ТЕХНИЧЕСКОЕ ОБСЛУЖИВАНИЕ

5-6

Руководство по эксплуатации

HySpeed HSD130 ДВЧ

Коды ошибок

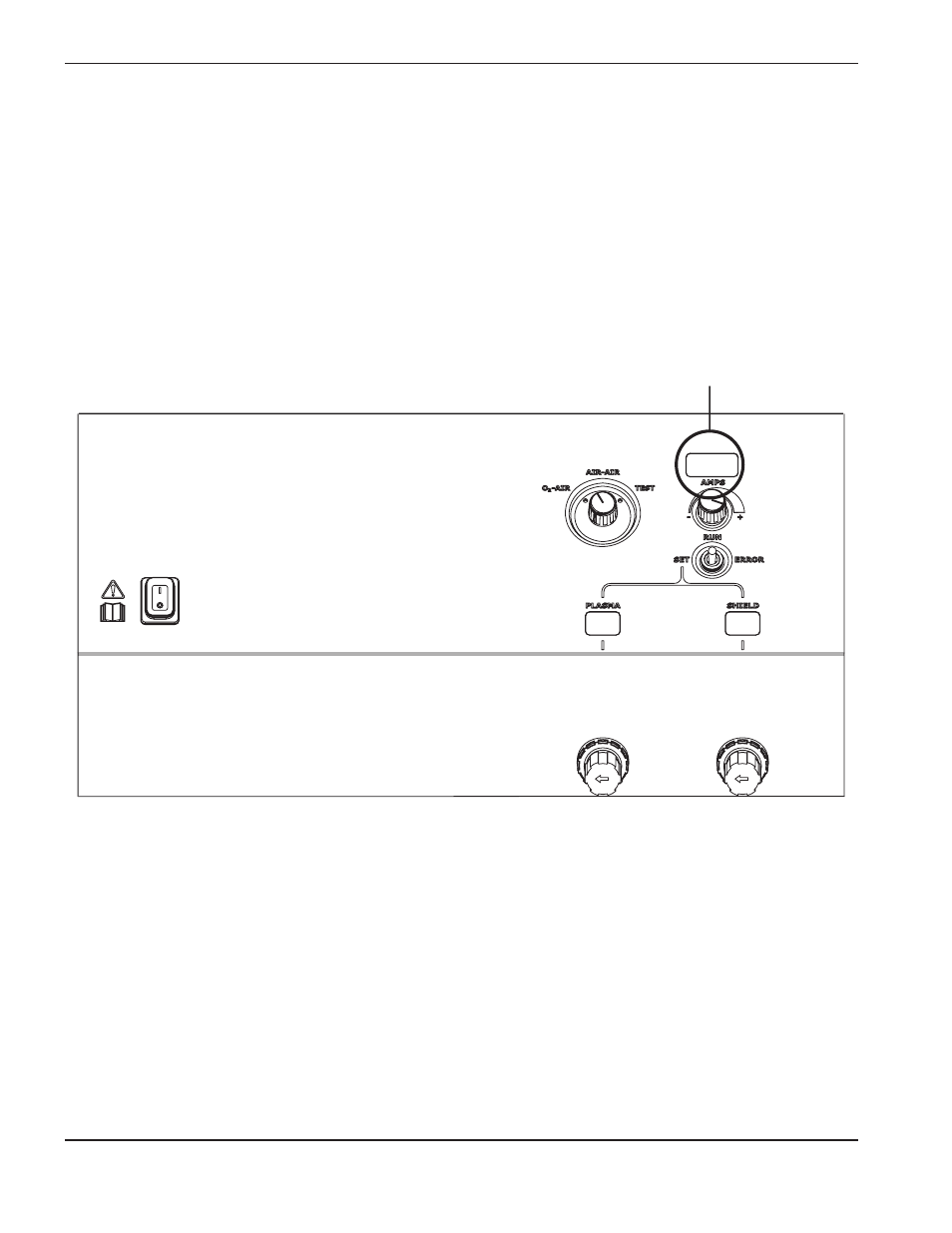

Установить селекторный переключатель на источнике тока в положение ERROR (ошибка). Состояния блока

электропитания показываются на 3-значном СИД-дисплее на блоке электропитания. Идентификационные

номера состояний состоят из дефиса и двух цифр, а коды ошибки состоят из трех цифр. Когда селекторный

переключатель установлен в положение ERROR (ошибка), идентификационный номер состояния будет

высвечиваться в течение 2 секунд. Затем в течение 2 секунд будет высвечиваться код ошибки. Этот цикл будет

продолжаться до тех пор, пока селекторный переключатель не будет установлен в другое положение.

3-значный дисплей

Страница 116 в инструкции по эксплуатации Hypertherm HSD130 Remote High Frequency Console

ТЕХНИЧЕСКОЕ ОБСЛУЖИВАНИЕ

Руководство по эксплуатации

HySpeed HSD130 ДВЧ

Коды ошибок

Установить селекторный переключатель на источнике тока в положение ERROR (ошибка) Состояния блока электропитания показываются на 3-значном СИД-дисплее на блоке электропитания Идентификационные номера состояний состоят из дефиса и двух цифр а коды ошибки состоят из трех цифр Когда селекторный переключатель установлен в положение ERROR (ошибка) идентификационный номер состояния будет высвечиваться в течение 2 секунд Затем в течение 2 секунд будет высвечиваться код ошибки Этот цикл будет продолжаться до тех пор пока селекторный переключатель не будет установлен в другое положение.

3-значный дисплей

MAINTENANCE

HySpeed HSD130 RHF

Instruction Manual

5-13

Error code troubleshooting (7 of

Error code

number

Name

Description

Corrective action

105

Low current

on CS1

A Current < 10 Amps has

been detected on chopper

channel 1 by

current sensor 1 during

the chopper test at

power-up.

1. Measure voltage across the current sensor (CS1).

a) Red to black = +15 VDC, green to black = -15 VDC,

white to black = 0 VDC at idle and varies with current

output (4 VDC = 100 amps).

b) If possible, take a voltage reading on current sensor

while trying to cut. Ratio is 4 VDC = 100 amps.

c) If the current sensor voltage is approximately 6.4 VDC

or greater at idle, replace the current sensor.

107

High current

on CS2

A Current > 35 Amps has

been detected on channel

2 by current sensor 2

during the chopper test at

power-up.

1. Verify that there is not a short circuit between the negative

lead and the work lead.

2. Measure voltage across the current sensor (CS2).

a) Red to black = +15 VDC, green to black = -15 VDC,

white to black = 0 VDC at idle and varies with current

output (4 VDC = 100 amps).

b) If possible, take a voltage reading on current sensor

while trying to cut. Ratio is 4 VDC = 100 amps.

c) If the current sensor voltage is approximately 6.4 VDC

or greater at idle, replace the current sensor.

108

Transfer at

power-up

The system has detected

current on the work lead >

3.5 amps during power-up.

1. Disconnect J6.6 on the I/O PCB (PCB6). If the problem is

resolved, replace PCB6.

109

Coolant flow

at power-up

Coolant flow is > 2 lpm

(0.6 gpm) when the pump

is off.

1. The coolant flow sensor was bypassed or the flow switch

is faulty. Replace the flow switch.

111

Coolant over

temp at

power-up

Coolant is indicating an

over temp at power-up.

1. Verify that the coolant temperature sensor has not been

jumped out or the wires to the sensor are not shorted out

in the harness.

2. If not, the coolant temperature is over the set point and

needs time to cool to 70° C (158° F).

116

Watchdog

interlock

An error occurred with the

CAN communication

system.

1. Verify that the power supply to gas console control cable is

not damaged and is properly connected to PCB4 and to

the back of the gas console.

2. Verify that the power supply to gas console power cable is

not damaged and is properly connected inside the power

supply and to the back of the gas console.

3. Use the CAN bus tester to verify CAN bus

communications.

-

Walid2525

- 1/2 Star Member

- Posts: 1

- Joined: Sun Apr 22, 2018 7:58 am

Problem with hypertherm hsd 130

Hello

I have a problem with my hypertherm 130 . Specially when I use a 130 oxygen/air. And the error message code 20 appears. » Lose arc pilote». But when I create a leak in the oxygen plasma it works. Can anyone explain how to resolve this problem.

Thank you

-

sphurley

- 3 Star Elite Contributing Member

- Posts: 445

- Joined: Sat Jul 04, 2015 10:43 pm

Re: Problem with hypertherm hsd 130

Post

by sphurley » Tue Apr 24, 2018 8:06 am

I would repost this up the the plasma cutter (Hypertherm) section for Jim Colt to reply.

Steve

Platform CNC Plasma table

CandCNC Ethercut IV DTHC

Hypertherm 85/CPC/RS485

Miller 350P

Miller Dynasty 280DX

-

METALWORX-IND

- 1 Star Member

- Posts: 23

- Joined: Fri Dec 01, 2017 3:44 pm

- Location: Nashville, Arkansas

Re: Problem with hypertherm hsd 130

Post

by METALWORX-IND » Thu Apr 26, 2018 2:48 pm

I have heard of people having similar problems in the past when the pressure was too high going into the auto gas control unit. Check and see what your pressure regulator on your oxygen is set at and try to adjust it down and see if that helps.

Return to “Hypertherm Plasma Cutters”

Jump to

- WELCOME CENTER, GOOD INFO & MEET OUR SPONSORS

- ↳ Introduce Yourself

- ↳ CNC Plasma Beginners Knowledge Base

- ↳ Contributing Membership Registration or Renewal

- ↳ PlasmaSpider Online Store

- ↳ Our Sponsors & Advertisers

- DXF DESIGN & PROJECT PICTURE SHARING FORUMS

- ↳ DXF Art — DXF Clip Art File Sharing Forum

- ↳ CNC Plasma Cutter Project Picture Gallery

- ↳ File Conversion Help Wanted

- GENERAL FORUMS

- ↳ CNC Plasma Cutters General Forum

- ↳ Plasma Cut Quality Forum

- ↳ Hypertherm’s Basic Tips to Improve Cut Quality

- ↳ Hypertherm’s 10 Common Plasma Cutting Mistakes

- ↳ Hypertherm’s Tips to Troubleshoot Cut Angularity

- ↳ Pricing, Advertising, & Marketing Your Products Forum

- ↳ Tech Tips From Other Members

- ↳ Classified Ads

- PLASMA CUTTER FORUMS

- ↳ Hypertherm Plasma Cutters

- ↳ Powermax Helpful Resources

- ↳ Powermax Cut Speed Charts

- ↳ Powermax Cut Speed Charts

- ↳ Powermax SYNC 65, 85, 105 Cut Speed Charts

- ↳ Powermax 45 Cut Speed Charts

- ↳ Powermax 65/85 Cut Speed Charts

- ↳ Powermax 105 Cut Speed Charts

- ↳ Powermax 125 Cut Speed Charts

- ↳ Powermax Fault Code, Diagnostics, & Troubleshooting Forums

- ↳ Powermax 65 & 85 Common Fault Code, Diagnotics, & Troubleshooting Forum

- ↳ 0-12 Fault Code

- ↳ 0-19 Fault Code

- ↳ 0-20 Fault Code

- ↳ 0-21 Fault Code

- ↳ 0-22 Fault Code

- ↳ 0-30 Fault Code

- ↳ 0-99 fault Code

- ↳ Displaying the Powermax 65 85 Service Screen

- ↳ Thermal Dynamics / Esab Plasma Cutters

- ↳ Cutmaster A40 Cut Speed Charts

- ↳ Cutmaster A60 Cut Speed Charts

- ↳ Cutmaster A80 Cut Speed Charts

- ↳ Cutmaster A120 Cut Speed Charts

- ↳ Lincoln & Miller Plasma Cutters

- ↳ RazorWeld, Everlast, & All Other Plasma Cutters

- ↳ Plasma Consumables

- CNC PLASMA TABLE & CONTROLLER FORUMS

- ↳ CandCNC Forum

- ↳ CandCNC Website

- ↳ FastCut CNC Forum

- ↳ FlashCut CNC Forum

- ↳ JD Squared Forum

- ↳ JD Squared Website

- ↳ MultiCam Forum

- ↳ Shop Sabre Forum

- ↳ Star-Lab CNC Forum

- ↳ Tracker CNC Forum

- ↳ Langmuir Crossfire Forum

- ↳ PlasmaCam, Samson, & Go Torch Forum

- ↳ Torchmate Forum

- ↳ DIY Plasma Table & Accessory Discussion Forum

- ↳ Various Manufacturers Forum

- CAD-CAM & CONTROL SOFTWARE FORUMS

- ↳ General Discussion

- ↳ Fusion 360 & AutoCAD Forum

- ↳ Get AutoDesk Fusion 360 FREE

- ↳ BobCAD

- ↳ C&CNC CommandCNC

- ↳ Corel Draw Graphics Suite

- ↳ CorelDRAW Free 30 day trial

- ↳ Quick & Helpful CorelDRAW Tutorial Videos

- ↳ Inkscape

- ↳ Download Inkscape for Windows

- ↳ Linux CNC — Plasmac

- ↳ Mach3 & Mach4 CNC

- ↳ Plasmacam — DesignEdge

- ↳ SheetCam

- ↳ Torchmate Software

- METAL FINISHING FORUMS

- ↳ Patina Finishes

- ↳ Steel F/X Your Metal Patina & Dye Connection

- ↳ Paint & Other Top Coats

- ↳ Powder Coat

- ↳ Abrasive & Texturing

- ↳ Dross/Slag Removal

- ACCESSORIES & RELATED TOOL FORUMS

- ↳ EasyScriber Drag Style Scriber for Hypertherm

- ↳ EasyScriber for Hypertherm, Thermal Dynamics, Razorweld, Esab

- ↳ Plate Markers, & Air Scribes

- ↳ Mig Welders, Tig Welders, Spot Welders

- ↳ Metal Bending, Rolling, Notching, Drilling, Saw Cutting

- ↳ Air Dryers, Air Filters, Air Compressors, Etc.

- ↳ Water Tables, Ventilation, Air Handling

- ↳ Fab Tables, Grind Stations, Material Storage & Handling

- ↳ Pen Markers, Remote Controls, Drawing Tablets, etc.

- ↳ 3D Printers & Printed Accessories

- ↳ Laser Engravers & Cutters

- ↳ Arclight Dynamics

-

PLEASE HELP ME LOCATE THE POSSIBLE CAUSES OF THIS ERROR

-

Re: HYPERTHERM HSD 130 ERROR 020

Contact your cnc machine builder, if they cannot help then ask them to work directly with Hypertherm tech service for your region. Jim Colt Hyperthermn

-

Re: HYPERTHERM HSD 130 ERROR 020

Originally Posted by jimcolt

Contact your cnc machine builder, if they cannot help then ask them to work directly with Hypertherm tech service for your region. Jim Colt Hyperthermn

thanks jim

Similar Threads

-

Replies: 8

Last Post: 02-06-2015, 03:56 PM

-

Replies: 3

Last Post: 11-01-2014, 11:22 PM

-

Replies: 0

Last Post: 07-17-2014, 04:12 PM

-

Replies: 0

Last Post: 05-05-2013, 05:40 AM

-

Replies: 0

Last Post: 04-26-2012, 07:53 AM

Tags for this Thread

Posting Permissions

- You may not post new threads

- You may not post replies

- You may not post attachments

- You may not edit your posts

- BB code is On

- Smilies are On

- [IMG] code is On

- [VIDEO] code is On

- HTML code is Off

Forum Rules