7

7

Diagnostics

7.1

Diagnostic messages

7.1.1

Classification and error responses

The diagnostic messages of the motor controller are classified as errors, warnings or information.

Type

Description

Error

When an error occurs, the motor controller changes to the

(Error)

error status (DOUT READY 1è 0). Errors always generate an

error reaction that has an effect on the behaviour of the

drive, e.g. stop behaviour, switching off the output stage

(è Tab. 7.2). To restore the ready status, errors require:

– elimination of the error cause

– an acknowledgment or a restart (reset)

Warning

Warnings have no influence on the behaviour of the drive

(Warning)

and do not need to be acknowledged. To avoid a sub

sequent error: Clarify the cause of the warning and elimin

ate it.

Information

Information messages have no influence on the behaviour

(Information)

of the drive and do not need to be acknowledged.

Tab. 7.1 Classification of the diagnostic messages

Error response

Free run-out

(Free-wheeling)

Quick stop deceleration

(QS deceleration)

Job deceleration

(Command deceleration)

End job

(Finish command)

2) Parameterisation with PNU 234 è B.4.5 or with FCT

Tab. 7.2 Error response (stop behaviour)

76

Description

– The output stage is switched off.

– The drive then gradually comes to rest.

– The movement is stopped immediately with the parameterised quick

stop deceleration.

– The output stage can then optionally

– The movement is stopped immediately with the deceleration used in

the current job.

– The output stage can then optionally

– The current job is executed until the target is reached

(Motion Complete).

– The output stage can then optionally

Festo – GDCP-CMMO-ST-LK-C-HP-EN – 2017-05b – English

FHPP

SCON.FAULT bit is set

The SCON.WARN bit

is set. If the cause

has been eliminated,

the bit is automatic

ally deleted again.

—

2)

be switched off.

2)

be switched off.

2)

be switched off.

-

Contents

-

Table of Contents

-

Bookmarks

Quick Links

Motor controller

CMMO-ST-C5-1-LKP

Description

Motor controller with

interface for

– IO-Link

– I-Port

– Modbus TCP

Device profile FHPP

8071674

2017-05b

[8071676]

Related Manuals for Festo CMMO-ST-C5-1-LKP

Summary of Contents for Festo CMMO-ST-C5-1-LKP

-

Page 1

Motor controller CMMO-ST-C5-1-LKP Description Motor controller with interface for – IO-Link – I-Port – Modbus TCP Device profile FHPP 8071674 2017-05b [8071676]… -

Page 2

Software identification: <xxx> Buttons in the software [xxx] [xxx] References to menu and sub-menu structures in the software FCT […] [xxx] FCT plug-in menu for components in the “Workplace” window FCT menu [xxx] FCT-main menu Festo – GDCP-CMMO-ST-LK-C-HP-EN – 2017-05b –… -

Page 3: Table Of Contents

……….Festo – GDCP-CMMO-ST-LK-C-HP-EN – 2017-05b – English…

-

Page 4

……….Festo – GDCP-CMMO-ST-LK-C-HP-EN – 2017-05b – English… -

Page 5

……….. . . B.4.20 Axis parameters: electrical Drives 1 – mechanical parameters ….Festo – GDCP-CMMO-ST-LK-C-HP-EN – 2017-05b – English… -

Page 6

…………… . Festo – GDCP-CMMO-ST-LK-C-HP-EN – 2017-05b – English… -

Page 7: Motor Controller Documentation

Motor controller documentation This documentation (GDCP-CMMO-ST-LK-C-HP-…) describes the Festo Handling und Positioning Profile (FHPP) for the motor controller CMMO-ST-C5-1-LKP. The full description of the motor controller includes the following documents: Always observe the general safety regulations for the motor controller in the equipment and functional description of the motor controller GDCP-CMMO-ST-LK-SY-…

-

Page 8: Version Status

Before using a newer firmware version: • Check whether a newer corresponding version of the FCT plug-in or user documenta tion is available è www.festo.com/sp. Service Please consult your regional Festo contact if you have any technical problems. Festo – GDCP-CMMO-ST-LK-C-HP-EN – 2017-05b – English…

-

Page 9: Fhpp With Motor Controller Cmmo-St

FHPP with motor controller CMMO-ST FHPP overview Tailored to the target applications for handling and positioning tasks, Festo has developed an optim ised device profile, the “Festo Handling and Positioning Profile (FHPP)”. The FHPP permits a uniform control and parameterisation for the various motor controllers from Festo, independent of the connection to different control devices.

-

Page 10: Interfaces

FHPP with motor controller CMMO-ST Interfaces Control and parameterisation via FHPP is supported in CMMO-ST-C5-1-LKP through various fieldbus interfaces corresponding to Tab. 1.1. Connection Interface Description è Chapter 2 IO-Link [X1] – IO-Link/I-Port and digital I/Os è Chapter 3 I-Port [X1] –…

-

Page 11: Io-Link

2) Required signals for controller enable can be parameterised (FCT) è section 2.2.1 3) Pins can be used for the 4th and 5th conductor of the I-Port / IO-Link cable Tab. 2.1 Port X1 I/O interface, pin 9 … 11 allocated for IO-Link Festo – GDCP-CMMO-ST-LK-C-HP-EN – 2017-05b – English…

-

Page 12: Parameterisation Of Io-Link Device

– “IO-Link” 4. In the FHPP Profile tab, determine and save the device profile (Save): – “FHPP channel” – “FHPP + FPC channel” After parameterisation, the IO-Link master can be configured è section 2.3. Festo – GDCP-CMMO-ST-LK-C-HP-EN – 2017-05b – English…

-

Page 13: Configuration Io-Link Master

The upload and download of all parameters to the controller can be implemented via EFPC with appropriate functional modules or function blocks è appendix C.4 Current IODD files, functional modules or function blocks è www.festo.com/sp Festo – GDCP-CMMO-ST-LK-C-HP-EN – 2017-05b – English…

-

Page 14: Example Of Cmmo-St At S7 1200

“Catalogue” window for selection of the IO- Link master Fig. 2.1 Example TIA-Portal – configure S7 7. Load configuration into controller. 8. Start the DeviceTool via the context menu of the IO-Link master. Festo – GDCP-CMMO-ST-LK-C-HP-EN – 2017-05b – English…

-

Page 15

Fig. 2.2 Example DeviceTool, assign IODD to the port 11.In the catalogue under “IO-Link 1.1”, “Festo AG & Co. KG”, “CMMO”, select the desired variant (standard FHPP or with FPC) and assign the IODD to the used port. 12.Load configuration into the device. -

Page 16: Port

I-Port I-Port The Festo-specific I-Port interface is used for exchange of serial data from decentralised function mod ules (devices) at field level. The LED C/Q on the motor controller displays the status of the I-Port connection. IO-Link/I-Port and digital I/O interface [X1]…

-

Page 17: Parameterisation Of I-Port Device

– “I-Port” 4. In the FHPP Profile tab, determine and save the device profile (Save): – “FHPP channel” – “FHPP + FPC channel” After parameterisation, the I-Port master can be configured è section 3.3. Festo – GDCP-CMMO-ST-LK-C-HP-EN – 2017-05b – English…

-

Page 18: Configuration Of I-Port Master

For some I-Port masters, device description files are available for the respective fieldbus. Specific module support of the I-Port devices through current GSD and ESI files, function al modules or function blocks è www.festo.com/sp Festo – GDCP-CMMO-ST-LK-C-HP-EN – 2017-05b – English…

-

Page 19: Modbus Tcp

“turn” these 2 bytes on the controller. This applies to the operations (function codes): 0x03, 0x10, 0x17 è section 4.3.2. This already takes place through the module if provided by Festo. Modbus telegram In general, a Modbus telegram is constructed correspondingly è Tab. 4.1 (the higher-value byte is always sent first).

-

Page 20: Modbus Tcp Interface [X18]

Wire pair 2 – Wire pair 4 – Wire pair 4 – Housing Screening Tab. 4.2 Allocation [X18] Type and design of cable Shielded twisted-pair STP, Cat.5 cables must be used for cabling. Festo – GDCP-CMMO-ST-LK-C-HP-EN – 2017-05b – English…

-

Page 21: Parameterisation Of Modbus-Tcp User

– control interface (Modbus, IO-Link, I-Port) – interface parameters (device profile, TCP-Port) – Network settings After parameterisation and restart of the motor controller, the Modbus master can be configured è section 4.3. Festo – GDCP-CMMO-ST-LK-C-HP-EN – 2017-05b – English…

-

Page 22: Parameterisation With The Integrated Web Server

– Write Multiple Registers (0x10) – Read/Write Multiple Registers (0x17) – Read Device Identification (0x2B) The start address is always “0”; the byte sequence is always “Big endian”. Tab. 4.3 shows the supported Modbus commands. Festo – GDCP-CMMO-ST-LK-C-HP-EN – 2017-05b – English…

-

Page 23

FHPP standard + FPC process input telegram I Read/write multiple registers exception (0x97) Field Bytes Values Byte no. Error code 0x97 Exception code 0x01: illegal function 0x02: illegal data address 0x03: illegal data value 0x04: server device failure Festo – GDCP-CMMO-ST-LK-C-HP-EN – 2017-05b – English… -

Page 24

FHPP standard I/O and FPC 10 … Read holding registers exception (0x83) Field Bytes Values Byte no. Error code 0x83 Exception code 0x01: illegal function 0x02: illegal data address 0x03: illegal data value 0x04: server device failure Festo – GDCP-CMMO-ST-LK-C-HP-EN – 2017-05b – English… -

Page 25

0x0008: FHPP standard + FPC Write multiple registers exception (0x90) Field Bytes Values Byte no. Error code 0x90 Exception code 0x01: illegal function 0x02: illegal data address 0x03: illegal data value 0x04: server device failure Festo – GDCP-CMMO-ST-LK-C-HP-EN – 2017-05b – English… -

Page 26

0x00: No fault Read exception status exception (0x87) Field Bytes Values Byte no. Error code 0x87 Exception code 0x01: illegal function 0x02: illegal data address 0x03: illegal data value 0x04: server device failure Festo – GDCP-CMMO-ST-LK-C-HP-EN – 2017-05b – English… -

Page 27

Read device identification exception (0xAB) Field Bytes Values Byte no. Error code 0xAB Exception code 0x01: illegal function 0x02: illegal data address 0x03: illegal data value 0x04: server device failure Tab. 4.3 Overview of Modbus function codes Festo – GDCP-CMMO-ST-LK-C-HP-EN – 2017-05b – English… -

Page 28: Data Objects For Modbus Command «Read Device Identification

A value of 0 deactivates the timeout. In case of a timeout, the fault message 47h or 48h is triggered è appendix D. The error response is adjustable from “warning” to “immediate shut-off of the output stage”. Festo – GDCP-CMMO-ST-LK-C-HP-EN – 2017-05b – English…

-

Page 29: Sequence Control And I/O Data

The positioning data are managed completely in the controller and sent directly to the motor con troller. Festo – GDCP-CMMO-ST-LK-C-HP-EN – 2017-05b – English…

-

Page 30: Fhpp Finite State Machine

TA11 negative TA12 Positioning job active Intermediate stop Operation enabled Fig. 5.1 Finite state machine You can find the explanation of the control and status bytes (CCON, SCON, …) in è section 5.3. Festo – GDCP-CMMO-ST-LK-C-HP-EN – 2017-05b – English…

-

Page 31: Create Ready Status

CCON.STOP = 1 CCON.ENABLE = 1 è CCON = xxx0.xx11 Block operation CCON.STOP = 0 è CCON = xxx0.xx01 1) Key: P = rising edge (positive), N = falling edge (negative), x = any Festo – GDCP-CMMO-ST-LK-C-HP-EN – 2017-05b – English…

-

Page 32: Positioning

Motion Complete = 0 Trigger intermediate stop CPOS.HALT = 1 } 0 Positioning job not yet completed. è CPOS = 0xxx.xxxN 1) Key: P = rising edge (positive), N = falling edge (negative), x = any Festo – GDCP-CMMO-ST-LK-C-HP-EN – 2017-05b – English…

-

Page 33

è CPOS = 0xxx.xxxN Jog positive CPOS.JOGP = 0 } 1 CPOS.HALT = 1 è CPOS = 0xx0.Pxx1 1) Key: P = rising edge (positive), N = falling edge (negative), x = any Festo – GDCP-CMMO-ST-LK-C-HP-EN – 2017-05b – English… -

Page 34

Direct application TA2: The condition that no new record may be processed no longer applies. TA5: A new record can be started at any time. Tab. 5.4 Special features dependent on FHPP operating mode Festo – GDCP-CMMO-ST-LK-C-HP-EN – 2017-05b – English… -

Page 35: Examples Of Control And Status Bytes

Optionally, acceptance of device control by the FCT can be blocked with CCON.LOCK = 1. } Step 1.3 Enable drive in record selection mode. } Homing: Example 4, Tab. 5.8. If there are malfunctions after switching on or after setting CCON.ENABLE. } Fault handling è example 3, Tab. 5.7. Festo – GDCP-CMMO-ST-LK-C-HP-EN – 2017-05b – English…

-

Page 36

CCON.ENABLE SCON.ENABLED malfunction with CCON.RESET SCON.FAULT CCON.RESET SCON.WARN SPOS.ACK SPOS.MC 1) Key: P = rising edge (positive), N = falling edge (negative), x = any Tab. 5.7 Control and status bytes “Malfunction handling” Festo – GDCP-CMMO-ST-LK-C-HP-EN – 2017-05b – English… -

Page 37

A rising edge at CPOS.HOM, (start homing) starts homing. The start is confirmed with SPOS.ACK (Acknowledge start) as long as CPOS.HOM is set. Movement of the axis is shown with SPOS.MOV. After successful homing, SPOS.B2 MC (Motion Complete) and SPOS.REF are set. Festo – GDCP-CMMO-ST-LK-C-HP-EN – 2017-05b – English… -

Page 38

With CPOS.B1 (START, start job) the preselected positioning job will be started. The start is con firmed with SPOS.ACK (Acknowledge start) as long as CPOS.START is set. Movement of the axis is shown with SPOS.MOV. At the end of the positioning task, SPOS.MC will be set. Festo – GDCP-CMMO-ST-LK-C-HP-EN – 2017-05b – English… -

Page 39

With CPOS.START, the preselected positioning task will be started. The start is confirmed with SPOS.ACK as long as CPOS.START is set. Movement of the axis is shown with SPOS.MOV. At the end of the positioning task, SPOS.MC is set. Festo – GDCP-CMMO-ST-LK-C-HP-EN – 2017-05b – English… -

Page 40: Configuration Of The I/O Data

è appendix C. If applicable, observe the specification in the bus master for the representation of words and double words (Intel/Motorola). For example, the representation via Modbus uses the “big endian” representation (high-order byte first). Festo – GDCP-CMMO-ST-LK-C-HP-EN – 2017-05b – English…

-

Page 41: I/O Data (Byte 1

Byte 4 Byte 5 Byte 6 Byte 7 Byte 8 Control and user data independent of the transmission mode è section C.2.2 Output FPCC data Input FPCS data Tab. 5.11 EFPC structure in general Festo – GDCP-CMMO-ST-LK-C-HP-EN – 2017-05b – English…

-

Page 42: Assignment Of The Control Bytes And Status Bytes (Overview)

– XLIM VLIM – COM2 COM1 applica – – Stroke Speed – Feedback control Absolute/ tion) limit limit mode (position, relative reached reached force, speed) Tab. 5.13 Overview, assignment of the status bytes Festo – GDCP-CMMO-ST-LK-C-HP-EN – 2017-05b – English…

-

Page 43: Description Of The Control Bytes

(HMI control) (to change parameters or con trol inputs). Operating Select Determining the FHPP operating mode. OPM1 mode Operating Bit 7 Bit 6 Operating mode selection Mode Record selection OPM2 Direct application Reserved Reserved Tab. 5.14 Control byte 1 Festo – GDCP-CMMO-ST-LK-C-HP-EN – 2017-05b – English…

-

Page 44

In the “Halt” status, a rising edge causes the position CLEAR ing path Remaining ing task to be deleted and a transition to the “Ready” Position status. – – Reserved, must be at 0. – Tab. 5.15 Control byte 2 Festo – GDCP-CMMO-ST-LK-C-HP-EN – 2017-05b – English… -

Page 45

Speed [% of the basic value] è PNU 540 Speed Velocity Preselection in speed mode Speed ramp [% of the basic value] è PNU 560 Speed ramp Velocity ramp Tab. 5.17 Control byte 4 – direct application Festo – GDCP-CMMO-ST-LK-C-HP-EN – 2017-05b – English… -

Page 46

Control byte 3 – record selection Control bytes 4 … 8 (reserved) – record selection Description B0 … 31 – – Reserved (= 0) Tab. 5.20 Control bytes 4 … 8 – record selection Festo – GDCP-CMMO-ST-LK-C-HP-EN – 2017-05b – English… -

Page 47: Description Of The Status Bytes

Device control through fieldbus possible. Operating Display Oper Feedback on FHPP operating mode. OPM1 mode feed ating Mode Bit 7 Bit 6 Operating mode back Record selection OPM2 Direct application Reserved Reserved Tab. 5.21 Status byte 1 Festo – GDCP-CMMO-ST-LK-C-HP-EN – 2017-05b – English…

-

Page 48

After MC, axis remains in tolerance window Drive Axis = 1: Homing information available; homing does not referenced Referenced need to be carried out = 0: Homing must be executed Tab. 5.22 Status byte 2 Festo – GDCP-CMMO-ST-LK-C-HP-EN – 2017-05b – English… -

Page 49

Speed [% of the basic value] è PNU 540 Speed Velocity Torque [% of the basic value] è PNU 555 Torque Torque Feedback in speed mode – – No function, = 0 Tab. 5.24 Status byte 4 – direct application Festo – GDCP-CMMO-ST-LK-C-HP-EN – 2017-05b – English… -

Page 50

Stroke limit reached XLIM reached LIMit reached = 0: Stroke limit not reached – – Reserved = 0 – – – Reserved = 0 – Tab. 5.27 Status byte 4 – record selection Festo – GDCP-CMMO-ST-LK-C-HP-EN – 2017-05b – English… -

Page 51

Status bytes 5 … 8 (position) – record selection Description Feedback of position [SINC] è appendix A.2, 32-bit B0 … 31 Position Position number Tab. 5.28 Status bytes 5 … 8 – record selection Festo – GDCP-CMMO-ST-LK-C-HP-EN – 2017-05b – English… -

Page 52: Control Via Fhpp

SPOS.ACK = rising edge: acknowledge start SPOS.REF = drive homed Requirement Device control through controller/fieldbus Motor controller in the status “Operation enabled” No command for jogging is present Tab. 6.1 Parameters and I/Os in homing Festo – GDCP-CMMO-ST-LK-C-HP-EN – 2017-05b – English…

-

Page 53: Methods Of Homing

Reference switch – negative direction Reference switch – positive direction Tab. 6.2 Possible homing methods Information on the sequence of homing methods è equipment and functional descrip tion of the motor controller, GDCP-CMMO-ST-LK-SY-..Festo – GDCP-CMMO-ST-LK-C-HP-EN – 2017-05b – English…

-

Page 54: Jogging

Period PNU 534.1 Fast speed PNU 531.1 Slow speed PNU 530.1 Jog positive CPOS.JOGP Jog negative CPOS.JOGN Acceleration/delay PNU 532.1 a– Fig. 6.1 Timing diagram jog operation (“Jog positive” shown as an example) Festo – GDCP-CMMO-ST-LK-C-HP-EN – 2017-05b – English…

-

Page 55: Teaching Via Fieldbus

Position comparator lower limit 1) Record number in direct mode via PNU 400.1 “Setpoint record number”; in case of record selection via record number, specify in control byte 3 Tab. 6.4 Overview of teach targets Festo – GDCP-CMMO-ST-LK-C-HP-EN – 2017-05b – English…

-

Page 56

CPOS.TEACH = N (falling edge, negative): Teach value Acknowledgement (FHPP) SPOS.TEACH = N (falling edge, negative): Value accepted Requirement Device control through controller/fieldbus Motor controller in the status “Operation enabled” Tab. 6.5 Parameters and I/Os when teaching Festo – GDCP-CMMO-ST-LK-C-HP-EN – 2017-05b – English… -

Page 57: Execute Record

If this destination cannot be reached with the parameterised speed, acceleration or de celeration, fault message 0x25 (path calculation) is reported. Festo – GDCP-CMMO-ST-LK-C-HP-EN – 2017-05b – English…

-

Page 58

SPOS.ACK = rising edge: acknowledge start SPOS.MOV = 1: Drive moves Requirement Device control through controller/fieldbus Motor controller in the status “Operation enabled” Valid record number is present Tab. 6.6 Parameters and I/Os with record selection Festo – GDCP-CMMO-ST-LK-C-HP-EN – 2017-05b – English… -

Page 59: Record Selection Flow Diagrams

As soon as “Start acknowledgement” is re record number. cognised by the controller, “Start” may be A currently running positioning task can be set to 0 again. stopped with “Stop”. Fig. 6.3 Flow diagram, record start/stop Festo – GDCP-CMMO-ST-LK-C-HP-EN – 2017-05b – English…

-

Page 60

Record is stopped with “halt”; actual record Rising edge at “Start” starts record N again; number N is retained; “Motion Complete” “Confirm halt” is set remains reset Fig. 6.4 Stop and continue flow diagram for record with halt Festo – GDCP-CMMO-ST-LK-C-HP-EN – 2017-05b – English… -

Page 61

Axis is moving SPOS.MOV Actual record N — 1 N + 1 number input data Stop record Delete remaining path Fig. 6.5 Flow diagram for stop record with halt and delete remaining path Festo – GDCP-CMMO-ST-LK-C-HP-EN – 2017-05b – English… -

Page 62: Record Structure

Force comparator, max. Upper limit of force comparator Force comparator damping Setpoint value for force comparator damping time time Time comparator, min. Lower limit of time comparator Time comparator, max. Upper limit of time comparator Festo – GDCP-CMMO-ST-LK-C-HP-EN – 2017-05b – English…

-

Page 63: Record Linking (Pnu 402)

Continuation takes place if the limit of the force com active parator has been reached. Time comparator active Continuation takes place if the limit of the time com active parator has been reached. Tab. 6.9 Step enabling conditions Festo – GDCP-CMMO-ST-LK-C-HP-EN – 2017-05b – English…

-

Page 64: Execute Direct Mode

1) The controller transfers a percentage value in the control bytes, which is multiplied by the base value to get the setpoint value Tab. 6.10 Parameters and I/Os in direct application of positioning mode Festo – GDCP-CMMO-ST-LK-C-HP-EN – 2017-05b – English…

-

Page 65

1) The controller transfers a percentage value in the control bytes, which is multiplied by the base value to get the setpoint value Tab. 6.11 Parameters and I/Os in direct application of force mode Festo – GDCP-CMMO-ST-LK-C-HP-EN – 2017-05b – English… -

Page 66

1) The controller transfers a percentage value in the control bytes, which is multiplied by the base value to get the setpoint value Tab. 6.12 Parameters and I/Os in direct application of speed mode Festo – GDCP-CMMO-ST-LK-C-HP-EN – 2017-05b – English… -

Page 67: Direct Mode Sequence

Start of the positioning task The sequence of the remaining control and status bits as well as the functions Halt and Stop reacts corresponding to the record selection function è Fig. 6.3, Fig. 6.4 and Fig. 6.5. Festo – GDCP-CMMO-ST-LK-C-HP-EN – 2017-05b – English…

-

Page 68

2 and the active speed control mode is displayed via the SDIR.COM1/2 bits. The signal SPOS.MC (Motion Complete) in this control mode reports “target speed reached”. Festo – GDCP-CMMO-ST-LK-C-HP-EN – 2017-05b – English… -

Page 69

2, and the active torque control mode is displayed via the SDIR.COM1/2 bits. The signal SPOS.MC (Motion Complete) in this control mode reports “carried out/done” or “Actual force = Setpoint force”. Festo – GDCP-CMMO-ST-LK-C-HP-EN – 2017-05b – English… -

Page 70: Monitoring Of The Drive Behaviour

è B.4.22 Target reached damping time (Motion Complete damp 1023 ing time, applicable for all task types) Acknowledgement (FHPP) SPOS.MC = 1: Motion Complete Tab. 6.16 Parameter and I/Os in Motion Complete Festo – GDCP-CMMO-ST-LK-C-HP-EN – 2017-05b – English…

-

Page 71: Following Error» Message

The error management of FCT permits parameterising the reaction to this message (2F ) (è FCT error management). If the following error has been configured as a warning, the message is automatically deleted when the actual value is again within the following error window. Festo – GDCP-CMMO-ST-LK-C-HP-EN – 2017-05b – English…

-

Page 72: Standstill Monitoring» Message

– The position controller attempts to return the actuator to the standstill window. Festo – GDCP-CMMO-ST-LK-C-HP-EN – 2017-05b – English…

-

Page 73

Standstill message window (standstill window) 1042 è B.4.24 Standstill delay time (damping time, standstill monit 1043 oring) Acknowledgement (FHPP) SPOS.STILL = 1: Exit standstill window Tab. 6.18 Parameters and I/Os in standstill monitoring Festo – GDCP-CMMO-ST-LK-C-HP-EN – 2017-05b – English… -

Page 74: Comparators

The limits are specified between -1000 to +1000 ‰ related to the force base value PNU 555. The message is active if the actual value for the parameterised time is within the window. 1) Only present in closed-loop operation. Tab. 6.19 Comparators Festo – GDCP-CMMO-ST-LK-C-HP-EN – 2017-05b – English…

-

Page 75

Speed comparator, min. Speed comparator, max. Speed comparator, damping time Force comparator, min. Force comparator, max. Force comparator, damping time Time comparator, min. Time comparator, max. Tab. 6.20 Parameters and I/Os in standstill monitoring Festo – GDCP-CMMO-ST-LK-C-HP-EN – 2017-05b – English… -

Page 76: Diagnostics

– The current job is executed until the target is reached (Finish command) (Motion Complete). – The output stage can then optionally be switched off. 2) Parameterisation with PNU 234 è B.4.5 or with FCT Tab. 7.2 Error response (stop behaviour) Festo – GDCP-CMMO-ST-LK-C-HP-EN – 2017-05b – English…

-

Page 77: Display Of A Diagnostic Event

Additionally, diagnostic events can be read from the diagnostic memory. Messages of type “informa tion” are not displayed and can only be read via FCT or web server. Additional information on the dia gnostic memory è 7.1.3. Festo – GDCP-CMMO-ST-LK-C-HP-EN – 2017-05b – English…

-

Page 78: Diagnostic Memory

(HH = hours, MM = minutes, SS = seconds, nnn = milliseconds). Time base is the respective switch-on time of the motor controller. Additional Additional information for Festo Service in case of complex faults information (Additional Info) 1) Not available via FHPP Tab.

-

Page 79: Fault Detection And Elimination

– Alternatively: Switch logic voltage off and back on. Restart via … Command [Component] [Online] [Restart Controller] FHPP Writing PNU 127:3 with the value 16 Tab. 7.8 Restart of the motor controller (software reset) Festo – GDCP-CMMO-ST-LK-C-HP-EN – 2017-05b – English…

-

Page 80: Parameterisation Of The Diagnostic Messages And Fault Clearance

Job deceleration — braking ramp of the current job, do not turn off output stage End job – continue to carry out job to Motion complete; do not switch off output stage Tab. 7.10 Error responses (code letters) Festo – GDCP-CMMO-ST-LK-C-HP-EN – 2017-05b – English…

-

Page 81: A Technical Appendix

Powers of ten exponent PNU 600 = -7 Unit of measurement PNU 601 = metre (0x01) Calculation: – 1 SINC: 1 * 10 m = 0.1 μm – 10,000 SINC: 10,000 * 10 m = 1 mm Festo – GDCP-CMMO-ST-LK-C-HP-EN – 2017-05b – English…

-

Page 82: Conversion Factors

Encoder resolution (Encoder Resolution) 1001 Array uint32 Gear ratio (Gear Ratio) 1002 Array uint32 Feed constant (Feed Constant) 1003 Array uint32 Axis parameter (Axis Parameter) 1005 Array uint32 Tab. A.2 Overview of parameters involved Festo – GDCP-CMMO-ST-LK-C-HP-EN – 2017-05b – English…

-

Page 83: B Reference Paramete

600 … 699 Parameters for unit conversion. Axis data: electric 1000 … 1099 All axis-specific parameters for electric drives, e.g. drives 1 gear ratio, feed constant, reference parameters. Tab. B.1 FHPP parameter structure Festo – GDCP-CMMO-ST-LK-C-HP-EN – 2017-05b – English…

-

Page 84: Access Protection And Master Control

Access protection and master control The user can prevent the drive from being operated simultaneously through the controller and the Festo Configuration Tool (FCT). The CCON.LOCK bit (block FCT access) and SCON.FCT/MMI bit (FCT mas ter control) are used for this.

-

Page 85: Overview Of Fhpp Parameters

(Festo Order Number) MMI parameters è B.4.4, page 100 Master control uint8 (Controllogic) Controller data memory 1 … 4 uint8 (Data Memory Control) Controller enable signals uint8 (Control Enable Signals) Tab. B.2 Device data Festo – GDCP-CMMO-ST-LK-C-HP-EN – 2017-05b – English…

-

Page 86: Diagnostics

(Permissible Malfunction Handling 1) Error reaction 1 1 … 255 uint16 (Error Reaction 1) Fault handling 1 1 … 255 uint16 (Malfunction Handling 1) Safety status uint8 (Safety State) Tab. B.3 Diagnostics Festo – GDCP-CMMO-ST-LK-C-HP-EN – 2017-05b – English…

-

Page 87: Process Data

(Status Comparator Outputs) FHPP data è B.4.7, page 112 FHPP status information 1, 2 uint32/ (FHPP State Information) int32 FHPP control information 1, 2 uint32/ (FHPP Control Information) int32 Tab. B.4 Process data Festo – GDCP-CMMO-ST-LK-C-HP-EN – 2017-05b – English…

-

Page 88: Record List

(MC During Record Continuation) Start delay 1 … 64 uint32 (Start Delay) Stroke limit 1 … 64 int32 (Stroke Limit) Factor torque pilot control 1 … 64 uint16 (Torque feed forward control factor) Festo – GDCP-CMMO-ST-LK-C-HP-EN – 2017-05b – English…

-

Page 89

Time comparator, max. 1 … 64 uint32 (Time Comparator, Max.) Setpoint value speed 1 … 64 int32 (Setpoint Value Velocity) Setpoint value force 1 … 64 int16 (Setpoint Value Force) Tab. B.5 Record list Festo – GDCP-CMMO-ST-LK-C-HP-EN – 2017-05b – English… -

Page 90: Project Data

(Velocity Fast – Phase 2) Acceleration/deceleration int32 (Acceleration/Deceleration) Time period phase 1 uint16 (Time Phase 1) Following error message window int32 (Following Error Window) Following error delay time uint16 (Following Error Timeout) Festo – GDCP-CMMO-ST-LK-C-HP-EN – 2017-05b – English…

-

Page 91

Direct mode speed è B.4.17, page 133 Basic value acceleration int32 (Base Value Acceleration) Speed message window reached int32 (Velocity Target Window) Stroke limiter int32 (Stroke Limitation) Message window for deviation int32 (Velocity Difference Error Window) Festo – GDCP-CMMO-ST-LK-C-HP-EN – 2017-05b – English… -

Page 92: Factor Group

B.3.6 Factor group Group/name Subindex Type Factor group è B.4.19, page 137 Position powers of ten exponent int8 (Position Notation Index) Position unit of measurement uint8 (Position Dimension Index) Tab. B.7 Factor group Festo – GDCP-CMMO-ST-LK-C-HP-EN – 2017-05b – English…

-

Page 93: Axis Parameters: Electric Drives 1

1 … 3 int32 (Velocities) Acceleration/deceleration 1013 int32 (Acceleration/Deceleration) Max. torque 1015 int16 (Max. Torque) Speed limit, stop detection 1016 int32 (Block Detection Velocity Limit) Damping time, stop detection 1017 uint16 (Block Detection Window Time) Festo – GDCP-CMMO-ST-LK-C-HP-EN – 2017-05b – English…

-

Page 94

(Standstill Window Timeout) Following error monitoring è B.4.25, page 147 Following error delay time 1045 uint16 (Following Error Timeout) Motor data è B.4.26, page 147 Current motor current 1059 int32 (Actual Current ) Festo – GDCP-CMMO-ST-LK-C-HP-EN – 2017-05b – English… -

Page 95

1074 uint32 (Actual Control Section Voltage) Current string currents 1075 1 … 3 int32 (Actual Phase Current) Torque pilot control 1080 uint16 (Torque Feed Forward Control) Tab. B.8 Axis parameters: electric drives 1 Festo – GDCP-CMMO-ST-LK-C-HP-EN – 2017-05b – English… -

Page 96: Descriptions Of Fhpp Parameters

Values with sign (8, 16, 32 bit) – int8: −128 … 127 – int16: −32,768 … 32,767 – int32: −2,147,483,648 … 2,147,483,647 Character (8 bit) – char: 0 … 255 (ASCII) Fig. B.1 Representation of the parameter entries Festo – GDCP-CMMO-ST-LK-C-HP-EN – 2017-05b – English…

-

Page 97: Device Data — Version Numbers

Reading of the FHPP version. The FHPP version number of the device consists of 4 numerals (e.g. “xxyy”). Format (16 bit, BCD) Numerals Significance Main version number Secondary version number Tab. B.11 PNU 102 Festo – GDCP-CMMO-ST-LK-C-HP-EN – 2017-05b – English…

-

Page 98: Device Data — Identification

Data type: uint16 FW … Access: ro Reading of the FCT version, which is required for operation of the firmware. The min. version number of the Festo Configuration Tool (FCT) consists of 4 numerals (e.g. “xxyy”). Format (16 bit, BCD) Numerals Significance…

-

Page 99

Subindex 1 … 30 Class: Array Data type: char FW … Access: ro Reading of the manufacturer’s designation of the drive (ASCII, 7-bit). Example: CMMO-ST-C5-1-LKP . Unused characters are filled with zero (00 =’\0’). Tab. B.14 PNU 120 PNU 121 User’s device name (User Device Name) -

Page 100: Device Data — Mmi Parameters

The controller can reserve master control exclusively with CCON.LOCK = 1. Reading Value Significance SCON.FCT/MMI 0x00 (0) Master control with Festo Configuration Tool (FCT) or web server 0x01 (1) Fieldbus has master control Presetting after every Power ON (switch on “control section” power supply) or restart controller (FCT). Writing…

-

Page 101

Through writing of the object, parameter values are loaded from the parameter file (permanent data memory of the motor controller). Value Significance 0x10 (16) Load parameter values from parameter file Tab. B.20 PNU 127 Festo – GDCP-CMMO-ST-LK-C-HP-EN – 2017-05b – English… -

Page 102: Diagnostic Parameters

Event 2 (Event 2) Type of second saved diagnostic message Subindex 3 … 200 Event 3 … 200 (Event 3 … 200) Type of 3rd … 200th saved diagnostic message Tab. B.22 PNU 200 Festo – GDCP-CMMO-ST-LK-C-HP-EN – 2017-05b – English…

-

Page 103

Event 2 (Event 2) Time of the 2nd saved diagnostic message Subindex 3 … 200 Event 3 … 200 (Event 3 … 200) Time of the 3rd … 200th saved diagnostic message Tab. B.24 PNU 202 Festo – GDCP-CMMO-ST-LK-C-HP-EN – 2017-05b – English… -

Page 104

Device fault (Device Fault) Subindex 1 Class: Var Data type: uint16 FW … Access: ro Read the active fault with the highest priority. If no fault is present, 0xFFFF (65535) is returned. Tab. B.27 PNU 205 Festo – GDCP-CMMO-ST-LK-C-HP-EN – 2017-05b – English… -

Page 105

0 entry (0th Entry) Diagnostic numbers 0 … 31 Subindex 2 1st entry (1st Entry) Diagnostic numbers 32 … 63 Subindex 32 31st entry (31th Entry) Diagnostic numbers 992 … 1023 Tab. B.29 PNU 221 Festo – GDCP-CMMO-ST-LK-C-HP-EN – 2017-05b – English… -

Page 106

Error response for the fault number 1. Subindex 3 … 255 Fault number 2 … 254 (Malfunction Number 2 … 254) Error responses for the fault numbers 2 … 254. Tab. B.31 PNU 234 Festo – GDCP-CMMO-ST-LK-C-HP-EN – 2017-05b – English… -

Page 107

Error response for the fault number 1. Subindex 3 … 255 Fault number 2 … 254 (Malfunction Number 2 … 254) Error responses for the fault numbers 2 … 254. Tab. B.33 PNU 242 Festo – GDCP-CMMO-ST-LK-C-HP-EN – 2017-05b – English… -

Page 108

Error response for the fault number 1. Subindex 3 … 255 Fault number 2 … 254 (Malfunction Number 2 … 254) Error responses for the fault numbers 2 … 254. Tab. B.34 PNU 246 Festo – GDCP-CMMO-ST-LK-C-HP-EN – 2017-05b – English… -

Page 109

Reserved (= 1) Note Only when all bits = 1 can the status be switched to “Ready”. 1) Parameterisation of the controller enable via è PNU 128 or FCT Tab. B.35 PNU 280 Festo – GDCP-CMMO-ST-LK-C-HP-EN – 2017-05b – English… -

Page 110: Process Data — General Process Data

Class: Var Data type: uint32 FW … Reading of the actual status of the local digital inputs. Significance 0 … 8 Reserved ENABLE (controller enable) [X1.6] 10 … 32 Reserved Tab. B.38 PNU 303 Festo – GDCP-CMMO-ST-LK-C-HP-EN – 2017-05b – English…

-

Page 111

1, this means that the variable (at least corresponding to the duration of the related damping time) is within the area defined from the min. and max. value. Control mode Position comparator Velocity comparator Force comparator Time comparator 4 … 7 Reserved Tab. B.41 PNU 312 Festo – GDCP-CMMO-ST-LK-C-HP-EN – 2017-05b – English… -

Page 112: Process Data — Fhpp-Data

Control information on byte 1 … 4 (e.g. CCON, CPOS, …) Subindex 2 FHPP control byte 5 … 8 (FHPP Control Byte 5…

Data type: int32 Control information on byte 5 … 8 (setpoint value 2) Tab. B.43 PNU 321 Festo – GDCP-CMMO-ST-LK-C-HP-EN – 2017-05b – English…

-

Page 113: Record List — Record Data

Time comparator, max. uint32 1 … 64 Setpoint value speed int32 1 … 64 Setpoint value force int16 1 … 64 Tab. B.44 Structure of the record list – record data for FHPP Festo – GDCP-CMMO-ST-LK-C-HP-EN – 2017-05b – English…

-

Page 114

Access: ro It is also valid if the drive is not in the record selection mode (Teach!). In record selection mode, this parameter is transmitted in the cyclic I/O data. Tab. B.45 PNU 400 Festo – GDCP-CMMO-ST-LK-C-HP-EN – 2017-05b – English… -

Page 115

FAST – Not supported/reserved – – Reserved Subindex 1 … 64 Record 1 … 64 (Record 1 … 64) Record control byte 1 of the record 1 … 64. Tab. B.46 PNU 401 Festo – GDCP-CMMO-ST-LK-C-HP-EN – 2017-05b – English… -

Page 116: Speed

– Speed record: without function – Force record: max. speed Subindex 1 … 64 Record 1 … 64 (Record 1 … 64) Max. speed of the record 1 … 64. Tab. B.49 PNU 406 Festo – GDCP-CMMO-ST-LK-C-HP-EN – 2017-05b – English…

-

Page 117: Acceleration

– Linear axis: [g] – Rotative axis: [kgm * 10 Subindex 1 … 64 Record 1 … 64 (Record 1 … 64) Load of the record 1 … 64. Tab. B.53 PNU 410 Festo – GDCP-CMMO-ST-LK-C-HP-EN – 2017-05b – English…

-

Page 118: Jerk Deceleration

– 1000 ‰ = force basic value, PNU 555 Subindex 1 … 64 Record 1 … 64 (Record 1 … 64) Max. force of the record 1 … 64. Tab. B.56 PNU 418 Festo – GDCP-CMMO-ST-LK-C-HP-EN – 2017-05b – English…

-

Page 119

– Speed record: max deviation from the setpoint speed [SINC/s] – Force record: no function Subindex 1 … 64 Record 1 … 64 (Record 1 … 64) End speed of the record 1 … 64. Tab. B.59 PNU 424 Festo – GDCP-CMMO-ST-LK-C-HP-EN – 2017-05b – English… -

Page 120: Mc With Record Sequencing

Quick Stop ramp and stops in a position-controlled manner. Monitoring can be deactiv ated by setting the bit RCB1.B5 (PNU 401). Subindex 1 … 64 Record 1 … 64 (Record 1 … 64) Stroke limit of the record 1 … 64. Tab. B.62 PNU 427 Festo – GDCP-CMMO-ST-LK-C-HP-EN – 2017-05b – English…

-

Page 121: Factor Torque Pilot Control

The torque pilot control is added to the current controller setpoint value. The value is calculated from the acceleration. Compare also è PNU 1080. Subindex 1 … 64 Record 1 … 64 (Record 1 … 64) Factor of the record 1 … 64. Tab. B.63 PNU 428 Festo – GDCP-CMMO-ST-LK-C-HP-EN – 2017-05b – English…

-

Page 122: Record List — Record Messages

Reading or parameterisation of the lower limit values [SINC/s] of the velocity comparator. Subindex 1 … 64 Record 1 … 64 (Record 1 … 64) Velocity comparator, min. of the record 1 … 64. Tab. B.67 PNU 433 Festo – GDCP-CMMO-ST-LK-C-HP-EN – 2017-05b – English…

-

Page 123: Velocity Comparator, Max

Reading or parameterisation of the upper limit values [‰ of the force basic value, PNU 555] of the force comparator. Subindex 1 … 64 Record 1 … 64 (Record 1 … 64) Force comparator, max. of the record 1 … 64. Tab. B.71 PNU 437 Festo – GDCP-CMMO-ST-LK-C-HP-EN – 2017-05b – English…

-

Page 124: Force Comparator, Damping Time

Subindex 1 … 64 Record 1 … 64 (Record 1 … 64) End speed of the record 1 … 64. Tab. B.75 PNU 441 Festo – GDCP-CMMO-ST-LK-C-HP-EN – 2017-05b – English…

-

Page 125: Project Data — General Project Data

Subindex 1 Class: Var Data type: int32 FW … Access: rw2 Reading or parameterisation of the max. permitted speed [SINC/s]. This value limits the speed in all operating modes. Tab. B.79 PNU 502 Festo – GDCP-CMMO-ST-LK-C-HP-EN – 2017-05b – English…

-

Page 126: Project Data — Force/Torque Mode

Reading or parameterisation of the max. current (force) [mA], with which the motor may be operated. The value is always positive. Internally, this limits the max. “positive” and “negative” current. Tab. B.82 PNU 512 Festo – GDCP-CMMO-ST-LK-C-HP-EN – 2017-05b – English…

-

Page 127: Project Data -Teach Mode

Position comparator upper limit 1) Record number in direct mode via PNU 400.1 “Setpoint record number”; in case of record selection via record number, specify in control byte 3 Tab. B.83 PNU 520 Festo – GDCP-CMMO-ST-LK-C-HP-EN – 2017-05b – English…

-

Page 128: Project Data — Fhpp-Direct Mode

Speed Setpoint value 1 Reserved Speed [SINC/s] è appendix A.2 Setpoint value 2 Reserved Actual value No function, = 0 Reserved Actual value Reserved Speed as absolute value [SINC/s] Tab. B.84 PNU 523 Festo – GDCP-CMMO-ST-LK-C-HP-EN – 2017-05b – English…

-

Page 129

Reading or parameterisation of the characterististics for the FHPP direct mode. Value Significance Binary Relative positioning type Setpoint value is relative to the last setpoint/target position Setpoint value is relative to the current position (default) 1…7 – Reserved Tab. B.85 PNU 524 Festo – GDCP-CMMO-ST-LK-C-HP-EN – 2017-05b – English… -

Page 130: Project Data — Jog Mode

Following error delay time (Following Error Timeout) Subindex 1 Class: Var Data type: uint16 FW … Access: rw2 Reading or parameterisation of the damping time in [ms] of the following error monitoring. Tab. B.91 PNU 539 Festo – GDCP-CMMO-ST-LK-C-HP-EN – 2017-05b – English…

-

Page 131: Project Data — Direct Mode Position

Access: rw1 Reading or parameterisation of the load that is moved in addition to the basic load during positioning. – Linear axis: [g] – Rotative axis: [kgm * 10 Tab. B.96 PNU 544 Festo – GDCP-CMMO-ST-LK-C-HP-EN – 2017-05b – English…

-

Page 132: Project Data — Force Direct Mode

Access: rw1 Basic value force in milliamperes [mA]. (The master transmits in the cyclic data a percentage value, which is multiplied by the basic value to calculate the final force.) Tab. B.101 PNU 555 Festo – GDCP-CMMO-ST-LK-C-HP-EN – 2017-05b – English…

-

Page 133: Project Data — Rotational Speed Direct Mode

Message window for deviation (Velocity Difference Error Window) Subindex 1 Class: Var Data type: int32 FW … Access: rw1 Reading or parameterisation of the permitted displacement [SINC/s] with active speed adjustment Tab. B.105 PNU 568 Festo – GDCP-CMMO-ST-LK-C-HP-EN – 2017-05b – English…

-

Page 134: Project Data — Direct Mode General

Position comparator, max. (Position Comparator, Max.) Subindex 1 Class: Var Data type: int32 FW … Access: rw1 Reading or parameterisation of the upper limit value [SINC] of the position comparator. Tab. B.110 PNU 586 Festo – GDCP-CMMO-ST-LK-C-HP-EN – 2017-05b – English…

-

Page 135

Subindex 1 Class: Var Data type: int16 FW … Access: rw1 Reading or parameterisation of the upper limit value [‰ basic value force, PNU 555] of the force comparator. Tab. B.116 PNU 592 Festo – GDCP-CMMO-ST-LK-C-HP-EN – 2017-05b – English… -

Page 136

Time comparator, max. (Time Comparator, Max.) Subindex 1 Class: Var Data type: uint32 FW … Access: rw1 Reading or parameterisation of the upper limit value [ms] of the time comparator. Tab. B.119 PNU 595 Festo – GDCP-CMMO-ST-LK-C-HP-EN – 2017-05b – English… -

Page 137: Factor Group

Reading or parameterisation of the system of measurement in relation to the basic unit. Value Significance 0x00 (0) Undefined/user specific 0x01 (1) Metre (SI unit) 0x41 (65) Degree 0xF0 (240) Inch 0xF6 (246) Revolutions Tab. B.121 PNU 601 Festo – GDCP-CMMO-ST-LK-C-HP-EN – 2017-05b – English…

-

Page 138: Axis Parameters: Electrical Drives 1 — Mechanical Parameters

Encoder increments Encoder resolution Motor revolutions Subindex 1 Encoder increments (Encoder Increments) Dependent on the encoder used, default: 0x000007D0 (2000) Subindex 2 Motor revolutions (Motor Revolutions) Fixed: 0x00000001 (1) Tab. B.123 PNU 1001 Festo – GDCP-CMMO-ST-LK-C-HP-EN – 2017-05b – English…

-

Page 139

Calculation of the feed constant: Feed Feed constant Spindle rotations Subindex 1 Feed (Feed) Numerator of the feed constant. Subindex 2 Spindle rotations (Shaft Revolutions) Denominator of the feed constant. Tab. B.125 PNU 1003 Festo – GDCP-CMMO-ST-LK-C-HP-EN – 2017-05b – English… -

Page 140: B.4.21 Axis Parameter: Electrical Drives 1 – Homing Parameters

Tab. B.127 PNU 1010 PNU 1011 Homing method (Homing Method) Subindex 1 Class: Var Data type: int8 FW … Access: rw1 Reading or parameterisation of the homing method è page 53. Tab. B.128 PNU 1011 Festo – GDCP-CMMO-ST-LK-C-HP-EN – 2017-05b – English…

-

Page 141

Speed limit, stop detection (Block Detection Velocity Limit) Subindex 1 Class: Var Data type: int32 FW … Access: rw2 Reading or parameterisation of the speed limit value for stop detection in homing (homing method: stop). Tab. B.132 PNU 1016 Festo – GDCP-CMMO-ST-LK-C-HP-EN – 2017-05b – English… -

Page 142: B.4.22 Axis Parameter: Electrical Drives 1 – Controller Parameters

The damping time begins when the target position window is reached. If the actual position has been in the target position window after the damping time has expired, the SPOS.MC bit is set. Tab. B.135 PNU 1023 Festo – GDCP-CMMO-ST-LK-C-HP-EN – 2017-05b – English…

-

Page 143

(Time Constant Velocity Filter) Time constant for filtering the motor rotational speed. Subindex 7 Max. correction speed (Max. Correction Velocity) Data type: int32 Max. speed contribution for correction of the following error. Tab. B.136 PNU 1024 Festo – GDCP-CMMO-ST-LK-C-HP-EN – 2017-05b – English… -

Page 144

PNU 1029 Quick stop deceleration (Quick Stop Deceleration) Subindex 1 Class: Var Data type: int32 FW … Access: rw2 Reading or parameterisation of the deceleration with Quick Stop [SINC/s Tab. B.140 PNU 1029 Festo – GDCP-CMMO-ST-LK-C-HP-EN – 2017-05b – English… -

Page 145: B.4.23 Axis Parameters: Electric Drives 1 – Electronic Rating Plate

Tab. B.143 PNU 1035 PNU 1036 Motor nominal torque (Motor Rated Torque) Subindex 1 Class: Var Data type: int32 FW … Access: rw2 Reading or parameterisation of the motor nominal torque [mNm]. Tab. B.144 PNU 1036 Festo – GDCP-CMMO-ST-LK-C-HP-EN – 2017-05b – English…

-

Page 146: B.4.24 Axis Parameters: Electric Drives 1 – Standstill Monitoring

FW … Access: rw2 Reading or parameterisation of the standstill monitoring time [ms]. Time during which the drive must be outside the standstill position window before standstill monitor ing responds. Tab. B.148 PNU 1043 Festo – GDCP-CMMO-ST-LK-C-HP-EN – 2017-05b – English…

-

Page 147: B.4.25 Axis Parameters: Electric Drives 1 – Following Error Monitoring

Current temperature output stage (Actual Temperature Output Stage) Subindex 1 Class: Var Data type: int8 FW … Access: ro Reading of the current temperature [°C] of the output stage (load section of the controller). Tab. B.153 PNU 1066 Festo – GDCP-CMMO-ST-LK-C-HP-EN – 2017-05b – English…

-

Page 148: B.4.28 Axis Parameters: Electric Drives 1 – General Drive Data

Current control section voltage (Actual Control Section Voltage) Subindex 1 Class: Var Data type: uint32 FW … Access: ro Reading of the current control section voltage [mV] of the controller. Tab. B.157 PNU 1074 Festo – GDCP-CMMO-ST-LK-C-HP-EN – 2017-05b – English…

-

Page 149

Greater loads are hereby applied to the drive. The factors are calculated from the parameters (motor, gear unit, feed constant, …) of the Festo Configuration Tools (FCT) and written to PNU 1080 and should not be changed. PNU 1080… -

Page 150: C Festo Parameter Channel (Fpc)

Tab. C.1 Cyclical I/O data FHPP standard + FPC The motor controller CMMO-ST only supports the extended functions of the Enhanced Festo Parameter Channel EFPC correspondingly è section C.2. Overview of EFPC The EFPC extended parameter channel permits automated transmission of parameters and larger data…

-

Page 151: C.2.2 Fpcc And Fpcs – Transmission Mode, Request And Response Id

Parameter transmitted (array, double word) xxxx0111 Task cannot be carried out with error number (trans mission of parameter or parameter file currently not possible) 3) Values not stated = reserved Tab. C.5 FPCS – coding response-ID Festo – GDCP-CMMO-ST-LK-C-HP-EN – 2017-05b – English…

-

Page 152: C.3 Parameter Transmission (Pnus, Internal Objects)

FPCS = 0001 0101 Sub-index = 0000 0010 Parameter number = 0000 0001 1011 1000 User data = 0000 0000 0000 0000 0001 0010 0011 0100 Fig. C.1 Example of parameter transmission sequence Festo – GDCP-CMMO-ST-LK-C-HP-EN – 2017-05b – English…

-

Page 153: C.3.4 Error Codes

Faulty sub-index 0x0B No supervising access 0x11 Task cannot be carried out in the operating status 0x65 Festo: ReqID is not supported 0x66 Festo: Parameter is write-only Tab. C.7 Error codes in parameter transmission Festo – GDCP-CMMO-ST-LK-C-HP-EN – 2017-05b – English…

-

Page 154: C.4 Parameter File Transmission

No data / size of the parameter file in bytes 010xxxxx Stop data transmission No data 011xxxxx Error No data / error code Tab. C.9 Package ID – 3 control or status bits Festo – GDCP-CMMO-ST-LK-C-HP-EN – 2017-05b – English…

-

Page 155: C.4.3 Parameter File And User Data Package

If all 6 bytes from the last transmitted data telegram are no longer needed, the remaining bytes are filled with zeros. The parameter file size, which was transmitted at the start, determines up to where the data have to be evaluated. Festo – GDCP-CMMO-ST-LK-C-HP-EN – 2017-05b – English…

-

Page 156: C.4.4 Checking And Activation Of The Parameter File

A stop or an error message can be written at any time in the control bits and interrupts the upload or download. A check of the sequence number then does not take place. Festo – GDCP-CMMO-ST-LK-C-HP-EN – 2017-05b – English…

-

Page 157: C.4.6 Examples Of Parameter File Transmission

Data = parameter file Request package 33 FPCC = 01000100 Package ID = 000 00001 No data Send complete FPCS = 01000011 Package ID = 010 00001 No data Fig. C.3 Sequence of parameter file upload Festo – GDCP-CMMO-ST-LK-C-HP-EN – 2017-05b – English…

-

Page 158

No data Send complete FPCC = 01000101 Package ID = 010 00001 No data Parameters saved FPCS = 01000011 Package ID = 010 00001 No data Fig. C.4 Sequence of parameter file download Festo – GDCP-CMMO-ST-LK-C-HP-EN – 2017-05b – English… -

Page 159

Package 2 faulty FPCC = 01000100 Package ID = 011 00011 Data = error code Confirm error FPCS = 01000011 Package ID = 011 00011 No data Fig. C.5 Error in parameter upload Festo – GDCP-CMMO-ST-LK-C-HP-EN – 2017-05b – English… -

Page 160

Data = error code 0x65 Festo: ReqID is not supported Fig. C.7 Error FPCC is not supported The value in FPCC cannot be evaluated. The request ID included in the FPCC is not supported. Festo – GDCP-CMMO-ST-LK-C-HP-EN – 2017-05b – English… -

Page 161

Fig. C.8 Error EFPC is blocked Certain functions are blocked during active parameter transmission, e.g. switching to download is not allowed during an upload, and vice versa, before transmission is stopped by the controller. Festo – GDCP-CMMO-ST-LK-C-HP-EN – 2017-05b – English… -

Page 162: C.4.7 Error Codes

Timeout in accessing the parameter file, e.g. error is still present and must be acknowledged Tab. C.11 Error codes in the parameter file transmission – error type 2 The errors differ regarding the effect on transmission è Tab. C.12: Festo – GDCP-CMMO-ST-LK-C-HP-EN – 2017-05b – English…

-

Page 163

(0x11) Job cannot be carried out upload or download can be continued. in the operating status To cancel the transmission, a stop com 101 (0x65) Festo: ReqID is not sup mand must be sent. ported Error type 2: is reported in package ID… -

Page 164: D Diagnostic Messages

Diagnostic messages Diagnostic messages Explanation of the parameterisable classification, error response, diagnostic memory options and acknowledgement option è 7.2.2. Festo – GDCP-CMMO-ST-LK-C-HP-EN – 2017-05b – English…

-

Page 165

• This error can also occur if the set motor current is too low to move the shaft and any possible load. Correct the settings for the motor current, if necessary. – Resettable: Error can be reset immediately. Definable error reaction(s): A Festo – GDCP-CMMO-ST-LK-C-HP-EN – 2017-05b – English… -

Page 166

General error Definable as: F/-/- Diagnostic memory: always An internal error has occurred. • Restart device. If the error occurs frequently, contact Festo Service. – Resettable: Error can be reset immediately. Definable error response(s): B Parameter file invalid Definable as: F/-/- Diagnostic memory: always No valid parameter set stored. -

Page 167

• This error can be reset immediately. Afterwards start a corresponding positioning record or move the drive by using the jogging function. Movements in a positive direction are blocked. – Resettable: Error can be reset immediately. Definable error response(s): A, B, C, E, F Festo – GDCP-CMMO-ST-LK-C-HP-EN – 2017-05b – English… -

Page 168

• This error can be reset immediately. Afterwards start a corresponding positioning record or move the drive by using the jogging function. Movements in a negative direction are blocked. – Resettable: Error can be reset immediately. Definable error response(s): A, B, C, E, F Festo – GDCP-CMMO-ST-LK-C-HP-EN – 2017-05b – English… -

Page 169

• Separate device from the entire peripheral equipment and check whether the error is still present after reset. If it is, it means there is an internal defect and the device has to be replaced. – Resettable: Cannot be reset; software reset is necessary. Definable error reaction(s): A Festo – GDCP-CMMO-ST-LK-C-HP-EN – 2017-05b – English… -

Page 170

• If the error is still present, it means there is an internal defect and the device has to be replaced. – Resettable: Error can be reset immediately. Definable error response(s): B, C, E, F Festo – GDCP-CMMO-ST-LK-C-HP-EN – 2017-05b – English… -

Page 171

If the error occurs again, please contact Festo Service. – Resettable: Error can be reset immediately. Definable error response(s): F, G Festo – GDCP-CMMO-ST-LK-C-HP-EN – 2017-05b – English… -

Page 172

• Determine the version of the hardware. You can ascertain the compatible firmware designs and download the appropriate firmware from the Festo website. – If defined as an error: Error can be reset immediately. Definable error reaction(s): A –… -

Page 173

• Check the mechanical system for sluggishness. • Reduce the ambient temperature; take output derating into account; improve heat dissipation. – For parameterisation as a warning: The warning disappears if the temperature is back below the danger threshold. Festo – GDCP-CMMO-ST-LK-C-HP-EN – 2017-05b – English… -

Page 174

Diagnostic memory: optional Homing error. A homing method block has been set, for example, in open-loop operation. • Select permitted reference travel method. – Resettable: Error can be reset immediately. Definable error response(s): E, F Festo – GDCP-CMMO-ST-LK-C-HP-EN – 2017-05b – English… -

Page 175

• Clear diagnostic memory. If the error is still present, the device needs to be replaced. – Resettable: Error can be reset immediately. Definable error response(s): F, G Festo – GDCP-CMMO-ST-LK-C-HP-EN – 2017-05b – English… -

Page 176

Error during initialization of the IO-Link protocol stack • Check the FHPP configuration with FCT. – Acknowledgeability: Error can only be acknowledged after eliminating the cause. Definable error response(s): A, B, C, D Festo – GDCP-CMMO-ST-LK-C-HP-EN – 2017-05b – English… -

Page 177

• Perform a firmware update. If the error is still present, the memory might be faulty. Then the device must be replaced. – Resettable: Cannot be reset; software reset is necessary. Definable error reaction(s): A Festo – GDCP-CMMO-ST-LK-C-HP-EN – 2017-05b – English… -

Page 178

– Acknowledgement option: Error can only be acknowledged after the cause is eliminated. Definable error response(s): A, B System information Definable as: -/-/ Diagnostic memory: always A device-specific system event has occurred. • This event is used for extended diagnostics. Festo – GDCP-CMMO-ST-LK-C-HP-EN – 2017-05b – English… -

Page 179: E Terms And Abbreviations

Electrical pulse generator (usually a rotor position encoder). The motor controller evaluates the generated electrical signals and cal culates from this the position and speed. Enhanced Festo Parameter Extended function of the Festo Parameter Channel (FPC), e.g. for Channel (EFPC) transmission of parameter files. Festo Configuration Tool (FCT) Software with uniform project and data management for supported types of equipment.

-

Page 180

(Profile Velocity mode) task with control of the speed or rotational speed. Teaching Operating mode for setting positions by approaching the target position, e.g. when creating positioning sets. Tab. E.1 Index of terms and abbreviations Festo – GDCP-CMMO-ST-LK-C-HP-EN – 2017-05b – English… -

Page 181: Index

….Motor controller ….. . . Festo – GDCP-CMMO-ST-LK-C-HP-EN – 2017-05b – English…

-

Page 183

Copyright: Festo AG & Co. KG Ruiter Straße 82 73734 Esslingen Germany Phone: +49 711 347-0 Fax: +49 711 347-2144 Reproduction, distribution or sale of this document or communica E-mail: tion of its contents to others without express authorization is service_international@festo.com…

|

|

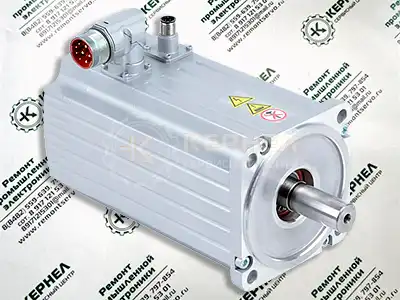

Ремонт двигателей FESTO

- FESTO EMMS-AS

- FESTO EMME-AS

- FESTO EMMB-AS

- FESTO EMMT-AS

Серводвигатели данного производителя имеют высокие параметры по перегрузкам, а также динамике разгона и широким диапазоном крутящего момента.

В процессе работы рано или поздно (зависит то эксплуатационных режимов) двигатели, как и другое промышленное оборудование выходит из строя, ремонт серводвигателя FESTO единственное экономически выгодное решение.

Специалисты сервисного центра «Кернел» более 20 лет проводят качественный ремонт двигателей FESTO в Подольске. Для максимально быстрого, а главное качественного ремонта серводвигателей FESTO потребуется специализированное помещение, оборудованное необходимым оборудованием, расходные материалы, компоненты для ремонта двигателей и конечно же квалифицированный персонал.

Благодаря вышеперечисленному ремонт двигателей FESTO проводится согласно всем техническим требованиям, в сжатые сроки. Каждый ремонт серводвигателя FESTO завершается проверкой на специализированном стенде с сервоконтроллерами FESTO в условиях максимально приближенных реальным.

Что входит в ремонт двигателей FESTO

- Внутренняя и внешняя очистка двигателя

- Изоляция обмоток двигателя

- Перемотка силовых обмоток серводвигателя

- Пролачивание и сушка обмоток серводвигателя

- Токарные работы (восстановление посадочного места подшипника)

- Замена подшипника двигателя

- Замена клеммников, силовых и сигнальных разъёмов

- Ремонт датчиков обратной связи (энкодера, резольвера)

- Изготовление и замена муфты энкодера

- Юстировка положения датчиков обратной связи (энкодера / резольвера)

Перемотка серводвигателей FESTO

Нет смысла перечислять все возможные сферы промышленности где работает данное промышленное оборудование, мы просто не найдем ни чего подобного. Электродвигатели FESTO работают как в нормальных условиях, так и в крайне агрессивных средах, что приводит к частому выходу из строя оборудования, это может быть короткое межвитковое замыкание в результате попадания скажем охлаждающей жидкости на силовые обмотки двигателя либо это может быть вызвано механическим износом, когда подшипник вырабатывает свой ресурс, что неизбежно приводит к биению крутящегося вала со всеми вытекающими из этого негативными последствиями.

Специалисты нашей компании в максимально кратчайшие сроки выполнят перемотку серводвигателя FESTO, мы делаем все возможные виды ремонта серводвигателей такие как:

- Чистка внешнего корпуса двигателя;

- Ремонт смазочной системы, замена смазки;

- Ремонт протяжка и замена рефлекторных крепежных соединений;

- Проверка крепления вентилятора;

- Перемотка статора серводвигателя;

- Перемотка ротора двигателя;

- Покрытие лаком лобовых обмоточных частей

- Ремонт якоря двигателя;

- Ремонт статора серводвигателя;

- Восстановление вала и посадочных мест;

- Замена подшипников и сальников;

- Токарные и фрезерные работы;

- Проверка серводвигателя без нагрузки и с нагрузкой.

Ошибки и неисправности двигателей FESTO

Неисправности двигателей FESTO

- Неисправность датчиков обратной связи (энкодер, резольвер, тахогенератор);

- Сбито юстировочное положение энкодера двигателя;

- Неисправность обмоток статора. (межвитковое замыкание, пробой изоляции на корпус и обрыв);

- Износ подшипников их заклинивание;

- Износ посадочных мест подшипников на фланцах серводвигателя;

- Износ сальников;

- Износ тормозной системы;

- Размагничивание магнитов на роторе, потеря магнитных свойств;

- Разрушение корпуса двигателя (механические повреждения или из-за работы в агрессивной среде) разъёмов;

- Выход из строя термодатчика.

Ошибки серводвигателя FESTO

В момент аварийного останова серводвигателя, контроллер в паре с которым работает серводвигатель, показывает код ошибки, устранение которой позволит заново запустить оборудование. К сожалению не все ошибки серводвигателя FESTO нельзя устранить самостоятельно, в некоторых случаях ошибку двигателя FESTO возможно удалить лишь, обратившись в сервисный центр.

В таблице ниже приведены некоторые ошибки серводвигателя FESTO отображаемые на сервоконтроллерах FESTO CMMO-ST-C5-1-DIOP и CMMO-ST-C5-1-DION.

|

Ошибка |

Описание |

Устранение |

|

05h |

Определение нулевого угла |

Не удалось однозначно определить положение ротора. Точка коммутации недействительна.)

–Возможность квитирования: ошибку можно квитировать незамедлительно. Параметризуемая (-ые) реакция (-ии) на ошибку: A |

|

0Dh |

Перегрузка по току |

Короткое замыкание в моторе, в кабелях или в тормозном прерывателе.

–Возможность квитирования: не квитируется, требуется сброс ПО. Параметризуемая (-ые) реакция (-ии) на ошибку: A |

|

0Eh |

Ошибка мотора I²t |

Предел I²t для мотора достигнут. Вероятно, мотор или система привода не подходит для выполнения данной задачи вследствие слишком малых размеров.)

–Возможность квитирования: ошибку можно квитировать только после устранения причины. Параметризуемая (-ые) реакция (-ии) на ошибку: B, C |

|

2Dh |

Предупреждение I²t для мотора |

Предел предупреждения I²t для мотора достигнут.)

–При параметризации в качестве предупреждения: предупреждение снимается, если значениеI²t становится ниже 80 %. |

|

2Fh |

Ошибка рассогласования |

Ошибка рассогласования стала слишком большой. Эта ошибка может возникнуть в режиме позиционирования и скорости.)

–При параметризации в качестве ошибки: ошибку можно квитировать только после устранения причины. Параметризуемая (-ые) реакция (-ии) на ошибку: B, C, E, F –При параметризации в качестве предупреждения: предупреждение снимается, если ошибка рассогласования возвращается в допустимый диапазон. |

Скачать руководство пользователя серводвигателей FESTO

|

Серводвигатель FESTO EMMS-AS руководство пользователя. |

Скачать PDF Скачать PDF |

|

Серводвигатель FESTO EMME-AS руководство пользователя. |

Скачать PDF Скачать PDF |

|

Серводвигатель FESTO EMMB-AS руководство пользователя. |

Скачать PDF Скачать PDF |

|

Серводвигатель FESTO EMMT-AS руководство пользователя. |

Скачать PDF Скачать PDF |

Ремонт и настройка энкодера и резольвера FESTO

Ремонт энкодера необходим при износе подшипников, так как это влечет за собой потерю точности датчика и в самом плохом развитии событий из-за разбитых подшипников может пострадать самая важная часть энкодера, кодирующие стекло. Помимо данной неисправности датчика угла поворота часто встречаются следующие:

- Грязное кодирующие стекло или диск;

- Поломка, неисправность сигнального разъема;

- Не правильная форма сигналов или их отсутствие;

- Наличие внутренней ошибки (для абсолютных энкодеров);

- Замыкание в электросхеме энкодера.

Также влечет за собой ремонт энкодера.

Ремонт резольвера необходим в следующих случаях:

- Обрыв одной из статорных (неподвижная часть) обмоток резольвера;

- Обрыв одной из обмоток ротора (вращающаяся часть) резольвера;

- Межвитковое замыкание одной из обмоток. Обычно происходит в части обмоток;

- Сбита позиция резольвера на двигателе.

Мы предлагаем не просто квалифицированный ремонт резольвера и энкодера в сжатые сроки, а также дополнительную экономию бюджета 60%-80% от стоимости нового датчика обратной связи. На все виды ремонта мы даем 6-и месячную гарантию

Ремонтом энкодера, на данный момент занимаются далеко не все организации предлагающие услуги по ремонту промышленного оборудования, в связи с крайне сложным процессом ремонта и последующей настройкой энкодера.

Сервисный центр «Кернел» предоставляет услуги по ремонту подобного сложного промышленного оборудования как энкодеры и резольверы.

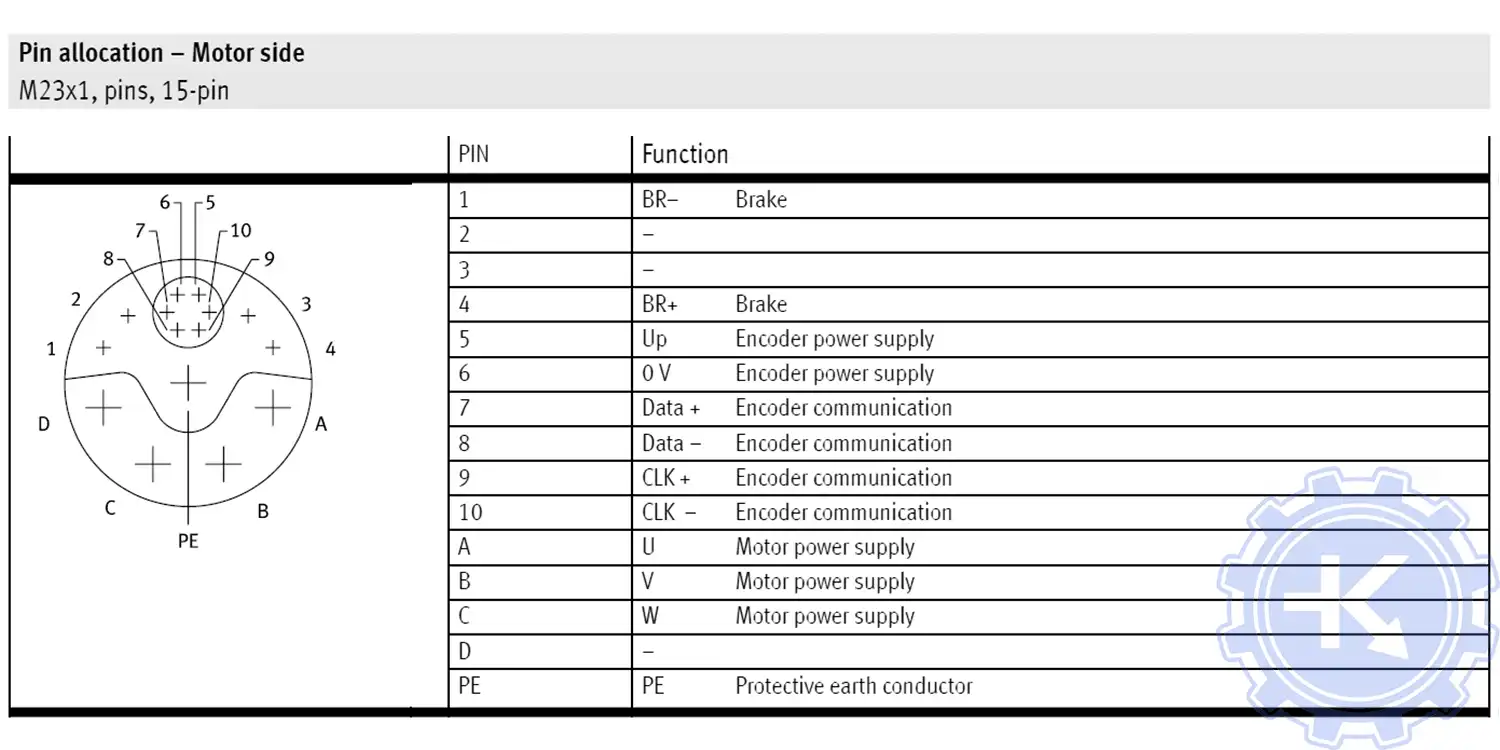

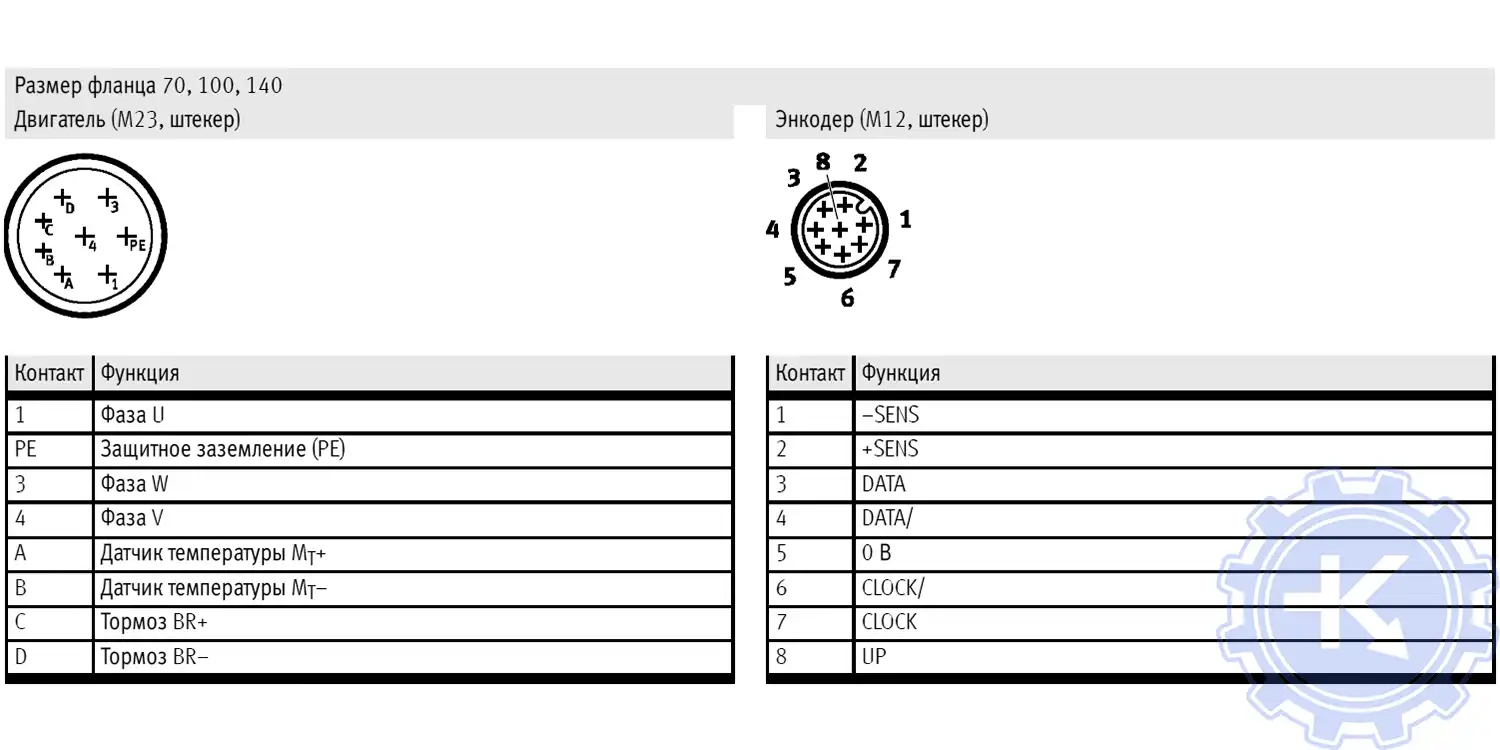

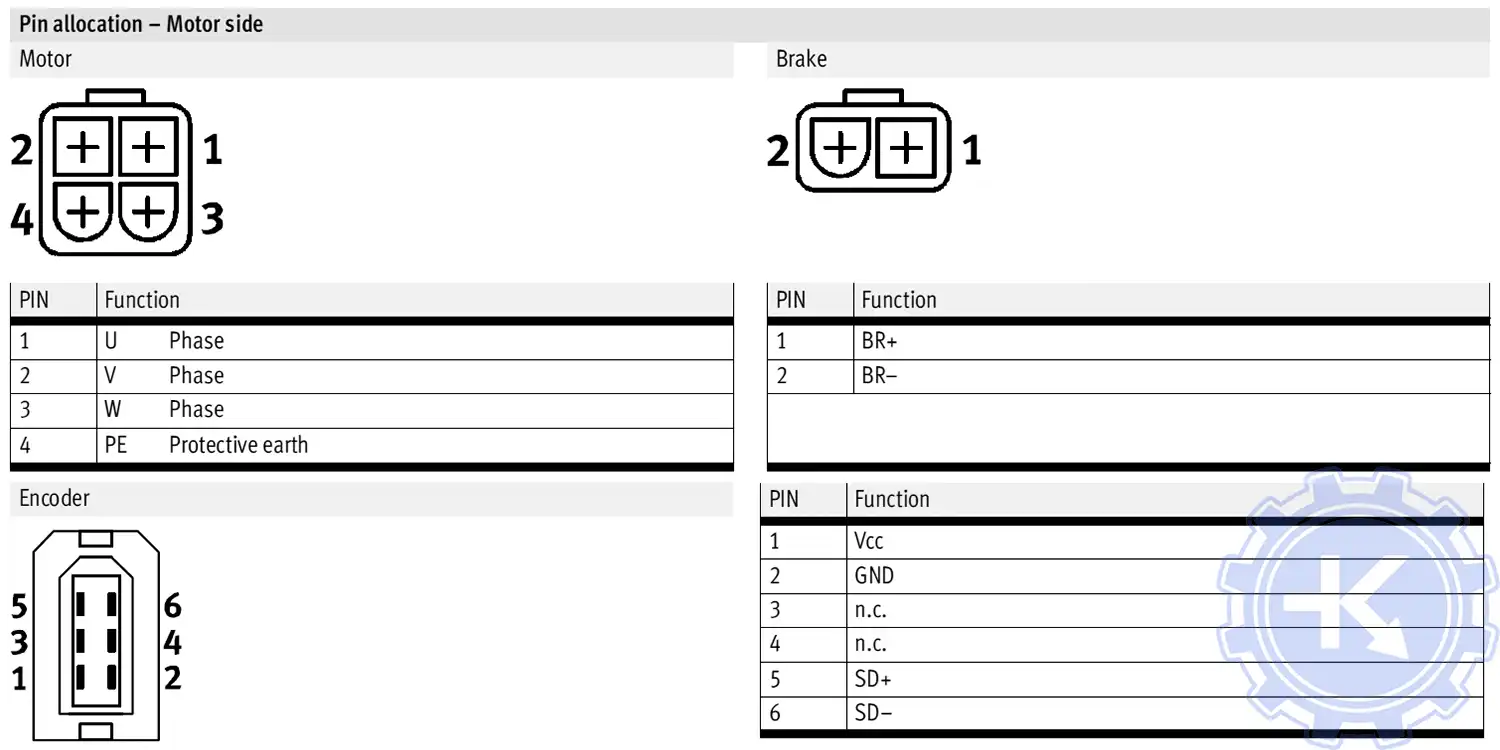

Распиновка разъемов энкодера и резольвера серводвигателей FESTO

|

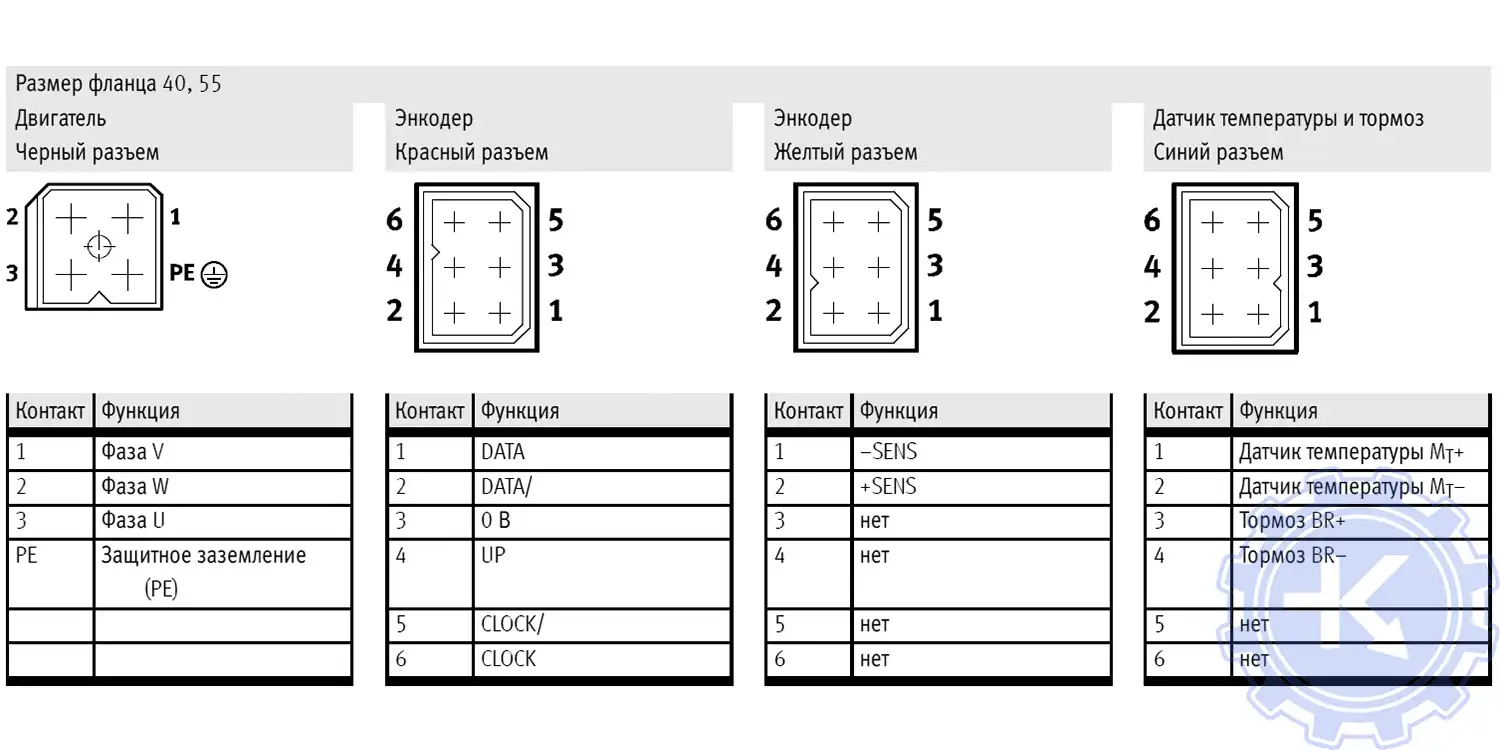

Серводвигатели EMMS-AS распиновка разъемов энкодера назначение контактов со стороны двигателя. |

|

|

|

|

|

|

|

|

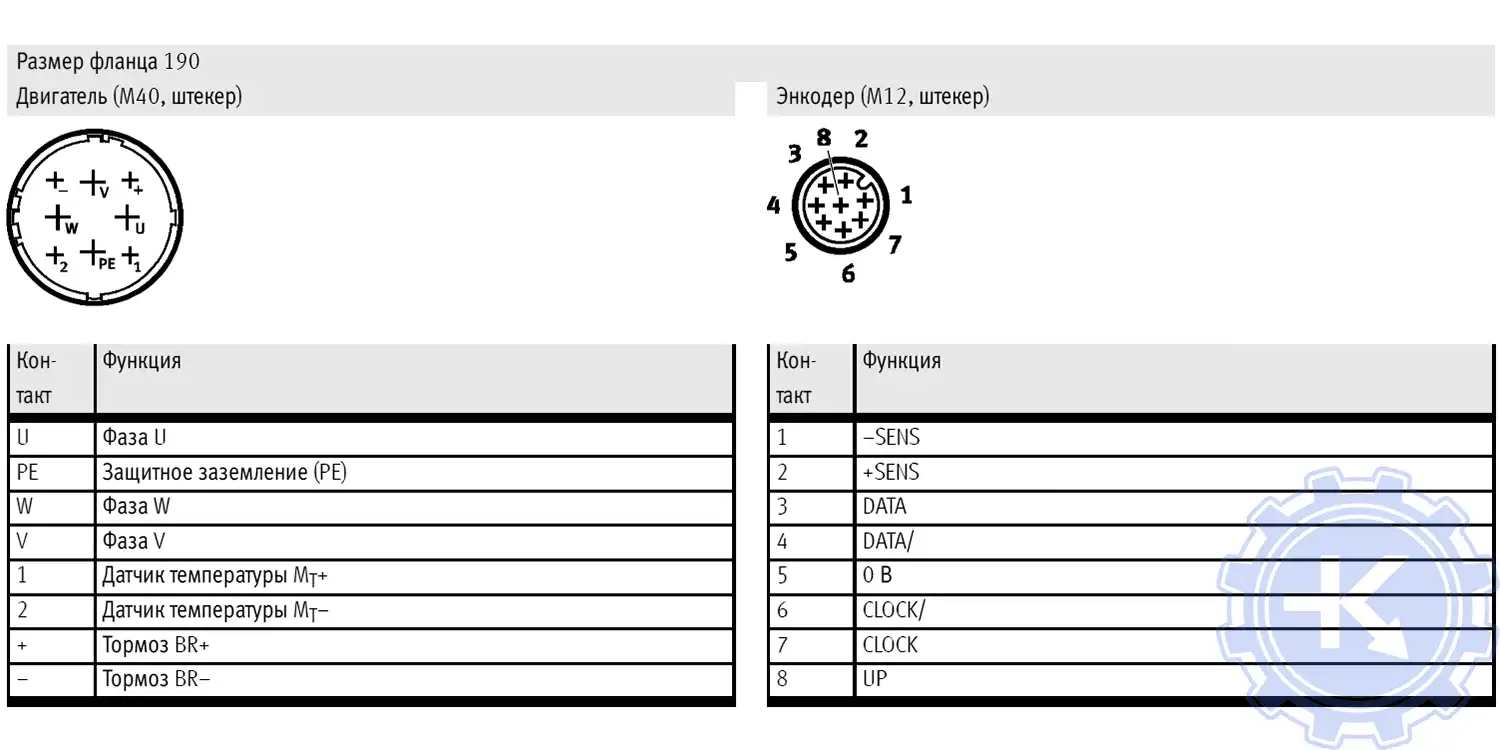

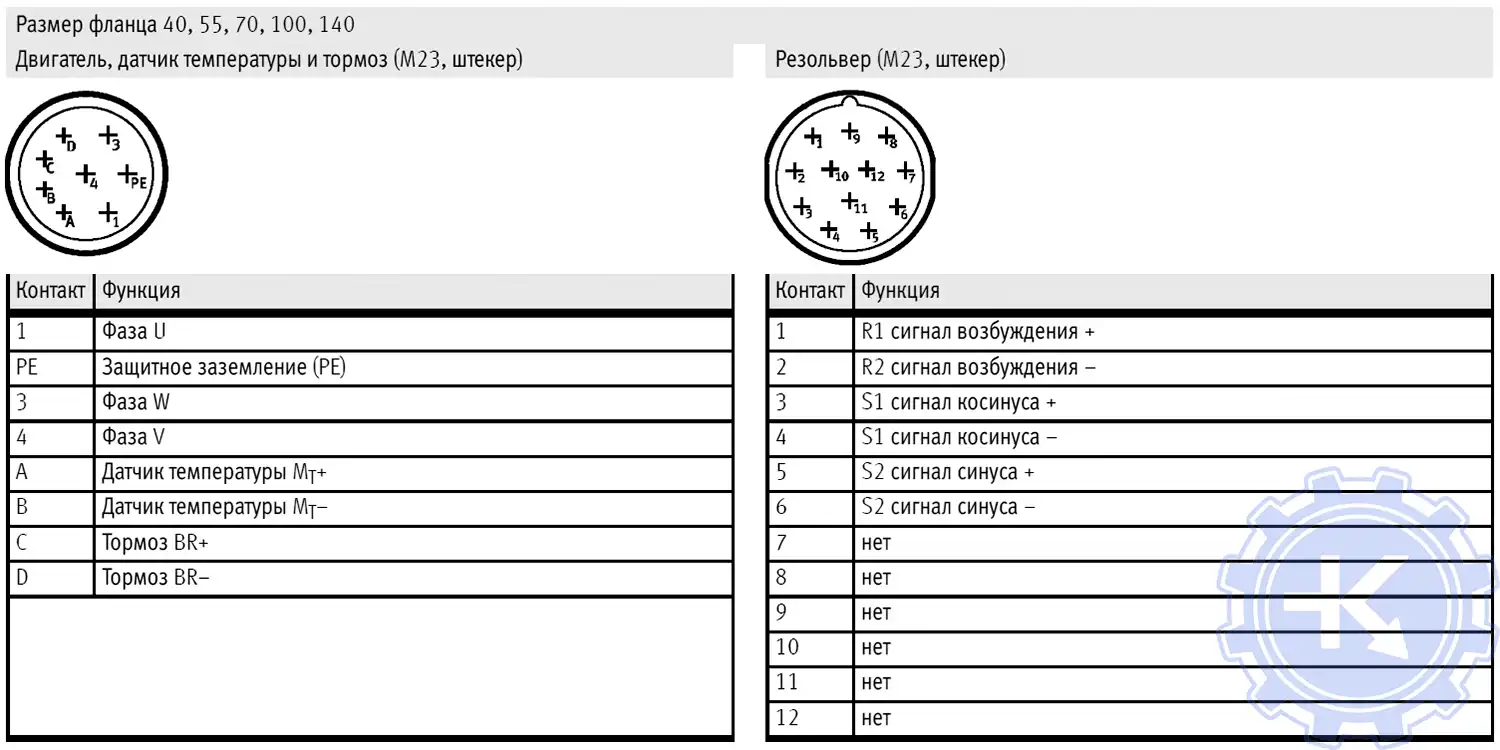

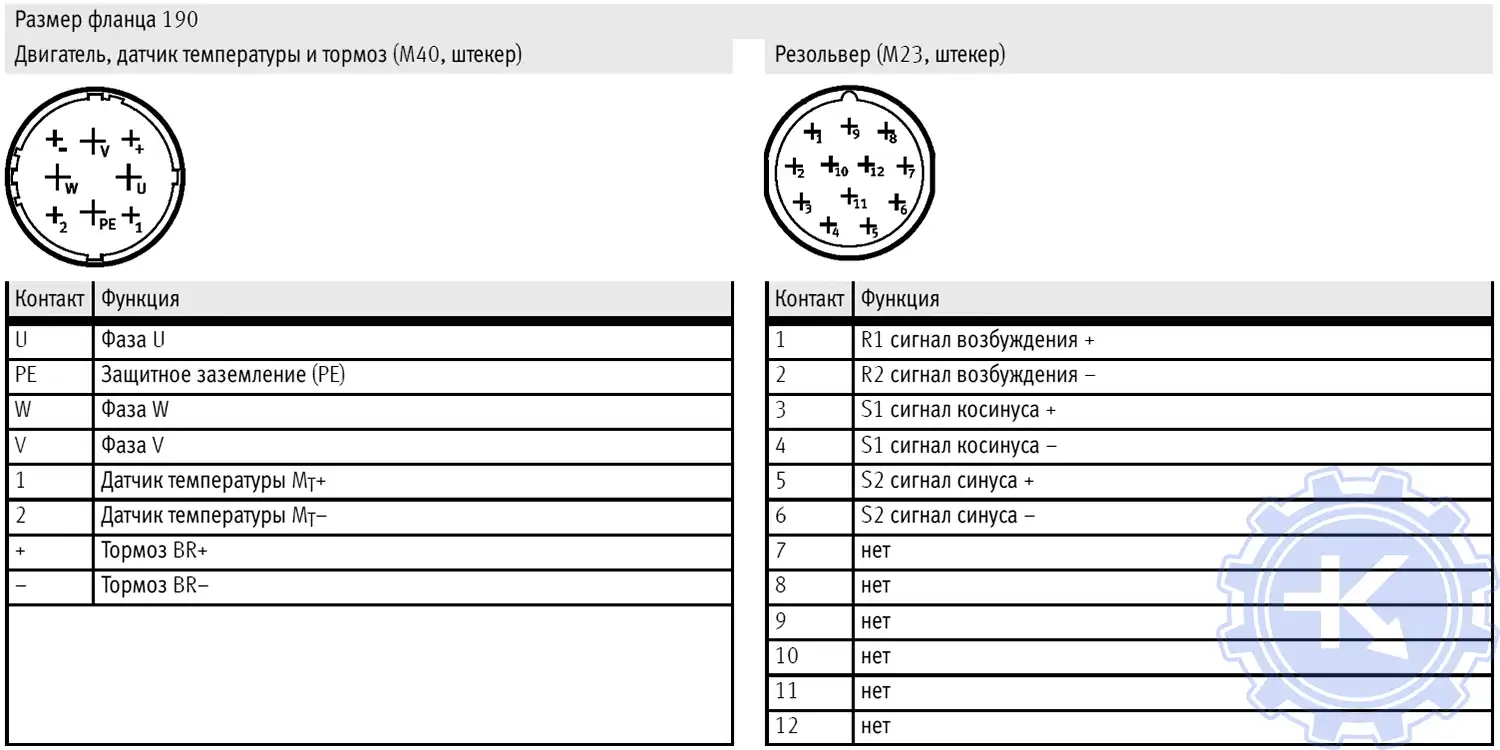

Серводвигатели EMMS-AS распиновка разъемов резольвера назначение контактов со стороны двигателя. |

|

|

|

|

|

Серводвигатели EMME-AS распиновка разъемов энкодера назначение контактов со стороны двигателя. |

Серводвигатели EMMB-AS распиновка разъемов энкодера назначение контактов со стороны двигателя. |

|

|

|

|

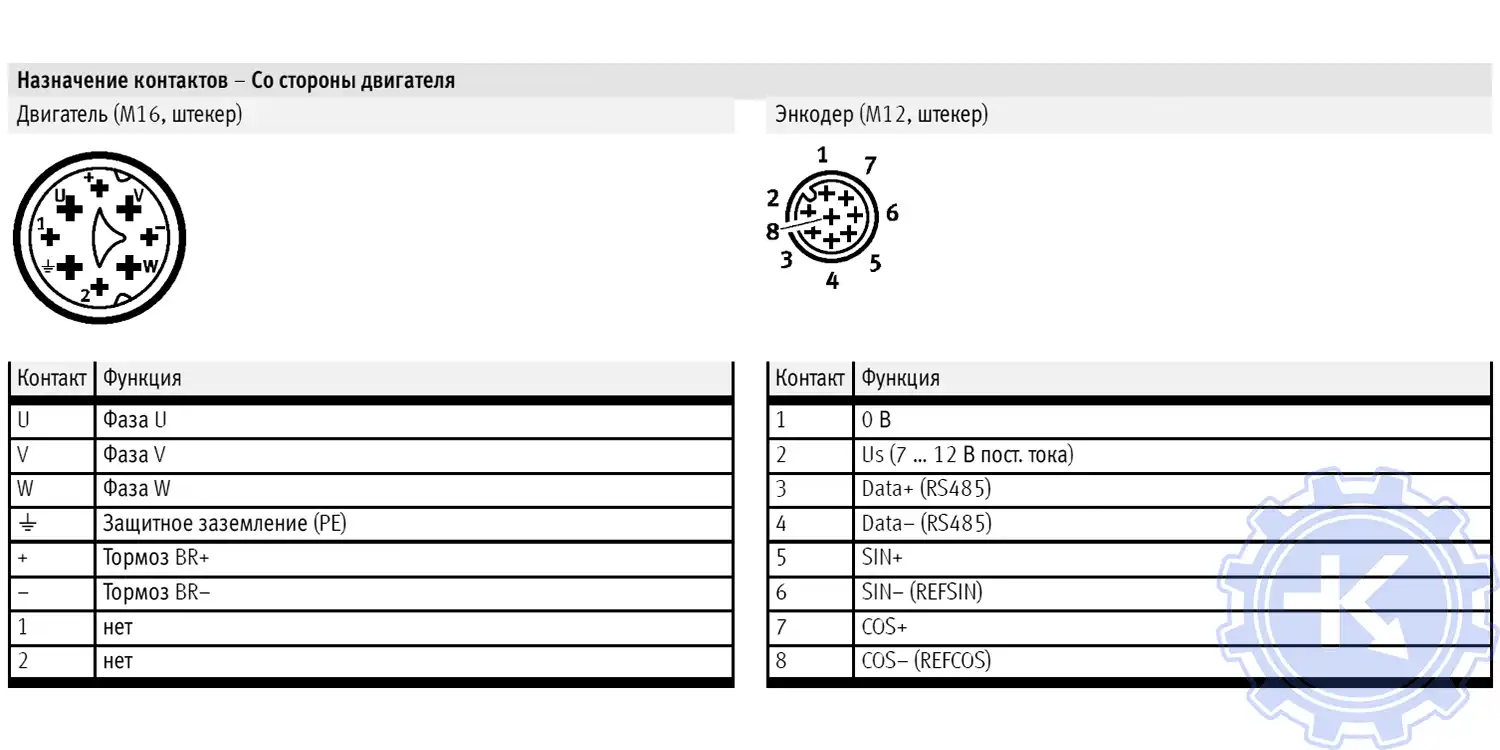

Серводвигатели EMMT-AS распиновка разъемов энкодера назначение контактов со стороны двигателя. |

|

|

|

Ремонт распространенных серводвигателей FESTO

Ремонт серводвигателей FESTO EMMS-AS

- Абсолютный энкодер.

- Цифровой однооборотный;

- Цифровой многооборотный.

- Резольвер.

Серводвигатель имеет различные варианты силовых обмоток, как для однофазного, так и зля трехфазного контроллера двигателя, что позволяет оптимизировать момент и улучшить скоростные характеристики.

Серводвигатели FESTO серии EMMS-AS имеют класс защиты IP65 с уплотнением разъемов электродвигателя, корпуса и IP21 вращающегося вала.

|

Размер фланца |

Типы серводвигателей FESTO серии EMMS-AS |

|

40мм. |

EMMS-AS-40-SK-LS-TS, EMMS-AS-40-SK-LS-TM, EMMS-AS-40-SK-LS-TMB, EMMS-AS-40-SK-LS-SRB, EMMS-AS-40-MK-LS-TSB |

|

55мм. |

EMMS-AS-55-SK-LS-TS, EMMS-AS-55-SK-LS-TM, EMMS-AS-55-SK-LS-RRB, EMMS-AS-55-SK-LS-TM-S1, EMMS-AS-55-SK-LS-RRB-S1 |

|

70мм. |

EMMS-AS-70-SK-LS-RMB-S1, EMMS-AS-70-SK-LV-RS, EMMS-AS-70-SK-LV-RM, EMMS-AS-70-SK-LV-RRB, EMMS-AS-70-SK-LV-RR-S1 |

|

100мм. |

EMMS-AS-100-SK-HS-RS, EMMS-AS-100-SK-HS-RM, EMMS-AS-100-SK-HS-RMB, EMMS-AS-100-SK-HS-RSB-S1, EMMS-AS-100-MK-HS-RS |

|

140мм. |

EMMS-AS-140-SK-HS-RS, EMMS-AS-140-SK-HS-RSB, EMMS-AS-140-SK-HS-RM, EMMS-AS-140-SK-HS-RMB, EMMS-AS-140-SK-HS-RR |

|

190мм. |

EMMS-AS-190-SK-HS-AM-S1, EMMS-AS-190-SK-HS-AMB-S1, EMMS-AS-190-SK-HS-AR-S1, EMMS-AS-190-SK-HS-ARB-S1 |

Ремонт серводвигателей FESTO EMME-AS

- Абсолютный энкодер.

- Цифровой однооборотный;

- Цифровой многооборотный.

Серводвигатель имеет различные варианты силовых обмоток, как для однофазного, так и зля трехфазного контроллера двигателя, что позволяет оптимизировать момент и улучшить скоростные характеристики.

Серводвигатели FESTO серии EMME-AS имеют класс защиты IP65 с уплотнением разъемов электродвигателя, корпуса и IP21 вращающегося вала.

|

Размер фланца |

Типы серводвигателей FESTO серии EMME-AS |

|

40мм. |

EMME-AS-40-S-LV-AS, EMME-AS-40-S-LV-ASB, EMME-AS-40-S-LV-AM, EMME-AS-40-S-LV-AMB, EMME-AS-40-M-LV-AS, EMME-AS-40-M-LV-ASB, EMME-AS-40-M-LV-AM, EMME-AS-40-M-LV-AMB |

|

60мм. |

EMME-AS-60-S-LS-AS, EMME-AS-60-S-LS-ASB, EMME-AS-60-S-LS-AM, EMME-AS-60-S-LS-AMB, EMME-AS-60-M-LS-AS, EMME-AS-60-M-LS-ASB, EMME-AS-60-M-LS-AM, EMME-AS-60-M-LS-AMB |

|

80мм. |

EMME-AS-80-S-LS-AS, EMME-AS-80-S-LS-ASB, EMME-AS-80-S-LS-AM, EMME-AS-80-S-LS-AMB, EMME-AS-80-S-HS-AS, EMME-AS-80-S-HS-ASB, EMME-AS-80-S-HS-AM, EMME-AS-80-S-HS-AMB, EMME-AS-80-M-LS-AS, EMME-AS-80-M-LS-ASB, EMME-AS-80-M-LS-AM, EMME-AS-80-M-LS-AMB, EMME-AS-80-M-HS-AS, EMME-AS-80-M-HS-ASB, EMME-AS-80-M-HS-AM, EMME-AS-80-M-HS-AMB |

|

100мм. |

EMME-AS-100-S-HS-AS, EMME-AS-100-S-HS-ASB, EMME-AS-100-S-HS-AM, EMME-AS-100-S-HS-AMB, EMME-AS-100-M-HS-AS, EMME-AS-100-M-HS-ASB, EMME-AS-100-M-HS-AM, EMME-AS-100-M-HS-AMB |

Ремонт серводвигателей FESTO EMMB-AS

- Абсолютный энкодер.

- Цифровой однооборотный.

Серводвигатель имеет различные варианты силовых обмоток, как для однофазного, так и зля трехфазного контроллера электродвигателя, что позволяет оптимизировать момент и улучшить скоростные характеристики.

Серводвигатели FESTO серии EMMB-AS имеют класс защиты IP65 с уплотнением разъемов электродвигателя, корпуса и IP21 вращающегося вала.

|

Размер фланца |

Типы серводвигателей FESTO серии EMMB-AS |

|

40мм. |

EMMB-AS-40-01-S, EMMB-AS-40-01-SB, EMMB-AS-40-01-K-S, EMMB-AS-40-01-K-SB |

|

60мм. |

EMMB-AS-60-02-S, EMMB-AS-60-04-S, EMMB-AS-60-02-SB, EMMB-AS-60-04-SB, EMMB-AS-60-02-K-S, EMMB-AS-60-04-K-S, EMMB-AS-60-02-K-SB, EMMB-AS-60-04-K-SB |

|

80мм. |

EMMB-AS-80-07-S, EMMB-AS-80-07-SB, EMMB-AS-80-07-K-S, EMMB-AS-80-07-K-SB |

Ремонт серводвигателей FESTO EMMT-AS

- Абсолютный энкодер.

- Цифровой однооборотный.

Серводвигатель имеет различные варианты силовых обмоток, как для однофазного, так и зля трехфазного контроллера электродвигателя, что позволяет оптимизировать момент и улучшить скоростные характеристики.

Серводвигатели FESTO серии EMMT-AS имеют класс защиты IP40 вращающегося вала двигателя, для корпуса двигателя с технологией подключения RWDR IP67.

|

Размер фланца |

Типы серводвигателей FESTO серии EMMT-AS |

|

60мм. |

EMMT-AS-60-S-LS-RS, EMMT-AS-60-S-LS-RSB, EMMT-AS-60-S-HS-RS, EMMT-AS-60-S-HS-RSB, EMMT-AS-60-S-HS-RMB, EMMT-AS-60-M-LS-RM, EMMT-AS-60-M-LS-RMB, EMMT-AS-60-M-HS-RM, EMMT-AS-60-M-HS-RSB, EMMT-AS-60-M-HS-RMB, EMMT-AS-60-L-LS-RS, EMMT-AS-60-L-LS-RM, EMMT-AS-60-L-LS-RSB, EMMT-AS-60-L-LS-RMB, EMMT-AS-60-L-HS-RS, EMMT-AS-60-L-HS-RM |

|

80мм. |

EMMT-AS-80-S-LS-RS, EMMT-AS-80-S-LS-RM, EMMT-AS-80-S-LS-RSB, EMMT-AS-80-S-LS-RMB, EMMT-AS-80-S-HS-RS, EMMT-AS-80-S-HS-RM, EMMT-AS-80-S-HS-RSB, EMMT-AS-80-S-HS-RSM, EMMT-AS-80-M-LS-RS, EMMT-AS-80-M-LS-RM, EMMT-AS-80-M-LS-RSB, EMMT-AS-80-M-LS-RMB, EMMT-AS-80-M-HS-RS, EMMT-AS-80-M-HS-RM, EMMT-AS-80-M-HS-RSB, EMMT-AS-80-M-HS-RMB |

|

100мм. |

EMMT-AS-100-S-HS-RS, EMMT-AS-100-S-HS-RM, EMMT-AS-100-S-HS-RSB, EMMT-AS-100-S-HS-RMB, EMMT-AS-100-M-HS-RS, EMMT-AS-100-M-HS-RM, EMMT-AS-100-M-HS-RSB, EMMT-AS-100-M-HS-RMB, EMMT-AS-100-L-HS-RS, EMMT-AS-100-L-HS-RM, EMMT-AS-100-L-HS-RSB, EMMT-AS-100-L-HS-RMB |

В данной статье перечислены далеко не все типы двигателей FESTO ремонт которых выполняет наш сервисный центр. Наряду с выше указанными серводвигателями FESTO мы также выполняем ремонт и перемотку двигателей других производителей.

Оставить заявку на ремонт двигателей FESTO

Оставить заявку на ремонт или перемотку двигателей FESTO в Подольске можно с помощью специальной формы, которая вызывается нажатием одноименной кнопки в верхней части страницы. Все вопросы, связанные с ремонтом серводвигателей FESTO в Подольске вы можете задать нашим менеджерам. Связаться с ними можно несколькими способами:

- Заказав обратный звонок (кнопка в правом нижнем углу сайта)

- Посредством чата (кнопка расположена с левой стороны сайта)

- Позвонив по номеру телефона:

- +7(8482) 79-78-54;

- +7(8482) 55-96-39;

- +7(917) 121-53-01

- Написав на электронную почту: 89171215301@mail.ru

Вот далеко не полный список производителей промышленной электроники и оборудования, ремонтируемой в нашей компании.

Table of Contents for Festo CMMO-ST-C5-1-DIOP:

-

2 Product description Festo – GDCP-CMMO-ST-EA-SY-EN – 2017-05c – English 25 Connection Description Server — Client The motor controller is connected as an active DHCP 1) server via an Ethernet line directly to the PC (point-to-point connection). The Ethernet interface used on the PC must have the following (standard) settings è Windows system control: – Obtain an IP address automatically – Obtain DNS server address automatically The DHCP server on the motor controller assigns

-

2 Product description 20 Festo – GDCP-CMMO-ST-EA-SY-EN – 2017-05c – English 2.3 Software for configuration and commissioning 2.3.1 FCT (Festo Configuration Tool) The Festo Configuration Tool (FCT) is the Windows-based software platform for parameterisation, com missioning and diagnosis of actuators with configurable motor-axis combinations and positioning systems (OMS). To prepare for commissioning, parameterisation on the PC can take place without a connection to the co

-

4 Installation 68 Festo – GDCP-CMMO-ST-EA-SY-EN – 2017-05c – English 4 Electrical installation Caution Unexpected and unintended movement of the drive during mounting, installation and maintenance work Before starting work: Switch off power supplies. Cancelling the enable signal on the controller is not sufficient. Secure the power supplies against accidental reactivation. 4.1 EMC-compliant wiring Note Interference caused by electromagnet

-

A Technical appendix Festo – GDCP-CMMO-ST-EA-SY-EN – 2017-05c – English 145 A.1.2 Operating and Environmental Conditions Operating and Environmental Conditions Ambient temperature [°C] 0 …+50 Storage temperature [°C] –25 …+75 Cooling Passive Temperature warning from output stage Output stage temperature exceeded [°C] , +85 Warning 0x33 Output stage temperature too low [°C] . -15 Warning 0x33 Switch-off temperature for output stage Output stage temperature exceeded [°C] , +95 error 0x15

-

5 Commissioning Festo – GDCP-CMMO-ST-EA-SY-EN – 2017-05c – English 95 Activating a password Password protection protects the controller from unauthorised modifications and prevents controlling access to the actuator via FCT or web server: 1. Adopt device control in the FCT (reset controller enable) 2. Enter the password for the FCT menu [Component][Online][Password]): – Maximum length of password: 16 characters – Permitted characters: aZ, AZ, 09 !»#$%&” ()*+,./:;<=>?@[\]^_{|}~ The password is case-sensitive. 3.

-

2 Product description 18 Festo – GDCP-CMMO-ST-EA-SY-EN – 2017-05c – English Write cycles to the permanent data memory A flash memory is integrated in the motor controller as a non-volatile memory element. With the fol lowing procedures, entries are written to the flash memory: – Download of a parameter file – Firmware update – Teaching with automatic storage – Backing up of parameters via FC

-

3 Mounting 66 Festo – GDCP-CMMO-ST-EA-SY-EN – 2017-05c – English 3.2 Mounting on an H-rail 1. Mount an H-rail (mounting rail in accordance with IEC/EN 60715: TH35–7.5 or TH35–15). 2. If not pre-installed: Screw the H-rail clip to the side of the control è Fig. 3.2 1 Use original screw. When using another screw: Please observe screw-in depth (max. 5 mm). 3. Attach motor controller from above to hook on bracket. 4. Press motor cont

-

B Control via Ethernet (CVE) Festo – GDCP-CMMO-ST-EA-SY-EN – 2017-05c – English 159 Description of transitions Condition for status transition Description 0 Start è Not ready to switch on This status transition always takes place unconditionally after a (re)start. 1 Not ready to switch on è Switch on disabled The self test of the logic supply has been completed successfully. Automatic chan

-

B Control via Ethernet (CVE) 166 Festo – GDCP-CMMO-ST-EA-SY-EN – 2017-05c – English Explanation of read and write access Code Meaning R The object is readable. W1 The object is writeable if the controller is in the “Control disabled” status (è Description of the finite state machine). W2 The object is writeable if the controller is in the «Control enabled» status (è Description of the f

-

B Control via Ethernet (CVE) 162 Festo – GDCP-CMMO-ST-EA-SY-EN – 2017-05c – English Status word (CVE object #1) bit abbrevi ation Description 0 SW.RTSO Ready to switch on The output stage can be switched on via CW.SO. Bits 0 … 3, 5 and 6 display the status of the device (x … irrelevant for this status) Value (binary) status xxxx xxxx x0xx 0000 Not ready to switch on xxxx xxxx x1xx 0000 Switch on disabled xxxx xxxx x01x 0001 Ready to swit

-

Description Motor controller with I/O interface CMMO-ST-C5-1-DIOP CMMO-ST-C5-1-DION 8071657 2017-05c [8071659] CMMOST-…-DION/DIOP Motor controller

Questions, Opinions and Exploitation Impressions:

You can ask a question, express your opinion or share our experience of Festo CMMO-ST-C5-1-DIOP device using right now.

(Ocr-Read Summary of Contents of some pages of the Festo CMMO-ST-C5-1-DIOP Document (Main Content), UPD: 03 June 2023)

-

143, 7 Maintenance, care, repair and replacement Festo – GDCP-CMMO-ST-EA-SY-EN – 2017-05c – English 143 7.3 Replacement Note Loss of parameterisation The motor controller parameters are reset to factory settings after replacement. Back up parameter file before replacement of motor controller with web server or with FCT (backup file). After installation of the new motor controller, download back…

-

158, B Control via Ethernet (CVE) 158 Festo – GDCP-CMMO-ST-EA-SY-EN – 2017-05c – English Description of states Status Description Brake A Start This state is assumed at power-on, on reset or when a reset command is entered (e.g. via the fieldbus). After executing the startup code the machine automatically reverts to status B. Closed B Not ready to switch on In this status CMMO-ST self tests are carried out. The output st…

-