Страница 1 из 2

-

Проблема в следующем. При охлаждении смеси в холодильном боксе, температура уходит в минус 2 градуса, после чего выскакивает ошибка работы перистальтической помпы ( большая нагрузка). Кто знает как в сервисных настройках поднять температуру на пару градусов , помогите пожалуйста!

Трубка помпы новая! Смесь родная и в правильных пропорциях. -

а контроллер тыкали ? у вас выставляется вязкость ? если по контроллеру все в порядке, то нужно ТРВ регулировать уменьшать фреон. как сам редуктор ? может он туго крутиться ?

вам нужно определить, что нет факторов, нарушающих работу и после лезти в настройки.

минус 2 это мало для фризера , это или не правильно показывает температуру датчик. так как срабатывает ошибка по току. перегрузка. или в редукторе вода.— Добавлено, 30 апр 2020 —

?? это вы о чем ?

Найдите QR-код на машине Carpigiani, и вы сможете быстро и легко получить доступ к любой документации, касающейся вашей модели. -

Это температура смеси в ёмкости такая становится или воздуха в объёме камеры?

-

В объеме камеры. Смесь должна охлаждаться до плюс трех ( на сколько мне известно)

— Добавлено, 5 май 2020 —

Трубка перистальтической помпы. Ее необходимо менять раз в год. За время эксплуатации она теряет эластичность и насос помпы определяет как более густую смесь.

— Добавлено, 5 май 2020, Дата первоначального сообщения: 5 май 2020 —

Спасибо. Гляну QRкод. Надеюсь найду.!!!

— Добавлено, 5 май 2020 —

По приготовлению мороженого фризер работает отлично! Консистенция хорошая и вал вращается нормально.

Еще раз уточняю! Проблемы начинаются после, того как температура в охлаждающей камере ( где емкость со смесью стоит) опускается ниже минус1 градуса. перистальтической помпе тяжело прокачивать смесь и вылетает ошибка. Пока в камере плюсовая температура все работает отлично. -

А что говорит производитель? Какая заводская уставка температуры в объёме должна быть?

И какую смесь используете? Кто производитель?У фризера один компрессор и на заморозку и на охлаждение объёма со смесью.

Последнее редактирование: 6 май 2020

-

я тут зашел в тупик если смесь до +3 то зачем загонять в минус ? смесь во фризере заливают и она ВСЯ должна превратиться в мягкое мороженое. ( или у вас есть какая то камера ?) фризер доводит до нужной консистенции и поддерживает ее . я правда один раз имел дело с фризером. но пришлось разбираться именно с состоянием жидкости , как и контролем .

зачем уводить ее в минус ? там ставиться защита, которая если будет мороженное густое увеличивается ток, и срабатывает защита редуктора. -

Мне нужна температура в обьеме для хранения смеси +2/+3.

Во время работы ( приготовления мороженого) в цилиндре со шнеком достигается минусовая температура и так должно быть чтоб мороженое сделать, а вот в емкости откуда помпа смесь подает в цилиндр минуса не должно быть. Иначе выпадает ошибка большой нагрузки на помпу. Так вот где найти настройки температуры внутри обьема для хранения смеси.???— Добавлено, 9 май 2020 —

Может есть у кого мануал по сервисным настройкам?! Московские сервисники Carpigiani монополисты и никому секретов не выдают….

— Добавлено, 9 май 2020, Дата первоначального сообщения: 9 май 2020 —

Смеси названия не помню, но она была закуплена и замешана правильно.

— Добавлено, 9 май 2020 —

Смесь охлаждается в обьеме для хранения мороженого и подается помпой в рабочий цилиндр. Вот меня интересуют настройки температуры обьема обьема хранения смеси! О остальном фризер работает отлично.

-

Доброго времени суток.

Если говорить о сервисных настройках гистерезисов и инерционностью повидения системы, то эта информации как правило закрыта для , так называемых » шаловливых ручек».

По заголовку Данной темы, мануал для операторов есть в свободном доступе.Последнее редактирование: 9 май 2020

-

Мануал для операторов ограничен по необходимым настройкам как время работы помпы, давление ( ток на эл.двигателе) остановки помпы, температура в обьеме охлаждения смеси…. Там более 50 пунктов настройки. Даже при замене шланга помпы режим настройки помпы проходит 24 минуты.

-

Здравствуйте. Так мануал, как таковой и предназначен для операторов, людей не обученных понимать алгоритмы и последовательность исполнительных механизмов. Вы запрашивайте тех/документацию для изменения одного из параметров в общей отработанной схеме. Это как правило приводит к коррекции и остальных параметров.

-

Здравствуйте! Есть проблема, при работе фризера, в камеру затекает жидкая смесь. В чем может быть причина?

-

Попробуйте, отсоединить помпу , промойте и проверьте соединительные шланги.

-

Всё сделали, промыли. Но проблема осталась. Более того из цилиндра перестало выходить готовое мороженое, а просто льется охлажденная жижа.. Видимо что-то не так с мозгами у фризера.

-

Попробуйте включить фризер не надевая раздаточный узел на цилиндр замораживания и проверить происходит ли понижение температуры, намораживается ли иней в цилиндре, пальцы подлипают от мороза к металлу.

Чтобы фризер в таком режиме заработал, там нужно замкнуть контакты, которые фиксируют, что раздаточный узел установлен. Шнеки вставлять не нужно. -

Спасибо за ответы! Попробуем

-

А на этой фотографии это не помпа воздуха ? которая закачивает воздух что мороженное было пышное воздушное . и из под сальника капает. если не стрелке указано место утечки.

-

Здравия,Форумчане и Спецы !

Здравия, Друзья !

Carpigiani Soft & go,начал «плеваться» (сори)), после выдачи пары нормальных порций.Трубку заменили.А он все так же ведет себя.

Возможна консультация помощь ? -

смотри от чего создается давление. и есть что контролирует давление или просто сапун забит, который воздух травит. Вот вы ходите плюнуть что делаете набираете воздух и..

-

Спасибо,Сергей !

Пробую пошагово. -

Самый простой вопрос. Когда была нажата кнопка пуска приготовления мороженого был ли откручен клапан справа на раздаточном узле.

Его надо открутить и дождаться, когда начнёт из него вытекать жидкая смесь, после этого закрутить.

Возможно, если этого не было сделано, не был выпущен воздух из камеры замораживания. Поэтому и брызгалось при раздаче готового мороженого.

Перистальтическая помпа подаёт в камеру не воздух как у китайских аппаратов, а смесь насыщенную воздухом.

Страница 1 из 2

Поделиться этой страницей

|

File |

Date |

Changes |

|

+ vers. SW |

||

|

mek_5.doc |

06/07/2007 |

— Tables HOT Settings as of for European markets updated |

|

SW: |

Ita-Eng-Fra-Deu |

— “Black” decal K3 also inserted |

|

k3soft23.mot |

— Updating of versions sw 22 |

|

|

k3shake23.mot |

— Daily cones not zeroed in blackout |

|

|

— Blackout stored in Events |

||

|

— Setup sensors: new procedure |

||

|

mek3_6.doc |

27/09/2007 |

— Note: with cards 116 the inductive sensor led does not fully switch off. |

|

SW: |

Ita-Eng-Fra-Deu |

|

|

k3soft23.mot |

||

|

k3shake23.mot |

||

|

Ita-Eng-Fra-Deu |

— solenoid valves position updated. Pages 5 and 66 |

|

|

mek3_7.doc |

18/10/2007 |

|

|

k3soft23.mot |

Ita-Eng-Fra-Deu |

|

|

k3shake23.mot |

||

|

Ita-Eng-Fra-Deu |

— keypad names upgraded |

|

|

mek3_7.doc |

24/10/2007 |

|

|

SW: |

Ita-Eng-Fra-Deu |

03/01/08 : wienerschnitzel becomes GM |

|

k3soft23.mot |

||

|

k3shake23.mot |

||

|

Ita-Eng-Fra-Deu |

Pages: |

|

|

mek3_8.doc |

12/02/2008 |

|

|

SW: |

Ita-Eng-Fra-Deu |

— 42: Step U11 inserted (not used) |

|

k3soft32.mot |

18,80,81 : Pasteurization IMS and autosetup |

|

|

k3shake32.mot |

||

|

Ita-Eng-Fra-Deu |

Pages: |

|

|

mek3_10.doc |

12/05/2008 |

|

|

SW: |

Ita-Eng-Fra-Deu |

— 11,72 : corrections to temperature checks |

|

k3soft32.mot |

||

|

k3shake32.mot |

||

|

Ita-Eng-Fra-Deu |

Pages: |

|

|

mek3_11.doc |

05/06/2008 |

|

|

SW: |

Ita-Eng-Fra-Deu |

— 36, 97 : Timeout Prd and Alarm ICE adjusted. Only stored in the Events and |

|

k3soft32.mot |

immediately restored. |

|

|

k3shake32.mot |

||

|

Ita-Eng-Fra-Deu |

— Cleaning updated, Alarm Belt, T85, MP in pasto break 10”ON/10’OFF, 5 |

|

|

mek3_12.doc |

23/04/2009 |

|

|

SW: |

Ita-Eng-Fra-Deu |

interventions of timeout prd, Programming Table updated M, T46 and |

|

k3soft37.mot |

description, revisions in black-out and alarms inserted. |

|

|

k3shake37.mot |

— 83, 122: Automatic calibration |

|

|

mek3_13.doc |

28/09/2009 |

|

|

SW: |

Ita-Eng-Fra-Deu |

|

|

k3soft37.mot |

||

|

k3shake37.mot |

— 13, 77: TEV and W displayed on the first production page and Lev (ms) |

|

|

mek3_14.doc |

22/01/2010 |

|

|

SW: |

— 32, 95: Pasto inhibited in Wash today |

|

|

k3soft42.mot |

Ita-Eng-Fra-Deu |

— 51: TET offset |

|

k3shake42.mot |

— 46,111: tab prog. |

|

|

— 107, 108: user prog. |

||

|

— 116: delay level |

||

|

mek3_15.doc |

16/03/2012 |

— 44, 45, 47, 109, 110, 113: Russian and modifications to the programming |

|

SW: |

table + corrections |

|

|

k3soft48.mot |

Ita-Eng-Fra- |

— 49, 114: note about trimmer hot |

|

k3shake45.mot |

Deu-Rus |

— 64, 131: correction to reprogramming |

|

— 58-63 and 125-130: corrections |

||

|

— 139: index |

||

|

mek3_16.doc |

17/05/2012 |

— 47, 113: sw version |

|

SW: |

— 45: U12 |

|

|

k3soft49.mot |

Ita-Eng-Fra- |

— 49: corrections |

|

k3shake49.mot |

Deu-Rus |

K 3

“ELECTRONICS HANDBOOK”

This handbook gives information and procedures to assist technicians in setting up and repairing the machine. This is the reason why this handbook is reserved for TECHNICIANS, only.

When turning power on to the machine, it carries out an operating self-test of the display and all leds light up.

The monitor displays a software version and the machine sets back at the function it was in when power was switched off (see BLACKOUT).

ABBREVIATIONS

For the sake of convenience some abbreviations have been included in this manual, namely:

|

EVRC |

Solenoid valve Cylinder Heating |

TEV |

Tank Thermostat |

|

1=shake 2=soft |

1=shake 2=soft |

||

|

EVFC |

Solenoid valve Cylinder Cooling |

TEC |

Cylinder Thermostat |

|

1=shake 2=soft |

1=shake 2=soft |

||

|

EVRV |

Solenoid valve Tank Heating |

TGV |

Tank Ice Thermostat |

|

1=shake 2=soft |

1=shake 2=soft |

||

|

EVFV |

Solenoid valve Tank Cooling |

TE |

Evaporator Thermostat |

|

1=shake 2=soft |

1=shake 2=soft |

||

|

EVRT |

Solenoid valve Topping Heating |

TET |

Topping Thermostat |

|

(soft side, only) |

(soft side, only) |

||

|

MA |

Beater Motor |

MMV |

Tank Mixer Motor |

|

1=shake 2=soft |

(one) |

||

|

MC |

Compressor Motor |

MIR-SF |

Micro Spigot – Photoelectric Sensor |

|

1=shake 2=soft |

|||

|

MP |

Pump Motor |

MV |

Fan Motor |

|

1=shake 2=soft |

1=shake 2=soft |

2

SOFT SIDE

SOFTWARE VERSION

When turning on to the machine, the display indicates the software version. FOR EXAMPLE

|

K3 Soft |

|

|

ver.k3soft23 |

meaning sw version = 23 |

If the machine fails to work, your Technician will always have to specify this number (software version), as well as the machine serial number you will find on the data plate, so as to take the best advantage of Carpigiani Technical Service.

3

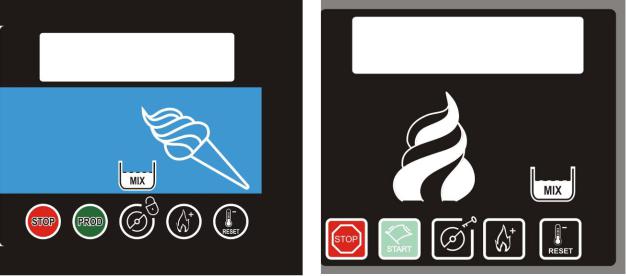

AVAILABLE CONTROLS

|

KA configuration |

General Market configuration |

Note 1

When pressing a key and relevant function is accepted, the machine keyboard block will emit a sound signal (beep).

Note 2

This handbook refers to machine standard configuration. As far as General Market version is concerned, we beg you to make reference to relevant keyboard.

4

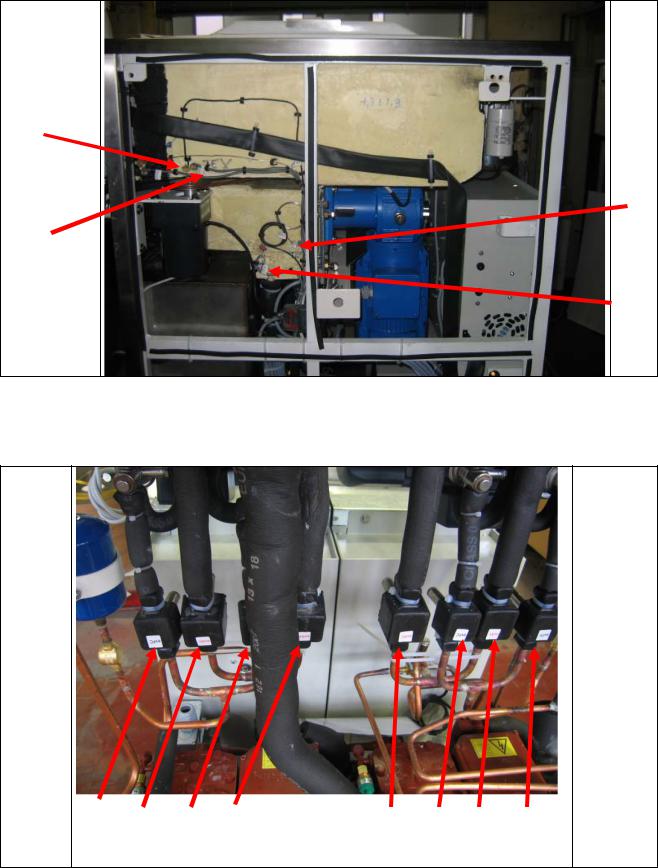

POSITION FOR SENSORS and SUNDAE SOLENOID VALVES

|

TEV2 – TEC2 – TGV2 – TE2 |

|

FRONT |

|

TGV2 |

|

TEC2 |

|

TEV2 |

|

TE2 |

SOLENOID VALVES — front sight

SHAKE

SOFT

|

EVFC1 EVRC1 EVFV1 EVRV1 |

EVRC2 EVFC2 EVRV2 EVFV2 |

5

6

DAYLIGHT TIME

From MARCH 30th to OCTOBER 30th included, daylight time is active.

The machine clock will automatically be moved ahead 1 hour for the daylight savings time change over. This means that when passing from 01:59 a.m. on 30th March to 02:00 a.m. on 30th March, the clock will automatically be moved ahead 1 hour. 1 minute after 01:59 a.m. the display will show 03:00 a.m. (summer time).

Passing from 01:59 a.m. on October 30th to 02:00 a.m. on October 30th, the time will be set back to normal for the end of daylight savings time. One minute after the clock reaches 01:59 a.m. on October 30th it will move back by 1 hour and the time displayed will be 01:00 a.m.

Clock time will then remain this way until next March 30th

Daylight time is only active when the step Ora Legale (Daylightsav Time) is set to Yes.

7

FUNCTIONS

STOP

In this function the machine is OFF and relative led is ON (stop button lights up). From the Stop position any other function may be selected. In order to change a function, IT IS ALWAYS NECESSARY to press the stop button for 2 seconds first. The display shows the following:

|

— ENGLISH — |

— ITALIAN — |

|

|

10:33:21 Fri |

10:33:21 Ven |

|

In order to set the machine at Stop from Production, Pasteurization and Storage, push the stop key and hold it down for 2 seconds. The machine will not recognize the stop command if the button is not held for at least 2 seconds, this helps avoid accidentally hitting the button and stopping the machine.

If the machine is left at Stop with mix above the level sensor, the writing “Why in STOP??” will be displayed flashing and with an intermittent beep after 30’’; it warns the user to set the machine at Production, Pasteurization or Storage.

MA – MP HOUR COUNTER RESET

If you continue to press

In order to reset MA counter, it is not only necessary to press Stop

8

TOTAL AND PARTIAL CONE COUNTER RESET

If you press Stop

Display as follows:

|

— ENGLISH — |

— ITALIAN — |

|

|

Reset Cone Count |

Azzeramento Coni |

|

Cone count is measured in groups of 5.

9

EVENTS

The machine is provided with a large memory that helps us store most of the events (historian).

To read the events stored in memory, you must have the machine in STOP

Press Stop

|

— ENGLISH- |

— ITALIAN — |

|||

|

**READ EVENTS*** |

*LETTURA EVENTI* |

|||

|

Log Number 00014 |

Numero Ev.00014 |

total events |

||

|

Year 2006 |

Anno 2006 |

|||

|

09:00:08 15 Feb |

09:00:08 15 Feb |

|||

|

Stop |

Stop |

The last screen shows the stored event, in this example it shows the STOP button was pressed at 8 seconds after 9 a.m. on Feb. 15th.

Events can then be scrolled with Increment

In order to leave the “Read events” mode, either press the Stop button for 2 seconds or do not touch any key for 30 seconds.

Stored events are Pasteurization steps, alarms, function changes, blackouts.

An Autosetup procedure does not cancel events from memory

10

TEMPERATURE CONTROLS

When the machine is in STOP with the mix in the tank at a low level (low level uncovered), the TEV temperature control is actuated.

If the TEV is greater than 15°C, the display visualises “Pasteurise !”. Therefore, pressing the Production key, the machine passes automatically to the Pasteurisation mode.

This control is not active during the successive 60 seconds after gaining access to the STOP function or during the successive 60 seconds after the spigot head has been closed.

If in all these cases, TEV<15°C, then all functions without any time limits are permitted.

From Stop, a time will be computed if the mix level is covering the level sensor. If down time exceeds 24 hours, the display will be as follows:

|

10:33:21 Fri |

10:33:21 Ven |

||

|

Wash Today !!! |

Lavare oggi !!! |

and Wash procedure must be executed: machine wash is forced and Production inhibited.

Reset conditions are the same as those for Wash (IMSSafety Magnetic Switch opening and reclosing).

11

SOFT ICE PRODUCTION

The access to Production is only enabled if the mix is above the minimum level sensor.

The product is cooled down in the cylinder till Hot programmed in step HOT 1 (see programming table) has been reached.

After the desired consistency has been reached (Hot), the beater goes on running for 3 more seconds (or a time programmed in step Ritardo Agitat.1 — Delay Beater 1) and it will then switch off

If necessary, tank storage will take place, now, provided that TEV2 (tank Thermostat 2) Temp. Conserv. — Storage Temp.

After reaching Hot, if no cone is dispensed, the beater will start every 10 minutes (Timer Ciclico — Cyclic Timer) and will run for 10 seconds, in order to control ice cream consistency: should this be below HOT 1 – Different Hot 1 (Hot 1 Different.), the compressor and relevant solenoid valve EVFC2 (Solenoid Valve Cylinder Cooling) will also start so as to bring ice cream back to the programmed consistency.

If HOT has already been reached and your machine is in stand-by mode of Production, when you dispense a cone, the beater motor will restart and run for 15 seconds to control the consistency.

During ice cream distribution, when mix in the tank is below the minimum level sensor, the display will show the message Aggiungere Mix — Add Mix , and only allow you to distribute the number of cones set in step Ultimi Coni — Last Cones.

MP runs for 6’’ (programmable in step T41) every 10’ (fix).

12

Once in Production mode, display shows the following:

|

— ENGLISH- |

— ITALIAN — |

|

|

Sundae Ready ! |

Gelato Pronto ! |

|

|

TEV +19°C W -14 |

TEV +19°C W -14 |

The first line on top refers to ice cream ready for distribution (Gelato Pronto ! — Sundae Ready !) or not yet at right consistency (Non Estrarre ! — Do not Serve !).

The display Non Estrarre ! — Do not Serve ! means that ice cream has not yet reached HOT

set in step Blocco Hot 1 — Hot Block 1 and you must thus wait. For further details, see paragraph DO NOT SERVE.

The second line refers to the number of days to next wash. The example above shows that there are still 14 days to wash day.

The second line concerns the TEV temperature, followed by the days (W=Wash) until the next wash.

By pressing Production, you move to the different “windows” or screens described below:

|

Key |

— ENGLISH — |

— ITALIAN — |

Notes |

|

|

Hopper +014°C |

Vasca +014°C |

TEV2 |

||

|

Cylinder +013°C |

Cilindro +013°C |

TEC2 |

||

In this window, the first line (on top) displays the hopper temperature:

= ON, when the hopper is cooled +014°C=sundae hopper temperature (TEV2)

The second line displays the cylinder temperature:

= ON, when the cylinder is cooled +013°C=sundae cylinder temperature (TEC2)

|

Set=100 Hot=085 |

Set=100 Hot=085 |

In this window, the first line (top) displays:

Set=100: Set HOT SOFT HOT=085: soft cylinder current consistency reading

|

Cones Today |

Coni Odierni |

|||

|

12345 |

12345 |

|||

In this window the display shows Cones of the day (starting from 0:00 to 23.59) :

12345 = number of cones relevant to SUNDAE side.

Daily cones are reset:

—on midnight switching

—by pressing Stop on switching on (see paragraph STOP)

13

|

Total Cones |

Coni Totali |

|||

|

0923456780 |

0923456780 |

|||

|

In this window, the display shows total Cones: |

||||

|

0923456780= number of cones relevant to Sundae side. |

To reset them, switch machine off and then on. Soon after switching power on (within 1 minute), press

Stop

|

TEV+010 |

TGV-022 |

TEV+010 |

TGV-022 |

TEV2 |

TGV2 |

||||

|

TEC+013 |

TE1-012 |

TEC+013 |

TE1-012 |

TEC2 |

TE2 |

||||

|

In this window the display shows all sensors relevant to SUNDAE side (no display of °C nor °F): |

|||||||||

|

TEV |

= Sundae side Hopper Thermostat |

||||||||

|

TEC |

= Sundae side Cylinder Thermostat |

||||||||

|

TGV |

= Sundae side Hopper Ice Thermostat |

||||||||

|

TE1 |

= Sundae side Cylinder Evaporator Thermostat |

||||||||

|

Topping |

+057 |

Topping |

+057 |

TET |

|||||

|

Set Topping +055 |

Set Topping +055 |

||||||||

In this window the display shows the Topping sensor (no display of °C nor °F) with relevant temperature set: Topping = Topping Thermostat

Set Topping = Topping Temperature Set

By pressing Production again, machine returns to its starting display.

14

DO NOT SERVE

When selecting Production, the display will be Non Estrarre ! — Do Not Serve ! meaning that the ice cream needs to reach an ideal consistency and therefore do not serve till the message switches off:

|

— ENGLISH — |

— ITALIAN — |

|||

|

Do Not Serve ! |

Non Servire ! |

|||

|

TEV +19°C W -14 |

TEV +19°C W -14 |

The first time when is accessed the Production the machine has to reach the Set HOT to extinguish the writing, the following times it will be had the standard operation through Hot Block

Once Hot Block has been reached, the routine operation starts.

Message on the display will be as follows:

|

Sundae Ready ! |

Gelato Pronto ! |

||

|

TEV +19°C W -14 |

TEV +19°C W -14 |

In particular:

If the consistency decreases below the value programmed in step Blocco Hot 1 — Hot Block 1, Non Servire ! — Do Not Serve ! will light up on the display. This means that ice cream is not ready for distribution.

Writing will become Gelato Pronto ! — Sundae Ready ! ONLY after that Blocco Hot 1 is reached.

If a cone is dispensed (MIR-Photoelectric sensor activated) while Non Servire ! — Do Not Serve ! is lit up on the display, all outputs will switch off (MA, MC, EVFC OFF; MP, will also turn OFF if it was ON).

If the hopper needs to cool for storage, MC + EVFV will be left ON.

As soon as the photocell is deactivated (no longer covered), Production restarts, so restarting MA and MC + EVFC.

If the consistency value goes below Hot Block – 5 points hysteresis, the message Non Servire ! — Do Not Serve ! will again light up on the display.

15

MIX OUT

When mix is low (below the medium level sensor), the first line on display will show the blinking message Aggiungere Mix ! — Add Mix ! and hopper medium level led on

the keyboard will light up

When the mix is below the medium level sensor, an intermittent acoustic warning (beep) will also be activated.

|

— ENGLISH — |

— ITALIAN — |

Notes |

|

|

low med. level |

|||

|

Add Mix ! |

Aggiungere Mix ! |

||

|

TEV +19°C W -14 |

TEV +19°C W -14 |

When mix is out (below the low level sensor) the first line on display will show a fixed message Mix Esaurita ! — Mix Out ! and hopper low level led on the keyboard will

light up

The second line displays the number of cones you can still distribute (Ultimi Coni — Last Cones) before the machine automatically sets at Storage mode.

|

— ENGLISH — |

— ITALIAN — |

Notes |

||

|

Low level out |

||||

|

Mix Out |

5 |

Mix Esaurita ! |

||

|

Last Cones |

Ultimi Coni 5 |

Nr of remaining cones |

||

Note:

With messages Aggiungere Mix ! — Add Mix ! and Mix Esaurita ! — Mix Out ! on display, the access to next Production screens is not allowed.

16

ICE IN THE CYLINDER

In Production, if the temperature TE2 reaches a value less than or equal to the one set in step Ghiaccio Cilin. — Ice Cylinder, alarm Ghiaccio Cilind. — Ice Cylinder will activate and will be stored among the events, ONLY.

This alarm is not displayed.

Under the said condition, all outputs to the cylinder will be deactivated and the machine will set to hopper cooling, if need be.

When Production timeout ends, consistency will be tested again in order to check whether TE2 has risen in the meantime higher than Ghiaccio Cilin. — Ice Cylinder.

TIMEOUT PRD

In Production, if consistency does not reach its set point within the time programmed in step Timeout Prd., the cycle will be forced to end as if HOT had been reached and the alarm will be stored among the events (not on display).

If Hot Block is not reached within 15 minutes after production starts, the machine will set to Stop and alarm Timeout Prd. will be displayed.

17

PASTEURIZATION

No Pasteurization process will ever start if the mix inside the tank is below medium level sensor.

Pasteurization process is automatically executed every day at 2:00am

(provided that time has been programmed in step Ora Avvio Pasto — Start Pasto

Time).

The machine is normally in Production and at the appointed Pasteurization time, it will automatically enter into the Pasteurization program and carry out the cycle.

Warning: if the front lid is open at the automatic Pasteurization time (Pasto Start Time), your machine will allow Production only after closing it.

If, step Ora Avvio Pasto — Start Pasto Time is set to “no” in the program, automatic Pasteurization is disabled and it can only be executed manually (General Market).

In order to activate Manual Pasteurization, press the Pasteurization key

Warning: 5 seconds after the access to Pasteurization, the cycle must be completed. If the Pasteurization is not successfully completed, your machine will NOT enter Production, till the execution of a full Pasteurization cycle.

To force the access to Pasteurization even though the machine is in reserve (medium

level low mix), it is necessary for you to press the Storage key

By this, you will “skip” hopper level control block and you can now press the Pasteurization button for 5 seconds to enter in Manual Pasteurization.

18

The product in both the hopper and the cylinder is heated up to 149°F (65°C), kept at this temperature for 30 minutes (fixed time), and then cooled down to reach the storage temperature.

At the end of the cycle, the monitor displays “Fine PastoPasto End —”, followed by date and time, meaning that the pasteurization process has been correctly executed.

The beater in the cylinders turns cyclically during Heating, pause, Cooling (149°F (65°C) down to 68°F (20°C) in the cylinder) and since the moment when the cylinder reaches the storage temperature; whereas, during cooling, from 68°F (20°C) down to cylinder storage temperatures, beating is continuous.

The beater inside the cylinder normally runs 15 seconds and stops 30 seconds

Even in the event that the tank reaches the storage temperature earlier than the cylinder and TE>68°F (20°C), the beater is ON (continuous).

19

|

Pasteurization Sundae side |

|

|

55° 65° 85° |

|

|

°C |

|

|

MA+MC+EVFC 15” ON |

|

|

MC+EVFV 90” ON |

|

|

TEC= 10°C |

20° |

|

MA+MC+EVRC 15” ON |

|

|

MC+EVRV 70” ON |

|

|

2° |

|

|

MA+MC+EVFC 15” ON |

|

|

MA+MC+EVRC 15” ON |

MC+EVFV 90” ON |

|

MC+EVRV 70” ON |

|

|

30’ |

Time |

Pasteurization Graph

Cycle Description

On heating cycle start between cylinder and hopper:

MA+MC+EVRC 15”ON and MC+EVRV 70”ON.

In Cooling, operation till TEC=20°C as follows:

MA+MC+EVFC 15”ON and MC+EVFV 90”ON.

When TEC reaches 20°C MA is always ON, also in hopper cooling:

MA+MC+EVFC 15”ON and MC+EVFV 90”ON.

20

HEATING

Heating is executed with “positive hysteresis”, meaning that if a temperature of 149°F (65°C) has been set, heating will be deactivated at 156.2°F (69°C) and will then restart at 149°F (65°C).

If you want to skip heating and 30 minute pause, press the Storage key

Once entering Pasteurization, the display is as follows:

|

— ENGLISH — |

— ITALIAN — |

Notes |

||

|

— Heating — |

-Riscaldamento- |

|||

|

Do Not Serve ! |

Non Servire ! |

In this window, first line (on top) displays:

-Riscaldamento- — Heating – i.e., heating step of Pasteurization process.

On the second line:

Non Servire ! — Do Not Serve ! meaning that ice cream must not be dispensed.

Pressing Pasteurization

|

Key |

— ENGLISH — |

— ITALIAN — |

Notes |

|

|

Hopper +023°C |

Vasca +023°C |

TEV2 |

||

|

Cylinder -013°C |

Cilindro -013°C |

TEC2 |

||

In this window, the first line (on top) displays the Hopper temperature (TEV2) whilst the second line displays the Cylinder temperature (TEC2).

: The arrow indicates what side is heated.

|

Key |

— ENGLISH — |

— ITALIAN — |

Notes |

||||

|

TEV+066 |

TGV+070 |

TEV+066 |

TGV+070 |

TEV2 |

TGV2 |

||

|

TEC+067 |

TE1+068 |

TEC+067 |

TE1+068 |

TEC2 |

TE2 |

||

In this window all sensor temperatures are displayed.

During Heating process, the compressor heats cylinder and hopper in turns.

Default times in heating step are normally 15 seconds for cylinders and 70 seconds for hopper.

21

ACTIVATED UNITS

On start, MP is activated for a fixed time of 30 seconds, where as MMV runs for the duration of the entire cycle.

In Cylinder Heating, the following units are activated: MA, MC, EVRC for 15 seconds (see the table below). The following units are activated: MC, EVRV, for 70 seconds (see the table below).

By EVRC, MP and MA it is always meant SUNDAE side.

If the hopper reaches the Pasteurization temperature earlier than the cylinder, beating in the cylinder will begin to run continuously.

Following checks are also executed:

|

If TEV < TEC |

by : |

>= 4°C |

ON EVRV 86” |

/ |

ON EVRC 15” |

||

|

If TEV < TEC |

by : |

>=3°C |

and |

<4°C |

ON EVRV 78” |

/ |

ON EVRC 15” |

|

If TEV < TEC |

by : |

>=2°C |

and <3°C |

ON EVRV 74” |

/ |

ON EVRC 15” |

|

|

If TEV < TEC |

by : |

>=1°C |

and |

<2°C |

ON EVRV 72” |

/ |

ON EVRC 15” |

DELTA TGV-TEV

(Alarm Belt)

Conditions for belt alarm are monitored under the following parameters:

—TEV and TGV sensors cannot already be in an alarm state of their own

—machine must be in Heating or Pasteurization Pause

In Heating of Pasteurization program, if TGV temperature turns > than the TEV temperature by the value programmed in step Delta TGV-TEV, Allarme Cinghia — Alarm Belt will be displayed and machine will set to Stop.

Check driving belt or whether the rotor is in its seat.

22

PAUSE

If you want to skip the 30 minute pause after the temperature of 149°F (65°C) has

been reached, press the Storage key

|

— ENGLISH — |

— ITALIAN — |

notes |

||

|

-Heating Pause- |

-Pausa Pasto- |

|||

|

Do Not Serve ! |

Non Servire ! |

In this window the first line (on top) displays:

-Pausa Pasto- -Heating Pause- i.e., Pasteurization pause (or break).

On second line:

Non Servire ! — Do Not Serve ! meaning that it must not be served in this step.

Pressing Pasteurization

|

Key |

— ENGLISH- |

— ITALIAN — |

Notes |

|

|

Hopper +065°C |

Vasca +065°C |

TEV2 |

||

|

Cylinder +066°C |

Cilindro +066°C |

TEC2 |

||

In this window the first line (on top) displays the Hopper temperature (TEV2) whilst the second line displays the Cylinder temperature (TEC2).

: The arrow indicates what side is heated.

|

Key |

— ENGLISH — |

— ITALIAN — |

Notes |

|

|

Pause Time 30:00 |

Tempo Pausa30:00 |

|||

In this window, Pause decreasing Time is displayed.

|

Key |

— INGLESE — |

— ITALIANO — |

Note |

||||

|

TEV+066 |

TGV+070 |

TEV+066 |

TGV+070 |

TEV2 |

TGV2 |

||

|

TEC+067 |

TE1+068 |

TEC+067 |

TE1+068 |

TEC2 |

TE2 |

||

In this window all sensor temperatures are displayed.

23

ACTIVATED UNITS

MMV runs for the duration of the entire cycle.

If the Pasteurization temperature is reached either by the cylinder or by the hopper, MMV will run continuously, whilst MA runs for 15 seconds and stops for 2 minutes, until pause time has finished.

If the cylinder needs be heated during the pasteurization pause, MA (will run continuously) MC and EVRC will start.

If the hopper, alone, needs be heated during the pasteurization pause, MC and EVRV will be activated.

If both the cylinder and hopper need to be heated at the same time during the pasteurization pause, heating will begin to cycle: 15sec. MA, MC and EVRC and 70 sec. MC and EVRV (still applicable times given in previous table relevant to ON-OFF times in relation to TEC and TEV temperatures).

MP will be activated in pause for 10” every 10’.

24

COOLING

The product is cooled down to the cylinder and hopper Storage temperatures (Temp.Conservaz. – Storage Temp.).

|

— ENGLISH — |

— ITALIAN — |

Notes |

||

|

— Cooling — |

-Raffreddamento- |

|||

|

Do Not Serve ! |

Non Servire ! |

In this window the first line (on top) displays

-Cooling- — Cooling — : i.e., Pasteurization cooling step.

On the second line:

Non Servire ! Do Not Serve ! : that it must not be served in this step.

Pressing Pasteurization

|

Key |

— ENGLISH — |

— ITALIAN — |

Notes |

|

|

Hopper +065°C |

Vasca +065°C |

TEV2 |

||

|

Cylinder +066°C |

Cilindro +066°C |

TEC2 |

||

In this window the first line (on top) displays the Hopper temperature (TEV2) whilst the second line displays the

Cylinder temperature (TEC2).

: The arrow indicates what side is cooled.

|

Key |

— ENGLISH — |

— ITALIAN — |

Notes |

||||

|

TEV+066 |

TGV+070 |

TEV+066 |

TGV+070 |

TEV2 |

TGV2 |

||

|

TEC+067 |

TE1+068 |

TEC+067 |

TE1+068 |

TEC2 |

TE2 |

||

In this window all sensor temperatures are displayed.

ACTIVATED UNITS

MMV runs for the duration of the entire cycle, till TEV reaches the Storage temperature.

In Cylinder Cooling, following units are activated: MA, MC, EVFC, MV 15 sec. (see table).

In Hopper Cooling, following units are activated: MC, EVFV, MV 90 sec. (see table).

On cycle end, the machine sets at Storage and — Fine Pasto –

25

(- Pasto End —) with time and relevant day of the week are displayed.

|

— ENGLISH- |

— ITALIAN — |

notes |

||

|

— Pasto End — |

— Fine Pasto — |

|||

|

10:17:50 Mon |

10:17:50 Mon |

In this window the first line (on top) displays:

— Fine Pasto – (- Pasto End —): i.e., Pasteurization (Storage) holding step.

On the second line:

— time and day of the week

ACTIVATED UNITS

When the Storage setpoint has been reached and the hopper needs to be cooled, MMV is activated for the duration of hopper cooling (in parallel with EVFV).

In Cylinder Cooling the following units are activated: MA, MC, EVFC, MV. In Hopper Cooling the following units are activated: MC, EVFV, MV.

Anti-icing

When the temperature TGV reaches a value smaller/same as –0.4°F (-18°C) (step Antigh.Vasca – Hopper Defrost) EVRV energizes (and EVFV goes on being energized). The display indicates an upward arrow. When TGV increases by the value programmed in the step Ist.Antig.Vasca – Hop.Defrost Hys, EVRV switches off.

26

STORAGE

The Storage program has the function to bring the product which is both inside the hopper and inside the cylinder to the temperature of 39.2°F (4°C) (this value can be programmed in step Temp.Conservaz. – Storage Temp.).

As far as the hopper is concerned, storage is controlled by TEV2 whereas, as to the cylinder, it is controlled by sensor TEC2.

Every time you set the machine at the function Storage, values of sensors TEC2 (temperature in the cylinder) and TEV2 (temperature in the hopper) are read.

If both the cylinder and hopper need be cooled at the same time, the hopper has priority over the cylinder.

Storage in that case takes place on a cyclic basis.

When storing the hopper EVFV + MC are activated for 90 seconds.

When storing the cylinder MA + MC + EVFC are activated for 15 seconds.

When entering the Storage mode, you will have the following display:

|

— ENGLISH — |

— ITALIAN — |

Notes |

||

|

Hopper +015°C |

Vasca +015°C |

TEV2 |

||

|

Cylinder +012°C |

Cilindro +012°C |

TEC2 |

In this window the first line (on top) displays the Hopper temperature (TEV2) whilst the second line displays the Cylinder temperature (TEC2).

: The arrow indicates what side is cooled

Pressing Storage

|

Tasto |

— ENGLISH — |

— ITALIAN — |

Notes |

||||

|

TEV+066 |

TGV+070 |

TEV+066 |

TGV+070 |

TEV2 |

TGV2 |

||

|

TEC+067 |

TE1+068 |

TEC+067 |

TE1+068 |

TEC2 |

TE2 |

||

In this window all sensor temperatures are displayed.

27

ACTIVATED UNITS

MMV runs during the entire cycle, till TEV reaches the Storage temperature. Active units in Cylinder Cooling: MA, MC, EVFC, MV for 15 seconds.

Active units in Hopper Cooling: MC, EVFV, MV for 90 seconds.

MP runs for 6’’ (programmable in step T41) every 10’ (fix).

28

TOPPING

This function is automatically activated in Production if:

—the topping tank has a sufficient quantity of water to cover topping level sensor,

—in Programming mode, step Set Topping is not = 0

-Hot has not been reached (when EVFC is off)

If the above conditions are met, MC and EVRT will start and heat topping water up to the temperature set in the Programming (usually 131°F (55°C)) and hold it at that temperature through thermostatic control.

If you exit from Production, warm gas will deactivate.

29

CLEANING

In this function MA and MP will be activated for 30”, after that, the machine will automatically return to Stop, so as to avoid a severe wear of the cylinders.

When entering Cleaning, the display will be as follows:

|

— ENGLISH- |

— ITALIAN — |

Notes |

||||

|

HOT=058 TEC+014 |

HOT=058 |

TEC+014 |

HOT2 |

TEC2 |

||

|

Beater + Pump ON |

Agita + |

Pompa ON |

In this window, the first line (on top) displays HOT1 and TEC2 The second line shows how to enable/disable the outlets:

— will be activated (Beater and Pump) for 30”.

Pressing Cleaning

|

HOT=058 |

TEC+014 |

HOT=058 TEC+014 |

HOT2 |

TEC2 |

||

|

Pump ON |

Pompa ON |

|||||

In this window, the first line (on top) displays HOT2 and TEC2.

MA will be deactivated and only does MP run for 30”.

By pressing Cleaning again

|

HOT=058 TEC+014 |

HOT=058 TEC+014 |

HOT1 |

TEC2 |

||

|

Beater ON |

Agitatore ON |

||||

In this window, the first line (on top) displays HOT2 and TEC2.

MP will be deactivated and only does MA run for 3 minutes.

|

By pressing Cleaning again |

: |

|||||

|

HOT=058 |

TEC+014 |

HOT=058 TEC+014 |

HOT2 |

TEC2 |

||

|

Beater + Heating |

Agitat + Riscald |

In this window, the first line (on top) displays HOT2 e TEC2.

MA and MC+EVRC will be activated till the Set TEC Cleaning (T85).

By pressing Cleaning again initial display will be shown.

30

MA AND MP HOUR COUNTER

By pressing the Pasteurization key from Cleaning, you will get the access to MA and MP hour counter display.

|

MP |

hours |

00000 |

Ore |

MP |

00000 |

||

|

MA |

hours |

00002 |

Ore |

MA |

00002 |

To exit from Hour Counter display and return to Cleaning, press Pasteurization

To reset the Hour Counters, see paragraph STOP.

31

|

WEEKLY CLEANING |

WASH DAYS |

In Production, the first screen displays the number of days to next wash:

|

— ENGLISH — |

— ITALIAN — |

|

|

Do Not Serve ! |

Non Servire ! |

|

|

TEV +19°C W -14 |

TEV +19°C W -14 |

Second line refers to the number of days to next wash. The example shows that wash is in 14 days.

The day the machine must be washed, the function Ice cream Production is inhibited and the machine will not accept the function. Display will be as follows:

|

08:10:05 Wed |

08:10:05 Mer |

||

|

Wash today! |

Lavare oggi ! |

In this condition, automatic Pasteurization is inhibited.

In order to set the number of days back to the programmed value (Giorni Lavaggio

– Wash Days) it is thus necessary to wash your machine or to remove the front lid and mount it back (or yet, disconnect and re-connect IMS).

Note

Wash day starts decrementing 23.53 to 23.56.

32

CLEANING THE DISPLAY

Keyboard block

By pressing the Cleaning key

This will enable you to clean the capacitive keyboard without causing any casual function changes.

The machine will remain in the same function.

In order to enable the keys back, press the Cleaning key

33

ALARMS

The machine issues possible alarm messages on the display and makes the writing blink.

In case of alarm which has reset, the writing will be on display in a fixed way (it will not blink).

To reset the writing, press Storage/Reset key

The machine can be used in ice cream production even if an alarm is active; if it is a critical alarm, the machine will not allow you to select ice cream production program; should this be the case, press STOP and do not use the machine till it is repaired.

Here below is the alarm list:

|

ALARM |

DESCRIPTION |

|

|

Aggiungere Mix |

The display indicates Aggiungere Mix Add Mix when the |

|

|

Add Mix |

mix is below the MEDIUM level sensor. An intermittent beep |

|

|

will be activated (only if step Abilita Beep Liv in |

||

|

Programming User is set to YES and the machine is not in |

||

|

Stop). |

||

|

Mix Esaurita |

The display indicates Mix Esaurita-Mix Out when the mix |

|

|

Mix Out |

is below the LOW level sensor. When the mix is below the |

|

|

low level sensor and in Production you distribute a number |

||

|

of cones same as/or higher than the value set in step Ultimi |

||

|

ConiLast Cones, not only will Mix EsauritaMix Out be |

||

|

displayed, but also your machine will move to Storage |

||

|

mode. |

||

|

Term.Sicur.Cil |

Cylinder Safety Thermostat SUNDAE tripped. |

|

|

Safety Therm.Cyl |

Machine sets at Stop. |

|

|

(TESC2) |

||

|

Term.Sicur.Vasca |

Hopper Safety Thermostat SUNDAE tripped. |

|

|

Safety Therm.Hop |

Machine sets at Stop. |

|

|

(TESV2) |

||

|

Termico Agitator |

Overload beater (bimetallic) motor SUNDAE tripped. |

|

|

34 |

|

Overload Beater |

Machine sets at Stop. |

|

(PTMA2) |

|

|

Pressostato |

Pressure Switch SUNDAE tripped. |

|

Pressure Switch |

Machine sets at Stop: |

|

(PR2) |

— after the 3rd tripping occurring within 1 hour |

|

— if pressure switch contact is opened 2 minutes running. |

|

|

If the machine was in Pasteurization mode, Pasteurization |

|

|

program shall be re-executed. |

|

|

Check cooling water flow (in water cooled units). |

|

|

Termico Compres. |

Overload Compressor Motor SUNDAE. |

|

Overload Compres |

Machine sets to Stop. |

|

(PTMC2) |

|

|

All. Sonda Vasca |

Hopper sensor SUNDAE faulty. |

|

Al. Hopper Probe |

This is a critical alarm: consequently, the machine sets to |

|

(TEV2) |

Stop, either from Production or from Storage and |

|

Pasteurization modes. |

|

|

All. Sonda Cilin |

Cylinder sensor SUNDAE faulty. |

|

Al. Cylind.Probe |

This is a critical alarm: consequently, the machine sets to |

|

(TEC2) |

Stop, from the Storage and Pasteurization modes, it does |

|

not however, se to Stop from production because |

|

|

consistency is controlled. |

|

|

All.Sonda Gh.Vas |

Tank evaporator sensor SUNDAE faulty. |

|

Al. IceHop.Probe |

This alarm does not cause a machine (which is in the |

|

(TGV2) |

running function) to stop. |

|

In Pasteurizing Heating mode the alarm is eliminated. |

|

|

Portello Aperto |

Safety Magnet Switch SUNDAE. |

|

Spigot Opened |

If opened 10 sec., it resets Wash message (Wash). |

|

(IMS2) |

IMS opening also resets Pasteurization flag, so that if the |

|

machine was in Pasteur. mode, you can directly enter |

|

|

Production by opening and closing the front lid. |

|

35

|

All. Sonda Evap. |

Alarm Cylinder evaporator sensor SUNDAE. |

|

Al. Evapor.Probe |

This alarm does not cause a machine (which is in the |

|

(TE2) |

running function) to stop. |

|

In Pasteurization Heating mode the alarm is eliminated. |

|

|

Ritorno tensione |

Power return after a blackout. |

|

Power On |

Check blackout table in Pasteurization and Production. |

|

Event stored in all functions except STOP. |

|

|

Ghiaccio Cilin. |

Anti-icing cylinder SUNDAE read by sensor TE2. |

|

Ice Cylinder |

|

|

(ICE2) |

In Production, when TE2 temp. gets lower than the value set |

|

in step Ghiaccio cilin. Ice Cylinder, machine sets to |

|

|

reached-HOT state and stores the alarm Ghiaccio Cilin. Ice |

|

|

Cylinder in the events. |

|

|

This alarm can be caused by an insufficient mix feeding to |

|

|

the cylinder. |

|

|

Check pump efficiency. |

|

|

If the alarm occurs in Stop, it is necessary to check/replace |

|

|

the sensor TE2 because temperature is not being “read” |

|

|

properly by the CPU. |

|

36

|

Timeout Prd. |

In Production, starting time of the beater motor is checked. |

|

Timeout Prd. |

If the beater motor is ON for 6 minutes (Timeout Prd.) and |

|

Hot has not been reached, the machine sets to a “reached- |

|

|

HOT state” with alarm “Timeout Prd.” in the events. |

|

|

The Timer will be reset on MIR and on MA starting. |

|

|

After 5 interventions the alarm remains on the display and |

|

|

the machine sets at Storage mode. |

|

|

Check mix charge in cylinder, pump in the hopper and |

|

|

freezing unit. |

|

|

Allarme cinghia |

In Heating Pasteurization, if the temperature TGV2 becomes |

|

Belt Alarm |

> than TEV2 value programmed in step DELTA TGV-TEV, |

|

(DELTA TGV-TEV) |

“Allarme cinghiaBelt alarm“ is displayed and the |

|

machine sets to Heating mode. |

|

|

Check the driving belt or if the rotor is in its seat. |

|

|

The alarm automatically resets. |

|

|

Warning: this alarm is not active if TEV or TGV probe is |

|

|

inhibited. |

|

|

W -n gg |

In Production, “TEV +19°C W –n” Wash in n days is |

|

W -n days |

displayed: this means that n days remain until machine |

|

(Wash) |

wash. Alarm Wash might also be caused by leaving machine |

|

in stop for 24 hours mix above the level sensor |

|

|

See WEEKLY CLEANING. |

|

37

|

Non Servire ! |

In Production, every time consistency value goes below the |

||

|

Do Not Serve ! |

one programmed in step Blocco Hot, cone red led lights up |

||

|

to indicate wait until ice cream is ready and “Non Servire |

|||

|

!” Do not Serve shows on the display. If, in such a case, |

|||

|

you try to distribute cones, all units stop (MA and MC) till |

|||

|

the photocell is no longer busy. As soon as it is set free, |

|||

|

both MA and MC re-start in order to bring ice cream to its |

|||

|

proper consistency. |

|||

|

No Acqua Topping |

When the Topping led is on, the level sensor in the topping |

||

|

No Topping Water |

tank must be covered with water, otherwise, heating will |

||

|

(AL16) |

automatically switch off and “No Acqua Topping” No |

||

|

Water Topping will be shown on the display. |

|||

|

All.Sonda Topping |

Alarm Topping (TET) sensor. |

||

|

Al.Topping Probe |

TET is the sensor indicating the temperature of topping tank. |

||

|

AL17 (TET) |

In case of trouble, All.Sonda Topping. Al. Topping Probe |

||

|

will be displayed. |

|||

|

Invertire Fasi |

It is necessary to exchange 2 phases on the threephase line |

||

|

Invert Phases! |

in order to get the correct beater rotation direction. The |

||

|

alarm resets by switching power off and on again (after |

|||

|

exchanging the phases). |

|||

|

Pastorizzare ! |

When machine has been set to Stop with mix above low |

||

|

Pasto needed ! |

level sensor for over 60 minutes, TEV temperature is |

||

|

checked and if it is 59°F (15°C) or higher, Pasteurization is |

|||

|

needed. So pressing the Production key, will cause the |

|||

|

machine to automatically set to Pasteurization, unless you |

|||

|

open its front lid and close it again. In this case, test on TEV |

|||

|

≥ 59°F (15°C) will be cancelled for a time of 60 minutes |

|||

|

and Production will be accepted. |

|||

|

If in all these cases, TEV<59°F (15°C), all functions will be |

|||

|

accepted with no time limits. |

|||

|

38 |

Why in STOP ?? If the machine is left in the Stop position with mix covering the level sensor, the message “Why in STOP?” will be displayed 30 seconds later and an intermittent beep will be emitted. All this to warn the user to set the machine to Production, Pasteurization or Storage.

Above mentioned message will be deleted by entering Production, having low mix level, or pressing Reset (Stor.) key.

To have the message back on the display, it is necessary to first enter Production, Storage or Pasteurization.

Temp Vasca calda A 4-hour timer is enabled in Production and Storage modes. Hopper Temp Warm If the TEV stays above 5°C for more than 4 hours

consecutively or if, when power returns after a blackout, TEV>5°C, the message “Hopper Temp Warm” is displayed. This can be cancelled by pressing the Storage key.

Signal only.

Temp Cilindro calda A 4-hour timer is enabled in Production and Storage modes. Barrel Temp Warm If the TEC stays above 5°C for more than 4 hours

consecutively or if, when power returns after a blackout, TEV>5°C, the message “Barrel Temp Warm” is displayed. This can be cancelled by pressing the Storage key.

Signal only.

Temp Vasca Boll A 1-hour timer is enabled in Production and Storage modes. Hopper Temp High If the TEV stays above 5°C for more than 1 hour

consecutively or if, when power returns after a blackout, TEV>15°C, the message “Hopper Temp High” is displayed. This can be cancelled by pressing the Storage key.

Signal only.

39

Temp Cilindr Bollen A 1-hour timer is enabled in Production and Storage modes. Barrel Temp High If the TEC stays above 5°C for more than 1 hour

consecutively or if, when power returns after a blackout, TEC>15°C, the message “Barrel Temp Hight” is displayed. This can be cancelled by pressing the Storage key.

Signal only

40

BLACKOUT

In the event of blackout, if the machine was in Cleaning, on power return, it sets to STOP.

While if it was in Heating mode in Pasteurization or in Pause mode during Pasteurization program, on power return, the machine is again in the function where it was before power failure (Power On on display).

If the machine was in:

Soft ice production, Storage or Cooling in Pasteurization, on power return, the machine checks the temperature TEV and how long the power failure lasted; if a blackout lasts more than what indicated in the table below, the machine will repeat the pasteurization completely and alarm “Ritorno Tensione” or “Power On” will be stored in the “events list“.

Otherwise, if blackout time is shorter than the one indicated in the table below, the machine will return to the function where it was before blackout.

|

Temperature TEV |

Timer |

||

|

68°C |

50°C |

30 minutes |

|

|

49°C |

15°C |

10 minutes |

|

|

14°C |

10°C |

20 minutes |

|

|

9°C |

4°C |

2 hours |

|

41

AUTOSETUP

If necessary, autosetup is only to be done after Carpigiani service’ authorization.

CAUTION: After an autosetup, sensor offset values are zeroed. Before executing it, it is consequently advisable to always carry out a Download for Programming Table.

The procedure sets all programmable values according to the one indicated in the column of relevant model.

To do that, switch machine off and then on again.

WAIT for 1 second after switching on and then press

Hold

K3 Soft ver.K3Soft23

Autosetup Done

followed by a beep. Release the key

The machine is now programmed according to the values indicated in the corresponding column (see programming table).

42

EVENT LIST

The machine is provided with a large memory that helps us store most of the events (function you select, alarms,…).

To read the events stored in the memory you must have the machine in STOP, then press

On the display you’ll get the last event occurred with relevant date and time. Es.:

|

— ENGLISH- |

— ITALIAN — |

|

|

12:10:36 22 May |

12:10:36 22 May |

|

|

Start Pasteur. |

Avvio Pasto |

First line is relevant to date/time and the second one to the event.

Events are scrolled with Increment

If you don’t push any button for 30 sec. or you push STOP, the machine will go to STOP.

The events list helps us understand when and how many times a certain alarm has occurred.

Moreover, we can have a report that tells us about the pasteurization cycle and check:

Pasteurization Start

Pause Start (End Heating)

Pause End (Start Cooling)

Pasteurization End

Blackout events

NB: The highest number of storable events is 1000.

A further event will cancel the last one (the thousandth).

While reading the events you can also delete them, holding Cleaning key down for 3’’.

43

(Ocr-Read Summary of Contents of some pages of the Carpigiani K3 Document (Main Content), UPD: 26 February 2023)

-

31, Carpigiani K 3 User’s guide This manual is for the exclusive use of licensees and employees of McDonald’s Systems Inc Page 31 of 63 Version 5: October 2012 5. WEEKLY CLEANING On a weekly basis, certain machine parts must be disassembled, washed, sanitized and re- assembled. The following is the list of operations to be performed weekly in addition to the regular daily cleaning procedure. Make sure your hands are clean and sanitized before performin…

-

14, Carpigiani K 3 User’s guide This manual is for the exclusive use of licensees and employees of McDonald’s Systems Inc Page 14 of 63 Version 5: October 2012 2.1.1 MILK SHAKE FUNCTIONS STOP BUTTON By pressing this button during operation, the machine stops (LED on). DISPLAY Comments 16:29:27 Tue When the machine is in STOP, the display shows Time and Date. PRODUCTION BUTTON Preparation (startup): O…

-

28, Carpigiani K 3 User’s guide This manual is for the exclusive use of licensees and employees of McDonald’s Systems Inc Page 28 of 63 Version 5: October 2012 3.2 SUNDAE SIDE Make sure your hands are clean and sanitized before performing the following procedures. 3.2.1. SANITIZING THE DOOR AREA SURFACE: a) Fill an empty pail with McD Sanitizer prepared in water at 70-90°F (21- 32°C) (1 packet in 2-1/2 gallons (9-1/2 litres) of water = 100 PPM) and mix…

-

10, Carpigiani K 3 User’s guide This manual is for the exclusive use of licensees and employees of McDonald’s Systems Inc Page 10 of 63 Version 5: October 2012 1.2.4 TECHNICAL FEATURES Model Hourly Production * Hopper capacity Flavors Electrical supply Installed power F…

-

35, Carpigiani K 3 User’s guide This manual is for the exclusive use of licensees and employees of McDonald’s Systems Inc Page 35 of 63 Version 5: October 2012 6.1.2 DRAINING AND CLEANING THE MILK SHAKE SIDE WARNING Every time the display shows “WASH TODAY” alarm, you have to push once the button in order to reset the alarm message. Drain the Milk Shake step 1 Put an empty p…

-

11, Carpigiani K 3 User’s guide This manual is for the exclusive use of licensees and employees of McDonald’s Systems Inc Page 11 of 63 Version 5: October 2012 1.2.6 AUTOMATIC PASTEURISATION CYCLE The machine has been pre-set in the factory to start automatically the pasteurisation cycle every night at 2 am. (the automatic pasteurisation time can be re-set at a different time by a trained technician. …

-

32, Carpigiani K 3 User’s guide This manual is for the exclusive use of licensees and employees of McDonald’s Systems Inc Page 32 of 63 Version 5: October 2012 WASHING NOTE DO NOT use tools that can scratch polished surfaces. Do use clean and sanitized brushes instead. step 1 Wash all pump components with the McD All Purpose Super Concentrate (APSC) and hot water at 122- 140°F (50-60°C) (or with hot McD APSC from the KayStar dispenser at the…

-

33, Carpigiani K 3 User’s guide This manual is for the exclusive use of licensees and employees of McDonald’s Systems Inc Page 33 of 63 Version 5: October 2012 5.3 CHECK TOPPING PUMP TEMPERATURE AND VOLUME NOTE This procedure should be performed in the morning when the pumps are disassembled and cleaned. step 1 Dispense one serving of topping into a sundae cup and discard this portion of material. step 2 D…

-

4, Carpigiani K 3 User’s guide This manual is for the exclusive use of licensees and employees of McDonald’s Systems Inc Page 4 of 63 Version 5: October 2012 8. PREVENTATIVE MAINTENANCE ……………………………………………………………………… 56 8.1 CHECK OUT LIST …………………………………………………………………………………………… 56 8.2 PERIODICAL CHECK-UP AND MAINTENANCE …………….…

-

12, Carpigiani K3 Carpigiani K 3 User’s guide This manual is for the exclusive use of licensees and employees of McDonald’s Systems Inc Page 12 of 63 Version 5: October 2012 1.2.9 MIXER (OPTIONAL) Operating procedure 1. Hold a cup under soft-serve dispensing nozzle. 2. Pull draw lever completely forward and fill up the cup. 3. Place a dome lid on top of the cup. Tip: Set the cup on a level surface. 4. Hold the cup under …

-

59, Carpigiani K 3 User’s guide This manual is for the exclusive use of licensees and employees of McDonald’s Systems Inc Page 59 of 63 Version 5: October 2012 9. TROUBLESHOOTING 9.1 ALARMS The machine issues possible alarm messages on the display and makes the writing blink. In case of alarm which has reset, the writing will be on display in a fixed way (it will not blink). To reset the writing, press Storage/Reset key . The machine can be used in ice cre…

-

55, Carpigiani K 3 User’s guide This manual is for the exclusive use of licensees and employees of McDonald’s Systems Inc Page 55 of 63 Version 5: October 2012 7. MONTHLY CLEANING 7.1 CLEAN MESH FILTERS (ONLY FOR AIR COOLED VERSION) It is necessary to clean the air filter every month, as follows: step 1 Locate and remove the filter from the equipment (see fig.). step 2 At the back sink, prepare a warm solution of McD All Purpose Super Concentrate (A…

-

21, Carpigiani K3 Carpigiani K 3 User’s guide This manual is for the exclusive use of licensees and employees of McDonald’s Systems Inc Page 21 of 63 Version 5: October 2012 LOCK BUTTON To clean the keyboard panel with a clean towel it is recommended to block the keys of the keyboard as follows: Keep the button pressed for 3 seconds, the respective led will flash indicating that the keyboard is locked. At this point you can clean the keyboard safe…

-

8, Carpigiani K3 Carpigiani K 3 User’s guide This manual is for the exclusive use of licensees and employees of McDonald’s Systems Inc Page 8 of 63 Version 5: October 2012 SOURCE OF CONTAMINATION PREVENTION 3 — Worn or damaged parts. 3a — Lubricate all rubber parts contacting the mix with a food grade lubricant. 3b — Inspect o-rings for damage. Only replace with factory approved parts. 3c — Regularly check drip troughs for excessive leakage. 4 — Incorrect cleaning and …

-

62, Carpigiani K 3 User’s guide This manual is for the exclusive use of licensees and employees of McDonald’s Systems Inc Page 62 of 63 Version 5: October 2012

… -

43, Carpigiani K 3 User’s guide This manual is for the exclusive use of licensees and employees of McDonald’s Systems Inc Page 43 of 63 Version 5: October 2012 6.2.3 DISASSEMBLING OF THE SUNDAE DISPENSING DOOR CAUTION Before disassembling the dispensing head, make sure that the hopper and the cylinder are completely drained. step 1 With the machine in STOP mode, rem…

-

5, Carpigiani K 3 User’s guide This manual is for the exclusive use of licensees and employees of McDonald’s Systems Inc Page 5 of 63 Version 5: October 2012 Conventional Symbols ATTENTION ELECTRIC SHOCK DANGER The staff involved is warned that the in observance of safety rules in carrying out the operation described may cause an electric shock. ATTENTION GENERAL DANGER The staff involved is warned that the operation described may do harm if not carried out in …

-

6, Carpigiani K3 Carpigiani K 3 User’s guide This manual is for the exclusive use of licensees and employees of McDonald’s Systems Inc Page 6 of 63 Version 5: October 2012 Removing machine from packaging 1. Check the Shock-watch label which indicates whether the goods have been mishandled; inspect the cardboard shipping carton for signs of damage. (See fig.1) 2. Cut the metal straps (beware of snapping metal), lift the cardboard carton up and off of the pallet (see picture 2). 3. Rem…

-

Руководства по ремонту

1

Carpigiani K3 каталог запчастей

(36 страниц)

- Языки:Английский

-

Тип:

PDF -

Размер:

3.97 MB

Просмотр

Carpigiani K3 (Кулинария) сервис мануалы в PDF-формате помогут найти неполадки и ошибки, а также осуществить ремонт Carpigiani K3 и восстановить работу устройства.

Table of Contents for Carpigiani K3:

-

Carpigiani K 3 User’s guide This manual is for the exclusive use of licensees and employees of McDonald’s Systems Inc Page 2 of 63 Version 5: October 2012 Table of Contents CONVENTIONAL SYMBOLS ……………………………………………………………………………………….. 5 REMOVING MACHINE FROM PACKAGING ……………………………………………………………… 6 WEEE (WASTE ELECTRICAL AND ELECTRONIC EQUIPMENT)

-

Carpigiani K 3 User’s guide This manual is for the exclusive use of licensees and employees of McDonald’s Systems Inc Page 4 of 63 Version 5: October 2012 8. PREVENTATIVE MAINTENANCE ……………………………………………………………………… 56 8.1 CHECK OUT LIST …………………………………………………………………………………………… 56 8.2 PERIODICAL CHECK-UP AND

-

Carpigiani K 3 User’s guide This manual is for the exclusive use of licensees and employees of McDonald’s Systems Inc Page 53 of 63 Version 5: October 2012 6.7 SYRUP SANITIZING, PRIMING AND CALIBRATION (SHAKE SIDE) Make sure your hands are clean and sanitized before performing the following procedures. Sanitizing the syrup lines: a) Fill an empty pail with McD sanitizer prepared in water 122-140°F (50-60°C) [1 packet in 2-1/2 gallons (9-1/2 liters)

-

Carpigiani K 3 User’s guide This manual is for the exclusive use of licensees and employees of McDonald’s Systems Inc Page 63 of 63 Version 5: October 2012 ®

-

Carpigiani K 3 User’s guide This manual is for the exclusive use of licensees and employees of McDonald’s Systems Inc Page 43 of 63 Version 5: October 2012 6.2.3 DISASSEMBLING OF THE SUNDAE DISPENSING DOOR CAUTION Before disassembling the dispensing head, make sure that the hopper and the cylinder are completely drained. step 1 With the machine in STOP mode, remove two retaining knobs (

-

Carpigiani K 3 User’s guide This manual is for the exclusive use of licensees and employees of McDonald’s Systems Inc Page 28 of 63 Version 5: October 2012 3.2 SUNDAE SIDE Make sure your hands are clean and sanitized before performing the following procedures. 3.2.1. SANITIZING THE DOOR AREA SURFACE: a) Fill an empty pail with McD Sanitizer prepared in water at 70-90°F (21- 32°C) (1 packet

-

Carpigiani K 3 User’s guide This manual is for the exclusive use of licensees and employees of McDonald’s Systems Inc Page 46 of 63 Version 5: October 2012 6.4 REASSEMBLY OF WASHED AND SANITIZED COMPONENT PARTS 6.4.1 REASSEMBLY OF THE SHAKE CYLINDER BEATER step 1 Lubricate the blade pin O-ring (#1271) and slide it onto the pin (#726). CAUTION! Check the rubber stoppers onto the bla

-

Carpigiani K 3 User’s guide This manual is for the exclusive use of licensees and employees of McDonald’s Systems Inc Page 48 of 63 Version 5: October 2012 6.4.2.1 Shake side warning – When using only 3 syrups. In case you are using only 3 syrup flavours, you should close the hole of the front lid using the tap ref. 1 delivered with the accessories. This step can fit only in the hole indicated by X in the fig. To block it firmly use the key ref. 2. By doing so, the forth syrup flavour that corre

-

Carpigiani K 3 User’s guide This manual is for the exclusive use of licensees and employees of McDonald’s Systems Inc Page 57 of 63 Version 5: October 2012 Rif. 1a Rif. 2 385 Rif 1b 8.2 PERIODICAL CHECK-UP AND MAINTENANCE Replace the syrup pump hose (#385) every 12 months or needed, for example in case of heavy use, replacement is suggested eve

-

Carpigiani K 3 User’s guide This manual is for the exclusive use of licensees and employees of McDonald’s Systems Inc Page 24 of 63 Version 5: October 2012 2.2 OPERATIONS 2.2.1 DISPENSING MILK SHAKE Once the milk shake has completed the freezing cycle and the LED is on solid, place a cup on the cup holder and press one of the “coloured cup” buttons (brown, red, yellow or blue) in order to dispense milk shake. The machine automatically dispenses th

-

Carpigiani K 3 User’s guide This manual is for the exclusive use of licensees and employees of McDonald’s Systems Inc Page 45 of 63 Version 5: October 2012 3) Sanitize 4) Air-Dry 1) Wash step 11 Dip a brush into the sanitizer solution thoroughly brush clean the syrup injectors located on the front panel just under the milk shake cylinder. Repeat steps 8 , 9 and 10 several times. IM

-

Carpigiani K 3 User’s guide This manual is for the exclusive use of licensees and employees of McDonald’s Systems Inc Page 33 of 63 Version 5: October 2012 5.3 CHECK TOPPING PUMP TEMPERATURE AND VOLUME NOTE This procedure should be performed in the morning when the pumps are disassembled and cleaned. step 1 Dispense one serving of topping into a sundae cup and discard this portion of material. step 2 Dispense the second serving into a sundae cup in the same way. st

-

Carpigiani K 3 User’s guide This manual is for the exclusive use of licensees and employees of McDonald’s Systems Inc Page 30 of 63 Version 5: October 2012 4.2 SUNDAE SIDE Make sure your hands are clean and sanitized before performing the following procedures. 4.2.1 SANITIZING THE DOOR AREA: a) Fill an empty pail with McD Sanitizer prepared in water at 70-90°F (21- 32°C) (1 packet in 2-1/2 gallons (9-1/2 litres) of water = 100 PPM) and mix the powder b) Return to the machine

-

Carpigiani K 3 User’s guide This manual is for the exclusive use of licensees and employees of McDonald’s Systems Inc Page 23 of 63 Version 5: October 2012 The following table illustrates all steps of the manager menu: Step (first row) Display ENG (second row) Min Max Default U01 Hours 00 23 U02 Minutes 00 59 U03 Day of Week Sun Sat U04 Day of Month 01 31 U05 Month Jan Dec U06 Year 2000 2099 U07 Language Eng DEU ENG U08 Start Prod. Time 00 23+no+auto 08

Questions, Opinions and Exploitation Impressions:

You can ask a question, express your opinion or share our experience of Carpigiani K3 device using right now.