hp-concentra-wrapper-portlet

Actions

Issue

An ‘Out of paper‘ message displays on the control panel, and the printer does not pick up or feed paper. The printer might make noises as though it is printing, but no paper moves through it.

Experiencing frequent or recurring paper feed issues?

Follow these guidelines to help prevent paper feed issues:

-

Make sure to push the paper tray into the product until it stops.

-

Load at least 10 sheets of paper into the tray, but do not overload the tray.

-

Do not push the paper too far into the tray.

-

Load only one type of paper at a time into the tray.

-

Use only clean unused paper in the tray.

-

Store paper in a cool dry place.

-

Reload paper that has been in the tray for a while. Avoid printing on paper that is dusty.

-

Wait for the product to complete a print job or to display an ‘Out of paper‘ message before reloading the tray.

Causes

Any of the following issues can cause paper feed issues:

-

The paper tray is not pushed into the product until it stops.

-

The paper tray is overloaded.

-

The paper is curled.

-

The print side or shiny side of the paper is not loaded face down in the tray.

-

The paper width guides are too tight against the paper stack.

-

The paper feed rollers are coated with dust.

-

Debris such a as paper clips or bits of paper might have fallen into the paper path.

Important: You must follow these solutions in the order presented to resolve the issue.

Main tray

Solution one: Reset the All-in-One

Sometimes, resetting the printer can clear a paper feed issue. Follow these steps to perform a reset, and then print a Printer Status Report.

Step one: Perform a power reset

Follow these steps to perform a power reset.

-

With the printer turned on, disconnect the power cord from the rear of the printer.

-

Unplug the power cord from the wall outlet.

-

Wait at least 15 seconds.

-

Plug the power cord back into the wall outlet.

-

Reconnect the power cord to the printer.

-

Turn the printer on.

Step two: Print a Printer Status Report

Follow these steps to print a test page.

-

Load plain white U.S. letter or A4 size paper in the tray, if it is not already loaded.

-

On the product control panel, touch the Settings icon (

), and then touch Tools.

-

Touch Printer Status Report. The product prints the test page.

-

If these steps resolved the issue, you do not need to continue troubleshooting.

-

If the issue persists, continue to the next solution.

Solution two: Check the paper, and then reload it

Paper feed issues might result from using ripped, dusty, curled, wrinkled, or bent paper. The quality of the paper can also make a difference. Use these guidelines to help avoid the issue.

-

Use only good quality paper that meets printer specifications.

-

Store all paper in a dry, cool place. Paper feed issues occur more often in humid environments.

-

Do not print on paper that is already printed. The dampness of the ink can cause the paper to stick together.

-

Wait for the printer to complete a job or for an Out of paper or Load Paper message to display before you reload the paper.

Step one: Check the condition of the paper

Follow these steps to check the condition of the paper.

-

Remove the stack of paper from the tray.

-

Check for obstructions inside the tray. Use a flashlight to view the mechanism inside the tray to make sure that nothing blocks the paper from engaging with the rollers. Even small pieces of paper can cause paper feed issues.

note:

If you find obstructions in the paper path, skip to the section on cleaning the rollers.

-

Examine the condition of the paper, and then replace any ripped, dusty, curled, wrinkled, or bent paper.

-

Make sure that all the paper in the stack is the same size and type. Never load mixed types of paper in the tray. The product can only process one type of paper at a time.

-

Tap the stack of paper on a flat surface to align the edges.

-

Make sure that the stack of paper contains no fewer than 10 sheets and no more than 25 sheets of paper.

note:

You need to use 10 to 25 sheets of paper only for purposes of these troubleshooting steps. When the issue is resolved, you can resume loading paper according to the paper tray capacity specifications for your product.

Step two: Reload the paper

Follow these steps to load U.S. letter or A4 size paper in the printer.

-

Raise the photo tray.

-

Slide the paper width guides to their outermost positions.

Figure : Slide paper width guides to their outermost positions

-

Load a stack of plain paper into the tray with the short edge facing toward the product and the print side down (if the paper has a print side). Push the stack into the tray until it stops.

Figure : Load paper into the tray

-

Slide the paper width guides until they rest against the edges of the paper.

Figure : Slide the paper width guides against the edges of the paper

-

Close the photo tray and the paper tray, pull the tray extender toward you, and then extend the paper catch until it is fully extended.

Step three: Print a Printer Status Report

Print a test page to make sure the hardware functions correctly.

How to print a Printer Status Report

Follow these steps to print a test page.

-

Load plain white U.S. letter or A4 size paper in the tray, if it is not already loaded.

-

On the product control panel, touch the Settings icon (

), and then touch Tools.

-

Touch Printer Status Report. The product prints the test page.

If the issue is not resolved, try loading different brands of paper and different types of paper, one type at a time. Then try printing the test page again.

-

If these steps resolved the issue, you do not need to continue troubleshooting.

-

If the issue persists, continue to the next solution.

Solution three: Clean the paper feed rollers

Dust, paper fiber, and other debris might accumulate on the paper feed rollers and cause paper feed issues. Follow these steps to clean the paper feed rollers.

Step one: Clean the paper feed rollers

Follow these steps to clean the paper feed rollers.

-

Gather the following materials:

-

A clean, lint-free cloth, or any cloth that does not come apart or leave fibers

-

Distilled, filtered, or bottled water (tap water might damage the printer)

-

-

Disconnect the USB cable from the rear of the printer if your printer is connected with a USB cable.

-

Press the Power button (

) to turn off the printer.

-

Disconnect the power cord from the rear of the printer.

-

Remove the two-sided printing accessory (duplexer) from the rear of the printer. Push the right side of the duplexer to the left, and then pull out the duplexer to remove it. Set the duplexer aside.

-

Push the duplexer to the left

-

Pull out the duplexer

Figure : Remove the duplexer

-

-

Lightly dampen a clean, lint-free cloth with bottled or distilled water, and then squeeze any excess liquid from the cloth.

-

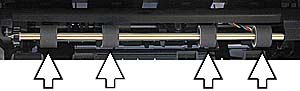

Press the cloth against the rollers, and then rotate the rollers upward with your fingers. Apply a moderate amount of pressure to remove any dust or dirt buildup.

Figure : Clean the rollers in the rear of the printer

-

Allow the rollers to dry for 10 or 15 minutes.

-

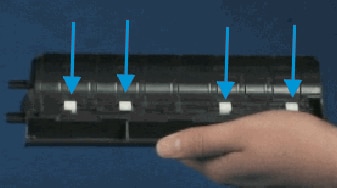

Check the rollers on the duplexer. Make sure that the rollers are not missing, that they turn easily, and that they are springy when you press them. If the rollers are damaged, replace the duplexer.

Figure : Check the rollers on the duplexer

-

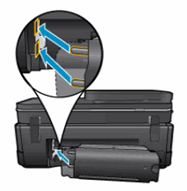

Reattach the duplexer to the rear of the printer. Insert the two pegs on the left side of the duplexer into the left side of the printer, and then gently push the duplexer into place. Make sure that the duplexer is firmly attached.

Figure : Reattach the duplexer

-

Reconnect the power cord to the rear of the printer.

-

If the printer does not turn on automatically, press the Power button (

) to turn it on.

Step two: Print a Printer Status Report

Print a test page to make sure that the hardware functions correctly.

How to print a Printer Status Report

Follow these steps to print a test page.

-

Load plain white U.S. letter or A4 size paper in the tray, if it is not already loaded.

-

On the product control panel, touch the Settings icon (

), and then touch Tools.

-

Touch Printer Status Report. The product prints the test page.

-

If the test page prints, try printing the original document again. If the issue is resolved, there is no need to continue troubleshooting.

-

If the test page prints, but the original document does not, continue with the next solution.

-

If the test page does not print, try printing the report again. Listen for the rubber paper rollers; you should be able to hear them rotating. Then try to slowly push the paper farther into the tray until the rollers pick up the paper. Be careful not to push the paper in too far, which can cause a paper jam.

-

If the test page prints when you slowly push the paper farther in, try printing the original document again. The paper might not have been loaded far enough into the printer. If the issue is resolved, there is no need to continue troubleshooting.

-

If the test page does not print when you slowly push the paper farther in, repeat the previous steps to clean the rollers again. If the issue continues after repeated cleaning, continue with next solution.

-

If the paper feeds through the printer only when you slowly push it farther in, repeat the previous steps to clean the rollers again. If the issue continues after repeated cleaning, continue with the next solution.

-

Solution four: Adjust the paper settings in the print driver

The printer might not pick up paper if the paper size and type in the paper tray do not match the size and type settings in the print driver.

-

Reload the paper you were using when the issue occurred.

-

Return to the document you were trying to print when the issue occurred.

-

Click File or click the Microsoft Office Button (

), and then click Print. The Print dialog box opens.

-

Select your printer, and then click Properties or Preferences. The Properties or Preferences dialog box opens.

-

Click the Paper/Quality tab.

-

From the Paper Size drop-down, make sure that the selected option matches your paper size. For example, if you have legal paper loaded in your printer, select Legal.

-

From the Media drop-down, select the paper type that matches the paper you have loaded in the printer.

-

Click OK to apply the settings.

-

Click OK from the Print dialog box to start the print job.

-

If the document prints, the issue is resolved, and there is no need to continue troubleshooting.

-

If the document prints on plain white paper, but not a special paper type, there is no need to continue troubleshooting. The problem is probably related to the paper that you tried to print on, or possibly a connectivity problem. Review the ‘Cause’ and ‘Experiencing frequent or recurring paper feed issues?’ sections at the beginning of this document to check other possibilities.

-

If the document does not print, continue to the solution to service the printer.

-

Photo Tray

Solution one: Reset the All-in-One

Sometimes, resetting the printer can clear a paper feed issue. Follow these steps to perform a reset, and then try printing the photo again.

Step one: Perform a power reset

Follow these steps to perform a power reset.

-

With the printer turned on, disconnect the power cord from the rear of the printer.

-

Unplug the power cord from the wall outlet.

-

Wait at least 15 seconds.

-

Plug the power cord back into the wall outlet.

-

Reconnect the power cord to the printer.

-

Turn the printer on.

Step two: Print the photo again

Try printing the photo again.

-

If these steps resolved the issue, you do not need to continue troubleshooting.

-

If the issue persists, continue to the next solution.

Solution two: Check the condition of the paper, check the photo tray, and then reload the paper

Paper feed issues might result from dusty, torn, wrinkled, wet, or folded paper in the photo tray. The quality of the paper can also make a difference. Use only good quality paper that meets product specifications. Follow these steps to check the condition of the paper.

Step one: Check the condition of the photo paper

Follow these steps to check the condition of the photo paper.

-

Remove the photo paper from the photo tray.

-

Check for obstructions inside the tray. Use a flashlight to view the mechanism inside the tray to make sure that nothing blocks the photo paper from engaging with the rollers. Even small pieces of photo paper can cause paper feed issues.

note:

If you find obstructions in the paper path, skip to the section on cleaning the paper rollers.

-

Examine the condition of the photo paper, and then replace any ripped, dusty, curled, wrinkled, or bent photo paper.

-

Make sure that all the photo paper in the stack is the same size and type. Never load mixed types of photo paper in the photo tray. The printer can process only one type of photo paper at a time.

-

Tap the stack of photo paper on a flat surface to align the edges.

-

Make sure that the stack of photo paper contains 5 or more sheets of photo paper.

note:

You need to use 5 sheets or more of photo paper only for purposes of these troubleshooting steps. When the issue is resolved, you can resume loading photo paper according to the paper tray capacity specifications for your printer.

Step two: Check the photo tray

Follow these steps to make sure that the photo tray fits in the printer correctly.

-

Grasp the photo tray, tilt it upward, and then pull it away from the printer to remove it.

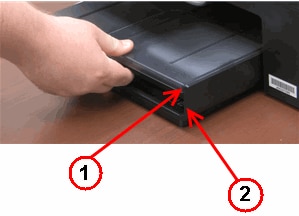

Figure : Grasp the photo tray

Figure : Tilt the tray upward and pull it away from the printer

Figure : The main tray with the photo tray removed

-

Slide the photo tray back into place at a slight upward angle until it stops, and then press the photo tray down and in to seat it correctly.

Figure : Reinsert the photo tray

-

Make sure that the front of the photo tray aligns with the end of the main tray. If the front of the photo tray does not line up with the end of the main tray, lift the photo tray at a slight upward angle, and then press the photo tray all the way into the printer.

-

Front of the photo tray

-

End of the main tray

Figure : Align the front of the photo tray with the end of the main tray

-

Step three: Reload the paper

Follow these steps to load photo paper into the printer’s photo tray.

-

Open the photo tray, and then slide the paper width guides to their outermost positions.

-

Load a stack of photo paper into the tray, with the short edge facing toward the product and the print side down. Push the stack into the tray until it stops.

Figure : Load photo paper into the tray

-

Slide the paper width guides in until they rest against the edges of the paper.

Figure : Slide the paper width guides until they rest against the edges of the paper

-

Close the photo tray.

Step three: Print the photo again

Try printing the photo again.

-

If these steps resolved the issue, you do not need to continue troubleshooting.

-

If the issue persists, continue to the next solution.

Solution three: Clean the paper feed rollers

Dust, paper fiber, and other debris might accumulate on the paper feed rollers and cause paper feed issues. Follow these steps to clean the paper feed rollers.

Step one: Clean the paper feed rollers

Follow these steps to clean the paper feed rollers.

-

Gather the following materials:

-

A clean, lint-free cloth, or any cloth that does not come apart or leave fibers

-

Distilled, filtered, or bottled water (tap water might damage the printer)

-

-

Disconnect the USB cable from the rear of the printer if your printer is connected with a USB cable.

-

Press the Power button (

) to turn off the printer.

-

Disconnect the power cord from the rear of the printer.

-

Remove the two-sided printing accessory (duplexer) from the rear of the printer. Push the right side of the duplexer to the left, and then pull out the duplexer to remove it. Set the duplexer aside.

-

Push the duplexer to the left

-

Pull out the duplexer

Figure : Remove the duplexer

-

-

Lightly dampen a clean, lint-free cloth with bottled or distilled water, and then squeeze any excess liquid from the cloth.

-

Press the cloth against the rollers, and then rotate the rollers upward with your fingers. Apply a moderate amount of pressure to remove any dust or dirt buildup.

Figure : Clean the rollers in the rear of the printer

-

Allow the rollers to dry for 10 or 15 minutes.

-

Check the rollers on the duplexer. Make sure that the rollers are not missing, that they turn easily, and that they are springy when you press them. If the rollers are damaged, replace the duplexer.

Figure : Check the rollers on the duplexer

-

Reattach the duplexer to the rear of the printer. Insert the two pegs on the left side of the duplexer into the left side of the printer, and then gently push the duplexer into place. Make sure that the duplexer is firmly attached.

Figure : Reattach the duplexer

-

Reconnect the power cord to the rear of the printer.

-

If the printer does not turn on automatically, press the Power button (

) to turn it on.

Step two: Print the photo again

Try printing the photo again.

-

If these steps resolved he issue, you do not need to continue troubleshooting.

-

If the issue persists, continue to the next solution.

Solution four: Adjust the paper settings in the print driver

The printer might not pick up paper if the paper size and type in the paper tray do not match the size and type settings in the print driver.

-

Return to the photo you were trying to print when the issue occurred.

-

Click File or click the Microsoft Office Button (

), and then click Print. The Print dialog box opens.

-

Select your printer, and then click Properties or Preferences. The Properties or Preferences dialog box opens.

-

Click the Paper/Quality tab.

-

From the Paper Size drop-down, make sure that the selected option matches the size of the photo paper in the photo tray.

note:

The photo tray supports up to 101.6 x 152.4 mm (4 x 6 in.) photo paper. Do not select a size larger than 101.6 x 152.4 mm (4 x 6 in.).

-

From the Paper Source drop-down list, select Photo Tray if it is not already selected.

note:

If the photo tray is not available in the Paper Source drop-down list, the paper size selected is likely too large for the photo tray. Select a paper size no larger than 101.6 x 152.4 mm (4 x 6 in.) to use the photo tray.

-

From the Media drop-down, select the paper type that matches the paper you have loaded in the printer.

-

Click OK to apply the settings.

-

Click OK from the Print dialog box to start the print job.

-

If the photo prints, the issue is resolved, and there is no need to continue troubleshooting.

-

If the photo does not print, continue to the next solution.

-

Solution five: Try to print a photo from the main tray

You can print photos from the main tray if the photo tray does not feed photo paper. Follow these steps to print photos from the main tray.

Step one: Load photo paper in the main tray

Follow these steps to load photo paper in the main tray.

-

Raise the photo tray lid.

-

Slide the photo paper width guide to its outermost position.

-

Remove the photo paper from the photo tray, and then lower the photo tray lid.

-

Lift the output tray, and then slide the paper width guide to its outermost position.

Figure : Slide the paper width guide to its outermost position

-

Gather 5 sheets of photo paper, and then tap the edges of the stack of photo paper on a flat surface to make sure that all the edges are even.

-

Load the photo paper into the tray with the short edge forward and the glossy side down. Slide the stack forward until it stops.

note:

Make sure that all the photo paper in the stack is the same size and type and is free from rips, dust, wrinkles, and curled or bent edges.

-

Slide the paper width guide inward until it stops at the edge of the photo paper. Do not push the guide in so tightly that it binds against the photo paper.

Figure : Slide the paper width guide inward until it stops at the edge of the photo paper

-

Lower the output tray.

Step two: Change the print settings

Follow these steps to change the print settings.

-

Return to the photo you were trying to print when the issue occurred.

-

Click File or click the Microsoft Office Button (

), and then click Print. The Print dialog box opens.

-

Select your printer, and then click Properties or Preferences. The Properties or Preferences dialog box opens.

-

Click the Paper/Quality tab.

-

From the Paper Size drop-down, make sure that the selected option matches the size of the photo paper in the photo tray.

note:

The photo tray supports up to 101.6 x 152.4 mm (4 x 6 in.) photo paper. Do not select a size larger than 101.6 x 152.4 mm (4 x 6 in.).

-

From the Paper Source drop-down list, select Photo Tray if it is not already selected.

note:

If the photo tray is not available in the Paper Source drop-down list, the paper size selected is likely too large for the photo tray. Select a paper size no larger than 101.6 x 152.4 mm (4 x 6 in.) to use the photo tray.

-

From the Media drop-down, select the paper type that matches the paper you have loaded in the printer.

-

Click OK to apply the settings.

-

Click OK from the Print dialog box to start the print job.

-

If the photo prints, the issue is resolved, and there is no need to continue troubleshooting.

-

If the photo does not print, continue to the solution to service the printer.

-

Service the All-in-One

Service or replace your HP product if the issue persists after completing all the preceding steps.

Go to Contact HP Customer Support to schedule a product repair or replacement. If you are in Asia Pacific, you will be directed to a local service center in your area.

To confirm your warranty status, go to HP Product Warranty Check. Repair fees might apply for out-of-warranty products.

Interpret control-panel messages, status-alert messages and event code errors

The control-panel messages and event code errors indicate the current product status or situations that might require action.

NOTE: Event log errors do not appear on the control-panel display. Access the event log to view or print the event log errors.

Control-panel messages appear temporarily and might require that you acknowledge the message by pressing the OK button to resume printing or by pressing the Stop button to cancel the job. With certain messages, the job might not finish printing or the print quality might be affected. If the message is related to printing and the auto-continue feature is on, the product will attempt to resume printing after the message has appeared for 10 seconds without acknowledgement.

For some messages, restarting the product might fix the problem. If a critical error persists, the product might require service.

___________________________________________________________________________

10.00.33

Description A used supply is in use (end of life).

Recommended action No action necessary.

10.00.35

Description An incompatible supply is in use.

Recommended action Install the correct HP print cartridge for this product (CE390A or CE390X).

NOTE: The CE390X cartridge is not compatible with the HP LaserJet Enterprise 600 M601.

10.00.60

Description The black cartridge is low.

Recommended action If print quality is no longer acceptable, replace the print cartridge.

TIP: Advise the customer that HP recommends that they have replacement supplies available to install when the print quality is no longer acceptable.

10.00.69

Description The black cartridge is very low.

Recommended action If print quality is no longer acceptable, replace the print cartridge.

TIP: Advise the customer that HP recommends that they have replacement supplies available to install when the print quality is no longer acceptable.

10.00.91

Description Cartridge motor stall.

Recommended action Replace the print cartridge.

10.0X.Y0 Supply memory error

Description The product cannot read or write to at least one print cartridge memory tag or a memory tag is missing from the print cartridge.

Memory error (Y = 0)

10.00.00 (event code) Black print cartridge

Memory tag missing (Y = 1)

10.00.10 (event code) Black print cartridge

Recommended action

Remove, and then reinstall the indicated print cartridge.

- If the error reappears, turn the power off, and then on.

- Check the cartridge memory tag. If it is damaged, replace the cartridge.

- If the error persists, replace the indicated print cartridge.

10.23.35

Description An incompatible fuser is in use.

Recommended action Replace the fuser.

TIP: Advise the customer that HP recommends that they have replacement supplies available to install when the print quality is no longer acceptable.

10.23.50

Description The fuser kit life was reset above the order threshold.

Recommended action No action necessary.

10.23.51

Description The fuser kit life was reset above the replace threshold.

Recommended action No action necessary.

10.23.52

Description The fuser kit life was reset above the reset threshold.

Recommended action No action necessary.

10.23.60

Description The product indicates when fuser kit is very low. The actual remaining fuse kit life might vary. You do not need to replace the fuser kit at this time unless print quality is no longer acceptable.

NOTE: After an HP supply has reached the very low threshold, the HP premium protection warranty ends.

Recommended action If print quality is no longer acceptable, replace the fuser kit. See the parts chapter in the service manual for the fuser kit part number.

TIP: Advise the customer that HP recommends that they have replacement supplies available to install when the print quality is no longer acceptable.

10.23.70 Printing Past Very Low

Description The product indicates when the fuser kit is very low. The actual remaining fuse kit life might vary. You do not need to replace the fuser kit at this time unless print quality is no longer acceptable.

NOTE: After an HP supply has reached the very low threshold, the HP premium protection warranty ends.

Recommended action If print quality is no longer acceptable, replace the fuser kit. See the parts chapter in the service manual for the fuser kit part number.

TIP: Advise the customer that HP recommends that they have replacement supplies available to install when the print quality is no longer acceptable.

10.26.15

Description The product indicates when the maintenance might need to be replaced.

Recommended action If print quality is no longer acceptable, replace the maintenance kit. See the parts chapter in the service manual for the maintenance kit part number.

TIP: Advise the customer that HP recommends that they have replacement supplies available to install when the print quality is no longer acceptable.

10.26.50

Description The maintenance kit was reset.

Recommended action No action required.

10.26.60

Description The product indicates when the maintenance kit is very low. The actual remaining maintenance kit life might vary. You do not need to replace the maintenance kit at this time unless print quality is no longer acceptable.

NOTE: After an HP supply has reached the very low threshold, the HP premium protection warranty ends.

Recommended action

If print quality is no longer acceptable, replace the maintenance kit. See the parts chapter in the service manual for the maintenance kit part number.

TIP: Advise the customer that HP recommends that they have replacement supplies available to install when the print quality is no longer acceptable.

10.XX.34 Used Supply In Use

Description The print cartridge is used.

10.00.34 (event code) Black print cartridge

Recommended action If you believe this is a genuine HP supply, go to http://www.hp.com/go/anticounterfeit.

NOTE: Removing a cartridge from one product and then installing it in a different product (for testing functionality) will cause this event code.

10.XX.40 Genuine HP Supplies Installed

Description A genuine HP print cartridge has been installed.

10.00.40 (event code) Black print cartridge

Recommended action No action necessary.

10.XX.41 Unsupported Supply In Use

Description The installed print cartridge is for a different product.

10.00.41 (event code) Black print cartridge

Recommended action Remove the print cartridge, and then install the correct cartridge for this product.

TIP: See the parts chapter in the service manual for the correct cartridge part number.

10.XX.70 Printing past very low

Description The product indicates when a supply level is very low. The actual remaining print cartridge life might vary. You do not need to replace the print cartridge at this time unless print quality is no longer acceptable.

NOTE: After an HP supply has reached the very low threshold, the HP premium protection warranty ends.

10.00.70 (event code) Black print cartridge

Recommended action If print quality is no longer acceptable, replace the print cartridge. See the parts chapter in the service manual for the correct cartridge part number.

TIP: Advise the customer that HP recommends that they have replacement supplies available to install when the print quality is no longer acceptable.

10.YY.15 Install <supply>

Description The indicated supply has been removed or installed incorrectly.

10.00.15 (event code) Black print cartridge

10.23.15 Fuser kit

Recommended action Replace or install the indicated supply. See the parts chapter in the service manual for the correct supply or kit part number.

10.YY.35 Incompatible <supply>

Description The indicated supply is not compatible with this product.

10.00.35 (event code) Black print cartridge

10.23.35 (event code) Fuser

Recommended action CAUTION: The fuser might be hot. Be careful when removing the fuser. Install a supply that is designed for this product. See the parts chapter in the service manual for the correct supply part number.

11.00.YY Internal clock error

Description The product real time clock has experienced an error.

◦ 01=dead clock

◦ 02=dead real time clock

Recommended action Whenever the product is turned off and then turned on again, set the time and date at the control panel. If the error persists, you might need to replace the formatter.

13.00.00

Description Generic jam event code.

Recommended action Check the product for a jam. See the clear jams section in the service manual.

13.00.EE

Description Unknown door open

Recommended action make sure that all of the doors and covers are closed.

13.A3.FF

Description Power on jam at the Tray 3 feed sensor.

Recommended action Check the product for a jam. See the clear jams section in the service manual.

13.D3.DZ

Description Late to duplex re-feed jam

◦ 13.D3.D1 (event code)

◦ 13.D3.D2 (event code)

◦ 13.D3.D3 (event code)

◦ 13.D3.D4 (event code)

◦ 13.D3.D5 (event code)

◦ 13.D3.D6 (event code)

◦ 13.D3.DD (event code)

◦ 13.D3.DE (event code)

Recommended action Check the product for a jam. See the clear jams section in the service manual.

13.E5.FF

Description A power on jam has occurred.

Recommended action Check the product for a jam. See the clear jams section in the service manual.

13.EA.EE

Description A door jam has occurred.

Recommended action Check the product for a jam. See the clear jams section in the service manual. Use the component test to isolate a faulty door switch or sensor.

13.EE.FF

Description A power on jam has occurred.

Recommended action Check the product for a jam. See the clear jams section in the service manual.

13.FF.EE

Description A door jam has occurred.

Recommended action Check the product for a jam. See the clear jams section in the service manual. Use the Manual sensors test or Tray/Bin manual sensors test to isolate a faulty door switch or sensor.

13.FF.FF

Description A power on residual paper jam has occurred (sensor).

Recommended action Check the product for a jam. See the clear jams section in the service manual. Use the Manual sensors test or Tray/Bin manual sensors test to isolate a faulty door switch or sensor.

13.WX.EE

Description This jam occurs when a door is opened during printing.

Recommended action Make sure that the doors are fully closed.

13.WX.FF

Description Power on residual paper jam This jam occurs when the paper exists at any of the paper path jam sensors at power on or door close. Due to the current FW timing requirements, the displayed jam code is always 13.FF.FF, only the event log will have 13.WX.FF

Recommended action Clear the jam. See the clear jams section in the service manual.

13.WX.YZ Fuser Area Jam

Description A jam in the fuser area has occurred.

Recommended action Clear the jam. See the clear jams section in the service manual. Make sure media is within specifications, check for obstructions in the fuser, check that the T2 roller is installed properly.

13.WX.YZ Fuser wrap jam

Description Recommended action Clear the jam. See the clear jams section in the service manual.

13.WX.YZ Jam below control panel

Description

13.B2.9Z (event code)

Page at duplex switchback jam.

Z = the source tray number

Recommended action Check the product for a jam. See the clear jams section in the service manual.

13.WX.YZ Jam in Tray 1

Description

13.B2.D1 (event code)

Late to registration jam, from Tray 1

This jam occurs when the paper does not reach the TOP sensor in designated amount of time from the start of paper pickup at printing from Tray 1 and duplex printing.

Recommended action Clear the jam. See the clear jams section in the service manual.

13.B2.D2 Late to registration jam, Tray 2

13.B2.D3 Late to registration jam, Tray 3

Note: Same as above.

13.WX.YZ Jam in Tray <X>

Description A misfeed jam has occurred.

Recommended action Clear the jam. See the clear jams section in the service manual.

13.WX.YZ Jam inside envelope feeder

Description A jam exists inside the envelope feeder.

Recommended action Clear the jam. See the clear jams section in the service manual.

13.WX.YZ Jam inside top cover

Description A jam exists inside the top cover.

Recommended action Clear the jam. See the clear jams section in the service manual.

14.00.XX

Description A feed roller error has occurred.

◦ 14.00.01 (event code)

◦ 14.00.02 (event code)

◦ 14.00.03 (event code)

◦ 14.00.04 (event code)

◦ 14.00.05 (event code)

◦ 14.00.06 (event code)

Recommended action Check the product and accessories feed rollers for dirt or damage. Clean or replace the rollers as necessary.

20.00.00 Insufficient memory: <Device> To continue, touch “OK”

Description The product has experienced a memory error. You might have tried to transfer too many fonts or macros.

Recommended action Touch the OK button to print the transferred data (some data might be lost), and then simplify the print job or install additional memory.

21.00.00 Page Too Complex

Description The page decompression process was too slow for the printer.

Recommended action Touch the OK button to continue printing (some data might be lost).

32.08.AX

Description

◦ 32.08.A1 (event code)

Shutdown event

◦ 32.08.A2 (event code)

Boot from normal shutdown event

◦ 32.08.A3 (event code)

Boot from abnormal shutdown event

Recommended action No action necessary.

32.1C.XX

Description

◦ 32.1C.01 (event code)

NVRAM backup/restore service backup started

◦ 32.1C.02 (event code)

NVRAM backup/restore service restore started

◦ 32.1C.03 (event code)

NVRAM backup/restore administrator backup started

◦ 32.1C.04 (event code)

NVRAM backup/restore administrator restore started

◦ 32.1C.05 (event code)

Backup/restore complete

◦ 32.1C.06 (event code)

Data model failed to clone job ticket

◦ 32.1C.07 (event code)

Backup restore permissions error

◦ 32.1C.08 (event code)

Not enough disk space to perform backup/restore or network share issue

◦ 32.1C.09 (event code)

Tried to restore a backup file that was not valid for this product

◦ 32.1C.0A (event code)

Backup file is invalid

◦ 32.1C.0B (event code)

Backup is from newer version of FW than what is currently on the product

◦ 32.1C.0C (event code)

Backup cancelled from the HP Embedded Web Server

◦ 32.1C.0D (event code)

Backup/restore failed, auto-reboot failed, or the product might be busy

◦ 32.1C.0E (event code)

Backup/restore timeout while communicating with the formatter

◦ 32.1C.0F (event code)

Backup/restore timeout while communicating with the finisher firmware

◦ 32.1C.10 (event code)

Backup/restore timeout while communicating with the scanner firmware

◦ 32.1C.11 (event code)

Backup/restore timeout while communicating with the engine

◦ 32.1C.12 (event code)

Backup/restore timeout while communicating with the disk

◦ 32.1C.13 (event code)

Scheduled backup failure

◦ 32.1C.14 (event code)

NVRAM restore timeout while communicating with the formatter

◦ 32.1C.15 (event code)

NVRAM restore timeout while communicating with the finisher firmware

◦ 32.1C.16 (event code)

NVRAM restore timeout while communicating with the scanner firmware

◦ 32.1C.17 (event code)

NVRAM restore timeout while communicating with the engine

◦ 32.1C.18 (event code)

Backup of copy subsystem failed

◦ 32.1C.19 (event code)

Backup of fax subsystem failed

◦ 32.1C.1A (event code)

Backup of digital send subsystem failed

◦ 32.1C.1B (event code)

Backup of print subsystem failed

◦ 32.1C.1C (event code)

Backup of networking subsystem failed

◦ 32.1C.1D (event code)

Backup of finishing subsystem failed

◦ 32.1C.1E (event code)

Restore of copy subsystem failed

◦ 32.1C.1F (event code)

Restore of fax subsystem failed

◦ 32.1C.20 (event code)

Restore of digital send subsystem failed

◦ 32.1C.21 (event code)

Restore of print subsystem failed

◦ 32.1C.22 (event code)

Restore of networking subsystem failed

◦ 32.1C.24 (event code)

NVRAM backup/restore successful

◦ 32.1C.25 (event code)

Reset of copy subsystem failed

◦ 32.1C.26 (event code)

Reset of fax subsystem failed

◦ 32.1C.27 (event code)

Reset of digital send subsystem failed

◦ 32.1C.28 (event code)

Reset of print subsystem failed

◦ 32.1C.29 (event code)

Reset of networking subsystem failed

◦ 32.1C.2A (event code)

Reset of finishing subsystem failed

◦ 32.1C.2B (event code)

Reset formatter timeout

◦ 32.1C.2C (event code)

Reset finisher timeout

◦ 32.1C.2D (event code)

Reset scanner timeout

◦ 32.1C.2E (event code)

Reset engine timeout

◦ 32.1C.2F (event code)

Reset failure

Recommended action

◦ 32.1C.01 (event code)

No action necessary

◦ 32.1C.02 (event code)

No action necessary

◦ 32.1C.03 (event code)

No action necessary

◦ 32.1C.04 (event code)

No action necessary

◦ 32.1C.05 (event code)

No action necessary

◦ 32.1C.06 (event code)

Retry

◦ 32.1C.07 (event code)

Retry

◦ 32.1C.08 (event code)

Remove stored jobs and retry

Use larger capacity storage device

Check network share

◦ 32.1C.09 (event code)

Use a valid backup file

◦ 32.1C.0A (event code)

Use a valid backup file

Reboot and observe state of product

Do a partition clean using the Preboot menu.

◦ 32.1C.0B (event code)

Use a valid backup file or put correct firmware version on the product.

◦ 32.1C.0C (event code)

No action necessary

◦ 32.1C.0D (event code)

Reboot and then retry the backup/restore

◦ 32.1C.0E (event code)

Turn the product off then on and retry

◦ 32.1C.0F (event code)

Turn the product off then on and retry

◦ 32.1C.10 (event code)

Turn the product off then on and retry

◦ 32.1C.11 (event code)

Turn the product off then on and retry

◦ 32.1C.12 (event code)

Turn the product off then on and retry

◦ 32.1C.13 (event code)

Turn the product off then on and retry

◦ 32.1C.14 (event code)

Turn the product off then on and retry

◦ 32.1C.15 (event code)

Turn the product off then on and retry

◦ 32.1C.16 (event code)

Turn the product off then on and retry

◦ 32.1C.17 (event code)

Turn the product off then on and retry

◦ 32.1C.18 (event code)

Turn the product off then on and retry

◦ 32.1C.19 (event code)

Turn the product off then on and retry

◦ 32.1C.1A (event code)

Turn the product off then on and retry

◦ 32.1C.1B (event code)

Turn the product off then on and retry

◦ 32.1C.1C (event code)

Turn the product off then on and retry

◦ 32.1C.1D (event code)

Turn the product off then on and retry

◦ 32.1C.1E (event code)

Turn the product off then on and retry

If the error persists, clear the firmware image from the active partition by using the Partial Clean item in the Preboot menu.

◦ 32.1C.1F (event code)

Turn the product off then on and retry

If the error persists, clear the firmware image from the active partition by using the Partial Clean item in the Preboot menu.

◦ 32.1C.20 (event code)

Turn the product off then on and retry

If the error persists, clear the firmware image from the active partition by using the Partial Clean item in the Preboot menu.

◦ 32.1C.21 (event code)

Turn the product off then on and retry

If the error persists, clear the firmware image from the active partition by using the Partial Clean item in the Preboot menu.

◦ 32.1C.22 (event code)

Turn the product off then on and retry

If the error persists, clear the firmware image from the active partition by using the Partial Clean item in the Preboot menu.

◦ 32.1C.24 (event code)

Turn the product off then on and retry.

◦ 32.1C.25 (event code)

Turn the product off then on and retry.

◦ 32.1C.26 (event code)

Turn the product off then on and retry.

◦ 32.1C.27 (event code)

Turn the product off then on and retry.

◦ 32.1C.28 (event code)

Turn the product off then on and retry.

◦ 32.1C.29 (event code)

Turn the product off then on and retry.

◦ 32.1C.2A (event code)

Turn the product off then on and retry.

◦ 32.1C.2B (event code)

Turn the product off then on and retry.

◦ 32.1C.2C (event code)

Turn the product off then on and retry.

◦ 32.1C.2D (event code)

Turn the product off then on and retry.

◦ 32.1C.2E (event code)

Turn the product off then on and retry.

◦ 32.1C.2f (event code)

Turn the product off then on and retry.

32.21.00

Description Corrupt firmware in external accessory

Recommended action Turn the product off, then on, and retry.

If the error persists, clear the firmware image from the active partition by using the Partial Clean item in the Preboot menu

33.01.XX

Description

◦ 33.01.01 (event code)

A restore process has occurred.

◦ 33.01.02 (event code)

A save process has occurred.

Recommended action No action necessary.

33.XX.YY Used board/disk

Description An encrypted board or disk with existing data previously locked to a different product has replaced the original. If you continue, data is permanently lost.

Recommended action To save the data on the board or disk, turn the product off. Replace the board or disk with another board or disk.

To delete the data on the board or disk and continue, touch the OK button.

40.00.01 USB I/O buffer overflow To continue, touch “OK”

Description The USB buffer has overflowed.

Recommended action Touch the OK button to print the transferred data (some data might be lost). Check the host configuration.

40.00.02 Embedded I/O buffer overflow To continue, touch “OK”

Description The product has experienced a JetDirect buffer overflow.

Recommended action Touch the OK button to print the transferred data (some data might be lost). Check the host configuration.

40.00.05 Embedded I/O bad transmission To continue, touch “OK”

Description The USB device has been removed.

Recommended action Touch the OK button to clear the error message. (Data will be lost.) Install the USB device.

41.02.00 Error

Description A beam detected misprint error.

Recommended action Turn the product off, and then on. If the error persists, replace the laser/scanner assembly.

41.03.YZ Unexpected size in envelope feeder To use another tray, touch “Options”

Description The product detected a different paper size than expected.

◦ Y = 0

Size mismatch. Detected media is longer or shorter than expected.

◦ Y = A

Size mismatch. Detected media too long.

◦ Y = B

Size mismatch. Detected media too short.

◦ Y = C

Size mismatch. Inter-page gap error.

◦ Z = D

Source is duplexer

◦ Z = E

Source is envelope feeder

◦ Z = 2

◦ Z = 3

Source is Tray 3

◦ Z = 4

Source is Tray 4

◦ Z = 5

Source is Tray 5

Recommended action Make sure that the feeder is loaded with the correct paper size and that the sliding paper guides are correctly adjusted. Use the Tray/Bin manual sensor test to verify that the envelope feeder paper sensor (PS1802) is correctly functioning.

If the error persists, replace the envelope feeder.

41.03.YZ Unexpected size in tray <X>

Description The product detected a different paper size than expected.

◦ Y = 0

Size mismatch. Detected media is longer or shorter than expected.

◦ Y = A

Size mismatch. Detected media too long.

◦ Y = B

Size mismatch. Detected media too short.

◦ Y = C

Size mismatch. Inter-page gap error.

◦ Z = D

Source is duplexer

◦ Z = E

Source is envelope feeder

◦ Z = 1

Source is Tray 1

Z = 2

Source is Tray 2

◦ Z = 3

Source is Tray 3

◦ Z = 4

Source is Tray 4

◦ Z = 5

Source is Tray 5

Recommended action Make sure that the tray is loaded with the correct paper size and that the sliding paper guides are correctly adjusted. Use the Tray/Bin manual sensor test to verify that the cassette media switch is correctly functioning. If the error persists, replace the lifter assembly.

41.05.YZ Unexpected type in tray <X>

Description The product detected a different paper type than expected.

◦ Y = 0 (expected type)

Unknown

◦ Y = 1 (expected type)

Normal media

◦ Y = 3 (expected type)

LBP OHT

◦ Y = 6 (expected type)

Non-assured OHT

◦ Y = 7 (expected type)

Heavy media

◦ Y = 8 (expected type)

Light media

◦ Y = 9 (expected type)

Rough media

◦ Y = C (expected type)

Heavy media 3

◦ Y = D (expected type)

Heavy media 2

◦ Z = 1 (detected type)

Normal media

◦ Z = 3 (detected type)

LBP OHT

◦ Z = 6 (detected type)

Non-assured OHT

◦ Z = 7 (detected type)

Heavy media

◦ Z = 8 (detected type)

Light media

◦ Z = 9 (detected type)

Rough media

◦ Z = B (detected type)

Heavy glossy media (glossy media 2)

◦ Z = C (detected type)

Heavy media 3

◦ Z = D (detected type)

Heavy media 2

Recommended action Load the tray with the size and type of paper indicated, or use another tray if available. If this message appears and the tray is loaded with the correct paper type, check the print driver settings to make sure they match the tray type settings.

Clean the Media Sensor. If the error persists, replace the paper pickup assembly.

41.XX.YZ Error To continue, touch “OK”

Description A product error has occurred.

◦ XX = error type

◦ Y = fuser mode

◦ Z = input tray

◦ XX = 02

Beam detect misprint

◦ XX = 09

Sub thermistor abnormally high

◦ XX = 18

Scan line inclination adjustment

◦ XX = 20

Image drum HV

◦ Y = 2

Normal typed (not AutoSense)

◦ Y = 3)

Light media 1, 2, 3: typed or AutoSense

◦ Y = 4

Heavy media 1: typed or AutoSense

◦ Z = 0

Envelope feeder

◦ Z = 1

Tray 1

◦ Z = 2

Tray 2

◦ Z = 3

Tray 3

◦ Z = 4

Tray 4

◦ Z = 5

Tray 5

◦ Z = 6

Tray 6

◦ Z = D

Duplexer

Recommended action Turn the product off, and then on.

If the error persists, replace the DC controller PCA.

42.XX.YY

Description Internal system failure

Recommended action Turn the product of,f then on, and retry.

If the error persists, clear the firmware image from the active partition by using the Partial Clean item in the Preboot menu.

47.00.XX

Description Back channel internal error

Recommended action Turn the product off, and then on again. Resend the print job. If the error persists, execute the Partial Clean item in the Preboot menu.

47.01.XX

Description Image transformer internal error

Recommended action Turn the product off, and then on again. Resend the print job. If the error persists, execute the Partial Clean item in the Preboot menu.

47.02.XX

Description Job parser internal error

Recommended action Turn the product off, and then on again. Resend the print job. If the error persists, execute the Partial Clean item in the Preboot menu.

47.03.XX

Description Print job internal error

Recommended action Turn the product off, and then on again. Resend the print job. If the error persists, execute the Partial Clean item in the Preboot menu.

47.04.XX

Description Print spooler 9100 internal error

Recommended action Turn the product off, and then on again. Resend the print job. If the error persists, execute the Partial Clean item in the Preboot menu.

47.05.00

Description Print spooler framework internal error

Recommended action Turn the product off, and then on again. Resend the print job. If the error persists, execute the Partial Clean item in the Preboot menu.

47.06.XX

Description Print App internal error

Recommended action Turn the product off, and then on again. Resend the print job. If the error persists, execute the Partial Clean item in the Preboot menu.

47.WX.YZ Printer Calibration Failed To continue, touch “OK”

Description The device is unable to access or implement one of the image patterns files.

Y = calibration type, Z = event

◦ 47.FC.20 (event code)

Error Diffusion Image not found at system initialization

◦ 47.FC.21 (event code)

Error Diffusion Store image failure

◦ 47.FC.22 (event code)

Error Diffusion Image not found

◦ 47.FC.23

Error Diffusion Print engine execution failure

◦ 47.FC.300 (event code)

Drum Speed Adjustment Image not found at system initialization

◦ 47.FC.31 (event code)Drum Speed Adjustment Store image failure

◦ 47.FC.32 (event code)

Drum Speed Adjustment Image not found

◦ 47.FC.33 (event code)

Drum Speed Adjustment Print engine execution failure

◦ 47.FC.40 (event code)

Pulse Width Modulation Image not found at system initializatione

◦ 47.FC.41 (event code)

Pulse Width Modulation Store image failure

◦ 47.FC.42 (event code)

Pulse Width Modulation Image not found

◦ 47.FC.43 (event code)

Pulse Width Modulation Print engine execution failure

Recommended action Turn the product off, and then on. If the error persists, reload the firmware.

49.XX.YY To continue turn off then on

Description A firmware error has occurred.

Recommended action

- Turn the product off, and then on.

- If the error returns, check the following:

- The error might be caused by a network connectivity problem.

- Damaged interface cable

- Damaged USB port

- Invalid network configuration setting

- The error might be caused by the print job.

- Invalid printer driver

- Problem with the software application

- Problem with the file

- If the error persists, perform a firmware upgrade.

50.WX.YZ Fuser error To continue turn off then on

Description

The fuser has experienced an error.

W = fuser error code, X = fuser mode, Y = previous printer sleep state, Z = next printer sleep state

Recommended action

W = 2

Fuser warm up failure

- Reconnect the connector (J128) between the fuser and the DC controller PCA.

- Turn the product off. Remove the fuser and then reinstall it. If the error persist, replace the fuser.

- If the error persists, replace the low-voltage power supply.

W = 3

Low temperature thermistor 1

- Reinstall the fuser. Check the connector (J128) between the fuser and the product. If it is damaged, replace the fuser.

- Reconnect the connector (J82) on the DC controller PCA.

- Replace the fuser.

- W = 2: Reconnect the connector (J62) on the low-voltage power supply PCA.

- If the error persists, replace the low-voltage power supply.

W = 4

High temperature thermistor 1

- Reinstall the fuser. Check the connector (J128) between the fuser and the product. If it is damaged,

replace the fuser.

- Reconnect the connector (J82) on the DC controller PCA.

- Replace the fuser.

- If the error persists, replace the low-voltage power supply.

W = 6

Drive circuit fault

- Check the power source. Make sure the power source meets product requirements.

NOTE: If the power source does not meet the power frequency requirement of 40 to 70Hz, the

fuser temperature control does not work properly and causes this error.

- Reconnect connectors J51, J52, J53, and J162 and DC controller PCA connectors J85, J95, and J96.

- If the error persists, replace the low-voltage power supply.

W = 10

Low temperature thermistor 2

- Reinstall the fuser. Check the connector (J128) between the fuser and the product. If it is damaged,

replace the fuser.

- Reconnect the connector (J62) on the low-voltage power supply PCA.

- If the error persists, replace the low-voltage power supply.

W = 11

High temperature thermistor 2

- Reinstall the fuser. Check the connector (J128) between the fuser and the product. If it is damaged,

replace the fuser.

- Reconnect the connector (J62) on the low-voltage power supply PCA.

- If the error persists, replace the low-voltage power supply.

W = 12

Fuser pressure release mechanism failure

- Reconnect the fuser connector (J128) and the DC controller PCA connector (J62).

- Check the fuser pressure release sensor flag. If the flag is damaged or not properly working, replace the fuser.

- Reconnect the fuser motor connector (J221) and the DC controller PCA connector (J89).

- Use the Component Test item in the Troubleshooting menu to test the fuser motor. If the motor fails the test, replace the fuser motor.

- If the error persists replace the fuser.

50.22.xx See This article for troubleshooting steps

51.00.YY Error

Description Laser/scanner error

◦ YY = 20

Black laser/scanner error

Recommended action

- Reconnect connector (J145) on the laser/scanner.

- Reconnect connectors (J86 and J93) on the DC controller.

- If the error persists, replace the laser/scanner.

52.XX.00 Error To continue turn off then on

Description Laser/scanner error

◦ XX = 00

laser/scanner motor startup error

◦ XX = 20

Laser/scanner rotation error

Recommended action

- Reconnect connector (J145) on the laser/scanner.

- Reconnect connectors (J86 and J93) on the DC controller.

- Use the scanner motor (M108) drive test in the component test to verify that the scanner motor is properly functioning. If it is not, replace the laser/scanner.

NOTE: Listen for a high pitched whine from the motor.

- If the error persists, replace the laser/scanner.

54.XX.YY Error

Description

A sensor error has occurred.

Recommended action

54.00.03

Environmental sensor (TH3) failure

- Turn the product off, and then reconnect the connector (J63) on the DC controller PCA. Turn the

product on.

- If the environment sensor has been removed or replaced, check the connector (J199) on the

environment sensor and the connector (J63) on the DC controller PCA.

- If the error persists, replace the environment sensor assembly.

54.06.21

Primary laser/scanner beam detect abnormality

- Turn the product off, and then on.

- If the product has had parts removed or replace, check the connector (J93) on the DC controller PCA.

- If the error persists, replace the laser/scanner assembly.

55.00.YY DC controller error To continue turn off then on

Description DC controller PCA error

◦ 55.00.01 (event code)

DC controller memory error

◦ 55.00.03 (event code

DC controller no engine response

◦ 55.00.04 (event code

DC controller communications timeout

Recommended action Turn the product off, and then on. If the error persists, replace the DC controller PCA.

55.0X.YY DC controller error To continue turn off then on

Description DC controller PCA error

◦ 55.01.06 (event code)

NVRAM memory data error warning

◦ 55.02.06 (event code)

NVRAM memory access error warning

Recommended action Turn the product off, and then on.

If the error persists, replace the DC controller PCA.

56.00.YY Error To continue turn off then on

Description Optional paper trays communication error

Recommended action Turn the product off, and then on. If the error persists, reseat the optional paper trays (1 x 500-sheet feeder and/or 3 x 500-sheet feeder). Check the input connectors for damage. If a connector is damaged, replace the connector.

57.00.0Y Error To continue turn off then on

Description Fan error

Recommended action

57.00.03

Main fan (FN101) failure

- Turn the product off, and then on. Listen for fan noise at the back corner of the product. If no noise is heard, replace the power supply fan (FN101).

- If the fan has been removed or replaced, check the connector (J64) on the DC controller PCA.

- If the error persists, replace the main fan (FN101).

57.00.04

Laser/scanner fan (FN102) failure

- If this part has been removed or replace, check the connector (J75) on the DC controller PCA.

- If the error persists, replace the laser/scanner fan (FN102).

57.00.06

Cartridge fan (FN301) failure

- If this part has been removed or replace, check the connector (J95) on the DC controller PCA.

- If the fan has been removed or replaced, check the connector (J66) on the DC controller PCA.

- If the error persists, replace the cartridge fan (FN301).

57.00.05

Cartridge front-side fan (FN103) failure

- Turn the product off, and then on. Listen for fan noise at the middle back of the product. If no noise

is heard, replace the cartridge front-side fan (FN103).

- If the fan has been removed or replaced, check the connector (J79) on the DC controller PCA.

- If the error persists, replace the cartridge front-side fan (FN103).

57.00.07

Duplex fan (FN107) failure

- Turn the product off, and then on. Listen for fan noise at the left side of the product. If no noise is

heard, replace the duplex fan (FN107).

- If the fan has been removed or replaced, check the connector (J64) on the DC controller PCA.

- If the error persists, replace the duplexer.

58.00.0Y Error To continue turn off then on

Description A sensor error has occurred.

Recommended action

58.00.05

Environmental sensor (TH3) failure

- Turn the product off.

- If this part has been removed or replace, check the connector (J63) on the DC controller PCA.

- If the error persists, replace the environmental sensor (TH3).

58.00.03

DC controller CPU failure

- Turn the product off.

- Check all of the connectors on the DC controller PCA.

- If the error persists, replace the DC controller PCA.

58.00.04

LVPS failure

- Turn the product off.

- If this part has been removed or replace, check the connector (J50) on the LVPS, and then check

the connector (J85 and J95) on the DC controller PCA.

- If the error persists, replace the LVPS.

59.00.YY error To continue turn off then on

Description A motor error has occurred.

◦ YY = 00

Paper path malfunction

Recommended action

59.00.20 or 59.00.30

Feed motor (M101) failure (start-up or rotational)

- Reconnect the connector (J191) on the feed motor and the connector (J91) on the DC controller PCA.

- Use the feed motor (M101) drive test in the Component test to verify that the motor is properly functioning. If is not, replace the feed motor (M101).

59.00.40 or 59.00.50

Fuser motor (M299) failure (start-up or rotational)

- Reconnect the connector (J221) on the feed motor and the connector (J89) on the DC controller PCA.

- Use the fuser motor (M299) drive test in the Component test to verify that the motor is properly functioning. If it is not, replace the fuser motor (M299).

59.00.60 or 59.00.70

Drum motor (M102) failure (start-up or rotational)

- Reconnect the connector (J187) on the drum motor and the connector (J87) on the DC controller PCA.

- Use the drum motor (M102) drive test in the Component test to verify that the motor is properly functioning. If it is not, replace the drum motor (M102).

59.A2.0x Error

Description A product error has occurred.

Recommended action

59.A2.02 or 59.A2.11

Lifter driver assembly Tray 2 failure

- Use the Tray/Bin manual sensor test to verify that the Tray 2 paper (PS107 and PS907) surface sensors are properly functioning.

- If this part has been removed or replace, check the connector (J73 and J94) on the on the DC controller PCA.

- Check the media stack surface sensor lever and place it in the correct position to move smoothly. Replace the media stack surface sensor lever if it is damaged.

- If the error persists, replace the lifter drive assembly (Tray 2).

59.A2.12 to 59.A2.15

Lifter driver assembly Tray 3 to 6 motor failure

- Reconnect the connectors (J1605 and J1608) on the paper feeder drive PCA.

- Reconnect the connectors (J1703 and J1707) on the paper cassette drive PCA.

- Replace the sheet feeder media stack surface sensor.

- If the error persists, replace the lifter motor for the specific sheet feeder.

60.00.0Y Tray <Y> lifting error

Description A tray lift motor error has occurred.

Recommended action

60.00.02

Lifter driver assembly Tray 2 failure

- Use the Tray/Bin manual sensor test to verify that the Tray 2 paper (PS107 and PS907) surface sensors are properly functioning.

- If this part has been removed or replace, check the connector (J73 and J94) on the on the DC controller PCA.

- Check the media stack surface sensor level and place it in the correct position to move smoothly.

Replace the sensor lever if it is damaged.

- Replace the media stack surface sensor.

- If the error persists, replace the lifter drive assembly (Tray 2).

60.00.12 to 60.00.15

Lifter driver assembly Tray 3 failure

- Use the Tray/Bin manual sensor test to verify that the Tray 3 paper (SR1 and SR2) surface sensors

are properly functioning.

- If this part has been removed or replace, check the connector (1605 and 1608) on the on the

paper feeder controller PCA.

- Reconnect the connectors (J1703 and J1707) on the sheet feeder PCA.

- Replace the sheet feeder media stack surface sensor.

- If the error persists, replace the lifter drive assembly (Tray 3-6).

62.00.00 No system To continue turn off then on

Description Internal system failure

Recommended action Turn the product off, and then on.

If the error persists, reload the firmware. If the error still persists, perform a firmware upgrade.

If the firmware upgrade does not resolve the problem, replace the hard disk.

65.X0.A1 Output accessory disconnected

Description

An external paper handling accessory connection has been interrupted.

Recommended action

- Turn the product off.

- Make sure that all packing materials have been removed from the paper handling accessory.

- Check the paper path for obstructions, or jammed paper.

- Check the accessory cable connection.

- Turn the product on. If the error persists, replace the accessory.

66.80.YY Stapler/Stacker failure

Description An external paper handling accessory error has occurred.

◦ 66.80.01 (event code)

Y-align malfunction

◦ 66.80.02 (event code)

Jogger malfunction

◦ 66.80.03 (event code)

Stapler malfunction

◦ 66.80.21 (event code)

Lift up malfunction

◦ 66.80.22 (event code)

Lift down malfunction

◦ 66.80.23 (event code)

Lift sensor malfunction

◦ 66.80.33 (event code)

Output roller malfunction

◦ 66.80.35 (event code)

Self priming malfunction

◦ 66.80.51 (event code)

System error (FW error)

◦ 66.80.55 (event code)

System error 5 (FW error)

◦ 66.80.56 (event code)

System error 6 (FW error)

◦ 66.80.57 (event code)

System error 7 (FW error)

◦ 66.80.58 (event code)

System error 8 (FW error)

◦ 66.80.59 (event code)

System error 9 (FW error)

◦ 66.80.60 (event code)

System error 10 (inter-page delay mismatch)

◦ 66.80.61 (event code)

System error 11 (lifter task trouble)

◦ 66.80.62 (event code)

System error 12 (inter-page delay mismatch)

◦ 66.80.63 (event code)

System error 13 (FW error)

◦ 66.80.64 (event code)

System error 14 (FW error)

◦ 66.80.65 (event code)

System error 15 (FW error)

◦ 66.80.70 (event code)

Page-info in flush

◦ 66.80.71 (event code)

Flush request in PDLV

◦ 66.80.72 (event code)

Delivery notice error

◦ 66.80.73 (event code)

Flush request in checking paper path

◦ 66.80.74 (event code)

Checking paper path start in PDLV

◦ 66.80.75 (event code)

Flush request in flush

◦ 66.80.76 (event code)

Non-flush complete

Recommended action

Turn the product off, and then on.

If the error persists, replace the paper handling device.

69.11.YY Error To continue turn off then on

Description Duplexer error

Recommended action

Turn the product off, and then on.

If the error persists, replace the duplexer.

70.00.00 Error To continue turn off then on

Description DC controller failure

Recommended action Turn the product off, and then on. If the error persists, replace the DC controller.

79.XX.YY Error To continue turn off then on

Description

This error can be caused by corrupted print jobs, software application issues, non-product specific

printer drivers, poor-quality USB or network cables, bad network connections or incorrect network

configurations, invalid firmware operations, or unsupported accessories.

Recommended action

- Turn the product off, and then on.

- If the error persists, check the following:

- The error might be caused by a network connectivity problem, such as a bad interface cable,

a bad USB port, or an invalid network configuration setting.

- The error might be caused by the print job, an invalid print driver, a problem with the

software application, or a problem with the file you are printing.

Make sure you are using the correct printer driver. Try printing using a different software

application. Try printing a different file or print job.

- Upgrading the product firmware might resolve the problem.

80.0X.YY Embedded JetDirect error

Description Embedded HP JetDirect print server critical error

◦ 80.01.80 (event code)

No heartbeat

◦ 80.01.81 (event code)

Reclaim timeout

◦ 80.01.82 (event code)

Invalid data length

◦ 80.01.8B (event code)

Invalid max outstanding packet header field

◦ 80.01.8C (event code)

Invalid channel mapping response

◦ 80.03.01 (event code)

No PGP buffers

◦ 80.03.02 (event code)

Channel table full

◦ 80.03.03 (event code)

Producer index not reset

◦ 80.03.04 (event code)

Consumer index not reset

◦ 80.03.05 (event code)

Queue position size too small

◦ 80.03.06 (event code)

Transport overflow

◦ 80.03.07 (event code)

No overflow packets

◦ 80.03.08 (event code)

Invalid identify response

◦ 80.03.09 (event code)

Invalid channel map return status

◦ 80.03.1080.03.10 (event code)

Invalid reclaim return status

◦ 80.03.12 (event code)

Datagram invalid buffer

◦ 80.03.13 (event code)

Max stream channels

◦ 80.03.14 (event code)

Max datagram channels

◦ 80.03.15 (event code)

Card reset failed

◦ 80.03.16 (event code)

Self test failure

◦ 80.03.17 (event code)

Unknown PGP packet

◦ 80.03.18 (event code)

Duplicate I/O channel.

Recommended action

Turn the product off, and then on.

If the error persists, replace the formatter.

81.YY.ZZ EIO-1 Card Failure

Description An EIO error has occurred.

◦ 81.01.80 (event code)

No heartbeat

◦ 81.01.81 (event code)

Reclaim timeout

◦ 81.01.82 (event code)

Invalid data length

◦ 81.01.8B (event code)

Invalid max outstanding

◦ 81.01.8C (event code)

Invalid channel mapping

◦ 81.03.01 (event code)

No PGP buffers

◦ 81.03.02 (event code)

Channel table full

◦ 81.03.03 (event code)

Producer index not reset

◦ 81.03.04 (event code)

Consumer index not reset

◦ 81.03.05 (event code)

Queue position size

◦ 81.03.06 (event code)

Transport overflow

◦ 81.03.07 (event code)

No overflow packets

◦ 81.03.08 (event code)

Invalid identify response

◦ 81.03.09 (event code)

Invalid channel map return

◦ 81.03.10 (event code)

Invalid reclaim return status

◦ 81.03.12 (event code)

Datagram invalid buffer

◦ 81.03.13 (event code)

Max stream channels

◦ 81.03.14 (event code)

Max datagram channels

◦ 81.03.15 (event code)

Card reset failed

◦ 81.03.16 (event code)

Self test failure

◦ 81.03.17 (event code)

Unknown PGP packet

◦ 81.03.18 (event code)

Duplicate I/O channel

Recommended action

Turn the product off, and then on.

If the error persists, replace the EIO device..

82.73.46 OR 82.73.47

Description A hard disk or compact flash disk cleaning failed. Usually caused by a failure of the disk hardware.

Recommended action

- Turn the product off, and then on.

- Use the Clean Disk item in the Preboot menu.

- Reload the firmware.

98.00.01 Corrupt data in firmware volume

Description

Data corruption has occurred in the firmware volume

Recommended action

Turn the product off, and then on.

Use the Clean Disk item in the Preboot menu.

Reload the firmware.

98.00.02 Corrupt data in solutions volume

Description Data corruption has occurred in the solutions volume

Recommended action Turn the product off, and then on. Use the Clean Disk item in the Preboot menu. Reload the firmware.

98.00.03 Corrupt data in configuration volume

Description

Data corruption has occurred in the configuration volume

Recommended action Turn the product off, and then on.

Use the Clean Disk item in the Preboot menu.

Reload the firmware.

98.00.04 Corrupt data in job data volume

Description Data corruption has occurred in the job data volume

Recommended action Turn the product off, and then on. Rerun the file erase function.

99.00.01 Upgrade not performed file is corrupt

Description A remote firmware upgrade (RFU) was not performed. CRC error in the firmware image (bad image).

Recommended action Download the RFU file and attempt the upgrade again.

99.00.02 Upgrade not performed timeout during receive

Description A remote firmware upgrade (RFU) was not performed. I/O timeout when reading header number and size. Indicates a problem with the network environment, not the device.

Recommended action The most common cause is an issue with the network environment. Make sure that there is a good connection to the device and attempt the upgrade again, or upgrade using the USB walk-up port.

99.00.03 Upgrade not performed error writing to disk

Description A remote firmware upgrade (RFU) was not performed.

Disk error. May indicate a problem or a hard disk failure. It might be necessary to check the connection to the hard disk or replace the hard disk.

Recommended action

- Download the RFU file and attempt the upgrade again.

- If the error persists, perform the Clean Disk process. You will then need to download firmware

from the Preboot menu.

- If the error persists, replace the hard disk.

99.00.04 Upgrade not performed timeout during receive

Description A remote firmware upgrade (RFU) was not performed. I/O timeout when reading rest of header.

Recommended action The most common cause is an issue with the network environment. Make sure that there is a good connection to the device and attempt the upgrade again, or upgrade using the USB walk-up port.

99.00.05 Upgrade not performed timeout during receive

Description A remote firmware upgrade (RFU) was not performed.

I/O timeout when reading image data.

Recommended action The most common cause is an issue with the network environment. Make sure that there is a good connection to the device and attempt the upgrade again, or upgrade using the USB walk-up port.

99.00.06 Upgrade not performed error reading upgrade

Description A remote firmware upgrade (RFU) was not performed.

Unexpected read error when reading header number and size.

Recommended action Download the RFU file and attempt the upgrade again.

- If the error persists, replace the hard disk.

99.00.07 Upgrade not performed error reading upgrade

Description A remote firmware upgrade (RFU) was not performed. Unexpected read error when reading rest of header.

Recommended action

- Download the RFU file and attempt the upgrade again.

- If the error persists, replace the hard disk.