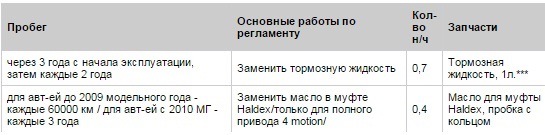

Данный рассказ будет весьма полезен тем, кто еще ни разу не менял масло в муфте Haldex.

Купил я машину с пробегом 40т.км и «возрастом» 2 года, т.е. сразу после завершения гарантии.

Листая Drive2 наткнулся на то, что часто возникает проблема с муфтой если вовремя не заменить в ней

масло и фильтр. Но так как я был уверен, что первую замену масло и фильтр сделал предыдущий хозяин согласно регламенту ТО на пробеге 30т.км. (я думал что дилер уж точно это впарит) и даже поленился проверить данную запись в сервисной книжке. Вторую замену я планировал сделать пораньше — на 50т.км.

Примерно на пробеге 48т.км я купил себе VAG-COM. При сканировании я увидел одну единственную ошибку:

00448 — Haldex Clutch Pump (V181) (Подкачивающий насос муфты)

011 — Open Circuit — Intermittent

Диагноз — накрылся подкачивающий насос муфты Haldex…Вот тут началось самое веселое…

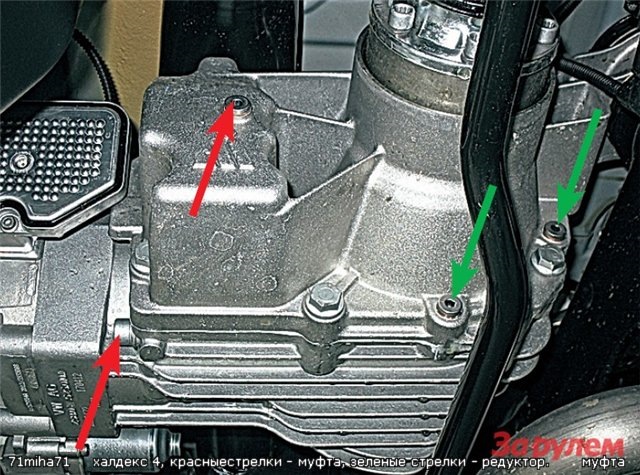

Новый насос на тот момент(октябрь 2015год) стоил примерно 18т.р…Начал узнавать как можно обойтись наименьшими жертвами. Если долго не расписывать, то в Москве есть человек по имени Михаил(71Miha71)

который специализируется на ремонте\восстановлению данных насосов. Стоимость работы примерно 6т.р…Но так как я не хотел снимать насос и отправлять в Москву решил чинить в своей городе.

В итоге его пробовали чинить 2 человека. При первой ремонте заменил фильтр и масло, но отремонтировать не удалось, далее был второй ремонт у другого «мастера». Данный мастер специализируется на перемотке эл. насосов, но отремонтировать так и не

удалось. Точнее насос работал, но не так как должен.

Особенностью насоса является, то что при определенном потреблении тока он должен нагнетать определенной давление. Датчика давления нет в муфте, по этому соленоид открывается в зависимости от потребляемого тока. Если в кратце — что бы его починить нужно в этом разбираться.

В итоге после второго не удачного ремонта, я все таки решил покупать новый ТАК КАК подвернулся новый насос по очень привлекательной цене.

После того как пришел новый насос, в виду того что насос постоянно снимался уровень масла(по идее чистого) был низким и я решил

заменить его снова. При сливе масла на котором я проездил 1000 км — оно было черным! Так что промывайте муфту при замене фильтра и масла.

Резюмирую хочу сказать следующее:

1. Меняйте масло и фильтр в муфте раз в 30т.км. (цена примерно 4т.р.)

2. Если у Вас сломался насос и у вас не золотые руки — у вас 2 наиболее верных путей развития

1. ОТправить на ремонт Михаилу

2. Купить новый.

Все остальные варианты — пустая трата время.

Проверить работу насоса можно запустив тест исполнительных механизмов(Output Test) в группе AWD. В момент прохождения теста

насос должен жужать.

Насчет ремонта почитать можно вот здесь:

forum.tiguans.ru/showthread.php?t=7906

forum.tiguans.ru/showthread.php?t=4186

forum.tiguans.ru/showthread.php?t=17179

ремонт насосов

forum.skoda-club.ru/viewtopic.php?f=46&t=52413

Номера для заказа:

Масло для муфты — G055175A2 – 1 литр. ( объем заливки 650 мл)

Фильтр от Volvo — 31325173 (комплект состоит из фильтра, крышечки, и новых болтов)

Всем добра.

-

#2,661

Ок, сформулирую вопрос по-другому. Как узнать, что причина отсутствия полного привода именно в насосе? На данный момент полный привод отсутствует, ошибка С111207 механическая неисправность насоса муфты халдекс. При попытке адаптации насоса Васей, процедура завершается по тайм аут. Соответственно не проходит. Привод отсутствует, при сбросе ошибки и попытке проехать по снегу, вылетает опять ошибка С111207 иногда следом С111307 неисправность полного привода вроде. Залил последнюю версию ПО в халдекс 7543, проблема не ушла. Адаптация в ODIS завершается успешно, но ошибка 207 появляется практически сразу. В чем проблема?

насосную (поршневую) часть разбирали, промывали, продували ?

Все у вас вроде как отлично вот только ошибка «появляется практически сразу».

При адаптации, слышали громкий звук срабатывания перепускного клапана ?

-

#2,662

Virj, на одном насосе разбирали в сервисе, второй я сегодня разобрал. Следов грязи незаметно совсем, но побрызгал очистителем тормозов, продул, собрал. На счёт звука клапана — нет не слышал. При запуске адаптации насос начинает работать, повышаются обороты и прям буквально через 20-30 секунд он отрубается. Видел видео адаптации, у меня даже первый этап не проходит, где насос раскручивается и потом громкий звук.

Вот кстати скрин ошибки с последней адаптации

-

#2,663

тогда доставайте клапан, осмотрите и его, возможно мусор попал и шарик не перекрывает канал (отв.)

-

#2,664

тогда доставайте клапан, осмотрите и его, возможно мусор попал и шарик не перекрывает канал (отв.)

Его можно открутить без съема муфты?

-

#2,665

Его можно открутить без съема муфты?

да

-

#2,666

Ребята подскажите пожалуйста!!!!!!! Отказал ПП, поехал поставил другой насос (ошибок не было) и все заработало (10 часов дня)!!! Ездил целый день все работало, вечером заехал домой на пару часов, выехал и опять не работает ПП. Что смотреть, куда копать????

-

#2,668

при таком «обилии» вводной информации (пп работал / отказал / поставил б/у насос, заработал / снова отказал) — сомневаюсь что будет возможность Вам помочь, здесь, на форуме.

Везде «копать» — насос б/у это совсем не гарантия того что он исправен, еще хуже вашего может быть и блок управления спалить. Предохранитель смотреть, А вообще, лучше отдать авто в руки тому кто в этом деле понимает.

-

#2,669

Всем доброго времени суток!

Стандартная ситуация, как я понял, покурив форум… Выезжая из заснеженной части дороги, почувствовал отсутствие полного привода. На приборке ошибок нет.

Одис говорит:

Код события 00448 011

Приоритет 3

Подкачивающий насос муфты халдекс обрыв цепи.

Отсюда вопрос. Есть ли кто поблизости (г. Ногинск) кто занимается переборкой насосов муфты халдекс (качественно!) ?

Если нет рядом никого, то хотябы ремкомплект посоветуйте хороший, чтобы допиливать ничего не пришлось, сам переберу.

-

#2,670

Konstantin84, не так давно сам лечил такую ошибку, покупал комплект на авито, коллектор, щетки, подшипник и сальник, по факту нужен был один коллектор, щетки практически без износа, сальник не сопливил, да и стоит сальник в корпусе под завальцовкой. Нашёл продавца у него есть якоря в сборе для 4 халдекса, ни чего не надо будет колхозить, будет надо скину контакты у него есть и токоприемники и щетки.

-

#2,671

Aleksandr 62, буду признателен за контакт. Завтра думал снять насос и посмотреть состояние

-

#2,673

Тигуан снова полноприводный. Купил ремкомплект (щетки, два колечка, коллектор, два подшипника и сальник) за 1400р. По факту стерлись только щетки и слегка коллектор, но заменил все, чтобы уже не лазить туда. Залил новое масло, установил новый фильтр и тачка загребла всеми колесами.

-

#2,674

Konstantin84, отписал в личку.

Aleksandr 62, пришли пожалуйста контакт в личку, буду благодарен.

Пока вроде все работает, но летом все-таки хочу профилактику провести.

-

#2,678

Ребята помогите!!!! Муфта не работает, ошибок нет, насос рабочий!!!

-

#2,679

Ребята помогите!!!! Муфта не работает, ошибок нет, насос рабочий!!!

Так не бывает… а чем ошибки смотрите?

- Forum

- Main Model-Line Discussion

- A3/S3/RS3

- 8V/8Y A3/S3/RS3

- Fault code c111207 (haldex)

-

01-26-2022 05:42 AM

#1

Junior Member

Two Rings

Fault code c111207 (haldex)

I changed the haldex fluid on my 2015 Audi S3 and ever since I keep slipping and my traction control light flashes when I rapidly accelerate at low speeds. I know they�re known for the pump to go bad but I�ve had no issues up to this point, only 65k miles. I wanted to remove the filter to check it and clean it if needed but I noticed that there was a ground wire of some sort and didn�t want to damage it so I didn�t end up getting to the filter. Is it possible to remove the filter without disconnecting the wire?

Sent from my iPhone using Audizine Forum

-

01-26-2022 01:18 PM

#2

Established Member

Two Rings

Originally Posted by es1055

I changed the haldex fluid on my 2015 Audi S3 and ever since I keep slipping and my traction control light flashes when I rapidly accelerate at low speeds. I know they�re known for the pump to go bad but I�ve had no issues up to this point, only 65k miles. I wanted to remove the filter to check it and clean it if needed but I noticed that there was a ground wire of some sort and didn�t want to damage it so I didn�t end up getting to the filter. Is it possible to remove the filter without disconnecting the wire?

Sent from my iPhone using Audizine Forum

Yes. When I swapped my Haldex fluid I just let the pump hang and removed the filter screen and cleaned it. You sure that you got enough fluid in there? Did you have the car level when filling?

2018 Audi S3 8V — EQT Stage 1 E85 OTS — EQT DSG Tune — MBRP Catback Exhaust — APR CAI — ECS Intake Hose — Leyo TIP — EQT HPFP

-

01-26-2022 03:36 PM

#3

Veteran Member

Four Rings

Yeah, sounds like something not quite right. hopefully you didn’t drain the haldex and fil the Diff. That’s a possibility you want to confirm — means haldex empty and thus non-functional and then diff over filled and with the wrong stuff.

2008 R8 V8 Manual: Uni 93 ECU tune * Avior Exhaust * Spacers * R8 Puddle lights * Custom mats. That is all lol.

-

01-26-2022 04:58 PM

#4

Junior Member

Two Rings

Originally Posted by Spinnetti

Yeah, sounds like something not quite right. hopefully you didn’t drain the haldex and fil the Diff. That’s a possibility you want to confirm — means haldex empty and thus non-functional and then diff over filled and with the wrong stuff.

Nah I definitely filled the haldex back up. Did it with a jack which is probably the reason for the issue. I�m gonna get a lift this weekend and redo it. Thank you guys!

Sent from my iPhone using Audizine Forum

-

01-26-2022 05:01 PM

#5

Veteran Member

Four Rings

— — — Updated — — —

— — — Updated — — —

Bookmarks

Bookmarks

Posting Permissions

- You may not post new threads

- You may not post replies

- You may not post attachments

- You may not edit your posts

- BB code is On

- Smilies are On

- [IMG] code is On

- [VIDEO] code is On

- HTML code is Off

Forum Rules

-

- Report

- Share

Hi All,

I purchased a 14 plate R dsg with 35k on it in November and over the last few weeks I’ve noticed traction issues so suspected Haldex problems. Checked with obd11 and it had the fault code C111207 so instead of messing around, I ordered a new pump and oil change kit and had it cleaned and fitted. The old filter was badly caked with crud so all seemed worthwhile and I then set about trying to do the pump relearn instructions. Couldn’t get it to work as it said «(13)function cannot be performed, mess. length or format incorrect» so read online that sometimes obd11 doesn’t work for this so then borrowed a vcds from a pal. I’ve just tried it and the fault code has come back on when ever the traction control light comes on and when i try to get the pump to relearn it says «ERROR: Conditions not correct or request sequence error» which sounds very similair to the obd11 problem! Is there anything anyone can recommend for me to try next as I’ve run out of ideas? The car was tried off the ground and the rear is spinning but I believe as soon as theres any real drag on the wheels, it will struggle due to lack of pressure from the pump and hence the lack of traction.

Thanks in advance for any help anyone can provide, SC.

- Quote

Link to comment

Share on other sites

-

Replies

83 -

Created

-

Last Reply

Top Posters In This Topic

-

39

-

10

-

8

-

6

Posted Images

-

- Report

- Share

Which instructions are you using to relearn the pump? Should be

Order of obdeleven parts

1. (22) AWD -> Output Tests -> Clutch Engaged/Disengaged 2 times for 30 seconds each.

2. (22) AWD -> Basic Settings -> Clear all adaptation values

3. (22) AWD -> Basic Settings -> Pump motor

- Quote

Link to comment

Share on other sites

- Author

-

- Report

- Share

Thanks for the reply.

Yes, that’s the obd11 instructions I tried, with and without engine running.

1. Has always failed says (31) function not available.

2. Works fine.

3. Always fails and says (13) Function can not be performed, mess. lengthy format incorrect.

😖

- Quote

Link to comment

Share on other sites

-

- Report

- Share

Maybe it’s the controller that’s failed.

- Quote

Link to comment

Share on other sites

-

- Report

- Share

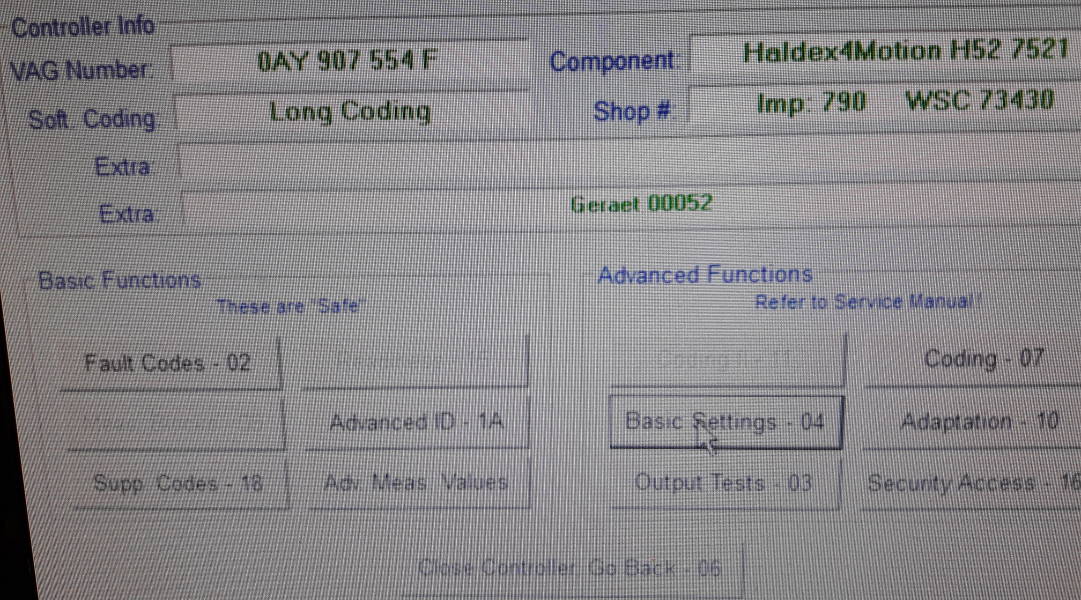

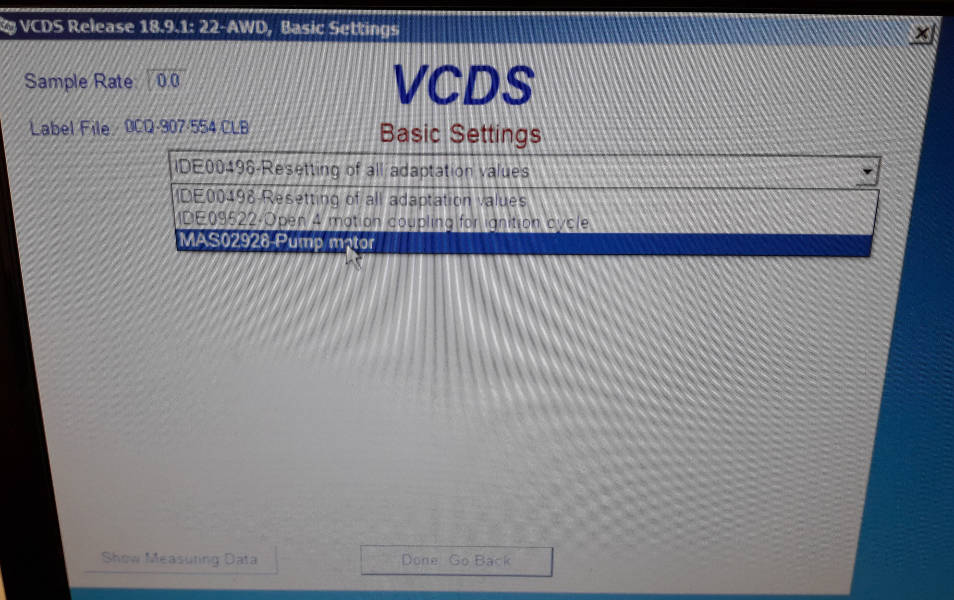

Using VCDS have you tried this. Taken from the Ross Tech forum:

Start the engine.

1. Open Controller 22 — AWD

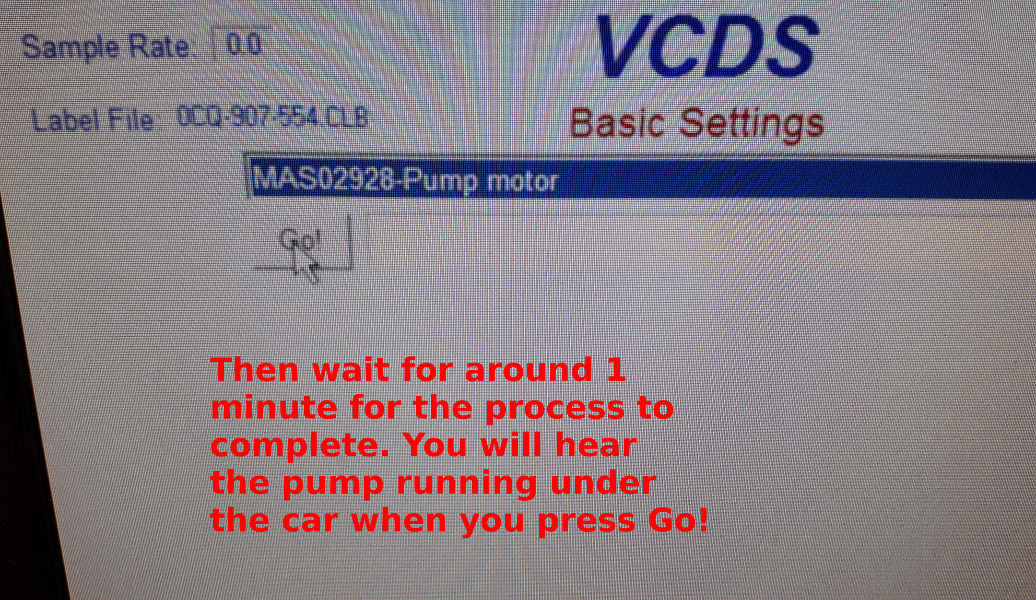

2. Open Basic Settings — 04

3. In Basic Settings use the drop down selection box to select «MAS02928 — Pump Motor»

4. Hit «Go» and let it run. Takes a minute or so, during which time I could hear the Haldex pump cycling up and down and relearning its function.

Worth searching on the Ross Tech website for solutions.

-

EcosseGolfR

-

1

- Quote

Link to comment

Share on other sites

- Author

-

- Report

- Share

6 minutes ago, stonefish said:

Using VCDS have you tried this. Taken from the Ross Tech forum:

Start the engine.

1. Open Controller 22 — AWD

2. Open Basic Settings — 04

3. In Basic Settings use the drop down selection box to select «MAS02928 — Pump Motor»

4. Hit «Go» and let it run. Takes a minute or so, during which time I could hear the Haldex pump cycling up and down and relearning its function.Worth searching on the Ross Tech website for solutions.

Thats exactly what I’ve tried with vcds but it gives the error conditions message I mentioned above😖

- Quote

Link to comment

Share on other sites

-

- Report

- Share

I assume you have then engine running when doing this?

Quote

MAKE SURE YOU HAVE THE ENGINE RUNNING TO SUCCESSFULLY CARRY OUT THE PUMP LEARN FUNCTION!!! ALSO IT DOES NOT WORK CORRECTLY WITH “OBD11” OR CHINA COPY VCDS!

- Quote

Link to comment

Share on other sites

- Author

-

- Report

- Share

2 minutes ago, TechieAli said:

I assume you have then engine running when doing this?

Yep but thanks.

- Quote

Link to comment

Share on other sites

-

- Report

- Share

6 hours ago, TechieAli said:

Maybe it’s the controller that’s failed.

Or the Haldex pump is the wrong part. Is it the same part number as the old one ? Maybe clean up the old pump and install it to see if you get the same error.

- Quote

Link to comment

Share on other sites

- Author

-

- Report

- Share

Yep, identical pump with same part number but thanks.

- Quote

Link to comment

Share on other sites

-

- Report

- Share

I’m probably clutching at straws, but maybe it is too cold. The VW guide (D4B80416638-Rear_Final_Drive.pdf) says oil temperature should be 20 to 40 degrees before doing fault finding.

Another alternative might be to use use security access code before trying the basic settings. VCDS usually gives you a code when you put your mouse over the box you enter the code. If that does nothing try 20103.

- Quote

Link to comment

Share on other sites

-

- Report

- Share

20 hours ago, scoobyc said:

Thanks for the reply.

Yes, that’s the obd11 instructions I tried, with and without engine running.

1. Has always failed says (31) function not available.

2. Works fine.

3. Always fails and says (13) Function can not be performed, mess. lengthy format incorrect.

😖

A long shot, but if you’re running OBD11 on Android, select system settings — apps & notifications — OBDeleven — Storage — CLEAR CACHE

You can also try CLEAR DATA but that will remove everything you’ve set up and may be a nuisance to reset.

- Quote

Link to comment

Share on other sites

-

- Report

- Share

2 hours ago, scoobyc said:

Yep, identical pump with same part number but thanks.

I’d still try connecting up the old pump to see if the apparent communication problem goes away. Also it is possible the (brand new) pump is faulty (not common, but definitely can happen).

- Quote

Link to comment

Share on other sites

-

- Report

- Share

Could the connections be corroded?

- Quote

Link to comment

Share on other sites

Audi A1 2015 onwards

- Audi A3 S3 RS3 / Sportback 2013 onwards

- Audi A3 Cabriolet 2014 onwards

- Audi Q3 2012 onwards

- Audi TT / TTS / TTRS Coupe/Roadster 2014 onwards

- Volkswagen Golf / Golf R / 4Motion 2013 onwards

- Volkswagen Passat / 4Motion / Santana 2015 onwards

- Volkswagen Sharan / syncro / 4Motion 2012 ownards

- Volkswagen Tiguan 2013 onwards

- Seat Alhambra 2012 onwards

- Seat Leon / Leon 4 2013 onwards

- Seat Altea Freetrack 2014 onwards

- Skoda Octavia / Scout 2013 onwards

- Skoda Yeti 2013 onwards

Generation 5 Haldex is the most simplified and cut back Haldex system to date, it has less components than ever before and is the lightest generation so far. A cynic might say the most “cost effective” system to manufacture! We are being inundated with customers contacting us with low mileage vehicles, around 15k to 30k miles and only 3 to 5 years old, where the 4wd system no longer works. Often they have been given astronomical quotes from main dealerships or aftermarket garages for potential repair quotes, usually in the region of £1500 to £3000 is common depending on what parts the garage is guessing at replacing!

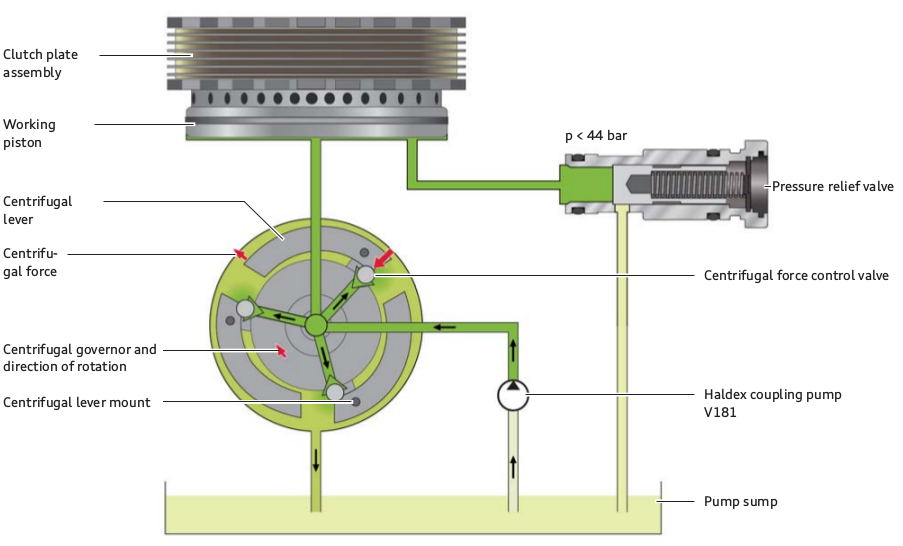

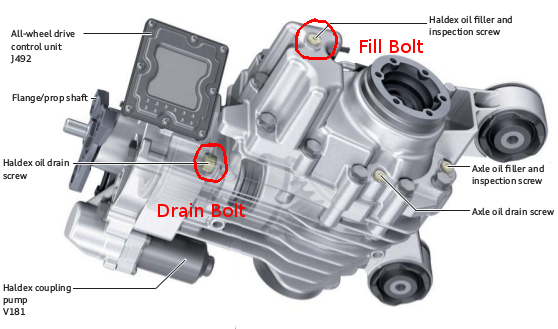

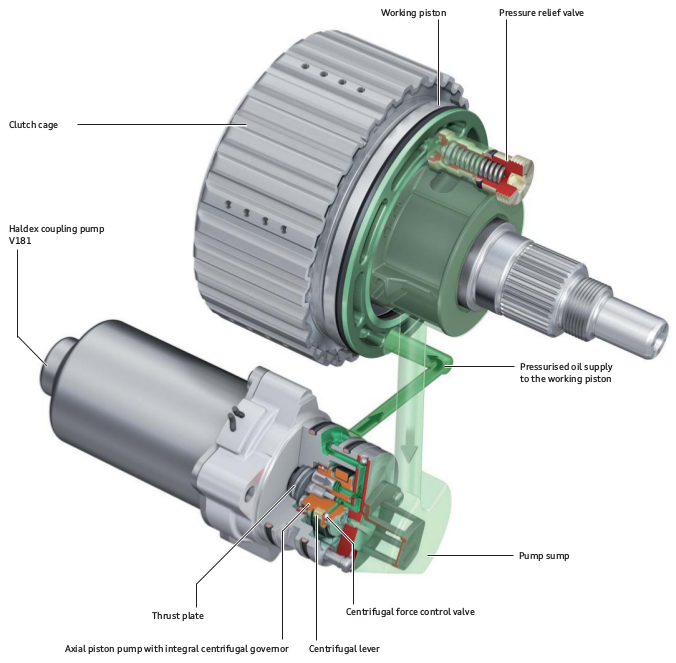

The system really only has a few components, as seen on the diagram. There is control unit which powers a pump – which is fitted with a strainer gauze, when pressure is made the piston applies force to the clutch pack which engages the 4wd. There is a pressure relief/blowoff valve which vents any excess oil pressure. And that is about all there is! There is no fine particle filter cartridge like the previous systems, which we suspect is the main cause of early failure. There is no “n373 Valve for Controlling Clutch Operating Angle”, nor any pressure sensors. Any pressure values shown on the diagnostic equipment measuring blocks like VCDS is purely estimated and calculated, thus they are purely fictitious.

Common Problems and Fault Codes

Often customers complain about no drive to the rear wheels, and typically there are no warning lights or error messages shown on the dashboard to illustrate the system is faulty, thus owners are unaware of the issue. Buyers of second hand cars often purchase these cars not working, so then never know any different. Only when it comes to winter time where they get stuck somewhere they then realise the rear wheels are not turning. With the more performance orientated cars such as Golf R, RS3, S3, TTS or TTRS, the lack of 4wd is more apparent as brisk acceleration usually causes the traction light to flash and power be limited – accompanied by lots of wheel spin, especially on wet roads or slippy surfaces.

When scanning the vehicle for fault codes, it is important to use some decent scanning system which can actually communicate with the Haldex control module which is “22 AWD”, otherwise you will find there is no fault codes stored! People often fall into this trap with cheap OBD2 code readers or phone apps. Fault codes which often occur are:-

- 131599 – All Wheel Drive Clutch – U0114 00 [009] – No Communication (typically ECU fault)

- 131599 – Control Module for All Wheel Drive Clutch – C1113 07 Intermittent error (typically ECU fault)

- 16670 – All-Wheel Drive – C1113 07 [008] – Mechanical Failure (typically pump type fault OR/AND transfer box)

- 16671 – Pump for Haldex Clutch – C1112 04 [008] Internal System Fault (faulty pump AND ecu needs repair)

- 16671 – Haldex clutch pump Faulty – C1112 04 passive/sporadic (faulty pump AND ecu needs repair)

- 16668 – Pump for Haldex Clutch C1112 07 [008] – Mechanical Failure Intermittent (typically Pump fault)

- 16666 – Pump for Haldex Clutch C1112 13 [008] – Open Circuit(typically pump type fault)

- C111307 – Mechanincal Malfunction – Passive / Sporadic (typically blocked pump, clean out and relearn or transfer box)

Typical Solutions

When the fault code 131599 is triggered it is often caused by damage or corrosion to the control unit, we can test and often repair these, they are easy to open by the 8 torx screws on the front and check for obvious signs of water ingress or blown/burnt components.

16671 – Pump for Haldex Clutch – C1112 04 [008] Internal System Fault OR ” C111204 Haldex Clutch Pump, Defective “

The ISF (internal system fault) is caused when the pump is defective, but even when fitting a new pump you often find the 16671 code will come back every time you clear it. This is a software fault in the Gen 5 control unit. Most of the time no amount of doing the “Pump Learn” will fix this, some will clear after the learn but most will not. There is an internal system table that is used by the firmware to calibrate the controller current/voltage sensing system. When this data is outside of certain values the ISF fault is triggered. A defective pump causes this problem. The solution is to either replace the controller, or send us the controller where we can carry out this data repair manually by removing the chip that stores the data, read it, manually change it, write it back, then solder it back on and re-assemble the controller. We do this under our fixed rate Haldex ECU repair service.

PUMP LEARN FUNCTION

It is common for owners to have a new pump fitted by a garage or main dealer and still the problem persists. When fitting a pump, or even just after a clean out and service it is essential to carry out the “pump learn” function in the “basic settings” of the Haldex control unit, VCDS/VAGCOM can do this and so can the main dealer ODIS system. Customers are often told there is “no adaption” or programming required to fit a new pump, this is incorrect!

The control unit learns how much power is required to run the pump until the pressure hits a certain threshold, it does this by monitoring how much current is consumed by the pump, when the pump is blocked, or faulty, the control unit learns/adapts some very low values which means when the Haldex controller tried to engage the pump, it does not supply enough power to make it engage. By carrying out the learn function when fitting a new pump, it will learn the correct power values and thus engage the system correctly.

Literally multiple times a week we get customers calling who have had new pumps fitted, often by main VW, Audi, or Skoda dealership, yet the system still does not work and they will not perform the pump learn process. Instead they then quote the customers on a brand new ECU/Haldex Controller, or they quote them on a complete new coupling/rear diff, plus labour. There is no documentation we know of in the “VAG Self Study Guides” / VAG workshop manuals that have any reference to the Pump Calibration / Learn function.

Very very rarely, the pressure relief blow off valve will stick open, this will cause the coupling to not engage 4wd as there is no oil pressure there to clamp the clutch plates together. We have brand new valves in stock, they are easy to replace and not very expensive.

Essentially what the learn function does, and you can listen to the pump run while it does it; the function ramps up the power to the pump slowly until the pressure hits the 44 bar blow off valve where is senses the drop in current. It does it a few times so the pump knows how much current and voltage it takes to achieve 44 bar. It then saves this value in the calibration values, and after a short drive it then calculates/estimates the 1 bar and 15 bar from the last measured 44 bar value.

AFTER THE LEARN HAS “COMPLETED SUCCESS”, THE VALUES USUALLY SAY “0” UNTIL THE VEHICLE IS TAKEN FOR A SHORT DRIVE, THIS IS DUE TO IT ESTIMATING THE 1 & 15 BAR VALUES FROM USE.

Here are some photos of how to carry out the pump learn function using VCDS VAGCOM

MAKE SURE YOU HAVE THE ENGINE RUNNING TO SUCCESSFULLY CARRY OUT THE PUMP LEARN FUNCTION!

MAKE SURE YOU HAVE THE ENGINE RUNNING TO SUCCESSFULLY CARRY OUT THE PUMP LEARN FUNCTION!

MAKE SURE YOU HAVE THE ENGINE RUNNING TO SUCCESSFULLY CARRY OUT THE PUMP LEARN FUNCTION!!!

BEWARE SOME DIAGNOSTIC TOOLS DO NOT COMPLETE THE LEARN FUNCTION CORRECTLY.

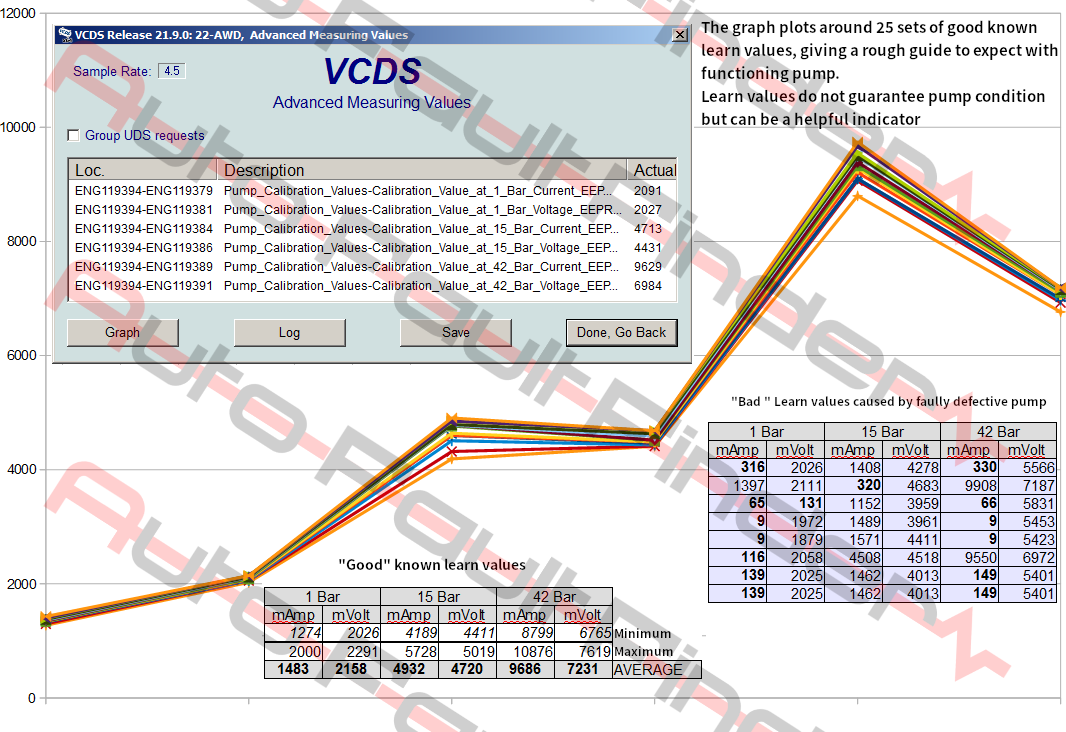

These are good typical learn values below, which can be found in the “advanced measuring values” on VCDS and other tools like Vag-CAN Pro etc. If the values are wildly different then more than likely the pump is no good. This is an indicator of a defective pump.

This image shows good known Pump Calibration Learn Values, and Bad learn values. Also there is average values, and minimum/maximum values which have been taken from a large sample of good working vehicles. Bad learn values are a good indicator for a failed pump, but good values do not guarantee a healthy pump although is a rough tool to use for fault finding.

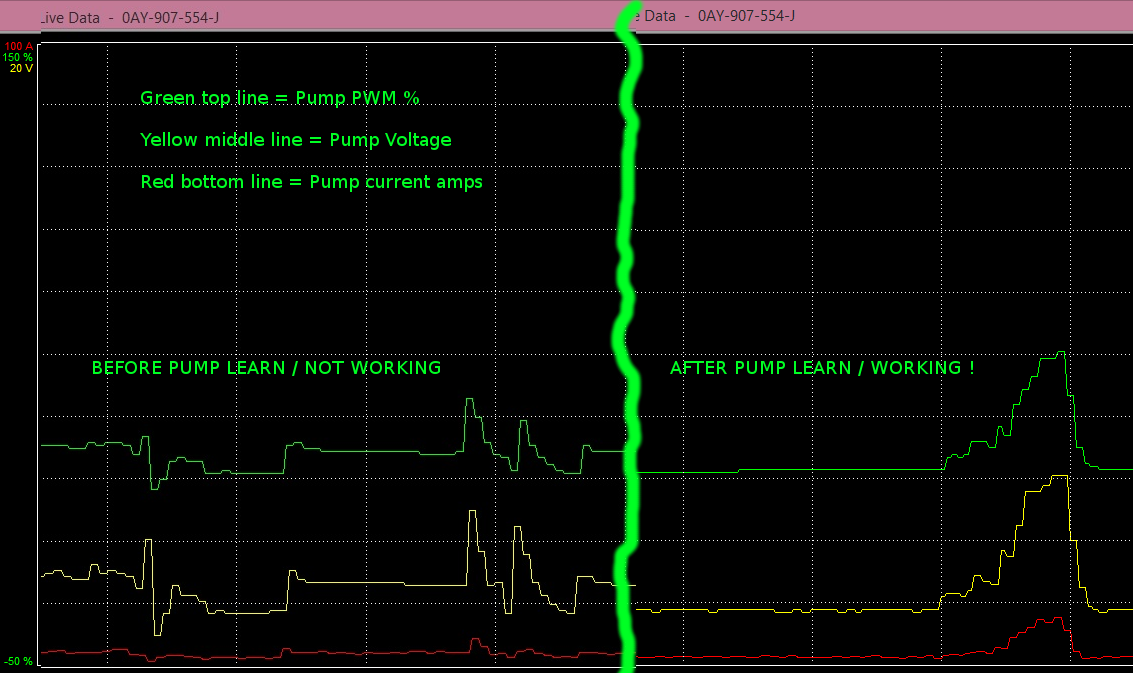

If you have system that is not working, a good starting point is to data log some of the measuring blocks for the pump control, these are the Pump PWM %, Pump current and Pump Voltage. Take the car somewhere that it can be launched to hopefully cause wheel spin somewhere safely and legal while data logging these values. This image is of a system before and after the pump learn function, as you can see there is almost twice the voltage and current being measured at the pump, and the PWM % green trace line shows the control unit is driving the pump harder thus the larger Voltage and Current values.

Oil Change guide

These Generation 5 Haldex systems have never been serviced correctly, many aftermarket VAG specialists are offering far better servicing where the pump is removed and cleaned which puts them in a far better position but still trouble often persists. Servicing is often not the solution to problems, it is more preventative maintenance. If the car is getting the 16671 or 16668 fault codes then often a new pump is required, but if the vehicle is just getting the 16670 fault code then often cleaning them out, and fresh oil will solve them but the “pump learn” function must be carried out.

- When doing an oil change, remove the pump, remove the fill bolt and drain bolt.

- Wash out sludge out of the coupling by blowing compressed air into the fill plug with the drain undone.

- Add a little clean oil to wash out the last of the sludge and blow out again.

- Blow the pump gauze clean with compressed air, refit the pump with new oil seal O rings with a little oil, refit the drain bolt.

- Fill will haldex fluid via the fill bolt until oil over spills. Refit the fill plug and clean up any mess.

Transfer Box Test

Make sure you are capable of doing this in a safe manor.

You are in control of your own safety. We are not liable for any damage or harm you may cause yourself, your workshop, other people, or your car. This test is only for automotive repair professional use only.

Lift the car so ONLY the front wheels are off the ground.

Get somebody or a camera to watch the propshaft.

Someone else to sit in the car, starts up the engine.

Apply foot brake, remove handbrake, put vehicle into drive gear.

Then very gently lift your foot off the brake so the front weeks start to turn.

Prop shaft is stationary = transfer box is faulty.

Prop shaft rotates = a Haldex issue.

Transfer Box Failure generally only effects modified vehicles, almost every example has been a remapped car. Very common with Golf R, S3, RS3, TTS, TTRS etc. These transfer boxes are not designed to be robust, this is a really good youtube video showing how they fail inside https://www.youtube.com/watch?v=nt33-EgQ4gk

Audi A1 2015 onwards

Audi A1 2015 onwards