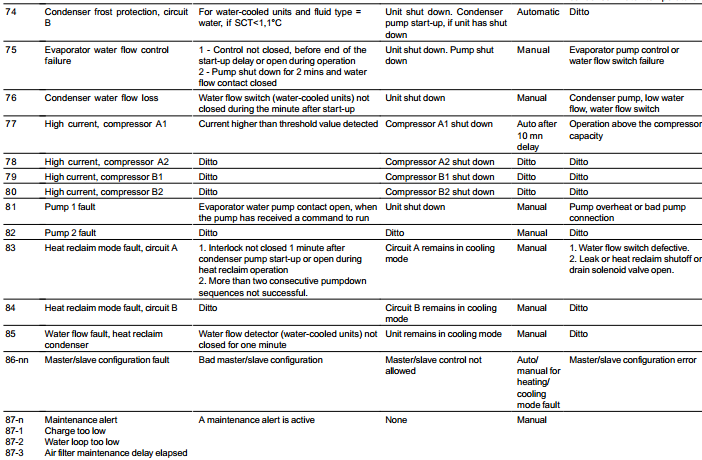

ALARM CODE DESCRIPTIONS (continued)

ALARM NAME

ALARM

CODE

30

Low refrigerant pressure failure,

circuit A

31

Low refrigerant pressure failure,

circuit B

32

High pressure failure, circuit A

33

High pressure failure, circuit B

34

Reverse compressor rotation,

circuit A

35

Reverse compressor rotation,

circuit B

36

Water heat exchanger frost

protection

37

Repeated low evaporator

suction temperature unloading,

circuit A

38

Repeated low evaporator suction

temperature unloading, circuit B

39

Repeated high pressure

unloading, circuit A

40

Repeated high pressure

unloading, circuit B

41

Repeated high discharge

temperature unloading in

heating mode, circuit A

42

Repeated high discharge

temperature unloading in

heating mode, circuit B

43

Repeated low suction

temperature unloading in

heating mode, circuit A

44

Repeated low suction

temperature unloading in

heating mode, circuit B

45

Low heat exchanger entering

water temperature in heating

mode

46

Safety interlock open

47

Pump #1 fault

48

Pump #2 fault

49

CCN emergency stop

50

Loss of communication with

System Manager

51

Communication failure with the

master or the slave unit

52

Initial factory configuration

required

53

Illegal factory configuration

54

Master/slave configuration error

Maintenance alerts

55-2

Water loop flow rate too low

55-4

Maintenance delay, pump 1,

elapsed

55-5

Maintenance delay, pump 2,

elapsed

55-6

Maintenance delay, water filter,

elapsed

Order No. 13444-76, 06.2005. Supersedes order No.: 13429-76, 06.2004.

Manufacturer reserves the right to change any product specification without notice.

ALARM DESCRIPTION

Circuit running and the suction pressure

below threshold

As above

Circuit running and the discharge pressure

exceeds the high pressure trip point

As above

One circuit compressor runs in reverse

rotation

As above

The heat exchanger entering or leaving

water sensor is below the frost trip point

More than 6 successive circuit capacity

unloads because of low suction temperature

override.

As above

More than 6 successive circuit capacity

unloads because of high pressure override.

As above

More than 8 successive circuit capacity

unloads because of high discharge

temperature

As above

More than 8 successive circuit capacity

unloads because of low suction temperature

As above

Heat exchanger temperature is too low (less

than 10°C), preventing unit start-up

Safety interlock not closed before end of the

start-up delay or opens during operation

Evap. water pump run contact opens while

the pump has received a command to be on

As above

CCN command received to shutdown the

unit

The unit is controlled by a System Manager

and communication with this module is lost

for more than 2 minutes

The master/slave link is broken due to a

loss of communication between the two

units for more than 2 minutes

All factory parameters are zero

Wrong factory configuration

Wrong master/slave configuration

A maintenance alert is active

ACTION TAKEN BY

RESET TYPE

THE CONTROL

Circuit shut down

Automatic when pressure returns to

normal and if the same fault has not

occurred the same day (machine

equipped with CCN/clock board, If not,

manual)

As above

As above

Circuit shut down

Manual, the high pressure switch must

be reset manually with the push-button

located on or in the pressure switch

As above

As above

As above

As above

As above

As above

Unit shut down

Automatic if the same alarm has not

tripped the same day (machine equipped

with CCN/clock board, If not, manual)

Circuit shut down

Manual

As above

As above

None

Automatic

As above

As above

As above

As above

As above

As above

As above

As above

As above

As above

Unit shut down

As above

Unit prevented to start

Manual

or shut down

Unit shut down

Manual

Unit shut down

Manual

Unit shut down

Manual

Unit returns to

Automatic when communication is re-

autonomous operating

established

mode

As above

As above

Unit prevented to start

Automatic

As above

Automatic

Master/slave control

Automatic

disabled

None

Manual

PROBABLE CAUSE

Shortage of refrigerant, filter blocked or

faulty pressure sensor

As above

Fan circuit fault, high condenser

entering air temperature

As above

Incorrect compressor wiring

As above

Low water flow or defective thermistor

Faulty pressure sensor, clogged filter or

low refrigerant charge

As above

Faulty transducer, high condenser

entering air temperature, high entering

water temperature, condenser fouled

fan flow rate too low.

As above

Pressure sensor faulty or heat

exchanger fouled

As above

Pressure sensor faulty, filter obstructed,

shortage of refrigerant, heat exchanger

fouled or fan faulty.

As above

As above

Evaporator pump control or water flow

switch failure

Pump overheat, incorrect pump

connection

As above

Network command

Defective CCN bus wiring or system

module failure

As above

No factory configuration

Factory configuration error

Master or slave configuration error

Manufactured by: Carrier s.a., Montluel, France.

Printed in the Netherlands on chlorine-free paper.

35

ALARM

CODE

1

2

3

5

6

7

9

10

11

12

13

14

15

16

17

18

21

22

23

24

ALARM NAME

Compressor A1 failure

Compressor A2 failure

Compressor A3 failure

Compressor B1 failure

Compressor B2 failure

Compressor B3 failure

Heat exchanger leaving fluid

thermistor failure

Heat exchanger entering fluid

thermistor failure

CHWS fluid thermistor failure

(master/slave)

Defrost sensor fault, circuit A

Defrost sensor fault, circuit B

OAT sensor failure

Discharge pressure transducer

failure, Circuit A

Discharge pressure transducer

failure, Circuit B

Suction pressure transducer

failure, Circuit A

Suction pressure transducer

failure, Circuit B

CCN/clock board failure

Loss of communication with

slave board

Loss of communication with

compressor slave board

Loss of communication with PD-

4 x DO slave board

ALARM DESCRIPTION

Motor safety input has opened due to

compressor overtemperature protection.

As above

As above

As above

As above

As above

Thermistor outside range

As above

As above

As above

As above

As above

Voltage delivered by the sensor is incorrect

Value read by the sensor is outside range

Voltage delivered by the sensor is incorrect

Value read by the sensor is outside range

The clock board is no longer detected

Communication has been lost with the slave

board (circuit B control)

Communication has been lost with the

compressor A3 + B3 control board

Communication has been lost with the

electric heating stage control board

ACTION TAKEN BY

THE CONTROL

Compressor is shut

down

As above

As above

As above

As above

As above

Unit shut down

As above

As above

Circuit shut down, if unit

is in heating mode

As above

As above

Circuit A shut down

Circuit B shut down

Circuit A shut down

Circuit B shut down

Unit shut down

Circuit B shut down

Compressors A3 + B3

shut down

Electric heating stages

shut down

RESET TYPE

Manual

As above

As above

As above

As above

As above

Automatic, if temp. measured by sensor

returns to permitted range of values

As above

As above

As above

As above

As above

Automatic if the voltage delivered by the

sensor returns to normal

As above

As above

As above

Automatic if board is detected again

Automatic if communication is re-

established

As above

As above

PROBABLE CAUSE

Compressor overheat

As above

As above

As above

As above

As above

Faulty thermistor, wiring error or

disconnection

As above

As above

As above

As above

As above

Defective transducer, wiring fault

As above

As above

As above

Defective CCN/clock board

Bus wiring fault, wrong software in slave

board or defective slave board

As above

As above

ALARM CODE DESCRIPTIONS

6 — DIAGNOSTICS — TROUBLESHOOTING

6.1 — General

The PRO-DIALOG control system has many fault tracing aid

functions. The local interface and its various menus give access

to all unit operating conditions. The test function makes it

possible to run a quick test of all devices on the unit. If an

operating fault is detected, an alarm is activated and an alarm

code is stored in the Alarm menu.

6.2 — Displaying alarms

The alarm LEDs on the summary interface (see section 4.1)

give a quick display of the status of each circuit and the unit as

a whole.

—

A flashing LED shows that the circuit is operating but

there is an alarm.

—

A steady LED shows that the circuit has been shut down

due to a fault.

The Alarm menu on the main interface displays up to 5 fault

codes that are active on the unit.

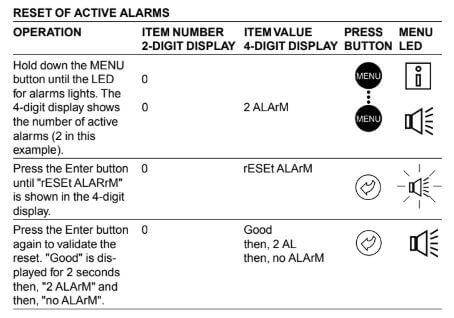

6.3 — Resetting alarms

When the cause of the alarm has been corrected the alarm can

be reset, depending on the type, either automatically on return

to normal, or manually when action has been taken on the unit.

Alarms can be reset even if the unit is running.

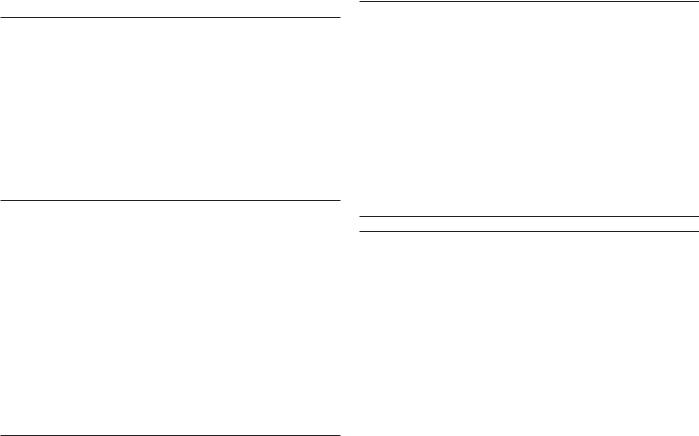

RESET OF ACTIVE ALARMS

OPERATION

ITEM NUMBER

ITEM VALUE

PRESS

MENU

2-DIGIT DISPLAY 4-DIGIT DISPLAY BUTTON LED

Hold down the MENU

button until the LED for

alarms lights. The 4-

digit display shows the

number of active

alarms (2 in this

example).

Press the Enter button

until «rESEt ALARrM» is

shown in the 4-digit

display.

Press the Enter button

again to validate the

reset. «Good» is

displayed for 2 seconds

then, «2 ALArM» and

then, «no ALArM».

0

0

2 ALArM

0

rESEt ALArM

0

Good

then, 2 AL

then, no ALArM

This means that an alarm can be reset without stopping the

machine. In the event of a power supply interrupt, the unit

restarts automatically without the need for an external com-

mand. However, any faults active when the supply is inter-

rupted are saved and may in certain cases prevent a circuit or a

unit from restarting.

A manual reset must be run from the main interface using the

following procedure:

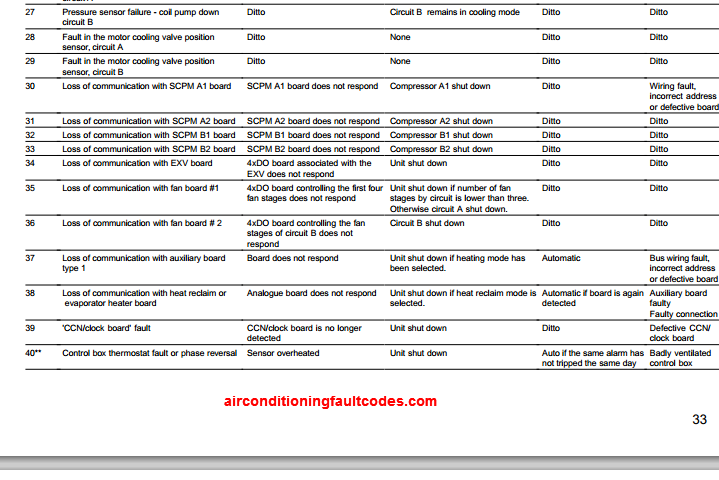

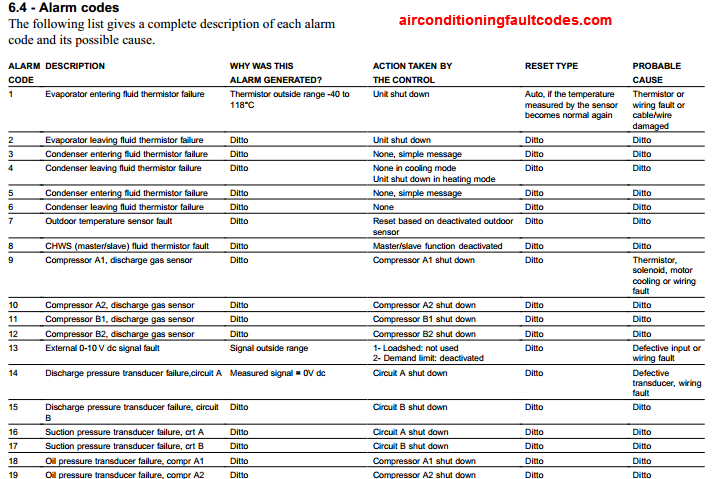

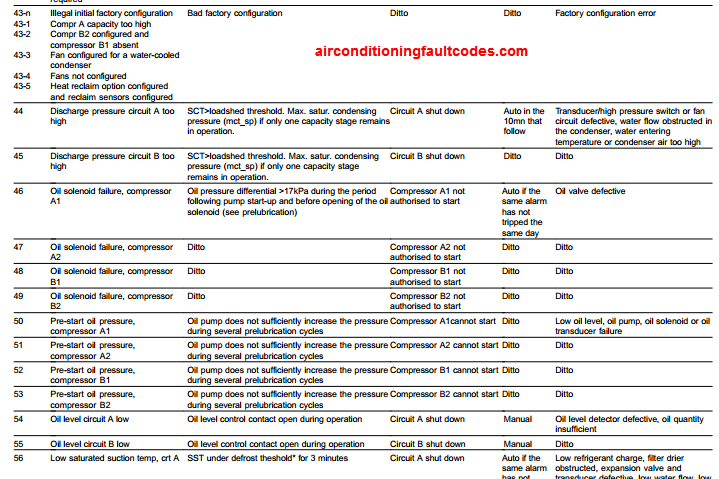

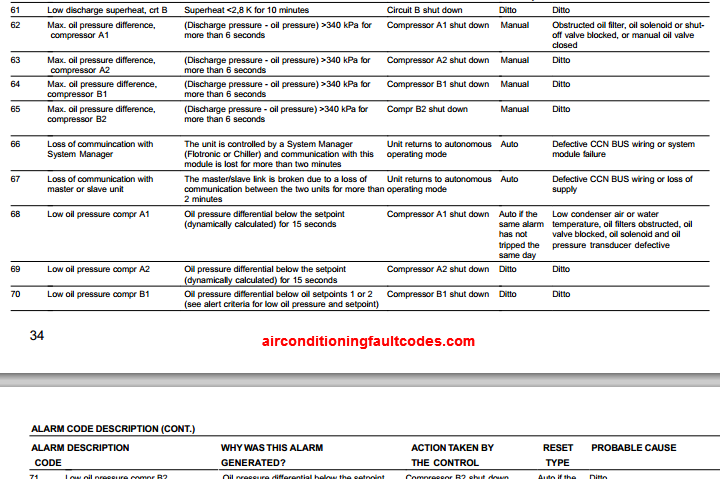

6.4 — Alarm codes

The following list gives a complete description of each alarm code and its possible cause.

Carrier is one of the oldest multinational corporations in the world, established in 1915 the company was one of the few that manufactured every single appliance part on its own. Building systems that lasted decades the company was solely focused on putting out appliances that make a name for themselves. Over the past decades, the company has gained a lot of achievements making them one of the few that have created a solid standing around the world.

Settled in more than 106 countries, Carrier is now available in six continents. Offering a wide range of appliances while keeping its main focus on its original air conditioning and heating system. These include air conditioning and heating solutions for residential and commercial buildings. One of the most promising appliances the company offers is its chillers which ensure smooth workings in various conditions.

When facing an error code we suggest you grab a pen and paper to note down the code rather than pressing various buttons on your Carrier Chiller. This way you will not risk damaging your appliance any further and will be able to find out the exact issue using the common error code list for Carrier Chiller error codes listed below. Once you nail down the issue you can easily call in a professional, or fix the issue yourself.

Alarm Codes

The following list gives a complete description of each alarm code and its possible cause.

| Alarm Codes | Description |

|---|---|

| 1 | Evaporator entering fluid thermistor failure |

| 2 | Evaporator leaving fluid thermistor failure |

| 3 | Condenser entering fluid thermistor failure |

| 4 | Condenser leaving fluid thermistor failure |

| 5 | Condenser entering fluid thermistor failure |

| 6 | Condenser leaving fluid thermistor failure |

| 7 | Outdoor temperature sensor fault |

| 8 | CHWS (master/slave) fluid thermistor fault |

| 9 | Compressor A1, discharge gas sensor |

| 10 | Compressor A2, discharge gas sensor |

| 11 | Compressor B1, discharge gas sensor |

| 12 | Compressor B2, discharge gas sensor |

| 13 | External 0-10 V dc signal fault |

| 14 | Discharge pressure transducer failure,circuit A |

| 15 | Discharge pressure transducer failure, circuit B |

| 16 | Suction pressure transducer failure, crt A |

| 17 | Suction pressure transducer failure, crt B |

| 18 | Oil pressure transducer failure, compr A1 |

| 19 | Oil pressure transducer failure, compr A2 |

| 20 | Oil pressure transducer failure, compr B1 |

| 21 | Oil pressure transducer failure, compr B2 |

| 22 | Economizer A1 transducer failure |

| 23 | Economizer A2 transducer failure |

| 24 | Economizer B1 transducer failure |

| 25 | Economizer B2 transducer failure |

| 26 | Pressure sensor failure — coil pump down circuit A |

| 27 | Pressure sensor failure — coil pump down circuit B |

| 28 | Fault in the motor cooling valve position sensor, circuit A |

| 29 | Fault in the motor cooling valve position sensor, circuit B |

| 30 | Loss of communication with SCPM A1 board |

| 31 | Loss of communication with SCPM A2 board |

| 32 | Loss of communication with SCPM B1 board |

| 33 | Loss of communication with SCPM B2 board |

| 34 | Loss of communication with EXV board |

| 35 | Loss of communication with fan board #1 |

| 36 | Loss of communication with fan board # 2 |

| 37 | Loss of communication with auxiliary board type 1 |

| 38 | Loss of communication with heat reclaim or evaporator heater board |

| 39 | ‘CCN/clock board’ fault |

| 40 | Control box thermostat fault or phase reversal |

| 41 | Unit emergency stop |

| 42 | Initial factory configuration required |

| 43-n | Illegal initial factory configuration |

| 43-1 | Compr A capacity too high |

| 43-2 | Compr B2 configured and compressor B1 absent |

| 43-3 | Fan configured for a water-cooled condenser |

| 43-4 | Fans not configured |

| 43-5 | Heat reclaim option configured and reclaim sensors configured |

| 44 | Discharge pressure circuit A too high |

| 45 | Discharge pressure circuit B too high |

| 46 | Oil solenoid failure, compressor A1 |

| 47 | Oil solenoid failure, compressor A2 |

| 48 | Oil solenoid failure, compressor B1 |

| 49 | Oil solenoid failure, compressor B2 |

| 50 | Pre-start oil pressure, compressor A1 |

| 51 | Pre-start oil pressure, compressor A2 |

| 52 | Pre-start oil pressure, compressor B1 |

| 53 | Pre-start oil pressure, compressor B2 |

| 54 | Oil level circuit A low |

| 55 | Oil level circuit B low |

| 56 | Low saturated suction temp, crt A |

| 57 | Low saturated suction temp, circuit B |

| 58 | High saturated suction temp, circuit A |

| 59 | High saturated suction temp, crt B |

| 60 | Low discharge superheat, circuit A |

| 61 | Low discharge superheat, crt B |

| 62 | Max. oil pressure difference, compressor A1 |

| 63 | Max. oil pressure difference, compressor A2 |

| 64 | Max. oil pressure difference, compressor B1 |

| 65 | Max. oil pressure difference, compressor B2 |

| 66 | Loss of commuincation with System Manager |

| 67 | Loss of communication with master or slave unit |

| 68 | Low oil pressure compr A1 |

| 69 | Low oil pressure compr A2 |

| 70 | Low oil pressure compr B1 |

| 71 | Low oil pressure compr B2 |

| 72 | Evaporator frost protection |

| 73 | Condenser frost protection, circuit A |

| 74 | Condenser frost protection, circuit B |

| 75 | Evaporator water flow control failure |

| 76 | Condenser water flow loss |

| 77 | High current, compressor A1 |

| 78 | High current, compressor A2 |

| 79 | High current, compressor B1 |

| 80 | High current, compressor B2 |

| 81 | Pump 1 fault |

| 82 | Pump 2 fault |

| 83 | Heat reclaim mode fault, circuit A |

| 84 | Heat reclaim mode fault, circuit B |

| 85 | Water flow fault, heat reclaim condenser |

| 86-nn | Master/slave configuration fault |

| 87-n | Maintenance alert |

| 87-1 | Charge too low |

| 87-2 | Water loop too low |

| 87-3 | Air filter maintenance delay elapsed |

| 87-4 | Pump 1 maintenance delay elapsed |

| 87-5 | Pump 2 maintenance delay elapsed |

| 87-6 | Water filter maintenance delay elapsed |

- 30GX and 30HXC series

- PRO-DIALOG Control

- Screw-Compressor Air- and

- Water-Cooled Liquid Chillers

- 50 Hz

The PRO-DIALOG Plus control system has many fault tracing aid functions. The local interface and its various menus give access to all unit operating conditions. The test function makes it possible to run a quick test of all devices on the unit. If an operating fault is detected, an alarm is activated and an alarm code is stored in the Alarm menu.

Diagnostics and Troubleshooting

Resetting Alarm Codes

When the cause of the alarm has been corrected the alarm can be reset, depending on the type, either automatically on return to normal, or manually when action has been taken on the unit. Alarms can be reset even if the unit is running. This means that an alarm can be reset without stopping the machine. In the event of a power supply interrupt, the unit restarts automatically without the need for an external com- mand. However, any faults active when the supply is inter- rupted are saved and may in certain cases prevent a circuit or a unit from restarting. A manual reset must be run from the main interface using the following procedure:

Reset of Active Alarms

Manuals Pdf

Carrier Chiller Manual Pdf

Carrier Chiller Alarm Codes Pdf

Air-cooled screw chillers 30xa installation, operation and maintenance manual pdf

Carrier AC Error Codes

- Author

- Recent Posts

Regarding error and fault codes, we believe sharing knowledge is the best way to help everyone. That is why we established ACErrorCode.com, to give you every bit of info you need as a customer. HVAC Expert Contact: dannyreese@acerrorcode.com Call: 916-954-2677

*If you can’t find the code you’re looking for on our site, please let us know, and we’ll update our database as soon as possible.

30RA/RH “B” 30RY/RYH “B”

PRO-DIALOG Control

AQUASNAP

Operation and maintenance instructions

|

TABLE OF CONTENTS |

||

|

1 — SAFETY CONSIDERATIONS……………………………………………………………………………………………………………………………….. |

4 |

|

|

1.1 |

— General …………………………………………………………………………………………………………………………………………………………… |

4 |

|

1.2 |

— Avoid electrocution ………………………………………………………………………………………………………………………………………….. |

4 |

|

2 — GENERAL DESCRIPTION …………………………………………………………………………………………………………………………………… |

4 |

|

|

2.1 |

— General …………………………………………………………………………………………………………………………………………………………… |

4 |

|

2.2 |

— Abbreviations used …………………………………………………………………………………………………………………………………………… |

4 |

|

3 — HARDWARE DESCRIPTION ……………………………………………………………………………………………………………………………….. |

5 |

|

|

3.1 |

— General …………………………………………………………………………………………………………………………………………………………… |

5 |

|

3.2 |

— Electrical supply to boards ………………………………………………………………………………………………………………………………… |

5 |

|

3.3 |

— Light emitting diodes on boards …………………………………………………………………………………………………………………………. |

5 |

|

3.4 |

— The sensors ……………………………………………………………………………………………………………………………………………………… |

5 |

|

3.5 |

— The output controls …………………………………………………………………………………………………………………………………………… |

5 |

|

3.6 |

— Connections at the user’s terminal block ……………………………………………………………………………………………………………… |

6 |

|

3.6.1 — General description …………………………………………………………………………………………………………………………………… |

6 |

|

|

3.6.2 — Volt-free contact on/off/cooling/heating without multiplexing ………………………………………………………………………. |

8 |

|

|

3.6.3 — Volt-free contact on/off/cooling/heating with multiplexing……………………………………………………………………………. |

8 |

|

|

3.6.4 — Demand limit or setpoint volt-free contact for single-circuit units ………………………………………………………………….. |

8 |

|

|

3.6.5 — Demand limit volt-free contact for dual-circuit units …………………………………………………………………………………….. |

8 |

|

|

3.6.6 — Water setpoint selection volt-free contact with multiplexing for dual-circuit units ……………………………………………. |

8 |

|

|

4 — SETTING UP PRO-DIALOG CONTROL ……………………………………………………………………………………………………………… |

9 |

|

|

4.1 |

— Local interface general features ………………………………………………………………………………………………………………………….. |

9 |

|

4.2 |

— Unit start/stop control ……………………………………………………………………………………………………………………………………… |

10 |

|

4.2.1 — Description …………………………………………………………………………………………………………………………………………….. |

10 |

|

|

4.2.2 — Stopping the unit in local mode ………………………………………………………………………………………………………………… |

10 |

|

|

4.2.3 — Starting unit and selecting an operating type ………………………………………………………………………………………………. |

10 |

|

|

4.3 |

— Menus …………………………………………………………………………………………………………………………………………………………… |

11 |

|

4.3.1 — Selecting a menu …………………………………………………………………………………………………………………………………….. |

11 |

|

|

4.3.2 — Selecting a menu item ……………………………………………………………………………………………………………………………… |

11 |

|

|

4.3.3 — Modifying the value of a parameter/access to a sub-menu ……………………………………………………………………………. |

11 |

|

|

4.3.4 — Expand display ……………………………………………………………………………………………………………………………………….. |

12 |

|

|

4.3.5 — Description of the Information menu …………………………………………………………………………………………………………. |

15 |

|

|

4.3.6 — Description of the Temperatures menu ………………………………………………………………………………………………………. |

17 |

|

|

4.3.7 — Description of the Pressures menu…………………………………………………………………………………………………………….. |

17 |

|

|

4.3.8 — Description of the Setpoints menu …………………………………………………………………………………………………………….. |

17 |

|

|

4.3.9 — Description of the Inputs menu …………………………………………………………………………………………………………………. |

18 |

|

|

4.3.10 — Description of the Outputs/Tests menu ……………………………………………………………………………………………………. |

19 |

|

|

4.3.11 — Description of the configuration menu …………………………………………………………………………………………………….. |

22 |

|

|

4.3.12 — Description of the Alarms menu ……………………………………………………………………………………………………………… |

28 |

|

|

4.3.13 — Description of the Alarms History menu ………………………………………………………………………………………………….. |

28 |

|

|

4.3.14 — Runtime menu description ……………………………………………………………………………………………………………………… |

28 |

2

|

5 — PRO-DIALOG CONTROL OPERATION ……………………………………………………………………………………………………………. |

29 |

||

|

5.1 |

— Start/stop control ……………………………………………………………………………………………………………………………………………. |

29 |

|

|

5.2 |

— Heating/cooling operation ……………………………………………………………………………………………………………………………….. |

30 |

|

|

5.2.1 — General ………………………………………………………………………………………………………………………………………………….. |

30 |

||

|

5.2.2 — Heating/cooling selection ………………………………………………………………………………………………………………………… |

30 |

||

|

5.3 |

— Evaporator water pump control ………………………………………………………………………………………………………………………… |

31 |

|

|

5.4 |

— Control interlock contact …………………………………………………………………………………………………………………………………. |

31 |

|

|

5.5 |

— Evaporator heater control ………………………………………………………………………………………………………………………………… |

31 |

|

|

5.6 |

— Control point ………………………………………………………………………………………………………………………………………………….. |

31 |

|

|

5.6.1 — Active setpoint ……………………………………………………………………………………………………………………………………….. |

31 |

||

|

5.6.2 — Reset……………………………………………………………………………………………………………………………………………………… |

33 |

||

|

5.7 |

— Demand limit …………………………………………………………………………………………………………………………………………………. |

33 |

|

|

5.8 |

— Night mode ……………………………………………………………………………………………………………………………………………………. |

33 |

|

|

5.9 |

— Capacity control ……………………………………………………………………………………………………………………………………………… |

33 |

|

|

5.10 |

— Head pressure control ……………………………………………………………………………………………………………………………………. |

33 |

|

|

5.11 |

— Defrost function ……………………………………………………………………………………………………………………………………………. |

34 |

|

|

5.12 |

— Additional electric heater stage control ……………………………………………………………………………………………………………. |

34 |

|

|

5.13 |

— Control of a boiler ………………………………………………………………………………………………………………………………………… |

34 |

|

|

5.14 |

— Master/slave assembly …………………………………………………………………………………………………………………………………… |

34 |

|

|

5.15 |

— Controlling Pro-Dialog units with a System Manager ……………………………………………………………………………………….. |

34 |

|

6 — DIAGNOSTICS — TROUBLESHOOTING ……………………………………………………………………………………………………………. |

35 |

|

|

6.1 |

— General …………………………………………………………………………………………………………………………………………………………. |

35 |

|

6.2 |

— Displaying alarms …………………………………………………………………………………………………………………………………………… |

35 |

|

6.3 |

— Resetting alarms …………………………………………………………………………………………………………………………………………….. |

35 |

|

6.4 |

— Alarm codes …………………………………………………………………………………………………………………………………………………… |

35 |

GENERAL LEGEND

Each of the following drawings is replaced in the whole document by the corresponding explanation:

Start/stop button

DELTA T. Example: temperature difference between entering and leaving heat exchanger temperatures

means character is flashing

The cover graphics are solely for illustration and forms no part of any offer for sale or any sale contract. The manufacturer reserves the right to change the design at any time without notice.

3

1 — SAFETY CONSIDERATIONS

1.1 — General

Installation, start-up and servicing of equipment can be hazardous if certain factors particular to the installation are not considered: operating pressures, presence of electrical components and voltages and the installation site (elevated plinths and built-up up structures). Only properly qualified installation engineers and highly qualified installers and technicians, fully trained for the product, are authorised to install and start-up the equipment safely. During all servicing operations all instructions and recommendations which appear in the installation and service instructions for the product, as well as on tags and labels fixed to the equipment and components and accompanying parts supplied separately, must be read, understood and followed.

•Apply all standard safety codes and practices.

•Wear safety glasses and gloves.

•Use the proper tools to move heavy objects. Move units carefully and set them down gently.

1.2 — Avoid electrocution

Only personnel qualified in accordance with IEC (International Electrotechnical Commission) recommendations may be permitted access to electrical components. It is particularly recommended that all sources of electricity to the unit be shut off before any work is begun. Shut off the main power supply at the main circuit breaker or isolator.

IMPORTANT: This equipment uses and emits electromagnetic signals. Tests have shown that the equipment conforms to all applicable codes with respect to electromagnetic compatibility.

RISK OF ELECTROCUTION: Even when the main circuit breaker or isolator is switched off, certain circuits may still be energised, since they may be connected to a separate power source.

RISK OF BURNS: Electrical currents cause components to get hot either temporarily or permanently. Handle power cable, electrical cables and conduits, terminal box covers and motor frames with great care.

Fanstart-up:

ATTENTION: In accordance with the operating conditions the fans can be cleaned periodically. A fan can start at any time, even if the unit has been shut down.

2 — GENERAL DESCRIPTION

2.1 — General

Pro-Dialog is a system for controlling single or dual-circuit 30RA/RY air-cooled liquid chillers or air-to-water 30RH/RYH heat pumps. Pro-Dialog controls compressor start-up needed to maintain the desired heat exchanger entering or leaving water temperature. In cooling mode it controls the operation of the fans to maintain the correct condensing pressure in each circuit. For heat pump units it controls and optimises the defrost cycles of each circuit in order to minimize the heating capacity reduction. Safety devices are constantly monitored by ProDialog to ensure their safe operation. Pro-Dialog also gives access to a Quick Test program covering all inputs and outputs.

All PRO-DIALOG controls can work in accordance with three independent modes:

•Local mode: the machine is controlled by commands from the user interface.

•Remote mode: the machine is controlled by remote contacts (volt-free contacts).

•CCN mode: the machine is controlled by commands from the Carrier Comfort Network (CCN). In this case, a data communication cable is used to connect the unit to the CCN communication bus.

The operating mode must be chosen with the Start/Stop button described in section 4.2.1. When the PRO-DIALOG system operates autonomously (Local or Remote mode) it retains all of its own control capabilities but does not offer any of the features of the CCN network.

2.2 — Abbreviations used

In this manual, the refrigeration circuits are called circuit A and circuit B. The compressors in circuit A are labelled A1, A2 and A3. Those in circuit B are B1, B2 and B3.

The following abbreviations are used frequently:

|

CCN |

: Carrier Comfort Network |

|

CCn |

: Operating type: CCN |

|

LED |

: Light Emitting Diode |

|

LOFF : Operating type: Local Off |

|

|

L-On |

: Operating type: Local On mode |

|

L-Sc |

: Operating type: Local On following a time schedule |

MASt : Operating type: master unit (master/slave assembly)

|

rEM |

: Operating type: by remote contacts |

|

SCT |

: Saturated Condensing Temperature |

|

SIO |

: Sensor Bus (internal communication bus linking the |

|

basic board to the slave boards) |

|

|

SST |

: Saturated Suction Temperature |

|

TXV |

: Thermal Expansion Valve |

4

3 — HARDWARE DESCRIPTION

3.1 — General

Figure 1

|

4 |

||

|

1 |

||

|

2 |

3 |

|

|

9 |

||

|

3 |

||

|

10 |

||

|

7 |

5 |

|

|

8 |

||

|

6 |

Legend

1CCN connector

2Red LED, status of the board

3Green LED, communication bus SIO

4Orange LED, communication bus CCN

5Remote master board customer control connection contacts

6Remote slave board customer control connection contacts

7Master board customer connection relay outputs

8Slave board customer connection relay outputs

9Master NRCP basic board

10Slave NRCP basic board

The control system consists of an NRCP-BASE board for single-circuit units and two NRCP-BASE boards (a master and a slave board) for dual-circuit units. Heat pump units equipped with optional additional heater stages use an additional board, type PD-AUX. All boards communicate via an internal SIO bus. The NRCP-BASE boards continuously manage the information received from the various pressure and temperature probes. The NRCP-BASE master board incorporates the program that controls the unit.

The user interface consists of two display blocks with up to 26 LEDs and 16 buttons (according to unit type). It is connected to the main basic board and gives access to a full array of control parameters.

3.2 — Electrical supply to boards

All boards, except the PD-RCPM board, are supplied from a common 24 V a.c. supply referred to earth.

CAUTION: Maintain the correct polarity when connecting the power supply to the boards, otherwise the boards may be damaged.

In the event of a power supply interrupt, the unit restarts automatically without the need for an external command. However, any faults active when the supply is interrupted are saved and may in certain cases prevent a circuit or unit from restarting.

3.3 — Light emitting diodes on boards

All boards continuously check and indicate the proper operation of their electronic circuits. A light emitting diode (LED) lights on each board when it is operating properly.

•The red LED flashing for a 2 second period on the NRCPBASE board indicates correct operation. A different rate indicates a board or a software failure.

•On dual-circuit units or units equipped with optional board, the green LED flashes continuously on all boards to show that the board is communicating correctly over its internal bus. If the LED is not flashing, this indicates a SIO bus wiring problem.

•The orange LED of the master board flashes during any communication via the CCN bus.

3.4 — The sensors

Pressure sensors

Two types of electronic sensors are used to measure the suction and discharge pressure in each circuit.

Thermistors

The evaporator water sensors are installed in the entering and leaving side. The outdoor temperature sensor is mounted below the control box. An optional water system temperature sensor can be used for master/slave assembly control (in the case of leaving water control).

In heat pump units a sensor placed on an air heat exchanger pipe ensures defrost operation.

5

3.5 — The controls

Evaporator pumps

The controller can regulate one or two evaporator pumps and takes care of automatic change-over between pumps.

Evaporator heater

It protects the evaporator (and the pipe heater for units without pump) against freezing if the unit is off.

Boiler

This relay output authorises start/stop of a boiler.

Condensate defrost heater

This heater is used for heat pump units and is located at the bottom of the air heat exchanger of each circuit. It prevents ice build-up, if defrost cycles are initiated at low outdoor temperatures.

3.6 — Connections at the user’s terminal block

3.6.1 — General description

The contacts below are available at the user’s terminal block on the NRCP-BASE board (see figure 1). Some of them can only be used if the unit operates in remote operating type (rEM).

The following table summarises the connections at the user’s terminal block.

SINGLE-CIRCUIT UNITS

|

Description |

Connector/channel |

Terminal |

Board |

Remarks |

Remarks |

|

|

Alarm relay output |

J3 / CH24 |

30 — 31 |

NRCP-BASE |

Indicates alarms |

Volt-free contact 24 V a.c. |

|

|

Boiler relay output |

J3 / CH25 |

37 — 38 |

NRCP-BASE |

Boiler start/stop control output. |

48 V d.c. max, 20 V a.c. or |

|

|

V d.c., 3 A max, 80 mA min, |

||||||

|

See section 5.13. |

||||||

|

external power supply. |

||||||

|

Connector: 4 pin |

||||||

|

WAGO 734-104 pitch 3.5. |

||||||

|

One per board needed. |

||||||

|

Contact 1: |

J4 / CH8 |

32 — 33 |

NRCP-BASE |

The contacts are used for unit start/stop and |

24 V a.c., 20 mA |

|

|

start/stop/heat/cool |

heat/cool control. They are only taken into |

|||||

|

account if the unit is under remote operation |

Connector: 8 pin WAGO |

|||||

|

control (rEM). |

||||||

|

Contact 2: |

J4 / CH9 |

63 — 64 |

NRCP-BASE |

734-168, pitch 3.5 |

||

|

start/stop/heat/cool |

||||||

|

See the description of these contacts in |

||||||

|

sections 3.6.2 and 3.6.3. |

||||||

|

Contact 3: |

J4 / CH10 |

73 — 74 |

NRCP-BASE |

Depending on the configuration, this dry |

||

|

demand limit selection or |

contact can be used for remote setpoint |

|||||

|

setpoint selection |

selection or demand limit selection (see |

|||||

|

sections 4.3.11.3 and 3.6.4). |

||||||

|

— The remote setpoint selection contact is |

||||||

|

only taken into account if the unit is in |

||||||

|

remote control operating type. |

||||||

|

— The remote demand limit selection contact |

||||||

|

is active whatever the operating type of the |

||||||

|

unit. |

||||||

|

User safety loop input |

J4 / CH11a |

34 — 35 |

NRCP-BASE |

This contact is mounted in series with the |

||

|

water flow control contact. It can be used for |

||||||

|

any customer safety loop that requires that |

||||||

|

the unit is stopped, if it is open. |

||||||

|

If it is unused this contact must be bridged. |

||||||

|

Connection to CCN |

J12 |

1 — 2 — 3 |

NRCP-BASE |

An RS-485 bus is used for connection to the |

Connector: 3 pin WAGO |

|

|

CCN. |

231-303, pitch 5.08 |

|||||

|

— Pin 1: signal + |

— Pin 2: ground — Pin 3: signal —

6

DUAL-CIRCUIT UNITS

|

Description |

Connector/channel |

Terminal |

Board |

Remarks |

Remarks |

|

Alarm relay output |

J3 / CH24 |

30A — 31A |

Master NRCP- |

Indicates alarms/alerts for circuit A* |

|

circuit A |

BASE |

|||

|

Alarm relay output |

J3 / CH24 |

30B — 31B |

Slave NRCP- |

Indicates alarms/alerts for circuit B* |

|

circuit B |

BASE |

|||

|

Boiler relay output |

J3 / CH25 |

37 — 38 |

Master NRCP- |

Boiler start/stop control output. |

|

BASE |

See section 5.13. |

Volt-free contact 24 V a.c. 48 V d.c. max, 20 V a.c. or V d.c., 3 A max, 80 mA min, external power supply.

Connector: 4 pin

WAGO 734-104 pitch 3.5. One per board needed.

|

Contact 1: |

J4 / CH8 |

32 — 33 |

Master NRCP- |

The contacts are used for unit start/stop and |

|

start/stop/heat/cool |

BASE |

heat/cool control. They are only taken into |

||

|

account if the unit is under remote operation |

||||

|

Contact 2: |

J4 / CH9 |

63 — 64 |

Master NRCP- |

control (rEM). |

|

start/stop/heat/cool |

BASE |

|||

|

See the description of these contacts in |

||||

|

sections 3.6.2 and 3.6.3. |

24 V a.c., 20 mA

Connector: 8 pin WAGO 734-168, pitch 3.5

|

Contact 3: |

J4 / CH10 |

73 — 74 |

Master NRCP- |

These dry contacts are used for demand |

|

demand limit selection |

BASE |

limit selection. See description of these |

||

|

contacts in section 3.6.5. |

||||

|

Contact 4: |

J4 / CH10 |

75 — 76 |

Slave |

The remote demand limit selection contact is |

|

demand limit selection |

NRCP-BASE |

active whatever the operating type of the |

||

|

unit. |

||||

|

Contact 5: |

J4 / CH8 |

65 — 66 |

Slave |

These dry contacts are used for setpoint |

|

setpoint selection |

NRCP-BASE |

selection. |

||

|

They are only taken into account if the unit is |

||||

|

in remote control operating type (rEM). |

||||

|

Control contact 6: |

J4 / CH9 |

67 — 68 |

Slave |

See the description of these contacts in |

|

setpoint selection |

NRCP-BASE |

sections 3.6.6. |

||

|

User safety loop input |

J4 / CH11a |

34 — 35 |

Master |

This contact is mounted in series with the |

|

NRCP-BASE |

water flow control contact. It can be used for |

|||

|

any customer safety loop that requires that |

||||

|

the unit is stopped, if it is open. |

||||

|

If it is unused this contact must be bridged. |

|

Connection to CCN |

J12 |

1 — 2 — 3 |

Master |

An RS-485 bus is used for connection to the |

|

NRCP-BASE |

CCN. |

|||

|

— Pin 1: signal + |

— Pin 2: ground — Pin 3: signal —

Connector: 3 pin WAGO 231-303, pitch 5.08

*The operation of these relays can vary depending on the user configuration. See section ‘Description of the User 2 configuration sub-menu’.

7

3.6.2 — Volt-free contact on/off/cooling/heating without multiplexing

If the automatic heating/cooling changeover function is not selected (see sections 4.3.11.3, 5.1 and 5.2) the operation of contacts 1 and 2 is as follows:

|

OFF |

ON cooling |

ON heating |

|

|

Contact 1 |

Open |

Closed |

Closed |

|

Contact 2 |

— |

Open |

Closed |

Contact status not significant

3.6.3 — Volt-free contact on/off/cooling/heating with multiplexing

If the automatic heating/cooling changeover function is selected (see sections 4.3.11.3, 5.1 and 5.2) the operation of contacts 1 and 2 is multiplexed:

|

OFF |

ON cooling |

ON heating |

ON auto |

|

|

Contact 1 |

Open |

Closed |

Closed |

Open |

|

Contact 2 |

Open |

Open |

Closed |

Closed |

NOTE: The automatic changeover function (ON auto) selects the cooling or heating mode based on the outdoor temperature (see section 5.2).

3.6.4 — Demand limit or setpoint volt-free contact for singlecircuit units

On single-circuit units contact 3 determines the selection of demand limit or setpoint, based on the configuration (see User Configuration 1 menu).

|

Demand limit selection |

Setpoint selection |

||

|

100% |

Limit 1 |

Setpoint 1 |

Setpoint 2 |

|

(no limit) |

|||

|

Contact 3 Open |

Closed |

Open |

Closed |

3.6.5 — Demand limit volt-free contact for dual-circuit units

On dual-circuit units the operation of the demand limit selection contacts is multiplexed. The demand limit setpoints are adjustable in the setpoint menu (see section 4.3.8).

|

100% |

Limit 1 |

Limit 2 |

Limit 3 |

|

|

(no limit) |

||||

|

Contact 3 |

Open |

Closed |

Open |

Closed |

|

Contact 4 |

Open |

Open |

Closed |

Closed |

3.6.6 — Water setpoint selection volt-free contact with multiplexing for dual-circuit units

On dual-circuit units the operation of the cold water or hot water setpoint selection contacts is multiplexed. The set-points are adjustable in the setpoint menu (see section 4.3.8). Auto means that the active setpoint is determined by the setpoint schedule (see section 5.6.1).

Cooling mode

|

Setpoint 1 |

Setpoint 2 |

Setpoint 3 |

Auto |

|

|

Contact 5 |

Open |

Open |

Closed |

Closed |

|

Contact 6 |

Open |

Closed |

Open |

Closed |

|

Heating mode |

||||

|

Setpoint 1 |

Setpoint 2 |

Setpoint 3 |

Auto |

|

|

Contact 5 |

Open |

Open |

Closed |

Closed |

|

Contact 6 |

Open |

Closed |

Open |

Closed |

8

4 — SETTING UP PRO-DIALOG CONTROL

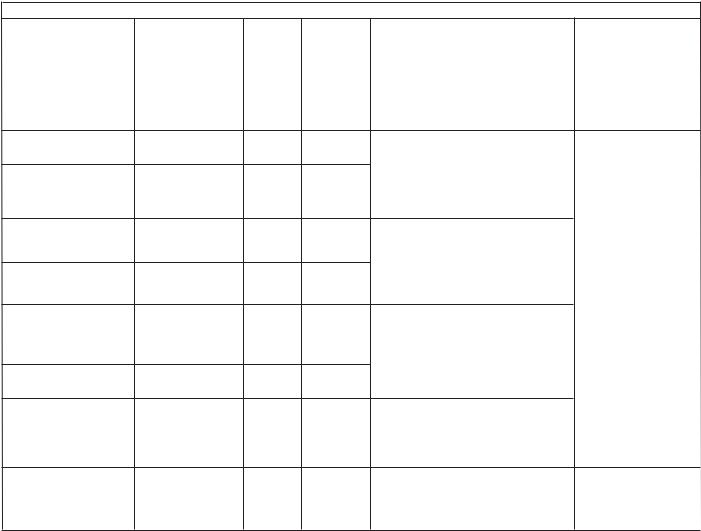

4.1 — Local interface general features

|

MAIN INTERFACE |

SUMMARY INTERFACE |

||||||||

|

MENU BLOCK |

PRO-DIALOG PLUS INTERFACE |

PRO-DIALOG JUNIOR INTERFACE |

The local interface enables a number of operating parameters to be displayed and modified.

The interface consists of two distinct parts: the main interface (left-hand section) and the summary interface (right-hand section).

Main interface

It gives access to all PRO-DIALOG data and operating functions. It consists of:

•A two-digit display showing the number of the item selected.

•A four-digit display showing the contents of the item selected.

•LEDs and buttons for unit start/stop, menu selection, menu item selection and value adjustment.

PRO-DIALOG Junior interface: On some units the local user interface consists only of a simplified main interface (left-hand section) that is identical to the main interface described below, but does not include the menu block diodes.

MAIN INTERFACE

|

BUTTON |

NAME |

DESCRIPTION |

||

|

Menu |

Permits the selection of a main menu. Each main menu is represented by an icon. The icon is lit if active. |

|||

|

Up arrow |

Permits scrolling through the menu items (in the two-digit display). If the modification mode is active this button authorises |

|||

|

increase of the value of any parameter. |

||||

|

Down arrow |

Permits scrolling through the menu items (in the two-digit display). If the modification mode is active this button authorises |

|||

|

decrease of the value of any parameter. |

||||

|

Enter |

Gives access to the modification mode, validates a modification or displays expanded item description. |

|||

|

Start/stop |

Authorises start or stop of the chiller in local mode or modification of its operating type. |

|||

|

MAIN INTERFACE MENU LED’S |

||||

|

LED* |

NAME |

DESCRIPTION |

INTERFACE DISLAY |

|

|

INFORMATION menu |

Displays the general operating parameters for the unit. |

Information |

||

|

TEMPERATURES menu |

Displays the unit operating temperatures. |

Temperatures |

||

|

kPa |

PRESSURES menu |

Displays the unit operating pressures. |

Pressures |

|

|

SETPOINTS menu |

Displays the unit setpoints and enables them to be modified. |

Setpoints |

||

|

INPUTS menu |

Displays the status of the unit digital and analogue inputs. |

Inputs |

||

|

OUTPUTS/TESTS menu |

Displays the status of the unit outputs and enables them to be tested. |

Outputs |

||

|

CONFIGURATIONS menu |

Displays the unit configuration and enables it to be modified. |

Confguration |

||

|

ALARMS menu |

Displays active alarms. |

Alarms |

||

|

ALARMS HISTORY menu |

Displays the history of the alarms. |

History |

||

|

RUNTIMES menu |

Displays the operating times and number of starts for the unit and the |

Runtimes |

||

|

compressors. |

* Not available on the PRO-DIALOG Junior interface.

9

The summary interface (right hand section) includes a mimic diagram of the unit, together with push-buttons and LEDs. It gives quick access to the main operating parameters of the unit.

SUMMARY INTERFACE LEDs*

LED INDICATION WHEN LIT

Green LED:

The unit is authorised to start or is already running

Red LED:

— Lit: circuit A or unit shut down by alarm

— Flashing: circuit A or unit running with alarm present

Red LED:

— Lit: circuit B or unit shut down by alarm

— Flashing: circuit B or unit running with alarm present

Red LED:

Water flow switch default or user safety lock open.

Green LED:

The evaporator pump is running.

Yellow LEDs:

From top to bottom — start/stop status of compressor A1, A2 and A3 or B1, B2 and B3. Flashing LED indicates that the circuit is in the protection or defrost mode (A or B).

Green LED:

The unit operates in heating mode.

Green LED:

The unit operates in cooling mode.

* Not available on the PRO-DIALOG Junior interface.

SUMMARY INTERFACE PUSH BUTTONS*

BUTTON DISPLAY

Blue button: evaporator leaving or entering water temperature in °C Gray button: outdoor air temperature in °C

Control point (setpoint + reset) in °C

Press 1: circuit A/B discharge pressure in kPa

Press 2: circuit A/B saturated condensing temperature in °C

Press 1: circuit A/B suction pressure in kPa

Press 2: circuit A/B saturated suction temperature in °C

Press 1: compressor A1/B1 operating hours in h/10 or h/100

Press 2: compressor A2/B2 operating hours in h/10 or h/100

Press 3: compressor A3/B3 operating hours in h/10 or h/100

* Not available on the PRO-DIALOG Junior interface.

4.2 — Unit start/stop control

4.2.1 — Description

The unit start/stop can be controlled by one of the following methods:

•Locally on the actual unit (Local control type)

•By remote control with the aid of user contacts (remote control type)

•By CCN control with the aid of the CCN (CCN control type)

The main interface includes a Start/Stop button which can be used to stop or start the unit in the local operating type or to select the remote or CCN operating type.

The available operating types are described in the following table.

The following operating types can be selected using the Start/Stop button:

OPERATING TYPES

|

4 DIGIT DISPLAY |

DESCRIPTION |

|

LOFF |

Local Off. The unit is halted in local mode. |

|

L-On |

Local On. The unit is in local control mode and is |

|

authorised to start. |

|

|

L-Sc* |

Local On — timer control. The unit is in local control |

|

mode. It is authorised to start if the period is occupied. |

|

|

If the timer program for unit operation is unoccupied, |

|

|

the unit remains shut down until the period becomes |

|

|

occupied. |

|

|

CCN* |

CCN. The unit is controlled by CCN commands. |

|

rEM* |

Remote. The unit is controlled by remote control |

|

contacts. |

|

|

MAST* |

Master Unit. The unit runs as a master in a two unit |

|

lead/lag arrangement. This is displayed if the unit is |

|

|

configured for master/slave control. |

Legend

*Displayed if the configuration requires it.

Section 5.1 gives a more detailed description of the commands to start/stop the unit, analysed by operating type.

4.2.2 — Stopping the unit in local mode

The unit can be stopped in local mode at any time by pressing the Start/Stop button.

TO STOP THE UNIT

|

BUTTON ACTION |

2-DIGIT DISPLAY |

4-DIGIT DISPLAY |

|

Press the Start/Stop |

C |

LOFF |

|

button for less than |

||

|

4 seconds (one short |

||

|

press is enough). |

||

|

If the button is |

t |

LOFF |

|

released, the unit stops |

||

|

without the need for |

||

|

further action. |

4.2.3 — Starting unit and selecting an operating type

The unit can be started in local mode, or unit operating type can be changed at any time using the Start/Stop button. In the example that follows, the unit is stopped (LOFF) and the user wants to start the unit in local mode.

START UP WITH THE PREVIOUSLY USED OPERATING TYPE WHEN THE UNIT IS STOPPED IN LOCAL MODE (LOFF)

|

BUTTON ACTION |

2-DIGIT |

4-DIGIT |

|

DISPLAY |

DISPLAY |

|

|

The unit is in local stop mode. The |

LOFF |

|

|

previously used operating type is local on |

||

|

(L-ON) |

||

|

Press the Start/Stop button for 4 seconds |

L-On |

|

|

(one short press-down is sufficient). L-ON |

||

|

illuminates immediately. «C» flashes in the |

||

|

2-digit display to show that the controller is |

||

|

awaiting confirmation. |

||

|

Press the Enter button to confirm the |

t |

L-On |

|

operating type. «t» is displayed in the 2-digit |

||

|

display to indicate the operating type |

||

|

selected. If the Enter button is not pressed |

||

|

soon enough, the controller will cancel the |

||

|

change and remain in the stop mode. |

10

CHANGING THE OPERATING TYPE

|

BUTTON ACTION |

2-DIGIT |

4-DIGIT |

||

|

DISPLAY |

DISPLAY |

|||

|

Continually press the operating type |

C |

LOFF |

||

|

selection button for more than 4 seconds. |

||||

|

Hold down the Start/Stop button. |

L-On |

|||

|

The available operating types are displayed |

L-Sc |

|||

|

one by one until the button is released. |

||||

|

rEM |

||||

|

Release the Start/Stop button if the |

L-On |

|||

|

operating type you want is displayed (in this |

||||

|

example L-On). «C» flashes in the 2-digit |

||||

|

display to show that the controller is |

||||

|

awaiting confirmation. |

||||

|

Press the Enter button to confirm the |

t |

L-On |

||

|

operating type selected (in this example: |

||||

|

L-On). «t» is displayed in the 2-digit display |

||||

|

to indicate the operating type selected. If the |

||||

|

Enter button is not pressed soon enough, |

||||

|

the controller will cancel the change and |

||||

|

continue to use the previous operating type. |

4.3 — Menus

4.3.1 — Selecting a menu

The MENU button authorises you to select a menu from the 10 main menus that are available. Each time you press this button one of the 10 LEDs lights up in turn alongside each of the icons representing a main menu. The active menu is the one against which the LED is lit. If a menu is empty then its LED is not lit. To scroll quickly through the menus, hold the MENU button down.

4.3.2 — Selecting a menu item

The up and down Arrow buttons let you scroll through the menu items. Menu item numbers are displayed in the two-digit display. The item number increases or decreases every time you press the up or down Arrow button. The menu items that are not in use or incompatible with the configuration are not displayed. The value or status associated with the active item is displayed in the four-digit display. To scroll quickly through the items, hold the up or down Arrow button down.

The following example shows how to access item 3 in the Pressures menu.

SELECTING A MENU ITEM

|

OPERATION |

PRESS |

MENU LED ITEM NUMBER |

|

BUTTON |

2-DIGIT |

|

|

DISPLAY |

||

|

Press the MENU button until the |

0 |

|

LED marked PRESSURE lights. |

|

|

Note: On the PRO-DIALOG Junior |

kPa |

|

interface the menu LEDs are not |

|

|

available. Instead, each time the |

|

|

menu button is pressed, the name |

|

|

of the active menu is dsplayed in |

|

|

the 4-digit display. In this example, |

|

|

press the MENU button until |

|

|

PRESSURE is displayed in the |

|

|

4-digit display. |

|

|

Press one of the Arrow buttons |

1 |

|

until the two-digit display shows 3 |

kPa |

|

(item number 3). |

|

|

2 |

|

|

3 |

4.3.3 — Modifying the value of a parameter/access to a submenu

Press the Enter button for more than 2 seconds to enter the modification mode or to select a sub-menu. This lets you correct the value of an item or select a sub-menu with the aid of the up and down Arrow buttons (if you are authorised to overwrite the item concerned). When modification mode is activated, the LED for the main menu to which the item belongs as well as the 2- digit display flash in the menu block. Once the required value is obtained, press the Enter button again to validate the change or to access the sub-menu. The LED for the menu to which the item and the 2-digit display belong then stops flashing, indicating that modification mode no longer applies.

In modification mode, the value to be modified increases or decreases in steps of 0.1 every time you press the Arrow buttons. Holding one of these buttons down increases the rate of increase or decrease.

NOTE: The access to a sub-menu may require entering a password. This is automatically requested. See section 4.3.11.2.

The following example shows how to modify the value of item 1 in the Setpoint menu.

11

Коды неисправностей Carrier Transicold.

Таблица отображает все возможные аварийные коды для всех возможных исполнений микропроцессоров.

Разным микропроцессорным контроллерам и версиям программного обеспечения присущи не все перечисленные аварийные коды неисправностей.

| Код | Сообщение | Состояние |

| AL0 | ENG.OIL | Давление масла в дизеле < 1 бар |

| AL1 | ENG.HOT | Температура двигателя > 110°C |

| AL2 | HI.PRESS | Высокое давление нагнетания |

| AL3 | STARTFAIL | Три неудачных запуска установки в режиме “Старт\Стоп” |

| AL4 | LOW.BATT | Напряжение АКБ ниже 10В |

| AL5 | HI.BATT | Напряжение АКБ больше 17В |

| AL6 | DEFRFAIL | Отмена оттаивания > 45 мин. |

| AL7 | ALT.AUX | Отказ генератора |

| AL8 | STARTER | Отказ стартера |

| AL9 | RA.SENSOR | Отказ датчика температуры RAS |

| AL10 | SA.SENSOR | Отказ датчика температуры SAS |

| AL11 | WT.SENSOR | Отказ датчика температуры двигателя |

| AL12 | HIGH CDT | Высокая температура нагнетания компрессора |

| AL13 | CD.SENSOR | Не используется |

| AL14 | SBY.MOTOR | Перегрузка электромотора |

| AL15 | FUSE BAD | Сгорел предохранитель |

| AL17 | DISPLAY | Отказ дисплея или повреждение шины между дисплеем и процессором |

| AL18 | SERVICE 1 | Необходимо сервисное обслуживание №1 |

| AL19 | SERVICE 2 | Необходимо сервисное обслуживание №2 |

| AL20 | RAS OUT | Температура в кузове “вне допуска” |

| Код | Неисправность |

| 00 | Нет аварийных сигналов. |

| 01 | Произошло отключение питания микропроцессора. На работе установки не отразится, отразится только на информации регистратора температуры.Восстановить питание и стереть код. |

| 02 | Отказ цепи или датчика температуры испарителя. Только для TG-VI и SR. Установка будет управляться датчиком нагнетаемого воздуха. |

| 03 | Отказ цепи или датчика температуры возвратного воздуха. Установка будет контролироваться датчиком нагнетаемого воздуха. |

| 04 | Отказ цепи или датчика температуры нагнетаемого воздуха (при его наличии). Установка будет контролироваться датчиком возвратного воздуха. |

| 05 | Отказ цепи или датчика температуры окружающей среды (только для SR). Установка будет работать с пониженной производительностью. |

| 06 | Отказ цепи или датчика температуры охлаждающей жидкости дизеля. Установка будет работать с пониженной производительностью. |

| 07 | Отказ цепи или датчика оборотов дизеля. Установка будет работать с пониженной производительностью. |

| 08 | Отказ цепи или датчиков температуры возвратного и нагнетаемого воздуха. Рефрижератор будет контролироваться датчиком температуры испарителя (только для TG-VI и SR). |

| 09 | Высокая температура испарителя. Рефрижератор работать не будет. |

| 10 | Высокое давление нагнетания или датчик высокого давления. Рефрижератор работать не будет. |

| 11 | Установка контролируется по дополнительному датчику. Информационный сигнал, относится к кодам 03 и 04. |

| 12 | Неисправность датчиков температуры испарителя. Рефрижератор работать не будет. |

| 13 | Нарушение калибровки датчиков температуры (несоответствие показаний температуры на дисплее и температуры в полуприцепе). Контролируйте температуру в полуприцепе через вентиляционный лючок отдельным термометром. |

| 14 | Завершение оттайки не по температуре, а по времени. Сотрите код, если он повторится снова, требуется ремонт режима оттайки. |

| 15 | Проверить свечи накаливания дизеля. |

| 16 | Не произведён ручной запуск дизеля. В течении 5-ти минут дизель не был запущен вручную (тумблер был в положении “ON”). Сотрите код и запустите дизель. |

| 17 | Двигатель не запускается в режиме Автостарт. Сотрите код, попробуйте запустить двигатель в ручном режиме “Continuous”. |

| 18 | Высокая температура охлаждающей жидкости дизеля. Проконтролируйте натяжение ремня помпы и уровень охлаждающей жидкости. Рефрижератор работать не будет, пока не остынет. |

| 19 | Низкое давление масла дизеля (TG-V – прерывание цепи по высокому давлению). Проконтролируйте уровень масла в дизеле, добавьте масло, если необходимо. |

| 20 | Двигатель не запустился в режиме Автостарт. Проконтролируйте уровень топлива, прокачайте дизельное топливо. |

| 21 | Проверить цикл охлаждения. |

| 22 | Проверить цикл нагрева. |

| 23 | Авария цикла охлаждения. Рефрижератор работать не будет до устранения поломки. |

| 24 | Авария цикла нагрева. Рефрижератор работать не будет до устранения поломки. |

| 25 | Проверить генератор или цепь зарядки. Проверьте натяжение ремня генератора. В 95 случаях из 100, неисправен генератор. Рефрижератор работать не будет до устранения поломки. |

| 26 | Проверить мощность охлаждения. Контроль производительности холодильной системы. Следите за температурой в полуприцепе. |

| 28 | Прервана предрейсовая проверка. Предрейсовый контроль был прерван, проверьте другие коды. Сотрите коды. |

| 29 | Неисправность электроцепи или редуктора воздушной заслонки испарителя. Установка не сможет оттаивать, следите за температурой в полуприцепе, возможно попадание теплого воздуха в грузовой отсек. |

| 30 | Воздушная заслонка испарителя заклинена (закрыта). Рефрижератор работать не будет до устранения поломки. |

| 31 | Неисправность датчика давления масла дизеля или давления масла. Рефрижератор работать не будет до устранения поломки. |

| 32 | Низкая производительность холодильной системы. Рефрижератор работать не будет до устранения поломки. |

| 33 | Проверить обороты дизеля. |

| 34 | Неисправность электроцепи модуляции. Проверьте выключатель или предохранитель, следите за температурой в полуприцепе. |

| 35 | Неисправность электрической цепи главного реле работы. Проверьте предохранитель на плате реле. |

| 36 | Неисправность в работе стояночного электропривода. Порван ремень электродвигателя. Рефрижератор работать не будет до устранения поломки. |

| 37 | Проверить уровень охлаждающей жидкости дизеля. |

| 38 | Несоответствие электрических фаз стояночного электропривода. Не включается стояночный электропривод. Переподключите стояночное питание. |

| 39 | Неисправность термостата дизеля. Установка будет работать с пониженным обогревом, следите за температурой в полуприцепе. |

| 40 | Неисправность цепи или соленоида высоких оборотов дизеля. Контролируйте работу установки на высоких оборотах дизеля. |

| 41 | Неверная температура охлаждающей жидкости дизеля. Проконтролируйте натяжение ремней и уровень охлаждающей жидкости. |

| 42 | Временное состояние перегрева. Агрегат будет работать только на малых оборотах дизеля. |

| 43 | Временное состояние перегрева. Агрегат будет работать только на малых оборотах дизеля. |

| 44 | Топливная система. Проконтролируйте уровень топлива в баке, добавьте если необходимо дизтопливо, сотрите код, повторите запуск дизеля. |

| 45 | Неисправность электрической цепи клапана горячих паров. Рефрижератор будет работать с уменьшенной точностью поддержания температуры. |

| 46 | Препятствие воздушному потоку внутри полуприцепа. Проверьте положение груза, заслонку и чистоту испарителя. |

| 47 | Датчик дополнительного испарителя (для мультитемпературных рефрижераторов). |

| 48 | Ремни, муфта сцепления и частота вращения ротора генератора. В большинстве случаев – неисправность генератора. Рефрижератор работать не будет до устранения поломки. |

| 49 | Неисправность цепей или датчиков температуры электронного регистратора температуры. Влияет только на регистратор температуры. |

| 50 | Сбой таймера системы регистратора температуры. Касается только информации регистратора температуры. Сотрите код, установите дату и время. |

| 51 | Неисправность цепи защитного отключения. |

| 52 | Неисправность электрической цепи режима обогрева. Может отсутствовать тепло. |

| 53 | Неисправность электрической цепи или клапана экономии топлива. Рефрижератор будет работать с пониженной производительностью на тепло. |

| 54 | Истекло время проведения тестового режима. Время диагностики истекло. Установка работает с пониженной производительностью. |

| 55 | Нарушение оборотов дизеля. Обороты дизеля вышыли за пределы нормы, контролируйте обороты. |

| 56 | Низкая скорость вентилятора испарителя. |

| 57 | Высокая скорость вентилятора испарителя. |

| 58 | Низкая скорость вентилятора конденсатора. |

| 59 | Высокая скорость вентилятора конденсатора. |

| 60 | Повышенное напряжение электрической сети. |

| 61 | Низкое напряжение АКБ. |

| 62 | Показания амперметра не точные. Рефрижератор работать не будет до устранения поломки. |

| 63 | Остановка дизеля, причина не известна. Контролируйте уровень топлива, масла и воздушного фильтра. Попробуйте прокачать топливо ручной помпой. |

| 64 | Напоминание о необходимости предрейсовой проверки. Выполните предрейсовый контроль для стирания кода. |

| 66 | Низкий уровень масла в дизеле. Проверьте уровень масла в двигателе, добавьте сколько необходимо. Рефрижератор работать не будет до устранения поломки. |

| 67 | Цепь соленоида линии хладагента (Pilot). Установка работает с пониженной производительностью. |

| 68 | Неисправность микропроцессора. |

| 69 | Намагничивание электроцепи. |

| 70 | Показания счётчиков мото-часов превышает 99 999. Не оказыват влияние на работу установки. |

| 71 | Счётчик мото-часов № 4 превышает настроенный предел измерений. Сигнал для установки интервала техобслуживания, зависит от выбора заказчика, не сказывается на работе холодильного агрегата. |

| 72 | Счётчик мото-часов № 5 превышает настроенный предел измерений. Сигнал для установки интервала техобслуживания, зависит от выбора заказчика, не сказывается на работе холодильного агрегата. |

| 73 | Счётчик мото-часов № 6 превышает настроенный предел измерений. Сигнал для установки интервала техобслуживания, зависит от выбора заказчика, не сказывается на работе холодильного агрегата. |

| 74 | Микропроцессор возвращен к заводским установкам. Изменились все программируемые настройки, на настройки “по умолчанию”. Рефрижератор работать не будет до устранения поломки. |

| 75 | Внутренний код неисправности микропроцессора. Рефрижератор работать не будет до устранения поломки. |

| 76 | Внутренний код неисправности микропроцессора. Рефрижератор работать не будет до устранения поломки. |

| 77 | Внутренний код неисправности микропроцессора. Рефрижератор работать не будет до устранения поломки. |

| 78 | Внутренний код неисправности микропроцессора. Рефрижератор работать не будет до устранения поломки. |

| 79 | Переполнена память регистратора данных. Не требуется принятия действий. Сотрите код. |

| 80 | Датчик температуры компрессора. |

| 81 | Высокая температура компрессора. |

| 82 | Остановка по высокой температуре компрессора. |

| 83 | Низкая температура охлаждающей жидкости. |

| 84 | Перезапуск невозможен. Проверьте другие коды. |

| 85 | Принудительная работа установки. Временное ненормальное состояние контроля, происходящее от других кодов. |

| 86 | Неверные показания датчика давления нагнетания. Установка работает с уменьшенной производительностью. |

| 87 | Датчик давления всасывания (TG-V – Ошибка прохождения проверки тестером). Установка работает с уменьшенной производительностью. |

| 88 | Авария микропроцессора. |

| 89 | Датчик электронного клапана постоянного давления. Установка работает с уменьшенной производительностью. |

| 93 | Низкое давление всасывания. |

| 94 | Датчик температур нагнетаемого воздуха дополнительного испарителя. |

| 100 | Авария обогревателя испарителя. |

| 102 | ЕСОТ Выход из параметров низкий. |

| 102 | Низкий уровень пропана. |

| 105 | Цепь соленоида давления в ресивере. Установка работает с уменьшенной производительностью на тепло. |

| 106 | Неисправен сбросной клапан конденсатора. Установка работает с уменьшенной производительностью. |

| 107 | Неисправен входной соленоид конденсатора. Установка работает с уменьшенной производительностью. |

| 108 | Неисправность цепи или датчика дверей полуприцепа. Дверь в открытом состоянии была более часа. |

| 109 | Высокое давление нагнетания или неисправен датчик. Не работайте на высоких оборотах дизеля. |

| 110 | Неисправен соленоид всасывающей линии. Установка работает с пониженной производительностью. |

| 111 | Установка некорректно сконфигурирована. Неверные режимы холодильной установки. Режимы микропроцессора неправильно подобраны. |

| 112 | Цепь вентиляторов дополнительных испарителей. Вентилятор не работает в указанном отсеке. |

| 113 | Цепь электрообогрева. |

| 114 | Множественные аварии, запуск невозможен. Проверьте и сотрите коды. |

| 123 | Температура на входе в испаритель. |

| 124 | Температура на выходе из испарителя. |

| 125 | СО Датчик уровня резервуара. |