |

× |

2.205 |

= |

lb |

|

km |

× |

0.6214 |

= |

mile |

|

m |

× |

3.281 |

= |

ft |

|

mm |

× |

0.03937 |

= |

in. |

Units of Torque:

|

N·m |

× |

0.1020 |

= |

kgf·m |

|

N·m |

× |

0.7376 |

= |

ft·lb |

|

N·m |

× |

8.851 |

= |

in·lb |

|

kgf·m |

× |

9.807 |

= |

N·m |

|

kgf·m |

× |

7.233 |

= |

ft·lb |

|

kgf·m |

× |

86.80 |

= |

in·lb |

Units of Pressure:

|

kPa |

× |

0.01020 |

= |

kgf/cm² |

|

kPa |

× |

0.1450 |

= |

psi |

|

kPa |

× |

0.7501 |

= |

cmHg |

|

kgf/cm² |

× |

98.07 |

= |

kPa |

|

kgf/cm² |

× |

14.22 |

= |

psi |

|

cmHg |

× |

1.333 |

= |

kPa |

Units of Speed:

km/h × 0.6214 = mph

Units of Power:

|

kW |

× |

1.360 |

= |

PS |

|

kW |

× |

1.341 |

= |

HP |

|

PS |

× |

0.7355 |

= |

kW |

|

PS |

× |

0.9863 |

= |

HP |

Units of Temperature:

PERIODIC MAINTENANCE 2-1

Periodic Maintenance

Table of Contents

|

Periodic Maintenance Chart ……………………………………………………………………………………… |

2-3 |

||

|

Torque and Locking Agent………………………………………………………………………………………… |

2-6 |

2 |

|

|

Specifications |

2-12 |

||

|

Special Tools ………………………………………………………………………………………………………….. |

2-14 |

||

|

Periodic Maintenance Procedures……………………………………………………………………………… |

2-15 |

||

|

Fuel System (DFI)…………………………………………………………………………………………………. |

2-15 |

||

|

Throttle Control System Inspection……………………………………………………………………….. |

2-15 |

||

|

Engine Vacuum Synchronization Inspection…………………………………………………………… |

2-15 |

||

|

Idle Speed Inspection …………………………………………………………………………………………. |

2-19 |

||

|

Idle Speed Adjustment………………………………………………………………………………………… |

2-20 |

||

|

Fuel Hose Inspection (fuel leak, damage, installation condition) ……………………………….. |

2-20 |

||

|

Evaporative Emission Control System Inspection (CAL and SEA-B1 Models)…………….. |

2-21 |

||

|

Cooling System…………………………………………………………………………………………………….. |

2-22 |

||

|

Coolant Level Inspection……………………………………………………………………………………… |

2-22 |

||

|

Radiator Hose and Pipe Inspection (coolant leak, damage, installation condition) ………. |

2-22 |

||

|

Engine Top End ……………………………………………………………………………………………………. |

2-23 |

||

|

Valve Clearance Inspection …………………………………………………………………………………. |

2-23 |

||

|

Valve Clearance Adjustment………………………………………………………………………………… |

2-24 |

||

|

Air Suction System Damage Inspection…………………………………………………………………. |

2-26 |

||

|

Clutch………………………………………………………………………………………………………………….. |

2-27 |

||

|

Clutch Operation Inspection ………………………………………………………………………………… |

2-27 |

||

|

Wheels/Tires………………………………………………………………………………………………………… |

2-28 |

||

|

Tire Air Pressure Inspection…………………………………………………………………………………. |

2-28 |

||

|

Wheel/Tire Damage Inspection…………………………………………………………………………….. |

2-28 |

||

|

Tire Tread Wear Inspection …………………………………………………………………………………. |

2-29 |

||

|

Wheel Bearing Damage Inspection ………………………………………………………………………. |

2-29 |

||

|

Final Drive……………………………………………………………………………………………………………. |

2-30 |

||

|

Drive Chain Lubrication Condition Inspection …………………………………………………………. |

2-30 |

||

|

Drive Chain Slack Inspection ……………………………………………………………………………….. |

2-31 |

||

|

Drive Chain Slack Adjustment ……………………………………………………………………………… |

2-31 |

||

|

Wheel Alignment Inspection ………………………………………………………………………………… |

2-32 |

||

|

Drive Chain Wear Inspection ……………………………………………………………………………….. |

2-32 |

||

|

Chain Guide Wear Inspection ………………………………………………………………………………. |

2-33 |

||

|

Brakes…………………………………………………………………………………………………………………. |

2-34 |

||

|

Brake Fluid Leak (Brake Hose and Pipe) Inspection ……………………………………………….. |

2-34 |

||

|

Brake Hose and Pipe Damage and Installation Condition Inspection…………………………. |

2-35 |

||

|

Brake Fluid Level Inspection………………………………………………………………………………… |

2-35 |

||

|

Brake Pad Wear Inspection …………………………………………………………………………………. |

2-36 |

||

|

Brake Operation Inspection …………………………………………………………………………………. |

2-36 |

||

|

Brake Light Switch Operation Inspection ……………………………………………………………….. |

2-36 |

||

|

Suspension………………………………………………………………………………………………………….. |

2-37 |

||

|

Front Forks/Rear Shock Absorber Operation Inspection ………………………………………….. |

2-37 |

||

|

Front Fork Oil Leak Inspection……………………………………………………………………………… |

2-38 |

||

|

Rear Shock Absorber Oil Leak Inspection ……………………………………………………………… |

2-38 |

||

|

Rocker Arm Operation Inspection…………………………………………………………………………. |

2-38 |

||

|

Tie-Rod Operation Inspection ………………………………………………………………………………. |

2-38 |

||

|

Steering ………………………………………………………………………………………………………………. |

2-39 |

||

|

Steering Play Inspection ……………………………………………………………………………………… |

2-39 |

||

|

Steering Play Adjustment…………………………………………………………………………………….. |

2-39 |

||

|

Steering Stem Bearing Lubrication ……………………………………………………………………….. |

2-40 |

2-2 PERIODIC MAINTENANCE

|

Steering Damper Oil Leak Inspection ……………………………………………………………………. |

2-41 |

|

Electrical System ………………………………………………………………………………………………….. |

2-42 |

|

Lights and Switches Operation Inspection……………………………………………………………… |

2-42 |

|

Headlight Aiming Inspection ………………………………………………………………………………… |

2-44 |

|

Headlight Aiming Adjustment……………………………………………………………………………….. |

2-44 |

|

Sidestand Switch Operation Inspection …………………………………………………………………. |

2-45 |

|

Engine Stop Switch Operation Inspection………………………………………………………………. |

2-46 |

|

Others…………………………………………………………………………………………………………………. |

2-47 |

|

Chassis Parts Lubrication …………………………………………………………………………………… |

2-47 |

|

Bolts, Nuts and Fasteners Tightness Inspection……………………………………………………… |

2-48 |

|

Replacement Parts ……………………………………………………………………………………………….. |

2-50 |

|

Air Cleaner Element Replacement………………………………………………………………………… |

2-50 |

|

Fuel Hose Replacement ……………………………………………………………………………………… |

2-50 |

|

Coolant Change …………………………………………………………………………………………………. |

2-54 |

|

Radiator Hose and O-ring Replacement………………………………………………………………… |

2-56 |

|

Engine Oil Change……………………………………………………………………………………………… |

2-57 |

|

Oil Filter Replacement ………………………………………………………………………………………… |

2-58 |

|

Brake Hose and Pipe Replacement………………………………………………………………………. |

2-59 |

|

Brake Fluid Change ……………………………………………………………………………………………. |

2-62 |

|

Master Cylinder Rubber Parts Replacement ………………………………………………………….. |

2-63 |

|

Caliper Rubber Parts Replacement ………………………………………………………………………. |

2-65 |

|

Spark Plug Replacement …………………………………………………………………………………….. |

2-69 |

PERIODIC MAINTENANCE 2-3