Create an account on the HP Community to personalize your profile and ask a question

Your account also allows you to connect with HP support faster, access a personal dashboard to manage all of your devices in one place, view warranty information, case status and more.

09-13-2022

11:16 AM

HP Recommended

- Mark as New

- Bookmark

- Subscribe

- Permalink

- Flag Post

Product: HP LaserJet Pro MFP M428fdw

Operating System: Microsoft Windows Server 2012 and older

Hello All,

We have around 30 printers that seem to just suddenly after 30 — 60 seconds blue screen and produce an error code D81B089C. Have performed service mode reset, same issue. I have a case open and was advised they need to be replaced, all 30 printers? Any help would be appreciated. I cannot find error code diagnostics or a way to downgrade the firmware to test.

Thanks.

1 ACCEPTED SOLUTION

09-13-2022

01:17 PM

HP Recommended

- Mark as New

- Bookmark

- Subscribe

- Permalink

- Flag Post

Do they work properly if not connected to network or USB? If so you could have a corrupted device sending bad print jobs. Also ensure these are plugged directly into the wall and not a splitter or surge protector.

If you find the information provided useful or solves your problems, help other users find the solution easier by giving kudos and marking my post as an accepted solution.

I am a volunteer, offering my knowledge to support fellow users, I do not work for HP nor speak for HP.

Was this reply helpful?

Yes

No

2 REPLIES 2

09-13-2022

01:17 PM

HP Recommended

- Mark as New

- Bookmark

- Subscribe

- Permalink

- Flag Post

Do they work properly if not connected to network or USB? If so you could have a corrupted device sending bad print jobs. Also ensure these are plugged directly into the wall and not a splitter or surge protector.

If you find the information provided useful or solves your problems, help other users find the solution easier by giving kudos and marking my post as an accepted solution.

I am a volunteer, offering my knowledge to support fellow users, I do not work for HP nor speak for HP.

Was this reply helpful?

Yes

No

09-19-2022

08:38 AM

HP Recommended

- Mark as New

- Bookmark

- Subscribe

- Permalink

- Flag Post

I appreciate your response. I wanted to post this so others will be able to track this error down since there’s not much information online. Our new building has eco friendly «smart» outlets that are controlled by a lighting server. Lets say there was some tweaking going on the night before that dropped the output below the specifications of the printers. Once the changes were reverted, we rebooted the printers and all is good. Not many cases would pertain to this, however, I would like to stress that these error codes in most cases are power related one way or another.

Thank you!

Was this reply helpful?

Yes

No

Be alert for scammers posting fake support phone numbers and/or email addresses on the community.

If you think you have received a fake HP Support message, please report it to us by clicking on «Flag Post».

† The opinions expressed above are the personal opinions of the authors, not of HP. By using this site, you accept the Terms of Use and Rules of Participation.

-

English

Open Menu

† The opinions expressed above are the personal opinions of the authors, not of HP. By using this site, you accept the <a href=»https://www8.hp.com/us/en/terms-of-use.html» class=»udrlinesmall»>Terms of Use</a> and <a href=»/t5/custom/page/page-id/hp.rulespage» class=»udrlinesmall»> Rules of Participation</a>.

Спустя какое-то время любая оргтехника начинает сбоить во время работы. Это также касается лазерных принтеров и МФУ Hawlett-Packard (HP). К счастью, данные устройства оснащены средством самодиагностики, которое информирует потребителя о возникшей проблеме. Вывод информации может осуществляться различными способами: специфическим миганием светодиодных индикаторов, появлением специальных кодов на сегментном дисплее, отображением информационных сообщений с кодом и описанием ошибки, а также вывод кода ошибки на персональный компьютер. В этой статье мы представим самые популярные коды ошибок лазерных принтеров HP с их расшифровкой и рекомендациями по устранению.

Первое, что нужно знать, так это то, что ошибки работы оргтехники делятся на несколько видов. Есть коды ошибок обычного информационного характера, которые просто показывают потребителю, что в данный момент делает печатающее устройство. Например, 00 READY ON LINE с кодом 10001 указывает лишь на то, что печатающее устройство готово к работе. В свою очередь, предупреждающие или сервисные коды ошибок HP, как правило, информируют о скором окончании онера, либо о том, что пора заменить какой-либо расходник. Страшнее всего, когда на дисплее принтера HP, появляется код критической ошибки. Возникновение подобного сообщения, обычно указывает на серьезную проблему с печатающим устройством (к примеру, поломка механизма протяжки бумаги, привода или блока лазера).

Быстрее всего узнать о возникшей проблеме можно по светодиодным индикаторам. В зависимости от их состояния можно приблизительно определить, что произошло с печатающим аппаратом. В частности, речь идет о следующем (пример взят из официального мануала HP LaserJet Pro M1132, M12a, M12w, P1102, P1102s, P1102w, P1106, P1108, P1109 и P1109w):

- Постоянно мигает индикатор Wi-Fi (беспроводной связи или локальной сети). Указывает на то, что принтер не может подключиться к сети. Нужно перенастроить параметры подключения, либо заменить модуль Wi-Fi.

- Постоянно мигает светодиод индикатора ошибки. Таким образом, устройство предупреждает о проблеме с тонер-картриджем. Также может указывать на то, что открыта верхняя крышка или на образования замятия бумаги/постороннего предмета.

- Постоянно горят два индикатора (обычно, это светодиод готовности и ошибки). Указывает на возникновение критической ошибки. Лучше всего не искать причину, а сразу обратиться в сервисный центр.

Кроме того, если после нажатия кнопки включения, ни один светодиод не загорается и принтер также не осуществляет пуск, то, скорее всего, возникли проблемы с блоком питания печатающего устройства. Далее представим таблицы с самыми популярными кодами ошибок принтеров HP.

Основные группы кодов ошибок лазерных принтеров HP

|

Код ошибки принтера HP |

Расшифровка |

Описание |

|

HP 10XXX |

Обычные сообщения информационного характера. |

Такие коды сообщают о готовности работы принтера, об отсутствии подключения (HP 10002) и т.д. |

|

HP 102XX |

Информационные сообщения о том, что устройство нуждается в обслуживании. |

Например, информирует об окончании тонера в картридже, а также о том, что пора заменить расходный материал. |

|

HP 11XXX |

Предупреждающие сообщения, касающиеся загрузки бумаги. |

Выводятся, когда в одном или нескольких лотках отсутствует бумажный носитель. Также может указывать на некорректность выставленного размера бумаги. |

|

HP 12XYY |

Серия кодов для лотков подачи бумаги. |

Указывают на наличие/отсутствие бумаги, а также на различные сбои в работе. |

|

HP 15XXY |

Серия кодов для лотков приема бумаги. |

Указывают на наличие/отсутствие бумаги, а также на различные сбои в работе. |

|

HP 20XXX |

Ошибки синтаксических команд. |

Появляются тогда, когда система обнаруживает нелогические команды, посылаемые печатающему устройству. |

|

HP 25XXX |

Ошибки, вызванные нарушением синтаксиса команд. |

Появляются тогда, когда система обнаруживает нелогические команды, посылаемые печатающему устройству. |

|

HP 27XXX |

Ошибки семантических команд. |

Появляются тогда, когда система обнаруживает нелогические команды, посылаемые печатающему устройству. |

|

HP 30XXX |

Ошибки, которые автоматически могут быть устранены. |

Тип информационных кодов, которые указывают на временные сбои в работе устройства, по типу, память принтера заполнена и т.д. |

|

HP 32XXX |

Ошибки файловой системы PJL. |

Появляются тогда, когда система обнаруживает сбои в работе системы. |

|

HP 35XXX |

Ошибки, которые можно сразу же решить выполнением определенных команд и продолжить работу. |

Такие коды приходят на дисплей принтера вместе с рекомендациями по их устранению. Например, когда нужно увеличить объем памяти. |

|

HP 40XXX |

Ошибки, которые можно решить выполнением определенных команд, но работа устройства прерывается. |

Такие коды приходят на дисплей принтера вместе с рекомендациями по их устранению. Например, когда необходимо перезагрузить печатающий аппарат, по той или иной причине. |

|

HP 41XYY |

Сервисные сообщения, касающиеся загрузки бумаги. |

Выводятся, когда во всех лотках отсутствует бумажный носитель. Указывает на некорректность выставленного размера бумаги, а также проблемы в работе данных частей принтера. |

|

HP 42XYY |

Сообщают о наличии замятия бумаги или постороннего предмета (актуально для HP LaserJet 5Si/ 5SiMx). |

В зависимости от кода можно максимально точно определить причину замятия бумаги. |

|

HP 43XYY |

Предупреждающие сообщения о проблемах с подключенными модулями. |

Многие офисные МФУ способны расширять свой функционал, за счет дополнительно подключенных моделей (лотков, податчиков, ADF и т.д.). Если в них обнаружатся сбои, то именно данные коды об этом проинформируют. |

|

HP 44XYY |

Сообщают о наличии замятия бумаги или постороннего предмета (актуально для HP LaserJet 4000/ 5000). |

В зависимости от кода можно максимально точно определить причину замятия бумаги. |

|

HP 50XXX |

Группа ошибок, указывающих на механические проблемы принтера. |

Если у принтера начал сбоить какой-то узел (печка, система охлаждения, блок лазера и т.д.), то принтер выдаст сообщение с кодом ошибки данной серии. |

|

HP 55XXX |

Ошибки, касающиеся персональных настроек печатающего устройства. |

Обычно можно исправить сбросом и перенастройкой принтера. |

На практике, вместо [X] и [Y] в коде будет указанно уникальное цифровое значение, соответствующее той или иной ошибке.

Коды ошибок принтеров и МФУ HP, выводимые на штатный дисплей устройства

|

Код ошибки принтера HP |

Содержание |

Расшифровка |

|

HP 10001 |

Принтер готов к работе (00). |

Принтер находится в режиме готовности, либо ему требуется незначительное сервисное обслуживание. Можно перезагрузить или очистить память принтера. Еще может помочь сброс настроек до заводских. |

|

Принтеру требуется сервисное обслуживание (68). |

||

|

Память принтера заполнена. Настройки не могут быть сохранены (68). |

||

|

HP 10002 |

Принтер не готов к работе (00). |

Принтер не готов к работе. Включить/разбудить/перезагрузить. |

|

Устройство нуждается в обслуживании (68). |

||

|

HP 10003 |

Осуществляется прогрев принтера (02). |

Печатающее устройство находится в режиме прогрева. Немного подождать, либо перезагрузить МФУ. |

|

HP 10004 |

Проводится самодиагностика печатающего устройства (05). |

Принтер создает тестовый отпечаток. Дождаться окончания процесса печати, либо перезагрузить устройство. |

|

Осуществляется печать страницы диагностики (05). |

||

|

HP 10005 |

Перезагрузка памяти (07). |

Параметры или память принтера были сброшены. Перенастроить печатающее устройство. |

|

Очистка памяти (07). |

||

|

HP 10006 |

Низкий уровень тонера в картридже (16). |

В тонер-картридже заканчивается красящее вещество. Заправить или купить новый картридж. |

|

HP 10007 |

Задание отменено. |

Очистите память принтера и очередь печати. Перезагрузите или перенастройте устройство. |

|

HP 10010 |

Буфер памяти принтера переполнен. |

Очистите память принтера и очередь печати. Перезагрузите или перенастройте устройство. |

|

HP 10011 |

Осуществляется подключение или отсутствует связь с дополнительными модулями принтера (18). |

Переподключить дополнительные лотки и прочие модули. Перезагрузить МФУ. |

|

HP 10013 |

Осуществляется печать тестовой страницы (04). |

Принтер создает тестовый отпечаток. Дождаться окончания процесса печати, либо перезагрузить устройство. |

|

HP 10014 |

Осуществляется печать тестовой страницы или листа конфигурации (06). |

Дождаться окончания процесса печати, либо перезагрузить устройство. |

|

HP 10015 |

Осуществляется печать шрифтов, поддерживаемых принтером (06). |

Дождаться окончания процесса печати, либо перезагрузить устройство. |

|

HP 10016 |

Осуществляется печать теста работы узлов печатающего устройства (15). |

Дождаться окончания процесса печати, либо перезагрузить устройство. |

|

HP 10017 |

Осуществляется демо-печать (06). |

Дождаться окончания процесса печати, либо перезагрузить устройство. |

|

HP 10018 |

Включение режима сброса настроек (09). |

Выйти из режима, перезагрузить принтер, либо выполнить сброс параметров (если устройство нуждается в этом). |

|

HP 10019 |

Включение режима сброса параметров активных портов (09). |

Выйти из режима, перезагрузить принтер, либо выполнить сброс параметров (если устройство нуждается в этом). |

|

HP 10020 |

Включение режима сброса параметров всех портов (09). |

Выйти из режима, перезагрузить принтер, либо выполнить сброс параметров (если устройство нуждается в этом). |

|

HP 10021 |

Осуществление сброса параметров принтера, в том числе очистка NVRAM (08). |

Дождаться окончания процесса, либо перезагрузить устройство. |

|

HP 10022 |

Осуществляется печать листа конфигурации (06). |

Дождаться окончания процесса печати, либо перезагрузить устройство. |

|

HP 10023 |

Осуществляется обработка задания. |

Дождаться окончания процесса, либо перезагрузить устройство. |

|

HP 10024 |

Осуществляется передача данных. |

Нужно принять/отменить задание, дождаться окончания процесса или перезагрузить принтер. |

|

HP 10025 |

Отказ в доступе к той или иной функции МФУ. |

Перезагрузить принтер, обратиться в СЦ за помощью. |

|

HP 10026 |

Невозможно отменить задание. |

Перезагрузить принтер, обратиться в СЦ за помощью. |

|

HP 10027 |

Забился тракт подачи бумаги. |

Следует очистить тракт от посторонних предметов, устранить замятие. |

|

HP 10028 |

Осуществляется печать журнала событий. |

Дождаться окончания процесса печати, либо перезагрузить устройство. |

|

HP 10029 |

Осуществляется подача бумаги. |

Дождаться окончания процесса, перезагрузить принтер, устранить проблему. |

|

HP 10030 |

Ошибки, связанные с системой команд PJL. |

Перезагрузить ноутбук, сбросить настройки принтера. |

|

HP 10031 |

Осуществляется самоочистка устройства. |

Дождаться окончания процесса, перезагрузить принтер, почистить устройство самостоятельно. |

|

HP 10032 |

Принтер не может распознать совместимый картридж. |

Установить оригинальный картридж, прошить принтер, заменить чип картриджа, сменить главную плату. |

|

HP 10033 |

Введен неверный PIN-код. |

Заново ввести код, сбросить настройки принтера. |

|

HP 10034 |

Прерывание задания. |

Очистить очередь печати, перезагрузить принтер, проверить подключение. Если все хорошо, продолжить работу. |

|

HP 10035 |

Можно продолжить выполнение прерванного задания. |

Подтвердить или отменить действие. |

|

HP 10036 |

Осуществление повторного прогрева печатающего устройства. |

Дождаться окончания процесса, перезагрузить принтер. |

|

HP 10200 |

Заканчивается черный тонер, но принтер еще может печатать. |

Временно продолжить работу. После придется перезаправить картридж или купить новый. |

|

HP 10201 |

Заканчивается голубой тонер, но принтер еще может печатать. |

Временно продолжить работу. После придется перезаправить картридж или купить новый. |

|

HP 10202 |

Заканчивается пурпурный тонер, но принтер еще может печатать. |

Временно продолжить работу. После придется перезаправить картридж или купить новый. |

|

HP 10203 |

Заканчивается желтый тонер, но принтер еще может печатать. |

Временно продолжить работу. После придется перезаправить картридж или купить новый. |

|

HP 10204 |

Требуется замена фотобарабана. |

Следует осуществить замену указанного расходника. |

|

HP 10205 |

Требуется замена черного фотобарабана. |

Следует осуществить замену указанного расходника. |

|

HP 10206 |

Требуется замена голубого фотобарабана. |

Следует осуществить замену указанного расходника. |

|

HP 10207 |

Требуется замена пурпурного фотобарабана. |

Следует осуществить замену указанного расходника. |

|

HP 10208 |

Требуется замена желтого фотобарабана. |

Следует осуществить замену указанного расходника. |

|

HP 10209 |

Требуется замена черного картриджа. |

Следует осуществить замену указанного расходника. |

|

HP 10210 |

Требуется замена голубого картриджа. |

Следует осуществить замену указанного расходника. |

|

HP 10211 |

Требуется замена пурпурного картриджа. |

Следует осуществить замену указанного расходника. |

|

HP 10212 |

Требуется замена желтого картриджа. |

Следует осуществить замену указанного расходника. |

|

HP 10213-10403 |

Различные коды сервисного обслуживания принтера, связанные с использованием расходных материалов. |

Заправить/заменить картридж, восстановить/заменить блок фотобарабана и т.д. Все зависит от информации, указанной в описании ошибки. |

Внимание: Не пытайтесь самостоятельно починить печатающий аппарат, если не имеете опыта сервисного обслуживания оргтехники. Лучше доверьте дело специалисту.

Коды ошибок E-серии для лазерных принтеров и МФУ HP

|

Код ошибки принтера HP |

Расшифровка |

Варианты решения |

|

HP E0 |

Указывает на замятие бумаги или наличие постороннего предмета. |

Извлечь замявшийся лист или иной предмет. Почистить или заменить ролик захвата бумаги. Проверить датчик и механизм протяжки бумаги. |

|

HP E1 |

Информирует об отсутствии бумаги в лотке подачи или установленный размер не соответствует. |

Загрузить или поправить бумагу. Проверить ролик захвата. Сменить задание на печать. |

|

HP E2 |

Предупреждает о том, что открыта дверца или датчик вышел из строя. |

Открыть/закрыть все крышки, проверить защелку и датчик. |

|

HP E3 |

Принтер не видит или не может распознать картридж. |

Поправить картридж, снять защитную чеку/пленку, прочистить чип картриджа и принтера и т.д. Подробнее, читайте в статье «Что делать, если принтер не распознает картридж». Почистить контакты и осуществить сервисное обслуживание принтера и картриджа. |

|

HP E4 |

Память печатающего устройства заполнена или ее не хватает. |

Очистить память принтера, сбросить настройки, прошить или сменить главную плату. |

|

HP E5 |

Проблема в работе механизма захвата или протяжки бумаги. |

Проверить наличие бумаги в лотке, поправить листы, пододвинуть флажок, почистить/заменить ролик захвата, проверить механизм протяжки, энкодер и датчик. Заменить или прошить главную плату. |

|

HP E6 |

Неизвестная ошибка работы принтера. |

Провести диагностику и сервисное обслуживание печатающего устройства. |

|

HP E7 |

Неизвестная аппаратная ошибка работы принтера. |

Провести диагностику и сервисное обслуживание печатающего устройства. |

|

HP E8 |

Критическая ошибка в работе сканера. |

Лучше всего отнести МФУ в сервисный центр. Однако можно разобрать и поправить линейку, либо осмотреть шестеренки привода (заменить, отремонтировать). |

|

HP E9 |

Неизвестная критическая ошибка работы принтера. |

Провести диагностику и сервисное обслуживание печатающего устройства. |

|

HP E10 |

Проблема в подключении дополнительных модулей. |

Перезапустить печатающий аппарат, выполнить переподключение проблемного модуля, проверить/заменить шлейф. |

|

HP E20 |

Не хватает памяти принтера для печати материала. |

Перезапустить устройство, очистить память и очередь печати, сменить задачу на печать. |

|

HP E21 |

Заполнена память печатающего устройства. |

Перезапустить устройство, очистить память и очередь печати, сменить задачу на печать, добавить оперативной памяти. |

|

HP E22 |

Сбой LPT-подключения или несоответствия драйвера принтера. |

Переподключить устройство к ПК, заменить кабель, переустановить драйвер. |

Также сюда стоит отнести ошибку HP 13.А, которая указывает на проблему с деталями механизма подачи бумаги (соленоидом, датчиком и т.д.).

Коды ошибок HP LaserJet, указывающие на проблемы аппаратной части устройства

|

Код ошибки принтера HP |

Расшифровка |

|

HP 50000 |

Данный код появляется в случае возникновения неизвестной ошибки, в работе аппаратной части печатающего устройства. |

|

HP 50001 |

Ошибка одного или нескольких модулей памяти, размещенных на плате форматера. |

|

HP 50002 |

Ошибка модуля оперативной памяти главной платы принтера. |

|

HP 50003 |

Код указывает на проблему двигателя печки лазерного принтера. |

|

HP 50004 |

Сработал датчик лазера, указывающий на проблему данной детали. |

|

HP 50005 |

Проблема с приводом сканера (скорее всего связанная с зеркалом). |

|

HP 50006 |

Проблема в приводе кулера. |

|

HP 50007 |

Потеря связи между контроллером и главной платой принтера. |

|

HP 50008 |

Код указывает на низкую температуру термоэлемента печки принтера. |

|

HP 50009 |

Код указывает на долгий период прогрева печки принтера до нужной температуры. |

|

HP 50010 |

Код указывает на высокую температуру прогрева печки принтера (перегрев). |

|

HP 50011 |

Неизвестная проблема, связанная с печкой лазерного МФУ. |

|

HP 50012 |

Проблема в работе датчика луча лазера. |

|

HP 50013 |

Проблема, связанная с блоком лазера принтера. |

|

HP 50014 |

Ошибка старта работы сканера. |

|

HP 50015 |

Ошибка движения линейки сканера. |

|

HP 50016-50019; HP 50030-50036 |

Проблема в слабом вращении или поломке одного из вентиляторов. |

|

HP 50020 |

Проблемы с механизмом подачи бумаги верхнего лотка. |

|

HP 50021 |

Проблемы с механизмом подачи бумаги нижнего лотка. |

|

HP 50022 |

Проблемы с механизмом подачи бумаги универсального лотка. |

|

HP 50023 |

Ошибка пуска основного электромотора принтера. |

|

HP 50024 |

Ошибка работы основного электромотора принтера. |

|

HP 50025 |

Ошибка подключения дополнительных модулей (актуально для больших офисных МФУ). |

|

HP 50026 |

Ошибка работы дополнительных модулей (актуально для больших офисных МФУ). |

|

HP 50027 |

Проблема в работе дуплекса принтера или МФУ (модуля двусторонней печати). |

|

HP 50028 |

Нарушение контакта между форматером и другими частями печатающего аппарата. |

|

HP 50029 |

Проблема в обработке или получении данных платой форматера. |

|

HP 50048-50063 |

Неизвестные ошибки принтера, связанные с распределением питания. |

|

HP 50064 |

Ошибка датчика совмещения желтого цвета. |

|

HP 50065 |

Ошибка датчика совмещения пурпурного цвета. |

|

HP 50066 |

Ошибка датчика совмещения голубого цвета. |

|

HP 50067 |

Ошибка датчика совмещения черного цвета. |

|

HP 50068 |

Несоответствие диапазона плотности желтого цвета. |

|

HP 50069 |

Несоответствие диапазона плотности пурпурного цвета. |

|

HP 50070 |

Несоответствие диапазона плотности голубого цвета. |

|

HP 50071 |

Несоответствие диапазона плотности черного цвета. |

|

HP 50072 |

Ошибка, возникающая из-за несоответствия данных датчика фазовой калибровки фотобарабана для желтого цвета. |

|

HP 50073 |

Ошибка, возникающая из-за несоответствия данных датчика фазовой калибровки фотобарабана для пурпурного цвета. |

|

HP 50074 |

Ошибка, возникающая из-за несоответствия данных датчика фазовой калибровки фотобарабана для голубого цвета. |

|

HP 50075 |

Ошибка, возникающая из-за несоответствия данных датчика фазовой калибровки фотобарабана для черного цвета. |

|

HP 505XX |

Сбой в работе прошивки лазерного принтера HP. |

|

HP 50599 |

Проблема с питанием платы форматера. |

Важно: В данном случае представлена только расшифровка кодов ошибок HP, так как в большинстве случаев устранить проблему очень сложно, даже для квалифицированного специалиста. Поэтому чаще всего приходится просто заменять испорченную деталь принтера.

Прочие коды ошибок лазерной оргтехники HP

|

Код ошибки принтера HP |

Расшифровка |

Варианты решения |

|

HP 10.XX.YY |

Проблема считывания данных с чипа картриджа (часто сопровождается сообщением «SUPPLY MEMORY ERROR»). |

Переустановить картридж, установить оригинальный картридж HP или сбросить ошибку (подробнее, читайте в статье «Как исправить ошибку памяти картриджа HP»). |

|

HP 10.32.XX |

Принтер определил, что установлен неоригинальный картридж. |

Проигнорировать и пользоваться принтером дальше (может перестать отображаться ресурс картриджа, а также будет часто выскакивать информационное окно о необходимости использования оригинальной продукции). Если нет такой возможности, проблему нужно решать уже исходя из особенностей оргтехники (замена чипа картриджа, прошивка принтера и т.д.). |

|

HP 11.01 и HP 11.02 |

Принтер постоянно запрашивает установку дату и времени, либо они отображаются некорректно. |

Необходимо заменить батарею или форматер принтера. |

|

HP 13.XX.YY (13.A, 13.02.00, 13.03.XX, 13.05.XX, 13.06.XX, 13.12.00, 13.20.00, 13.21.00) |

Произошло замятие бумаги. |

Извлеките замятую бумагу или посторонний предмет. Перезагрузите принтер, проверьте датчики бумаги, а также механизм протяжки бумаги. |

|

HP 20 INSUFFICIENT MEMORY |

Перегрузка оперативной памяти принтера. |

Нажмите продолжить печать, но при этом часть данных может быть утеряна. Лучше переделать файл и отправить его заново на печать. Также можно попробовать очистить память принтера или расширить, за счет установки дополнительного модуля. |

|

HP 21 PAGE TOO COMPLEX |

Принтер не может сжать изображение из-за его сложности. |

Нажмите продолжить печать, но при этом часть данных может быть утеряна. Упростите задание для печати. |

|

HP 22 EIO BUFFER OVERFLOW (EMBEDDED, PARALLEL, USB) |

Переполнен буфер памяти принтера или передаются по определенному каналу слишком объемный материал. |

Нажать продолжить, но данные будут утеряны. Проверить соединения, переключить порты или заменить кабели. |

|

HP 40 EMBEDDED I/O BAD TRANSMISSION |

Ошибка передачи данных. |

Нажать продолжить, на данные будут утеряны. Перезагрузить принтер и отправить повторное задание. Переустановить/заменить серверную карту или плату форматера. |

|

HP 41.3 UNEXPECTED PAPER SIZE IN TRAY X |

Формат бумаги не соответствует заданным параметрам. |

Установить бумагу соответствующего формата или сменить настройки печати. Сменить лоток (если их несколько). Проверить работу механизма протяжки и всех датчиков бумаги. Избавить МФУ от наличия посторонних предметов. |

|

HP 41.5 UNEXPECTED TYPE IN TRAY X |

Тип бумаги не соответствует заданным параметрам. |

Установить бумагу соответствующего типа или сменить настройки печати. Сменить лоток (если их несколько). Проверить работу механизма протяжки и всех датчиков бумаги. Избавить МФУ от наличия посторонних предметов. |

|

HP 41.X ERROR |

Неизвестная ошибка, связанная с протягиванием бумаги. |

Можно попробовать перезагрузить МФУ, почистить ролики захвата бумаги, либо разбирать и искать проблему по пути следования бумаги. |

|

HP 49.XXXXX ERROR |

Критическая ошибка, связанная с микропрограммой (прошивкой, firmware) принтера. |

Перезагрузите принтер, после чего отмените все задания печати, очистите очередь, проверьте обновления для принтера (обновите) и снова попытайтесь печатать при помощи фирменного ПО. Не помогло, пробуйте наоборот понизить версию прошивки, либо перепрошить принтер, установив на него дамп с нового устройства. Замените плату форматера. |

|

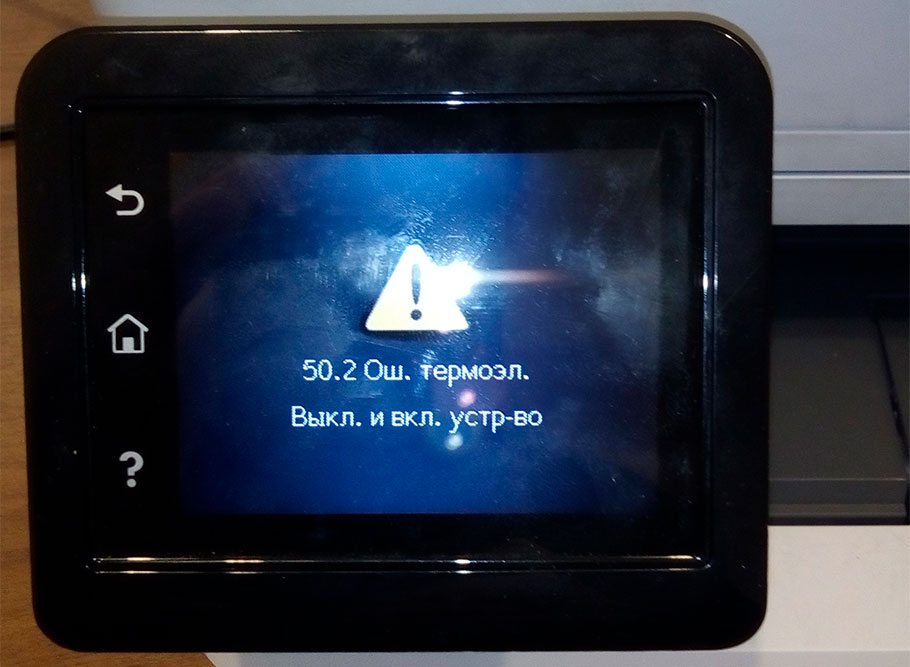

HP 50.X FUSER ERROR |

Проблема в работе печки лазерного принтера. |

Выключить принтер и дать ему отдохнуть около 30 минут. Проверить блок печки, почистить и заменить термоэлемент (если он в этом нуждается). Заменить весь блок, БП или плату микроконтроллера. |

|

HP 51.1X ERROR |

Проблема в работе датчика синхронизации луча лазера. |

Перезагрузить МФУ, проверить контакты, шлейфы и различные подключения. Заменить блок лазера или плату микроконтроллера. |

|

HP 52.XX.0 PRINTER ERROR |

Проблема в работе драйвера двигателя лазерного блока. |

Перезагрузить МФУ, проверить контакты, шлейфы и различные подключения. Заменить блок лазера или плату микроконтроллера. |

|

HP 53.10.01 PRINTER ERROR |

Принтер не поддерживает модуль памяти DIMM. |

Перезагрузить принтер. Переустановить или заменить модуль памяти. Заменить форматер. |

|

HP 55.XX.YY DC CONTROLLER ERROR |

Ошибка контроллера DC. |

Перезагрузить принтер. Проверить соединения на плате контроллера, либо заменить плату. |

|

HP 56.XX ERROR |

Неизвестная ошибка, возникшая во время печати. |

Перезапустить принтер. Проверить все контакты. Провести диагностику. |

|

HP 57.XX PRINTER ERROR |

Проблема в работе вентилятора лазерного принтера. |

Проверить кулер на работоспособность, почистить, смазать или заменить. |

|

HP 58.XX ERROR |

Неизвестная ошибка, связанная с работой процессора принтера. |

Проверить все контакты платы контроллера или заменить ее. |

|

HP 59.XX ERROR Main Motor |

Проблема в работе главного электромотора принтера. |

Выключить принтер и дать ему немного отдохнуть. Разобрать и проверить подключения и сам электромотор. Заменить в случае неисправности. |

|

HP 62 NO SYSTEM |

Принтер не может обнаружить систему управления. |

Перезапустить печатающее устройство, обновить прошивку, сменить главную плату. |

|

HP 64 ERROR |

Неизвестная ошибка, связанная с буфером хранения данных для лазера. |

Перезапустить печатающее устройство, обновить прошивку, сменить главную плату. |

|

HP 68.X PERMANENT STORAGE FULL |

Ошибка, связанная с переполнением памяти NVRAM. |

Продолжить печать, перезапустить принтер, очистить буфер памяти. |

|

HP 79.XXXX ERROR |

Критическая ошибка, связанная с аппаратной частью принтера или МФУ. |

Здесь может быть все что угодно. Нужно перезагружать принтер, разбирать и искать проблему. Чаще всего, дело заключается в неисправности материнской платы устройства. |

|

HP 8X. XXXX EIO ERROR |

Критическая ошибка подключения дополнительного модуля. |

Перезапустить принтер, переподключить модуль, обновить прошивку. Заменить плату форматера. |

Внимание: Не пытайтесь самостоятельно починить печатающий аппарат, если не имеете опыта сервисного обслуживания оргтехники. Лучше доверьте дело специалисту.

Системные ошибки плоттеров HP DesignJet T920| 930 | T1500 | T1530 | T2500 | T2530 | T3500

В этом разделе описываются все коды системных ошибок, которые могут возникнуть при использовании плоттеров данных серий, и описание проблем, чтобы знать в каком узле искать причину неисправности.

|

Системная ошибка |

Описание проблемы |

|

01.7:10 |

Ошибка связи между главной платой и форматером |

|

01.0:10 |

Проблема с главной платой |

|

01.1:10 |

Ошибка главной платы |

|

01.2:10 |

Проблема с резервным копированием NVM |

|

01.7:10 |

Ошибка связи между главной платой и форматером |

|

02.1:10 |

Проблема с платой каретки |

|

03.2:10 |

Проблема с вентиляторами охлаждения E-Box |

|

03:10 |

Проблема с блоком питания |

|

05.1:10 |

Проблемы с вентилятором охлаждения платы форматера |

|

05.4:10 |

Поврежденные данные в форматоре |

|

05.5:10 |

BIOS должен быть обновлен (совет) |

|

05.7:10 |

Проблемы синхронизации между панелью управления и устройством форматирования |

|

06:03 and 06:10 |

Проблемы с NVM на жестком диске |

|

06.1:10 |

Не обнаружен жесткий диск |

|

06.2:10 |

Жесткий диск не может быть разблокирован |

|

06.3:10 |

Поврежден жесткий диск |

|

08:04 |

Потеряна связь между передней панелью и форматором |

|

08:08 |

Не срабатывают иконки на передней панели |

|

08:10 |

Обнаруженные неполадки в аппаратной части передней панели |

|

08:11 |

Пропала связь между передней панелью и плоттером |

|

09:01 |

Замятие бумаги в узле сканера |

|

09:01:10 |

Ошибка мотора сканера |

|

09:02 |

Сканер не откалиброван |

|

09:02:10 |

Ошибка элемента A в CIS (в узле сканера) |

|

09:03 |

Ошибка файла I/O |

|

09:03:10 |

Ошибка элемента B в CIS (в узле сканера) |

|

09:04 |

Не загружена библиотека |

|

09:04:10 |

Ошибка элемента C в CIS (в узле сканера) |

|

09:05:10 |

Ошибка элемента D в CIS (в узле сканера) |

|

09:06:10 |

Ошибка элемента E в CIS (в узле сканера) |

|

09:08:11 |

Вышел из строя кабель питания узла сканера |

|

09:09:11 |

Вышел из строя USB-кабель узла сканера |

|

09:10:04 |

Сканер находится в режиме SAFE MODE (безопасный режим) |

|

09:10:10 |

Ошибка SCU (Плата Контроллера Сканера) |

|

11:10 |

Ошибка кабеля (шлейфа) каретки |

|

21.2:13 |

Отказ подвижного механизма в сервисной станции |

|

21:13 |

Проблема мотора сервисной станции |

|

22.0:00 |

Ошибка станции подачи чернил со стороны сервисной станции |

|

22.1:00 |

Ошибка станции подачи чернил со стороны передней панели |

|

24:10 |

Обнаружена ошибка в системе чернильных трубок |

|

26:01 |

Ошибка подачи чернил, обнаруженная во время диагностического теста IDS |

|

27:01 |

Слишком много чернил при вспрыске сопел |

|

41:03 |

Электрическая проблема (неисправность, предел тока, перегрев) в моторе протяжки бумаги |

|

42:03 |

Электрическая проблема (неисправность, предел тока, перегрев) в моторе протяжки каретки |

|

45.1:03 and 45.1:10 |

Ошибка верхнего намотчика рулона |

|

45.2:03 and 45.2:10 |

Ошибка нижнего намотчика рулона |

|

46.1:10 |

Ошибка в верхнем насосе системы продувки PHA |

|

46.2:10 |

Ошибка в в нижнем насосе системы продувки PHA |

|

47:03 and 47:10 |

Ошибка мотора маховика |

|

47.5:10 |

Ошибка датчика перемещения мотора маховика |

|

48:00 |

Отказ системы привода PRS |

|

52:10 |

Ошибка датчика — Drop detector |

|

54.4:03 |

Ошибка мотора подъемника Pinchwheel |

|

55:10 |

Не удается получить доступ к EEPROM линейного датчика |

|

56:01 |

Ошибка считывания между диском и платой энкодера |

|

59.1:09 |

Две электрических узла были заменены одновременно |

|

59.2:00 |

Установлена неподдерживаемая или повторно используемая деталь |

|

59.3:10 |

Неправильно сохраненная информация в CryptoAsic |

|

59.4:10 |

Ошибка CryptoAsic |

|

59.5:19 |

Несоответствие типов CryptoAsic |

|

59.6:19 |

Несоответствие серийного номера плоттера |

|

59.7:14 |

Общая ошибка CryptoAsic |

|

60.1:11 |

Ошибка инициализации (не удается прочитать RFID-метку) |

|

60.2:17 |

Ошибка инициализации (RFID содержит неверные данные) |

|

61:01 |

Неверный или неподдерживаемый формат файла |

|

61:04.1 |

Шрифты PostScript отсутствуют |

|

61:04.2 |

Неизвестный идентификатор PostScript ID |

|

61:08 |

Неверный тип бумаги, указанный в задании |

|

61:08.1 |

Задание не может быть напечатано, так как оно защищено паролем |

|

61:08.2 |

Задание содержит ошибки формата или неверные настройки |

|

61:09 |

Внезапное прерывание задания |

|

61:10 |

Тайм-аут задания |

|

63:04 |

Ошибка сетевого интерфейса |

|

63:10 |

Ошибка сетевого интерфейса |

|

63:20 |

Потенциальная проблема в сетевом интерфейсе |

|

71:03 |

Недостаточно памяти |

|

71:08 |

Несоответствующий список отображения. Уменьшите разрешение до 300 точек |

|

72.02 |

Следует выполнить сервисную калибровку |

|

74:01 |

Ошибка загрузки файла обновления микропрограммы |

|

74.1:04 |

Ошибка загрузки данных предварительной настройки бумаги |

|

74.08:04 |

Проблема обновления прошивки |

|

76:03 |

Жесткий диск заполнен |

|

78:08 |

Бумага не поддерживает печать без полей |

|

78.1:04 |

Область параметров бумаги отсутствует в файле параметров бумаги |

|

79:03 |

Общая ошибка прошивки |

|

79:04 |

Общая ошибка прошивки |

|

79.2:04 |

Общая ошибка операционной системы |

|

80:03 |

Ошибка мотора укладчика |

|

81:01 |

Выключение сервопривода бумаги, возможно замятие бумаги |

|

86:01 |

Отключение сервопривода оси сканирования, возможно замятие бумаги |

|

87:01 |

Проблема чтения энкодера оси сканирования |

|

89:03 |

Ошибка мотора пандуса укладчика |

|

90:03 |

Ошибка мотора valves |

|

93.0.n:10 |

Ошибка давления чернил в первом тесте во время заполнения печатающей головки для цвета n |

|

93.1.n:10 |

Температурная погрешность при первом испытании на вспрыск во время заполнения печатающей головки для цвета n |

|

93.2.n:10 |

Ошибка давления чернил во втором тесте во время заполнения печатающей головки для цвета n |

|

93.3.n:10 |

Температурная погрешность при втором тесте на вспрыск во время заполнения печатающей головки для цветаn |

Чтение кода системной ошибки

Коды системных ошибок объясняют, какой компонент или система вышли из строя, и какие действия следует предпринять для их устранения.

Коды системных ошибок отображаются непосредственно на передней панели (их также можно увидеть на информационной странице) и определены в формате XX.YZ. или XX. n: YZ.м.

● XX: Подсистема или процесс (2 цифры)

● nor m: Подсистема или индекс процесса (необязательно), например для определения цвета картриджа

● Y: Кто должен выполнить действие (1 цифра): 0 для пользователя или 1 для сервисного инженера

● Z: Действие для выполнения (1 цифра)

Ремонт плоттеров HP DesignJet T930 | T1530 | T2530 | T3500 от компании Дока-Сервис в Москве и области.

Цены на ремонт плоттера HP DesignJet T930 | T1530 | T2530 | T3500

Create an account on the HP Community to personalize your profile and ask a question

Your account also allows you to connect with HP support faster, access a personal dashboard to manage all of your devices in one place, view warranty information, case status and more.

Common problems for Connectivity Issues

06-03-2023

10:28 PM

HP Recommended

- Mark as New

- Bookmark

- Subscribe

- Permalink

- Flag Post

Product: HP LaserJet Pro MFP M428fdw

what does error message D81B089C on my HP LaserJet Pro MFP M428fdw

Be alert for scammers posting fake support phone numbers and/or email addresses on the community.

If you think you have received a fake HP Support message, please report it to us by clicking on «Flag Post».

† The opinions expressed above are the personal opinions of the authors, not of HP. By using this site, you accept the Terms of Use and Rules of Participation.

-

English

Open Menu

† The opinions expressed above are the personal opinions of the authors, not of HP. By using this site, you accept the <a href=»https://www8.hp.com/us/en/terms-of-use.html» class=»udrlinesmall»>Terms of Use</a> and <a href=»/t5/custom/page/page-id/hp.rulespage» class=»udrlinesmall»> Rules of Participation</a>.

Правила форума

Картинки и фотографии (если они нужны в сообщении) надо загружать только как вложения к своему сообщению (через кнопку Добавить файлы). Тогда картинки будут автоматически отображаться в сообщении.

-

conan2000@mail.ru

- Сообщения: 104

- Стаж: 1 год 9 месяцев

- Благодарил (а): 3 раза

- Поблагодарили: 13 раз

-

Репутация:

HP M428dw кирпич

Сообщение

conan2000@mail.ru »

Принесли изначально с такой картинкой — мол аппарат сам обновлялся и в момент обновления — питание отключили . Со слов пользователей.

На картинке висит — по USB не определяется

Мои действия — разобрал — для прошивки NAND . там уже другая микросхема нанд S34ML04G200TFI00 SPANSION Видимо ревизия платы новая .

Попытка не пытка залил дамп — отсюда https://remont-aud.net/dump/printera_i_ … 1-0-112008

Дисплей вообще не включился , по USB булькнуло но не определилось ..

Пробовал teton_dist_002.2014A_nonassert_appsigned_lbi_rootfs_secure_signed.ful2 отправить на usbprns2 Тишина ..

Вернул родной дамп на программаторе — так и висит .

Собрал от греха подальше , вернул в нынешнее состояние .. Микросхем новых NAND S34ML04G200TFI00 SPANSION у меня нет и новой ревизии дампа тоже нет .

- Вложения

-

-

-

-

conan2000@mail.ru

- Сообщения: 104

- Стаж: 1 год 9 месяцев

- Благодарил (а): 3 раза

- Поблагодарили: 13 раз

-

Репутация:

HP M428dw кирпич

Сообщение

conan2000@mail.ru »

Родной дамп из принтера — при считывание в несколько проходов . всегда разные показатели , верификация не совпадает ..

С дампом из ссылки тоже самое .

Ради интереса впаял NAND TC58 NVG 2S3 ETA OO залил дамп из ссылки , сравнил файлы после записи и чтения одинаковы . дисплей включился (в зеленом цвете ) и на дисплее была надпись 1234 и все , по USB булькнул но определился как неизвестное на Win 7

Последний раз редактировалось conan2000@mail.ru 23 фев 2023, 17:52, всего редактировалось 1 раз.

-

VVC

- Сообщения: 125

- Стаж: 1 год 9 месяцев

- Благодарил (а): 4 раза

- Поблагодарили: 20 раз

-

Репутация:

HP M428dw кирпич

Сообщение

VVC »

это флип-биты….прогер не умеет корректировать.

я имею ввиду структуру файла по разделам и размеры спаров

-

VVC

- Сообщения: 125

- Стаж: 1 год 9 месяцев

- Благодарил (а): 4 раза

- Поблагодарили: 20 раз

-

Репутация:

HP M428dw кирпич

Сообщение

VVC »

в родном и скаченном дампах разные спары (128 против 64 байт)…а ещё на этих платах бывает Micron MT29F4G08ABADA, он тоже не совпадает по геометрии с вашей родной.

Думаю, если писать неродной дамп, нужно в ту же микруху, с которой он был снят.

-

conan2000@mail.ru

- Сообщения: 104

- Стаж: 1 год 9 месяцев

- Благодарил (а): 3 раза

- Поблагодарили: 13 раз

-

Репутация:

HP M428dw кирпич

Сообщение

conan2000@mail.ru »

VVC писал(а): ↑23 фев 2023, 18:56

.а ещё на этих платах бывает Micron MT29F4G08ABADA, он тоже не совпадает по геометрии с вашей родной.

Верно это уже с факсом идут Micron MT29F4G08ABADA .FDW

В моем случае аппарат без факса 428 DW на борту NAND S34ML04G200TFI00 SPANSION

-

- 28 Ответы

- 10987 Просмотры

-

Последнее сообщение

-

- 5 Ответы

- 1940 Просмотры

-

Последнее сообщение

-

- 17 Ответы

- 1334 Просмотры

-

Последнее сообщение

-

- 9 Ответы

- 379 Просмотры

-

Последнее сообщение

-

- 7 Ответы

- 915 Просмотры

-

Последнее сообщение

– Compatible Printer model: HP LaserJet M775 Enterprise 700 color MFP

– HP LaserJet M775 Enterprise 700 color MFP Error Codes with instructions guide:

HP LaserJet M775 Enterprise 700 color MFP

- Code: 10.00.00

- Display: 10.0X.Y0 Supply memory error

- Description: Memory error

Black print cartridge - Remedy: 1. Remove, and then reinstall the indicated print cartridge. 2. If the error reappears, turn the power off, and then on. 3. Check the cartridge e-label. If it is damaged, replace the cartridge. 4. If the error persists, replace the indicated print cartridge.

- Code: 10.00.10

- Display: 10.0X.Y0 Supply memory error

- Description: E-label missing

Black print cartridge - Remedy: 1. Remove, and then reinstall the indicated print cartridge. 2. If the error reappears, turn the power off, and then on. 3. Check the cartridge e-label. If it is damaged, replace the cartridge. 4. If the error persists, replace the indicated print cartridge.

- Code: 10.00.15

- Display: 10.YY.15 Install <supply>

- Description: The indicated supply has been removed or installed incorrectly.

Black print cartridge - Remedy: Replace or install the indicated supply.

- Code: 10.00.25

- Display: 10.YY.25 Wrong cartridge in <color> slot

- Description: The indicated cartridge is installed in the wrong position.

Black print cartridge - Remedy: Install the indicated cartridge in the correct position. From left to right, the correct cartridge

- Code: 10.00.34

- Display: 10.XX.34 Used supply in user sch

- Description: The indicated cartridge is used.

Black print cartridge - Remedy: Make sure this is a genuine HP supply.

- Code: 10.00.35

- Display: 10.YY.35 Incompatible <supply>

- Description: The indicated cartridge is not compatible with this product.

Black print cartridge - Remedy: Install a supply that is designed for this product.

- Code: 10.00.40

- Display: 10.XX.40 Genuine HP supplies installed

- Description: More than one genuine HP print cartridge has been installed.

Black print cartridge - Remedy: No action necessary.

- Code: 10.00.41

- Display: 10.XX.41 Unsupported supply in use

- Description: The indicated print cartridge is for a different product.

Black print cartridge - Remedy: Remove the indicated print cartridge, and then install the correct cartridge for this product.

- Code: 10.00.70

- Display: 10.XX.70 Printing past very low

- Description: The product indicates when one of the consumables is very low. The actual remaining consumable life might vary. You do not need to replace the consumable at this time unless print quality is no longer acceptable.

Black print cartridge - Remedy: If print quality is no longer acceptable, replace the indicated print cartridge or fuser kit.

- Code: 10.01.00

- Display: 10.0X.Y0 Supply memory error

- Description: Memory error

Cyan print cartridge - Remedy: 1. Remove, and then reinstall the indicated print cartridge. 2. If the error reappears, turn the power off, and then on. 3. Check the cartridge e-label. If it is damaged, replace the cartridge. 4. If the error persists, replace the indicated print cartridge.

- Code: 10.01.10

- Display: 10.0X.Y0 Supply memory error

- Description: E-label missing

Cyan print cartridge - Remedy: 1. Remove, and then reinstall the indicated print cartridge. 2. If the error reappears, turn the power off, and then on. 3. Check the cartridge e-label. If it is damaged, replace the cartridge. 4. If the error persists, replace the indicated print cartridge.

- Code: 10.01.15

- Display: 10.YY.15 Install <supply>

- Description: The indicated supply has been removed or installed incorrectly.

Cyan print cartridge - Remedy: Replace or install the indicated supply.

- Code: 10.01.25

- Display: 10.YY.25 Wrong cartridge in <color> slot

- Description: The indicated cartridge is installed in the wrong position.

Cyan print cartridge - Remedy: Install the indicated cartridge in the correct position. From left to right, the correct cartridge

- Code: 10.01.34

- Display: 10.XX.34 Used supply in user sch

- Description: The indicated cartridge is used.

Cyan print cartridge - Remedy: Make sure this is a genuine HP supply.

- Code: 10.01.35

- Display: 10.YY.35 Incompatible <supply>

- Description: The indicated cartridge is not compatible with this product.

Cyan print cartridge - Remedy: Install a supply that is designed for this product.

- Code: 10.01.40

- Display: 10.XX.40 Genuine HP supplies installed

- Description: More than one genuine HP print cartridge has been installed.

Cyan print cartridge - Remedy: No action necessary.

- Code: 10.01.41

- Display: 10.XX.41 Unsupported supply in use

- Description: The indicated print cartridge is for a different product.

Cyan print cartridge - Remedy: Remove the indicated print cartridge, and then install the correct cartridge for this product.

- Code: 10.01.70

- Display: 10.XX.70 Printing past very low

- Description: The product indicates when one of the consumables is very low. The actual remaining consumable life might vary. You do not need to replace the consumable at this time unless print quality is no longer acceptable.

Cyan print cartridge - Remedy: If print quality is no longer acceptable, replace the indicated print cartridge or fuser kit.

- Code: 10.02.00

- Display: 10.0X.Y0 Supply memory error

- Description: Memory error

Magenta print cartridge - Remedy: 1. Remove, and then reinstall the indicated print cartridge. 2. If the error reappears, turn the power off, and then on. 3. Check the cartridge e-label. If it is damaged, replace the cartridge. 4. If the error persists, replace the indicated print cartridge.

- Code: 10.02.10

- Display: 10.0X.Y0 Supply memory error

- Description: E-label missing

Magenta print cartridge - Remedy: 1. Remove, and then reinstall the indicated print cartridge. 2. If the error reappears, turn the power off, and then on. 3. Check the cartridge e-label. If it is damaged, replace the cartridge. 4. If the error persists, replace the indicated print cartridge.

- Code: 10.02.15

- Display: 10.YY.15 Install <supply>

- Description: The indicated supply has been removed or installed incorrectly.

Magenta print cartridge - Remedy: Replace or install the indicated supply.

- Code: 10.02.25

- Display: 10.YY.25 Wrong cartridge in <color> slot

- Description: The indicated cartridge is installed in the wrong position.

Magenta print cartridge - Remedy: Install the indicated cartridge in the correct position. From left to right, the correct cartridge

- Code: 10.02.34

- Display: 10.XX.34 Used supply in user sch

- Description: The indicated cartridge is used.

Magenta print cartridge - Remedy: Make sure this is a genuine HP supply.

- Code: 10.02.35

- Display: 10.YY.35 Incompatible <supply>

- Description: The indicated cartridge is not compatible with this product.

Magenta print cartridge - Remedy: Install a supply that is designed for this product.

- Code: 10.02.40

- Display: 10.XX.40 Genuine HP supplies installed

- Description: More than one genuine HP print cartridge has been installed.

Magenta print cartridge - Remedy: No action necessary.

- Code: 10.02.41

- Display: 10.XX.41 Unsupported supply in use

- Description: The indicated print cartridge is for a different product.

Magenta print cartridge - Remedy: Remove the indicated print cartridge, and then install the correct cartridge for this product.

- Code: 10.02.70

- Display: 10.XX.70 Printing past very low

- Description: The product indicates when one of the consumables is very low. The actual remaining consumable life might vary. You do not need to replace the consumable at this time unless print quality is no longer acceptable.

Magenta print cartridge - Remedy: If print quality is no longer acceptable, replace the indicated print cartridge or fuser kit.

- Code: 10.03.00

- Display: 10.0X.Y0 Supply memory error

- Description: Memory error

Yellow print cartridge - Remedy: 1. Remove, and then reinstall the indicated print cartridge. 2. If the error reappears, turn the power off, and then on. 3. Check the cartridge e-label. If it is damaged, replace the cartridge. 4. If the error persists, replace the indicated print cartridge.

- Code: 10.03.10

- Display: 10.0X.Y0 Supply memory error

- Description: E-label missing

Yellow print cartridge - Remedy: 1. Remove, and then reinstall the indicated print cartridge. 2. If the error reappears, turn the power off, and then on. 3. Check the cartridge e-label. If it is damaged, replace the cartridge. 4. If the error persists, replace the indicated print cartridge.

- Code: 10.03.15

- Display: 10.YY.15 Install <supply>

- Description: The indicated supply has been removed or installed incorrectly.

Yellow print cartridge - Remedy: Replace or install the indicated supply.

- Code: 10.03.25

- Display: 10.YY.25 Wrong cartridge in <color> slot

- Description: The indicated cartridge is installed in the wrong position.

Yellow print cartridge - Remedy: Install the indicated cartridge in the correct position. From left to right, the correct cartridge

- Code: 10.03.34

- Display: 10.XX.34 Used supply in user sch

- Description: The indicated cartridge is used.

Yellow print cartridge - Remedy: Make sure this is a genuine HP supply.

- Code: 10.03.35

- Display: 10.YY.35 Incompatible <supply>

- Description: The indicated cartridge is not compatible with this product.

Yellow print cartridge - Remedy: Install a supply that is designed for this product.

- Code: 10.03.40

- Display: 10.XX.40 Genuine HP supplies installed

- Description: More than one genuine HP print cartridge has been installed.

Yellow print cartridge - Remedy: No action necessary.

- Code: 10.03.41

- Display: 10.XX.41 Unsupported supply in use

- Description: The indicated print cartridge is for a different product.

Yellow print cartridge - Remedy: Remove the indicated print cartridge, and then install the correct cartridge for this product.

- Code: 10.03.70

- Display: 10.XX.70 Printing past very low

- Description: The product indicates when one of the consumables is very low. The actual remaining consumable life might vary. You do not need to replace the consumable at this time unless print quality is no longer acceptable.

Yellow print cartridge - Remedy: If print quality is no longer acceptable, replace the indicated print cartridge or fuser kit.

- Code: 10.22.50

- Display: 10.22.50

- Description: The transfer kit life was reset above the order threshold. A new ITB was installed.

- Remedy: No action necessary.

- Code: 10.22.51

- Display: 10.22.51

- Description: The transfer kit life was reset above the replace threshold. A new ITB was installed.

- Remedy: No action necessary.

- Code: 10.22.52

- Display: 10.22.52

- Description: The transfer kit life was reset above the reset threshold. A new ITB was installed.

- Remedy: No action necessary.

- Code: 10.23.15

- Display: 10.YY.15 Install <supply>

- Description: The indicated supply has been removed or installed incorrectly.

Fuser kit - Remedy: Replace or install the indicated supply.

- Code: 10.23.35

- Display: 10.YY.35 Incompatible <supply>

- Description: The indicated cartridge is not compatible with this product.

Fuser CAUTION: The fuser might be hotBe careful when removing the fuser. - Remedy: Install a supply that is designed for this product.

- Code: 10.23.50

- Display: 10.23.50

- Description: The fuser kit life was reset above the order threshold. A new fuser was installed.

- Remedy: No action necessary.

Solved HP LaserJet M775 Enterprise 700 color MFP Error codes

- Code: 10.23.51

- Display: 10.23.51

- Description: The fuser kit life was reset above the replace threshold. A new fuser was installed.

- Remedy: No action necessary.

- Code: 10.23.52

- Display: 10.23.52

- Description: The fuser kit life was reset above the reset threshold. A new ITB was installed.

- Remedy: No action necessary.

- Code: 10.23.70

- Display: 10.23.70 Printing past very low

- Description: The product indicates when fuser kit is very low. The actual remaining fuse kit life might vary. You do not need to replace the fuser kit at this time unless print quality is no longer acceptable. CAUTION: After an HP supply has reached the very low threshold, the HP premium protection warranty ends.

- Remedy: If print quality is no longer acceptable, replace the fuser kit.

- Code: 10.23.70

- Display: 10.XX.70 Printing past very low

- Description: The product indicates when one of the consumables is very low. The actual remaining consumable life might vary. You do not need to replace the consumable at this time unless print quality is no longer acceptable.

The product indicates when the fuser kit is very low. The actual remaining fuser kit life might vary. You do not need to replace the fuser kit at this time unless print quality is no longer acceptable. - Remedy: If print quality is no longer acceptable, replace the indicated print cartridge or fuser kit.

- Code: 10.31.15

- Display: 10.YY.15 Install <supply>

- Description: The indicated supply has been removed or installed incorrectly.

Toner collection unit (TCU) - Remedy: Replace or install the indicated supply.

- Code: 10.39.50

- Display: 10.39.50 New Document Feeder Kit

- Description: A new document feeder maintenance kit has been installed and New Document Feeder Kit has been selected from the control panel menus.

- Remedy: No action necessary.

- Code: 10.39.53

- Display: 10.39.53

- Description: Document feeder kit recommend clean prompt.

- Remedy: Remove the document feeder pick roller, feed roller, and the separation pad assemblies. Clean the rollers and pad with a damp lint free cloth.

- Code: 10.39.55

- Display: 10.39.55 Clean Document Feeder Rollers

- Description: The document feeder separation pad and rollers need to be cleaned.

- Remedy: Remove the document feeder pick roller, feed roller, and the separation pad assemblies. Clean the rollers and pad with a damp lint free cloth.

- Code: 10.39.56

- Display: 10.39.56

- Description: Scanned past document feeder scheduled cleaning prompt.

- Remedy: Remove the document feeder pick roller, feed roller, and the separation pad assemblies. Clean the rollers and pad with a damp lint free cloth.

- Code: 10.39.60

- Display: 10.39.60 Document Feeder Kit low

- Description: The document feeder pick roller, feed roller, and separation pad are near their end of life.

- Remedy: No action necessary.

- Code: 10.39.69

- Display: 10.39.69 Document Feeder Kit very low

- Description: The document feeder pick roller, feed roller, and separation pad are at their end of life.

- Remedy: Order and install a document feeder maintenance kit.

- Code: 10.39.70

- Display: 10.39.70 Scanning past very low

- Description: The document feeder pick roller, feed roller, and separation pad are at their end of life.

- Remedy: Order and install a document feeder maintenance kit.

- Code: 10.39.71

- Display: 10.39.71 Document Feeder has stopped

- Description: The document feeder pick roller, feed roller, and separation pad are at their end of life.

- Remedy: Order and install a document feeder maintenance kit.

- Code: 11.00.YY

- Display: 11.00.YY Internal clock error

- Description: The product real-time clock has experienced an error. • 01: Internal clock battery has zero voltage. • 02: Real-time clock has failed.

- Remedy: Turn the product off, and then on again. Set the time and date at the control panel. If the error persists, replace the formatter.

- Code: 13.00.00

- Display: 13.00.00

- Description: Generic jam event code.

- Remedy: Check the product for a jam.

- Code: 13.80.A1

- Display: 13.80.A1

- Description: Stapler/stacker inlet sensor stay jam. The inlet sensor SR9 does not detect the trailing edge of paper within a specified period after it detects the leading edge.

- Remedy: 1. Open right-upper door, and then remove any jammed media. 2. Make sure that the paper meets HP specifications. 3. Check for an obstruction in the paper path inside the right upper door. 4. Defeat the upper right door sensors SW1, and then print a page. Verify that the stapler/stacker input rollers turn. If the rollers do not turn, replace the feed guide assembly.

- Code: 13.80.D1

- Display: 13.80.D1

- Description: Stapler/stacker inlet sensor delay jam. The inlet sensor SR9 does not detect the leading edge of paper within a specified period after the leading edge reaches the fuser output sensor PS6 in the product.

- Remedy: 1. Open right-middle door, and then remove any jammed media from the fuser. 2. Make sure that the paper meets HP specifications. 3. Check for an obstruction in the paper path inside the right upper door. 4. Defeat the upper right door sensors SW1, and then print a page. Verify that the stapler/stacker input rollers turn. If the rollers do not turn, replace the feed guide assembly.

- Code: 13.80.F1

- Display: 13.80.F1

- Description: Stapler/stacker inlet sensor residual jam. The inlet sensor (SR9) detects a presence of paper when the printer is turned on.

- Remedy: 1. Open right-middle door, and then remove any jammed media-make sure to also check the fuser area. 2. If the error persists, replace the feed guide assembly.

- Code: 13.80.FF

- Display: 13.80.FF

- Description: Stapler/stacker inlet sensor residual jam. The inlet sensor (SR9) detects a presence of paper when the printer is turned on.

- Remedy: 1. Open right-middle door, and then remove any jammed media from the fuser. 2. Open right-upper door, and then remove any jammed media. 3. If the error persists, replace the feed guide assembly.

- Code: 13.84.A1

- Display: 13.84.A1 Jam in lower bin area

- Description: Stapler/stacker outlet sensor 1 stay jam. The media feed sensor SR2 does not detect the leading edge of the media within a specified period after the leading edge reaches the inlet sensor SR9.

- Remedy: 1. Open right-upper door, and then remove any jammed media. 2. Make sure that the paper meets HP specifications. 3. Check for an obstruction in the paper path inside the right upper door. 4. If the error persists, replace the operation assembly.

- Code: 13.84.F1

- Display: 13.84.F1

- Description: Stapler/stacker sensor 1 residual jam. The media feed sensor SR2 detects a presence of paper when the product is turned on.

- Remedy: 1. Open right-upper door, and then remove any jammed media. 2. If the error persists, replace the operation assembly.

- Code: 13.85.A1

- Display: 13.85.A1 Jam inside right cover

- Description: Stapler/stacker outlet sensor 2 stay jam. The staple tray media presence sensor SR4 detects a presence of media after a specified period from when the stack ejection operation is complete.

- Remedy: 1. Open right-upper door, and then remove any jammed media. 2. Make sure that the paper meets HP specifications. 3. Check for an obstruction in the paper path inside the right upper door. 4. If the error persists, replace the operation assembly.

- Code: 13.85.F1

- Display: 13.85.F1 Jam inside right cover

- Description: Stapler/stacker outlet sensor 2 residual jam. The staple tray media presence sensor SR4 detects a presence of paper when the product is turned on

- Remedy: 1. Open right-upper door, and then remove any jammed media. 2. If the error persists, replace the operation assembly.

- Code: 13.89.31

- Display: 13.89.31 Staple jam inside right cover

- Description: Staple jam. The stapler sensor senses a staple arm position change after a specified period from when the stapler motor starts rotating and when the stapler sensor senses the staple arm returning to home position within a specified period from when the stapler motor reverses.

- Remedy: 1. Open right-upper door, and then remove the staple cartridge. 2. Remove any jammed staples in the cartridge. Reinstall the cartridge. 3. Make sure that the paper meets HP specifications. 4. Remove the staple cartridge, and then remove one staple sheet from the cartridge. 5. If the error persists, replace the stapler assembly.

- Code: 13.8A.EE

- Display: 13.8A.EE

- Description: Stapler/stacker door 1 jam. The stapler Stacker right-upper access door was opened during print job.

- Remedy: 1. Close the door. 2. Check for obstructions that cause the right upper door to not properly close. 3. Check the sensor flag on the right-upper door for damage. 4. If the error persists after closing the right upper door, replace right door switch assembly.

- Code: 13.A3.D3

- Display: 13.A3.D3

- Description: Misfeed jam from tray 3. No-pick jam from tray 3. The leading edge of paper fed from Tray 3 is stopped before SR1 HCI Tray 3 media feed sensor PS3302 (sensor does not detect the leading edge of paper within a specified period), including a two time retry, after the HCI right cassette pickup solenoid is turned on.

- Remedy: 1. Open Tray 3, remove any jammed paper, and then close the tray. 2. Inspect the Tray 3 pick, feed and separation rollers. Clean or replace if necessary. 3. Check the connectors at the feed sensor, solenoid, feed motor, and the controller PCA. 4. Use the Tray/bin manual sensor tests to toggle the Tray 3 feed sensor. If the sensor or lever is not properly functioning, replace the Tray 3 paper pickup assembly. 5. Use the Component tests to activate the Tray 3 solenoid (listen for the solenoid to activate). If the solenoid is not properly functioning, replace the Tray 3 paper pickup assembly. 6. Use the Component tests to activate the Tray 3 motor (listen for the motor to activate). If the motor is not properly functioning, replace the Tray 3 pickup motor.

- Code: 13.A3.D3

- Display: 13.A3.D3

- Description: Late to registration jam, from tray 3. The leading edge of paper fed from Tray 3 is stopped before PS5 after passing SR1.

- Remedy: 1. Open the right door, clear any jammed paper, and then close the door. 2. Check for obstructions in the paper path. 3. Verify that the second transfer roller is seated properly and not worn or deformed. Replaced it if necessary. 4. Check the pickup, feed, and separation rollers from the source tray. Replace them if they are worn or defective. 5. Verify that the registration assembly shutter is properly functioning. Replace it if it is damaged. 6. Use the manual sensor tests to toggle the TOP sensor (PS5). If the sensor is not properly functioning, replace the registration sensor assembly. 7. Check the connectors (J122S) on the DC controller and (J537) on the PS5 sensor. 8. Use the Component tests to activate the pickup motor and pickup solenoid/clutch for the source tray. If the motor or solenoid/clutch is not properly functioning, replace the motor or solenoid/ clutch assembly.

- Code: 13.A3.D4

- Display: 13.A3.D4

- Description:

Late to tray 3 feed sensor jam, from tray 4. Late to path jam from Tray 4. This jam occurs when the paper does not reach the Tray 3 feed sensor SR1 in designated amount of time after the Tray 4 feed sensor SR1 sensed the leading edge.

500-sheet trays • The leading edge of paper fed from Tray 4 is stopped before Tray 3 SR1 after passing Tray 4 SR1.

High capacity input feeder • The HCI media feed sensor PS3301 does not detect the leading edge of paper within a specified period after the Tray 4 cassette media feed sensor PS3305 detects the leading edge of paper. - Remedy: 1. Open the lower-right door, remove any jammed paper, and then close the door. 2. Inspect the Tray 4 pick, feed and separation rollers. Clean or replace if necessary. 3. Check the connectors at the feed sensor, solenoid, feed motor, and the controller PCA. 4. Use the Tray/bin manual sensor tests to toggle the Tray 4 feed sensor. If the sensor or lever is not properly functioning, replace the Tray 4 paper pickup assembly. 5. Use the Component tests to activate the Tray 4 solenoid (listen for the solenoid to activate). If the solenoid is not properly functioning, replace the Tray 4 paper pickup assembly. 6. Use the Component tests to activate the Tray 4 motor (listen for the motor to activate). If the motor is not properly functioning, replace the Tray 4 pickup motor. 7. Use the Tray/bin manual sensor tests to toggle the Tray 3 feed sensor. If the sensor or lever is not properly functioning, replace the Tray 3 paper pickup assembly or HCI crossing paper feed assembly.

- Code: 13.A3.D4

- Display: 13.A3.D4

- Description: Late to registration jam, from Tray 4. The leading edge of paper fed from Tray 4 is stopped before PS5 after passing SR1.

- Remedy: 1. Open the right door, clear any jammed paper, and then close the door. 2. Check for obstructions in the paper path. 3. Verify that the second transfer roller is seated properly and not worn or deformed. Replaced it if necessary. 4. Check the pickup, feed, and separation rollers from the source tray. Replace them if they are worn or defective. 5. Verify that the registration assembly shutter is properly functioning. Replace it if it is damaged. 6. Use the manual sensor tests to toggle the TOP sensor (PS5). If the sensor is not properly functioning, replace the registration sensor assembly. 7. Check the connectors (J122S) on the DC controller and (J537) on the PS5 sensor. 8. Use the Component tests to activate the pickup motor and pickup solenoid/clutch for the source tray. If the motor or solenoid/clutch is not properly functioning, replace the motor or solenoid/ clutch assembly.

- Code: 13.A3.D5

- Display: 13.A3.D5

- Description: Late to tray 3 feed sensor jam, from tray 5. Late to path jam from Tray 5. This jam occurs when the paper does not reach the Tray 3 feed sensor SR1 in specified amount of time after the Tray 5 feed sensor SR81 sensed the leading edge.

- Remedy: 1. Open the lower-right door, remove any jammed paper, and then close the door. 2. Inspect the Tray 5 pick, feed and separation rollers. Clean or replace if necessary. 3. Check the connectors at the feed sensor, solenoid, feed motor, and the controller PCA. 4. Use the Tray/bin manual sensor tests to toggle the Tray 5 feed sensor. If the sensor or lever is not properly functioning, replace the Tray 5 paper pickup assembly. 5. Use the Component tests to activate the Tray 5 solenoid (listen for the solenoid to activate). If the solenoid is not properly functioning, replace the Tray 5 paper pickup assembly. 6. Use the Component tests to activate the Tray 5 motor (listen for the motor to activate). If the motor is not properly functioning, replace the Tray 5 pickup motor. 7. Use the Tray/bin manual sensor tests to toggle the Tray 3 feed sensor. If the sensor or lever is not properly functioning, replace the Tray 3 paper pickup assembly.

- Code: 13.A3.D6

- Display: 13.A3.D6

- Description: Late to tray 3 feed sensor jam, from tray 6. Late to path jam from Tray 6. The leading edge of paper fed from Tray 6 is stopped before Tray 3 SR1 after passing Tray 6 SR91.

- Remedy: 1. Open the lower-right door, remove any jammed paper, and then close the door. 2. Inspect the Tray 6 pick, feed and separation rollers. Clean or replace if necessary. 3. Check the connectors at the feed sensor, solenoid, feed motor, and the controller PCA. 4. Use the Tray/bin manual sensor tests to toggle the Tray 6 feed sensor. If the sensor or lever is not properly functioning, replace the Tray 6 paper pickup assembly. 5. Use the Component tests to activate the Tray 6 solenoid (listen for the solenoid to activate). If the solenoid is not properly functioning, replace the Tray 6 paper pickup assembly. 6. Use the Component tests to activate the Tray 6 motor (listen for the motor to activate). If the motor is not properly functioning, replace the Tray 6 pickup motor. 7. Use the Tray/bin manual sensor tests to toggle the Tray 3 feed sensor. If the sensor or lever is not properly functioning, replace the Tray 3 paper pickup assembly.

- Code: 13.A3.FF

- Display: 13.A3.FF

- Description: Power on jam, tray 3 feed sensor. Power on residual paper jam. This jam occurs when the paper exists at SR1 at power on or door close. Due to the current firmware timing requirements, the displayed jam code is always 13.FF.FF (the event log will have 13.WX.FF).

- Remedy: 1. Open the lower-right door, clear any jammed paper, and then close the door. 2. Use the Tray/bin manual sensor tests to toggle the Tray 3 feed sensor. If the sensor or lever is not properly functioning, check the connectors to the sensor. If the error persists, replace the Tray 3 paper pickup assembly.

- Code: 13.A4.D4

- Display: 13.A4.D4

- Description: Late to tray 4 feed sensor jam, from Tray 4. No-pick jam from Tray 4.

500-sheet trays • The leading edge of paper fed from Tray 4 does not reach Tray 4 SR1 in specified amount of time.

High capacity input feeder • Tray 4 media feed sensor PS3305 does not detect the leading edge of paper within a specified period, including two times retry, after the HCI left cassette pickup solenoid is turned on. - Remedy: 500-sheet trays

a. Open Tray 4, clear any jammed paper, and then close the tray. b. Open the lower-right door, clear any jammed paper, and then close the door.

High capacity input feeder

a. Open Tray 4, clear any jammed paper, and then close the tray. b. Open Tray 3, release the jam access tray and clear any jammed paper, and then close the tray.

500-sheet trays and high capacity input feeder

1. Inspect the Tray 4 pick, feed and separation rollers. Clean or replace if necessary. 2. Check the connectors at the feed sensor, solenoid, feed motor, and the controller PCA. 3. Use the Tray/bin manual sensor tests to toggle the Tray 4 feed sensor. If the sensor or lever is not properly functioning, replace the Tray 4 paper pickup assembly. 4. Use the component tests to activate the Tray 4 solenoid (listen for the solenoid to activate). If the solenoid is not properly functioning, replace the Tray 4 paper pickup assembly. 5. Use the component tests to activate the Tray 4 motor (listen for the motor to activate). If the motor is not properly functioning, replace the Tray 4 pickup motor.

- Code: 13.A4.D5

- Display: 13.A4.D5

- Description: Late to path jam from Tray 5. This jam occurs when the paper does not reach the Tray 4 feed sensor SR1 in designated amount of time after the Tray 5 feed sensor SR81 sensed the leading edge.

- Remedy: 1. Open the lower-right door, remove any jammed paper, and then close the door. 2. Inspect the Tray 5 pick, feed and separation rollers. Clean or replace if necessary. 3. Check the connectors at the feed sensor, solenoid, feed motor, and the controller PCA. 4. Use the Tray/bin manual sensor tests to toggle the Tray 5 feed sensor. If the sensor or lever is not properly functioning, replace the Tray 5 paper pickup assembly. 5. Use the Component tests to activate the Tray 5 solenoid (listen for the solenoid to activate). If the solenoid is not properly functioning, replace the Tray 5 paper pickup assembly. 6. Use the Component tests to activate the Tray 5 motor (listen for the motor to activate). If the motor is not properly functioning, replace the Tray 5 pickup motor.

- Code: 13.A4.D6

- Display: 13.A4.D6