-

Contents

-

Table of Contents

-

Troubleshooting

-

Bookmarks

Quick Links

Steam Sterilizer

E9 INSPECTION

E9 RECORDER

E9 MED

s e r v i c e m a n u a l

ENGLISH

0051

Related Manuals for Euronda E9 INSPECTION

Summary of Contents for Euronda E9 INSPECTION

-

Page 1

Steam Sterilizer E9 INSPECTION E9 RECORDER E9 MED s e r v i c e m a n u a l ENGLISH 0051… -

Page 3: Table Of Contents

4.7 DELIVERY OF TECHNICAL DOCUMENTATION ………………..28 5 — DESCRIPTION OF CYCLE AND MAIN PERFORMANCE DATA ……..29 5.1 E9 INSPECTION COMPONENTS ……………………..29 5.2 CYCLE FOR E9 INSPECTION WITH SEPARATOR DRAINING PUMP …………31 5.2.1 Phase 0: Turning on the sterilizer ……………………..32…

-

Page 4

5.2.16 Vacuum phase II …………………………47 5.2.17 Pressure levelling phase II ……………………….48 5.2.18 End of cycle phase …………………………49 5.3 CYCLE FOR E9 INSPECTION/RECORDER WITH CIRCUIT U-234 (since firmware 7.01) ……50 5.3.1 Turning on the sterilizer ……………………….50 5.3.2 Phase 1: Start, water outgas system emptying and steam generator filling (U-234 circuit) …….. -

Page 5

9.2.6.2 TAB. 06: TANK SUPPORT AND SICCE MICROPUMP ASSEMBLY …………115 9.2.6.3 TAB. 06: TANK SUPPORT AND MICROPUMP ASSEMBLY E9 U-234 / RECORDER / MED ….116 9.2.7.1 TAB. 07: CHASSIS, WATER OUTGAS SYSTEM AND CROSSPIECE ASSEMBLY E9 INSPECTION / RECORDER …………………………..117 9.2.7.2 TAB. -

Page 6

ONTENTS AUTOCLAVE 9.2.9.1 TAB. 09: BOILER/ELECTROMAGNET ASSEMBLY E9 INSPECTION / RECORDER ……. 127 9.2.9.2 TAB. 09: BOILER/ELECTROMAGNET ASSEMBLY E9 MED …………..129 9.2.10 TAB. 10: FRONT PANEL ASSEMBLY E9 ………………….131 9.2.11 TAB. KIT: ACCESSORIES KIT E9 ……………………132 10 — PRODUCT VERSIONS ………………..133 10.1 REGISTRATIONS OF MODIFICATIONS TO E9 HARDWARE ………….. -

Page 7: Introduction

Euronda S.p.A. is the sole owner and reserves all rights to them. Euronda S.p.A. reserves the right to make modifications or improvements to the manual or the unit without notice and without being obliged to update previous production and manuals.

-

Page 8: How To Obtain A New Copy Of The Manual

NTRODUCTION AUTOCLAVE HOW TO OBTAIN A NEW COPY OF THE MANUAL If the manual is lost or destroyed, ask Euronda S.p.A. for a new copy. Provide the following information: name and model of the unit; name and address where the manual should be sent.

-

Page 9: Safety

2 — Safety GENERAL SAFETY WARNINGS Before using the equipment, read the safety information carefully. Non-observance could cause accidents or damage to the machine or injure the operator. Before using the unit, operators must have perfectly understood the meanings and functions of all the controls.

-

Page 10: Safety Devices

2 — S AFETY AUTOCLAVE 2.2 SAFETY DEVICES Electrical safety Description Effect Double-pole thermal safety switch for protecting the Disconnects main electrical power supply device against short-circuits. Protection of the electronic board against short- Disconnects one or more low-voltage circuits circuits: both the transformer and the entire low- voltage circuit are self-protected Thermal protection…

-

Page 11: Residue Risks

It is forbidden to remove, modify, tamper with or in any way neutralize the safety devices. Euronda S.p.A. declines all liability for accidents to people or damage or malfunctions of the unit if the above instruction is not observed. Periodically check the safety systems (see chap. 8 “Maintenance”).

-

Page 12: Safety Signs On The Unit

2 — S AFETY AUTOCLAVE Danger of contamination. The water used in the discharge tank may, if not properly sterilized, contain contaminated residues: wear latex safety gloves when draining. Danger of injury to hands. Even if the unit is not in operation, its cooling fan is always on if power supply to the machine is connected.

-

Page 13: Technical Data

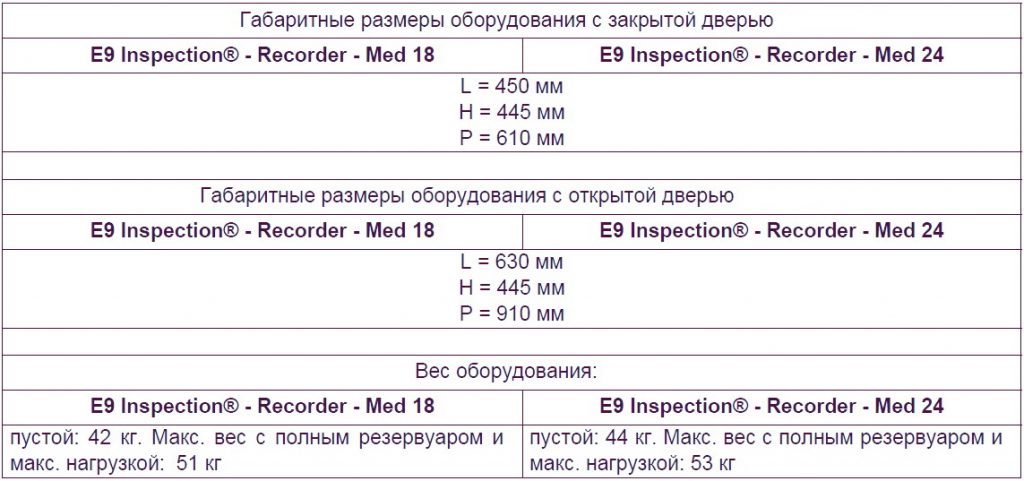

3 — Technical data 3.1 OVERALL SPACE REQUIRED Fig. 3.1-1 Overall dimensions of the unit with the door closed (Fig. 3.1-1): E9 INSPECTION/RECORDER/MED 18 E9 INSPECTION/RECORDER/MED 24 L = 450 mm H = 445 mm P = 610 mm Overall dimensions of the unit with the door open (Fig. 3.1-1):…

-

Page 14: Technical Data And Noise

3 — T ECHNICAL DATA AUTOCLAVE 3.2 TECHNICAL DATA AND NOISE CHARACTERISTICS E9 INSPECTION 18 E9 INSPECTION 24 230 V Power supply voltage 50 Hz Mains frequency 2300 W Power output 10 A Absorbed current 3 sterilization cycles Sterilization cycles Vacuum test — Bowie &…

-

Page 15: Quality Of Water

3 — T ECHNICAL DATA AUTOCLAVE 3.3 QUALITY OF WATER With reference to standard EN 13060, the table below indicates the recommended limit values (maximum) for contaminating agents, as well as the chemical-physical characteristics of the water used for condensate* and inlet water.

-

Page 16: Serial Numbers Coding

3 — T ECHNICAL DATA AUTOCLAVE 3.4 SERIAL NUMBERS CODING Autoclaves serial number is made of a combination of three letters and six numbers. The serial number identifies the autoclave model and the chamber capacity. E9 18 (half band heater) EDI000000 E9 24 (half band heater) EDK000000…

-

Page 17: Installation

4 — Installation 4.1 POSITIONING THE UNIT Lift the unit with care and do not turn it upside down. The packaging and the equipment are fragile, handle with care. Transport as fragile. THE HANDLES ON THE PACKAGING (1 of Fig. 4.1-1) MUST ONLY BE USED FOR VERTICAL LIFTING.

-

Page 18: Installing The Unit

4 — I NSTALLATION AUTOCLAVE Fig. 4.1-3 Fig. 4.1-4 INSTALLING THE UNIT Installation is a fundamental operation for the subsequent use and correct functioning of the unit. ATTENTION: the unit MUST be installed by specialised technicians. First, update the service booklet by writing the date of installation in the relative box and signing it.

-

Page 19

Making the electrical connections: Check that the power supply voltage indicated on the rear label (Fig. 4.2.1-2) corresponds to that available at the point of installation. E9 INSPECTION 18 E9 INSPECTION 24 Fig. 4.2.1-2 The unit must be connected with an overload cut-out switch to a system fitted with an adequate earth system that conforms to the standards applicable in the country of installation. -

Page 20

4 — I NSTALLATION AUTOCLAVE Only use the original lead. ONLY USE ORIGINAL SPARE PARTS. After making the electrical connections, remove the clamp holding the electromagnet in place and install any accessory devices. Filling the tanks: The unit features two separate tanks: one for the clean water required for the cycles, and one for the used water that is collected at the end of the cycles. -

Page 21

Installation registration The functioning of Settings, Maintenance, Service and Diagnostic menus in E9 MED is the same as the E9 INSPECTION / RECORDER menus. The only difference is in the display’s graphics. Register the date of installation from the control panel. -

Page 22

4 — I NSTALLATION AUTOCLAVE — If YES is pressed, the Date/time setting Setting Date and Time screen appears. Using the keys, select the correct — If NO is pressed, you go to the Program day, press OK to pass on to the choice of Menu;… -

Page 23: Operator Registration

4 — I NSTALLATION AUTOCLAVE User Registration E.g.: Name Registration With the keys, select the After selecting the item Name from User registration, a screen appears in which the respective item and complete registration three items present are selected one by one: using the small keyboard, as in the example the screens used for registering the user’s indicated below.

-

Page 24: Performing The Vacuum Test

4 — I NSTALLATION AUTOCLAVE SELECT OPERATOR The cycle that follows the operator selection, the last XXXXX———————— selected voice remains highlighted. YYYYY ZZZZZ VVVVV KKKKK ▼ ▲ 3.1.1 Note : this screen appears only if at least one operators name is set up . Please see User’s Manual for more informations.

-

Page 25: Performing The B134 Cycle

4 — I NSTALLATION AUTOCLAVE Starting the Vacuum Test If required, press INFO to open the test Press START to begin the test; the control screen. following screen appears. This screen appears when the test finishes. The door release symbol indicates that the door can be opened, and you return to the Programme Menu. If the test is completed but gives a negative outcome, the E34 alarm message appears (see Chap.

-

Page 26: Labels Printing (Only E9 Recorder)

4 — I NSTALLATION AUTOCLAVE When the cycle has finished, the Cycle End Maintaining drying screen appears. At this point, the door This operation is performed automatically to release symbol indicates that the door can prevent condensation from forming inside be opened;…

-

Page 27

4 — I NSTALLATION AUTOCLAVE Now must be setted the type of paper in use. In the initial screen select “Main menu”, then in the following screens select: “Service”, “Memory-print functions”, “Kind of print” and finally “Labels”. To label the sterilized material with its expiration date the expire period must be setted. In the initial screen select “Main menu”, then in the following screens select: “Service”, “Memory-print functions”, “Expire period”… -

Page 28: Delivery Of Technical Documentation

4 — I NSTALLATION AUTOCLAVE ATTENTION: DANGER OF BURNS. When the unit finishes the sterilisation cycle and the door is opened to remove the sterilised instruments, the inner parts of the boiler and door are still very hot. These must not be touched directly in order to avoid getting burnt. Use the relative extractor tool (see Chap.

-

Page 29: Description Of Cycle And Main Performance Data

5 — Description of cycle and main performance data 5.1 E9 INSPECTION COMPONENTS The E9 Inspection sterilizer comprises the following elements: NAME OF SIGNAL DESCRIPTION Characteristics COMPONENTS Main switch 250V 12A Two-way solenoid valve for discharging steam at the OD6A/OD6B 24 VDC end of the cycle, power draw 9 W;…

-

Page 30

5 — D ESCRIPTION OF CYCLE AND MAIN PERFORMANCE DATA AUTOCLAVE Manually resettable safety thermostat (band heater for 230 VAC chamber), calibrated to 200°C FAN1 OD17A/OD17B Radiator fan, power draw 35 W 230 VAC PT1000 probe inside boiler (working space inside PTC1 chamber) PT1000 probe outside boiler (mounted on external… -

Page 31: Cycle For E9 Inspection With Separator Draining Pump

5 — D ESCRIPTION OF CYCLE AND MAIN PERFORMANCE DATA AUTOCLAVE 5.2 CYCLE FOR E9 INSPECTION WITH SEPARATOR DRAINING PUMP E9 service manual GB r7…

-

Page 32: Phase 0: Turning On The Sterilizer

The unit can be filled with water either manually or using the mains water function with the support of a deionizer (see Appendix 10 “Euronda Aquafilter” and Chap. 6.7 “Tanks: instructions for filling and emptying” in the instructions manual). When the minimum water level sensor trips, the deionizer solenoid valve EV6 is powered and opens to let the water flow into the tank until the maximum level sensor trips.

-

Page 33: Start-Vacuum Phase V1/I

5 — D ESCRIPTION OF CYCLE AND MAIN PERFORMANCE DATA AUTOCLAVE 5.2.2 Start-Vacuum phase V1/I Pressure Discharge START-VACUUM PHASE V The following are powered: 1. EV1: closes the pressure discharge circuit 2. EV3: closes the bacteriological filter 3. EV4: opens the water inlet to the air separator 4.

-

Page 34: Vacuum Phase V1/Ii

5 — D ESCRIPTION OF CYCLE AND MAIN PERFORMANCE DATA AUTOCLAVE 5.2.3 Vacuum phase V1/II Pressure Discharge VACUUM PHASE V 3 seconds after WP1 stops working, EV2 is powered and EV4 and EV1 are de-energised. This allows the vacuum pump to create a depression inside the chamber by pumping air through EV1 ed EV2, hence by-passing the water circuit the air separator is connected to.

-

Page 35: Vacuum Phase V1/Iii

5 — D ESCRIPTION OF CYCLE AND MAIN PERFORMANCE DATA AUTOCLAVE 5.2.4 Vacuum phase V1/III Pressure Discharge VACUUM PHASE V When the pressure inside the chamber reaches -0.82 bar, EV2 is de-energised and the pump continues to pump from EV1 to separate the air from the water in the air separator. If in 4 minutes the pressure inside the chamber does not reach to -0.86 bar, EV3 ON for 15 sec, in order to clean the hydraulic circuit from E9 service manual GB r7…

-

Page 36: Water Inlet Phase

5 — D ESCRIPTION OF CYCLE AND MAIN PERFORMANCE DATA AUTOCLAVE 5.2.5 Water inlet phase Pressure Air tap WATER INLET PHASE When a pressure of -0.86 bar is reached, EV1 and EV4 are powered while EV5 is de-energised. The vacuum pump stops working and the generator heater R1 is powered at 50%.

-

Page 37: Water Outgas System Drain Phase

5 — D ESCRIPTION OF CYCLE AND MAIN PERFORMANCE DATA AUTOCLAVE 5.2.6 Water outgas system drain phase Draining Svuotamento Air tap Presa aria WATER OUTGAS SYSTEM (W.O.S.) DRAIN PHASE After EV4 is de-energized, pump WP2 works for 120 seconds (NME up to EEG060999/EEH060999) for 8 seconds (SICCE from EEG061000/EEH061000) (draining any water remaining in the water outgas system).

-

Page 38: Pressure Increase Phase P

5 — D ESCRIPTION OF CYCLE AND MAIN PERFORMANCE DATA AUTOCLAVE 5.2.7 Pressure increase phase P Pressione Pressure Recupero Recovery PHASE P — PRESSURE INCREASE After further 15 seconds, R1 Resistance is supplied at 80%, after 80 seconds at 100%; this permits to generate steam.

-

Page 39: Water Transfer Phase

5 — D ESCRIPTION OF CYCLE AND MAIN PERFORMANCE DATA AUTOCLAVE 5.2.8 Water transfer phase Pressure Pressione Air tap Presa aria WATER TRANSFER PHASE When the pressure reaches +0.40 bar, the heater R1 is disconnected from the power supply; after 1 second, EV4 is powered to allow the water to be transferred from the chamber to the air separator and pump WP1 is powered for 2 seconds to prevent the PTC3 probe from detecting an elevated temperature during transfer.

-

Page 40: Vacuum — Thermodynamic Vacuum Phase V

5 — D ESCRIPTION OF CYCLE AND MAIN PERFORMANCE DATA AUTOCLAVE 5.2.9 Vacuum — Thermodynamic vacuum phase V Scarico pressione Pressure discharge Air vent Scarico aria PHASE V – VACUUM – THERMODYNAMIC VACUUM After 18 seconds, the fan is powered at 100%, EV4 and EV1 are de-energised, while EV5 is powered. After another 5 seconds, the vacuum pump starts working and EV2 is powered.

-

Page 41: Vacuum 2,3,4 Phase V2

5 — D ESCRIPTION OF CYCLE AND MAIN PERFORMANCE DATA AUTOCLAVE 5.2.10 Vacuum 2,3,4 phase V2 Vuoto Vacuum Scarico aria Air vent PHASE V — VACUUM 2, 3, 4 If the temperature detected by the PTC4 probe is greater than 60°C, the vacuum pump stops working and EV2 and EV5 are de-energised.

-

Page 42: Pressure Increase/Sterilization Phase P

5 — D ESCRIPTION OF CYCLE AND MAIN PERFORMANCE DATA AUTOCLAVE 5.2.11 Pressure increase/Sterilization phase P Pressure Pressione PHASE P — PRESSURE INCREASE/ STERILIZATION The fourth rising of pressure brings to sterilization. 4°C below set-point value, WP1 pump makes four water injections (1 second ON, alternated with 2 seconds’…

-

Page 43: Sterilization Phase

5 — D ESCRIPTION OF CYCLE AND MAIN PERFORMANCE DATA AUTOCLAVE 5.2.12 Sterilization phase Pressione Pressure Scarico pressione Pressure discharge STERILIZATION PHASE If inside the chamber is signalled a pressure of +0,2 bar higher than set point, EV2 and EV5 electro-valves are supplied for about 600 ms to allow the discharge of superfluous pressure.

-

Page 44: Steam Discharge Phase

5 — D ESCRIPTION OF CYCLE AND MAIN PERFORMANCE DATA AUTOCLAVE 5.2.13 Steam discharge phase Scarico pressione Pressure discharge STEAM DISCHARGE PHASE When the sterilization phase is finished (4, 18, 20 minutes according to the selected cycle) there takes place the pressure discharge and consequently the drying phase, whose duration time can be set up by user (auto = 15, 20, 25, 30 minutes;…

-

Page 45: Steam Discharge Phase I

5 — D ESCRIPTION OF CYCLE AND MAIN PERFORMANCE DATA AUTOCLAVE 5.2.14 Steam discharge phase I Vuoto Vacuum Scarico aria Air vent STEAM DISCHARGE PHASE I After 8 seconds WP2 stop working, EV2 is de-energized, EV5 is supplied and VP1 pump begins to create vacuum inside the chamber.

-

Page 46: Pressure Levelling Phase I

5 — D ESCRIPTION OF CYCLE AND MAIN PERFORMANCE DATA AUTOCLAVE 5.2.15 Pressure levelling phase I Scarico Separator Separatore discharge Pressure levelling Livellamento barico Aspirazione aria Air intake PRESSURE LEVELLING PHASE I After 4 minutes takes place the drying pause phase. EV3 is de-energized, supplied and then de-energized with intervals of one second (to avoid any sudden pressure variation), the fan is supplied at 40%, EV5 is de- energized, the vacuum pump is not supplied any longer, while WP2 pump works for 5 seconds (WP1= OFF).

-

Page 47: Vacuum Phase Ii

5 — D ESCRIPTION OF CYCLE AND MAIN PERFORMANCE DATA AUTOCLAVE 5.2.16 Vacuum phase II Vuoto Pressure levelling Air intake Scarico aria VACUUM PHASE II After 60 seconds, EV3 is powered, EV1 de-energised and the pump (WP1=ON) recreates a vacuum. EV5 is powered three seconds after the pump starts.

-

Page 48: Pressure Levelling Phase Ii

5 — D ESCRIPTION OF CYCLE AND MAIN PERFORMANCE DATA AUTOCLAVE 5.2.17 Pressure levelling phase II Livellamento barico Pressure levelling Aspirazione aria Air intake PRESSURE LEVELLING PHASE II After 8 minutes have elapsed (if set up to auto= 15 min) or 13, 18, 23 respectively for drying period of 20, 25, 30 minutes, the ventilation phase takes place: RES2 is supplied no more, EV3 is de-energized and allows the air to enter from the bacteriological filter.

-

Page 49: End Of Cycle Phase

5 — D ESCRIPTION OF CYCLE AND MAIN PERFORMANCE DATA AUTOCLAVE 5.2.18 End of cycle phase Separator discharge Scarico separatore END OF CYCLE PHASE After further 2 seconds, VP1 stops working, WP2 works for 5 seconds (in order to discharge water from separator) and when the pressure in the chamber reaches ±…

-

Page 50: Cycle For E9 Inspection/Recorder With Circuit U-234 (Since Firmware 7.01)

The unit can be filled with water either manually or using the mains water function with the support of a deionizer (see Appendix 10 “Euronda Aquafilter” and Chap. 6.7 “Tanks: instructions for filling and emptying” in the instructions manual). When the minimum water level sensor trips, the deionizer solenoid valve EV6 is powered and opens to let the water flow into the tank until the maximum level sensor trips.

-

Page 51: Phase 1: Start, Water Outgas System Emptying And Steam Generator Filling (U-234 Circuit)

5 — D ESCRIPTION OF CYCLE AND MAIN PERFORMANCE DATA AUTOCLAVE 5.3.2 Phase 1: Start, water outgas system emptying and steam generator filling (U-234 circuit) W.O.S. PHASE 1 Vacuum pump takes external air from the bacteriological filter and pushes it into the water outgas system (W.O.S.) through EV8 and EV2.

-

Page 52: Phase 2: Steam Generator Emptying (U-234 Circuit)

5 — D ESCRIPTION OF CYCLE AND MAIN PERFORMANCE DATA AUTOCLAVE 5.3.3 Phase 2: Steam generator emptying (U-234 circuit) W.O.S. PHASE 2 Vaccum pump reduces pressure in the water outgas system in order to move water from the steam generator to the water separator through EV1. Energized components: 1.

-

Page 53: Phase 3: Water Outgas System Filling (U-234 Circuit)

5 — D ESCRIPTION OF CYCLE AND MAIN PERFORMANCE DATA AUTOCLAVE 5.3.4 Phase 3: Water outgas system filling (U-234 circuit) W.O.S. PHASE 3 Vacuum pump begins reduce pressure into the W.O.S. in order to move water (pumped by WP1 for 30 seconds) into the W.O.S.

-

Page 54: Phase 4: Vacuum Into Chamber And Water Outgas System (U-234 Circuit)

5 — D ESCRIPTION OF CYCLE AND MAIN PERFORMANCE DATA AUTOCLAVE 5.3.5 Phase 4: Vacuum into chamber and water outgas system (U-234 circuit) W.O.S. PHASE 4 After 30 seconds, WP1 stops working. Vacuum pump continues in reducing pressure into the chamber (through EV1) and into W.O.S.

-

Page 55: Phase 5: Water Separator Emptying And Steam Generator Filling (U-234 Circuit)

5 — D ESCRIPTION OF CYCLE AND MAIN PERFORMANCE DATA AUTOCLAVE 5.3.6 Phase 5: Water separator emptying and steam generator filling (U-234 circuit) W.O.S. PHASE 5 When pressure is lowered down to -0.80 bar (0.2 absolute bar), vacuum pump suction is moved to the bacteriological filter by EV7 switching and so water flows from the W.O.S.

-

Page 56: Phase 6: Pressure Rise (U-234 Circuit)

5 — D ESCRIPTION OF CYCLE AND MAIN PERFORMANCE DATA AUTOCLAVE 5.3.7 Phase 6: Pressure rise (U-234 circuit) W.O.S. PHASE 6 When the steam generator is full, it starts the water heating till the pressure into the chamber reaches the value +0.3 bar (1.3 absolute bar).

-

Page 57: Phase 7: Emptying And Vacuum (U-234 Circuit)

5 — D ESCRIPTION OF CYCLE AND MAIN PERFORMANCE DATA AUTOCLAVE 5.3.8 Phase 7: Emptying and vacuum (U-234 circuit) W.O.S PHASE 7 Once the pressure reaches +0.3 bar (1.3 absolute bar), EV4 is opened and water is pushed by pressure to the W.O.S.

-

Page 58: Pressure Rise (U-234 Circuit)

5 — D ESCRIPTION OF CYCLE AND MAIN PERFORMANCE DATA AUTOCLAVE 5.3.9 Pressure rise (U-234 circuit) W.O.S. PHASE P3 – PRESSURE RISE/STERILIZATION The third pressure rise takes to the sterilization phase. 4 °C before the temperature setpoint the water pump WP1 injects water four times following the procedure 1 second ON, 2 seconds OFF so that the temperature setpoint is reached smoothly.

-

Page 59: Cycle For E9 Med (Up To Ego090100 18 L And Up To Egp090080 24 L)

The unit can be filled with water either manually or using the mains water function with the support of a deionizer (see Appendix 10 “Euronda Aquafilter” and Chap. 6.7 “Tanks: instructions for filling and emptying” in the instructions manual). When the minimum water level sensor trips, the deionizer solenoid valve EV6 is powered and opens to let the water flow into the tank until the maximum level sensor trips.

-

Page 60: Phase 1: Vacuum Into Chamber

5 — D ESCRIPTION OF CYCLE AND MAIN PERFORMANCE DATA AUTOCLAVE 5.4.2 Phase 1: Vacuum into chamber PHASE 1 Vacuum pump continues in reducing pressure into the chamber (through EV1). Energized components: 1. VACUUM PUMP 2. EV7 3. EV8 -0,5 -1,5 E9 service manual GB r7…

-

Page 61: Phase 2: Steam Generator Filling

5 — D ESCRIPTION OF CYCLE AND MAIN PERFORMANCE DATA AUTOCLAVE 5.4.3 Phase 2: Steam generator filling PHASE 2 When pressure is lowered down to -0.80 bar (0.2 absolute bar), vacuum pump stops and the water pump injects the water into the steam generator. Energized components: 1.

-

Page 62: Phase 3: Pressure Rise

5 — D ESCRIPTION OF CYCLE AND MAIN PERFORMANCE DATA AUTOCLAVE 5.4.4 Phase 3: Pressure rise PHASE 3 When the steam generator is full, it starts the water heating till the pressure into the chamber reaches the value +0.3 bar (1.3 absolute bar). If necessary, water injections are executed. Energized components: 1.

-

Page 63: Phase 4: Water Separator Emptying And Vacuum

5 — D ESCRIPTION OF CYCLE AND MAIN PERFORMANCE DATA AUTOCLAVE 5.4.5 Phase 4: Water separator emptying and vacuum PHASE 4 Once the pressure reaches 0 bar (1 absolute bar) the vacuum pump switches on and so pushes the water into the separator to the used water tank.

-

Page 64: Third Pressure Rise And Sterilisation

5 — D ESCRIPTION OF CYCLE AND MAIN PERFORMANCE DATA AUTOCLAVE 5.4.6 Third pressure rise and sterilisation PHASE P3 – PRESSURE RISE/STERILIZATION The third pressure rise takes to the sterilization phase. 4 °C before the temperature setpoint the water pump WP1 injects water four times following the procedure 1 second ON, 2 seconds OFF so that the temperature setpoint is reached smoothly.

-

Page 65: Drying Phase

5 — D ESCRIPTION OF CYCLE AND MAIN PERFORMANCE DATA AUTOCLAVE 5.4.7 Drying phase DRYING PHASE When the sterilisation period ends, EV1 opens and the steam flows through the radiator. The vacuum pump keeps working for 15 minutes so to get the complete drying. Energized components: 1.

-

Page 66: Cycle For E9 Med (Since Ego090101 18 L And Since Egp090081 24 L)

The unit can be filled with clean water either manually or using the mains water function with the support of a deionizer (see Appendix 10 “Euronda Aquafilter” and Chap. 6.7 “Tanks: instructions for filling and emptying” in the instructions manual). When the minimum water level sensor trips, the deionizer solenoid valve EV6 is powered and opens to let the water flow into the tank until the maximum level sensor trips.

-

Page 67: Phase 1: Start And Chamber Emptying

5 — D ESCRIPTION OF CYCLE AND MAIN PERFORMANCE DATA AUTOCLAVE 5.5.2 Phase 1: Start and chamber emptying PHASE 1 When the preheating is finished, the vacuum pump begins the air removal from the chamber. The vacuum pump works until the pressure is lowered to -0,80 bar (0,2 bar absolute). Are energized: 1.

-

Page 68: Phase 2: Water Injection Into The Chamber

5 — D ESCRIPTION OF CYCLE AND MAIN PERFORMANCE DATA AUTOCLAVE 5.5.3 Phase 2: Water injection into the chamber PHASE 2 When the vacuum setpoint is reached (-0,80 bar for V and for V ) the water is injected into the chamber.

-

Page 69: Phase 3: Pressure Rise

When the chamber is filled with the necessary quantity of water, the band heater is supplied at its maximum in order to vaporize the water. During the pressure rise, differently from E9 INSPECTION and RECORDER, no more water injections are executed. The pressure rises up to +0,2 bar in P…

-

Page 70: Phase 4: Pressure Discharge And Emptying

5 — D ESCRIPTION OF CYCLE AND MAIN PERFORMANCE DATA AUTOCLAVE 5.5.5 Phase 4: Pressure discharge and emptying PHASE 4 When the pressure into the chamber reaches +0,2 bar (1,2 bar absolute) at the end of P , EV1 switches and the steam is pushed out, condensed into the radiator, then the condensed water is stored into the separator.

-

Page 71: Phase 5: Pressure Rise And Separator Emptying

5 — D ESCRIPTION OF CYCLE AND MAIN PERFORMANCE DATA AUTOCLAVE 5.5.6 Phase 5: Pressure rise and separator emptying PHASE 5 At the end of V and V the pressure is -0,80 bar, the vacuum pump is working and the separator is full of water. Switching EV1 the chamber is sealed and the following pressure rise begins.

-

Page 72: Phase 6: Pressure Balancing

5 — D ESCRIPTION OF CYCLE AND MAIN PERFORMANCE DATA AUTOCLAVE 5.5.7 Phase 6: Pressure balancing PHASE 6 At the cycle end the pressure into the chamber is lower than the external pressure because the drying phase is carried out in vacuum conditions. For the final pressure balancing EV2 opens and the external air flows through the bacteriological filter into the chamber.

-

Page 73: Examples Of Sterilization Cycle Reports

5 — D ESCRIPTION OF CYCLE AND MAIN PERFORMANCE DATA AUTOCLAVE 5.6 EXAMPLES OF STERILIZATION CYCLE REPORTS E9 service manual GB r7…

-

Page 74: Description Of Test And Main Performance Data

6 — Description of test and main performance data 6.1 GRAPH OF COMPLETE VACUUM TEST This test is performed in order to check the performance of the unit, in particular: the efficiency of the vacuum pump; the seal of the pneumatic circuit.

-

Page 75: Phase 0: Starting

6 — D ESCRIPTION OF TEST AND MAIN PERFORMANCE DATA AUTOCLAVE In order to obtain a correct result, the test must be performed “cold”, i.e.: within 3 minutes of switching on the unit. If the test is selected when PTC2 has reached a temperature greater than or equal to 50°C, or if 3 minutes or more minutes elapse before the test is selected, the display will inform you that the Vacuum test is no longer available.

-

Page 76: Vacuum Phase

6 — D ESCRIPTION OF TEST AND MAIN PERFORMANCE DATA AUTOCLAVE 6.1.2 Vacuum phase Pressione Pressure VACUUM PHASE After the START button is pressed, the following are powered: mechanical safety electromagnet EV2: opened to allow the air to be pumped from the chamber EV3: closed to close the bacteriological filter EV5: opened to allow the air to be pumped from the chamber Vacuum pump, to pump the air from the sterilization chamber…

-

Page 77: Pressure Levelling/Maintenance Phase

6 — D ESCRIPTION OF TEST AND MAIN PERFORMANCE DATA AUTOCLAVE 6.1.3 Pressure levelling/Maintenance phase Pressione Pressure PRESSURE LEVELLING/MAINTENANCE PHASE After reaching a depression of -0.86 bar, the following are powered: EV1: to close the pressure discharge circuit EV2 is de-energised EV5 is de-energised The vacuum pump also stops working During this phase, the pressure is levelled for 5 minutes and then maintained for 10 minutes.

-

Page 78: Pressure Levelling Phase

6 — D ESCRIPTION OF TEST AND MAIN PERFORMANCE DATA AUTOCLAVE 6.1.4 Pressure levelling phase Pressure levelling Livellamento barico PRESSURE LEVELLING PHASE After the vacuum has been maintained for 10 minutes and the system has checked the seal of the pneumatic circuit (otherwise an alarm message is displayed), EV3 is opened: the air enters from the bacteriological circuit and the system returns to its initial pressure.

-

Page 79: Bowie&Dick Test

6 — D ESCRIPTION OF TEST AND MAIN PERFORMANCE DATA AUTOCLAVE 6.2 BOWIE&DICK TEST This is a chemical-physical test that is also known as the Brown test: the indicator is a heat-sensitive sheet that is placed in the middle of a packet made up of various layers of paper and foam rubber. The B&D test simulates the performance of the unit with regard to the sterilization of porous loads, in particular: the efficiency of the preliminary vacuum and the penetration of steam within the pores;…

-

Page 80

6 — D ESCRIPTION OF TEST AND MAIN PERFORMANCE DATA AUTOCLAVE Preliminary vacuum steps Sterilization phase WARNING: only perform the Helix test after a sterilisation cycle. Test results must be assessed on the basis of the instructions provided by the Producer of the test. -

Page 81: Maintenance

OR BY THE TECHNICIANS AUTHORISED BY THE ASSISTANCE SERVICE OF EURONDA S.p.A. Observe the intervals prescribed or shown in this manual. The E9 INSPECTION activates memorandum messages to assist the user in performing both the ordinary and the extraordinary maintenance operations.

-

Page 82

7 — M AINTENANCE AUTOCLAVE From the Main Menu, use the key to Maintenance select the item Maintenance, then press OK Use the keys to select the item to confirm. desired, and press OK to confirm. If Periodic maintenance, see chap. 8.2; If Extraordinary maintenance: see chap. -

Page 83: Periodic Maintenance

Activate Counters: the number of cycles to perform before the message appears begins from the value the counters stopped at. The periodic maintenance operations are described and illustrated in the “E9 INSPECTION” user instruction manual. — With or OK, you go back to the previous screen.

-

Page 84: Extraordinary Maintenance

7.3 EXTRAORDINARY MAINTENANCE WARNING: extraordinary maintenance must only be performed by specialists authorised by Euronda S.p.A. Any jobs not included in the periodic maintenance section in the instruction manual provided with the unit are considered as extraordinary maintenance.

-

Page 85

After 1000 cycles or after two years from installation (the date can be seen at the bottom of the screen), a memorandum message appears recommending a general overhaul of the unit. This can only be performed by specialists authorised by Euronda S.p.A. The reminder message appears each time the unit is switched on, until the overhaul has been performed. -

Page 86: Technical Menu

7 — M AINTENANCE AUTOCLAVE Replacing the bacteriological filter Unscrew the bacteriological filter (1 of Fig. 8.3 — 1) by turning it anticlockwise; Screw on the new filter by turning it clockwise until it is tight. Fig. 8.3-1 Replancing the door seal Grip the lip of the seal with two fingers and remove it;…

-

Page 87

7 — M AINTENANCE AUTOCLAVE In case of wrong password: This screenshot disappears after 3 seconds and returns to main Menu Process Controller Wrong password ▼ ▲ 7.4.1 Set water input Insert serial number Reset cycles Hydraulic leakage Insert serial number Probes adjustment Hydraulic leakage Test components… -

Page 88

7 — M AINTENANCE AUTOCLAVE Reset cycles Push YES and return to 7.4.2 This function reset the counter at the first level, it doesn’t reset the main counter. Reset cycles counter? CONFIGURATION. Push YES and return to 7.4.2 and the cycles will be deleted. -

Page 89

7 — M AINTENANCE AUTOCLAVE Hydraulic Leakage +0.00 bar At cycle end, appears 7.4.2.4.1 If you push the INFO button 110.0 °C If you push the STOP button from 3.2 mm:ss Stop Info Hydraulic Leakage Unlock door and go to 7.4.2 Process Controller Cycle end Open the door… -

Page 90

7 — M AINTENANCE AUTOCLAVE Hydraulic Leakage Push Door 7.4.2 This test made it possibile to increase pressure up to 2,05 bar for 30’ without active alarms. Process Controller In case of Leackage, perform thist test cycle. Manual stop Unlock the door Door 7.4.2.4.2 Probes Adjustment… -

Page 91

7 — M AINTENANCE AUTOCLAVE Probes Adjustment If you push STOP from 3.2 OR 3.4 3.3, +10.00 Kpa If you push NO 3.2 OR 3.4 ELSE 3.8 AND 7.4.2.5.2 Phase V1 – 2c mm:ss Return Stop Probes Adjustment Ti (valore reale) (valore reale) Manual stop Pleas wait… -

Page 92

7 — M AINTENANCE AUTOCLAVE Push RETURN 7.4.2 Test Items (all components are set to normal values) ▼ ▲ 7.4.2.6 Visualize parameters This screenshot shows the machine instant function arameters. Push RETURN 7.4.2 RMS +230.6 V mm:ss Return 7.4.2.7 E9 service manual GB r7… -

Page 93

7 — M AINTENANCE AUTOCLAVE CONFIGURATION: this screenshot show how to select and print: — operators setup — past cycles parameters — ordinary and extraordinary maintenance period — probes correction range — instant parameters Cycles stop: For marketing and law agreements reasons, it is possible to inhibit certain cycles, by factory programming. -

Page 94: Components List E9 Inspection (U-234 / Recorder Circuit)

7 — M AINTENANCE AUTOCLAVE 7.5 COMPONENTS LIST E9 INSPECTION (U-234 / RECORDER CIRCUIT) NAME OF COMPONENTS DESCRIPTION Characteristics SIGNAL Main switch 250V 12A Two-way solenoid valve for discharging steam at the end OD6A/OD6B 24 VDC of the cycle, power draw 9 W; normally open (NO)

-

Page 95

7 — M AINTENANCE AUTOCLAVE NAME OF COMPONENTS DESCRIPTION Characteristics SIGNAL PTC4 NTC10000 temperature probe mounted on radiator PTC5 Temperature probe mounted on CPU card Pressure sensor Float sensor for MIN distilled water level, contact normally closed (NC) Float sensor for MAX distilled water level, contact normally closed (NC) Float sensor for MAX used water level, contact normally closed (NC) -

Page 96: Components And Diagrams

8 — Components and diagrams 8.1 WIRING DIAGRAM…

-

Page 97

8 — C OMPONENTS AND DIAGRAMS AUTOCLAVE ITEM DESCRIPTION ITEM DESCRIPTION Manually resettable safety thermostat Main switch (steam generator) Solenoid valve for discharging pressure Manually resettable safety thermostat at the end of the cycle (band heater on chamber) Solenoid valve for air prevacuum and PTC1 Probe inside boiler water-air separation Solenoid valve for bacteriological filter… -

Page 98: Hydraulic Diagram

8 — C OMPONENTS AND DIAGRAMS AUTOCLAVE 8.2 HYDRAULIC DIAGRAM 8.2.1 Hydraulic diagram E9 W.O.S. ITEM DESCRIPTION ITEM DESCRIPTION Solenoid valve for discharging pressure at Electronic pressure sensor the end of the cycle Solenoid valve for air prevacuum and water- Safety valve air separation Solenoid valve for bacteriological filter.

-

Page 99: Hydraulic Diagram E9 U-234

8 — C OMPONENTS AND DIAGRAMS AUTOCLAVE 8.2.2 Hydraulic diagram E9 U-234 W.O.S. 8.2.3 Hydraulic diagram E9 MED (since EGO090101 18 L and since EGP090081 24 L) E9 service manual GB r7…

-

Page 100: Spare Parts Catalogue

9 — S PARE PARTS CATALOGUE AUTOCLAVE 9 — Spare parts catalogue 9.1 EXPLODED GENERAL DIAGRAM OF E9 INSPECTION E9 service manual GB r7…

-

Page 101: Index Of Tables

9 — S PARE PARTS CATALOGUE AUTOCLAVE 9.2 INDEX OF TABLES Tab. 01 Safety housing assembly Tab. 02 Door assembly Tab. 03 Control panel assembly Tab. 04 Tank and power board + pressure transducer Tab. 05 Vacuum pump and radiator assembly Tab.

-

Page 102: Tab. 01: Safety Housing Assembly E9

9 — S PARE PARTS CATALOGUE AUTOCLAVE 9.2.1 TAB. 01: SAFETY HOUSING ASSEMBLY E9 REF. ITEM N° DESCRIPTION 533798 tank cover door 572385 button-head screw 4×6 531507 tank cover 524724 painted LH side panel 572487 button-head screw 4×10 524722 painted RH side panel 530668 yellow adhesive warning label 524726…

-

Page 103: Tab. 02: Door Assembly E9 Inspection / Recorder

9 — S PARE PARTS CATALOGUE AUTOCLAVE 9.2.2.1 TAB. 02: DOOR ASSEMBLY E9 INSPECTION / RECORDER REF. ITEM N° DESCRIPTION door assembly 532946 handle A.1.1 570719 dowel 5×10 533480 E9 door 530682 «EURONDA» adhesive label 530669 lagging 571730 «B type inspection» adhesive label…

-

Page 104: Tab. 02: Door Assembly E9 Med

ITEM N° DESCRIPTION door assembly 910412 532946 handle A.1.1 570719 dowel 5×10 533484 E9 door 530682 «EURONDA» adhesive label 590831 lagging 530669 «B type inspection» adhesive label 571730 washer 5×15 572363 screw 3.5×13 arm + porthole assembly 320263 572504 screw 5×12…

-

Page 105: Tab. 03: Control Panel Assembly E9 Inspection

9 — S PARE PARTS CATALOGUE AUTOCLAVE 9.2.3.1 TAB. 03: CONTROL PANEL ASSEMBLY E9 INSPECTION REF. ITEM N° DESCRIPTION complete control panel 330056 563240 micro-switch 533153 control panel 532266 adhesive for control panel 564645 complete printer 815002 thermal paper 57 mm…

-

Page 106: Tab. 03: Control Panel Assembly E9 Recorder

9 — S PARE PARTS CATALOGUE AUTOCLAVE 9.2.3.2 TAB. 03: CONTROL PANEL ASSEMBLY E9 RECORDER REF. ITEM N° DESCRIPTION complete control panel 563240 micro-switch 533165 control panel 532324 adhesive for control panel 572373 3×8 TB screw 564645 complete printer 815005 labels roll (10 rolls pack) 562216 display…

-

Page 107: Tab. 03: Control Panel Assembly E9 Med

9 — S PARE PARTS CATALOGUE AUTOCLAVE 9.2.3.3 TAB. 03: CONTROL PANEL ASSEMBLY E9 MED REF. ITEM N° DESCRIPTION complete control panel 563240 micro-switch 561180 26-way flat cable 561182 40-way flat cable 533166 E9 MED control panel 532325 E9 MED control panel sticker (item removed) 523524 brass spacer…

-

Page 108: Tab. 04: Tank And Power Card + Pressure Transducer Assembly E9

9 — S PARE PARTS CATALOGUE AUTOCLAVE 9.2.4.1 TAB. 04: TANK AND POWER CARD + PRESSURE TRANSDUCER ASSEMBLY E9 REF. ITEM N° DESCRIPTION 330112 E9 tank assembly 533693 tank 540052 white silicone tank gasket 564401 level sensor 523740 tank water supply filter fixing nut (supplied with sensor 564401) black washer (supplied with sensor 564401) O-ring (supplied with sensor 564401)

-

Page 109

9 — S PARE PARTS CATALOGUE AUTOCLAVE REF. ITEM N° DESCRIPTION – card + pressure transducer assembly 570497 nut M3 523519 spacer for main card 571728 flat washer M3 572373 screw 3×8 571148 elbow union 1/4-6/4 522026 pressure transducer fixing ring 571133 union nut 1/4 527071… -

Page 110: Med

9 — S PARE PARTS CATALOGUE AUTOCLAVE 9.2.4.2 TAB. 04: TANK AND POWER CARD + PRESSURE TRANSDUCER ASSEMBLY E9 U-234 / RECORDER / MED REF. ITEM N° DESCRIPTION tank assembly E9 U-234 / RECORDER / MED 533693 tank E9 540528 tank silicone gasket 564401 level sensor…

-

Page 111

9 — S PARE PARTS CATALOGUE AUTOCLAVE REF. ITEM N° DESCRIPTION A.23 571743 OR gasket A.24 571199 union M/F 1/8 A.25 571165 union M1/8 PG A.26 572286 check valve 1/4 A.27 571208 union F1/4 for tube Ø 6/8 A.28 571123 union M1/8 for tube Ø… -

Page 112: Tab. 05: Vacuum Pump And Radiator Assembly E9

9 — S PARE PARTS CATALOGUE AUTOCLAVE 9.2.5.1 TAB. 05: VACUUM PUMP AND RADIATOR ASSEMBLY E9 REF. ITEM N° DESCRIPTION 320829 vacuum pump assembly 525099 vacuum pump A.2 + A.3 540655 pump gasket kit 541146 silicone tube Ø 6/10 571119 elbow union M 1/4 7 540871 black adj.

-

Page 113: Tab. 05: Vacuum Pump And Radiator Assembly E9 U-234 / Recorder / Med

9 — S PARE PARTS CATALOGUE AUTOCLAVE 9.2.5.2 TAB. 05: VACUUM PUMP AND RADIATOR ASSEMBLY E9 U-234 / RECORDER / MED REF. ITEM N° DESCRIPTION vacuum pump assembly 571119 elbow union M1/4 PG7 571114 T-shaped union F/M/F (no E9 MED) 541146 silicone tube Ø…

-

Page 114: Tab. 06: Tank Support And Nme Micropump Assembly

9 — S PARE PARTS CATALOGUE AUTOCLAVE 9.2.6.1 TAB. 06: TANK SUPPORT AND NME MICROPUMP ASSEMBLY REF. ITEM N° DESCRIPTION 321192 tank support assembly 526289 tank support 572487 screw 4×10 533320 santoprene pipette for vibrating pump 541146 silicone tube Ø 6/10 541080 rubber vibration-proof support for vibrating pump 525104…

-

Page 115: Tab. 06: Tank Support And Sicce Micropump Assembly

9 — S PARE PARTS CATALOGUE AUTOCLAVE 9.2.6.2 TAB. 06: TANK SUPPORT AND SICCE MICROPUMP ASSEMBLY RIF. CODICE DESCRIZIONE Q.TÀ 321192 tank support assembly 526289 tank support 572487 TS screw 4×10 533320 santoprene pipette for vibrating pump 541146 silicone tube Ø 6/10 541080 rubber vibration-proof support for vibrating pump 525104…

-

Page 116: Tab. 06: Tank Support And Micropump Assembly E9 U-234 / Recorder / Med

9 — S PARE PARTS CATALOGUE AUTOCLAVE 9.2.6.3 TAB. 06: TANK SUPPORT AND MICROPUMP ASSEMBLY E9 U-234 / RECORDER / MED REF. ITEM N° DESCRIPTION tank support assembly 526289 tank support 572487 screw TS 4×10 533320 santropene pipette for vibrating pump 541146 silicone tube Ø…

-

Page 117: Recorder

9 — S PARE PARTS CATALOGUE AUTOCLAVE 9.2.7.1 TAB. 07: CHASSIS, WATER OUTGAS SYSTEM AND CROSSPIECE ASSEMBLY E9 INSPECTION / RECORDER REF. ITEM N° DESCRIPTION frame assembly 526007 E9 autoclave chassis 571729 flat stainless steel washer 571721 notched washer ext. 4 mm…

-

Page 118

9 — S PARE PARTS CATALOGUE AUTOCLAVE REF. ITEM N° DESCRIPTION A.18 816047 teflon tube Ø 6/8 A.20 571120 elbow union PG F 1/4 A.21 816011 Aquafilter socket A.22 571720 stainless steel notched washer 3 A.23 572373 button-head screw 3×8 A.24 571162 elbow union PG M 1/4… -

Page 119: Tab. 07: Chassis And Crosspiece Assembly E9 Med

9 — S PARE PARTS CATALOGUE AUTOCLAVE 9.2.7.2 TAB. 07: CHASSIS AND CROSSPIECE ASSEMBLY E9 MED REF. ITEM N° DESCRIPTION frame assembly 526007 E9 MED painted chassis 571729 flat washer 571721 notched washer 4 mm 572432 screw 4×8 523262 base-plate SMF 18 litres 523262 base-plate SMF 24 litres 562550…

-

Page 120

9 — S PARE PARTS CATALOGUE AUTOCLAVE REF. ITEM N° DESCRIPTION A.18 816047 teflon tube Ø 6/8 A.20 571120 elbow union F 1/4 Ø 6/8 A.21 816011 Aquafilter socket A.22 571720 notched washer Ø 3 A.23 572373 screw 3×8 A.24 571162 straight union M 1/4 571140… -

Page 121: Tab. 08: Solenoid Valve Assembly E9

9 — S PARE PARTS CATALOGUE AUTOCLAVE 9.2.8.1 TAB. 08: SOLENOID VALVE ASSEMBLY E9 REF. ITEM N° DESCRIPTION 360946 premounted EV3 valve 570109 hose clip 816047 teflon tube Ø 6/8 571148 elbow union PG F 1/4-7 572286 one-way valve M/F 1/4 571127 elbow union M/F 1/4 571183…

-

Page 122

9 — S PARE PARTS CATALOGUE AUTOCLAVE REF. ITEM N° DESCRIPTION 541146 silicone tube Ø 6/10 B.10 572432 cheese-head socket screw M4x8 B.11 571146 elbow union M/F 1/4 B.12 572286 check valve M/F 1/4 B.13 816047 teflon tube Ø 6/8 360945 EV1-EV4 assembly (serial numer EEG and EEH) 360944… -

Page 123: Tab. 08: Solenoid Valve Assembly E9 U-234 / Recorder

9 — S PARE PARTS CATALOGUE AUTOCLAVE 9.2.8.2 TAB. 08: SOLENOID VALVE ASSEMBLY E9 U-234 / RECORDER REF. ITEM N° DESCRIPTION Q.TÀ 360943 premounted EV2 valve 541146 silicone tube Ø 6/10 571119 elbow union PG M 1/4 562330 solenoid valve EV2 A.3.1 solenoid valve body A3.2…

-

Page 124

9 — S PARE PARTS CATALOGUE AUTOCLAVE REF. ITEM N° DESCRIPTION Q.TÀ premounted EV1-EV4 valves 541146 silicone tube Ø 6/10 571119 elbow union PG M 1/4 562331 solenoid valve EV4 C.3.1 solenoid valve body C.3.2 solenoid valve piston 523519 spacer M/F M3x12 572432 screw TCCE M4x8 562322… -

Page 125: Tab. 08: Solenoid Valve Assembly E9 Med

9 — S PARE PARTS CATALOGUE AUTOCLAVE 9.2.8.3 TAB. 08: SOLENOID VALVE ASSEMBLY E9 MED REF. ITEM N° DESCRIPTION 360963 premounted EV2 valve 816046 teflon tube Ø 4/6 571127 elbow union M1/4 for tube Ø 4/6 562331 solenoid valve EV2 A.3.1 solenoid valve body A3.2…

-

Page 126

9 — S PARE PARTS CATALOGUE AUTOCLAVE REF. ITEM N° DESCRIPTION 360961 premounted EV1 valve 571207 union F1/8G for tube Ø 6/8 571124 union M1/4 for tube Ø 6/8 816047 teflon tube Ø 6/8 572175 plug M1/4 572432 screw M4x8 562330 solenoid valve EV1 C.6.1… -

Page 127: Tab. 09: Boiler/Electromagnet Assembly E9 Inspection / Recorder

9 — S PARE PARTS CATALOGUE AUTOCLAVE 9.2.9.1 TAB. 09: BOILER/ELECTROMAGNET ASSEMBLY E9 INSPECTION / RECORDER REF. ITEM N° DESCRIPTION 320332 (18l) – 320334 (24l) boiler/electromagnet assembly (s.n. EEG e EEH) 320333 (18l) – 320335 (24l) boiler/electromagnet assembly (s.n. EDI e EDK) 522495 aut.

-

Page 128

9 — S PARE PARTS CATALOGUE AUTOCLAVE REF. ITEM N° DESCRIPTION A.24 570498 stainless steel hex nut M4 A.25 571729 flat washer 4x9x0.8 A.26 564479 generator temperature probe PTC3 A.27 527222 copper tube A.28 564059 generator heater w/shell A.29 571188 water inlet union (with generator) 18 l 571123 + 572175… -

Page 129: Tab. 09: Boiler/Electromagnet Assembly E9 Med

9 — S PARE PARTS CATALOGUE AUTOCLAVE 9.2.9.2 TAB. 09: BOILER/ELECTROMAGNET ASSEMBLY E9 MED REF. ITEM N° DESCRIPTION 320352 (18 litri) – 320353 (24 litri) boiler/electromagnet assembly 522502 boiler E9 MED 18 litres 522503 boiler E9 MED 24 litres 572175 cap M 1/4 572488 screw 6×18…

-

Page 130

9 — S PARE PARTS CATALOGUE AUTOCLAVE REF. ITEM N° DESCRIPTION A.24 570498 nut M4 A.25 571729 flat washer 4/9/0,8 360266 electromagnet assembly 572507 screw 3×16 563238 lever micro-switch 531822 plastic spacer 526398 electromagnet bracket 562438 electromagnet 572432 screw M4x8 571721 notched washer Ø… -

Page 131: Tab. 10: Front Panel Assembly E9

Ø 4/6 A.13 A.14 + A.15 572229 turret kit for E9 A.16 563723 serial connector 523961 front panel E9 INSPECTION / RECORDER A.17 523972 painted front panel E9 MED 572339 black 4×12 screw 533159 lower panel 563722 serial connector…

-

Page 132: Tab. Kit: Accessories Kit E9

9 — S PARE PARTS CATALOGUE AUTOCLAVE 9.2.11 TAB. KIT: ACCESSORIES KIT E9 REF. ITEM N° DESCRIPTION accessory kit E9 561727 power cable (Europe) 523526 + 531300 metal spacers with PVC cap Ø 8 H16 340060 CPC M union + PVC tube 1.5 mt A.3.1 571130 CPC M union…

-

Page 133: Product Versions

10 — Product versions 10.1 REGISTRATIONS OF MODIFICATIONS TO E9 HARDWARE Please visit: www.eurondatec.com…

-

Page 134: Troubleshooting

11 — Troubleshooting 11.1 SUMMARY OF ALARM SIGNALS NOTE for reading this chapter. The following table summarises all the alarms that can appear on the E9 INSPECTION display: the second column (PHASE) of the table refers to the above diagram.

-

Page 135

11 — T ROUBLESHOOTING AUTOCLAVE CODE PHASE DESCRIPTION POSSIBLE REASON ACTION BRIEF Main power supply: voltage Sudden drop in mains Check voltage level Brief 1-17 drop. voltage of ±10%. Blackout 1 Momentary cut-out of 1 Wait for mains voltage to Brief mains voltage. -

Page 136

11 — T ROUBLESHOOTING AUTOCLAVE CODE PHASE DESCRIPTION POSSIBLE REASON ACTION BRIEF Prevacuum time-out if -0.86 1 Leak from hydraulic circuit. Inspect the pneumatic Brief (-0,80 form 6.05 ) bar is not (Please go to circuit for leaks and reached in 10’ (1st vacuum www.eurondatec.com) check the vacuum pump. -

Page 137

11 — T ROUBLESHOOTING AUTOCLAVE CODE PHASE DESCRIPTION POSSIBLE REASON ACTION BRIEF Vacuum test: leak during Leak from hydraulic circuit Check the tubes, unions, Brief maintenance phase. porthole and solenoid Vacuum Rate of leak ::::::::: valves for leaks. test If ∆P/∆t = p3-p2/10 ≥ 13 mbar. -

Page 138

11 — T ROUBLESHOOTING AUTOCLAVE CODE PHASE DESCRIPTION POSSIBLE REASON ACTION BRIEF Chamber heater: high PTC2 temperature probe out Replace temperature Brief temperature is the PTC2 of calibration. probe. 2-17 sensor measures a temperature higher than 190°C. Chap. 8 Boiler heater not working if 1 Safety thermostat tripped. -

Page 139

11 — T ROUBLESHOOTING AUTOCLAVE CODE PHASE DESCRIPTION POSSIBLE REASON ACTION BRIEF External memory: data 1 Bad connection between 1 Check the connection transfer error, data not serial port and power card. between the serial port downloaded to logger. and the power card. Out of 2 Bad connection between 2 Check the connection… -

Page 140: Repair Briefs

: Checking and/or replacing the level sensor : Checking and/or replacing the fan : Replacing the door gasket : Updating the E9 Inspection firmware : Removing and replacing the vacuum pump heads : Removing and replacing the safety thermostat : Replacing the front panel assembly…

-

Page 141

11 — T ROUBLESHOOTING AUTOCLAVE CHECKING THE VOLTAGE LEVEL brief Maintenance tools required — Voltmeter Procedure — Connect a voltmeter in parallel to the mains power supply, start a sterilization cycle and check voltage fluctuation: the voltage level must remain within 10% of the rated input voltage. — If the above fluctuations exceed ±10%, check that there are no other appliances with high power draws (aspirators, compressors, casting machines, etc.) connected to the same power supply. -

Page 142

11 — T ROUBLESHOOTING AUTOCLAVE REPLACING THE DISPLAY BOARD brief Maintenance tools required — Socket wrench M3 — Medium Philips screwdriver — Small Philips screwdriver Procedure — Remove the right-hand panel by unscrewing the 3 Philips screws (1) and remove the flat cables (2 and 3) connecting the display to the power card and the micro-switch (6). -

Page 143

11 — T ROUBLESHOOTING AUTOCLAVE CALIBRATING THE TEMPERATURE PROBE brief — If the temperature probe needs calibrating, get in touch with the Euronda S.p.A. technical assistance service. REPLACING THE EV2 AND EV5 SOLENOID VALVE COILS brief Maintenance tools required — Tester… -

Page 144

N.B.: Make sure that the probe (4) enters 55 mm into its housing. CALIBRATING THE PRESSURE TRANSDUCER brief — If the pressure transducer needs calibrating, get in touch with the Euronda S.p.A. technical assistance service. E9 service manual GB r7… -

Page 145

11 — T ROUBLESHOOTING AUTOCLAVE PERFORMING THE VACUUM TEST brief Procedure — Disconnect the unit from the mains power supply and remove the left-hand panel. — Perform a vacuum test as shown in Chap. 6 and make sure that the pressurised components do not leak and that there are no overflows into the tubes or components. -

Page 146

11 — T ROUBLESHOOTING AUTOCLAVE CHECKING AND/OR REPLACING THE EV1 SOLENOID VALVE brief Maintenance tools required — Medium Philips screwdriver — Seeger wrench — Adjustable wrench Procedure — Disconnect the unit from the mains power supply and remove the left- hand panel. -

Page 147

11 — T ROUBLESHOOTING AUTOCLAVE CHECKING AND/OR REPLACING THE PTC1 PROBE brief Maintenance tools required — Small Philips screwdriver — Adjustable wrench — Tester — Loctite thread sealant 542 Procedure — Disconnect the unit from the mains power supply and remove the right-hand panel. — Disconnect the probe (1) from the card: the wires are the first two from the top on the terminal board (see wiring diagram Chap. -

Page 148

11 — T ROUBLESHOOTING AUTOCLAVE CHECKING AND/OR REPLACING THE PTC2 PROBE brief Maintenance tools required — Permanent marker pen — Small Philips screwdriver — Medium Philips screwdriver — Cutter — Tester — Socket wrench Procedure — Disconnect the unit from the mains power supply and remove the right, left and rear panels. — Disconnect the probe from the power card (wires 3 and 4 from the top, see wiring diagram Chap. -

Page 149

11 — T ROUBLESHOOTING AUTOCLAVE CHECKING AND/OR REPLACING THE PTC3 PROBE brief Maintenance tools required — Small Philips screwdriver — Medium Philips screwdriver — Tester Procedure — Disconnect the unit from the mains power supply and remove the right and left panels. — Disconnect the probe (1) from the card (wires 5 and 6 from the top on the terminal board, see wiring diagram Chap. -

Page 150

11 — T ROUBLESHOOTING AUTOCLAVE CHECKING AND/OR REPLACING THE PS1 PRESSURE TRANSDUCER brief Maintenance tools required — Small Philips screwdriver — Medium Philips screwdriver — Tester Procedure — Disconnect the unit from the mains power supply and remove the right and rear panels. — Check the connections (last three cables from the bottom of the terminal board, see wiring diagram Chap. -

Page 151

11 — T ROUBLESHOOTING AUTOCLAVE CHECKING AND/OR REPLACING THE ELECTROMAGNET brief Maintenance tools required — Allen key n°3 — Medium Philips screwdriver — Small Philips screwdriver — Plastic clamp Procedure — Disconnect the unit from the mains power supply and remove the right-hand panel. — Reconnect the unit to the mains and run a cycle: when it starts, check that the pin of the electromagnet (1) leaves its housing, in other words, the tip of the electromagnet must be flush with the coil after the cycle starts. -

Page 152

11 — T ROUBLESHOOTING AUTOCLAVE CHECKING AND/OR REPLACING THE SW2 MICRO-SWITCH brief Maintenance tools required — Allen key n°3 — Medium Philips screwdriver — Small Philips screwdriver — Plastic clamp Procedure — Disconnect the unit from the mains power supply and remove the right panel and the control panel guard. To do this, remove the flat cables from the card and push in the microswitch before pushing up the panel. -

Page 153

11 — T ROUBLESHOOTING AUTOCLAVE DISMOUNTING THE MAIN CARD brief Maintenance tools required — Small Philips screwdriver — Medium Philips screwdriver — Plastic clamp — Cutting nippers Procedure — Disconnect the unit from the mains power supply and remove the right-hand panel. — Disconnect the mains power supply and remove all the flat cables and electrical connections. -

Page 154

11 — T ROUBLESHOOTING AUTOCLAVE CHECKING AND/OR REPLACING THE RES2 BAND HEATER brief Maintenance tools required — Permanent marker pen — Small Philips screwdriver — Medium Philips screwdriver — Plastic clamp — Tester — Adjustable wrench — Cutting nippers Procedure — Disconnect the unit from the mains power supply and remove the right, left and rear panels. -

Page 155

11 — T ROUBLESHOOTING AUTOCLAVE CHECKING AND/OR REPLACING THE WATER INJECTION PUMP brief Maintenance tools required — Medium Philips screwdriver — External power unit (200V) — Plastic and metal clamps Procedure — Disconnect the unit from the mains power supply and remove the rear panel. -

Page 156

11 — T ROUBLESHOOTING AUTOCLAVE CHECKING AND/OR REPLACING THE LEVEL SENSOR brief Maintenance tools required — Tester — Medium Philips screwdriver — Universal adjustable wrench — Plastic clamp Procedure — Disconnect the unit from the mains power supply and remove the right and rear panels. — Unscrew the 5 screws (1) and remove the cover. -

Page 157

11 — T ROUBLESHOOTING AUTOCLAVE CHECKING AND/OR REPLACING THE FAN brief Maintenance tools required — Medium Philips screwdriver — Plastic clamp Procedure — Disconnect the unit from the mains power supply and remove the right and rear panels. — Power the unit and makes sure the fan is truly blocked. Disconnect the power supply. -

Page 158

11 — T ROUBLESHOOTING AUTOCLAVE UPDATING THE E9 INSPECTION FIRMWARE brief Maintenance tools required — Medium Philips screwdriver Procedure — Disconnect the unit from the mains power supply and remove the right-hand panel. — Connect the PC to the serial socket inside the autoclave (1) with a 9-way serial cable — Run the “xc16xflash”… -

Page 159

11 — T ROUBLESHOOTING AUTOCLAVE REMOVING AND REPLACING THE SAFETY THERMOSTAT brief Maintenance tools required — Medium Philips screwdriver — Small Philips screwdriver — Standard pliers Procedure — Disconnect the unit from the mains power supply and remove the right and left panels. — Undo the projecting black cap (1), unscrew the two fixing screws (2);… -

Page 160

11 — T ROUBLESHOOTING AUTOCLAVE REPLACING THE SAFETY VALVE brief Maintenance tools required — Pliers for metal clamps — Open-ended wrench n° 20 — Adjustable wrench — Loctite thread sealant 542 (red) Procedure — Disconnect the unit from the mains power supply and remove the rear and left panels. -

Page 161

11 — T ROUBLESHOOTING AUTOCLAVE REPLACING THE INTEGRATED PRINTER brief Maintenance tools required — Socket wrench M3 — Medium Philips screwdriver — Small Philips wrench Procedure — Remove the right-hand panel by unscrewing the 3 Philips screws (1) and remove the flat cables (2 and 3) connecting the display to the power card and the micro-switch (6). -

Page 162: Required Maintenance Tools

11 — T ROUBLESHOOTING AUTOCLAVE 11.3 REQUIRED MAINTENANCE TOOLS The following pages show a list of all the tools required by maintenance men together with photos to make it easier to identify the tool or instrument. Only use good quality tools. Regularly check the tools for wear and replace worn or damaged ones.

-

Page 163

11 — T ROUBLESHOOTING AUTOCLAVE Fig. Description Figure Set of Philips screwdrivers Standard hammer Standard pliers Green Loctite Cutting nippers Pin punch D 5 BETA pliers for metal clamps Up to s/n EEG060999 EEH060999 E9 service manual GB r7… -

Page 164

11 — T ROUBLESHOOTING AUTOCLAVE Fig. Description Figure Multimeter T-wrench D 18 Cutter Red Loctite 542 Serial – USB adapter E9 service manual GB r7… -

Page 165: Demolition

If the unit is sold, hand over all the technical documentation to the new purchaser, inform him/her about any repair work carried out and how to use and service the machine. Also inform Euronda S.p.A. of the sale and provide it with data about the new purchaser.

-

Page 166: Appendix

Deionizer is a device that makes it possible to obtain water for feeding the tank of the unit by connecting directly to the main water supply system. The water thus obtained has characteristics that comply with the table shown in Appendix 8. The interface between the E9 INSPECTION autoclave and ®…

-

Page 167

The external printer is equipped with an 8-needle impact printing mechanism, of the rapid type, that uses plain paper. On the other hand, the printer that is integrated in the E9 INSPECTION uses thermal paper and, therefore, the data on the print reports is destined to fade gradually and to disappear over time. -

Page 168

EURONDA S.p.A. via dell’Artigianato, 7 — 36030 Montecchio Precalcino (VI) — ITALY Tel. +39 0445 329811 — Fax +39 0445 865246 — Internet: www.euronda.com — E-mail: info@euronda.com…

This manual is also suitable for:

E9 med

Паровой стерилизатор euronda e9 — устройство, спроектированное и созданное для стерилизации медицинских, стоматологических, ветеринарных и ортопедических инструментов, которые можно подвергать стерилизации паром при температуре от 121°C до 134°C.

Автоматический скоростной автоклав euronda e9 класса «B» с предвакуумом и вакуумной помпой.

- Тройная система защиты: автономный защитный клапан, защитный термостат, система электронного отключения при нештатной ситуации.

- Система электронной блокировки двери автоклава во время цикла стерилизации.

- Возможность подключения к системе канализации для обеспечения автоматического слива отработанной воды.

- Возможность подключения деионизатора воды Aquafilter, позволяющего производить автоматическое наполнение емкости чистой воды.

- Раздельные емкости чистой и отработанной воды.

- Предусмотрено подключение внешнего запоминающего устройства E-Memory.

- Встроенный сепаратор пара.

- Бактериологический фильтр.

Автоклав euronda e9 описание

Автоклав евронда е9 полностью автоматический паровой стерилизатор для стерилизации инструментов в упаковке и без упаковки.

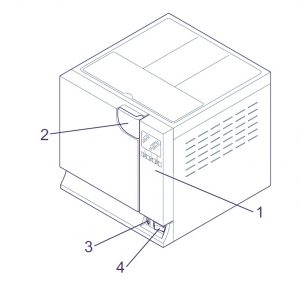

Передние элементы

1) Панель управления. Используется для установки, визуализации и управления всеми функциями устройства, а также для распечатки полезной информации оборудования.

2) Ручка для открытия двери. Внутри находится блок безопасности.

3) Порт для внешней памяти “E- Memory — System” или внешний принтер.

4) Кнопка включения-выключения ВКЛ.-ВЫКЛ. (ONOFF).

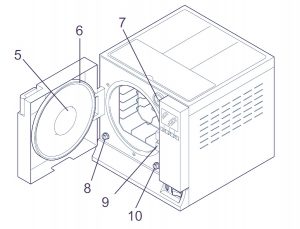

Устройства фронтальной части при открытой двери

5) Круглая дверь.

6) Прокладка.

7) Бактериологический фильтр.

9) Закрывающий механизм с электромагнитным стержнем и внутренним микровыключателем безопасности.

10) Патрубок для слива чистой воды.

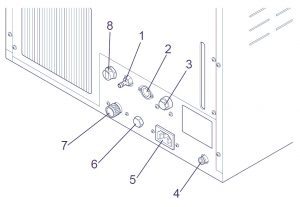

Устройства на задней панели

1) Выпускное отверстие при переполнении.

2) Электрический интерфейс деионизатора.

3) Предохранительный термостат (только для euronda e9 MED, начиная с № серии EGO090101 18 литров и EGP090081 24 литра).

4) Патрубок для слива воды дегазатора.

5) Розетка питания.

6) Гидравлическое соединение деионизатора.

7) Предохранительный клапан.

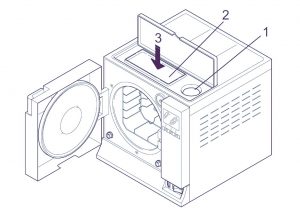

Верхние элементы

1) Клапан ручной заливки дистиллированной воды.

2) Отделение для хранения предметов.

3) Бак, расположенный внутри устройства, под отделением для хранения предметов.

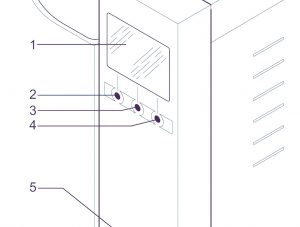

Описание панели управления евронда е9

1) Графический ЖК-дисплей (320×240 точек). Включает линейку управления, всегда находящуюся на экране, и напрямую связанную с тремя кнопками под линейкой.

2,3,4) Кнопки выбора и передвижения. Эти кнопки имеют не одну функцию, а зависят от линейки управления на экране (1).

5) Встроенный принтер.

Автоклав euronda e9 размеры и вес

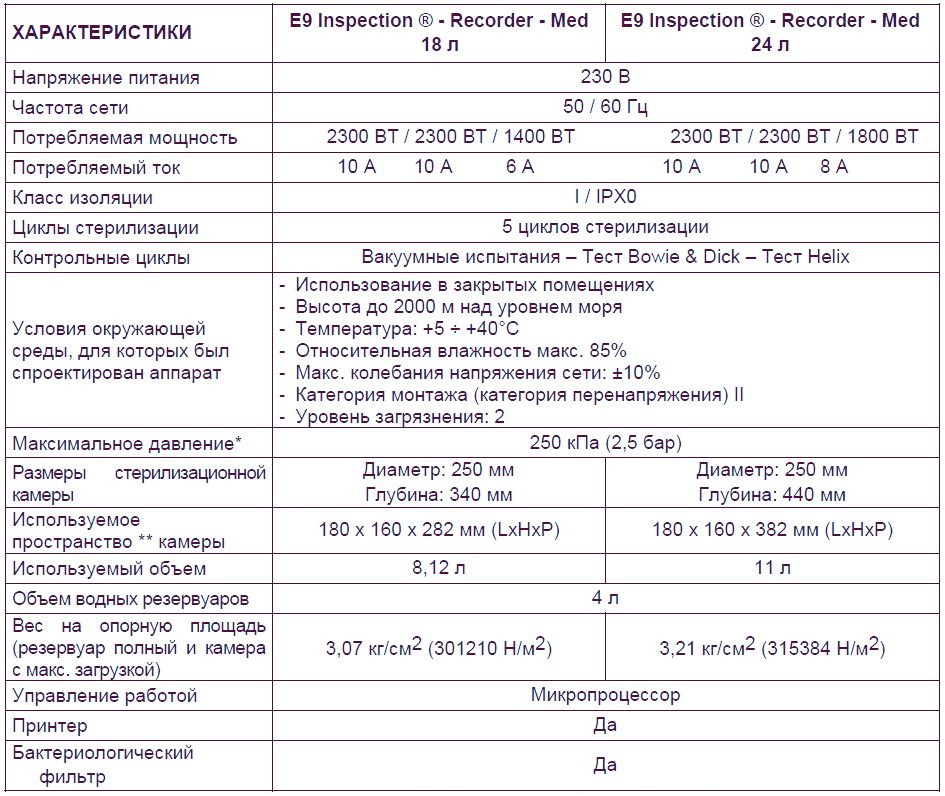

Автоклав euronda e9 технические характеристики

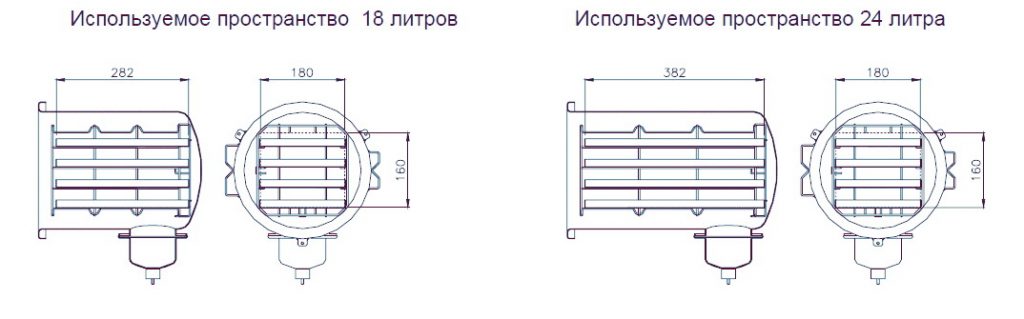

Euronda e9 размер камеры

Внутренний размер камеры стерилизации, доступный для стерилизации материалов.

Встроенный принтер euronda e9

Встроенный принтер для моделей euronda e9 inspection и euronda e9 med

Автоклавы euronda e9 med и euronda e9 inspection настроен таким образом, чтобы данные о продолжающемся процессе стерилизации всегда распечатывались вместе с типом выбранного цикла стерилизации, фазой цикла, значениями температуры и давления, временными интервалами и общей продолжительностью в минутах. После завершения каждого цикла, принтер также распечатывает итоговый отчет о результате цикла и общей продолжительности, независимо от того, удачно ли прошел цикл или нет, и независимо от того, был ли он прекращен оператором или был подан сигнал тревоги. Функция печати итогового отчета может быть отключена по желанию

- Принтер работает только при условии наличия в нем заправленной бумаги.

- Если не поместить рулон бумаги, принтер не работает.

- Зеленый светодиод POWER, имеющийся на принтере, всегда горит, когда принтер работает.

- Красный светодиод ERROR, имеющийся на принтере, горит, когда есть проблема, например, закончилась бумага, крышка закрыта неверно и т д.

- Кнопка FEED, имеющаяся на принтере, служит для протягивания бумаги.

- Нажать один раз на кнопку для продвижения вперед бумаги на одну строку.

- Можно держать кнопку нажатой для постоянного продвижения вперед бумаги.

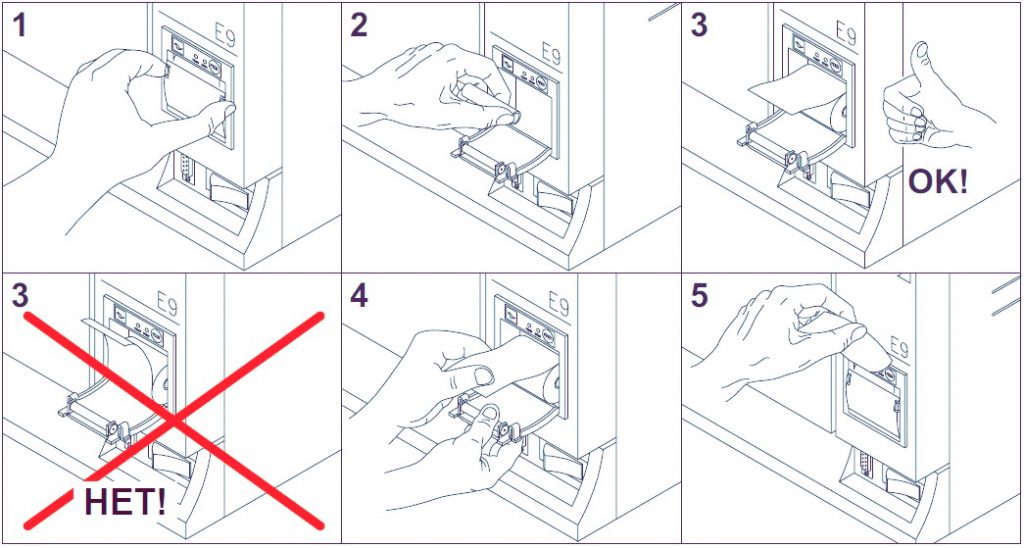

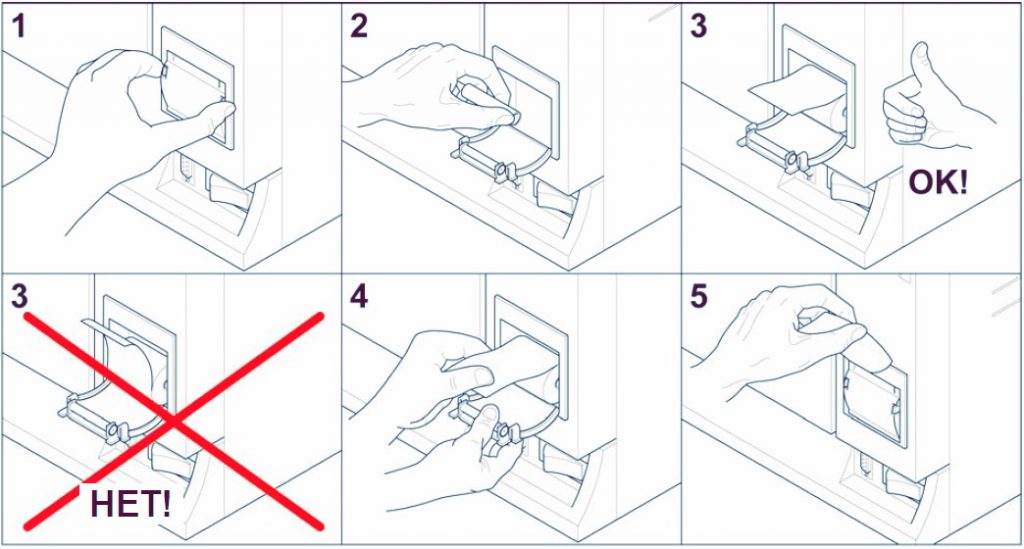

Для заправки нового рулона бумаги:

- Откройте крышку бумажного рулона, придерживая обе стороны пальцами и немного потянув ее на себя.

- Выньте использованный рулон.

- Вставьте новый рулон бумаги, как показано на рисунке; убедитесь, что бумага разматывается в нужном направлении.

- Вытяните наружу небольшой край бумаги и закройте крышку.

- Оторвите лишнюю бумагу.

Используйте рулоны с термобумагой со следующими характеристиками: ширина: 57 — 58 мм, макс. диаметр: 40 мм

Встроенный принтер для модели euronda e9 recorder

Автоклав euronda E9 recorder оборудован встроенным термическим принтером на передней панели и выдает наклейки для идентификации пакетов. Оборудование настроено таким образом, чтобы при положительном результате цикла, распечатывались данные о номере серии автоклава, номере цикла стерилизации, операторе, дате стерилизации и дате срока годности стерилизации (выбирается оператором). Количество этикеток выбирается оператором перед запуском цикла. Помимо количества этикеток, выбранного оператором, автоклав всегда выдает конечную обобщающую этикетку об изменении состояния.

Если цикл стерилизации прошел с отрицательным результатом, принтер выдает обобщающую этикетку о том, что изменение состояния не произошло. Принтер работает только при условии наличия в нем заправленной бумаги.

Для заправки нового рулона бумаги:

- Откройте крышку бумажного рулона, придерживая обе стороны пальцами и немного потянув ее на себя.

- Выньте использованный рулон.

- Вставьте новый рулон бумаги, так, чтобы боковые суппорты с держателем рулона принтера совпали с самой трубкой держателя рулона; убедитесь, что бумага разматывается в направлении сверху вниз, а не наоборот.

- Вытяните наружу небольшой край бумаги и закройте крышку.

- Оторвите лишнюю бумагу.

Автоклав euronda e9 техническое обслуживание

Как и вся медицинская техника, данный аппарат должен использоваться надлежащим образом, нуждается в регулярном ТО. Это обеспечит длительную эксплуатацию аппарата, безопасность и эффективность оборудования.

Чтобы предупредить возникновение потенциально опасных для оператора ситуаций, техническая служба должна осуществлять регулярное техническое обслуживание и проверки аппарата.

- Чтобы поддерживать оборудование в хорошем рабочем состоянии, периодически протирайте все наружные части мягкой влажной тканью, смоченной в нейтральном моющем средстве (не используйте коррозийные или абразивные средства).

- Не используйте обычные грубые ткани или металлические (или абразивные) щетки для очистки металлов.

- Перед началом каждого цикла, тщательно протирайте влажной тряпкой прокладки люка.

- Образование пятен белого цвета на дне камеры указывает на то, что используемая деминерализованная вода плохого качества.

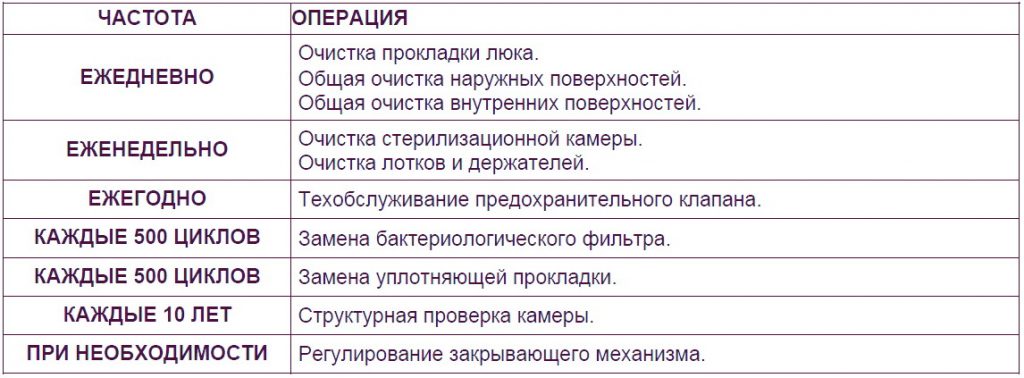

Периодичность технического обслуживания

Скачать инструкцию на автоклав euronda e9

Скачать инструкцию и другую документацию на автоклав euronda e9 можно здесь.

Руководство пользователя ( user manual ) на русском языке автоклав euronda e9 скачать.

Сервисная инструкция ( service manual ) на английском языке автоклав euronda e9 скачать.

Регистрационное удостоверение автоклав euronda e9 скачать.

Декларация о соответствии автоклав евронда е9 скачать.

Так же смотрите автоклав MELAG MELAtronic 23, 17, 15.

Если в процессе работы автоклава возникают ошибки, встроенная система блокирует часть функций, отключает режимы. В большинстве случаев при наличии ошибок нормального пользоваться стерилизатором невозможно. Более того — это может быть опасно не только для стерилизуемой загрузки, но и для оператора автоклава.

Ремонт и устранение ошибок автоклава — задача квалифицированного инженера, профильного сервисного центра. Для успешного восстановления функциональности и безопасности автоклава необходимо не только общее понимание принципов работы паровых стерилизаторов, но и знание особенностей конкретных моделей, типовых проблем и методов их решения.

Одна из наших специализаций — сложный ремонт стерилизационного оборудования.

Обращайтесь, мы оперативно решим все возможные проблемы с вашим оборудованием.

В данном материале собраны списки кодов ошибок различных автоклавов и описаны самые распространенные из них.

Важно. Если вы видите на экране (или в распечатке встроенного принтера автоклава) ошибку — сработала система защиты и самодиагностики стерилизатора.

Система контроля ошибок работы автоклава. Самодиагностика паровых стерилизаторов.

В современные автоклавы устанавливается огромное количество датчиков для всех систем: от закрытия и блокировки двери во время стерилизации до качества используемой воды, температуры и давления на различных этапах стерилизационного цикла в рабочей камере, парогенераторе и других частях автоклава.

Встроенный контроллер на основной плате управления постоянно мониторит все эти параметры, а также — динамику (скорость) их изменения. Например, если температура или давление в камере для основного цикла стерилизации поднимаются или сбрасываются очень медленно, автоклав не перейдет к следующему этапу.

Как отображаются ошибки на экране автоклава

Автоклав выдает ошибку? Как правило, даже самые дорогие и многофункциональные премиум-стерилизаторы оснащаются не очень большим дисплеем (а модели среднего и начального уровня могут иметь только цифровое табло), поэтому общепринятая практика — отображать на дисплее численно-буквенный код ошибки работы автоклава. Часто — с буквенным обозначением E, Err, ERROR, например E5, E7, Er02, Err5 и т.д.

Расшифровку возможных ошибок можно найти в сервисных инструкциях или на сайтах производителей стерилизаторов. В данном материале мы также приводим официальные расшифровки самых “популярных” ошибок автоклавов.

При этом важно понимать, что формулировка ошибки указывает инженеру только направление поиска неисправности (а в некоторых случаях истинная причина может скрываться в совершенно другом блоке, поэтому даже зная код ошибки и его точное значение, всегда необходимо проводить полную диагностику всего автоклава для выявления всех неисправностей.

Какие ошибки при работе автоклава появляются чаще всего

У каждого производителя и каждой модели автоклава есть своя специфика, но по статистике основные (распространенные) типы ошибок чаще всего следующие:

- Ошибка качества воды: используется некачественная, не дистиллированная вода, неисправен датчик воды или внутренние поверхности трактов, фильтры содержат инородные элементы, биоматериал.

- Ошибка блокировки двери автоклава: не закрыта дверь, не работает механизм электронной блокировки, не срабатывают концевые датчики и т.д.

- Ошибки температуры парогенератора и рабочей камеры автоклава: слишком высокая температура парогенератора, камеры, слишком быстро / медленно падает или поднимается температура. Причин этой группы ошибок может быть множество: от неисправностей самих датчиков но проблем с терморегуляторами и нагревательными элементами / ТЭНами.

- Утечка вакуума, давления: отдельный и очень распространенный вид ошибок. Чаще всего связан с проблемами герметичности двери, уплотнителем, работой компрессоров и т.д.

- Ошибки давления в рабочей камере автоклава: автоклав не держит давление, давление не поднимается, давление в камере сбрасывается слишком медленно и т.д.

- Ошибки рабочих режимов автоклава: например, температура и давление не соответствуют друг другу, отсутствует предварительное вакуумирование, предварительный нагрев

- Ошибки, прямо указывающие на неисправность автоклава: Например, сломан микровыключатель двери (концевой датчик), загрязнен фильтр и т.д.

Не важно, какую ошибку выдает автоклав, помните то, о чем мы писали выше: даже при явном указании на неисправность необходима полная проверка всего аппарата.

Коды ошибок популярных паровых стерилизаторов

Далее приводим таблицы — списки ошибок популярных автоклавов. Данная информация поможет сориентироваться в направлении поиска неисправностей, если вы видите одну из таких ошибок на дисплее своего автоклава — сообщите ее сервисному инженеру, это поможет в подготовке к ремонту / выезду.

Ошибки автоклавов Woson (Восон)

Очень часто к нам обращаются за помощью по ошибкам автоклавов Woson (например, TanzoC23). Ниже приводим список кодов ошибок на основе этой модели. Для многих автоклавов производителя описание схожее, но рекомендуем каждый раз сверяться с соответствующим руководством.

Вы также можете написать нам на Email, Whatsapp, позвонить по номерам в контактах.

|

E01 |

Медленный нагрев |

|

E02 |

Ошибка сброса давления |

|

E03 |

Открытая дверь |

|

E04 |

Низкое давление |

|

E05 |

Медленный спад давления |

|

E06 |

Медленное вакуумирование |

|

E07 |

Окружающее давление |

|

E08, E09 |

Микропереключатели передней и задней двери сломаны |

|

E10 |

Низкий предварительный нагрев |

|

E11 |

Высокая температура |

|

E12 |

Низкая температура |

|

E13 |

Ошибка автоматической подачи воды |

|

E17 |

Ошибка качества воды |

|

E23 |

Давление и температура не совпадают |

|

E24 |

Вока не стерильна |

|

E25 |

Ошибка воздушного фильтра |

|

E27 |

Серьезная утечка |

|

E31, E32, E33 E34 |

Ошибка термодатчиков 1 — 4 |

|

E51, E52, E53, E54 |

Датчик температуры высокий уровень выхода |

|

E71 |

Сенсор давления низкий уровень выхода |

|

E72 |

Сенсор давления высокий уровень выхода |

|

E14 |

Ошибка несоответствия внутренних сенсоров / Повреждение сигнала |

|

E99 |

Автоклав не набирает температуру в 134 градуса. / Экстренный выход (зависит от версии микропрограммы и других особенностей) |

Еще один вариант индикации ошибок автоклава Woson: с обозначениями Err / Er. Характерны для многих моделей.

|

Err7 |

Переработка по времени / Сверхурочная работа — одна из самых распространенных ошибок, возникающих при работе автоклавов Woson. Необходима последовательная проверка герметичности камеры, клапанов, всех датчиков, помп и компрессоров, полная диагностика автоклава. |

|

Err12 |

Ошибка вакуума (вакуумирования / вакуумной системы) |

|

Er98 |

Электропитание автоклава было отключено во время выполнения рабочего цикла. Необходимо проверить силовые и управляющие цепи, уточнить, не было ли внеплановых / веерных отключений, колебаний парамертов электросети. |

|

Er99 / Er00 |

Принудительный выход. Нормальный ход выполнения цикла был прерван оператором |

Ошибки автоклава Woson Tanzo-E

Альтернативный вариант таблицы с кодами ошибок автоклавов Woson Tanzo-E

|

Er01 |

Превышены допустимые температуры парогенератора |

|

Er02 |

Превышен температурный режим нагревательного кольца |

|

Er03 |

Температура рабочей камеры за пределами нормы |

|

Er04 |

Возникла ошибка в настройках параметров температуры и давления |

|

Er05 |

Ошибка сброса давления (повышенное) |

|

Er06 |

Ошибка двери рабочей камеры (открыта во время рабочего цикла) |

|

Er07 |

Аналогично параметру Err07. Переработка по времени |

|

Er08 |

Высокое давление |

|

Er09 |

Датчик температуры рабочей камеры фиксирует температуру за пределами нормы (низкая или высокая). Ошибка характерна для сисетм с двойными сенасорами. |

|

Er10 |

Температурный режим не соответстует давлению |

|

E12 |

Вакуумирование выполнено с ошибкой |

|

Er14 |

Показатели двойных сенсоров температуры находятся в слишком широком диапазоне (не соответствуют друг другу) |

Ошибки автоклава DGM

Ошибки автоклавов производства DGM рассматриваем на примере популярной модели DGM 130. Данный производитель обозначает сообщения о сбоях как Er

|

Er2 |

Давление пара в системе подачи низкое |

|

Er3 |

Высокая температура рабочей камеры |

|

Er4 |

Слишком высокое давление рабочей камеры |

|

Er5 |

Ошибка вакуумного насоса |

|

Er6 |

Контактор PP выключен, нет питания |

|

Er7 |

Ошибка температурного датчика в рабочей камере |

|

Er8 |

Ошибка датчика давления в рабочей камере |

|

Er9 |

Ошибка датчика давления в рубашке |

|

Er12 |

Нет пара на входе стерилизатора |

|

Er14 |

Ошибка температурного датчика в емкости PP |

|

Er15 |

Низкий уровень воды в емкости PP |

|

Er16 |

Ошибка защиты от пара |

|

Er31 — 38 |

Ошибки двери |

Дополнительно, на стерилизаторах со встроенным парогенератором возможны следующие сообщения:

|

Er21 |

Отсутствует вода для парогенератора |

|

E22 |

Ошибка насоса или датчика воды парогенератора |

|

E23 |

Ошибка времени прогрева |

|

Er24 |

Ошибка отключения нагревателей |

|

Er25 |

Ошибка термореле генератора |

Ошибки автоклавов MELAG (Мелаг)

Современные серии автоклавов Melag Euroklav, Vacuklav в зависимости от модели могут комплектоваться как простым двухстрочным дисплеем для отображения текста, так и полноценным цветным экраном с довольно хорошим разрешением.

Помимо непосредственно кодов ошибок на дисплее могут отображаться системные сообщения, рекомендации и предупреждения (то есть неисправность еще не зафиксирована, но продолжение работы невозможно до принятия соответствующих действий).

Предупреждения

|

Warning! Door open |

Неплотно закрыта дверца |

|

Warning! No water |

Уровень воды при внутренней подаче ниже минимальной отметки |

|

Warning! No feed water |

Вода не достигла датчика воды (при внешней подаче) |

|

Wastewater tank Full |

Заполнена камера отработанной воды |

|

Water quality Poor |

Низкое качество воды, но возможен ручной старт |

|

Water quality Bad |

Неприемлемое, опасное качество воды, старт невозможен |

|

Exchange Sterile filter |

Требуется замена фильтров (возможны и другие причины этого сообщения) |

|

Printer is not ready / Printer memory full |

нет связи с принтером / заполнена память встроенного принтера |

|

Please service |

Необходимо сервисное обслуживание |

Информация об ошибках автоклавов Melag

|

Malfunction 1: Vacuum system |

Ошибка скорости набора вакуума |

|

Malfunction 2: Steam generator |

Длительный нагрев, ошибка парогенератора |

|

Malfunction 4: Pressure release |

Давление долго не нормализуется |

|

Malfunction 8: Timebase |

Ошибка таймера, системный сбой |

|

Malfunction 9: Door open |

Открыта дверь |

|

Malfunction 10: Steamgen. Too hot |

Ошибка температуры или алгоритма работы парогенератора |

|

Malfunction 12 Door lock |

Проблемы с открытием дверцы |

|