- Manuals

- Brands

- Advanced Control Manuals

- DC Drives

- M420 Series

- Basic reference manual

-

Bookmarks

Quick Links

Summary of Contents for Advanced Control M420 Series

-

Page 2

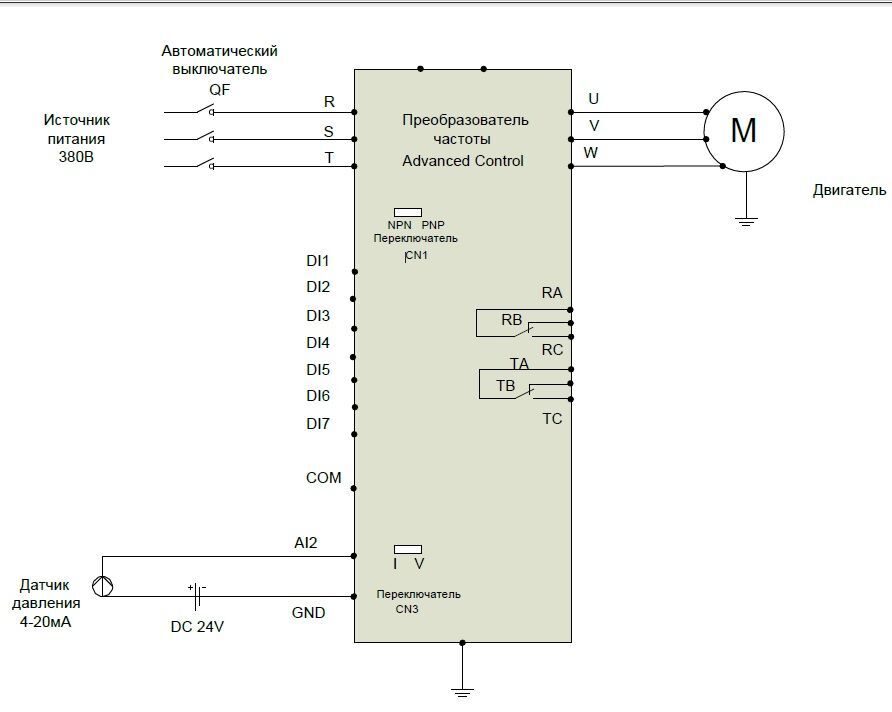

M420 General Flux Vector Control Inverter Basic Reference Guide 1. Typical wiring Braking resistor The three- phase 380V power input +24V 485+ Default Serial Multi function input terminal 1 485- communication port Default Multi function input terminal 2 Matching Analog output voltage or resistance Multi function input terminal 3 current through the CN2… -

Page 3

CN3 dial switch voltage or current for a given Relay output 2 Fig.2. Inverters of 22~75Kw Attention: This figure is just for M420 series of inverter (22~75KW brake unit is the selective part, plese declare it in order request if it’s needed.) -

Page 4

M420 General Flux Vector Control Inverter Basic Reference Guide Braking resistor DC reactor BR420 The three- phase 380V power input +24V 485+ Default Serial Multi function input terminal 1 485- communication port Default Multi function input terminal 2 Matching Analog output voltage or resistance Multi function input terminal 3 current through the CN2… -

Page 5

M420 General Flux Vector Control Inverter Basic Reference Guide 2. Main circuit terminals and wiring Main circuit terminals of single-phase Terminal Terminal Name Description Single-phase power supply input Connect to the single-phase 220 VAC L1、L2 terminals power supply Positive and negative terminals Common DC bus input point. -

Page 6

M420 General Flux Vector Control Inverter Basic Reference Guide The capacitor or surge absorber can’t be connected to the output side of the inverter, or it may damage the inverter. If the motor cable is too long, for the influence of the distribute capacitance, it’s easily to have electrical resonance, causing the damage of the insulation or large leakage current which make the inverter over-current protection. -

Page 7

M420 General Flux Vector Control Inverter Basic Reference Guide mode. DI4-COM Digital input 4 2) Impedance: 3.3 kΩ. 3) Input voltage range: 9 ~30V HDI5-COM Digital input 5 4) HDI5 can be used as high-speed input port. Voltage or current output is decided by dial AO1-GND Analog output 1 switches CN2 and CN7. -

Page 8

Trouble Shooting M420 General Flux Vector Control Inverter User Manual 3. Operation and Display 3.1. Operation and Display Interface Introduction We can change the function parameter, monitor the working status and control (start up/stop) the running inverter through the operation panel. The appearance and function are like below: Fig.4. -

Page 9

Trouble Shooting M420 General Flux Vector Control Inverter User Manual 3.1.1. Description of Function LED Indicator LED Symbol Unit Implication Color Freq. Unit LED on— current parameter is frequency Green value Current Unit LED on— current parameter is current value Green Voltage Unit LED on—… -

Page 10

The meaning of the function code group of M420 as follows: Function code Function Explanation group description Basic function Compatible with M420 series of function code F0~FF parameter group motor parameter motor parameter, acceleration and deceleration H0~H3 group time, control method, all can be set independently. -

Page 11

Trouble Shooting M420 General Flux Vector Control Inverter User Manual 3.3. Instruction of Function Code Viewing and Modification Methods Function code parameter of M420 inverter adopts three-level menu, it can view and monitor the parameter by operation panel. The three-level menu includes function parameter set (level 1 menu) →Function code (level 2 menu) →Function code setup value (level 3 menu). -

Page 12

M420 General Flux Vector Control Inverter User Manual Trouble Shooting 4. Trouble Shooting 4.1. Fault Warnings and Solutions If faults happened on the running process, the inverter will stop to output immediately to protect the motor, and the corresponding fault relay of the inverter has contact action at the same time so the panel will display the fault code. -

Page 13

Trouble Shooting M420 General Flux Vector Control Inverter User Manual Display Fault Name Possible Causes Solutions 1: Eliminate external faults. 1: The output circuit is grounded 2: Perform the motor auto- or short circuited. tuning. 2: Motor parameter is not right. 3: Increase the deceleration 3: The deceleration time is too short. -

Page 14

M420 General Flux Vector Control Inverter User Manual Trouble Shooting Display Fault Name Possible Causes Solutions or install a braking resistor. 1. Instantaneous power failure occurs. 2. The input voltage exceeds the 1. Reset the fault. allowed range. 2. Adjust the input voltage to Err12 Undervoltage 3. -

Page 15

Trouble Shooting M420 General Flux Vector Control Inverter User Manual Display Fault Name Possible Causes Solutions 1: The three-phase power input is abnormal. Power input 2: The drive board is faulty. 1: Eliminate external faults. Err23 3: The lightening board is faulty. 2: Seek for maintenance. -

Page 16

M420 General Flux Vector Control Inverter User Manual Trouble Shooting Display Fault Name Possible Causes Solutions 1: Reduce the load, or 1: The load is too heavy or the change the inverter with Fast current rotor is locked. Err33 larger power. limit fault 2: The acceleration time is 2: Increase the acceleration… -

Page 17

Trouble Shooting M420 General Flux Vector Control Inverter User Manual 4.2. Common Faults and Treating Methods The inverter will possibly be confront with below faults, please refer to the mentioned methods to have simple diagnosis and find the solutions. Tab.4. Common faults and treating methods serial Fault Name Possible Causes… -

Page 18

M420 General Flux Vector Control Inverter User Manual Trouble Shooting serial Fault Name Possible Causes Solutions number 1: The parameters are set 1:Check and reset the incorrectly. parameters in group F5. 2: The external signal is incorrect. 2: Re-connect the external The DI 3:Wrong location of the DI dial signal cables. -

Page 19

Function Code Table M420 General Flux Vector Control Inverter User Manual 5. Function code table The symbols in the function code table are described as follows: «☆»:The parameter can be modified when the AC drive is in either stop or running state. «★»:The parameter cannot be modified when the AC drive is in the running state. -

Page 20

M420 General Flux Vector Control Inverter User Manual Function code Table Function Parameter Name Setting Range Default Property Code Group F0: Standard Function Parameters Drive model: 5 digital display, ● F0-00 Drive model 53#.## 2 decimal point 0: for general purpose 0: for general purpose ●… -

Page 21

Function Code Table M420 General Flux Vector Control Inverter User Manual Function Parameter Name Setting Range Default Property Code (Retentive after stop). 2: AI1 3: AI2 4: Multi-reference. 5: Simple PLC. 6: PID 7: Communication setting. 8: Pulse setting. 0: Relative to maximum frequency. -

Page 22

M420 General Flux Vector Control Inverter User Manual Function code Table Function Parameter Name Setting Range Default Property Code 0: Same direction ☆ F0-13 Rotation direction 1: Reverse direction 2: Reverse forbidden 50.0Hz–1200.0 Hz(F0-20=1) Maximum output ★ F0-14 50.00Hz frequency 50.0Hz–600.00 Hz(F0-20=2) 0: Set by F0-16 1: AI1… -

Page 23

Function Code Table M420 General Flux Vector Control Inverter User Manual Function Parameter Name Setting Range Default Property Code Unit’s digit: Binding operation keypad command to frequency source. 0: No Binding 1:Digital setting 2: AI1 3: AI2 4: Multi-speed 5: Simple PLC ☆… -

Page 24

M420 General Flux Vector Control Inverter User Manual Function code Table Function Parameter Name Setting Range Default Property Code 0.00s~300.00s (F0-21 = 2) Over modulation voltage ★ F0-25 0% to 10% boost Model ☆ Carrier frequency 0.5kHz~16.0kHz F0-26 dependent Carrier frequency 0: No ☆… -

Page 25

Function Code Table M420 General Flux Vector Control Inverter User Manual Function Parameter Name Setting Range Default Property Code time Startup DC braking ★ F1-06 current/ Pre-excited 0%~100% current Startup DC braking time/ ★ F1-07 0.0s~100.0s 0.0s Pre-excited time 0: Linear Acceleration/Deceleration ★… -

Page 26

M420 General Flux Vector Control Inverter User Manual Function code Table Function Parameter Name Setting Range Default Property Code 2: Decelerate to stop. Deceleration time of ★ nonstop at instantaneous F1-24 0.0s to 100.0s 10.0s stop Effective voltage of ★ nonstop at instantaneous F1-25 60% to 85%… -

Page 27

Function Code Table M420 General Flux Vector Control Inverter User Manual Function Parameter Name Setting Range Default Property Code Multi-point V/F ★ F2-03 0.00Hz to F2-05 3.00Hz frequency 1 (F1) Multi-point V/F voltage 1 ★ F2-04 0.0% to 100.0% 8.0% (V1) Multi-point V/F ★… -

Page 28

M420 General Flux Vector Control Inverter User Manual Function code Table Function Parameter Name Setting Range Default Property Code V/F separation Frequency voltage declining independently. Stop mode selection upon ☆ F2-19 V/F separation 1: Frequency declining after voltage declines to 0. Group F3:Vector Control Parameters ☆… -

Page 29

Function Code Table M420 General Flux Vector Control Inverter User Manual Function Parameter Name Setting Range Default Property Code Speed loop feedback filter ☆ F3-18 0.000s to 1.000s 0.015s time Speed loop output filter ☆ 0.000s to 1.000s F3-19 0.000s time 0: F3-21 1: AI1… -

Page 30

M420 General Flux Vector Control Inverter User Manual Function code Table Function Parameter Name Setting Range Default Property Code 0.1A to 6000.0 A (motor rated power >30kW). ★ Rated motor frequency 0.01Hz to F0-14 F4-05 50.00Hz Rated motor 1 rotational F4-01 ★… -

Page 31

Function Code Table M420 General Flux Vector Control Inverter User Manual Function Parameter Name Setting Range Default Property Code 7:Speed Decrease 8:Coast to stop 9:Fault reset (RESET) 10:RUN pause ★ F5-05 DI6 function selection 11 : External fault normally open (NO) input. 12:Constant speed 1 13:Constant speed 2 14:Constant speed 3… -

Page 32

M420 General Flux Vector Control Inverter User Manual Function code Table Function Parameter Name Setting Range Default Property Code deceleration time selection 17:DI for acceleration/ deceleration time selection : Frequency source switchover 19 : MOTPOT setting clear (terminal, keypad) : Command source switchover terminal 1… -

Page 33

Function Code Table M420 General Flux Vector Control Inverter User Manual Function Parameter Name Setting Range Default Property Code frequency source X and preset frequency 40:Switchover between auxiliary frequency source Y and preset frequency 41:Switchover between motor 1 and motor 2 42:Reserved 43:PID parameter switchover 44 :… -

Page 34

M420 General Flux Vector Control Inverter User Manual Function code Table Function Parameter Name Setting Range Default Property Code Unit’s:DI1; Ten’s:DI2; Hundred’s:DI3; Kilobit:DI4; Myriabit:DI5 ☆ F5-15 AI1 minimum input 0.00V to 10.00V 0.00V Corresponding setting of ☆ F5-16 -100.0% to 100.00% 0.0% AI1 minimum input ☆… -

Page 35

Function Code Table M420 General Flux Vector Control Inverter User Manual Function Parameter Name Setting Range Default Property Code ☆ F5-37 0.0s DI2 On delay time 0.0s to 3600.0s ☆ F5-38 0.0s DI2 Off delay time 0.0s to 3600.0s ☆ F5-39 0.0s DI3 On delay time… -

Page 36

M420 General Flux Vector Control Inverter User Manual Function code Table Function Parameter Name Setting Range Default Property Code 0:Voltage style 1:Current style Group F6: Output Terminals ☆ 0:No output F6-00 Relay 1 function 1:AC drive running ☆ F6-01 Relay 2 function 2:Fault output 3:Frequency-level detection FDT1 reached… -

Page 37

Function Code Table M420 General Flux Vector Control Inverter User Manual Function Parameter Name Setting Range Default Property Code 23:Frequency 1 reached 24:Module temperature reached 25:Load lost 26:Accumulative power-on time reached 27:Clocking reached output 28:Current running time reached 29:Set count value reached 30:Designated count value reached 31: Motor 1 and motor 2… -

Page 38

M420 General Flux Vector Control Inverter User Manual Function code Table Function Parameter Name Setting Range Default Property Code ☆ Same as Y1 output selection F6-05 FMR output selection 0: Running frequency AO1 output function ☆ F6-09 1: Set frequency selection 2: Output current 3: Output power… -

Page 39

Function Code Table M420 General Flux Vector Control Inverter User Manual Function Parameter Name Setting Range Default Property Code Minimum corresponds to ☆ 0.00V to 10.00V 0.00v F6-18 AO2 output ☆ F6-19 AO2 maximum output F6-17 to 100.0% 100.0% Maximum corresponds to ☆… -

Page 40

M420 General Flux Vector Control Inverter User Manual Function code Table Function Parameter Name Setting Range Default Property Code 0: Default mode 1: 0.1Hz 2: 0.5Hz ☆ F7-16 Keypad knob accuracy 3: 1Hz 4: 2Hz 5: 4Hz 6: 5Hz 7: 8Hz 8: 10Hz 0: Run at frequency lower limit Running mode when set… -

Page 41

Function Code Table M420 General Flux Vector Control Inverter User Manual Function Parameter Name Setting Range Default Property Code 1: STOP/RESET key enabled in any operation mode. 0: Forward JOG. 1: Switchover between forward rotation and reverse rotation. Quick/JOG function ★… -

Page 42

M420 General Flux Vector Control Inverter User Manual Function code Table Function Parameter Name Setting Range Default Property Code 1 to 0xffff Bit00: Set frequency 0001 Bit01: Bus voltage (V) 0002 Bit02: DI input status 0004 Bit03: DO output status 0008 Bit04: AI1 voltage (V) 0010 Bit05: AI2 voltage (V) -

Page 43

Function Code Table M420 General Flux Vector Control Inverter User Manual Function Parameter Name Setting Range Default Property Code Setting of current running ☆ F7-38 0.0min to 6500.0min 0.0min time ☆ F7-39 High level timing 0.0s to 6000.0s 2.0s ☆ F7-40 Low level timing 0.0s to 6000.0s… -

Page 44

M420 General Flux Vector Control Inverter User Manual Function code Table Function Parameter Name Setting Range Default Property Code Frequency reached ☆ F7-57 0.00Hz to F0-14 50.00Hz detection value 2 Frequency reached ☆ F7-58 0% to 100% detection duration 2 Zero current detection ☆… -

Page 45

Function Code Table M420 General Flux Vector Control Inverter User Manual Function Parameter Name Setting Range Default Property Code Module temperature ☆ F7-69 0℃ to 90℃ 70℃ threshold Output power correction ☆ F7-70 0.001 to 3.000 1.000 coefficient Linear speed display Linear speed = F-71 * HDI1 ☆… -

Page 46

M420 General Flux Vector Control Inverter User Manual Function code Table Function Parameter Name Setting Range Default Property Code 0 to 247 ☆ F8-02 Local address (0 is Broadcast address) ☆ 0ms to 30ms F8-03 Response delay ☆ 0.0s to 30.0s F8-04 Communication timeout 0.0s… -

Page 47

Function Code Table M420 General Flux Vector Control Inverter User Manual Function Parameter Name Setting Range Default Property Code 0: Disable Input phase loss protection ☆ F9-14 selection 1: Enable 0: Disable Output phase loss ☆ F9-15 protection selection 1: Enable 0: Disable Short-circuit to ground ☆… -

Page 48

M420 General Flux Vector Control Inverter User Manual Function code Table Function Parameter Name Setting Range Default Property Code 0 to 22222 Unit’s digit: Communication fault – Err27 0: Coast to stop 1: Stop according to stop mode 2:Continue to run Fault protection action Ten’s digit: External equipment ☆… -

Page 49

Function Code Table M420 General Flux Vector Control Inverter User Manual Function Parameter Name Setting Range Default Property Code 0: Current running frequency 1: Set frequency Frequency selection for ☆ F9-26 continuing to run upon 2: Frequency upper limit fault 3: Frequency lower limit 4: Backup frequency(F9-27) Backup frequency upon… -

Page 50

M420 General Flux Vector Control Inverter User Manual Function code Table Function Parameter Name Setting Range Default Property Code ☆ FA-02 PID setting change time Response time:0.00s to 650.00s 0.00s 0: AI1 1: AI2 2: AI1 — AI2 3: Communication setting ☆… -

Page 51

Function Code Table M420 General Flux Vector Control Inverter User Manual Function Parameter Name Setting Range Default Property Code 0: No switchover PID parameter switchover 1: Switchover via DI ☆ FA-21 condition 2: Automatic switchover based on deviation PID parameter switchover 0.0% to FA-23 ☆… -

Page 52

M420 General Flux Vector Control Inverter User Manual Function code Table Function Parameter Name Setting Range Default Property Code amplitude Jump frequency ☆ Fb-02 0.0% to 50.0% 0.0% amplitude ☆ Fb-03 Swing frequency cycle 0.1s to 3000.0s 10.0s Triangular wave rising ☆… -

Page 53

Function Code Table M420 General Flux Vector Control Inverter User Manual Function Parameter Name Setting Range Default Property Code ☆ FC-12 Reference 12 -100.0% to 100.0% 0.0% ☆ FC-13 Reference 13 -100.0% to 100.0% 0.0% ☆ FC-14 Reference 14 -100.0% to 100.0% 0.0% ☆… -

Page 54

M420 General Flux Vector Control Inverter User Manual Function code Table Function Parameter Name Setting Range Default Property Code 0 to 3 Acceleration/deceleration ☆ FC-23 time of simple PLC (Means acceleration/deceleration reference 2 time 1 to 4 respectively ) Running time of simple ☆… -

Page 55

Function Code Table M420 General Flux Vector Control Inverter User Manual Function Parameter Name Setting Range Default Property Code reference 8 (Means acceleration/deceleration time 1 to 4 respectively ) Running time of simple ☆ FC-36 0.0~6500.0 PLC reference 9 0 to 3 Acceleration/deceleration ☆… -

Page 56

M420 General Flux Vector Control Inverter User Manual Function code Table Function Parameter Name Setting Range Default Property Code Running time of simple ☆ FC-48 0.0~6500.0 PLC reference 15 0 to 3 Acceleration/deceleration ☆ FC-49 time of simple PLC (Means acceleration/deceleration reference 15 time 1 to 4 respectively )… -

Page 57

Function Code Table M420 General Flux Vector Control Inverter User Manual Function Parameter Name Setting Range Default Property Code ☆ -200.0% to 200.0% Fd-01 Torque digital setting 150.0% Forward maximum 0.00Hz to maximum ☆ Fd-03 50.00Hz frequency(F0-14) frequency in torque Reverse maximum 0.00Hz to maximum ☆… -

Page 58

M420 General Flux Vector Control Inverter User Manual Function code Table Function Parameter Name Setting Range Default Property Code ☆ FE-10 AI curve 2 inflexion 1 input FE-00 to FE-04 3.00 Corresponding setting of ☆ FE-11 -100.0% to 100.0% 30.0% AI curve 2 inflexion 1 input ☆… -

Page 59

Function Code Table M420 General Flux Vector Control Inverter User Manual Function Parameter Name Setting Range Default Property Code 3: Acceleration/deceleration time 3 4: Acceleration/deceleration time 4 Group H1: Motor 2 Parameters 0: No auto-tuning ★ Auto-tuning selection 1: Static auto-tuning H1-00 2: Complete auto-tuning Model… -

Page 60

M420 General Flux Vector Control Inverter User Manual Function code Table Function Parameter Name Setting Range Default Property Code Acceleration time of ☆ 1.0s to 600.0s H1-12 10.0s complete auto-tuning Deceleration time of ☆ 1.0s to 600.0s H1-13 10.0s complete auto-tuning Group H2: Motor 2 V/F Control Parameters ☆… -

Page 61

Function Code Table M420 General Flux Vector Control Inverter User Manual Function Parameter Name Setting Range Default Property Code 0 to 30000 Excitation adjustment ☆ H3-14 1300 integral gain Ki 100 to 200 ☆ Flux braking gain H3-15 50% to 200% Field weakening torque ☆… -

Page 62

M420 General Flux Vector Control Inverter User Manual Function code Table Function Parameter Name Setting Range Default Property Code Group L0: System Parameters 0: Disable Parameters only for ☆ L0-00 reading 1: Enable Group L1: User — defined Parameters 0: Disable Clear user-defined ☆… -

Page 63

Function Code Table M420 General Flux Vector Control Inverter User Manual Function Parameter Name Setting Range Default Property Code ☆ L1-19 User-defined parameters 19 uF0-00 uF0-00 to uU1-xx ☆ L1-20 User-defined parameters 20 uF0-00 to uU1-xx uF0-00 ☆ L1-21 User-defined parameters 21 uF0-00 uF0-00 to uU1-xx ☆… -

Page 64

M420 General Flux Vector Control Inverter User Manual Function code Table Function Parameter Name Setting Range Default Property Code 350.0V ☆ L2-06 Random PWM depth 0 to 6 0: No current output 1: Normal operation ☆ L2-07 0Hz running way 2: Output with DC braking current F1-16 0: Limitation mode 0… -

Page 65

Function Code Table M420 General Flux Vector Control Inverter User Manual Function Parameter Name Setting Range Default Property Code ☆ L3-18 AO2 measured voltage 2 -9.999V to 10.000V 8.000V ☆ L3-19 AO2 target voltage 2 -9.999V to 10.000V 8.000V Group L4: Master-slave Control Parameters 0: Disable Master-slave control ★… -

Page 66

M420 General Flux Vector Control Inverter User Manual Function code Table Function Parameter Name Setting Range Default Property Code holding time Braking period current ★ L5-03 50.0% to 200.0% 120.0% threshold Braking actuation ★ L5-04 0.00Hz to 20.00Hz 1.50Hz frequency Braking actuation delay 0.0s to 20.0s ★… -

Page 67

Function Code Table M420 General Flux Vector Control Inverter User Manual Function Parameter Name Min. Unit Property Code Err04: Overcurrent during acceleration Err05: Overcurrent during deceleration Err06: Over current at constant speed Err08: Overvoltage during acceleration Err09: Overvoltage during deceleration Err10: Overvoltage at constant speed Err12: Under voltage… -

Page 68

M420 General Flux Vector Control Inverter User Manual Function code Table Function Parameter Name Min. Unit Property Code Err34: Load becoming 0 Err35: Control power supply fault Err37: Control power supply fault Err39: Current running time reached Err40: Accumulative running time reached Err42: Motor switchover fault during running… -

Page 69

Function Code Table M420 General Flux Vector Control Inverter User Manual Function Parameter Name Min. Unit Property Code ● U0-19 Power-on time upon the 2 fault 1min ● U0-20 Running time upon the 2 fault 1min ● U0-21 Reserved ● U0-22 Reserved ●… -

Page 70

M420 General Flux Vector Control Inverter User Manual Function code Table Function Parameter Name Min. Unit Property Code ● U1-10 PID setting, PID setting ( percentage)×FA-05 ● U1-11 PID feedback, PID feedback ( percentage)×FA-05 ● U1-12 Count value ● U1-13 Length value ●… -

Page 71

Function Code Table M420 General Flux Vector Control Inverter User Manual Function Parameter Name Min. Unit Property Code ● U1-33 Target voltage upon V/F separation ● Output voltage upon V/F separation U1-34 ● Reserved U1-35 ● U1-36 Current motor number ●…

- Manuals

- Brands

- Advanced Control Manuals

- DC Drives

- M420 Series

- Basic reference manual

-

Bookmarks

Quick Links

Summary of Contents for Advanced Control M420 Series

-

Page 2

M420 General Flux Vector Control Inverter Basic Reference Guide 1. Typical wiring Braking resistor The three- phase 380V power input +24V 485+ Default Serial Multi function input terminal 1 485- communication port Default Multi function input terminal 2 Matching Analog output voltage or resistance Multi function input terminal 3 current through the CN2… -

Page 3

CN3 dial switch voltage or current for a given Relay output 2 Fig.2. Inverters of 22~75Kw Attention: This figure is just for M420 series of inverter (22~75KW brake unit is the selective part, plese declare it in order request if it’s needed.) -

Page 4

M420 General Flux Vector Control Inverter Basic Reference Guide Braking resistor DC reactor BR420 The three- phase 380V power input +24V 485+ Default Serial Multi function input terminal 1 485- communication port Default Multi function input terminal 2 Matching Analog output voltage or resistance Multi function input terminal 3 current through the CN2… -

Page 5

M420 General Flux Vector Control Inverter Basic Reference Guide 2. Main circuit terminals and wiring Main circuit terminals of single-phase Terminal Terminal Name Description Single-phase power supply input Connect to the single-phase 220 VAC L1、L2 terminals power supply Positive and negative terminals Common DC bus input point. -

Page 6

M420 General Flux Vector Control Inverter Basic Reference Guide The capacitor or surge absorber can’t be connected to the output side of the inverter, or it may damage the inverter. If the motor cable is too long, for the influence of the distribute capacitance, it’s easily to have electrical resonance, causing the damage of the insulation or large leakage current which make the inverter over-current protection. -

Page 7

M420 General Flux Vector Control Inverter Basic Reference Guide mode. DI4-COM Digital input 4 2) Impedance: 3.3 kΩ. 3) Input voltage range: 9 ~30V HDI5-COM Digital input 5 4) HDI5 can be used as high-speed input port. Voltage or current output is decided by dial AO1-GND Analog output 1 switches CN2 and CN7. -

Page 8

Trouble Shooting M420 General Flux Vector Control Inverter User Manual 3. Operation and Display 3.1. Operation and Display Interface Introduction We can change the function parameter, monitor the working status and control (start up/stop) the running inverter through the operation panel. The appearance and function are like below: Fig.4. -

Page 9

Trouble Shooting M420 General Flux Vector Control Inverter User Manual 3.1.1. Description of Function LED Indicator LED Symbol Unit Implication Color Freq. Unit LED on— current parameter is frequency Green value Current Unit LED on— current parameter is current value Green Voltage Unit LED on—… -

Page 10

The meaning of the function code group of M420 as follows: Function code Function Explanation group description Basic function Compatible with M420 series of function code F0~FF parameter group motor parameter motor parameter, acceleration and deceleration H0~H3 group time, control method, all can be set independently. -

Page 11

Trouble Shooting M420 General Flux Vector Control Inverter User Manual 3.3. Instruction of Function Code Viewing and Modification Methods Function code parameter of M420 inverter adopts three-level menu, it can view and monitor the parameter by operation panel. The three-level menu includes function parameter set (level 1 menu) →Function code (level 2 menu) →Function code setup value (level 3 menu). -

Page 12

M420 General Flux Vector Control Inverter User Manual Trouble Shooting 4. Trouble Shooting 4.1. Fault Warnings and Solutions If faults happened on the running process, the inverter will stop to output immediately to protect the motor, and the corresponding fault relay of the inverter has contact action at the same time so the panel will display the fault code. -

Page 13

Trouble Shooting M420 General Flux Vector Control Inverter User Manual Display Fault Name Possible Causes Solutions 1: Eliminate external faults. 1: The output circuit is grounded 2: Perform the motor auto- or short circuited. tuning. 2: Motor parameter is not right. 3: Increase the deceleration 3: The deceleration time is too short. -

Page 14

M420 General Flux Vector Control Inverter User Manual Trouble Shooting Display Fault Name Possible Causes Solutions or install a braking resistor. 1. Instantaneous power failure occurs. 2. The input voltage exceeds the 1. Reset the fault. allowed range. 2. Adjust the input voltage to Err12 Undervoltage 3. -

Page 15

Trouble Shooting M420 General Flux Vector Control Inverter User Manual Display Fault Name Possible Causes Solutions 1: The three-phase power input is abnormal. Power input 2: The drive board is faulty. 1: Eliminate external faults. Err23 3: The lightening board is faulty. 2: Seek for maintenance. -

Page 16

M420 General Flux Vector Control Inverter User Manual Trouble Shooting Display Fault Name Possible Causes Solutions 1: Reduce the load, or 1: The load is too heavy or the change the inverter with Fast current rotor is locked. Err33 larger power. limit fault 2: The acceleration time is 2: Increase the acceleration… -

Page 17

Trouble Shooting M420 General Flux Vector Control Inverter User Manual 4.2. Common Faults and Treating Methods The inverter will possibly be confront with below faults, please refer to the mentioned methods to have simple diagnosis and find the solutions. Tab.4. Common faults and treating methods serial Fault Name Possible Causes… -

Page 18

M420 General Flux Vector Control Inverter User Manual Trouble Shooting serial Fault Name Possible Causes Solutions number 1: The parameters are set 1:Check and reset the incorrectly. parameters in group F5. 2: The external signal is incorrect. 2: Re-connect the external The DI 3:Wrong location of the DI dial signal cables. -

Page 19

Function Code Table M420 General Flux Vector Control Inverter User Manual 5. Function code table The symbols in the function code table are described as follows: «☆»:The parameter can be modified when the AC drive is in either stop or running state. «★»:The parameter cannot be modified when the AC drive is in the running state. -

Page 20

M420 General Flux Vector Control Inverter User Manual Function code Table Function Parameter Name Setting Range Default Property Code Group F0: Standard Function Parameters Drive model: 5 digital display, ● F0-00 Drive model 53#.## 2 decimal point 0: for general purpose 0: for general purpose ●… -

Page 21

Function Code Table M420 General Flux Vector Control Inverter User Manual Function Parameter Name Setting Range Default Property Code (Retentive after stop). 2: AI1 3: AI2 4: Multi-reference. 5: Simple PLC. 6: PID 7: Communication setting. 8: Pulse setting. 0: Relative to maximum frequency. -

Page 22

M420 General Flux Vector Control Inverter User Manual Function code Table Function Parameter Name Setting Range Default Property Code 0: Same direction ☆ F0-13 Rotation direction 1: Reverse direction 2: Reverse forbidden 50.0Hz–1200.0 Hz(F0-20=1) Maximum output ★ F0-14 50.00Hz frequency 50.0Hz–600.00 Hz(F0-20=2) 0: Set by F0-16 1: AI1… -

Page 23

Function Code Table M420 General Flux Vector Control Inverter User Manual Function Parameter Name Setting Range Default Property Code Unit’s digit: Binding operation keypad command to frequency source. 0: No Binding 1:Digital setting 2: AI1 3: AI2 4: Multi-speed 5: Simple PLC ☆… -

Page 24

M420 General Flux Vector Control Inverter User Manual Function code Table Function Parameter Name Setting Range Default Property Code 0.00s~300.00s (F0-21 = 2) Over modulation voltage ★ F0-25 0% to 10% boost Model ☆ Carrier frequency 0.5kHz~16.0kHz F0-26 dependent Carrier frequency 0: No ☆… -

Page 25

Function Code Table M420 General Flux Vector Control Inverter User Manual Function Parameter Name Setting Range Default Property Code time Startup DC braking ★ F1-06 current/ Pre-excited 0%~100% current Startup DC braking time/ ★ F1-07 0.0s~100.0s 0.0s Pre-excited time 0: Linear Acceleration/Deceleration ★… -

Page 26

M420 General Flux Vector Control Inverter User Manual Function code Table Function Parameter Name Setting Range Default Property Code 2: Decelerate to stop. Deceleration time of ★ nonstop at instantaneous F1-24 0.0s to 100.0s 10.0s stop Effective voltage of ★ nonstop at instantaneous F1-25 60% to 85%… -

Page 27

Function Code Table M420 General Flux Vector Control Inverter User Manual Function Parameter Name Setting Range Default Property Code Multi-point V/F ★ F2-03 0.00Hz to F2-05 3.00Hz frequency 1 (F1) Multi-point V/F voltage 1 ★ F2-04 0.0% to 100.0% 8.0% (V1) Multi-point V/F ★… -

Page 28

M420 General Flux Vector Control Inverter User Manual Function code Table Function Parameter Name Setting Range Default Property Code V/F separation Frequency voltage declining independently. Stop mode selection upon ☆ F2-19 V/F separation 1: Frequency declining after voltage declines to 0. Group F3:Vector Control Parameters ☆… -

Page 29

Function Code Table M420 General Flux Vector Control Inverter User Manual Function Parameter Name Setting Range Default Property Code Speed loop feedback filter ☆ F3-18 0.000s to 1.000s 0.015s time Speed loop output filter ☆ 0.000s to 1.000s F3-19 0.000s time 0: F3-21 1: AI1… -

Page 30

M420 General Flux Vector Control Inverter User Manual Function code Table Function Parameter Name Setting Range Default Property Code 0.1A to 6000.0 A (motor rated power >30kW). ★ Rated motor frequency 0.01Hz to F0-14 F4-05 50.00Hz Rated motor 1 rotational F4-01 ★… -

Page 31

Function Code Table M420 General Flux Vector Control Inverter User Manual Function Parameter Name Setting Range Default Property Code 7:Speed Decrease 8:Coast to stop 9:Fault reset (RESET) 10:RUN pause ★ F5-05 DI6 function selection 11 : External fault normally open (NO) input. 12:Constant speed 1 13:Constant speed 2 14:Constant speed 3… -

Page 32

M420 General Flux Vector Control Inverter User Manual Function code Table Function Parameter Name Setting Range Default Property Code deceleration time selection 17:DI for acceleration/ deceleration time selection : Frequency source switchover 19 : MOTPOT setting clear (terminal, keypad) : Command source switchover terminal 1… -

Page 33

Function Code Table M420 General Flux Vector Control Inverter User Manual Function Parameter Name Setting Range Default Property Code frequency source X and preset frequency 40:Switchover between auxiliary frequency source Y and preset frequency 41:Switchover between motor 1 and motor 2 42:Reserved 43:PID parameter switchover 44 :… -

Page 34

M420 General Flux Vector Control Inverter User Manual Function code Table Function Parameter Name Setting Range Default Property Code Unit’s:DI1; Ten’s:DI2; Hundred’s:DI3; Kilobit:DI4; Myriabit:DI5 ☆ F5-15 AI1 minimum input 0.00V to 10.00V 0.00V Corresponding setting of ☆ F5-16 -100.0% to 100.00% 0.0% AI1 minimum input ☆… -

Page 35

Function Code Table M420 General Flux Vector Control Inverter User Manual Function Parameter Name Setting Range Default Property Code ☆ F5-37 0.0s DI2 On delay time 0.0s to 3600.0s ☆ F5-38 0.0s DI2 Off delay time 0.0s to 3600.0s ☆ F5-39 0.0s DI3 On delay time… -

Page 36

M420 General Flux Vector Control Inverter User Manual Function code Table Function Parameter Name Setting Range Default Property Code 0:Voltage style 1:Current style Group F6: Output Terminals ☆ 0:No output F6-00 Relay 1 function 1:AC drive running ☆ F6-01 Relay 2 function 2:Fault output 3:Frequency-level detection FDT1 reached… -

Page 37

Function Code Table M420 General Flux Vector Control Inverter User Manual Function Parameter Name Setting Range Default Property Code 23:Frequency 1 reached 24:Module temperature reached 25:Load lost 26:Accumulative power-on time reached 27:Clocking reached output 28:Current running time reached 29:Set count value reached 30:Designated count value reached 31: Motor 1 and motor 2… -

Page 38

M420 General Flux Vector Control Inverter User Manual Function code Table Function Parameter Name Setting Range Default Property Code ☆ Same as Y1 output selection F6-05 FMR output selection 0: Running frequency AO1 output function ☆ F6-09 1: Set frequency selection 2: Output current 3: Output power… -

Page 39

Function Code Table M420 General Flux Vector Control Inverter User Manual Function Parameter Name Setting Range Default Property Code Minimum corresponds to ☆ 0.00V to 10.00V 0.00v F6-18 AO2 output ☆ F6-19 AO2 maximum output F6-17 to 100.0% 100.0% Maximum corresponds to ☆… -

Page 40

M420 General Flux Vector Control Inverter User Manual Function code Table Function Parameter Name Setting Range Default Property Code 0: Default mode 1: 0.1Hz 2: 0.5Hz ☆ F7-16 Keypad knob accuracy 3: 1Hz 4: 2Hz 5: 4Hz 6: 5Hz 7: 8Hz 8: 10Hz 0: Run at frequency lower limit Running mode when set… -

Page 41

Function Code Table M420 General Flux Vector Control Inverter User Manual Function Parameter Name Setting Range Default Property Code 1: STOP/RESET key enabled in any operation mode. 0: Forward JOG. 1: Switchover between forward rotation and reverse rotation. Quick/JOG function ★… -

Page 42

M420 General Flux Vector Control Inverter User Manual Function code Table Function Parameter Name Setting Range Default Property Code 1 to 0xffff Bit00: Set frequency 0001 Bit01: Bus voltage (V) 0002 Bit02: DI input status 0004 Bit03: DO output status 0008 Bit04: AI1 voltage (V) 0010 Bit05: AI2 voltage (V) -

Page 43

Function Code Table M420 General Flux Vector Control Inverter User Manual Function Parameter Name Setting Range Default Property Code Setting of current running ☆ F7-38 0.0min to 6500.0min 0.0min time ☆ F7-39 High level timing 0.0s to 6000.0s 2.0s ☆ F7-40 Low level timing 0.0s to 6000.0s… -

Page 44

M420 General Flux Vector Control Inverter User Manual Function code Table Function Parameter Name Setting Range Default Property Code Frequency reached ☆ F7-57 0.00Hz to F0-14 50.00Hz detection value 2 Frequency reached ☆ F7-58 0% to 100% detection duration 2 Zero current detection ☆… -

Page 45

Function Code Table M420 General Flux Vector Control Inverter User Manual Function Parameter Name Setting Range Default Property Code Module temperature ☆ F7-69 0℃ to 90℃ 70℃ threshold Output power correction ☆ F7-70 0.001 to 3.000 1.000 coefficient Linear speed display Linear speed = F-71 * HDI1 ☆… -

Page 46

M420 General Flux Vector Control Inverter User Manual Function code Table Function Parameter Name Setting Range Default Property Code 0 to 247 ☆ F8-02 Local address (0 is Broadcast address) ☆ 0ms to 30ms F8-03 Response delay ☆ 0.0s to 30.0s F8-04 Communication timeout 0.0s… -

Page 47

Function Code Table M420 General Flux Vector Control Inverter User Manual Function Parameter Name Setting Range Default Property Code 0: Disable Input phase loss protection ☆ F9-14 selection 1: Enable 0: Disable Output phase loss ☆ F9-15 protection selection 1: Enable 0: Disable Short-circuit to ground ☆… -

Page 48

M420 General Flux Vector Control Inverter User Manual Function code Table Function Parameter Name Setting Range Default Property Code 0 to 22222 Unit’s digit: Communication fault – Err27 0: Coast to stop 1: Stop according to stop mode 2:Continue to run Fault protection action Ten’s digit: External equipment ☆… -

Page 49

Function Code Table M420 General Flux Vector Control Inverter User Manual Function Parameter Name Setting Range Default Property Code 0: Current running frequency 1: Set frequency Frequency selection for ☆ F9-26 continuing to run upon 2: Frequency upper limit fault 3: Frequency lower limit 4: Backup frequency(F9-27) Backup frequency upon… -

Page 50

M420 General Flux Vector Control Inverter User Manual Function code Table Function Parameter Name Setting Range Default Property Code ☆ FA-02 PID setting change time Response time:0.00s to 650.00s 0.00s 0: AI1 1: AI2 2: AI1 — AI2 3: Communication setting ☆… -

Page 51

Function Code Table M420 General Flux Vector Control Inverter User Manual Function Parameter Name Setting Range Default Property Code 0: No switchover PID parameter switchover 1: Switchover via DI ☆ FA-21 condition 2: Automatic switchover based on deviation PID parameter switchover 0.0% to FA-23 ☆… -

Page 52

M420 General Flux Vector Control Inverter User Manual Function code Table Function Parameter Name Setting Range Default Property Code amplitude Jump frequency ☆ Fb-02 0.0% to 50.0% 0.0% amplitude ☆ Fb-03 Swing frequency cycle 0.1s to 3000.0s 10.0s Triangular wave rising ☆… -

Page 53

Function Code Table M420 General Flux Vector Control Inverter User Manual Function Parameter Name Setting Range Default Property Code ☆ FC-12 Reference 12 -100.0% to 100.0% 0.0% ☆ FC-13 Reference 13 -100.0% to 100.0% 0.0% ☆ FC-14 Reference 14 -100.0% to 100.0% 0.0% ☆… -

Page 54

M420 General Flux Vector Control Inverter User Manual Function code Table Function Parameter Name Setting Range Default Property Code 0 to 3 Acceleration/deceleration ☆ FC-23 time of simple PLC (Means acceleration/deceleration reference 2 time 1 to 4 respectively ) Running time of simple ☆… -

Page 55

Function Code Table M420 General Flux Vector Control Inverter User Manual Function Parameter Name Setting Range Default Property Code reference 8 (Means acceleration/deceleration time 1 to 4 respectively ) Running time of simple ☆ FC-36 0.0~6500.0 PLC reference 9 0 to 3 Acceleration/deceleration ☆… -

Page 56

M420 General Flux Vector Control Inverter User Manual Function code Table Function Parameter Name Setting Range Default Property Code Running time of simple ☆ FC-48 0.0~6500.0 PLC reference 15 0 to 3 Acceleration/deceleration ☆ FC-49 time of simple PLC (Means acceleration/deceleration reference 15 time 1 to 4 respectively )… -

Page 57

Function Code Table M420 General Flux Vector Control Inverter User Manual Function Parameter Name Setting Range Default Property Code ☆ -200.0% to 200.0% Fd-01 Torque digital setting 150.0% Forward maximum 0.00Hz to maximum ☆ Fd-03 50.00Hz frequency(F0-14) frequency in torque Reverse maximum 0.00Hz to maximum ☆… -

Page 58

M420 General Flux Vector Control Inverter User Manual Function code Table Function Parameter Name Setting Range Default Property Code ☆ FE-10 AI curve 2 inflexion 1 input FE-00 to FE-04 3.00 Corresponding setting of ☆ FE-11 -100.0% to 100.0% 30.0% AI curve 2 inflexion 1 input ☆… -

Page 59

Function Code Table M420 General Flux Vector Control Inverter User Manual Function Parameter Name Setting Range Default Property Code 3: Acceleration/deceleration time 3 4: Acceleration/deceleration time 4 Group H1: Motor 2 Parameters 0: No auto-tuning ★ Auto-tuning selection 1: Static auto-tuning H1-00 2: Complete auto-tuning Model… -

Page 60

M420 General Flux Vector Control Inverter User Manual Function code Table Function Parameter Name Setting Range Default Property Code Acceleration time of ☆ 1.0s to 600.0s H1-12 10.0s complete auto-tuning Deceleration time of ☆ 1.0s to 600.0s H1-13 10.0s complete auto-tuning Group H2: Motor 2 V/F Control Parameters ☆… -

Page 61

Function Code Table M420 General Flux Vector Control Inverter User Manual Function Parameter Name Setting Range Default Property Code 0 to 30000 Excitation adjustment ☆ H3-14 1300 integral gain Ki 100 to 200 ☆ Flux braking gain H3-15 50% to 200% Field weakening torque ☆… -

Page 62

M420 General Flux Vector Control Inverter User Manual Function code Table Function Parameter Name Setting Range Default Property Code Group L0: System Parameters 0: Disable Parameters only for ☆ L0-00 reading 1: Enable Group L1: User — defined Parameters 0: Disable Clear user-defined ☆… -

Page 63

Function Code Table M420 General Flux Vector Control Inverter User Manual Function Parameter Name Setting Range Default Property Code ☆ L1-19 User-defined parameters 19 uF0-00 uF0-00 to uU1-xx ☆ L1-20 User-defined parameters 20 uF0-00 to uU1-xx uF0-00 ☆ L1-21 User-defined parameters 21 uF0-00 uF0-00 to uU1-xx ☆… -

Page 64

M420 General Flux Vector Control Inverter User Manual Function code Table Function Parameter Name Setting Range Default Property Code 350.0V ☆ L2-06 Random PWM depth 0 to 6 0: No current output 1: Normal operation ☆ L2-07 0Hz running way 2: Output with DC braking current F1-16 0: Limitation mode 0… -

Page 65

Function Code Table M420 General Flux Vector Control Inverter User Manual Function Parameter Name Setting Range Default Property Code ☆ L3-18 AO2 measured voltage 2 -9.999V to 10.000V 8.000V ☆ L3-19 AO2 target voltage 2 -9.999V to 10.000V 8.000V Group L4: Master-slave Control Parameters 0: Disable Master-slave control ★… -

Page 66

M420 General Flux Vector Control Inverter User Manual Function code Table Function Parameter Name Setting Range Default Property Code holding time Braking period current ★ L5-03 50.0% to 200.0% 120.0% threshold Braking actuation ★ L5-04 0.00Hz to 20.00Hz 1.50Hz frequency Braking actuation delay 0.0s to 20.0s ★… -

Page 67

Function Code Table M420 General Flux Vector Control Inverter User Manual Function Parameter Name Min. Unit Property Code Err04: Overcurrent during acceleration Err05: Overcurrent during deceleration Err06: Over current at constant speed Err08: Overvoltage during acceleration Err09: Overvoltage during deceleration Err10: Overvoltage at constant speed Err12: Under voltage… -

Page 68

M420 General Flux Vector Control Inverter User Manual Function code Table Function Parameter Name Min. Unit Property Code Err34: Load becoming 0 Err35: Control power supply fault Err37: Control power supply fault Err39: Current running time reached Err40: Accumulative running time reached Err42: Motor switchover fault during running… -

Page 69

Function Code Table M420 General Flux Vector Control Inverter User Manual Function Parameter Name Min. Unit Property Code ● U0-19 Power-on time upon the 2 fault 1min ● U0-20 Running time upon the 2 fault 1min ● U0-21 Reserved ● U0-22 Reserved ●… -

Page 70

M420 General Flux Vector Control Inverter User Manual Function code Table Function Parameter Name Min. Unit Property Code ● U1-10 PID setting, PID setting ( percentage)×FA-05 ● U1-11 PID feedback, PID feedback ( percentage)×FA-05 ● U1-12 Count value ● U1-13 Length value ●… -

Page 71

Function Code Table M420 General Flux Vector Control Inverter User Manual Function Parameter Name Min. Unit Property Code ● U1-33 Target voltage upon V/F separation ● Output voltage upon V/F separation U1-34 ● Reserved U1-35 ● U1-36 Current motor number ●…

|

|

Ремонт MICROMASTER 420

По причине особой сложности Ремонт MICROMASTER 420 производится исключительно на территории сервисного центра. Частотный преобразователь MICROMASTER 420 является крайне сложной промышленной электроникой соответственно ремонт MICROMASTER 420 можно доверить только настоящим профессионалам своего дела с богатым опытом работы в данном направлении.

Все специалисты нашего сервисного центра имеют высшее техническое образование, огромный опыт и максимально полную материальную базу включая новейшее высокотехнологичное диагностическое оборудование благодаря чему ремонт MICROMASTER 420 проходит максимально эффективно.

Инженеры сервисного центра уделяют максимальное внимание к качеству исполнения ремонта, программирования и настройке частотного преобразователя, не зависимо от производителя данного промышленного оборудования. Именно поэтому мы смело даем гарантию на ремонт MICROMASTER 420 и замененные в процессе ремонта компоненты шесть месяцев.

Особое внимание заслуживает тот факт, что ремонт MICROMASTER 420 в производится исключительно с использованием оригинальных запасных частей, на компонентном уровне с применением высокотехнологичного оборудования, квалифицированным персоналом с инженерным образованием.

Ремонт распространенных частотнрых преобразователей MICROMASTER 420

Если на вашем производстве появились проблемы с частотным преобразователем MICROMASTER 420, ошибка которую вы не можете сбросить самостоятельно, мы всегда рады вам помочь. Обращайтесь в сервисный центр «Кернел». Специалисты нашей компании в минимальные сроки проведут глубокую диагностику частотного преобразователя и последующий ремонт MICROMASTER 420 в . Оставьте заявку на ремонт частотного преобразователя используя форму на сайте.

Ниже приведен далеко не полный список частотных преобразователей MICROMASTER 420 ремонт которых выполняет наш сервисный центр.

|

6SE6420-2UC11-2AA1 6SE6420-2UC12-5AA1 6SE6420-2UC13-7AA1 6SE6420-2UC15-5AA1 6SE6420-2UC17-5AA1 6SE6420-2UC21-1BA1 6SE6420-2UC21-5BA1 6SE6420-2UC22-2BA1 6SE6420-2UC23-0CA1 6SE6420-2AB11-2AA1 |

6SE6420-2AB12-5AA1 6SE6420-2AB13-7AA1 6SE6420-2AB15-5AA1 6SE6420-2AB17-5AA1 6SE6420-2AB21-1BA1 6SE6420-2AB21-5BA1 6SE6420-2AB22-2BA1 6SE6420-2AB23-0CA1 6SE6420-2UC25-5CA1 6SE6420-2UC24-0CA1 |

Ошибки MICROMASTER 420

При появлении неисправности на дисплее частотного преобразователя MICROMASTER 420 отобразится код ошибки, в файле ниже приведены все ошибки MICROMASTER 420 и возможные способы их устранения.

При возникновении ошибки преобразователь отключается и на индикации появляется код ошибки.

УКАЗАНИЕ

Сообщения об ошибках могут квитироваться следующим образом:

- Возможность 1: Отключить преобразователь от сети и снова подключить

- Возможность 2: на AOP или BOP

- Возможность 3: Через цифровой вход 3

Предупреждения

Предупреждения сохраняются в параметре r2110 под своим кодовым номером (к примеру, A0503 = 503) и могут загружаться оттуда. Подробное описание всех предупреждений можно найти в Списке параметров.

Сброс сообщений об ошибках, предупреждений

Работа без сбоев с точки зрения приложения является решающим критерием приемлемости приводной системы. Но для специальных приложений бесперебойная работа требуется и тогда, когда имеет место перегрузка или внешние обстоятельства вызывают ошибку. В таких приложениях (к примеру, мешалка) бесперебойная работа более важна, чем защита приводной системы. В MICROMASTER 420 можно подавить до 3-х сообщений об ошибках/предупреждений с индексированными параметрами P2100 и P2101. Выбор сообщений об ошибках/предупреждений (см. раздел «Сообщения об ошибках/предупреждения») устанавливается с помощью параметра P2100, а реакция выбирается с помощью параметра P2101. Корреляция между подавлением и реакцией осуществляется через индекс 0 — 2 обоих параметров. Для реакций возможны следующие установки:

- 0 нет реакции, нет индикации

- 1 реакция останова ВЫКЛ1

- 2 реакция останова ВЫКЛ2

- 3 реакция останова ВЫКЛ3

- 4 нет реакции, только предупреждение

Пример:

Предупреждение A0911 указывает на то, что привод увеличивает врем выбега по рампе, чтобы не допустить перенапряжения. Для подавления этого сообщения установить следующие параметры:

p2100[0] = 911 (выбор предупреждения A0911)

P2101[0] = 0 (нет реакции, нет индикации)

Все возможные предупреждения и ошибки MICROMASTER 420 описаны в руководстве пользователя, которое вы можете скачать с нашего сайта в удобном формате- pdf.

Скачать руководство пользователя MICROMASTER 420 мануал.pdf

Устранение причины ошибки частотного преобразователя MICROMASTER 420 и ее сброс позволит в кратчайшие сроки возобновить работу дорогостоящего оборудования. К сожалению не все ошибки можно исправить самостоятельно, некоторые ошибки MICROMASTER 420 возможно исправить только в специализированных сервисных центрах.

MICROMASTER 420 программирование

Настройка параметров, программирование MICROMASTER 420 в является заключительным звеном в процессе ремонта частотного преобразователя и требует профессионального подхода. Именно финальный этап программирования MICROMASTER 420 наглядно покажет качество выполненного ремонта MICROMASTER 420.

К слову, мы уделяем особое внимание качеству и смело даем гарантию на все выполненные ремонтно-восстановительные работы шесть месяцев, гарантия так же распространяется на запасные части, которые были заменены в процессе ремонта.

Хочется обратить внимание на то, что мы стараемся провести ремонт и программирование MICROMASTER 420 в максимально сжатые сроки, тем самым минимизируем простой дорогостоящего промышленного оборудования.

MICROMASTER 420 ввод в эксплуатацию

Инженеры сервисного центра «Кернел» не только выполняют качественный ремонт MICROMASTER 420 и программирование частотного преобразователя. Так же мы предоставляем услугу запуска в эксплуатацию оборудования от стадии проектирования до выпуска первой продукции.

Именно этап запуска в эксплуатацию MICROMASTER 420 отвечает за долгий и безаварийный процесс работы промышленного оборудования, тем самым позволяя получить максимальную прибыль и сэкономить на незапланированном ремонте.

По-настоящему качественный ввод в эксплуатацию MICROMASTER 420 может выполнить только высококвалифицированный специалист с богатым опытом работы в данном направлении. Найти подобного специалиста достаточно сложно, но, если вы обращаетесь в наш сервисный центр вам не придется об этом думать.

ДляпараметрированияпреобразователяВыможетеиспользоватьоднуизоп-ционныхоператорскихпанелей, таких как «Базовая Операторская Панель»(BOP) или «Расширенная Панель Оператора» (AOP). Для более удобного обслуживания и параметрирования преобразователей можно использовать специальный инструмент – Drive Monitor – программу для настройки и документирования.

|

Блок схема MICROMASTER 420 |

|

|

В нашей команде работают исключительно профессионалы своего дела, а за время существования нашей компании мы ввели в эксплуатацию не одну сотню частотных преобразователей в том числе и MICROMASTER 420, с каждым разом получая и накапливая драгоценный опыт.

О MICROMASTER 420

Базовая панель оператора (BOP), поставляемая как опция, дает возможность доступа к параметрам преобразователя и обеспечивает специфическую пользовательскую настройку MICROMASTER 420. BOP может использоваться для конфигурирования большинства преобразователей MICROMASTER 420. Поэтому нет необходимости покупать свою панель BOP для каждого преобразователя. Панель имеет сегментные индикаторы для чтения и записи параметров преобразователя. Панель не имеет возможности собственного хранения информации и параметров после её снятия.

Линейка промышленной электроники, которую восстанавливают специалисты сервисного центра «Кернел» не имеет ограничений, мы выполняем качественный ремонт промышленной электроники и оборудования абсолютно любых производителей не зависимо от года выпуска и наличия технической документации.

Оставить заявку на ремонт MICROMASTER 420

Оставить заявку на ремонт или программирование MICROMASTER 420 в можно с помощью специальной формы, которая вызывается нажатием одноименной кнопки в верхней части страницы. Все вопросы, связанные с ремонтом MICROMASTER 420 в вы можете задать нашим менеджерам. Связаться с ними можно несколькими способами:

- Заказав обратный звонок (кнопка в правом нижнем углу сайта)

- Посредством чата (кнопка расположена с левой стороны сайта)

- Позвонив по номеру телефона: +7(8482) 79-78-54; +7(917) 121-53-01

- Написав на электронную почту: 89171215301@mail.ru

Вот далеко не полный список производителей промышленной электроники и оборудования, ремонтируемой в нашей компании.

International English

6.3

In the event of a failure, the inverter switches off and a fault code appears on the display.

Table 6-2

Fault Code

F0001

Overcurrent

F0002

Overvoltage

F0003

Undervoltage

F0004

Inverter

Overtemperature

F0005

Inverter I

F0011

Motor Overtemperature

2

I

F0041

Stator resistance

measurement failure

94

MICROMASTER 420 Fault Codes

Description

1. Motor power does not

correspond to the inverter

power.

2. Motor lead short circuit

3. Earth fault

Supply voltage out of tolerance

load is regenerating.

Mains supply removed when

inverter is running.

Ambient temperature outside of

limits,

Fan failure

2

T

Inverter is overloaded

1. Motor overloaded.

T

2. Motor data incorrect.

3. Check parameter for motor

thermal time constant.

4. Check parameter for motor I

warning level.

5. Long time period operating at

low speeds

Stator resistance measurement

failure

Possible Causes

2

t

6. TROUBLESHOOTING

Diagnosis & Remedy

1. Check whether the motor power

corresponds to the inverter

power.

2. Check that the cable length limits

have not been exceeded.

3. Check motor cable and motor for

short-circuits and earth faults.

4. Check whether the motor

parameters correspond with the

motor being used.

5. Check the stator resistance

(P0350).

6. Increase the ramp-up-time

(P1120).

7. Reduce the boost set in (P1310),

(P1311) and (P1312).

8. Check whether the motor is

obstructed or overloaded.

1. Check whether the supply voltage

is within the limits indicated on the

rating plate.

2. Check if dc-link voltage

controller (P1240) is enabled and

parameterized correctly.

3. Increase the ramp-down time

(P1121).

1. Check whether the supply voltage

is within the limits indicated on the

rating plate.

2. Check the supply is not subject to

temporary failures or voltage

reductions.

1. Check that the integral fan rotates

when drive is running.

2. Check if pulse frequency is set to

default value.

3. Ambient temperature could be

higher than specified for the

inverter.

4. Check that air inlet and outlet

points are not obstructed.

1. Check if load duty-cycle is within

specified limits.

2. Check that motor power

corresponds to inverter power

1. Check motor data.

2. Check loading on motor.

3. Boost settings too high (P1310,

P1311, P1312)

1. Check if the motor is connected to

the inverter

2. Check that the motor data has

been entered correctly.

MICROMASTER 420 Operating Instructions

6SE6400-5AA00-0BP0

- Manuals

- Brands

- Siemens Manuals

- DC Drives

- MICROMASTER 420

- Operating instruction

-

Contents

-

Table of Contents

-

Troubleshooting

-

Bookmarks

Quick Links

MICROMASTER

Operating Instructions

Issue A2

User Documentation

Related Manuals for Siemens Micromaster 420

Summary of Contents for Siemens Micromaster 420

- Page 1

MICROMASTER Operating Instructions Issue A2 User Documentation… - Page 3

Overview Installation Commissioning MICROMASTER 420 Using the MICROMASTER 420 Operating Instructions System Parameters User Documentation Troubleshooting MICROMASTER 420 Specifications Supplementary Information Appendices Valid for Release Inverter Type Control Version MICROMASTER 420 October 2000 Index Issue: A2… - Page 4

We welcome suggestions for improvement. MICROMASTER® is a registered trademark of Siemens. Siemens handbooks are printed on chlorine-free paper that has been produced from managed sustainable forests. No solvents have been used in the printing or binding process. - Page 5

♦ Getting Started Guide The Getting Started Guide is designed to give you quick access to all the basic information required to install and set up your MICROMASTER 420 for operation. ♦ Operating Instructions The Operating Instructions provide detailed information for installation and operation of your MICROMASTER 420. -

Page 6: Using The

Siemens. Contact address Should any questions or problems arise while reading this manual, please contact the Siemens office concerned using the form provided at the back this manual. MICROMASTER 420 Operating Instructions 6SE6400-5AA00-0BP0…

-

Page 7: Micromaster

Please read the information carefully, since it is provided for your personal safety and will also help prolong the service life of your MICROMASTER 420 Inverter and the equipment you connect to it. General Warnings ♦…

- Page 8

The connection of power, motor and control cables to the inverter must be carried out as shown in Figure 2-4 on page 25, to prevent inductive and capacitive interference from affecting the correct functioning of the inverter. MICROMASTER 420 Operating Instructions 6SE6400-5AA00-0BP0… - Page 9

EN 60204, 9.2.5.4) Repair Warnings ♦ Repairs on equipment may only be carried out by Siemens Service, by repair centers authorized by Siemens or by qualified personnel who are thoroughly acquainted with all the warnings and operating procedures contained in this manual. - Page 10

International English FOREWORD MICROMASTER 420 Operating Instructions 6SE6400-5AA00-0BP0… -

Page 11: Table Of Contents

Ambient operating conditions ………………19 Mechanical Installation ………………..20 Electrical Installation ………………..21 Commissioning ………………….27 Front Panels for the MICROMASTER 420 …………..29 General operation ………………….. 34 Using the MICROMASTER 420 …………….37 Frequency Setpoint………………… 38 Command Sources (P0700) ………………38 OFF and braking Functions ………………

- Page 12

D — Removing ‘Y’ Cap Frame Size A ………………115 E — Removing ‘Y’ Cap Frame Sizes B and C …………….117 F — User Parameter Settings …………………. 119 G — Applicable Standards ………………….121 H — List of Abbreviations………………….123 Index ……………………..125 MICROMASTER 420 Operating Instructions 6SE6400-5AA00-0BP0… - Page 13

Motor and Power Connections ………………23 Figure 2-4 Wiring Guidelines to Minimize the Effects of EMI …………. 25 Figure 3-1 Panels available for the MICROMASTER 420 Inverter ………… 29 Figure 3-2 Basic operation with SDP………………..30 Figure 3-3 Buttons on the Basic Operator Panel…………….31 Figure 3-4 Changing parameters via the BOP……………… - Page 14

MICROMASTER 420 Operating Instructions 6SE6400-5AA00-0BP0… -

Page 15: Overview

OVERVIEW International English Overview This Chapter contains: A summary of the major features of the MICROMASTER 420 range. The MICROMASTER 420………………. 16 Features ……………………16 MICROMASTER 420 Operating Instructions 6SE6400-5AA00-0BP0…

-

Page 16: The Micromaster 420

Comprehensive protective functions provide excellent inverter and motor protection. The MICROMASTER 420 with its default factory settings, is ideal for a large range of simple motor control applications. The MICROMASTER 420 can also be used for more advanced motor control applications via its comprehensive parameter lists.

-

Page 17: Installation

General data relating to installation ♦ Dimensions of Inverter ♦ Wiring guidelines to minimize the effects of EMI ♦ Details concerning electrical installation General……………………18 Ambient operating conditions ………………19 Mechanical Installation ………………..20 Electrical Installation ………………..21 MICROMASTER 420 Operating Instructions 6SE6400-5AA00-0BP0…

-

Page 18: General

Apply 25% of input voltage for 2 hours Increase volts to 50% for a further 2 hours Increase volts to 75% for a further 2 hours Increase volts to 100% for a further 2 hours Inverter ready for run signal MICROMASTER 420 Operating Instructions 6SE6400-5AA00-0BP0…

-

Page 19: Ambient Operating Conditions

Overheating Mount the inverter vertically to ensure optimum cooling. Additional ventilation may be required for horizontal mounting. Ensure that the inverter’s air vents are not obstructed. Allow 100 mm clearance above and below the inverter. MICROMASTER 420 Operating Instructions 6SE6400-5AA00-0BP0…

-

Page 20: Mechanical Installation

4 washers M5 204 mm 8.03″ 245 mm Tightening 9.65″ torque (unit to cabinet) with washers fitted: 3 Nm 174 mm 185 mm 195 mm 6.85″ 7.28″ 7.68″ Figure 2-1 Drill pattern for MICROMASTER 420 MICROMASTER 420 Operating Instructions 6SE6400-5AA00-0BP0…

-

Page 21: Electrical Installation

A type B RCD is used. The trip limit of the RCD is 300mA. The neutral of the supply is grounded. Only one inverter is supplied from each RCD. The output cables are less than 50m (screened) or 100m (unscreened). MICROMASTER 420 Operating Instructions 6SE6400-5AA00-0BP0…

- Page 22

To tighten up the power terminal screws use a 4 — 5 mm cross-tip screwdriver. Access to the power and motor terminals The procedure for accessing the power and motor terminals on the MICROMASTER 420 Inverter is illustrated in Appendices B and C. Please also refer to the photographs showing the Power Terminal connections and the Control Terminal connections on the inside of the back cover of this manual. - Page 23

2. INSTALLATION International English N/L2 L/L1 (Ground) (Ground) Figure 2-2 MICROMASTER 420 Connection Terminals OPTIONAL FILTER (Class B only) CONTACTOR MICROMASTER MOTOR FUSE L/L1 N/L2 SINGLE PHASE TYPICAL INSTALLATION OPTIONAL FILTER CONTACTOR MICROMASTER MOTOR FUSE THREE PHASE Figure 2-3 Motor and Power Connections… - Page 24

♦ Use screened or armored cables for the motor connections and ground the screen at both ends using the cable clamps Warning Safety regulations must not be compromised when installing inverters! MICROMASTER 420 Operating Instructions 6SE6400-5AA00-0BP0… - Page 25

Use suitable clips to fix motor and control cable screens securely to metal back plate Note To enhance the screening of the motor and control cables, the optional Gland Plate can be used (not shown in Figure 2-4). MICROMASTER 420 Operating Instructions 6SE6400-5AA00-0BP0… - Page 26

International English 2. INSTALLATION MICROMASTER 420 Operating Instructions 6SE6400-5AA00-0BP0… -

Page 27: Commissioning

Basic Operator Panel (BOP) ♦ An 8-step guide at the end of the Chapter, which provides a simple procedure for changing parameters Front Panels for the MICROMASTER 420 …………..29 General operation ………………….. 34 MICROMASTER 420 Operating Instructions 6SE6400-5AA00-0BP0…

- Page 28

Only qualified personnel may enter settings in the control panels. Particular attention must be paid to safety precautions and warnings at all times. The MICROMASTER 420 is supplied with a Status Display Panel (SDP) and default parameter settings that cover the following requirements: ♦… -

Page 29: Front Panels For The Micromaster 420

Front Panels for the MICROMASTER 420 Front panels The front panels shown below are available for use with the MICROMASTER 420 Inverters. The panel on the left is supplied with the inverter as standard and is referred to as the Status Display Panel (SDP). The Basic Operator Panel (BOP) and Advanced Operator Panel (AOP) are available as options.

-

Page 30: Table 3-2 Default Settings For Operation Using The Bop

Commissioning with the Basic Operator Panel (BOP) The Basic Operator Panel (BOP), which is available as an option, provides access to the inverter parameters and enables you to customize the settings of your MICROMASTER 420. The BOP can be used to configure several MICROMASTER 420 150.00 Inverters.

-

Page 31: Figure 3-3 Buttons On The Basic Operator Panel

To change the Frequency Setpoint via the BOP set P1000 = 1. Pressing this button decreases the displayed value. Decrease value To change the Frequency Setpoint via the BOP set P1000 = 1. Figure 3-3 Buttons on the Basic Operator Panel MICROMASTER 420 Operating Instructions 6SE6400-5AA00-0BP0…

-

Page 32: Figure 3-4 Changing Parameters Via The Bop

Note — Busy Message In some cases — when changing parameter values — the display on the BOP shows » — — — -«. This means the inverter is busy with tasks of higher priority. MICROMASTER 420 Operating Instructions 6SE6400-5AA00-0BP0…

-

Page 33: Figure 3-5 Typical Motor Rating Plate Example

Figure 3-6. 1 kΩ Figure 3-6 Motor Overload PTC Connection Note: To enable the trip function, set parameter P0701, P0702 or P0703 = 29. MICROMASTER 420 Operating Instructions 6SE6400-5AA00-0BP0…

-

Page 34: General Operation

(P0005 = 21) the corresponding setpoint is displayed approximately every 1.0 seconds while the inverter is stopped. 3. The inverter is programmed at the factory for standard applications on Siemens four- pole standard motors that have the same power rating as the inverters. When using other motors it is necessary to enter the specifications from the motor’s rating plate.

- Page 35

3. When the inverter reaches 50 Hz, press the ‘DOWN’ Button. Motor speed and display is decreased. 4. Change the direction of rotation with the FORWARD / REVERSE Button. 5. The red button STOPS the motor. MICROMASTER 420 Operating Instructions 6SE6400-5AA00-0BP0… - Page 36

AOUT + 12 0-20mA AOUT — Serial Link (RS485) The Analogue input circuit can be alternatively configured to provide an additional digital input (DIN4) as shown. DIN4 – 0V (Isolated) Figure 3-7 Inverter block diagram MICROMASTER 420 Operating Instructions 6SE6400-5AA00-0BP0… -

Page 37: Using The Micromaster 420

4. USING THE MICROMASTER 420 International English Using the MICROMASTER 420 This Chapter contains: ♦ An explanation of the various methods of controlling your inverter Frequency Setpoint………………… 38 Command Sources (P0700) ………………38 OFF and braking Functions ………………39 Control Modes (P1300)………………..40 Faults and warnings………………..

-

Page 38: Frequency Setpoint

International English 4. USING THE MICROMASTER 420 Warnings ♦ When operating electrical devices, it is impossible to avoid applying hazardous voltages to certain parts of the equipment. ♦ Emergency Stop facilities according to EN 60204 IEC 204 (VDE 0113) must remain operative in all operating modes of the control equipment.

-

Page 39: Off And Braking Functions

4. USING THE MICROMASTER 420 International English Reversing the motor Standard Terminal 6 (DIN 2) Options see P0700 to P0704 OFF and braking Functions 4.3.1 OFF1 This command (produced by canceling the ON command) causes the inverter to come to a standstill at the selected ramp-down rate.

-

Page 40: Control Modes (P1300)

P1236 Control Modes (P1300) The various modes of operation of the MICROMASTER 420 control the relationship between the speed of the motor and the voltage supplied by the inverter. There are four modes of operation:…

-

Page 41: System Parameters

♦ An in-depth description of what the parameter actually does Overview of MICROMASTER System Parameters ..Error! Bookmark not defined. Introduction to MICROMASTER System Parameters… Error! Bookmark not defined. System Parameters and Definitions ……Error! Bookmark not defined. MICROMASTER 420 Operating Instructions 6SE6400-5AA00-0BP0…

-

Page 42: Overview Of Micromaster System Parameters

The MM420 is therefore delivered with the following default settings: ♦ Motor Parameters to suit a Siemens 4 pole motor to match the drive power and voltage. ♦ Setpoint control from the Analog input; 0 – 10V corresponding to 0 to 50 Hz or 0 to 60 Hz (North America).

-

Page 43: Introduction To Micromaster System Parameters

♦ If an attempt is made to change a parameter that cannot be changed in this status, for example, cannot be changed whilst running or can only be changed in quick commissioning, then will be displayed. MICROMASTER 420 Operating Instructions 6SE6400-5AA00-0BP0…

- Page 44

Reset to Factory default To reset all parameters to the factory default settings; the following parameters should be set as follows: 1. Set P0010=30. 2. Set P0970=1. Note The reset process takes approximately 10 seconds to complete. MICROMASTER 420 Operating Instructions 6SE6400-5AA00-0BP0… - Page 45

0340 Calculation of motor parameters 0350 Stator resistance, line-to-line 0611 Motor I t time constant 0614 Motor I t overload warning level 0640 Motor overload factor 1910 Select motor data identification 1912 Identified stator resistance MICROMASTER 420 Operating Instructions 6SE6400-5AA00-0BP0… - Page 46

0010 Commissioning Parameter filter 0010 Commissioning Parameter filter 0918 Profibus address 0947 Last fault code 0927 Parameters changeable via 2110 Warning history 2000 Reference frequency 2197 CO/BO: Status word 1 monitor 2010 USS baud rate 2011 USS address MICROMASTER 420 Operating Instructions 6SE6400-5AA00-0BP0… - Page 47

PI: tranducer type 2272 CO: PI scaled feedback signal 2273 CO: PI error 2280 PI: proportional gain 2285 PI: integral time 2291 PI: output upper limit 2292 PI: output lower limit 2294 CO: PI output MICROMASTER 420 Operating Instructions 6SE6400-5AA00-0BP0… -

Page 48: System Parameters And Definitions

“User defined parameter list – see P0013 (Level 3) for details on use” “Standard”: allows access into most frequently used parameters “Extended”: allows extended access to inverter I/O functions “Expert”: for expert use only. “Service”: only for use by authorized service personnel –password protected. MICROMASTER 420 Operating Instructions 6SE6400-5AA00-0BP0…

- Page 49

Quick Commissioning Factory setting Notes: This parameter must be reset to 0 before the inverter will run (Automatic when P3900 ≠ 0 (default)). The accessible parameters are also affected by the User Access Level parameter (P0003). MICROMASTER 420 Operating Instructions 6SE6400-5AA00-0BP0… - Page 50

P0040. P0040 Reset energy consumption meter Resets energy consumption display to zero. Possible Settings: 0 = No reset 1 = Reset r0039 to 0 Note: Reset occurs when “P” is pressed. MICROMASTER 420 Operating Instructions 6SE6400-5AA00-0BP0… - Page 51

Inverter overload Notes: The individual status bits can be configured to the digital output using P0731. To enable the user to read the relevant parameter bits display, refer to the diagram below: > & » MICROMASTER 420 Operating Instructions 6SE6400-5AA00-0BP0… - Page 52

Actual frequency ≥ setpoint Bit 6 Voltage < threshold Bit 7 Voltage > threshold Bit 8 Bit 9 reserve PI frequency < threshold Bit A Bit b PI saturation Note: Refer to the bitmap diagram on page 51. MICROMASTER 420 Operating Instructions 6SE6400-5AA00-0BP0… - Page 53

Rated drive power [kW] or [hp] Displays the nominal motor power rating, which can be supplied by the inverter. Note: The display will be in kW or hp dependent on the setting of P0100 MICROMASTER 420 Operating Instructions 6SE6400-5AA00-0BP0… - Page 54

Υ Υ Υ Υ = = = = 440-480 95.75% == == == ==∆/Υ ∆/Υ ∆/Υ ∆/Υ= = = = 220-240/380-420 V 45kg P0344 11.1-11.3 A 19.7-20.6/11.4-11.9 A P0308 P0311 P0309 Note: This parameter can only be changed when P0010=1. MICROMASTER 420 Operating Instructions 6SE6400-5AA00-0BP0… - Page 55

This parameter is only visible when P0100 = 1, i.e. when the motor power is entered in hp. Note: A setting of 0 will cause the value to be calculated internally. P0310 Motor frequency rating [50] ‘ ’ Nominal motor frequency (Hz) from rating plate — see diagram P0304 MICROMASTER 420 Operating Instructions 6SE6400-5AA00-0BP0… - Page 56

The value entered in P0350 is the one from the method last used. P0611 Motor I t time constant 16000 [***] Defines motor thermal time constant and is automatically calculated from the motor data (P0340). Note: Larger number increases time taken for calculated motor temperature to change. MICROMASTER 420 Operating Instructions 6SE6400-5AA00-0BP0… - Page 57

29 External trip 33 Disable additional setpoint (defined in P1000) 99 Enable BICO parameterization – for expert use only Can only be reset via P0700 or P3900 = 1, 2 or factory setting P0970 = 1 MICROMASTER 420 Operating Instructions 6SE6400-5AA00-0BP0… - Page 58

29 External trip 33 Disable additional setpoint (defined in P1000) Enable BICO parameterization – for expert use only Can only be reset via P0700 or P3900 = 1, 2 or factory setting P0970 = 1. MICROMASTER 420 Operating Instructions 6SE6400-5AA00-0BP0… - Page 59

Bit 01 «Digital input 2» 0 OFF 1 Active Bit 02 «Digital input 3» 0 OFF 1 Active Bit 03 «Digital input 4 (Via AIN)» 1 Active Note When the signal is active the segment is lit. MICROMASTER 420 Operating Instructions 6SE6400-5AA00-0BP0… - Page 60

Controller output at lower limit (P2291) Closed Open Note These are the most common settings. Other settings are possible in Expert mode. r0752 Analog input voltage Displays the smohthed analog input value in volts before the characteristic block MICROMASTER 420 Operating Instructions 6SE6400-5AA00-0BP0… - Page 61

When monitoring is enabled and a deadband is defined (P0761), a fault condition will be generated (F0080) when the analog input voltage falls below 50% of the deadband voltage. Note: This function is disabled if the analog scaling block (see P0757 – P0760) is programmed to output negative setpoints. MICROMASTER 420 Operating Instructions 6SE6400-5AA00-0BP0… - Page 62

Value X2 of analog input scaling Sets value of X2 as described in P0757 [10] ‘•’ P0760 Value Y2 of analog input scaling -99999 99999 Sets value of Y2 as described in P0757 [100] ‘•’ MICROMASTER 420 Operating Instructions 6SE6400-5AA00-0BP0… - Page 63

P0758 = -100% P0761 = 0.1 (0.1V either side of center) P2000 = 50Hz Note: Fmin (P1080) should be zero when using center zero setup. There is no hysteresis at the end of the dead band MICROMASTER 420 Operating Instructions 6SE6400-5AA00-0BP0… - Page 64

Defines x2 of output characteristic P0780 Value Y2 of analog output characteristics [20] ‘•’ Defines y2 of output characteristic P0781 Analog output deadband ‘•’ Sets the width of a dead-band in mA for the analog output. MICROMASTER 420 Operating Instructions 6SE6400-5AA00-0BP0… - Page 65

E.g. if you want to set value 15, you will need to set the display to indicate 15 in Binary (with the separating bars in-between “b — — n n” or if you wanted to set 11 – “b — — r n” etc. MICROMASTER 420 Operating Instructions 6SE6400-5AA00-0BP0… - Page 66

Index 2 is only used if a 2 fault occurs before the 1 is acknowledged. P0970 Factory reset Resets all parameters to their default values. To do this, you need to set P0010=30, then P0970=1 P0100 is set according DIP Switch setting MICROMASTER 420 Operating Instructions 6SE6400-5AA00-0BP0… - Page 67

The most common settings are: Keypad (Motor potentiometer) setpoint Analog input Fixed frequency setpoint USS via RS232 USS via RS485 terminals Optional Communication Board Other settings including an additional setpoint can be selected using the table above. MICROMASTER 420 Operating Instructions 6SE6400-5AA00-0BP0… - Page 68

P1002 Fixed frequency 2 -650 ‘ • ’ Defines fixed frequency setpoint 2 See description for P1001 P1003 Fixed frequency 3 -650 [10] ‘ • ’ Defines fixed frequency setpoint 3 See description for P1001 MICROMASTER 420 Operating Instructions 6SE6400-5AA00-0BP0… - Page 69

Reverse direction is allowed – it is possible to change motor direction using the keypad (Motor potentiometer) setpoint (increase / decrease frequency either by using digital inputs or keypad up / down buttons) Reverse direction inhibited MICROMASTER 420 Operating Instructions 6SE6400-5AA00-0BP0… - Page 70