Standard Chiller/HP modulare per compressore a vite con driver CAREL

21.3

AL:001 Unit No. 1 Offline

AL:002 Unit No. 2 Offline

AL:003 Unit No.3 Offline

AL:004 Unit No.4 Offline

AL:011 Serious alarm from digital input

AL:012 Phase monitor alarm

AL:013 Evaporator flow-switch alarm

AL:014 Condenser flow-switch alarm

AL:015 Oil level alarm

AL:016 High pressure alarm (pressure switch)

AL:017 Low pressure alarm (pressure switch)

AL:018 Evaporator Pump thermal Cutout

AL:019 Condenser Pump thermal cutout

AL:020 Compressor thermal cutout

AL:021 Condenser 1 Thermal cutout

AL:022 Condenser 2 Thermal cutout

AL:031 Antifreeze alarm

AL:032 Low pressure differential alarm

AL:033 High pressure alarm (transducer)

AL:034 Low pressure alarm (transducer)

AL:035 High delivery temperature alarm

AL:036 High voltage alarm

AL:037 High current alarm

AL:041 Alarm: clock card failed or disconnected

AL:051 Evaporator pump maintenance

AL:052 Condenser pump maintenance

AL:053 Compressor Maintenance

AL:060 Probe B1 failed or not connected

AL:061 Probe B2 failed or not connected

AL:062 Probe B3 failed or not connected

AL:063 Probe B4 failed or not connected

AL:064 Probe B5 failed or not connected

AL:065 Probe B6 failed or not connected

AL:066 Probe B7 failed or not connected

AL:067 Probe B8 failed or not connected

AL:101 Diver 1 probe status

AL:102 Diver 1 EEPROM error

AL:103 Diver 1 stepped motor error

AL:104 Diver 1 battery error

AL:105 High pressure (MOP) driver 1

AL:106 Low pressure (LOP) driver 1

AL:107 Low super-heat alarm, driver 1

AL:108 Valve not shut while driver 1 being disabled

AL:109 Driver 1 high intake temperature

AL:110 Standby due to EEPROM /battery recharge / or open valve error, driver 1

AL:111 LAN disconnected, driver 1

AL:201 Diver 2 probe error

AL:202 Diver 2 EEPROM error

AL:203 Diver 2 stepped motor error

AL:204 Diver 2 battery error

AL:205 High pressure (MOP) driver 2

AL:206 Low pressure (LOP) driver 2

AL:207 Low super-heat alarm, driver 2

AL:208 Valve not shut while driver 2 being disabled

AL:209 Driver 2 high intake temperature

AL:210 Standby due to EEPROM /battery recharge / or open valve error, driver 2

AL:211 LAN disconnected, driver 2

Cod.: +030221241 Rel. 1.0 dated 25 September 03

47

Подробнее устранение неисправностей описано в руководстве по эксплуатации каждой модели.

На нашем сайте представлены запасные части для оборудования Carel.

Для подбора запасных частей Carel сообщите нам полную маркировку блока и наименование запчасти любым удобным способом.

Коды ошибок управляющих блоков для систем вентиляции и кондиционирования Carel (PCOxs электро)

| Код | Описание ошибки |

|---|---|

| E01 | Поступил сигнал от пожарной сигнализации |

| E02 | Неисправен датчик наружной температуры |

| E03 | Неисправен датчик температуры в помещении |

| E04 | Неисправен датчик температуры приточного воздуха |

| E05 | Неисправен датчик температуры возвращаемого теплоносителя |

| E08 | Неисправен датчик температуры возвращаемого теплоносителя после нагревателя второго нагрева |

| E09 | Неисправен датчик влажности приточного воздуха |

| E10 | Неисправен датчик влажности воздуха в помещении |

| E12 | Неисправен датчик температуры насыщения |

| E13 | Один или несколько аналоговых входов под ручным управлением |

| E14 | Один или несколько аналоговых выходов под ручным управлением |

| E15 | Один или несколько дискретных входов под ручным управлением |

| E16 | Один или несколько дискретных выходов под ручным управлением |

| E17 | Нет сигнала статуса от приточного вентилятора |

| E18 | Нет сигнала статуса от вытяжного вентилятора |

| E19 | Нет сигнала статуса от вытяжного и (или) приточного вентилятора |

| E20 | Низкая наружная температура для использования режима «лето» |

| E21 | Запуск заблокирован. Низкая температура возвращаемого теплоносителя или клапан в контуре нагревателя открыт менее чем на 80% (или иное значения согласно St13) |

| E22 | Защита от замерзания водяного нагревателя. Предварительная тревога |

| E23 | Защита от замерзания водяного нагревателя. Основная тревога |

| E24 | Неисправен насос в контуре водяного нагревателя |

| E25 | Защита от замерзания водяного нагревателя второго нагрева. Предварительная тревога |

| E26 | Защита от замерзания водяного нагревателя второго нагрева. Основная тревога |

| E27 | Неисправен насос в контуре водяного нагревателя 2 |

| E28 | Перегрев электронагревателя |

| E29 | Активировано оттаивание рекуператора |

| E30 | Неисправен привод ротора рекуператора |

| E31 | Неисправен компрессорно-конденсаторный агрегат (ККА) |

| E32 | Фильтр на притоке загрязнен |

| E33 | Фильтр на вытяжке загрязнен |

| E34 | Фильтр загрязнен |

| E37 | Отсутствует связь с платой расширения |

| E39 | Получен внешний сигнал тревоги |

| E40 | Перезапуск после подачи питания |

| E41 | Термозащита приточного вентилятора |

| E42 | Термозащита вытяжного вентилятора |

| E43 | Термозащита вентиляторов |

-

Bookmarks

Quick Links

2

pCO

— controllore elettronico programmabile

2

pCO

electronic programmable controller

Manuale d’installazione

User manual

LEGGI E CONSERVA

QUESTE ISTRUZIONI

READ AND SAVE

THESE INSTRUCTIONS

Related Manuals for Carel pCO2

Summary of Contents for Carel pCO2

-

Page 1

— controllore elettronico programmabile electronic programmable controller Manuale d’installazione User manual LEGGI E CONSERVA QUESTE ISTRUZIONI READ AND SAVE THESE INSTRUCTIONS… -

Page 3

Vogliamo farvi risparmiare tempo We wish to save you time and e denaro! money! LEGGI E CONSERVA Vi assicuriamo che la completa lettura We can assure you that a thorough QUESTE ISTRUZIONI di questo manuale vi garantirà una reading of this manual will guarantee READ AND SAVE THESE INSTRUCTIONS corretta installazione ed un sicuro… -

Page 5

Indice: Index: INTRODUZIONE INTRODUCTION CARATTERISTICHE GENERALI GENERAL FEATURES : SMALL, MEDIUM, LARGE : SMALL, MEDIUM, LARGE Programmability Programmabilità HARDWARE STRUCTURE ARCHITETTURA HARDWARE Instrument and accessory codes Codici degli strumenti ed accessori Meaning of the inputs/outputs Significato degli ingressi/uscite TERMINAL USER IL TERMINALE UTENTE Contrast control in LCD Display Regolazione del contrasto dei display a LCD… -

Page 7

The pCO represents the evolution of the well-known pCO electronic sviluppato da Carel e destinato a molteplici applicazioni nel campo del control, developed by Carel and designed for multiple applications in condizionamento dell’aria e della refrigerazione. La nuova gamma è… -

Page 8

32 KB E2PROM memory for memoria E2PROM per i parametri. the parameters. 1.2 Programmabilità 1.2 Programmability Carel ha la possibilità di essere programmato con il sistema di The Carel pCO can be programmed using the EasyTools development sviluppo EasyTools che offre i seguenti vantaggi: system, which offers the following advantages: •… -

Page 9

2. ARCHITETTURA HARDWARE 2. HARDWARE STRUCTURE L’architettura del pCO Carel prevede: The structure of the Carel pCO features: • il controllore pCO , dotato di microprocessore a 16 bit dedicato • the pCO control, fitted with a 16-bit microprocessor for running the… -

Page 10

Una possibile architettura hardware è così definita: The hardware structure is defined as follows: 1. terminale utente con tastiera, display e LED di segnalazione; 1. user terminal with keypad, display and LED signals; 2. pCO (versione SMALL); 2. pCO (SMALL version); 3. -

Page 11

2.1 Codici degli strumenti ed accessori 2.1 Instrument and accessory codes interface and control version versione interfaccia e controllo with 1+1 MB Flash memory code a 1+1 MB di memoria Flash codice LARGE PCO2000AL0 LARGE PCO2000AL0 MEDIUM PCO2000AM0 MEDIUM PCO2000AM0 SMALL PCO2000AS0 SMALL… -

Page 12

RS232 modem serial scheda interfaccia stampante per display grafico PCOSERPRN0 connection board for pCO PCO200MDM0 scheda controllo umidificatore a vapore Carel OEM PCOUMID000 printer interface board for graphic display PCOSERPRN0 nuova scheda controllo umidificatore a vapore control board for Carel OEM steam humidifier… -

Page 13

13. connector, address definition and LED for pLAN local network; 13. connettore, indirizzamento e LED per la rete locale pLAN; 14. hatch for inserting the RS485 (for serial connection to Carel 14. sportello per l’inserimento della scheda seriale RS485 (per supervisor) or RS232 serial board (for modem interface);… -

Page 14

connettore segnale descrizione J12-4 contatto normalmente aperto relè n. 3 J12-5 comune relè: 1, 2, 3 J13-1 comune relè: 4, 5, 6 J13-2 contatto normalmente aperto relè n. 4 J13-3 contatto normalmente aperto relè n. 5 J13-4 contatto normalmente aperto relè n. 6 J13-5 comune relè: 4, 5, 6 J14-1… -

Page 15

2.2 Meaning of the inputs/outputs This table summarises the inputs and the outputs and provides a brief description of each. connector signal description J1-1 power supply +24Vdc or 24Vac J1-2 power supply reference J2-1 universal analogue input 1 (NTC, 0/1V, 0/10V, 0/20mA, 4/20mA) J2-2 universal analogue input 2 (NTC, 0/1V, 0/10V, 0/20mA, 4/20mA) J2-3… -

Page 16

connector signal description J16-1 common relay: 9, 10, 11 J16-2 normally-open contact relay no. 9 J16-3 NO10 normally-open contact relay no. 10 J16-4 NO11 normally-open contact relay no. 11 J16-5 common relay: 9, 10, 11 J17-1 NO12 normally-open contact relay no. 12 J17-2 common relay no. -

Page 17

3. IL TERMINALE UTENTE 3. TERMINAL USER 3.1 Regolazione del contrasto dei display a LCD 3.1 Contrast control in LCD Display I modelli con display LCD 4×20 sono dotati di potenziometro per la 4×20 LCD display models have a trimmer for adjusting the display regolazione del contrasto del display. -

Page 18

3.5 Display LCD 4×20 montaggio a pannello 3.5 4×20 LCD Display for panel mounting Caratteristiche Characteristics codice PCOI000CB* code PCOI000CB* numero righe number of rows numero colonne number of columns altezza carattere (mm) font height (mm) È disponibile inoltre: Other features available: •… -

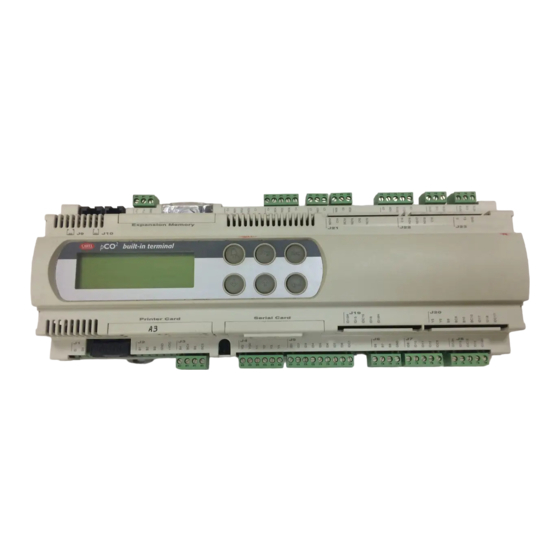

Page 19

3.8 Display built-in 3.8 Built-in display Le tre versioni (SMALL, MEDIUM, LARGE) prevedono una versione The three versions (SMALL, MEDIUM, LARGE) feature a version with con display e tastiera direttamente integrata sul contenitore plastico: display and keypad directly built into the plastic case: Caratteristiche Characteristics codici*… -

Page 20

3.9.1 Utilizzo tipico dei tasti nelle applicazioni standard Carel 3.9.1 Typical use of the buttons in standard Carel applications visualizza i valori rilevati dalle sonde; displays the values measured by the probes menu menu visualizza i valori relativi alla manutenzione dei dispositivi (ore displays the values relating to the maintenance of the devices di utilizzo del dispositivo e reset contaore di funzionamento);… -

Page 21

3.10 Funzionalità e caratteristiche del terminale con 3.10 Functions and features of the terminal with display grafico graphic display I font di caratteri sono configurabili dall’utente-programmatore, sia The fonts of the digits can be configured by the user-programmer, both come stile sia come dimensione. for style and dimension. -

Page 22

3.10.2 Scheda inverter per alimentazione della lampada 3.10.2 Inverter card for powering the fluorescent light on the fluorescente (CFL) del display e connessione al pCO display (CFL) and connecting to the pCO Questa scheda consente di alimentare la lampada fluorescente di This card provides power to the fluorescent back-lighting on the display retro-illuminazione del display e permette al controllore di pilotare and allows the main board to correctly control the display used. -

Page 23

4. INSTALLAZIONE 4. INSTALLATION 4.1 Ancoraggio del pCO 4.1 Anchoring the pCO Il pCO va installato su guida DIN. Per il fissaggio alla guida DIN, è The pCO should be installed on a DIN rail. To fasten the unit to the sufficiente una leggera pressione del dispositivo preventivamente DIN rail, lightly press it against the rail. -

Page 24

4.3 Avvertenze per l’installazione — ambienti di 4.3 Installation warnings — destination and connection destinazione e collegamento environments Evitare il montaggio delle schede negli ambienti che presentino le Avoid mounting of the boards in environments with the following seguenti caratteristiche: characteristics: •… -

Page 25

4.4.1 Connecting active temperature and humidity probes Al pCO possono essere collegate tutte le sonde attive di temperatura The pCO can be connected to all the Carel series AS* active ed umidità della serie AS* Carel configurate come 0/1 V oppure come temperature and humidity probes configured as 0/1V or 4/20mA. -

Page 26

The pCO can be connected to all Carel series SPK* active pressure della serie SPK* Carel o qualsiasi sensore di pressione presente sul probes or any pressure sensor on the market with an 0/20mA or mercato con segnale 0/20 mA o 4/20 mA. Gli ingressi che possono 4/20mA signal. -

Page 27

4.4.5 Collegamento degli ingressi analogici selezionati come 4.4.5 Connecting the ON/OFF selectable analogue inputs ON/OFF Il pCO permette di configurare alcuni The pCO allows some analogue inputs to ingressi analogici come ingressi digitali puliti. be configured as clean digital inputs. The built-in terminal Gli ingressi che possono accettare questi inputs in question are B4, B5, B9, B10. -

Page 28

4.5 Collegamento degli ingressi digitali 4.5 Connecting the digital inputs Il pCO prevede fino a 18 ingressi digitali per il collegamento a The pCO features up to 18 digital inputs for connecting safety devices, sicurezze, allarmi, stati di dispositivi, consensi remoti. Questi ingressi alarms, device status, remote triggers. -

Page 29

4.5.2 Ingressi digitali alimentati a 24 Vdc 4.5.2 Digital inputs powered at 24Vdc La figura seguente rappresenta uno tra i più comuni schemi di The following figure represents one of the more common connection collegamento degli ingressi digitali a 24 Vdc. diagrams for the 24Vdc digital inputs. -

Page 30

4.5.3 Ingressi digitali alimentati a 230 Vac 4.5.3 Digital inputs powered at 230Vac La figura seguente rappresenta uno tra i più comuni schemi di The following figure represents one of the more common connection collegamento degli ingressi digitali a 230 Vac. Ogni gruppo (vedi diagrams for the 230Vac digital inputs. -

Page 31

4.6 Collegamento delle uscite analogiche 4.6 Connecting the analogue outputs Il pCO fornisce fino a sei uscite analogiche a 0/10 V optoisolate The pCO provides up to six optically-isolated 0/10V analogue outputs alimentate esternamente a 24 Vac/Vdc. La Fig. 4.6.1 rappresenta lo powered externally at 24Vac/Vdc. -

Page 32

4.7.2 Uscite digitali a relè a stato solido (SSR) 4.7.2 Solid state relay digital outputs (SSR) The pCO also features a version with solid state relays (SSR) for Il pCO prevede anche una versione con relè a stato solido (SSR) per piloting devices which require an unlimited number of switchings which comando di dispositivi che necessitano di un numero illimitato di would not be supported by electromechanical relays. -

Page 33

(code S90CONN00*) from the power board (code PCOB* and cavo telefonico (cod. S90CONN00*) proveniente dalla scheda di PCO2*) into the relative jack. The model with graphic display (code potenza (cod. PCO2*) nell’apposita presa. Il modello con display grafico PCOT00OGH0) is fitted with a further screw terminal block. -

Page 34

4.9 Installazione dell’EPROM di programma del 4.9 Installing the program EPROM in the terminal with terminale con display grafico graphic display Prima di inserire/rimuovere la EPROM togliere l’alimentazione del Before inserting/removing the EPROM disconnect the power supply to terminale con display grafico. the terminal with graphic display. -

Page 35

(nodo) ad un’altra. one location (node) to another. Ogni pCO può inoltre essere collegato alla rete di supervisione Carel, Each pCO can be connected to a CAREL supervisory network, using mediante le schede opzionali PCO2004850. -

Page 36

5.1 Indirizzamento pCO 5.1 Addressing the pCO L’indirizzo è impostabile nel range 1-31 utilizzando i dip-switch 1-5. Il The address can be set in the range 1-31 using the dip-switches 1-5. valore dell’indirizzo si ottiene tramite la Tab. 5.1.1. The value of the address is obtained as in Tab. 6.1.1. R G V Fig. -

Page 37

it. -

Page 38

5.4 Connessioni elettriche pLAN 5.4 pLAN electrical connections La connessione tra schede in pLAN si effettua usando esclusivamente Connection between boards in a pLAN network is carried out using an un cavo schermato AWG20/22 costituito da una coppia ritorta e lo AWG20/22 shielded cable, made up of a twisted pair plus shield. -

Page 39

AWG 20/22 AWG 20/22 AWG 20/22 built-in terminal built-in terminal built-in terminal Fuse Fuse Fuse Fig. 5.4.3 AVVERTENZE IMPORTANTI: IMPORTANT WARNINGS: • il collegamento a terra deve essere effettuato sulla stessa linea di • the ground connection must be made to the same ground (same terra (stesso polo di terra, per tutte le schede pCO ground pole, for all the pCO boards);… -

Page 40

Fig. 5.5..2.b Fig. 5.5.2.a built-in terminal Fig. 5.5..3 Fig. 5.5.4 Solo in ambienti particolarmente rumorosi è consigliato aggiungere le Only in particularly noisy environments should the ferrites also be ferriti anche sul connettore per pLAN (J11, cavo schermato): added on the pLAN connector (J11, shielded cable): •… -

Page 41

Communication standard RS485 baud-rate (kbit/s) 65,2 baud-rate (kbit/s) 65,2 protocollo Multimaster (protocollo di Protocol Multimaster (Carel proprietary proprietà Carel) control) lunghezza massima della rete (m) Maximum length of the network 500 metres Tab.5.6.1 — cod. +030221835 rel. 3.0 — 18.02.03… -

Page 42

) verso la chiave. PCO201KEY0: 1MB flash key for pCO to be used with 1+1MB pCO PCO201KEY0: chiave con 1 MB di flash per pCO2 da usarsi con un PCO2xxxAxx or PCO2xxxBxx. con 1+1 MB: PCO2xxxAxx o PCO2xxxBxx. PCO202KEY0: 2MB flash key for pCO… -

Page 43

6.3 Scheda seriale per supervisione e teleassistenza 6.2 RS485 serial board for supervisor and RS485: PCO2004850 telemaintenance: PCO2004850 La scheda PCO2004850 è un’opzione del controllore elettronico pCO The PCO2004850 board is an option for the pCO electronic control che permette l’interfacciamento di quest’ultimo ad una rete RS485. which allows the latter to interface with an RS485 network. -

Page 44

6.7 Board for OEM humidifier management This interface allows the control of the fundamental parameters of the 6.7 Scheda per gestione umidificatore OEM OEM humidifiers manufactured by Carel (level and conductivity of the Questa interfaccia permette di water in the… -

Page 45

The pCO board features 3 signal LEDs (red, yellow and signalling LED Sulla scheda pCO2 sono presenti 3 LED di green) that provide information on the operation of the segnalazione (rosso, giallo e verde) i quali forniscono board and the status of the connection to… -

Page 46

WinLoad not suitable or incorrect Software Protection Password. communicating with WinLoad. used as I/O Expansion Carel supervisor protocol (slave) active on serial 0. *: casi in cui pCO regredisce allo stato Basso Livello: — In fase di avvio il pCO rileva la presenza del WinLoad collegato. -

Page 47

7.3 Aggiornamento software con Winload32 In all Carel 16-bit pCO sistema controllers the resident software can be In tutti i controllori Carel a 16 bit del pCO Sistema è possibile updated from a PC. To do this, Carel provides the WinLoad32.exe pro- aggiornare il software residente utilizzando un PC. -

Page 48

Rx-/Tx- Rx+/Tx+ probe 1 probe 2 probe 3 (0/1 Vdc o 4/20 mA) +VDC Carel NTC probe PT1000 digital output 1 digital output 2 digital output 3 analog output 1 (0/10 Vdc) analog output 2 (0/10 Vdc) analog output 3 (0/10 Vdc) -

Page 49

La figura seguente (Fig. 8.2) indica una configurazione nella quale The following figure (Fig. 7.2) shows a special configuration where viene ulteriormente facilitato il cablaggio dei carichi. Bisogna comunque wiring of devices is further facilitated. In any case you must consider tenere in considerazione che il max valore di corrente sopportabile da that the max current value which can be supported by each terminal is ciascun morsetto è… -

Page 50

10/55 Hz) si consiglia di fissare tramite fascette i cavi collegati al pCO 10/55Hz), we suggest you to fasten, through fastening clamps, the a circa 3 cm di distanza dai connettori. cables connected to the pCO2 at about 3cm of distance from the connectrors. 9.2 Caratteristiche elettriche pCO alimentazione (controllore con terminale connesso) 22/40 Vdc e 24 Vac ±15% 50/60 Hz. -

Page 51

5, 8, 10, rispettivamente sulle schede SMALL, MEDIA, LARGE tipo • passivo: sensore di temperatura NTC Carel (-50/90 °C; R/T 10 kΩ ± 1% a 25 °C, =3,435 °K ± 1%), PT1000 (-100/200 °C; R/T 1000 Ω/°C) o input digitale pulito, 25/80 selezionabili via software (ingressi: B4, B5, B9, B10);… -

Page 52

9.2.2 Ingressi digitali 9.2.2 Digital inputs tipo ingressi optoisolati a 24 Vac 50/60 Hz o 24 Vdc o 230 Vac 50/60 Hz. Per gli ingressi a 230 Vac l’isolamento è principale) n. massimo 8, 14, 18, rispettivamente sulle schede: SMALL, MEDIA, LARGE, secondo le combinazioni riportate qui sotto: taglia scheda n. -

Page 53

9.2.4 Uscite digitali 9.2.4 Digital outputs n. massimo 8, 13, 18, rispettivamente sulle schede: SMALL, maximum no. 8, 13, 18, respectively on the SMALL, MEDIA, MEDIA, LARGE LARGE boards tipo a relè elettromeccanici type electromechanical relay Tab. 9.2.4.1 Tab. 9.2.4.1 Sono raggruppate a 3 con due morsetti di polo comune per un facile These are divided into 3 groups with two common pole terminals to assemblaggio dei poli comuni. -

Page 54

(per incollaggio sul contenitore plastico) adhesive on edge (for attaching to plastic case) Tab. 9.4.1.2 Tab. 9.4.1.2 Policarbonato tastiera (standard Carel) per PCOT*CB* e PCOI* Keypad polycarbonate label (Carel standard) for PCOT*CB* and PCOI* spessore (mm) 0,175 thickness (mm) 0.175… -

Page 55

9.4.2 Caratteristiche elettriche terminale 9.4.2 Terminal electrical specifications alimentazione 24 Vac (da trasformatore di Classe II e separato) per PCOI00PGL0/PCOT00PGL0 21/30 Vdc (dalla sch. di potenza per mezzo del cavo telefonico) per tutti gli altri modelli 80C52 — 8MHz condizioni di funzionamento -10T55 (-10/60 ºC, 14/149 °F) per PCOT000L60 e PCOT00PGH0 0T50 (0/50 ºC, 32/122 °F) per tutti gli altri modelli, 90% U.R. -

Page 56

10. MONTAGGIO TERMINALE UTENTE 10. USER TERMINAL MOUNTING 10.1 Montaggio a pannello 10.1 Panel mounting 10.1.1 PCOT* 10.1.1 PCOT* Riferimenti Fig. 10.1.1.1, (dimensioni in mm). Legend Fig. 7.1.1.1, (dimensions in mm). descrizione description coperchio posteriore rear cover pannello panel dima di foratura drilling template coperchio anteriore front cover… -

Page 57

11. DIMENSIONI 11. DIMENSIONS AVVERTENZA: tutte le quote riportate sulle figure che seguono sono WARINING: all the dimensions are in mm. espresse in mm. 11.1 pCO 11.1 pCO LARGE (18 moduli DIN) LARGE (18-DIN modules) built-in terminal Fuse Fig. 11.1.1 MEDIUM (18 moduli DIN) MEDIUM (18-DIN modules) built-in terminal… -

Page 58

11.2 Terminale utente 11.2 Terminal user 11.2.1 PCOT* 11.2.1 PCOT 170 mm 170 mm 170 mm 43 mm __________ __________ A____ B____ Room 1 Parem __________ Graphic Temp __________ __________ on/off alarm enter on/off alarm enter on/off alarm enter Fig. 11.2.1.1 1. -

Page 59

. Nel caso in cui sia ancora the power supplied by the pCO . If this is still near zero, contact prossima a zero contattare l’assistenza Carel; in caso contrario la the Carel service department; otherwise, the removed connection connessione tolta metteva in corto circiuto l’alimentazione. -

Page 60

Il valore di pressione “Ps” che la sonda sta inviando è così ricavabile The pressure value “Ps” sent by the probe can be calculated as (FS = Fondo Scala): follows (FS=Full Scale): Ps = (Vmis/50 — 0,004) x (FSmax — FSmin) / 0,016 + Fsmin Ps = (Vread/50 — 0.004) x (FSmax — FSmin) / 0.016 + Fsmin Esempio: la sonda impiegata ha Fsmin = -0,5 bar, Fsmax = 7 bar;… -

Page 61

2. che il dimensionamento del trasformatore di alimentazione (non 2. that the ratings of the power transformer (not supplied by CAREL) fornito da CAREL) sia corretto (vedi paragrafo ALIMENTAZIONE); are correct (see paragraph on POWER) 3. -

Page 64

Agenzia / Agency: CAREL S.p.A. Via dell’Industria, 11 — 35020 Brugine — Padova (Italy) Tel. (+39) 049.9716611 — Fax (+39) 049.9716600 e-mail: carel@carel.com — www.carel.com…

-

Bookmarks

Quick Links

2

pCO

— controllore elettronico programmabile

2

pCO

electronic programmable controller

Manuale d’installazione

User manual

LEGGI E CONSERVA

QUESTE ISTRUZIONI

READ AND SAVE

THESE INSTRUCTIONS

Related Manuals for Carel pCO2

Summary of Contents for Carel pCO2

-

Page 1

— controllore elettronico programmabile electronic programmable controller Manuale d’installazione User manual LEGGI E CONSERVA QUESTE ISTRUZIONI READ AND SAVE THESE INSTRUCTIONS… -

Page 3

Vogliamo farvi risparmiare tempo We wish to save you time and e denaro! money! LEGGI E CONSERVA Vi assicuriamo che la completa lettura We can assure you that a thorough QUESTE ISTRUZIONI di questo manuale vi garantirà una reading of this manual will guarantee READ AND SAVE THESE INSTRUCTIONS corretta installazione ed un sicuro… -

Page 5

Indice: Index: INTRODUZIONE INTRODUCTION CARATTERISTICHE GENERALI GENERAL FEATURES : SMALL, MEDIUM, LARGE : SMALL, MEDIUM, LARGE Programmability Programmabilità HARDWARE STRUCTURE ARCHITETTURA HARDWARE Instrument and accessory codes Codici degli strumenti ed accessori Meaning of the inputs/outputs Significato degli ingressi/uscite TERMINAL USER IL TERMINALE UTENTE Contrast control in LCD Display Regolazione del contrasto dei display a LCD… -

Page 7

The pCO represents the evolution of the well-known pCO electronic sviluppato da Carel e destinato a molteplici applicazioni nel campo del control, developed by Carel and designed for multiple applications in condizionamento dell’aria e della refrigerazione. La nuova gamma è… -

Page 8

32 KB E2PROM memory for memoria E2PROM per i parametri. the parameters. 1.2 Programmabilità 1.2 Programmability Carel ha la possibilità di essere programmato con il sistema di The Carel pCO can be programmed using the EasyTools development sviluppo EasyTools che offre i seguenti vantaggi: system, which offers the following advantages: •… -

Page 9

2. ARCHITETTURA HARDWARE 2. HARDWARE STRUCTURE L’architettura del pCO Carel prevede: The structure of the Carel pCO features: • il controllore pCO , dotato di microprocessore a 16 bit dedicato • the pCO control, fitted with a 16-bit microprocessor for running the… -

Page 10

Una possibile architettura hardware è così definita: The hardware structure is defined as follows: 1. terminale utente con tastiera, display e LED di segnalazione; 1. user terminal with keypad, display and LED signals; 2. pCO (versione SMALL); 2. pCO (SMALL version); 3. -

Page 11

2.1 Codici degli strumenti ed accessori 2.1 Instrument and accessory codes interface and control version versione interfaccia e controllo with 1+1 MB Flash memory code a 1+1 MB di memoria Flash codice LARGE PCO2000AL0 LARGE PCO2000AL0 MEDIUM PCO2000AM0 MEDIUM PCO2000AM0 SMALL PCO2000AS0 SMALL… -

Page 12

RS232 modem serial scheda interfaccia stampante per display grafico PCOSERPRN0 connection board for pCO PCO200MDM0 scheda controllo umidificatore a vapore Carel OEM PCOUMID000 printer interface board for graphic display PCOSERPRN0 nuova scheda controllo umidificatore a vapore control board for Carel OEM steam humidifier… -

Page 13

13. connector, address definition and LED for pLAN local network; 13. connettore, indirizzamento e LED per la rete locale pLAN; 14. hatch for inserting the RS485 (for serial connection to Carel 14. sportello per l’inserimento della scheda seriale RS485 (per supervisor) or RS232 serial board (for modem interface);… -

Page 14

connettore segnale descrizione J12-4 contatto normalmente aperto relè n. 3 J12-5 comune relè: 1, 2, 3 J13-1 comune relè: 4, 5, 6 J13-2 contatto normalmente aperto relè n. 4 J13-3 contatto normalmente aperto relè n. 5 J13-4 contatto normalmente aperto relè n. 6 J13-5 comune relè: 4, 5, 6 J14-1… -

Page 15

2.2 Meaning of the inputs/outputs This table summarises the inputs and the outputs and provides a brief description of each. connector signal description J1-1 power supply +24Vdc or 24Vac J1-2 power supply reference J2-1 universal analogue input 1 (NTC, 0/1V, 0/10V, 0/20mA, 4/20mA) J2-2 universal analogue input 2 (NTC, 0/1V, 0/10V, 0/20mA, 4/20mA) J2-3… -

Page 16

connector signal description J16-1 common relay: 9, 10, 11 J16-2 normally-open contact relay no. 9 J16-3 NO10 normally-open contact relay no. 10 J16-4 NO11 normally-open contact relay no. 11 J16-5 common relay: 9, 10, 11 J17-1 NO12 normally-open contact relay no. 12 J17-2 common relay no. -

Page 17

3. IL TERMINALE UTENTE 3. TERMINAL USER 3.1 Regolazione del contrasto dei display a LCD 3.1 Contrast control in LCD Display I modelli con display LCD 4×20 sono dotati di potenziometro per la 4×20 LCD display models have a trimmer for adjusting the display regolazione del contrasto del display. -

Page 18

3.5 Display LCD 4×20 montaggio a pannello 3.5 4×20 LCD Display for panel mounting Caratteristiche Characteristics codice PCOI000CB* code PCOI000CB* numero righe number of rows numero colonne number of columns altezza carattere (mm) font height (mm) È disponibile inoltre: Other features available: •… -

Page 19

3.8 Display built-in 3.8 Built-in display Le tre versioni (SMALL, MEDIUM, LARGE) prevedono una versione The three versions (SMALL, MEDIUM, LARGE) feature a version with con display e tastiera direttamente integrata sul contenitore plastico: display and keypad directly built into the plastic case: Caratteristiche Characteristics codici*… -

Page 20

3.9.1 Utilizzo tipico dei tasti nelle applicazioni standard Carel 3.9.1 Typical use of the buttons in standard Carel applications visualizza i valori rilevati dalle sonde; displays the values measured by the probes menu menu visualizza i valori relativi alla manutenzione dei dispositivi (ore displays the values relating to the maintenance of the devices di utilizzo del dispositivo e reset contaore di funzionamento);… -

Page 21

3.10 Funzionalità e caratteristiche del terminale con 3.10 Functions and features of the terminal with display grafico graphic display I font di caratteri sono configurabili dall’utente-programmatore, sia The fonts of the digits can be configured by the user-programmer, both come stile sia come dimensione. for style and dimension. -

Page 22

3.10.2 Scheda inverter per alimentazione della lampada 3.10.2 Inverter card for powering the fluorescent light on the fluorescente (CFL) del display e connessione al pCO display (CFL) and connecting to the pCO Questa scheda consente di alimentare la lampada fluorescente di This card provides power to the fluorescent back-lighting on the display retro-illuminazione del display e permette al controllore di pilotare and allows the main board to correctly control the display used. -

Page 23

4. INSTALLAZIONE 4. INSTALLATION 4.1 Ancoraggio del pCO 4.1 Anchoring the pCO Il pCO va installato su guida DIN. Per il fissaggio alla guida DIN, è The pCO should be installed on a DIN rail. To fasten the unit to the sufficiente una leggera pressione del dispositivo preventivamente DIN rail, lightly press it against the rail. -

Page 24

4.3 Avvertenze per l’installazione — ambienti di 4.3 Installation warnings — destination and connection destinazione e collegamento environments Evitare il montaggio delle schede negli ambienti che presentino le Avoid mounting of the boards in environments with the following seguenti caratteristiche: characteristics: •… -

Page 25

4.4.1 Connecting active temperature and humidity probes Al pCO possono essere collegate tutte le sonde attive di temperatura The pCO can be connected to all the Carel series AS* active ed umidità della serie AS* Carel configurate come 0/1 V oppure come temperature and humidity probes configured as 0/1V or 4/20mA. -

Page 26

The pCO can be connected to all Carel series SPK* active pressure della serie SPK* Carel o qualsiasi sensore di pressione presente sul probes or any pressure sensor on the market with an 0/20mA or mercato con segnale 0/20 mA o 4/20 mA. Gli ingressi che possono 4/20mA signal. -

Page 27

4.4.5 Collegamento degli ingressi analogici selezionati come 4.4.5 Connecting the ON/OFF selectable analogue inputs ON/OFF Il pCO permette di configurare alcuni The pCO allows some analogue inputs to ingressi analogici come ingressi digitali puliti. be configured as clean digital inputs. The built-in terminal Gli ingressi che possono accettare questi inputs in question are B4, B5, B9, B10. -

Page 28

4.5 Collegamento degli ingressi digitali 4.5 Connecting the digital inputs Il pCO prevede fino a 18 ingressi digitali per il collegamento a The pCO features up to 18 digital inputs for connecting safety devices, sicurezze, allarmi, stati di dispositivi, consensi remoti. Questi ingressi alarms, device status, remote triggers. -

Page 29

4.5.2 Ingressi digitali alimentati a 24 Vdc 4.5.2 Digital inputs powered at 24Vdc La figura seguente rappresenta uno tra i più comuni schemi di The following figure represents one of the more common connection collegamento degli ingressi digitali a 24 Vdc. diagrams for the 24Vdc digital inputs. -

Page 30

4.5.3 Ingressi digitali alimentati a 230 Vac 4.5.3 Digital inputs powered at 230Vac La figura seguente rappresenta uno tra i più comuni schemi di The following figure represents one of the more common connection collegamento degli ingressi digitali a 230 Vac. Ogni gruppo (vedi diagrams for the 230Vac digital inputs. -

Page 31

4.6 Collegamento delle uscite analogiche 4.6 Connecting the analogue outputs Il pCO fornisce fino a sei uscite analogiche a 0/10 V optoisolate The pCO provides up to six optically-isolated 0/10V analogue outputs alimentate esternamente a 24 Vac/Vdc. La Fig. 4.6.1 rappresenta lo powered externally at 24Vac/Vdc. -

Page 32

4.7.2 Uscite digitali a relè a stato solido (SSR) 4.7.2 Solid state relay digital outputs (SSR) The pCO also features a version with solid state relays (SSR) for Il pCO prevede anche una versione con relè a stato solido (SSR) per piloting devices which require an unlimited number of switchings which comando di dispositivi che necessitano di un numero illimitato di would not be supported by electromechanical relays. -

Page 33

(code S90CONN00*) from the power board (code PCOB* and cavo telefonico (cod. S90CONN00*) proveniente dalla scheda di PCO2*) into the relative jack. The model with graphic display (code potenza (cod. PCO2*) nell’apposita presa. Il modello con display grafico PCOT00OGH0) is fitted with a further screw terminal block. -

Page 34

4.9 Installazione dell’EPROM di programma del 4.9 Installing the program EPROM in the terminal with terminale con display grafico graphic display Prima di inserire/rimuovere la EPROM togliere l’alimentazione del Before inserting/removing the EPROM disconnect the power supply to terminale con display grafico. the terminal with graphic display. -

Page 35

(nodo) ad un’altra. one location (node) to another. Ogni pCO può inoltre essere collegato alla rete di supervisione Carel, Each pCO can be connected to a CAREL supervisory network, using mediante le schede opzionali PCO2004850. -

Page 36

5.1 Indirizzamento pCO 5.1 Addressing the pCO L’indirizzo è impostabile nel range 1-31 utilizzando i dip-switch 1-5. Il The address can be set in the range 1-31 using the dip-switches 1-5. valore dell’indirizzo si ottiene tramite la Tab. 5.1.1. The value of the address is obtained as in Tab. 6.1.1. R G V Fig. -

Page 37

it. -

Page 38

5.4 Connessioni elettriche pLAN 5.4 pLAN electrical connections La connessione tra schede in pLAN si effettua usando esclusivamente Connection between boards in a pLAN network is carried out using an un cavo schermato AWG20/22 costituito da una coppia ritorta e lo AWG20/22 shielded cable, made up of a twisted pair plus shield. -

Page 39

AWG 20/22 AWG 20/22 AWG 20/22 built-in terminal built-in terminal built-in terminal Fuse Fuse Fuse Fig. 5.4.3 AVVERTENZE IMPORTANTI: IMPORTANT WARNINGS: • il collegamento a terra deve essere effettuato sulla stessa linea di • the ground connection must be made to the same ground (same terra (stesso polo di terra, per tutte le schede pCO ground pole, for all the pCO boards);… -

Page 40

Fig. 5.5..2.b Fig. 5.5.2.a built-in terminal Fig. 5.5..3 Fig. 5.5.4 Solo in ambienti particolarmente rumorosi è consigliato aggiungere le Only in particularly noisy environments should the ferrites also be ferriti anche sul connettore per pLAN (J11, cavo schermato): added on the pLAN connector (J11, shielded cable): •… -

Page 41

Communication standard RS485 baud-rate (kbit/s) 65,2 baud-rate (kbit/s) 65,2 protocollo Multimaster (protocollo di Protocol Multimaster (Carel proprietary proprietà Carel) control) lunghezza massima della rete (m) Maximum length of the network 500 metres Tab.5.6.1 — cod. +030221835 rel. 3.0 — 18.02.03… -

Page 42

) verso la chiave. PCO201KEY0: 1MB flash key for pCO to be used with 1+1MB pCO PCO201KEY0: chiave con 1 MB di flash per pCO2 da usarsi con un PCO2xxxAxx or PCO2xxxBxx. con 1+1 MB: PCO2xxxAxx o PCO2xxxBxx. PCO202KEY0: 2MB flash key for pCO… -

Page 43

6.3 Scheda seriale per supervisione e teleassistenza 6.2 RS485 serial board for supervisor and RS485: PCO2004850 telemaintenance: PCO2004850 La scheda PCO2004850 è un’opzione del controllore elettronico pCO The PCO2004850 board is an option for the pCO electronic control che permette l’interfacciamento di quest’ultimo ad una rete RS485. which allows the latter to interface with an RS485 network. -

Page 44

6.7 Board for OEM humidifier management This interface allows the control of the fundamental parameters of the 6.7 Scheda per gestione umidificatore OEM OEM humidifiers manufactured by Carel (level and conductivity of the Questa interfaccia permette di water in the… -

Page 45

The pCO board features 3 signal LEDs (red, yellow and signalling LED Sulla scheda pCO2 sono presenti 3 LED di green) that provide information on the operation of the segnalazione (rosso, giallo e verde) i quali forniscono board and the status of the connection to… -

Page 46

WinLoad not suitable or incorrect Software Protection Password. communicating with WinLoad. used as I/O Expansion Carel supervisor protocol (slave) active on serial 0. *: casi in cui pCO regredisce allo stato Basso Livello: — In fase di avvio il pCO rileva la presenza del WinLoad collegato. -

Page 47

7.3 Aggiornamento software con Winload32 In all Carel 16-bit pCO sistema controllers the resident software can be In tutti i controllori Carel a 16 bit del pCO Sistema è possibile updated from a PC. To do this, Carel provides the WinLoad32.exe pro- aggiornare il software residente utilizzando un PC. -

Page 48

Rx-/Tx- Rx+/Tx+ probe 1 probe 2 probe 3 (0/1 Vdc o 4/20 mA) +VDC Carel NTC probe PT1000 digital output 1 digital output 2 digital output 3 analog output 1 (0/10 Vdc) analog output 2 (0/10 Vdc) analog output 3 (0/10 Vdc) -

Page 49

La figura seguente (Fig. 8.2) indica una configurazione nella quale The following figure (Fig. 7.2) shows a special configuration where viene ulteriormente facilitato il cablaggio dei carichi. Bisogna comunque wiring of devices is further facilitated. In any case you must consider tenere in considerazione che il max valore di corrente sopportabile da that the max current value which can be supported by each terminal is ciascun morsetto è… -

Page 50

10/55 Hz) si consiglia di fissare tramite fascette i cavi collegati al pCO 10/55Hz), we suggest you to fasten, through fastening clamps, the a circa 3 cm di distanza dai connettori. cables connected to the pCO2 at about 3cm of distance from the connectrors. 9.2 Caratteristiche elettriche pCO alimentazione (controllore con terminale connesso) 22/40 Vdc e 24 Vac ±15% 50/60 Hz. -

Page 51

5, 8, 10, rispettivamente sulle schede SMALL, MEDIA, LARGE tipo • passivo: sensore di temperatura NTC Carel (-50/90 °C; R/T 10 kΩ ± 1% a 25 °C, =3,435 °K ± 1%), PT1000 (-100/200 °C; R/T 1000 Ω/°C) o input digitale pulito, 25/80 selezionabili via software (ingressi: B4, B5, B9, B10);… -

Page 52

9.2.2 Ingressi digitali 9.2.2 Digital inputs tipo ingressi optoisolati a 24 Vac 50/60 Hz o 24 Vdc o 230 Vac 50/60 Hz. Per gli ingressi a 230 Vac l’isolamento è principale) n. massimo 8, 14, 18, rispettivamente sulle schede: SMALL, MEDIA, LARGE, secondo le combinazioni riportate qui sotto: taglia scheda n. -

Page 53

9.2.4 Uscite digitali 9.2.4 Digital outputs n. massimo 8, 13, 18, rispettivamente sulle schede: SMALL, maximum no. 8, 13, 18, respectively on the SMALL, MEDIA, MEDIA, LARGE LARGE boards tipo a relè elettromeccanici type electromechanical relay Tab. 9.2.4.1 Tab. 9.2.4.1 Sono raggruppate a 3 con due morsetti di polo comune per un facile These are divided into 3 groups with two common pole terminals to assemblaggio dei poli comuni. -

Page 54

(per incollaggio sul contenitore plastico) adhesive on edge (for attaching to plastic case) Tab. 9.4.1.2 Tab. 9.4.1.2 Policarbonato tastiera (standard Carel) per PCOT*CB* e PCOI* Keypad polycarbonate label (Carel standard) for PCOT*CB* and PCOI* spessore (mm) 0,175 thickness (mm) 0.175… -

Page 55

9.4.2 Caratteristiche elettriche terminale 9.4.2 Terminal electrical specifications alimentazione 24 Vac (da trasformatore di Classe II e separato) per PCOI00PGL0/PCOT00PGL0 21/30 Vdc (dalla sch. di potenza per mezzo del cavo telefonico) per tutti gli altri modelli 80C52 — 8MHz condizioni di funzionamento -10T55 (-10/60 ºC, 14/149 °F) per PCOT000L60 e PCOT00PGH0 0T50 (0/50 ºC, 32/122 °F) per tutti gli altri modelli, 90% U.R. -

Page 56

10. MONTAGGIO TERMINALE UTENTE 10. USER TERMINAL MOUNTING 10.1 Montaggio a pannello 10.1 Panel mounting 10.1.1 PCOT* 10.1.1 PCOT* Riferimenti Fig. 10.1.1.1, (dimensioni in mm). Legend Fig. 7.1.1.1, (dimensions in mm). descrizione description coperchio posteriore rear cover pannello panel dima di foratura drilling template coperchio anteriore front cover… -

Page 57

11. DIMENSIONI 11. DIMENSIONS AVVERTENZA: tutte le quote riportate sulle figure che seguono sono WARINING: all the dimensions are in mm. espresse in mm. 11.1 pCO 11.1 pCO LARGE (18 moduli DIN) LARGE (18-DIN modules) built-in terminal Fuse Fig. 11.1.1 MEDIUM (18 moduli DIN) MEDIUM (18-DIN modules) built-in terminal… -

Page 58

11.2 Terminale utente 11.2 Terminal user 11.2.1 PCOT* 11.2.1 PCOT 170 mm 170 mm 170 mm 43 mm __________ __________ A____ B____ Room 1 Parem __________ Graphic Temp __________ __________ on/off alarm enter on/off alarm enter on/off alarm enter Fig. 11.2.1.1 1. -

Page 59

. Nel caso in cui sia ancora the power supplied by the pCO . If this is still near zero, contact prossima a zero contattare l’assistenza Carel; in caso contrario la the Carel service department; otherwise, the removed connection connessione tolta metteva in corto circiuto l’alimentazione. -

Page 60

Il valore di pressione “Ps” che la sonda sta inviando è così ricavabile The pressure value “Ps” sent by the probe can be calculated as (FS = Fondo Scala): follows (FS=Full Scale): Ps = (Vmis/50 — 0,004) x (FSmax — FSmin) / 0,016 + Fsmin Ps = (Vread/50 — 0.004) x (FSmax — FSmin) / 0.016 + Fsmin Esempio: la sonda impiegata ha Fsmin = -0,5 bar, Fsmax = 7 bar;… -

Page 61

2. che il dimensionamento del trasformatore di alimentazione (non 2. that the ratings of the power transformer (not supplied by CAREL) fornito da CAREL) sia corretto (vedi paragrafo ALIMENTAZIONE); are correct (see paragraph on POWER) 3. -

Page 64

Agenzia / Agency: CAREL S.p.A. Via dell’Industria, 11 — 35020 Brugine — Padova (Italy) Tel. (+39) 049.9716611 — Fax (+39) 049.9716600 e-mail: carel@carel.com — www.carel.com…

Подробнее устранение неисправностей описано в руководстве по эксплуатации каждой модели.

На нашем сайте представлены запасные части для оборудования Carel.

Для подбора запасных частей Carel сообщите нам полную маркировку блока и наименование запчасти любым удобным способом.

Коды ошибок управляющих блоков для систем вентиляции и кондиционирования Carel (PCOxs электро)

| Код | Описание ошибки |

|---|---|

| E01 | Поступил сигнал от пожарной сигнализации |

| E02 | Неисправен датчик наружной температуры |

| E03 | Неисправен датчик температуры в помещении |

| E04 | Неисправен датчик температуры приточного воздуха |

| E05 | Неисправен датчик температуры возвращаемого теплоносителя |

| E08 | Неисправен датчик температуры возвращаемого теплоносителя после нагревателя второго нагрева |

| E09 | Неисправен датчик влажности приточного воздуха |

| E10 | Неисправен датчик влажности воздуха в помещении |

| E12 | Неисправен датчик температуры насыщения |

| E13 | Один или несколько аналоговых входов под ручным управлением |

| E14 | Один или несколько аналоговых выходов под ручным управлением |

| E15 | Один или несколько дискретных входов под ручным управлением |

| E16 | Один или несколько дискретных выходов под ручным управлением |

| E17 | Нет сигнала статуса от приточного вентилятора |

| E18 | Нет сигнала статуса от вытяжного вентилятора |

| E19 | Нет сигнала статуса от вытяжного и (или) приточного вентилятора |

| E20 | Низкая наружная температура для использования режима «лето» |

| E21 | Запуск заблокирован. Низкая температура возвращаемого теплоносителя или клапан в контуре нагревателя открыт менее чем на 80% (или иное значения согласно St13) |

| E22 | Защита от замерзания водяного нагревателя. Предварительная тревога |

| E23 | Защита от замерзания водяного нагревателя. Основная тревога |

| E24 | Неисправен насос в контуре водяного нагревателя |

| E25 | Защита от замерзания водяного нагревателя второго нагрева. Предварительная тревога |

| E26 | Защита от замерзания водяного нагревателя второго нагрева. Основная тревога |

| E27 | Неисправен насос в контуре водяного нагревателя 2 |

| E28 | Перегрев электронагревателя |

| E29 | Активировано оттаивание рекуператора |

| E30 | Неисправен привод ротора рекуператора |

| E31 | Неисправен компрессорно-конденсаторный агрегат (ККА) |

| E32 | Фильтр на притоке загрязнен |

| E33 | Фильтр на вытяжке загрязнен |

| E34 | Фильтр загрязнен |

| E37 | Отсутствует связь с платой расширения |

| E39 | Получен внешний сигнал тревоги |

| E40 | Перезапуск после подачи питания |

| E41 | Термозащита приточного вентилятора |

| E42 | Термозащита вытяжного вентилятора |

| E43 | Термозащита вентиляторов |

-

Page 1: User Manual

/ easy compact / easy split electronic digital thermostats with defrost control User manual NO POWER & SIGNAL CABLES TOGETHER READ CAREFULLY IN THE TEXT! I n t e g r a t e d C o n t r o l S o l u t i o n s & E n e r g y S a v i n g s…

- Page 3

The technical specifi cations shown in the manual may be changed without prior warning. The liability of CAREL in relation to its products is specifi ed in the CAREL general contract conditions, available on the website www.carel.com and/or by specifi c agreements with customers; specifi cally, to the extent where allowed… -

Page 5: Table Of Contents

Content 1. INTRODUCTION 1.1 Main characteristics ………………..7 1.2 Models ……………………7 1.3 Main diff erences between easy, easy compact and easy split ..9 1.4 NTC and PTC probes ………………9 1.5 Accessories ………………….9 1.6 Defi nitions …………………..9 2. ASSEMBLY AND INSTALLATION 2.1 Assembly …………………..10 2.2 Electrical connections ………………11…

-

Page 7: Introduction

1.1 Main characteristics The following table lists the main features of the easy, easy compact and easy split controllers. Features…

- Page 8

fan management with comp. off 4.10 night-time operation with light 4.11 management Table 1.b * available but cannot be set from the keypad nor the programming key. easy/easy compact/easy split +030220791 — rel. 3.2 — 13.07.2010… -

Page 9: Main Diff Erences Between Easy, Easy Compact And Easy Split

PTC, and 10 kΩ for the NTC. The type of probe installable depends on the model (order code). The easy split models, on the other hand, only use NTC and high temperature NTC probes (50 KΩ at 25°C), selected by parameter.

-

Page 10: Assembly And Installation

(formation of corrosive patina with possible oxidation (*) do not over-tighten the screws. and reduction of insulation. To install easy, easy compact and easy split: make an opening in the panel based on the drilling template, 71×29 mm. Dismantling using the screws from the front •…

-

Page 11: Electrical Connections

• the probes can be installed up to a maximum distance of 30 m from the controller (10 m for easy split). To extend the distance of the probes, 230Vac or use cables with a minimum cross-section of 1 mm2, shielded where…

- Page 12

(*) For codes PJEZ*8**5* the temperature range is -10T50 °C and the maximum current is 16 A. See the table of technical specifi cations. ———— = recommended internal power supply connections. easy/easy compact/easy split +030220791 — rel. 3.2 — 13.07.2010… -

Page 13: Wiring Diagram For Multiple Units

120 ohm Fig. 2.h easy split: The serial connection for the easy split models with 4 relays depends on the setting of parameter H7, as the management of the fourth relay (RL4) and serial communication are mutually exclusive. The factory setting is H7=1, which means the fourth relay is enabled. To enable connection to the supervisor network: power down the controller;…

-

Page 14: User Interface And Start Up

EZY together (2 — more than 3 s: accesses and 3) activate Keypad functions for easy and easy compact M models the parameter setting menu parameter (models with keypad only) (enter password 22) reset — mutes the audible alarm…

-

Page 15: Easy Split

Display the controller to make it operative. CAREL then recommends to check that the display does not show any alarm signals (see par. “5.1 Table of alarms and signals” on page 31), then set the time and date (in the models fi tted with RTC, see par. “4.11 Clock and time band parameters”…

- Page 16

Press DOWN for more than 3 s (activated only if the temperature conditions are right, for easy split only if the light output is not set, H1≠4). Alternatively, on easy split models, if the light output is set (H1=4), the defrost can be activated by pressing UP and DOWN together, when H6=1). -

Page 17: Functions And Parameters

This chapter describes all the functions of the easy, easy compact and Example: In the case of bottle coolers, typically used in supermarkets, easy split. See Table 1.b for the compatibility of the functions with the when the doors are opened frequently, due to the greater thermal inertia model used.

-

Page 18: Temperature Control

Used to enable or disable the temperature display with the resolution to Value that automatically increases the set point temperature during the the tenths of a degree between -20 and + 20 (easy and easy split) or -10 night-time operation time bands.

-

Page 19: Continuous Cycle

(H1=7). 4.6 Compressor protection The easy, easy compact and easy split controllers are fi tted with an automatic compressor protection system to avoid continual starts or stops of the unit. The protection is based on the times in minutes set for parameters c0;…

-

Page 20: Defrost

• from the keypad pressing the DOWN button for 3 s (manual defrost) (for easy split H1 must be ≠4. If H1=4 the UP and DOWN buttons can be pressed together, when H6=1); dt: end defrost temperature set point/defrost temperature threshold •…

- Page 21

(only manual defrosts from the keypad or multifunction contact) or to set dI to a value which is greater than the maximum set interval. easy/easy compact/easy split +030220791 — rel. 3.2 — 13.07.2010… -

Page 22: Alarm Parameters

A4: 3rd input confi guration (easy compact) The multifunction input is only available on the easy models with three inputs; is not available on the easy compact models. A0: alarm and fan temperature diff erential This parameter is used to set the functions of the input.

- Page 23

(1) contact open= alarm detected unit 1 contact closed= normal operation. When A4=1 easy can be connected to an external contact for immediately dP (2) d5 (2) signalling alarms. The alarm signal can be delayed by setting parameter unit 2… - Page 24

14 Product probe again). Table 4.o AC-AE/2 A4=0, 1, 2, 3: see A4=0, 1, 2, 3 for easy, easy compact in previous paragraph. AC-AE A4=4 Curtain switch and night-time operation See the previous paragraph. In easy split models if the light output is Fig. -

Page 25: Door Open/Closed Management

Door switch with evaporator fan off and light not managed A4=13 for easy split). See A4=7 for easy, easy compact in previous paragraph. In easy split models with light output confi gured (H1=4), the status of the light output remains unchanged.

- Page 26

Easy split Closing the door the fi rst time: the controller maintains the previous status: In easy split models the algorithm for managing the door depends on • the fans and/or compressor (see parameter ‘A4’) remain off ; the type of unit selected, according to parameter Ado, and the setting •… -

Page 27: Evaporator Fan Management Parameters

The evaporator fan control temperature is measured by probe 2, (connector 10). To know which output is associated with the fan, see the wiring diagram for the “easy” model used (see par. “2.2 Electrical connections” page 11). Important: these parameters are not available in the compact models.

-

Page 28: Clock And Time Band Parameters

Parameters for setting up to 4 defrost time bands 4.11 Clock and time band parameters d1d…d4d Defrost event day setting The RTC (Real Time Clock), not available on the easy compact models, is d1d…d4d=0 no defrost event used to manage the defrost function, curtain switch/night-time operation d1d…d4d=1…7 Monday to Sunday…

-

Page 29: Rapid Parameter Set Selection (Ezy)

Examples of operation: the digital input. On easy split models there are also the light and second compressor outputs, with or without rotation. example 1…

- Page 30

When set to a positive value (values from 0 to 31 are used REQ2 by CAREL for the basic models), if a parameter, including the set point, is modifi ed from the keypad, the value becomes negative. This allows any modifi cations made the parameters compared to the initial settings to be monitored. -

Page 31: Tables Of Alarms And Parameters

5. TABLES OF ALARMS AND PARAMETERS 5.1 Table of alarms and signals Note: in easy split controllers, when starting control (powering up When an alarm is activated, the display shows the corresponding message the controller and/or switching from OFF status), the high that fl ashes alternating with the temperature;…

-

Page 32: Data Error

• press the SET button for more than 3 s to permanently save the parameters and exit the parameter setting procedure. easy/easy compact/easy split +030220791 — rel. 3.2 — 13.07.2010…

-

Page 33: Table Of Easy Parameters

X, Y, C (*) AUX time band ON day days X, Y, C (*) AUX time band ON hours X, Y, C (*) AUX time band ON minutes X, Y, C (*) easy/easy compact/easy split +030220791 — rel. 3.2 — 13.07.2010…

-

Page 34: Table Of Easy Compact Parameters

S (with 1 & 2 probes) Table 5.d Warning Warning the easy compact models only display two digits. If the range is below -99 and above 99, the terminal will display “- — “. easy/easy compact/easy split +030220791 — rel. 3.2 — 13.07.2010…

-

Page 35: Table Of Easy Split Parameters

S,C (*) night time band ON day S,C (*) night time band ON hours S,C (*) nOM night time band ON minutes S,C (*) night time band OFF day S,C (*) easy/easy compact/easy split +030220791 — rel. 3.2 — 13.07.2010…

-

Page 36: Table Of Ezy Parameter Sets

(reverse) digital input alarm management defrost with temp. control (d0= 4) defrost by temperature (d0=4) easy/easy compact/easy split +030220791 — rel. 3.2 — 13.07.2010…

- Page 37

(reverse) digital input alarm management defrost with temp. control (d0= 4) defrost by temperature (d0=4) easy/easy compact/easy split +030220791 — rel. 3.2 — 13.07.2010… -

Page 38: Troubleshooting

• F1 (evaporator fan control set point) too low. • post-dripping delay set 3. if F0=0 • F2=1 and the compressor is off • dripping in progress • post-dripping in progress Table 5.i easy/easy compact/easy split +030220791 — rel. 3.2 — 13.07.2010…

-

Page 39: Technical Specifications

Warning : do not run the power cable less than 3 cm from the bottom of the device or the probes; for the connections, only use Fig. 6.b copper wires. 65,29 71×29 Fig. 6.a easy/easy compact/easy split +030220791 — rel. 3.2 — 13.07.2010…

-

Page 40: Easy Split Technical Specifi Cations

(**) Minimum T OFF between two starts must be greater than 1 min. (***) Conformity to UL873 only corresponds to models without plastic case. Terminal Power board 103.5 Ø 4 38,29 71×29 Fig. 6.c Fig. 6.d easy/easy compact/easy split +030220791 — rel. 3.2 — 13.07.2010…

-

Page 41: Electromagnetic Compatibility

6.4 Electromagnetic compatibility The easy and easy compact series is compliant with the EU standards on electromagnetic compatibility: • for household appliances EN 55014-2 and EN 55014-1; • for residential, commercial and light industrial environments EN 50082-1 and EN 50081-1;…

- Page 42

Notes… - Page 44

Agenzia / Agency: CAREL INDUSTRIES — HQs Via dell’Industria, 11 — 35020 Brugine — Padova (Italy) Tel. (+39) 049.9716611 — Fax (+39) 049.9716600 e-mail: carel@carel.com — www.carel.com…

Подробнее устранение неисправностей описано в руководстве по эксплуатации каждой модели.

На нашем сайте представлены запасные части для оборудования Carel.

Для подбора запасных частей Carel сообщите нам полную маркировку блока и наименование запчасти любым удобным способом.

Коды ошибок управляющих блоков для систем вентиляции и кондиционирования Carel (PCOxs электро)

| Код | Описание ошибки |

|---|---|

| E01 | Поступил сигнал от пожарной сигнализации |

| E02 | Неисправен датчик наружной температуры |

| E03 | Неисправен датчик температуры в помещении |

| E04 | Неисправен датчик температуры приточного воздуха |

| E05 | Неисправен датчик температуры возвращаемого теплоносителя |

| E08 | Неисправен датчик температуры возвращаемого теплоносителя после нагревателя второго нагрева |

| E09 | Неисправен датчик влажности приточного воздуха |

| E10 | Неисправен датчик влажности воздуха в помещении |

| E12 | Неисправен датчик температуры насыщения |

| E13 | Один или несколько аналоговых входов под ручным управлением |

| E14 | Один или несколько аналоговых выходов под ручным управлением |

| E15 | Один или несколько дискретных входов под ручным управлением |

| E16 | Один или несколько дискретных выходов под ручным управлением |

| E17 | Нет сигнала статуса от приточного вентилятора |

| E18 | Нет сигнала статуса от вытяжного вентилятора |

| E19 | Нет сигнала статуса от вытяжного и (или) приточного вентилятора |

| E20 | Низкая наружная температура для использования режима «лето» |

| E21 | Запуск заблокирован. Низкая температура возвращаемого теплоносителя или клапан в контуре нагревателя открыт менее чем на 80% (или иное значения согласно St13) |

| E22 | Защита от замерзания водяного нагревателя. Предварительная тревога |

| E23 | Защита от замерзания водяного нагревателя. Основная тревога |

| E24 | Неисправен насос в контуре водяного нагревателя |

| E25 | Защита от замерзания водяного нагревателя второго нагрева. Предварительная тревога |

| E26 | Защита от замерзания водяного нагревателя второго нагрева. Основная тревога |

| E27 | Неисправен насос в контуре водяного нагревателя 2 |

| E28 | Перегрев электронагревателя |

| E29 | Активировано оттаивание рекуператора |

| E30 | Неисправен привод ротора рекуператора |

| E31 | Неисправен компрессорно-конденсаторный агрегат (ККА) |

| E32 | Фильтр на притоке загрязнен |

| E33 | Фильтр на вытяжке загрязнен |

| E34 | Фильтр загрязнен |

| E37 | Отсутствует связь с платой расширения |

| E39 | Получен внешний сигнал тревоги |

| E40 | Перезапуск после подачи питания |

| E41 | Термозащита приточного вентилятора |

| E42 | Термозащита вытяжного вентилятора |

| E43 | Термозащита вентиляторов |

Промышленный контроллер pCOxs – производная серии устройств фирмы «Carel», представлен на текущий момент устаревшей модификацией системы. Однако аппаратура успешно используется до сего дня под управление HVAC (Heating Ventilation Air Conditioning) и других систем. В принципе, вполне надёжная и удобная для эксплуатации система, на практике показавшая удовлетворительную работу. По сравнению с промышленными контроллерами других фирм-производителей, демонстрирует вполне достойную альтернативу. Рассмотрим этот прибор, а также возможности программирования.

Промышленный контроллер pCOxs фирмы «Carel»

Внешне прибор выглядит компактно исполненной электронной аппаратурой, заключённой внутри корпуса из прочного поливинилхлорида. Лицевая панель выполнена под расположение кнопок управления в количестве шести штук, плюс внедрён контрольный дисплей. На корпусе имеются вентиляционные пазы, специально сделанные для обеспечения охлаждающего эффекта по отношению к электронной плате. Все терминальные соединители обозначены.

Вот таким выглядит промышленный контроллер pCOxs производства компании «Carel» — продукт на момент 2021 года, однако, снятый с производства в пользу серии c. pCO5

Электроника на промышленный контроллер pCOxs предполагает питание переменным напряжением 24 вольт, для получения которого используется понижающий сетевой трансформатор 220/24. Также допускается подключение питания постоянным током с напряжением 20-60 вольт.

Не допускается использование промышленного контроллера pCOxs в местах, где относительная влажность более 90%, где возможны сильные вибрации или удары. Недопустим залив аппаратуры водой, эксплуатация в условиях агрессивных загрязняющих сред, в местах, способствующих образованию коррозии, окисления и т. п. Также необходимо исключать высокий уровень магнитных и / или радиочастотных помех.

Как установить промышленный контроллер pCOxs?

Корпус на промышленный контроллер pCOxs сделан с расчётом установки внутри шкафов на DIN-рейку. Для того чтобы закрепить прибор, достаточно завести аппарат на DIN-рейку и лёгким нажимом на корпус зафиксировать на месте. Задние «язычки» крепления защелкнутся, блокируя устройство на DIN-рейке.

Снять устройство так же просто, как и установить. Достаточно использовать отвёртку в качестве рычага, чтобы поднять блокирующие прибор выступы. Таким способом поднимаются «язычки», удерживающие аппарат в заблокированном положении пружинами.

Электропитание контроллера подключается между терминальными выводами, обозначенными «G» и «G0». Используется питающее напряжение 24 вольта переменного тока или 20/60 вольт постоянного тока. В случае питания переменным током, как правило, применяется трансформатор класса II, минимальным номиналом 25 ВА.

Источник питания контроллера и терминала требуется разделять с цепями питания иных электрических компонентов, устанавливаемых в составе электрического щита управления. Обязательно задействовать предохранитель 250 вольт 1A в линии питания контроллера. Блок питания необходимо функционально изолировать от всех входов / выходов и последовательных соединений.

Терминальные соединения на аналоговые входы

Аналоговые входы на промышленный контроллер pCOxs допускают настройку практически всех типов распространённых датчиков NTC (0/1В, 0/10В, 0/20мА, 4/20мА). Различные типы датчиков подбираются с помощью программного обеспечения.

Промышленный контроллер pCOxs допускает подключение активных датчиков температуры и влажности серии «Carel AS», настроенных как по напряжению 0/1В (только для сигнала влажности, не температуры), так и по току 4/20 мА. Для подключения такого типа датчиков используются терминальные входы «B1», «B2». Схема подключения представлена ниже.

Схема подключения активных датчиков температуры/влажности на входной терминал промышленного контроллера pCOxs производства фирмы «Carel»

Вообще, все аналоговые входы прибора, от «B1» до «B4», совместимы с 2-проводными датчиками типа «NTC» после настройки программы. Промышленный контроллер pCOxs рассчитан на подключение ко всем активным датчикам давления серии «Carel SPK». Или же к любому другому датчику давления, которым обеспечивается сигнал 0/20 мА или 4/20 мА.

Кроме всего прочего, прибор допустимо подключить ко всем активным датчикам давления серии «Carel SPKT» или любому другому датчику давления, доступному на рынке. Главное чтобы соблюдался принцип наличия логометрического сигнала 0/5В. Соответственно, терминальные входы «B1», «B2», «B3», «B4» рассчитаны под приём сигналов этих датчиков после настройки программы на плате.

Терминальные соединения на цифровые входы

Конструкцией на промышленный контроллер pCOxs обеспечиваются до 6 цифровых входов с контактами без потенциала для подключения:

Весь набор этих входов работает от напряжения 24 вольта постоянного тока с гарантированным током на контакте 6 мА.

Схема терминальных подключений по цифровым входам промышленного контроллера фирмы «Carel» серии pCOxs

Также прибор обеспечивает два аналоговых выхода по уровням 0/10 вольт без оптовой развязки и один аналоговый выход PWM с нарезкой фазы. Кроме этого устройством обеспечивается до 5 цифровых выходов под электромеханические реле. Реле делятся на три группы. Каждая группа допускает разное напряжение.

Также существуют версии с твердотельными реле (pCO1002ax0 и pCO1002bx0) для управления устройствами, которые требуют неограниченного количества циклов переключения. Следовательно, поддержка электромеханическими реле здесь не предусмотрена. Назначение для нагрузок с питанием от 24 вольт переменного/постоянного тока с максимальной мощностью.

Установка пользовательского терминала

Соединить пользовательский терминал и промышленный контроллер pCOxs допустимо через 6-жильный телефонный кабель, поставляемый фирмой «Carel». Подключение осуществляется простой вставкой телефонного штекера в разъём «J10» платы прибора и в разъём «B» на пользовательском терминале.

Промышленный контроллер pCOxs поддерживает подключение к локальной сети «pLAN», что позволяет передавать данные или информацию из одного места в другое. Каждый аппарат можно подключить к супервизорной сети «Carel» с помощью дополнительных плат.

Терминалы приборов могут контролировать переменные управления:

Если один или несколько терминалов отключены или неисправны, программа управления продолжит работать на каждой исправной плате.

Согласно техническим раскладкам фирмы-производителя, подключение к ПК осуществляется при помощи дополнительных модулей, созданных опять же самой фирмой. В частности, используется преобразователь интерфейсов USB/RS485, с которым аппарат соединяется через разъём «pLAN»(J11).

Подключение на компьютер по интерфейсу USB/RS485 может потребоваться, к примеру, для обновления прошивки или загрузки в контроллер другой прикладной программы. Однако практика показала, что помимо фирменного преобразователя вполне возможны применения других преобразователей, к примеру, китайского образца, как на картинке ниже:

Преобразователь интерфейсов USB/RS485 производства китайской народной республики. Работает не хуже фирменного преобразователя «Carel»

В качестве программного обеспечения используется фирменная программа от «Carel», именуемая «pCOManager». Скачивается бесплатно на официальном сайте, для чего потребуется регистрация как пользователя. Находится программное обеспечение на вкладке «Software & Support». Там же можно найти ряд других утилит.

Видео в тему: расклад важных функций контроллера Carel

Видеоролик ниже даёт представление о системных функциях промышленного контроллера Carel pCOxs, посредством которых выстраивается работа вентиляционной системы определённой конфигурации:

Как восстановить загрузку контроллера Carel pCOxs?

Видеоролик ниже демонстрирует пример восстановления функции загрузки промышленного контроллера Carel pCOxs. Такой дефект встречается иногда на практике и требует исправления для нормальной работы. В некоторых случаях показанный метод помогает:

При помощи информации: KSA

КРАТКИЙ БРИФИНГ

Источники:

https://zetsila. ru/%D0%BF%D1%80%D0%BE%D0%BC%D1%8B%D1%88%D0%BB%D0%B5%D0%BD%D0%BD%D1%8B%D0%B9-%D0%BA%D0%BE%D0%BD%D1%82%D1%80%D0%BE%D0%BB%D0%BB%D0%B5%D1%80-pcoxs-%D0%B4%D0%BB%D1%8F-hvac/

-

Page 1

controlador electrónico programable programmable electronic controller Manual deI Usuario User manual… -

Page 3

¡Queremos ahorrarle tiempo y dinero! We wish to save you time and money! Le aseguramos que la lectura completa de este We can assure you that a thorough reading of this manual le garantizará una instalación correcta y manual will guarantee correct installation and safe use of un uso seguro del producto descrito. -

Page 5: Table Of Contents

Indice: Index: INTRODUCIÓN INTRODUCTION CARACTERÍSTICAS GENERALES GENERAL CHARACTERISTICS 1.1 pCO Programabilidad 1.2 Programmability ARQUITECTURA DEL HARDWARE HARDWARE STRUCTURE Códigos de los instrumentos y accesorios 2.1 Instruments and accessory codes Significado de las entradas/salidas 2.2 Meaning of the inputs/outputs EL TERMINAL DEL USUARIO THE USER TERMINAL 3.1 Adjusting the contrast on the LCD display Ajuste del contraste del display LCD…

-

Page 6

12.2 Montaje en pared 12.2 Wall-mounting 13. DIMENSIONS DIMENSIONES 13.1 pCO 13.1 pCO 13.2 Terminal del usuario 13.2 User terminal TROUBLESHOOTING RESOLUCIÓN DE PROBLEMAS manual — cod. +030220347 — rel. 1.0 — 18.03.03… -

Page 7: Características Generales

EasyTools, con las siguientes ventajas: system, with the following advantages: • transfer of the software to differ ent types of CAREL hardware. • transferencia del software a distintos tipos de hardware de CAREL. Las aplicaciones desarrolladas para el pCO, pCO…

-

Page 8: Arquitectura Del Hardware

RS485 standard, is made using the optional serial linea serie de supervisión / telegestión basada en el estándar RS485, cards (pCOXS004850) and the CAREL or ModBus communication se realiza utilizando las tarjetas serie opcionales (PCO1004850) y el protocol.

-

Page 9

Fig. 2.1 The power of the application software means that the user terminal Gracias a la potencia del programa de aplicación, el terminal del usuario permite: allows: • la programación inicial de la máquina con acceso protegido por • the initial programming of the unit, with password-protected access to contraseña para garantizar la seguridad;… -

Page 10: Códigos De Los Instrumentos Y Accesorios

Un posible arquitectura de hardware es la siguiente: One possible set of hardware is as follows: 1. terminal del usuario con teclado, display y LEDs de señalización; 1. user terminal with keypad, display and signal LEDs; 2. pCO 2. pCO 3.

-

Page 11

A continuación se muestra una descripción del pCO refiriéndose al The following is a description of the pCO with reference to the layout: esquema: Fig. 2.1.1 1 Power supply connector [G (+), G0 (-)] 24 Vac or 20/60 Vdc; 1 Conector para la alimentación [G (+), G0 (-)] 24 VCA o 20/60 VCC; 2 Entrada (24 VCA) en corte de fase y entradas analógicas 2 Phase cutting and analogue inputs (24 Vac): NTC, 0/1 V, 0/5 V, 0/20 mA, NTC, 0/1 V, 0/5 V, 0/20 mA, 4/20 mA, +5Vref para alimentación de… -

Page 12: Significado De Las Entradas/Salidas

2.2 Significado de las entradas/salidas 2.2 Meaning of the inputs/outputs Esta tabla resume las entradas y las salidas y una breve descripción This table summarises the inputs and the outputs and provides a brief de cada una. description of each. conector señal descripción…

-

Page 13: El Terminal Del Usuario

3. THE USER TERMINAL 3. EL TERMINAL DEL USUARIO 3.1 Regulación del contraste del display LCD 3.1 Adjusting the contrast on the LCD display Los modelos con display LCD 4×20 están dotados de un potenciómetro The models with 4×20 LCD display have a trimmer for adjusting the para la regulación del contraste del display.

-

Page 14: Display Lcd Gráfico Montaje En Pared O Panel

3.4 Display LCD gráfico montaje en pared o panel 3.4 Graphic LCD display for wall or panel mounting Characteristics Características código PCOT00PGH0 code PCOT00PGH0 128 x 64 px, gráfico, 128 x 64 pixels, retroiluminado graphic, backlit 128 x 64 px, gráfico, 128 x 64 pixels, retroiluminado graphic, backlit…

-

Page 15: Teclado De Terminal Pco

3.7 Display de 3 dígitos LED 32 x 72 3.7 3 digit LED display, 32×72 Características Characteristics código PCOT32RN00 code PCOT32RN00 número de dígitos LED number of LED digits número de botones number of buttons Fig. 3.7.1 3.8 Teclado de terminal pCO 3.8 pCO terminal keypad nº…

-

Page 16: Funcionalidad Y Características Del Terminal Con Display Gráfico

3.8.1 Funciones típicas de los botones en las aplicaciones 3.8.1 Typical functions of the buttons in standard CAREL estándar de CAREL applications muestra los valores medidos por las sondas; displays the values measured by the probes; displays the values correspond. to the maintenance of the…

-

Page 17

3.9.1 Tarjeta de display gráfico 3.9.1 Graphic display board La tarjeta soporta el microprocesador, la memoria y la EPROM, que The board supports the microprocessor, the memory and the EPROM almacena el programa de aplicación para la gestión del display y del that stores the application program for managing the display and the teclado. -

Page 18: Instalación

3.9.3 Escudo protector (tarjeta de impresora opcional) 3.9.3 Protective shield (optional printer card) Para todos los modelos del terminal gráfico For all pCO graphic terminal models an pCO existe la posibilidad de insertar una optional card can be inserted in the pin tarjeta opcional para la gestión de una connector marked by number 2 in impresora serie, en el conector de pines…

-

Page 19: Installation Warnings — Destination And Connection Environments

4.3 Advertencia para la instalación — ambientes de destino y 4.3 Installation warnings — destination and connection de conexión environments Evitar el montaje de las tarjetas en ambientes de las siguientes Avoid installing the boards in environments with the following características: characteristics: •…

-

Page 20: Connecting The Analogue Inputs

0-1 V y por lo tanto no siempre es compatible con 0-1 V, and therefore is not always compatible with the standard 10 la señal estándar de 10 mV/°C de las sondas CAREL (para temperatu- mV/°C signal from the CAREL probes (for negative temperatures or ras negativas y superiores a 100 °C puede generar una alarma de la…

-

Page 21

The pCO can be connected to all the CAREL SPK* series active la serie SPK* de CAREL o cualquier otra sonda de presión disponible pressure probes or any other pressure sensor available on the market en el mercado con señal de 0/20 mA ó 4/20 mA. Las entradas que with a 0/20 mA or 4/20 mA signal. -

Page 22

The pCO can be connected to all the CAREL SPKT series active la serie SPKT de CAREL o cualquier sonda de presión presente en el probes pressure or any other pressure sensor available on the market mercado con señal de 0/5 V proporcional. Las entradas que pueden with an 0/5V ratiometric signal. -

Page 23: Connecting The Digital Inputs

4.5 Conexión de las entradas digitales 4.5 Connecting the digital inputs El pCO proporciona hasta 6 entradas digitales, con contactos libres de The pCO features up to 6 digital inputs, with voltage-free contacts, for tensión, para conectar dispositivos de seguridad, alarmas, indicadores connecting safety devices, alarms, device status indicators, remote del estado de dispositivos, interruptores remotos, etc.

-

Page 24: Connecting The 0/10 Vdc Analogue Outputs

4.6 Conexión de las salidas analógicas de 0/10 VCC 4.6 Connecting the 0/10Vdc analogue outputs El pCO dispone de dos salidas analógicas a 0/10 V. La Fig. 4.6.1 The pCO provides two 0/10 V. Fig. 4.6.1 shows the electrical representa el esquema eléctrico de conexión. connection diagram.

-

Page 25: Connecting The Digital Outputs

4.8 Conexión de las salidas digitales 4.8 Connecting the digital outputs El pCO dispone de hasta 5 salidas digitales con relés electromecánicos. The pCO features up to 5 digital outputs with electromechanical Para facilitar la instalación los terminales comunes de los tres primeros relays.

-

Page 26: Instalación Del Terminal Del Usuario

The connection between the user terminal and the pCO is made mediante un cable telefónico de 6 vías, suministrado por CAREL. Para using a 6-way telephone cable supplied by CAREL. To make the efectuar la conexión basta insertar el conector telefónico en el terminal…

-