- Manuals

- Brands

- Genie Manuals

- Boom Lifts

- GS-2646

Manuals and User Guides for Genie GS-2646. We have 14 Genie GS-2646 manuals available for free PDF download: Service And Repair Manual, Service Manual, Maintenance Manual, Operator’s Manual

Genie GS-2646 Service And Repair Manual (343 pages)

Scissor Lifts

Brand: Genie

|

Category: Lifting Systems

|

Size: 19.04 MB

Table of Contents

-

Introduction

2

-

Find a Manual for this Model

2

-

Serial Number Range

3

-

Revision History

4

-

Serial Number Legend

6

-

-

Safety Rules

7

-

Table of Contents

9

-

April

12

-

Gs-1530 / Gs

14

-

-

Specifications

17

-

Machine Specifications

17

-

Gs-30 • Gs-32 • Gs-46 • Gs

17

-

April

18

-

-

Performance Specifications (Models Without Proportional Lift Function)

19

-

April

19

-

Gs-30 • Gs-32 • Gs-46 • Gs

20

-

-

Performance Specifications (Models with Proportional Lift)

21

-

Hydraulic Oil Specifications

23

-

Hydraulic Component Specifications

26

-

Manifold Component Specifications

27

-

Hydraulic Hose and Fitting Torque Specifications

28

-

Torque Procedure

29

-

-

Repair Procedures

31

-

Introduction

31

-

-

Platform Controls

33

-

Circuit Board

35

-

Joystick

36

-

Platfrom Controls Alarm

36

-

Platform Emergency Stop Button

37

-

-

Ground Controls

38

-

Software Revision Level

39

-

Machine Setup

40

-

Loading or Updating Machine Software

41

-

Using a Wi-Fi Router to Connect to the Smartlink Web Service Tool

46

-

Service Override Mode

48

-

Level Sensors

50

-

Manual Platform Lowering Cable

65

-

Outrigger Calibration

67

-

-

Hydraulic Tank

68

-

Hydraulic Pump

69

-

How to Remove the Hydraulic Pump

70

-

-

Manifolds

72

-

Function Manifold Components — GS-1530, GS-1532, GS-1930 and GS-1932

72

-

Function Manifold Components — GS-2032, GS-2632, GS-3232, GS-2046, GS-2646 and GS-3246

74

-

Function Manifold Components — GS-4047

76

-

Check Valve Manifold Components — GS-1530, GS-1532, GS-1930 and GS-1932

78

-

Lift Pressure Selector Manifold Components — GS-4047

79

-

Outrigger Function Manifold Components — GS-3232

80

-

Outrigger Cylinder Manifold Components — GS-3232

81

-

Valve Adjustments — Function Manifold

82

-

Valve Coils

88

-

-

Steer Axle Components

90

-

Yoke and Drive Motor

90

-

Steer Cylinder

91

-

Steer Bellcrank

92

-

-

Non-Steer Axle Components

93

-

Drive Brake

93

-

-

Brake Release Hand Pump Components

94

-

Scissor Components

95

-

Scissor Assembly, GS-1530 and GS-1532

96

-

Scissor Assembly, GS-1930 and GS-1932

102

-

Scissor Assembly, GS-2032 and GS-2046

110

-

Scissor Assembly, GS-2632 and GS-2646

117

-

Scissor Assembly, GS-3232 and GS-3246

125

-

Scissor Assembly, GS-4047

134

-

Scissor Arm Wear Pads

142

-

Platform Height Sensor

144

-

Lift Cylinder

146

-

Pressure Transducer

157

-

Platform Overload System

159

-

Platform Overload Recovery

164

-

-

Platform Components

166

-

Platform

166

-

Platform Extension Deck

167

-

-

Battery Charger

168

-

Selecting a Charge Profile

169

-

-

Diagnostics

171

-

Introduction

171

-

GCON I/O Map Without Load Sense (All Machines Except GS-3232)

174

-

GCON I/O Map with Load Sense (All Machines Except GS-3232)

175

-

GCON I/O Map Without Load Sense GS-3232 Only)

176

-

GCON I/O Map with Load Sense (GS-3232 Only)

178

-

Operation Indicator Codes (OIC)

180

-

Diagnostic Trouble Codes (DTC)

180

-

Troubleshooting «HXXX» and «PXXX» Faults

181

-

Fault Inspection Procedure

182

-

Type «HXXX» Faults

184

-

Type «PXXX» Faults

188

-

Type «UXXX» Faults

189

-

Type «FXXX» Faults

192

-

Type «CXXX» Faults

195

-

Battery Charger

197

-

Charger Fault Codes

198

-

Charger Error Codes

199

-

-

-

Schematics

203

-

Introduction

203

-

Electrical Component and Wire Color Legends

204

-

Wiring Diagram Ground and Platform Controls

206

-

Limit Switch Legend

207

-

Electrical Symbol Legend

208

-

Hydraulic Symbols Legend

209

-

-

Hydraulic Schematics

210

-

Hydraulic Component Reference Legend

210

-

Hydraulic Component Abbreviation Legend

211

-

Hydraulic Schematic, GS-1530, 1532, 1930, 1932 (from Serial Number GS3010A-110000, GS3011C-10000, GS3014D-101, GS3016P-142281)

212

-

GS3212C-10000 to GS3214C-11873, GS4612A-110000 to

213

-

-

Hydraulic Schematic, GS-2032, 2632, 3232, 2046, 2646, 3246

214

-

Hydraulic Schematic, GS-2032, 2632, 3232, 2046, 2646, 3246 (from Serial Number GS3214A-119071, GS3214C-11874

214

-

Hydraulic Schematic, GS-3232 (from Serial Number GS3211A-110000, GS3212C-10000, GS3216P-142677)

215

-

Hydraulic Schematic, GS-4047 (from Serial Number GS4712C-101 to GS4714C-1459)

216

-

Hydraulic Schematic, GS-4047

216

-

(From Serial Number GS4714C-1460, GS4714D-101, GS4716P-101)

217

-

(From Serial Number GS3010A-110000 to GS3011A-110827)

220

-

-

-

Electrical Schematics — ANSI / CSA Models

220

-

Electrical Schematic, GS-1530 / GS-1930, ANSI / CSA (from Serial Number GS3011A-110828 to GS3014A-136972, GS3014D-101 to GS3015D-1113)

224

-

Electrical Schematic, GS-1530 / GS-1930

224

-

GS3016P-142281 to GS3016P-158208)

228

-

-

Electrical Schematic, GS-1530/1930, ANSI/CSA

231

-

Electrical Schematic, GS-3232, ANSI / CSA

233

-

(From Serial Number GS3211A-110000 to GS3214A-135714)

234

-

-

Electrical Schematic, GS-3232, ANSI / CSA

234

-

(From Serial Number GS3214A-135715 to GS3215A-141898)

238

-

-

Electrical Schematic, GS-3232, ANSI / CSA (from Serial Number GS3215A-141899, GS3216P-142677 to GS3216P-146462)

242

-

Electrical Schematic, GS-2032, 2632, 2046, 2646, ANSI / CSA

249

-

GS4612A-110000 to GS4614A-135366, GS4613D-101 to GS4615D-1303)

250

-

-

Electrical Schematic, GS-2032, 2632, 2046, 2646, ANSI/CSA

250

-

GS4614A-135367 to GS4615A-137959, GS4615D-1304)

254

-

-

Electrical Schematic, GS-2032, 2632, 2046, 2646, ANSI / CSA (from Serial Number GS3216P-146463, GS4616D-4433, GS4616P-139711)

262

-

Electrical Schematic, GS-3246, GS4047 ANSI / CSA (from Serial Numbers GS4616D-4433, GS4616P-139711, GS4716D-3102, GS4716P-101)

272

-

-

Electrical Schematics — CE and Australia Models

273

-

Electrical Schematic GS-1530, 1532, 1930, 1932, (from Serial Number GS3010A-110000 to GS3011A-110827) as / CE

274

-

Electrical Schematic, GS-1530/32_GS-1930/32 (from Serial Number GS3011A-110828 to GS3014A-136972, GS3011C-10000 to

278

-

Electrical Schematic, GS-1530, 1532, 1930, 1932, AS/CE

282

-

GS3015D-1114 to GS3016D-5426, GS3016P-142281 to GS3016P-158208)

282

-

-

Electrical Schematic, GS-1530, 1532, 1930, 1932, AS/CE

286

-

(From Serial Numbers GS3015D-5427, GS3016P-158209)

286

-

-

Electrical Schematic, GS-3232, as / CE

288

-

Gs3215C-14503)

288

-

-

Electrical Schematic, GS-3232, as / CE (from Serial Number GS3214A-135715 to GS3215A-141898, GS3215C-14504)

292

-

Electrical Schematic, GS-3232, as / CE (from Serial Numbers GS3215A-141899, GS3216P-142676 to GS3216P-146462)

296

-

Electrical Schematic, GS-3232, CE / as (from Serial Number GS3216P-146463)

300

-

Electrical Schematic, GS-2032, 2632, 2046, 2646, as / CE

303

-

GS4613D-101 to GS4615D-1303)

304

-

-

Electrical Schematic, GS-2032, 2632, 2046, 2646, AS/CE

308

-

GS3215C-14378, GS4614A-135367 to GS4615A-137959, GS4615C-14504, GS4615D-1304)

308

-

-

Electrical Schematic, GS-2032, 2632, 2046, 2646, as / CE

312

-

GS3216P-146462, GS4615A-137960, GS4616P-138362 to

312

-

-

Electrical Schematic, GS-2032, 2632, 2046, 2646, as / CE (from Serial Numbers GS3216P-146463, GS4616P-139711)

316

-

Electrical Schematic, GS-3246, as / CE

318

-

Electrical Schematic, GS-3246, as / CE

322

-

Electrical Schematic, GS-3246, as / CE

326

-

GS4615A-137960, GS4616P-138362 GS4616P to GS4616P-139710)

326

-

-

Electrical Schematic, GS-3246, as / CE (from Serial Number GS4616D-4433, GS4616P-139711)

330

-

Electrical Schematic, GS-4047, as / CE

332

-

GS4712C-101 to GS4715C-2130, GS4714D-101 to GS4715D-749)

332

-

-

Electrical Schematic, GS-4047, as / CE (from Serial Number GS4715C-2131, GS4715D-750 to GS4716D-3101)

336

-

Electrical Schematic, GS-4047, as / CE (from Serial Number GS4716D-3102)

340

-

Advertisement

Genie GS-2646 Service And Repair Manual (335 pages)

Scissor lifts

Brand: Genie

|

Category: Boom Lifts

|

Size: 17.47 MB

Table of Contents

-

Find a Manual for this Model

2

-

Serial Number Range

3

-

Revision History

4

-

Serial Number Legend

5

-

Safety Rules

6

-

Table of Contents

8

-

-

Specifications

17

-

Machine Specifications

17

-

Performance Specifications (Models Without Proportional Lift Function)

19

-

Performance Specifications (Models with Proportional Lift)

21

-

Hydraulic Specification

23

-

Hydraulic Component Specifications

26

-

Manifold Component Specifications

27

-

Hydraulic Hose and Fitting Torque Specifications

28

-

Torque Procedure

29

-

-

Repair Procedures

31

-

Introduction

31

-

-

Platform Controls

33

-

Circuit Board

35

-

Joystick

36

-

Platfrom Controls Alarm

36

-

Platform Emergency Stop Button

37

-

-

Ground Controls

38

-

Software Revision Level

39

-

Machine Setup

40

-

Loading or Updating Machine Software

41

-

Using a Wi-Fi Router to Connect to the Smartlink Web Service Tool

46

-

Service Override Mode

48

-

Level Sensors

50

-

Manual Platform Lowering Cable

65

-

Outrigger Calibration

67

-

-

Hydraulic Tank

68

-

Hydraulic Pump

69

-

Function Pump

69

-

How to Remove the Hydraulic Pump

70

-

-

Manifolds

72

-

Function Manifold Components — GS-1530, GS-1532, GS-1930 and GS-1932

72

-

Function Manifold Components — GS-2032, GS-2632, GS-3232, GS-2046, GS-2646 and GS-3246

74

-

Function Manifold Components — GS-4047

76

-

Check Valve Manifold Components — GS-1530, GS-1532, GS-1930 and GS-1932

78

-

Lift Pressure Selector Manifold Components — GS-4047

79

-

Outrigger Function Manifold Components — GS-3232

80

-

Outrigger Cylinder Manifold Components — GS-3232

81

-

Valve Adjustments — Function Manifold

82

-

Valve Coils

88

-

-

Steer Axle Components

90

-

Yoke and Drive Motor

90

-

Steer Cylinder

91

-

Steer Bellcrank

92

-

-

Non-Steer Axle Components

93

-

Drive Brake

93

-

-

Brake Release Hand Pump Components

94

-

Scissor Components

95

-

Scissor Assembly, GS-1530 and GS-1532

96

-

Scissor Assembly, GS-1930 and GS-1932

102

-

Scissor Assembly, GS-2032 and GS-2046

110

-

Scissor Assembly, GS-2632 and GS-2646

117

-

Scissor Assembly, GS-3232 and GS-3246

125

-

Scissor Assembly, GS-4047

134

-

Scissor Arm Wear Pads

142

-

Platform Height Sensor

144

-

Lift Cylinder

146

-

Pressure Transducer

157

-

Platform Overload System

159

-

Platform Overload Recovery

164

-

-

Platform Components

166

-

Platform

166

-

Platform Extension Deck

167

-

-

Diagnostics

169

-

Introduction

169

-

GCON I/O Map Without Load Sense (All Machines Except GS-3232)

172

-

GCON I/O Map with Load Sense (All Machines Except GS-3232)

173

-

GCON I/O Map Without Load Sense GS-3232 Only)

174

-

GCON I/O Map with Load Sense (GS-3232 Only)

176

-

Operation Indicator Codes (OIC)

178

-

Diagnostic Trouble Codes (DTC)

178

-

Troubleshooting «HXXX» and «PXXX» Faults

179

-

Fault Inspection Procedure

180

-

Type «HXXX» Faults

182

-

Type «PXXX» Faults

186

-

Type «UXXX» Faults

187

-

Type «FXXX» Faults

190

-

Type «CXXX» Faults

193

-

-

Schematics

195

-

Introduction

195

-

Electrical Component and Wire Color Legends

196

-

Wiring Diagram Ground and Platform Controls

198

-

Limit Switch Legend

199

-

Electrical Symbol Legend

200

-

Hydraulic Symbols Legend

201

-

-

Hydraulic Schematics

202

-

Hydraulic Component Reference Legend

202

-

Hydraulic Component Abbreviation Legend

203

-

Hydraulic Schematic, GS-1530, 1532, 1930, 1932 (from Serial Number GS3010A-110000, GS3011C-10000, GS3014D-101, GS3016P-142281)

204

-

GS4614C-10000 to GS4614C-12073)

205

-

-

Hydraulic Schematic, GS-2032, 2632, 3232, 2046, 2646, 3246

206

-

Gs4614C-12074, Gs4614D-101)

206

-

-

Hydraulic Schematic, GS-3232 (from Serial Number GS3211A-110000) (from Serial Number GS3212C-10000)

207

-

Hydraulic Schematic, GS-4047 (from Serial Number GS4712C-101 to GS4714C-1459)

208

-

Hydraulic Schematic, GS-4047

208

-

Gs4714D-101)

209

-

-

-

Electrical Schematics — ANSI / CSA Models

216

-

Electrical Schematic, GS-1530 / GS-1930, ANSI / CSA (from Serial Number GS3011A-110828 to GS3014A-136972, GS3014D-101 to GS3015D-1113, GS3011C-10000 to GS3015C-18038)

216

-

Electrical Schematic, GS-1530 / GS-1930

216

-

Gs3015D-1114, Gs3016P-142281)

219

-

-

Electrical Schematic, GS-1530/1930, ANSI/CSA

220

-

Gs3016P-158209)

224

-

-

Electrical Schematic, GS-3232, ANSI / CSA

225

-

Electrical Schematic, GS-3232, ANSI / CSA from

226

-

Electrical Schematic, GS-3232, ANSI / CSA (from Serial Number GS3215A-141899, GS3216P-142677)

234

-

Electrical Schematic, GS-2032, 2632, 2046, 2646, ANSI / CSA (from Serial Number GS3211A-110000 to GS3214A-135714, GS4612A-110000 to GS4614A-135366, GS4613D-101 to GS4615D-1303)

241

-

Electrical Schematic, GS-2032, 2632, 2046, 2646, ANSI/CSA

246

-

Electrical Schematic, GS-2032, 2632, 2046, 2646, ANSI / CSA

247

-

Electrical Schematic, GS-2032, 2632, 2046, 2646, ANSI / CSA

248

-

Electrical Schematic, GS-3246 / GS-4047, ANSI / CSA

255

-

GS4714D-101 to GS4715D-749)

255

-

-

Electrical Schematic, GS-3246 / GS-4047, ANSI / CSA

256

-

Electrical Schematic, GS-3246, GS4047 ANSI / CSA

257

-

Gs4616D-4433, Gs4716D-3102)

263

-

-

-

Electrical Schematics — CE and Australia Models

265

-

Electrical Schematic GS-1530, 1532, 1930, 1932, (from Serial Number GS3010A-110000 to GS3011A-110827) as / CE

266

-

Electrical Schematic, GS-1530/32_GS-1930/32 (from Serial Number GS3011A-110828 to GS3014A-136972, GS3011C-10000 to

270

-

Electrical Schematic, GS-1530, 1532, 1930, 1932, AS/CE

278

-

Electrical Schematic, GS-3232, as / CE

280

-

GS3214A-135714, GS3212C-10000 to GS3215C-14503)

280

-

-

Electrical Schematic, GS-3232, as / CE

284

-

Gs3215A-141898, Gs3215C-14504)

284

-

-

Electrical Schematic, GS-3232, as / CE (from Serial Numbers GS3215A-141899, GS3216P-142677 to GS3216P-146462)

288

-

Electrical Schematic, GS-3232, CE / as (from Serial Number GS3216P-146463)

292

-

Electrical Schematic, GS-2032, 2632, 2046, 2646, as / CE

295

-

GS4612C-10000 to GS4615C-14503, GS4613D-101 to GS4615D-1303)

297

-

GS4614A-135367 to GS4615A-137959, GS4615C-14504, GS4615D-1304)

301

-

-

Electrical Schematic, GS-2032, 2632, 2046, 2646, as / CE

301

-

Electrical Schematic, GS-2032, 2632, 2046, 2646, as / CE (from Serial Numbers GS3216P-146463, GS4616P-139711)

308

-

Electrical Schematic, GS-3246, as / CE

310

-

Gs4615D-1303)

310

-

Gs4615A-137959, Gs4615C-14504, Gs4615D-1304)

314

-

-

Electrical Schematic, GS-3246, as / CE

318

-

Gs4616P-138383)

318

-

-

Electrical Schematic, GS-3246, as / CE

322

-

Gs4616D-4433, Gs4716D-3102)

322

-

-

Electrical Schematic, GS-4047, as / CE

324

-

GS4715C-2130, GS4714D-101 to GS4715D-749)

325

-

-

Electrical Schematic, GS-4047, as / CE

328

-

Gs4715D-750)

328

-

-

Electrical Schematic, GS-4047, as / CE (from Serial Number GS4716D-3101)

332

-

Genie GS-2646 Service Manual (298 pages)

Brand: Genie

|

Category: Scissor Lifts

|

Size: 13.15 MB

Table of Contents

-

Introduction

2

-

Serial Number Information

2

-

Serial Number Legend

3

-

Safety Rules

5

-

Table of Contents

7

-

G Machine Specifications

15

-

Performance Specifications

16

-

Hydraulic Specifications

17

-

Manifold Component Specifications

18

-

Hydraulic Hose and Fitting Torque Specifications

19

-

Pre-Delivery Preparation Report

24

-

Maintenance Inspection Report

27

-

-

-

-

Checklist a Procedures

28

-

Inspect the Manuals and Decals

28

-

Perform Pre-Operation Inspection

29

-

Perform Function Tests

29

-

Perform 30 Day Service

30

-

Grease the Steer Yokes

30

-

-

Checklist B Procedures

31

-

Inspect the Batteries

31

-

Inspect the Electrical Wiring

34

-

Inspect the Electrical Contactor

35

-

Inspect the Tires, Wheels and Castle Nut Torque

35

-

Test the Emergency Stop

36

-

Test the Key Switch

36

-

Test the Automotive-Style Horn (if Equipped)

37

-

Test the Drive Brakes

38

-

Test the Drive Speed — Stowed Position

41

-

Test the Drive Speed — Raised Position

42

-

Test the Slow Drive Speed

43

-

Perform Hydraulic Oil Analysis

44

-

Inspect the Hydraulic Tank Cap Venting System

44

-

Check the Module Tray Latch Components

45

-

Inspect the Voltage Inverter (if Equipped)

46

-

Test the down Limit Switch and the Pothole Limit Switches

47

-

Test the up Limit Switch (if Equipped) and the Outrigger Limit Switches (if Equipped)

50

-

-

Checklist C Procedures

51

-

Test the Platform Overload System (if Equipped)

51

-

Replace the Hydraulic Tank Breather Cap — Models with Optional Hydraulic Oil

53

-

-

Checklist D Procedures

54

-

Check the Scissor Arm Wear Pads

54

-

Replace the Hydraulic Tank Return Filter Element

57

-

-

Checklist E Procedure

58

-

Test or Replace the Hydraulic Oil

58

-

-

Platform Controls

62

-

Circuit Boards

62

-

Controller Adjustments

64

-

Software Configuration

69

-

Outrigger ECM

74

-

Outrigger Controls Software Update

77

-

-

Platform Components

94

-

Platform

94

-

Platform Extension

95

-

-

Scissor Components

96

-

Scissor Assembly, GS-1530 and GS-1532

97

-

Scissor Assembly, GS-1930 and GS-1932

103

-

Scissor Assembly, GS-2032 and GS-2046

111

-

Scissor Assembly, GS-2632 and GS-2646

117

-

Scissor Assembly, GS-3232 and GS-3246

125

-

Lift Cylinder

132

-

Platform Overload System

137

-

-

Ground Controls

139

-

Manual Platform Lowering Cable

139

-

Level Sensors

140

-

-

Hydraulic Pump

146

-

Function Pump

146

-

Function Manifold Components — GS-1530, GS-1532, GS-1930 and GS-1932

148

-

Function Manifold Components — GS-2032, GS-2632, GS-3232, GS-2046, GS-2646 and GS-3246

150

-

Outrigger Function Manifold Components — GS-3232

152

-

Outrigger Cylinder Manifold Components — GS-3232

153

-

Check Valve Manifold Components — GS-1530, GS-1532, GS-1930 and GS-1932

154

-

Valve Adjustments — Function Manifold

155

-

Valve Coils

159

-

-

Hydraulic Tank

161

-

Steer Axle Components

162

-

Yoke and Drive Motor

162

-

Steer Cylinder

163

-

Steer Bellcrank

164

-

-

Non-Steer Axle Components

165

-

Drive Brake

165

-

-

Brake Release Hand Pump Components

166

-

Outrigger Components

167

-

Outrigger Cylinder

167

-

Fault Code Chart

171

-

Outrigger Fault Code Chart

173

-

Hydraulic Schematics

175

-

-

Electrical Component Legend

176

-

Wire Color Legend

177

-

ECM Pin-Out Legend

178

-

Outrigger ECM Pin-Out Legend

179

-

Limit Switch Legend

182

-

Electrical Symbols Legend

183

-

Component Reference and Hydraulic Symbols Legend

288

-

(From Serial Number GS3205-75407 to GS3206-80131) GS-2046/2646/3246 (from Serial Number GS4605-75438 to GS4606-79027)

292

-

(From Serial Number GS3206-80132 to GS3207-84866) GS-2046/2646/3246 (Form Serial Number GS4606-79028 to GS4607-84839)

294

-

(From Serial Number GS3208C-101)

295

-

-

Advertisement

Genie GS-2646 Service Manual (236 pages)

Brand: Genie

|

Category: Lifting Systems

|

Size: 7.63 MB

Table of Contents

-

Introduction

2

-

Table of Contents

5

-

Machine Specifications

13

-

Performance Specifications

14

-

Hydraulic Specifications

15

-

Manifold Component Specifications

16

-

Hydraulic Hose and Fitting Torque Specifications

18

-

-

Scheduled Maintenance Procedures

21

-

Pre-Delivery Preparation Report

22

-

Maintenance Inspection Report

25

-

-

Checklist a Procedures — Rev B

26

-

Perform Pre-Operation Inspection

26

-

Perform Function Tests

26

-

Perform 30 Day Service

27

-

Grease the Steer Yokes

27

-

-

Checklist B Procedures — Rev C

28

-

Inspect the Electrical Wiring

29

-

Inspect the Tires and Wheels (Including Castle Nut Torque)

30

-

Test the Key Switch

30

-

Test the Automotive-Style Horn (if Equipped)

31

-

Test the Drive Brakes

32

-

Test the Drive Speed — Stowed Position

34

-

Test the Drive Speed — Raised Position

35

-

Perform Hydraulic Oil Analysis

36

-

Replace the Hydraulic Tank Return Filter

36

-

Check the Module Tray Latch Components

37

-

-

Checklist C Procedure — Rev C

39

-

Check the Scissor Arm Wear Pads

39

-

-

Checklist D Procedure — Rev a

40

-

Test or Replace the Hydraulic Oil

40

-

-

Platform Controls — Rev B

42

-

Circuit Boards

43

-

Joystick Controller

43

-

Controller Adjustments

45

-

Software Configuration

53

-

-

Platform Components — Rev a

56

-

Platform

56

-

Platform Extension

57

-

-

Scissor Components — Rev a

58

-

Scissor Assembly, GS-2046

59

-

Scissor Assembly, GS-2646

65

-

Scissor Assembly, GS-3246

73

-

Lift Cylinder

82

-

-

Ground Controls — Rev B

86

-

Manual Platform Lowering Cable, GS-2046 and GS-2646

86

-

Manual Platform Lowering, GS-3246

87

-

Toggle Switches

88

-

Control Relays

89

-

Tilt Level Sensor (before Serial Number 50444)

90

-

Tilt Level Sensor (after Serial Number 50443)

94

-

-

Hydraulic Pump — Rev a

98

-

Function Pump

98

-

-

Function Manifold — Rev B

100

-

Function Manifold Components (from Serial Number 17408 to 17481)

100

-

Function Manifold Components (from Serial Number 17482 to 36044)

102

-

Function Manifold Components (after Serial Number 36044)

104

-

Function Manifold Components — Models with Traction Control

106

-

Valve Adjustments — Function Manifold

108

-

Platform Lift Relief Valve Manifold Components, GS-3246 Models (before Serial Number 36045)

115

-

Valve Adjustments — Lift Relief Manifold, GS-3246 Models (before Serial Number 36045)

116

-

Valve Coils

118

-

-

Hydraulic Tank — Rev a

120

-

Hydraulic Tank

120

-

-

Steer Axle Components — Rev a

121

-

Yoke and Drive Motor

121

-

Steer Cylinder

123

-

Steer Bellcrank

124

-

-

Non-Steer Axle Components — Rev a

125

-

Drive Brake

125

-

-

Brake Release Hand Pump Components — Rev a

126

-

Brake Release Hand Pump Components

126

-

Fault Code Chart (after Serial Number 17407) — Rev a

129

-

-

Chart 1

130

-

All Functions will Not Operate — Rev a

130

-

Pump Motor will Not Operate — Rev a

132

-

All Functions Inoperative, Power Unit Starts and Runs — Rev a

134

-

Ground Controls Inoperative

135

-

Platform Controls Inoperative

136

-

Platform up Function Inoperative — Rev a

137

-

Platform down Function Inoperative — Rev a

138

-

Steer Left Function Inoperative — Rev a

140

-

Electrical Schematic

157

-

Platform Controls Wiring Diagram

162

-

Electrical Schematic

170

-

Electrical Schematic

171

-

Electrical Schematic

172

-

Electrical Schematic

174

-

Electrical Schematic

176

-

Electrical Schematic

178

-

Electrical Schematic

179

-

Electrical Schematic

180

-

Electrical Schematic

182

-

Electrical Schematic

183

-

Electrical Schematic

184

-

Hydraulic Schematic GS-2046 and GS-2646

219

-

Hydraulic Schematic GS-2046 and GS-2646

220

-

Hydraulic Schematic, GS-2046 and GS-2646

221

-

Genie GS-2646 Service Manual (236 pages)

Scissor Lifts

Brand: Genie

|

Category: Lifting Systems

|

Size: 16.59 MB

Table of Contents

-

Introduction

2

-

Table of Contents

5

-

Part

12

-

Machine Specifications

13

-

Performance Specifications

14

-

Hydraulic Specifications

15

-

Manifold Component Specifications

16

-

Hydraulic Hose and Fitting Torque Specifications

18

-

Scheduled Maintenance Procedures

21

-

Actionrental.com

21

-

Pre-Delivery Preparation Report

22

-

Maintenance Inspection Report

25

-

-

Checklist a Procedures — Rev B

26

-

Perform Pre-Operation Inspection

26

-

Perform Function Tests

26

-

Perform 30 Day Service

27

-

Grease the Steer Yokes

27

-

-

Checklist B Procedures — Rev C

28

-

Inspect the Electrical Wiring

29

-

Inspect the Tires and Wheels (Including Castle Nut Torque)

30

-

Test the Key Switch

30

-

Test the Automotive-Style Horn (if Equipped)

31

-

Test the Drive Brakes

32

-

Test the Drive Speed — Stowed Position

34

-

Test the Drive Speed — Raised Position

35

-

Perform Hydraulic Oil Analysis

36

-

Replace the Hydraulic Tank Return Filter

36

-

Check the Module Tray Latch Components

37

-

-

Checklist C Procedure — Rev C

39

-

Check the Scissor Arm Wear Pads

39

-

-

Checklist D Procedure — Rev a

40

-

Test or Replace the Hydraulic Oil

40

-

-

Platform Controls — Rev B

42

-

Circuit Boards

43

-

Joystick Controller

43

-

Controller Adjustments

45

-

Software Configuration

53

-

-

Platform Components — Rev a

56

-

Platform

56

-

Platform Extension

57

-

-

Scissor Components — Rev a

58

-

Scissor Assembly, GS-2046

59

-

Scissor Assembly, GS-2646

65

-

Scissor Assembly, GS-3246

73

-

Lift Cylinder

82

-

-

Ground Controls — Rev B

86

-

Manual Platform Lowering Cable, GS-2046 and GS-2646

86

-

Manual Platform Lowering, GS-3246

87

-

Toggle Switches

88

-

Control Relays

89

-

Tilt Level Sensor (before Serial Number 50444)

90

-

Tilt Level Sensor (after Serial Number 50443)

94

-

-

Hydraulic Pump — Rev a

98

-

Function Pump

98

-

-

Function Manifold — Rev B

100

-

Function Manifold Components (from Serial Number 17408 to 17481)

100

-

Function Manifold Components (from Serial Number 17482 to 36044)

102

-

Function Manifold Components (after Serial Number 36044)

104

-

Function Manifold Components — Models with Traction Control

106

-

Valve Adjustments — Function Manifold

108

-

Platform Lift Relief Valve Manifold Components, GS-3246 Models (before Serial Number 36045)

115

-

Valve Adjustments — Lift Relief Manifold, GS-3246 Models (before Serial Number 36045)

116

-

Valve Coils

118

-

-

Hydraulic Tank — Rev a

120

-

Hydraulic Tank

120

-

-

Steer Axle Components — Rev a

121

-

Yoke and Drive Motor

121

-

Steer Cylinder

123

-

Steer Bellcrank

124

-

-

Non-Steer Axle Components — Rev a

125

-

Drive Brake

125

-

-

Brake Release Hand Pump Components — Rev a

126

-

Brake Release Hand Pump Components

126

-

Electrical Schematic

157

-

Platform Controls Wiring Diagram

162

-

Electrical Schematic

171

-

Electrical Schematic

172

-

Electrical Schematic

176

-

Electrical Schematic

179

-

Electrical Schematic

180

-

Electrical Schematic

183

-

Electrical Schematic

184

-

Electrical Schematic

187

-

Electrical Schematic

188

-

Electrical Schematic

191

-

Electrical Schematic

192

-

Hydraulic Schematic, GS-2046 and GS-2646

219

-

-

Genie GS-2646 Service Manual (163 pages)

Scissor Lifts

Brand: Genie

|

Category: Lifting Systems

|

Size: 4.72 MB

Table of Contents

-

Introduction

2

-

Table of Contents

7

-

Specifications

13

-

Machine Specifications, GS-2646

14

-

Machine Specifications, GS-3246

15

-

Hydraulic Specifications, All Models

16

-

Performance Specifications, All Models

16

-

Hydraulic Hose and Fitting Torque Specifications

17

-

Machine Specifications, GS-2046

13

-

-

Scheduled Maintenance Inspections

19

-

Maintenance Inspection Report

22

-

-

Scheduled Maintenance Procedures

23

-

Inspect the Decals and Placards

24

-

Inspect the Operator’s and Safety Manuals

24

-

Inspect for Damage and Loose or Missing Parts

25

-

Check for Hydraulic Leaks

26

-

Check the Hydraulic Oil Level

26

-

Test the Platform and Ground Controls

27

-

Test the Manual Platform Lowering Operation

28

-

Test the Tilt Sensor

28

-

Test the Lift/Drive Select Switch

29

-

Test the Pothole Guards

29

-

Perform 30 Day Service

30

-

Check the Batteries

31

-

Inspect the Electrical Wiring

32

-

Inspect the Tires and Wheels (Including Castle Nut Torque)

33

-

Test the Key Switch

33

-

Test the Emergency Stop Buttons

34

-

Test the Service Horn

34

-

Test the Drive Brakes

35

-

Test the Drive Speed — Raised Position

37

-

Test the Drive Speed — Stowed Position

37

-

Check the Electrical Contactor

38

-

Perform Hydraulic Oil Analysis

38

-

Replace the Hydraulic Return Filter

39

-

Check the Module Tray Latch Components

40

-

Test or Replace the Hydraulic Oil

41

-

Fault Code Chart before Serial Number 17408

45

-

Normal Operation Code Chart before Serial Number 17408

48

-

Fault Code Chart (after Serial Number 17407)

50

-

-

1 All Functions will Not Operate

51

-

2 Pump Motor will Not Operate

56

-

Pump Motor will Not Operate after Serial Number 6900

56

-

All Functions Inoperative, Power Unit Starts and Runs (no Applicable Code)

58

-

-

5 Ground Controls Inoperative, Platform Controls Operate Normally

59

-

6 Platform Controls Inoperative, Ground Controls Operate Normally

60

-

7 Platform up Function Inoperative

62

-

8 Platform down Function Inoperative

63

-

Platform down Function Inoperative GS-3246 Models

65

-

-

10 Steer Left Function Inoperative

67

-

11 Steer Right Function Inoperative

69

-

12 All Drive Functions Inoperative, All Other Functions Operate Normally

71

-

13 Brake Release Function Inoperative

73

-

15 Drive Reverse Function Inoperative

75

-

16 Machine will Not Drive at Full Speed

76

-

Machine Drives at Full Speed with Platform Raised

78

-

Electrical Components

84

-

Module Tray Legend (before Serial Number 6901)

86

-

Module Tray Legend (after Serial Number 6900)

87

-

Electrical Symbols Legend

88

-

Electrical Schematic (before Serial Number 6901)

90

-

Electrical Schematic (from Serial Number 6901 to 8931)

94

-

Electrical Schematic (from Serial Number 8932 to 17407)

98

-

Electrical Schematic (after Serial Number 17407)

102

-

Ground Controls and Level Sensor Box Legend

105

-

Platform Controls Legend (before Serial Number 17408)

106

-

Platform Controls Legend (after Serial Number 17407)

107

-

Hydraulic Symbols Legend

108

-

Hydraulic Schematic (before Serial Number 17482)

109

-

Hydraulic Schematic (after Serial Number 17481)

111

-

-

Platform Controls

114

-

Joystick Controller

114

-

Software Configuration

115

-

How to Set the Dip Switch Codes

116

-

Toggle Switches

118

-

-

Platform Components

119

-

Platform

119

-

Platform Extension

120

-

-

Scissor Components

122

-

Scissor Assembly, GS-2046

123

-

Scissor Assembly, GS-2646

129

-

Scissor Assembly, GS-3246

137

-

Lift Cylinder

144

-

-

Ground Controls

147

-

Manual Platform Lowering Cable, GS-2046 & GS-2646

147

-

-

Hydraulic Pump

149

-

Function Manifold Components (before Serial Number 11501)

150

-

Function Manifold Components (after Serial Number 11500)

152

-

Valve Adjustments — Function Manifold

154

-

Genie GS-2646 Maintenance Manual (97 pages)

Scissor Lifts

Brand: Genie

|

Category: Lifting Systems

|

Size: 2.64 MB

Table of Contents

-

Models Included in this Manual

3

-

Find Additional Manuals for Your Model

3

-

Glossary of Terms

4

-

Revision History

5

-

Safety Rules

7

-

Table of Contents

9

-

-

Performance Specifications

12

-

Function Speeds GS-30, GS-32, GS-46, GS-47

12

-

Function Speeds GS-69, GS-84, GS-90

12

-

Drive Speeds

14

-

-

Torque Specifications

15

-

Tires and Wheels

15

-

-

Battery Specifications

16

-

Battery Specifications — DC and be Models

16

-

-

Engine Specifications

17

-

Engine Operator and Maintenance Manuals

17

-

Deutz Engine Models

17

-

Perkins Engine Models

18

-

Ford Engine Models

18

-

Kubota Engine Models

19

-

Kohler Engine Models

19

-

GM Engine Models

20

-

-

Hydraulic Specifications

21

-

Hydraulic Relief Valves

21

-

Hydraulic and Drive Hub Fluid Capacities

23

-

Hydraulic Oil Specifications

24

-

Hydraulic Hose and Fitting Torque Specifications

27

-

Torque Procedure

28

-

-

Maintenance Procedures

31

-

Introduction

31

-

Maintenance Schedule

33

-

Pre-Delivery Preparation Report

34

-

Scheduled Maintenance Inspection Report — Scissor Lifts

35

-

Programmed Maintenance Inspection Report — Scissor Lifts

36

-

-

Commissioning Procedures

37

-

Perform 50 Hour Service

37

-

Perform Engine Maintenance — 50 Hours

37

-

Perform 150 Hour Service

38

-

-

Quarterly Maintenance Procedures

39

-

Check for Open Bulletins and Owner Registration

39

-

Battery Inspection

40

-

Check the Module Tray Latch Components

42

-

Inspect the Battery Balancer — GS-69 DC

43

-

Inspect the Electrical Wiring

44

-

Inspect the Electrical Contactor

45

-

DC and GS-69 be

45

-

Inspect the Voltage Inverter (if Equipped)

45

-

Test the Flashing Beacons (if Equipped)

46

-

Visual Inspection of the Hydraulic Oil

47

-

Inspect the Hydraulic Filters

48

-

Check the Exhaust System — Engine Models

49

-

Inspect the Fuel Tank Check Valve Venting System — GS-69 RT Gas Models

49

-

Test the Fuel Select Operation — Gasoline/Lpg Models

50

-

Check and Adjust the Engine RPM

51

-

Inspect the Tires, Wheels and Lug Nut Torque

53

-

Confirm the Proper Brake Configuration — GS-69, GS-84, GS-90

54

-

Test the Drive Brakes

54

-

Test the Drive Speed — Stowed Position

55

-

Test the Drive Speed — Raised Position

55

-

Test the down Limit Switch, Level Sensor and Pothole Limit Switches

56

-

And GS-47

56

-

-

Test the Platform Gate Proximity Switches and the Extension Deck Limit Switch — GS-2646 AV, GS-2646 AV35

60

-

-

Annual Maintenance Procedures

62

-

Check the Drive Hub Oil Level and Fastener Torque

62

-

Test the Function Pump — GS-69 be and GS-69 DC

62

-

Test the Oscillate Axle — GS-90

63

-

Test the down Limit Switch Descent Delay — GS-69, GS-84 and

66

-

Equipped)

66

-

-

Test the Platform Overload Pressure Transducer and Platform Height Sensor — GS-30, GS-32, GS-46 and GS-47 (if Equipped)

68

-

(If Equipped)

71

-

-

Test the Platform Overload System — GS-69 (if Equipped)

73

-

Test the Platform Overload System — GS-84 and GS-90 (if Equipped)

75

-

-

Programmed Maintenance Procedures

77

-

P0-1 Inspect the Engine Air Filter — GS-69 RT

77

-

P0-2 Grease the Steer Yokes — GS-30, GS-32, GS-46 and GS-47

78

-

P0-3 Deutz Engine Maintenance — under 1000 Hours

79

-

P0-4 Ford Engine Maintenance — under 1000 Hours

80

-

P0-5 Kohler Engine Maintenance — under 1000 Hours

81

-

P0-6 Kubota Engine Maintenance — under 1000 Hours

82

-

P0-7 Perkins Engine Maintenance — under 1000 Hours

83

-

P0-8 GM Engine Maintenance — under 1000 Hours

84

-

P1-1 Perform Engine Maintenance — 1000 Hours

85

-

P1-2 Replace the Drive Hub Oil — GS-69, GS-84 and GS-90

86

-

P2-1 Perform Engine Maintenance — 2000 Hours

86

-

P2-2 Replace the Hydraulic Filters

87

-

P2-3 Check the Free-Wheel Configuration — GS-84 and GS-90

88

-

P2-4 Check the Scissor Arm Wear Pads (and Slider Blocks, if Equipped)

90

-

P2-5 Grease the Steer Axle Wheel Bearings — GS-69 be and GS-69 DC

93

-

P2-6 Test or Replace the Hydraulic Oil

94

-

P3-1 Perform Engine Maintenance — 3000 Hours

95

-

Genie GS-2646 Operator’s Manual (86 pages)

Scissor Lift

Brand: Genie

|

Category: Lifting Systems

|

Size: 9.97 MB

Table of Contents

-

Table of Contents

2

-

Introduction

3

-

Hazard Classification

4

-

Intended Use

4

-

Safety Sign Maintenance

4

-

-

Symbol and Hazard Pictorials Definitions

5

-

General Safety

7

-

Gs-30 • Gs-32 • Gs-46 • Gs

10

-

Personal Fall Protection

12

-

-

Personal Safety

12

-

Tip-Over Hazards

13

-

Electrocution Hazards

13

-

-

Work Area Safety

13

-

Crushing Hazard

16

-

Operation on Slopes Hazards

16

-

Fall Hazards

17

-

Collision Hazards

17

-

Bodily Injury Hazard

18

-

Explosion and Fire Hazards

18

-

Damaged Machine Hazards

19

-

Component Damage Hazards

19

-

Battery Safety

19

-

Burn Hazards

19

-

Lifting Hazard

20

-

Electrocution/Burn Hazards

20

-

Tip-Over Hazard

20

-

Lockout after each Use

20

-

Panel Carrier Safety

21

-

-

Legend

22

-

Ground Control Panel

25

-

Controls

25

-

Platform Control Panel

26

-

Pre-Operation Inspection Fundamentals

30

-

-

Inspections

30

-

Pre-Operation Inspection

31

-

Function Test Fundamentals

32

-

Test the Up/Down Functions

33

-

Test Emergency Stop

33

-

At the Ground Controls

33

-

Test Emergency Lowering

34

-

Test the Horn

34

-

Test the Function Enable Switch and the Up/Down Functions

36

-

Test the Drive Function Button

36

-

Test the Steering

37

-

Test Drive and Braking

37

-

Test the Tilt Sensor Operation

38

-

Test Elevated Drive Speed

38

-

Test the Pothole Guards

38

-

Test the Outrigger Function (GS-3232)

39

-

Workplace Inspection Fundamentals

43

-

Workplace Inspection Checklist

43

-

Inspection for Decals with Words GS-1530 and GS-1930

44

-

Inspection for Decals with Words GS-2032, GS-2632 and GS-3232

46

-

Inspection for Decals with Words GS-2046, GS-2646, GS-3246 and GS-4047

48

-

Inspection for Decals with Symbols GS-1530 and GS-1930

50

-

Inspection for Decals with Symbols GS-2032, GS-2632 and GS-3232

52

-

Inspection for Decals with Symbols GS-2046, GS-2646, GS-3246 and GS-4047

54

-

Fundamentals

56

-

-

Operating Instructions

56

-

Operation from Ground

57

-

Operation from Platform

57

-

Emergency Lowering

57

-

Emergency Stop

57

-

To Position Outriggers (GS-3232 Models)

58

-

To Steer

58

-

To Drive

59

-

To Select Drive Speed

59

-

Controller Identification

59

-

To Position Platform

59

-

Driving on a Slope

62

-

To Determine the Slope Grade

62

-

Operation from Ground with Controller

63

-

Operational Indicator Codes

63

-

Battery Level Indicator

63

-

How to Use the Safety Arm

64

-

How to Fold down the Guardrails

64

-

How to Raise the Guardrails

65

-

Panel Carrier Assembly

66

-

Panel Restraints

66

-

Install the Restraints to the Rail

66

-

Install Panel Cradles

67

-

Panel Cradle Operation

67

-

Battery and Charger Instructions

68

-

Maintenance-Free Batteries

68

-

Standard Batteries

68

-

To Charge Battery

68

-

-

Transport and Lifting Instructions

69

-

Brake Release Operation

70

-

Securing to Truck or Trailer for Transit

71

-

Lifting the Machine with a Forklift

72

-

Lifting Instructions

73

-

Center of Gravity Table

73

-

Maintenance Symbols Legend

74

-

Check the Hydraulic Oil Level

74

-

Genie GS-2646 Operator’s Manual (67 pages)

Brand: Genie

|

Category: Boom Lifts

|

Size: 2.77 MB

Table of Contents

-

Table of Contents

2

-

Introduction

3

-

Symbol and Hazard Pictorials Definitions

5

-

General Safety

7

-

Personal Safety

10

-

Work Area Safety

11

-

Legend

18

-

Controls

21

-

Inspections

25

-

Workplace Inspection

33

-

Operating Instructions

38

-

Emergency Stop

47

-

Emergency Lowering

47

-

To Retract Outrigger

48

-

To Steer

48

-

To Drive

48

-

Driving on a Slope

48

-

Gs-30 • Gs-32 • Gs

48

-

To Determine Slope Grade

49

-

Error Indicators

49

-

-

Transport and Lifting Instructions

53

-

Maintenance

57

-

Specifications

59

Genie GS-2646 Operator’s Manual (69 pages)

Brand: Genie

|

Category: Boom Lifts

|

Size: 5.16 MB

Table of Contents

-

Table of Contents

2

-

Introduction

3

-

Symbol and Hazard Pictorials Definitions

5

-

General Safety

7

-

Personal Safety

9

-

Work Area Safety

10

-

Legend

18

-

Controls

21

-

Inspections

27

-

Operating Instructions

44

-

Emergency Lowering

45

-

Transport and Lifting Instructions

52

-

Maintenance

57

-

Specifications

59

Genie GS-2646 Operator’s Manual (69 pages)

Brand: Genie

|

Category: Lifting Systems

|

Size: 6.14 MB

Table of Contents

-

Table of Contents

2

-

Introduction

3

-

Symbol and Hazard Pictorials Definitions

5

-

General Safety

7

-

Personal Safety

9

-

Work Area Safety

10

-

Legend

18

-

Controls

21

-

Inspections

25

-

Operating Instructions

42

-

Gs-30 • Gs-32 • Gs-46 • Gs

49

-

Transport and Lifting Instructions

52

-

Maintenance

57

-

Specifications

59

Genie GS-2646 Operator’s Manual (68 pages)

Brand: Genie

|

Category: Lifting Systems

|

Size: 9.33 MB

Table of Contents

-

Table of Contents

2

-

Introduction

3

-

Symbol and Hazard Pictorials Definitions

5

-

General Safety

7

-

Gs-30 • Gs-32 • Gs-46 • Gs

9

-

Personal Safety

10

-

Work Area Safety

11

-

Legend

19

-

Controls

22

-

Inspections

28

-

Operating Instructions

44

-

Transport and Lifting Instructions

52

-

Maintenance

57

-

Specifications

59

Genie GS-2646 Operator’s Manual (62 pages)

Brand: Genie

|

Category: Scissor Lifts

|

Size: 4.57 MB

Table of Contents

-

Table of Contents

2

-

Introduction

3

-

Symbol and Hazard Pictorials Definitions

5

-

General Safety

7

-

Personal Safety

9

-

Work Area Safety

10

-

Legend

18

-

Controls

21

-

Inspections

25

-

Operating Instructions

40

-

Transport and Lifting Instructions

48

-

Maintenance

52

-

Specifications

54

Genie GS-2646 Operator’s Manual (39 pages)

Brand: Genie

|

Category: Boom Lifts

|

Size: 2.27 MB

Table of Contents

-

Table of Contents

2

-

Safety

3

-

Legend

11

-

Controls

12

-

Pre-Operation Inspection

14

-

Maintenance

16

-

Function Tests

18

-

Workplace Inspection

23

-

Operating Instructions

24

-

Transport Instructions

29

-

Decals

30

-

Specifications

34

Advertisement

Related Products

-

Genie GS-2046

-

Genie GTH-1048

-

Genie GS-1532

-

Genie GS-1930

-

Genie GS-1530

-

Genie GS-1932

-

Genie GS-3232

-

Genie GS-3246

-

Genie GTH-2306

-

Genie GS-2646 AV

Genie Categories

Lifting Systems

Garage Door Opener

Boom Lifts

Security Camera

Digital Camera

More Genie Manuals

September 2016

DTC

Message on

Number

GCON LCD

F003:SWITCHFAULT

F003

DOWN LIMIT1:BAT+

F005:SWITCHFAULT

F005

POTHOLE:BAT+

F007:SWITCHFAULT

F007

CHASSISTILT:BAT+

F008:SENSORFAULT

F008

OVLD XDUCER:BAT+

F009:SENSORFAULT

F009

OVLD XDUCER:BAT-

F010:SENSORFAULT

F010

PLAT HEIGHT:BAT+

F011:SENSORFAULT

F011

PLAT HEIGHT:BAT-

F031:SWITCHFAULT

F031

OAC SWITCH:BAT+

F034:SENSORFAULT

F034

OVLD:PLAT HEIGHT

F035:SENSORFAULT

F035

OVLD RANGE:LOW

F036:SENSORFAULT

F036

OVLD RANGE:HI

F072:SENSORFAULT

F072

FUNCTION CUT B+

F073:SENSORFAULT

F073

DECK SENSOR B+

Part No. 1272218

Problem

Description

Short circuit of the down limit #1 switch at

system startup.

Short circuit of the pothole limit #1 switch at

system startup.

Short circuit of the chassis digital tilt switch at

system startup.

Short circuit of the Platform Overload

Transducer circuit to battery positive.

Short circuit of the Platform Overload

Transducer circuit to battery negative.

Short circuit of the Platform Height Sensor

circuit to battery positive.

Short circuit of the Platform Height Sensor

circuit to battery negative.

Short circuit of the obstruction above chassis

switch to battery positive.

Height Sensor settings are not calibrated

correctly.

Height Sensor setting is lower than calibrated

stowed height.

Height Sensor setting is higher than

calibrated maximum height.

Function Cutout sensor B+ fault.

Power Deck sensor B+ fault.

GS-2646 AV • GS-2646 AV35

Service and Repair Manual

Possible

Causes

• Short circuit of the down limit switch circuit.

• Down limit #1 switch short circuit

• GCON ECM

• Short circuit of the pothole switch circuit.

• Pothole limit #1 switch short circuit

• GCON ECM

• Short circuit of the chassis digital tilt switch

circuit.

• Chassis digital tilt switch short circuit

• GCON ECM

• Short circuit in the transducer circuit.

• Faulty pressure transducer

• GCON ECM

• Short circuit in the transducer circuit.

• Faulty pressure transducer

• GCON ECM

• Short circuit in the platform height circuit.

• Faulty platform height sensor

• GCON ECM

• Short circuit in the platform height circuit.

• Faulty platform height sensor

• GCON ECM

• Short circuit of the obstruction above chassis

switch to battery positive.

• GCON

• Short circuit in the level roll sensor circuit.

• Faulty level sensor

• GCON ECM

• Short circuit in the level roll sensor circuit.

• Faulty level sensor

• GCON ECM

• Short circuit in the left front outrigger sensor

circuit.

• Faulty pressure transducer

• GCON ECM

• Short circuit in the left front outrigger sensor

circuit.

• Faulty pressure transducer

• GCON ECM

• Short circuit in the right front outrigger sensor

circuit.

• Faulty pressure transducer

• GCON ECM

Failure

Mode

All functions

inhibited except

platform down.

All functions

inhibited except

platform down as long

as machine is in the

elevated position. If

machine is in stowed

position, all

functionality is

resumed.

All functions

inhibited except

platform down as long

as machine is in the

elevated position. If

machine is in stowed

position, all

functionality is

resumed.

All functions inhibited.

All functions inhibited.

All functions

inhibited except

platform down as long

as machine is in the

elevated position. If

machine is in stowed

position, all

functionality is

resumed.

All functions

inhibited except

platform down as long

as machine is in the

elevated position. If

machine is in stowed

position, all

functionality is

resumed.

All functions inhibited.

All functions inhibited.

All functions inhibited.

All functions inhibited.

All functions inhibited.

All functions inhibited.

91

Please note: Fault Codes showing on ground control can be found starting on page 182 of the Genie Scissor Service and Repair Manual found here or

by visiting Genie Service Manuals web page found here. For service for your Genie Scissor Lift please contact your

local Genie dealer via the Dealer Locator.

——————————————————————————————-

Did you ever wish a machine would simply tell you what is wrong with it and how to fix it? Better yet, what if the user of a scissor lift calls you up with a service call, tells you the diagnostic information and you are able to resolve it over

the phone? The onboard diagnostics capability of Genie® slab scissors gives you that convenience today, and continues to get even better. With 272 diagnostic trouble codes and 6 operation indicator codes, Genie scissor lifts tell you the problem

and where to look to solve it.

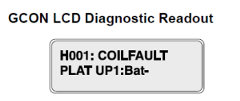

Diagnostic Trouble Codes (DTC)

These codes are generated by the Genie SmartLink Diagnostic Systems (GSDS) on board diagnostic system to indicate that a device or circuit malfunction has been detected. There are five types of DTC,

checking out the various systems; hydraulic, battery/power, user interface, sensors/switches, and controls. These codes are displayed on the alpha numeric platform control display and on the ground control (GCON) display.

How easy is that?

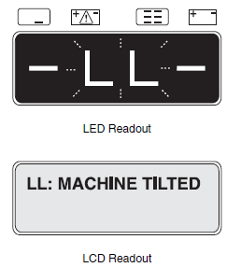

Operation Indicator Codes (OIC)

OIC codes are generated by the GSDS to indicate when the operator has inadvertently placed the scissor into an abnormal operating status. A common example is when the operator has driven

the scissor onto a surface that is not level and attempts to raise it. The scissor will alert the operator and prevent raising the scissor. The platform display and the ground control display OIC codes and status.

These error codes are available on current Genie scissor lifts, and as Genie adds new and additional technology to its products, such as telematics, CAN bus, and WiFi, this

information will become available from anywhere you are, connected over the internet through your computer or smartphone. Rapid and easy troubleshooting means more uptime and higher utilization resulting in better total cost of ownership.

Not sure if your scissor lift is equipped with Smartlink? Below you will find a list of Smartlink equipment Genie Runabouts and Genie Scissor lifts:

- Genie Runabout: GR-12, GR-15, GR-20 / GRC-12 /QS-12R, QS-15R, QS-20R, QS-12W, QS15W, QS20W

- Serial range: GR10-2000 and up, GRC11-1000 and up ,QS11-1000 and up

- Slab Scissors: GS-1530 / GS-1532, GS-1930 / GS-1932, GS-2032/2632/3232, GS-2046/2646/3246

- Serial range: GSXX10A-110000 and up

- Slab Scissors: GS-4047

- Serial range: GS4712C-101 and up

- RT Electric Scissors: GS-2669 DC, GS-3369 DC, GS4069 DC

- Serial range: GS6912-1300 and up

- RT Hybrid Scissors: GS-2669 BE, GS-3369 BE, GS4069 BE

- Serial range: GS6914-5000 and up

For more information on fault codes please reference the Genie Scissor Service and Repair Manual found here, beginning

on page 182 or contact your dealer by visiting the Genie Dealer Locator

File Specifications:1746/1746078-gs2646av.pdf file (07 Feb 2023) |

Accompanying Data:

Genie GS-2646AV Lifting Systems PDF Service And Repair Manual (Updated: Tuesday 7th of February 2023 02:10:19 AM)

Rating: 4.2 (rated by 78 users)

Compatible devices: GR-12, GS-2632, IWP Super Series, GS-3390, S-45 XC, GS-2046, GS-2646, GTH-3007 Stage B.

Recommended Documentation:

Service And Repair Manual (Text Version):

(Ocr-Read Summary of Contents of some pages of the Genie GS-2646AV Document (Main Content), UPD: 07 February 2023)

-

42, Service and Repair Manual September 2016 Ground Controls 32 GS-2646 AV • GS-2646 AV35 Part No. 1272218 11 Place the new level sensor on to the level sensor bracket with the «Y» on the level sensor closest to the ground controls of the machine and the «X» on the level sensor closest to the steer end of the machine. Tip — over hazard. Failure to install the level sensor as instructed, cou…

-

91, Genie GS-2646AV September 2016 Service and Repair Manual GCON I/O Map (with powered extension deck) Part No. 1272218 GS-2646 AV • GS-2646 AV35 81 GCON Pin Number Circuit Function I/O Type Wire Gauge and Color J-3 Connector – Green J3-01 No Circuit N/A N/A J3-02 GCON — Alarm Digital Output 18 BL J3-03 Switch/Sensor Power Digital Output 14 RD J3-04 Automotive Horn Digital Output 18 WH J3-05 Pothole Limit Switch Digital Input 18 OR/RD J3-06 Gr…

-

116, Service and Repair Manual September 2016 106 Electrical Schematic • GS-2646 AV and GS-2646 AV35 (with manual extension deck) (from GS4612A-110000)

… -

108, Service and Repair Manual September 2016 Limit Switch Legend 98 GS-2646 AV • GS-2646 AV35 Part No. 1272218 Limit Switch Legend 1 pothole switches LS7, LS8 2 down limit switch LS6 3 quick disconnect limit switch LS30 (no charger option) 4 powered extension deck LS29 (option) 5 front gate PX3 (steer end) 6 rear gate PX4 (non-steer end)

… -

99, September 2016 Service and Repair Manual Type «UXXX» Faults Part No. 1272218 GS-2646 AV • GS-2646 AV35 89 DTC Number Message on GCON LCD Problem Description Possible Causes Failure Mode U001 U001:SWITCHFAULT GCON MAIN FTN EN Short circuit of the GCON main function enable switch at system startup. • Short circuit of the GCON main function enable switch • GCON…

-

123, September 2016 Service and Repair Manual Hydraulic Schematics Part No. 1272218 GS-2646 AV • GS-2646 AV35 113 Section 6 Hydra ulic Sc hemat ics Hydraulic Schematic

… -

25, September 2016 Service and Repair Manual Ground Controls Part No. 1272218 GS-2646 AV • GS-2646 AV35 15 The ground controls, used to operate the machine from the ground, can also be used to tune the performance of the machine. The ground controls consist of an Electronic Control Module (ECM), emergency stop button, selector/key switch and circuit breaker. Activating the function e…

-

114, Service and Repair Manual September 2016 104 GS-2646 AV • GS-2646 AV35 Part No. 1272218 Electrical Schematic • GS-2646 AV and GS-2646 AV35 (with manual extension deck) (from GS4612A-110000)

… -

86, Service and Repair Manual September 2016 76 GS-2646 AV • GS-2646 AV35 Part No. 1272218 This page intentionally left blank.

… -

6, Genie GS-2646AV Service and Repair Manual September 2016 Safety Rules vi GS-2646 AV • GS-2646 AV35 Part No. 1272218 Personal Safety Any person working on or around a machine must be aware of all known safety hazards. Personal safety and the continued safe operation of the machine should be your top priority. Read each procedure thoroughly. This manual and the decals on the machine, use signa…

-

1, Service and Repair Manual Serial Number Range GS-2646AV from GS4612A-110000 from GS4616P- 138362 to GS4616P- 141799 This manual includes: Repair procedures Fault Codes Electrical and Hydraulic Schematics GS-2646AV 35 from GS46P-…

-

17, September 2016 Service and Repair Manual Specifications Part No. 1272218 GS-2646 AV • GS-2646 AV35 7 SAE O-ring Boss Port (tube fitting — installed into Aluminum) (all types) SAE Dash Size Torque -4 14 ft-lbs / 19 Nm -6 23 ft-lbs / 31.2 Nm -8 36 ft-lbs / 54.2 Nm -10 62 ft-lbs / 84 Nm -12 84 ft-lbs / 114 Nm -16 125 ft-lbs / 169.5 Nm -20 151 ft-lbs / 204.7 Nm -24 184 ft-lbs / 249.5 Nm Ad…

-

62, Service and Repair Manual September 2016 Manifolds 52 GS-2646 AV • GS-2646 AV35 Part No. 1272218 7 Turn the machine off. Hold the steer relief valve with a wrench and remove the cap (schematic item AH). 8 Adjust the internal hex socket. Turn it clockwise to increase the pressure or counterclockwise to decrease the pressure. Component damage hazard. Do not adjust the relief v alve pressures higher than spec…

-

29, September 2016 Service and Repair Manual Ground Controls Part No. 1272218 GS-2646 AV • GS-2646 AV35 19 Bootloader Mode 1 Open the GCON compartment. Note: Some models will require opening the ground control box to access the GCON. 2 Turn the key switch to the ground controls position and pull out the red Emergency Stop button to the on position at the platform controls. 3 At the groun…

-

34, Genie GS-2646AV Service and Repair Manual September 2016 Ground Controls 24 GS-2646 AV • GS-2646 AV35 Part No. 1272218 3 Locate the diagnostic port on the side of the GCON. Remove one of the fasteners securing the cover and set aside. Loosen the other fastener. Do not remove it. a diagnostic port 4 Connect one end of a CAT5 Ethernet cable into the diagnostic port. Connect the other end into the ethernet…

-

Genie GS-2646AV User Manual

-

Genie GS-2646AV User Guide

-

Genie GS-2646AV PDF Manual

-

Genie GS-2646AV Owner’s Manuals

Recommended: 2318594-D-WH, MVP-5150, 2011 Element, DTP HWP 4K 231 D

Links & Tools

Operating Impressions, Questions and Answers: